Patents

Literature

317 results about "Fractional Precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method which uses specific precipitation reactions to separate or collect substances from a solution.

Recycling method for treating stainless steel pickling acid pickle and wastewater

ActiveCN104310647AHigh operating costsSimple processWater treatment compoundsWaste water treatment from metallurgical processWash waterLaterite

The invention relates to a recycling method for treating stainless steel pickling acid pickle and wastewater, belonging to the field of treatment of industrial acid pickle and wastewater in iron and steel and metallurgy industries. The acid pickle and wash wastewater generated during stainless steel pickling are collected according to quality and category and the acid pickle is subjected to acid recycling. The acid pickle and wash wastewater are treated through fractional precipitation by adopting lime as a neutralizing agent. Calcium sulfate or calcium fluoride or a mixture of calcium sulfate and calcium fluoride is obtained through precipitation under the acidic condition (the pH value is equal to 3.0+ / -0.5) and can serve as a cement filler or a material for brickmaking or a building material after heavy metal polluted calcium salt is removed. A metal hydroxide is obtained through precipitation under the alkaline condition (the pH value is not more than 9.0) and can serve as a stainless steel smelting raw material as the quality of the product is better than that of the imported laterite-nickel ores in China. The calcium nitrate containing wastewater obtained after the acid pickle is treated is not needed to be discharged or treated and can be recycled. After being treated, the wash wastewater can be reused as production line wash water.

Owner:上海博士高环保科技有限公司

Apparatus, methods and compositions for biotechnical separations

InactiveUS20020010145A1Low costImprove performanceGenetic material ingredientsTyresFractional PrecipitationPlasmid dna

