Optical-level quartz crystal temperature-variable temperature difference method growth technique

A quartz crystal, optical grade technology, applied in crystal growth, single crystal growth, single crystal growth and other directions, can solve the problem of difficult to meet the high pixel requirements of digital cameras, difficult to meet optical grade quartz crystal corrosion tunnel density index, optical uniformity index, Spectral transmittance index high performance requirements, etc., to achieve stable Q value, uniform size, and good optical uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

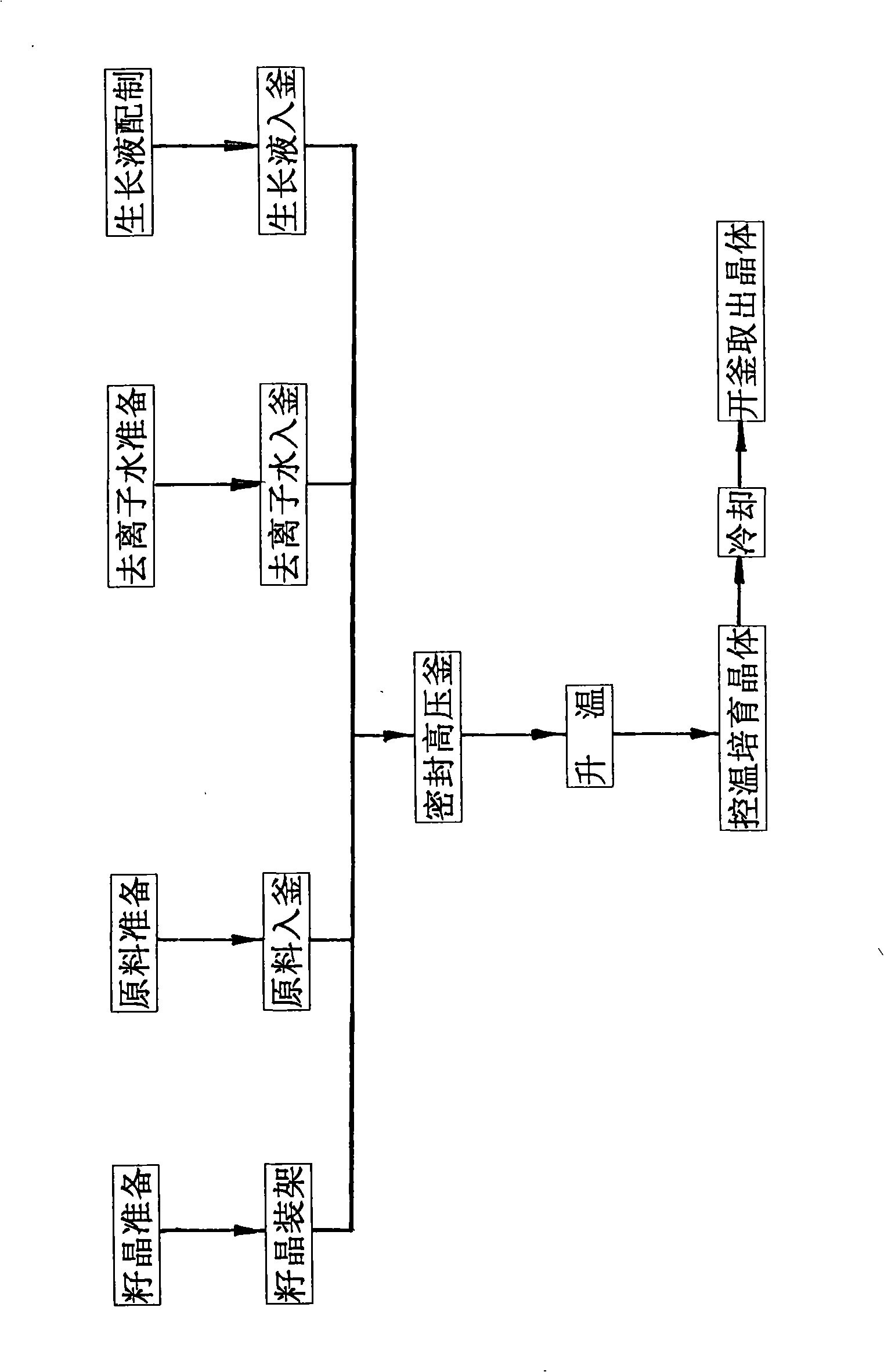

[0028] The accompanying drawings show the process flow of the optical-grade quartz crystal growth process by variable temperature and temperature difference method of the present invention.

[0029] 1. Preparation stage

[0030] The seed crystal is the seed crystal of artificial quartz crystal, and the seed crystal should be processed according to the size of the crystal growth first. The seeds themselves are processed from crystals whose veins are grade A and inclusions above class Ia. The processing method uses a high-precision multi-knife cutting machine. The auxiliary material is 600-800 mesh emery, and the speed is 80-100 times / min. . Seed crystal orientation: The thickness of the Y block seed wafer in the Z direction is 1.8±0.2mm, the surface parallelism reaches 0.05mm, and the corrosion tunnel density is less than 10 / cm 2 .

[0031]Seed crystal cleaning: Put the cut and oriented seed crystal into a basin, soak it in washing powder to remove oil, then use an ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com