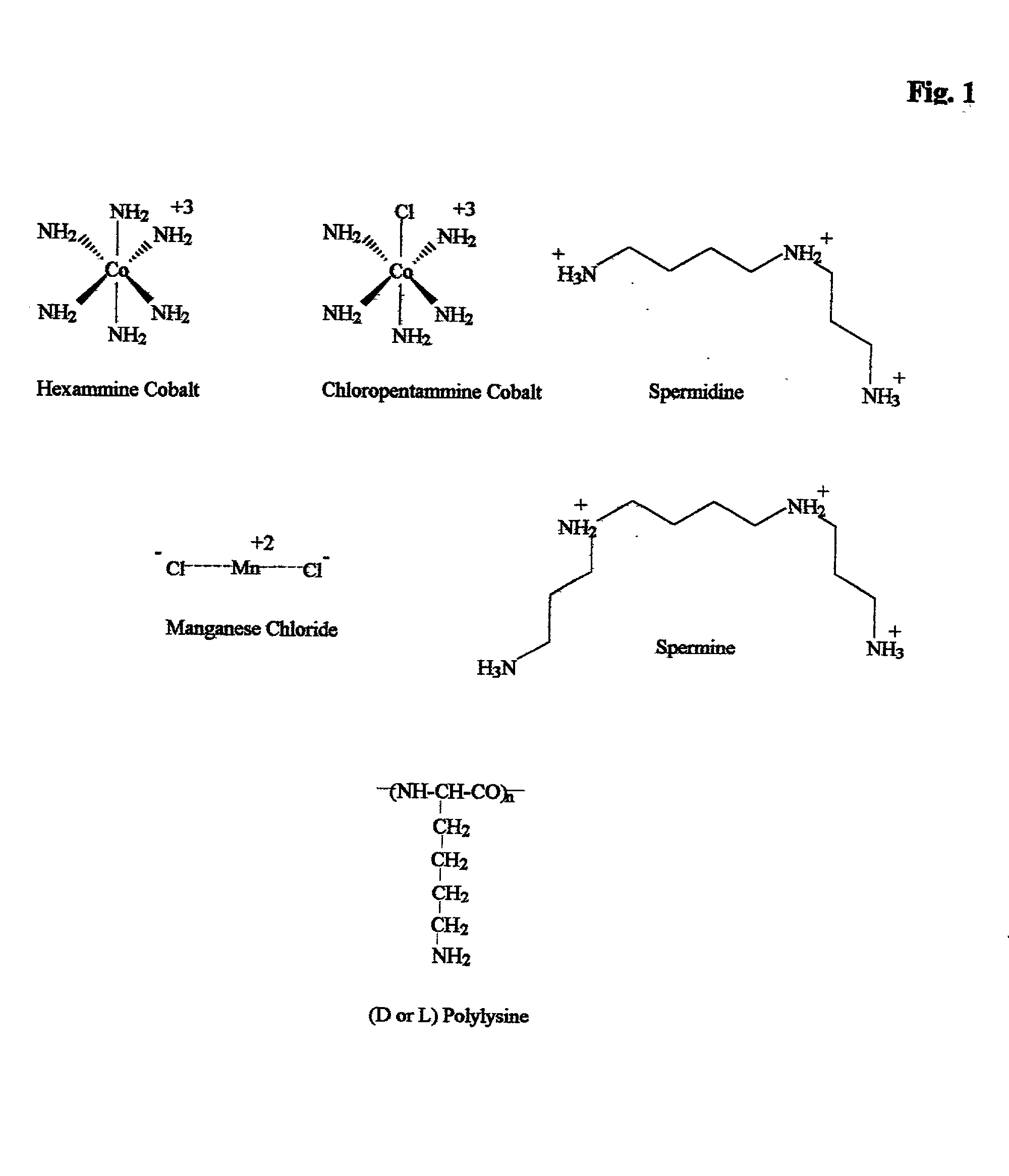

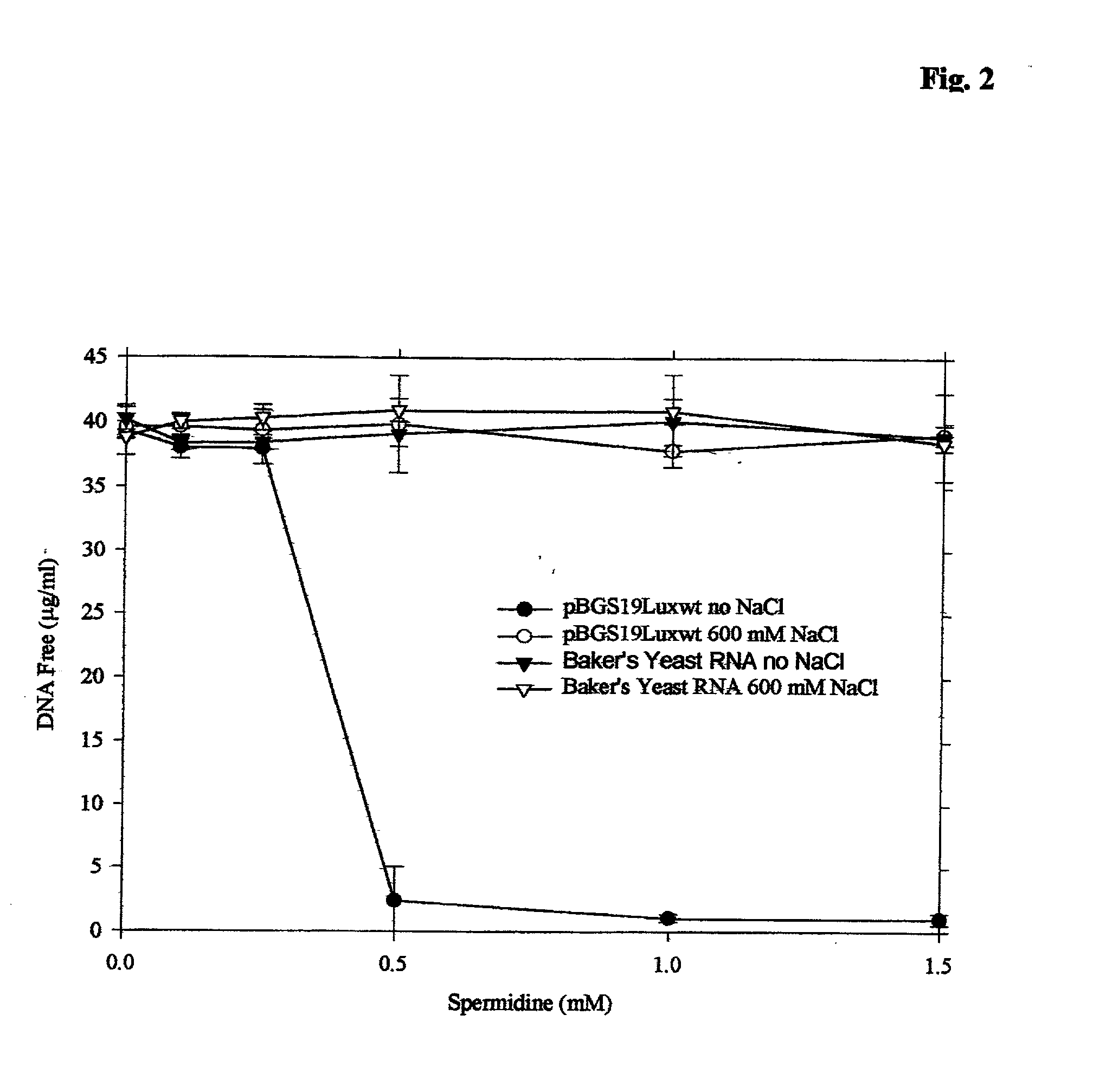

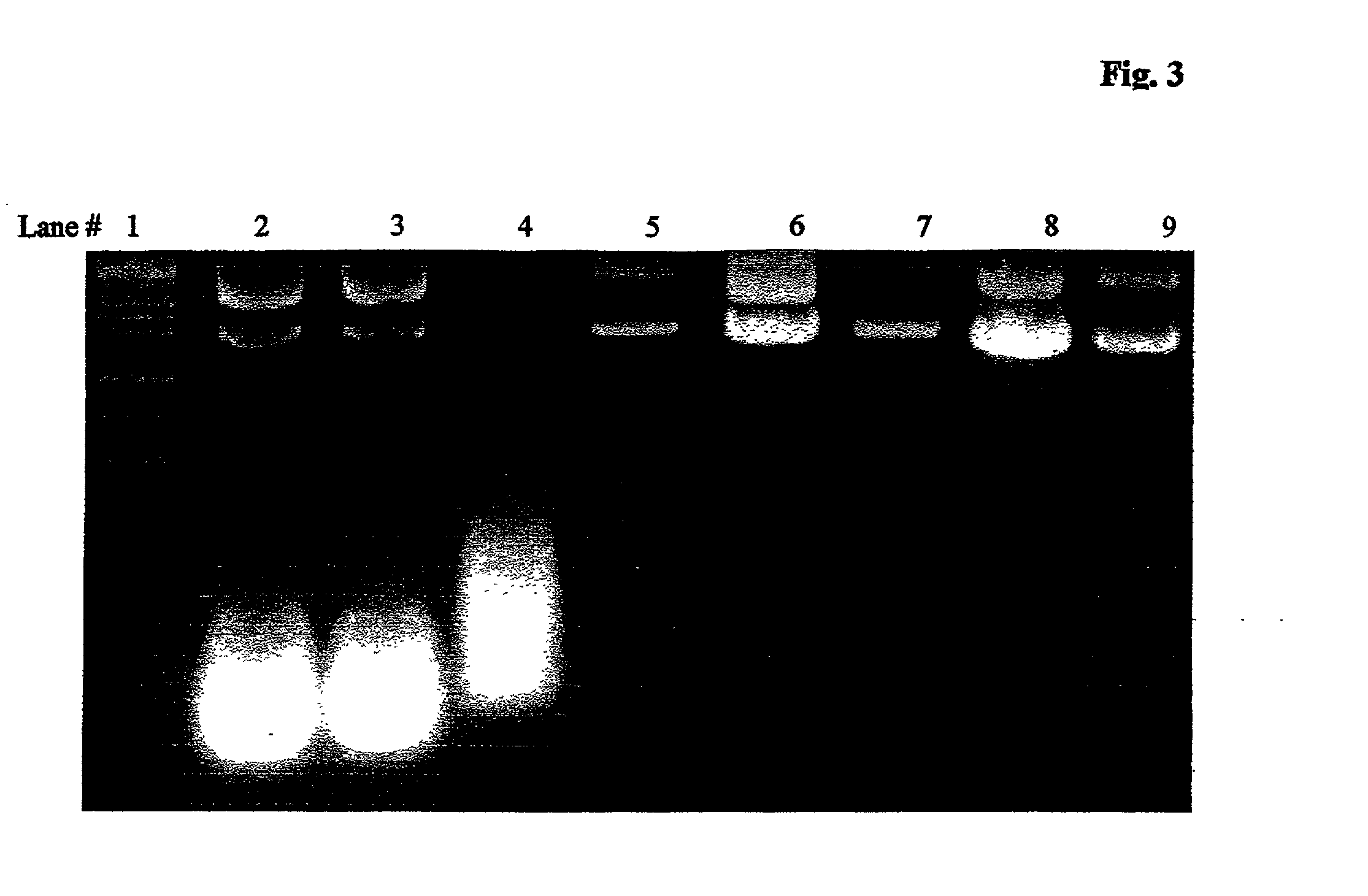

embodiments of the invention include purification of DNA, preferably plasmid DNA, by use of selective precipitation, preferably by addition of compaction agents Also included is a scaleable method for the liquid-phase separation of DNA from RNA. RNA may also be recovered by fractional precipitation according to the invention. RNA, commonly the major contaminant in DNA preparations, can be left in solution while valuable purified plasmid DNA is directly precipitated. Endotoxin can also be kept to very low levels. The invention includes mini-preps, preferably of plasmid and chromosomal DNA to obtain sequenceable and restriction digestible DNA in high yields in multiple simultaneous procedures. As a method of assay, a labeled probe is precipitated by hybridizing it to a target, (erg. chromosomal DNA, oligonucleotides, Ribosomal RNA, tRNA), and thereafter precipitating the probe / target complex with compaction agents and leaving in solution any unhybridized probe.

Owner:WILLSON RICHARD C III +1

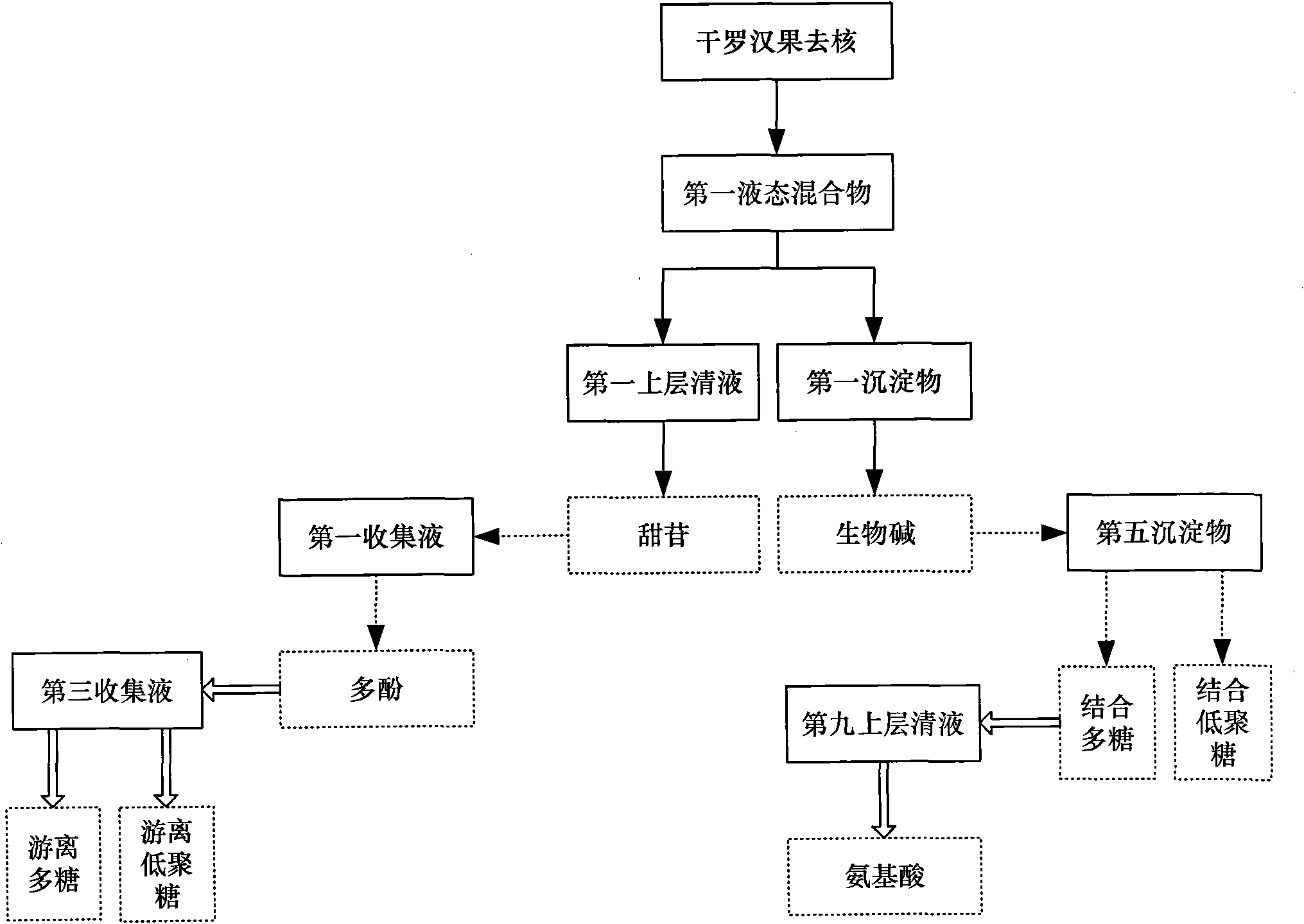

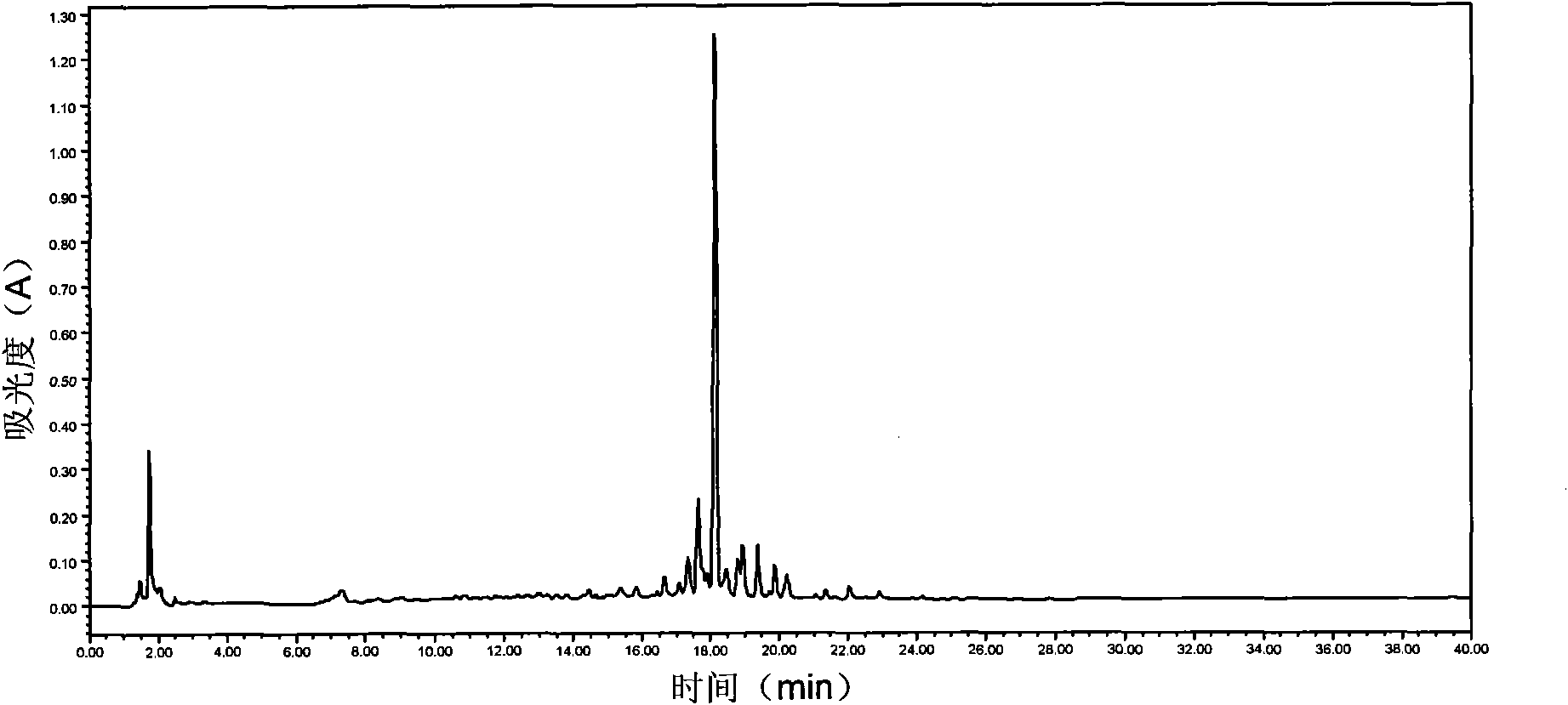

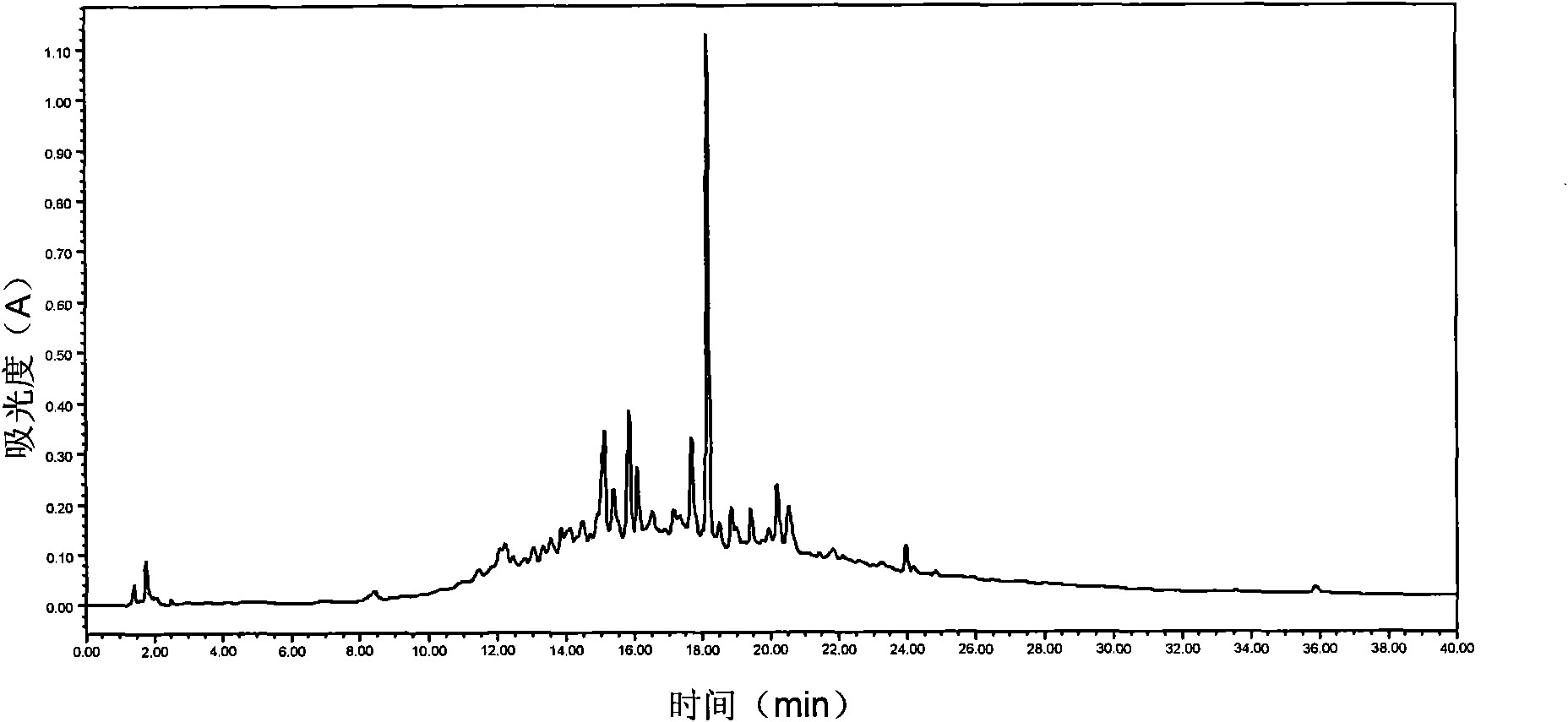

Method for extracting various active components from dried fructus momordicae

The invention discloses a method for extracting various active components from dried fructus momordicae, which belongs to the technical field of extraction separation of the effective components of natural products. The method comprises the following steps: firstly, denucleating the dried fructus momordicae; then carrying out watering flash extraction and centrifugation on peel and pulp to obtain precipitates and a supernate; respectively carrying out XAD chromatography for two times or upper polyamide-XAD chromatography and D213 column decoloration on the supernate to obtain mogroside and polyphenol; carrying out acid solution extraction and D113 column separation on the precipitates to obtain alkaloid; carrying out concentration and ethanol fractional precipitation on waste liquid to obtain polysaccharide and oligosaccharide; and hydrolyzing waste residues by using gastric enzymes to obtain the polysaccharide, the oligosaccharide and amino acids. The invention realizes the comprehensive utilization of the medicinal materials of the fructus momordicae, reduces the production cost and increases the additional value and the economic benefit of the product by adopting an advanced extraction technology.

Owner:BEIHANG UNIV

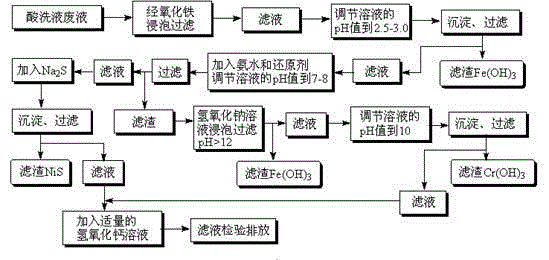

Method for treating stainless steel pickling waste liquor and recovering iron, chromium and nickel

InactiveCN104805291AHigh puritySolve processingWater contaminantsWaste water treatment from metallurgical processFerric hydroxideFractional Precipitation

The invention discloses a method for treating stainless steel pickling waste liquor and recovering iron, chromium and nickel. According to the method, a sodium hydroxide solution is adopted to control the pH of the stainless steel pickling waste liquor to achieve the purpose of recovery of iron, chromium and nickel through fractional precipitation. Because pH ranges of deposition of the iron, chromium and nickel elements are overlapped, part of iron oxide-hydroxide is precipitated firstly in a separation and recovery process, residual iron and chromium elements are co-precipitated out, and then chromium is precipitated and dissolved under the strong alkaline condition to realize final separation of iron and chromium. Due to presence of ammonia water and a reducing agent, the nickel element exists in the form of ions or a nickel ammine complex, is dissolved in the waste liquor, and finally reacts with a sulfide to precipitate NiS. The method has the characteristics of low cost, easiness in control, high separation and recovery rate of the iron, chromium and nickel elements and the like. The method can treat the stainless steel pickling waste liquor effectively, and the natural environment cannot be polluted after emission; the recovered metal elements have the recycling economic benefits, and the method has high application value and important technological innovation meaning.

Owner:NANYANG NORMAL UNIV

Method for recycling metal components from waste lithium ion batteries

InactiveCN101988156AAchieve recyclingSimple processProcess efficiency improvementFractional PrecipitationElectrical battery

The invention provides a method for recycling metal components from waste lithium ion batteries. The method comprises the steps of: crushing the waste lithium ion batteries into solid powder, adding a mixed solution of diluted hydrochloric acid and diluted nitric acid after crushing so as to dissolve LiCoO2, Cu and Al in the solid powder, and then filtering; adding an alkaline substance into a solution obtained through filtering, controlling the pH value of the solution obtained through filtering, filtering to obtain Al(OH)3, then adding the alkaline substance into a solution obtained through filtering, controlling the pH value of the solution obtained through filtering, filtering to obtain Cu(OH)2, then adding the alkaline substance into a solution obtained through filtering, controlling the pH value of the solution obtained through filtering, and filtering to obtain Co(OH)2. In the method, by controlling the PH value range of the solution, the pure Co(OH)2, Cu(OH)2 and Al(OH)3 can be obtained through fractional precipitation. The method has the characteristics of simple process, less equipment investment, low recycle cost and high recycle efficiency, and cannot cause secondary pollution in the recycle process.

Owner:路密

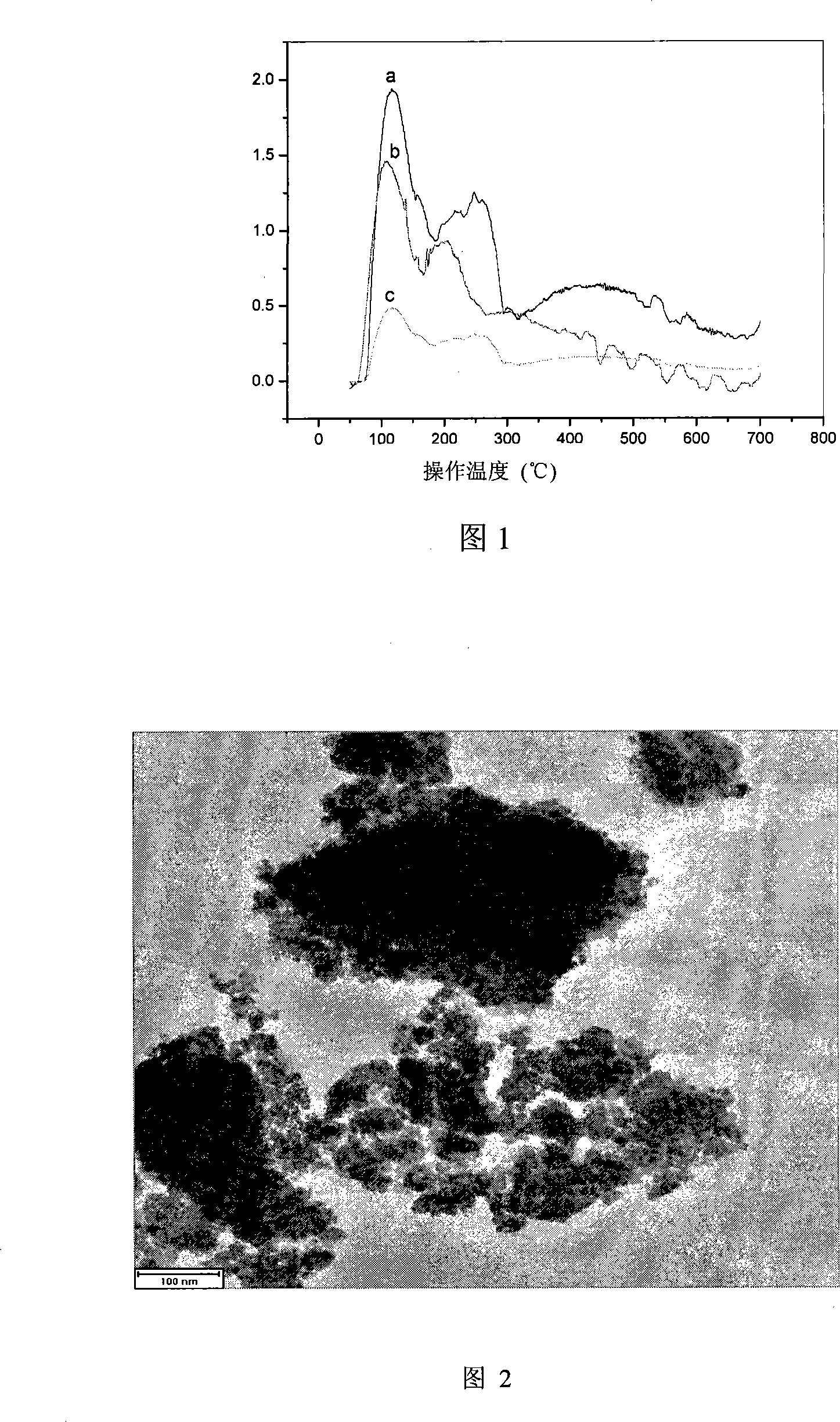

W-Sn nano composite metal oxide gas-sensing material and preparation method thereof

InactiveCN101182197AThermally stableWith structural stabilityFractional PrecipitationParticle-size distribution

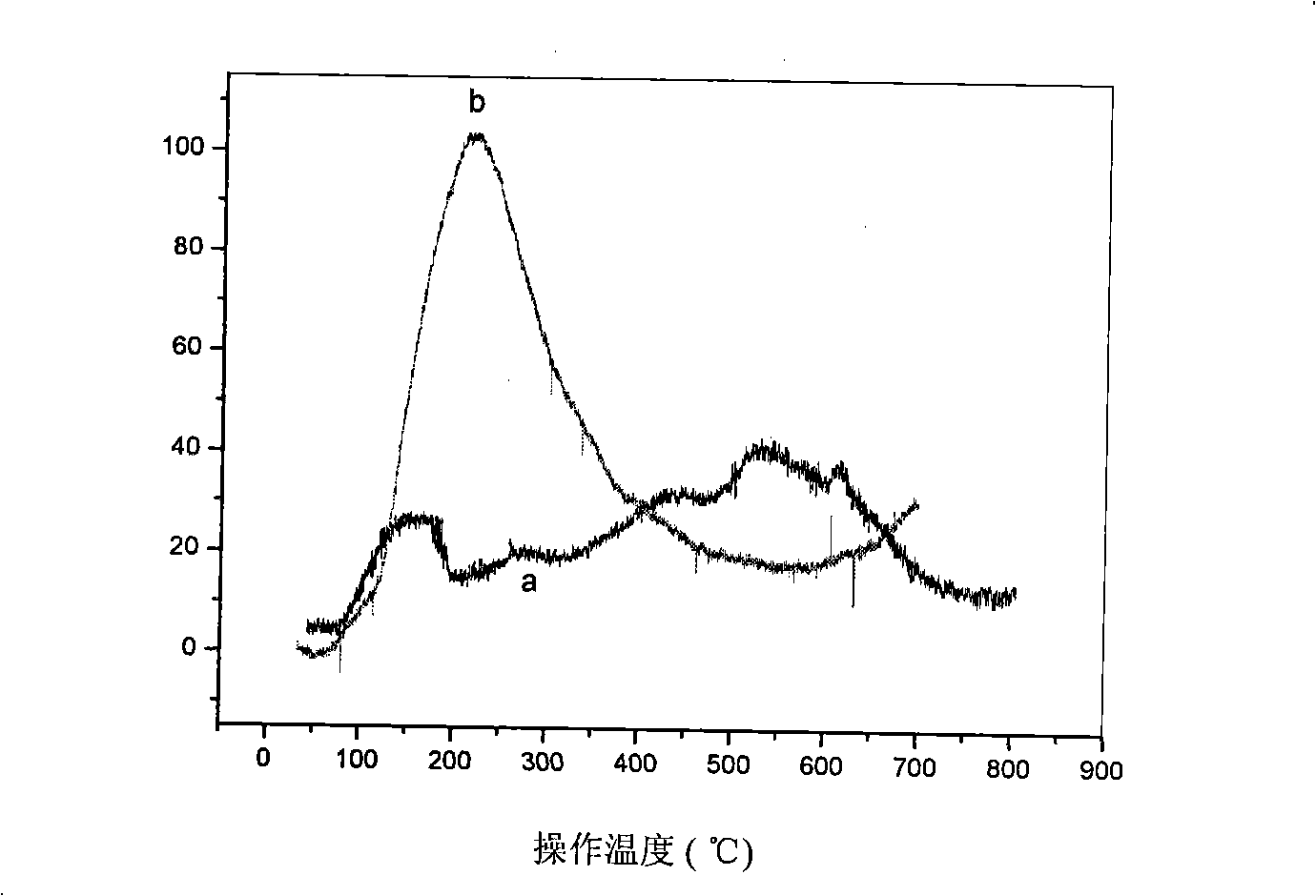

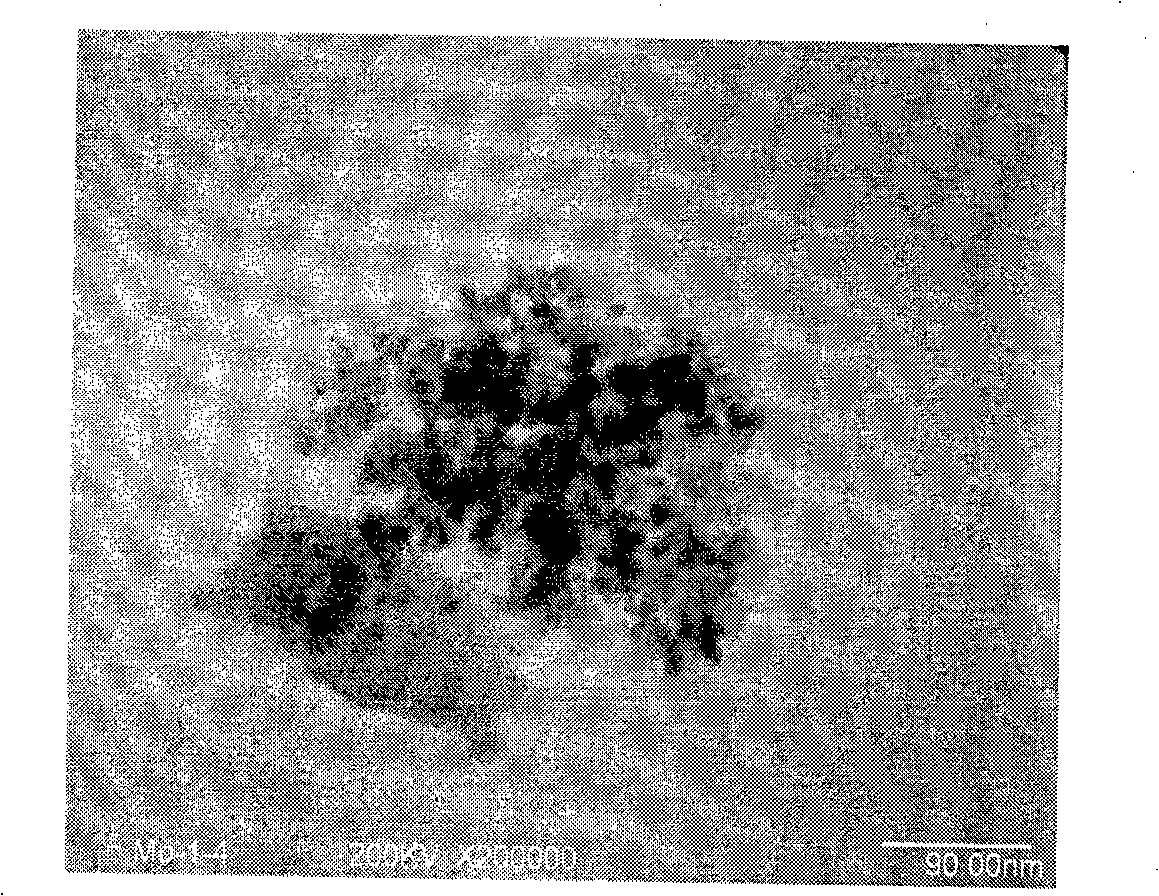

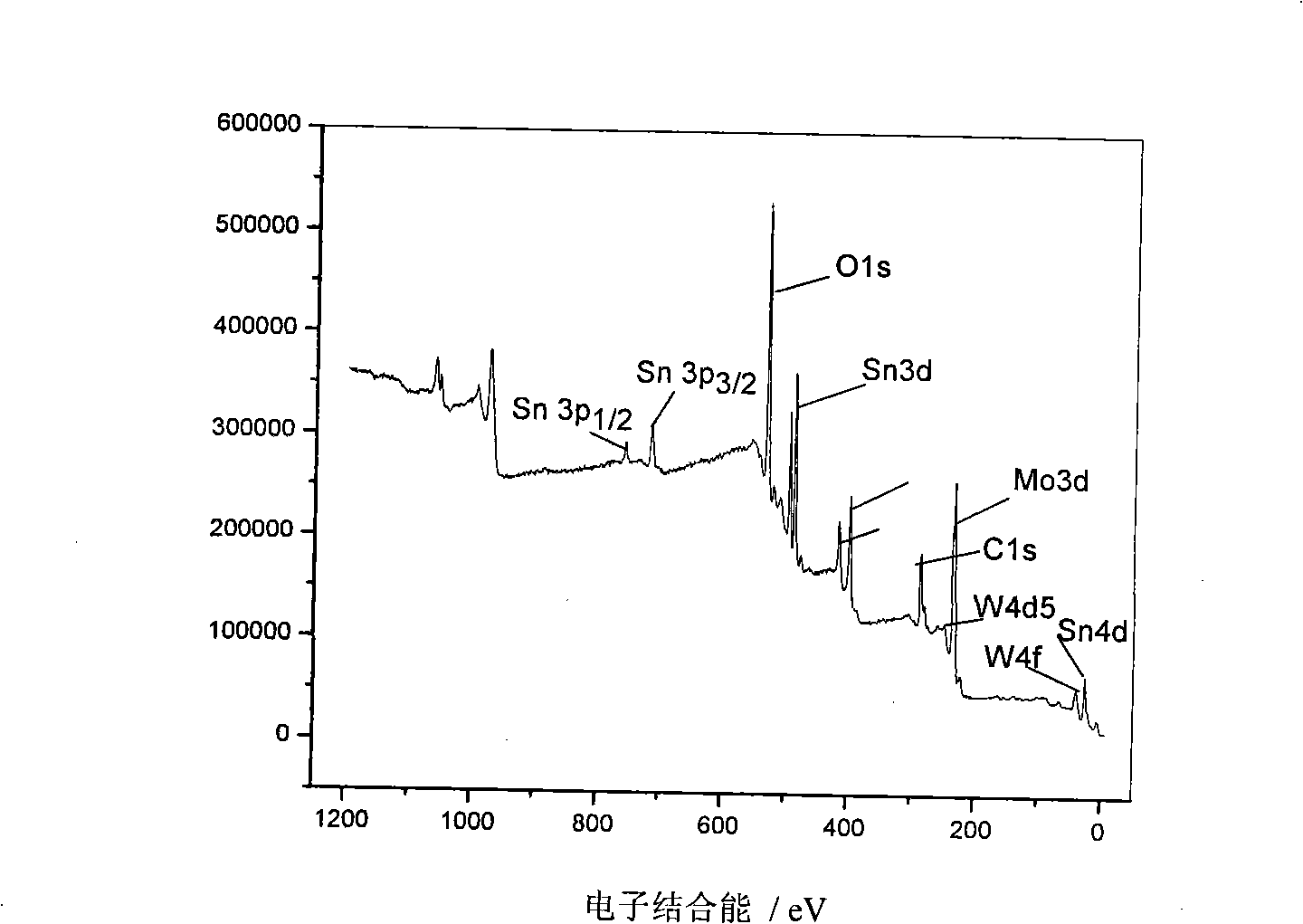

The invention relates to a W-Sn nanocomposite metal oxide gas sensitive material and a preparation method thereof. The composite metal oxide is a composite of WO3 and SnO2, expressed as WO3-SnO2, wherein the Sn / W molar ratio is 1-20:1, the particle size distribution is 5.0-30.0nm, and the specific surface area is 15.0-60.0m2 / g . The preparation method of this composite metal oxide adopts the step-by-step precipitation method. First, α-stannic acid is precipitated with tin salt, dispersed in water at a certain concentration, and then dropped into the tungsten salt solution with the above molar ratio of Sn / W to adjust The pH value is until the precipitation is complete. After drying, the precursor is roasted at a temperature of 400°C to 1000°C to make a nanocomposite powder. The powder is made into a sensor element, which has high adsorption performance and high sensitivity for NO2, and high selectivity for reducing gases.

Owner:BEIJING UNIV OF CHEM TECH

Extraction separation method of algae polysaccharide

InactiveCN1412203AIncrease profitAchieve co-extractionDrug biological activitySize-exclusion chromatography

The extraction and separation method of algae polysaccharide is characterized by that the present invention utilzies the characteristics of polysaccharide and glucoprotein which are dissolved in water, adopts water extraction method to make extraction, uses ethyl alcohol to make fractional precipitation to make separation, finally adopts the anion-exchange column and gel exclusion chromatography to purity polysaccharide, in which the biological activity of protein and protein polysaccharide can be retained.

Owner:ZHEJIANG UNIV

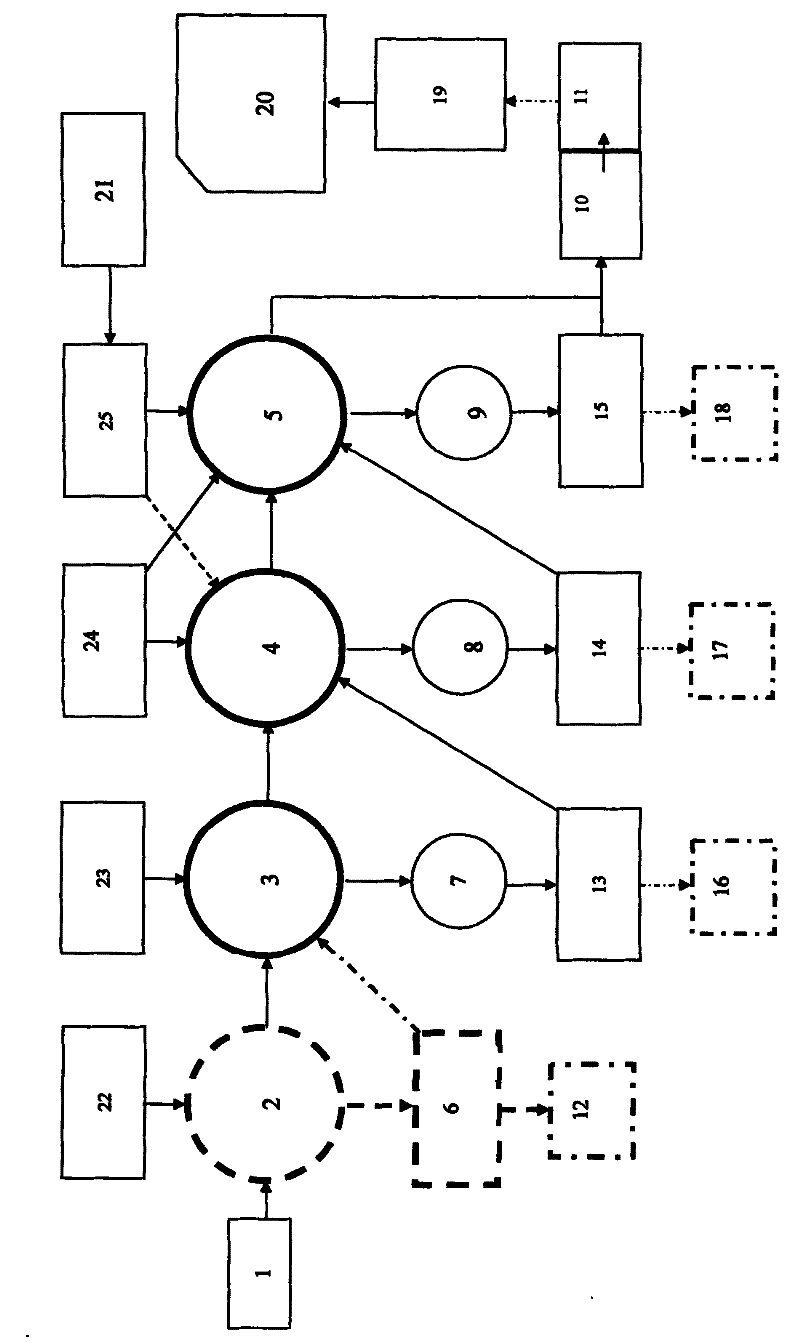

System for treatment of acid mine drainage and resource recovery of iron, aluminum, copper and zinc in drainage

ActiveCN102311189AEliminate pollutionEliminate hidden dangers of secondary pollutionWater contaminantsMultistage water/sewage treatmentSolubilityAcid mine drainage

The invention belongs to the field of wastewater treatment and specially, relates to a system for treatment of acid mine drainage and resource recovery of iron, aluminum, copper and zinc in drainage. The system is characterized in that the system is composed of an iron removal system, an aluminum removal system, a copper removal system, a zinc removal system, a sedimentation basin 1 and a sedimentation basin 2 by sequential connection. Based on differences of precipitation performances of a metal ion under pH conditions and differences of solubility products (Ksp) of a reaction between copperand a sulfur-containing organic chelating agent and a reaction between zinc and the sulfur-containing organic chelating agent, through a fractional precipitation method, iron, aluminum, copper, zinc and the like are separated effectively; resource recovery and utilization is realized; hidden troubles of secondary pollution caused by waste residues are eliminated; and treated drainage reaches a reuse standard and can is fed directly into mineral processing pool for reuse. The system has the advantages of simple process, good effect of drainage treatment, stable operation, low costs of treatment, capital construction investment, energy consumption and operation, and wide application prospect.

Owner:马前 +1

Method of synthetically and highly effectively reclaiming nickel and magnesium resource from nickel-containing serpentine

InactiveCN101016581AReduce leachingReduce consumptionProcess efficiency improvementAcid fracturingFractional Precipitation

The invention discloses a method to reclaim nickel magnesium resource from Ni-bearing serpentinite, which comprises the following steps: óƒ bruising the Ni-bearing serpentinite firstly; grinding to 0.074mm-2.0mm through ball; setting the grinding density at 20%-60%; ó getting ore pulp; adding into autoclave; stirring; adding into strong acid with pH value at 0.5-3; ó� heating-up; stirring; reacting with leaching reaction time of acid fracturing boil at 30min-240min and temperature at 90-220 deg.c and pressure at 110Kpa-2300Kpa; óœ finishing the reaction; filtering; getting nickel magnesium leachate; separating and reclaiming nickel magnesium product with traditional fractional precipitation method; or reclaiming the resource with extraction solvent or ion exchange. This invention can increase the quality of product and decrease the preparing cost.

Owner:FUJIAN SHUNCHANG JINZI MINE

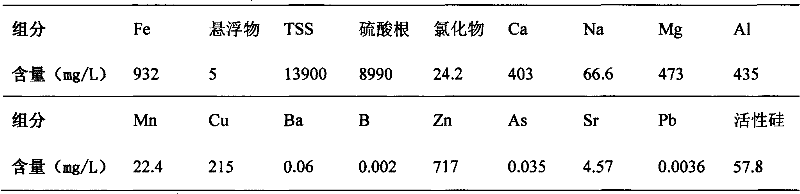

Method for cogeneration of TiO2 and Al2O3 by using titanium-bearing blast furnace slag mineralized carbon dioxide

InactiveCN106082322AAvoid miningFacilitate mass transferProductsAluminium compoundsAluminium hydroxideSlag

The invention discloses a method for cogeneration of TiO2 and Al2O3 by using titanium-bearing blast furnace slag mineralized carbon dioxide CO2. The method comprises the following steps: (1) mixing and roasting titanium-bearing blast furnace slag and ammonium sulfate so as to obtain roasting slag and an ammonia gas, and absorbing the ammonia gas with water so as to obtain ammonia water; (2) leaching the roasting slag with water, and filtering so as to obtain leachate and leaching residues; (3) enabling the leaching residues of the step (2) and the ammonia water of the step (1) to react with carbon dioxide so as to obtain mineralized slag and mineralization mother liquor; (4) adjusting the pH value of the leachate of the step (2) by using the ammonia water of the step (1), performing fractional precipitation, and filtering so as to obtain metatitanic acid, aluminum hydroxide precipitate and a magnesium-enriched solution; (5) enabling the magnesium-enriched solution of the step (4), the ammonia water of the step (1) and the carbon dioxide to react to obtain magnesium carbonate precipitate and mineralization mother liquor; (6) mixing the mineralization mother liquor of the step (3) and the step (5), evaporating, cooling, and crystallizing so as to obtain an ammonium sulfate solid for cycle use; (7) respectively calcining the precipitate of the step (4), thereby obtaining TiO2 and Al2O3.

Owner:SICHUAN UNIV

Method for separating and purify dermatansulfate and low-molecular heparan sulfate from sodium heparan product

ActiveCN1850864AStable separationImprove solubilityOrganic active ingredientsDermatan sulfateSodium heparin

The invention relates to a method to separate and purify dermatan sulfate and low molecule heparan sulfate from sodium heparin by-product. It uses the by-product of producing sodium heparin as raw material taking fractional precipitation through alcohol to gain raw dermatan sulfate; uses nitrite and nitrous acid ester compounding as oxidant to degrade the heparan sulfate into low molecule heparan sulfate and taking fractional precipitation through alcohol to separate high purity dermatan sulfate and low molecule heparin sulfate.

Owner:NANJING KING FRIEND BIOCHEM PHARMA CO LTD

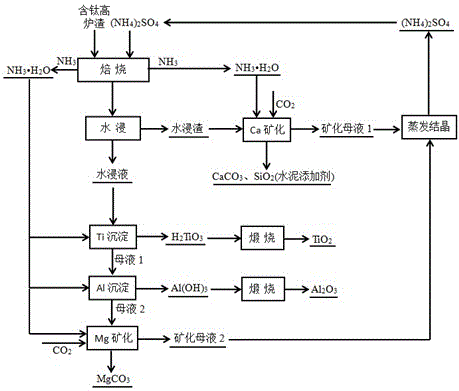

Method for recycling valuable metal from copper smelting white smoke

The invention relates to a method for recycling valuable metal from copper smelt white smoke and belongs to the technical field of resource recycling. The method includes the steps that the white smoke collected from a second electric field, a third electric field and a fourth electric field through an electric copper smelting smoke collection device serves as a raw material, a first-level power wave circulating cleaning solution serves as a leaching agent, the liquid-solid mass ratio is 8-10:1, leaching is conducted at the normal temperature, and lead-rich slag with the metal grade larger than 40wt% is obtained; sodium sulfide is added to a leaching solution for fractional precipitation so as to recycle copper and rich arsenic, the metal grade of copper-rich slag is larger than 40wt / %, the content of the arsenic in the arsenic-rich slag is larger than 35 wt%, finally, sodium carbonate is added for zinc precipitation, and the metal grade of the zinc-rich slag is larger than 45 wt / %; the valuable metal mentioned above can be used as raw materials for use or sale after being enriched, stockpiling or landfill requirements can be met after the metal is cured, and the arsenic open stub is formed. By the adoption of the method, circulating acid pickle serves as the leaching agent, the system waste acid treatment amount is reduced, valuable elements in the waste acid can be recycled, leaching operation and precipitation operation are conducted at the normal temperature, operation is convenient, and the method has good application and popularization value.

Owner:KUNMING UNIV OF SCI & TECH +1

Method for comprehensively recovering valuable metal from copper tellurium slag

InactiveCN102994766AReduce the impactReduce pollutionProcess efficiency improvementBinary selenium/tellurium compoundsFractional PrecipitationSlag

The invention discloses a method for comprehensively recovering valuable metal from copper tellurium slag. The copper tellurium slag is dissolved by using nitric acid, so that silver, copper and bismuth in the copper tellurium slag are basically dissolved in a solution; tellurium is oxidized into tellurium oxide, thereby entering undissolved slag. Silver, copper and bismuth are separated and recovered via fractional precipitation of the solution; and tellurium is separated and recovered via alkaline leaching of the undissolved slag. The method solves the problems that cost of a conventional process is high, copper recovery rate and tellurium recovery rate are not high, and that silver and bismuth cannot be recovered in the conventional process; influences on the environment of the production process are reduced; a whole process is simple; and pollutions toward the environment is small. The method is simple in the whole production process, low in cost and small pollutions toward the environment, has high comprehensive recovery rate, and realizes complete separation of silver, copper, bismuth and tellurium. The obtained products have high purity; and the recovery rate of silver, copper, bismuth and tellurium is higher than 99%.

Owner:SIHUI CITY HONGMING PRECIOUS METALS

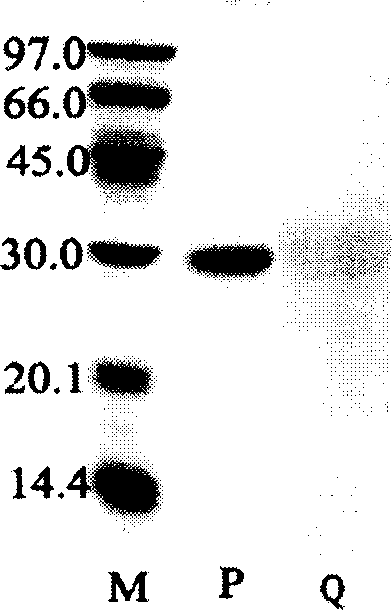

Agglutinin protein of astragalus root and preparation method thereof

InactiveCN1687115AGood antifungal activityEnhanced inhibitory effectAntimycoticsPeptide/protein ingredientsIon exchangeAgglutination

The present invention provides an agglutinant protein obtained by separating plant astragalus root and purifying its extract and its preparation method. In the concrete, said invention uses the astragalus root as raw material, and utilizes ammonium sulfate with different saturations to make fractional precipitation and multistep ion exchange column chromatography so as to obtain astragalus agglutinant protein which can be used for blood agglutination and has the obvious antifungal action.

Owner:CHINA AGRI UNIV

Method for preparing tremellan with low molecular weight and novel medicinal application thereof

The invention discloses a method for preparing tremellan with low molecular weight from Tremella fueiformis Berk and application of the tremellan with low molecular weight in treatment for chronic atrophic gastritis and serving as an adjuvant medicament in tumor therapy. The method for preparing the tremellan with low molecular weight comprises the following steps of: cleaning the Tremella fueiformis Berk, homogenating, adding solution of acid water, extracting for 1 to 3 hours by using the acid water at certain temperature and under certain pressure, neutralizing extracting solution of the acid water until the extracting solution is neutral by using alkaline water, centrifuging, concentrating supernatant to an appropriate volume, and preparing the tremellan through ultrafiltration membranes with different molecular weight cutoffs or an ethanol fractional precipitation method. The tremellan with low molecular weight prepared by the method is used for treating chronic atrophic gastritis and carrying out pharmacodynamics research of adjuvant medicaments in tumor therapy, and the medicinal effect is high.

Owner:高其品

Method for increasing antioxidation activity of flammulina velutipes polysaccharide

ActiveCN103073648AImprove polysaccharide extraction rateImproves antioxidant activityDPPHFractional Precipitation

The present invention discloses a preparation method for increasing antioxidation activity of flammulina velutipes polysaccharide, wherein an enzymolysis control method is adopted to regulate and control molecular weight distribution of flammulina velutipes polysaccharide, flammulina velutipes is sequentially subjected to crushing, impurity removing, hot water extraction, protein removing, concentration and ethanol fractional precipitation separation to obtain the flammulina velutipes polysaccharide, and an enzyme method is adopted to carry out degradation control so as to reduce a molecular weight of the flammulina velutipes polysaccharide to 19000-30000 Da. The flammulina velutipes polysaccharide prepared by using the method is suitable for industrial production, wherein a polysaccharide extraction rate is increased by 2.5-3.5 times compared with a polysaccharide extraction rate of the traditional water extraction method, significant antioxidation activity is provided, IC50 of the flammulina velutipes polysaccharide in a DPPH.radical system is 1.69-2.12 mg / mL, and an ORAC value can be up to 923 mumol Trolox / g.

Owner:SOUTH CHINA UNIV OF TECH

Method for ultrasound strengthen, extraction and purification of longan and litchi polysaccharide

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

MoO3-SnO2 base doped nano composite metal oxide and method for producing the same

InactiveCN101294928AHigh sensitivityHigh selectivityMaterial analysis by electric/magnetic meansCross sensitivityFractional Precipitation

The invention relates to a nanometer composite metal oxide with doped MoO3-SnO2 base and preparing method thereof; the chemical general equation of the nanometer composite metal oxide with doped MoO3-SnO2 base can be expressed as: Y-MoO3-SnO2, wherein, the mole ratio of Sn / Mo is 0.1 to 10 : 1, Y represents the doped metal oxide, and the quality ratio of the metal elements of the Y and the Sn is 0 to 0.05 :1; the invention adopts a fractional precipitation method, comprising the following steps: Alpha-stannic acid precipitate is prepared by pink salt, the filtered precipitate is scattered in the water so as to prepare Alpha-stannic acid sol the concentration of which is 0.02 to 0.2M, molybdenum salt solution is added by dipping, the pH value is regulated till the precipitation is completed, and the nanometer composite powder is prepared by drying and roasting; the powder is prepared into a sensor element which has higher sensitivity for NO2, CO and C2H5OH, the sensitivity and the selectivity thereof for NO2, CO and C2H5OH gas are improved by doping and wrapping a little of metal oxide, thus reducing the cross sensitivity of the NO2, CO and C2H5OH gas.

Owner:BEIJING UNIV OF CHEM TECH

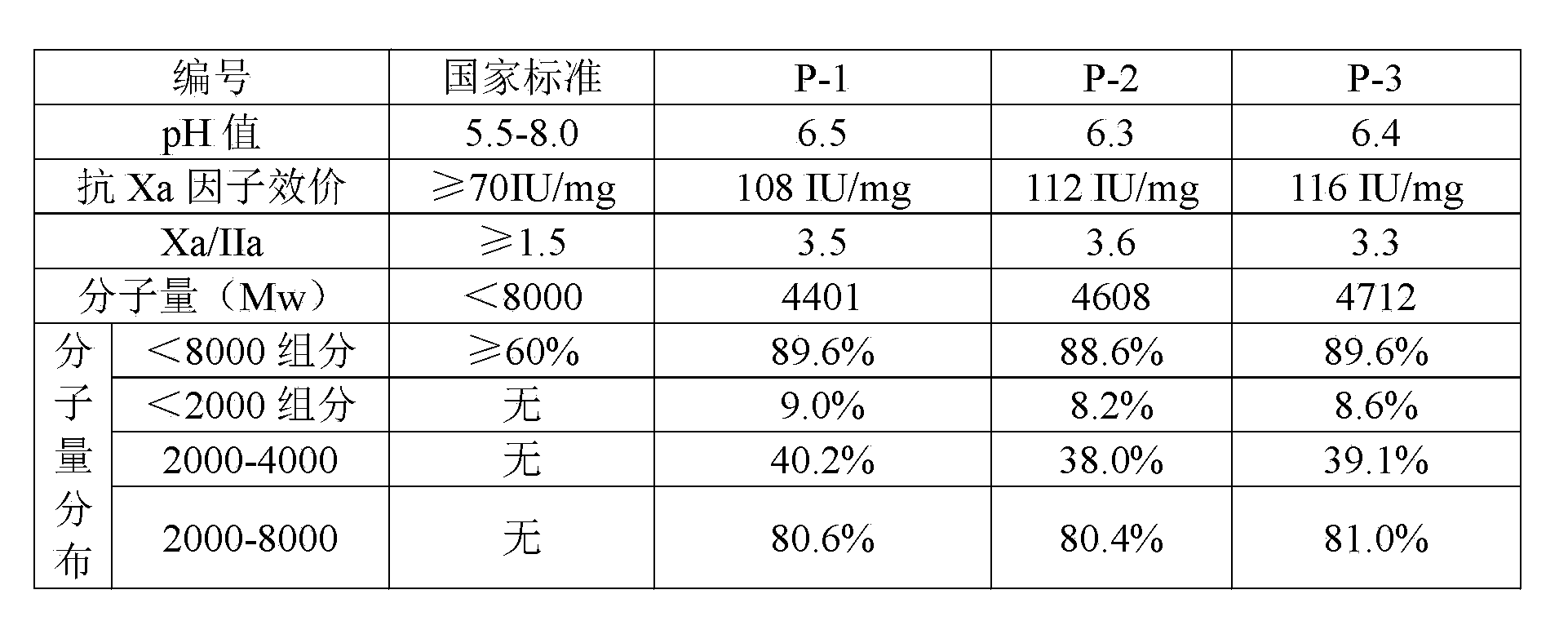

Preparation and purification process for nadroparin calcium

ActiveCN103382232AEfficient separationChange fractional precipitation methodBlood disorderExtracellular fluid disorderFractional PrecipitationDepolymerization

The invention relates to a preparation and purification process for nadroparin calcium. The process comprises the following steps: depolymerization; reduction; recrystallization; chromatography; and filtration. According to the invention, the process can effectively extract a fragment with a narrow molecular weight distribution range; nadroparin calcium is obtained through improvement of a preparation process for low-molecular-weight heparin calcium, an out-dated solvent fractional precipitation method is changed, conditions for anion exchange chromatography are optimized, and the fragment both meeting requirements for molecular weight of LMWH in China and according with molecular weight distribution of nadroparin calcium are obtained through gradient?elution.

Owner:CHANGSHAN BIOCHEM PHARM JIANGSU CO LTD

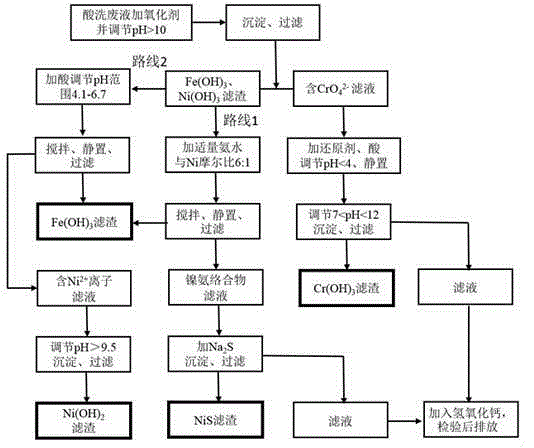

Recovery processing method of stainless steel acid pickling waste liquid containing iron, chromium and nickel

InactiveCN104787928AEasy to separateSolve the problem of low purityIron oxides/hydroxidesMultistage water/sewage treatmentFractional PrecipitationSS - Stainless steel

The invention discloses a recovery processing method of stainless steel acid pickling waste liquid containing iron, chromium and nickel. The recovery processing method comprises the following steps: (1) oxidizing chrome (III) ions in an alkaline condition, and separating the oxidized chrome (III) ions from iron and nickel; (2) reducing chrome in an acidic condition to trivalent chrome, and precipitating the trivalent chrome in the form of hydroxide; (3) separating nickel and iron elements through the ammonia leaching or fractional precipitation method, separating the iron elements in the form of Fe (OH)3, and obtaining the final product of the nickel element in the form of NiS or Ni(OH)2. According to the invention, the technological universality is high, the stainless steel acid pickling waste liquid with different concentrations can be separated, the characteristics of low cost, easiness in control of technological conditions, simple equipment and high recycling rate of valuable metal elements are realized, the problem about the sewage pollution of a stainless steel production enterprise can be effectively solved, the recycled metal elements can be reutilized, the economic benefit of the enterprise can be increased, and the dual significances of environmental protection and resource utilization are realized.

Owner:NANYANG NORMAL UNIV

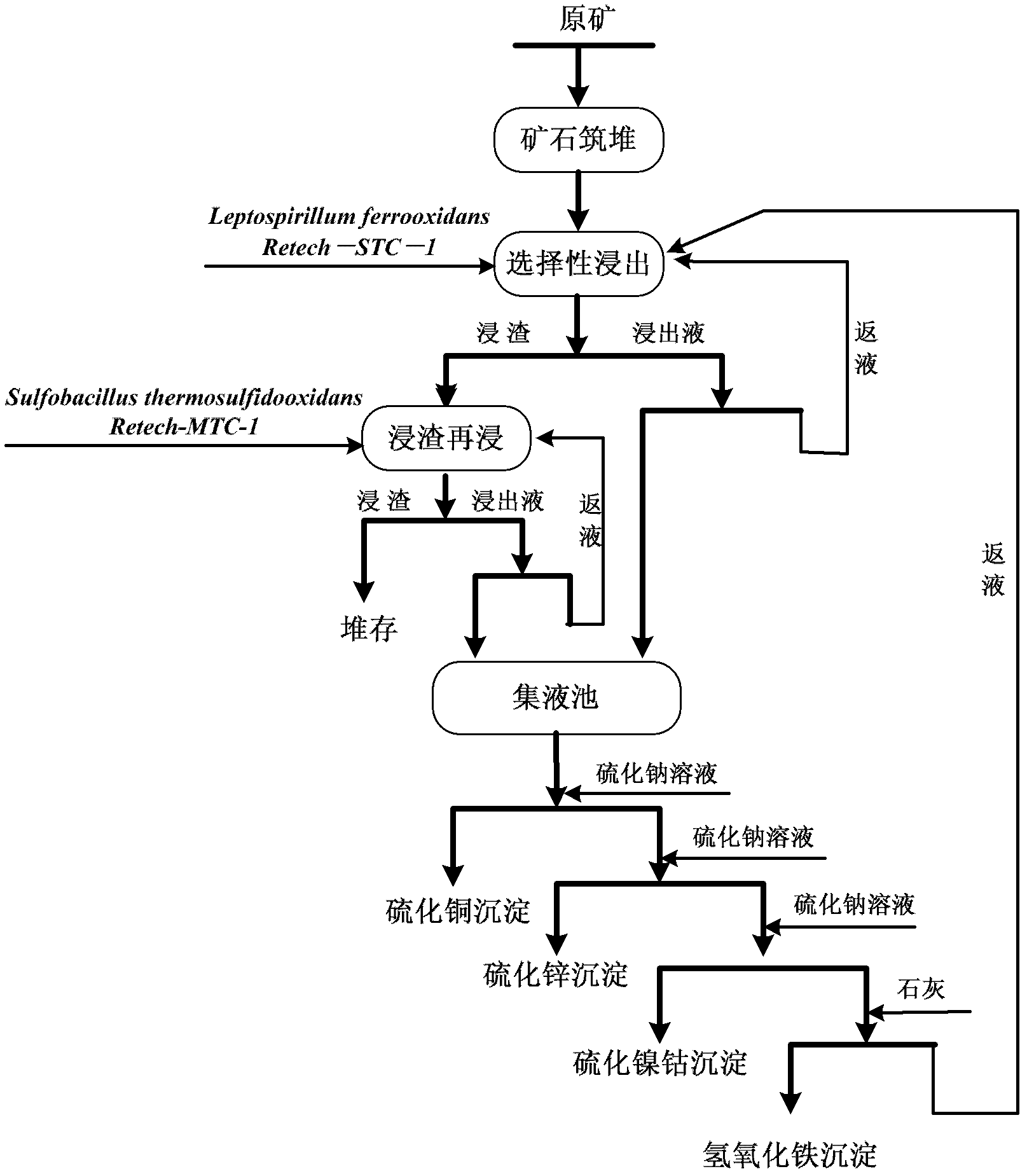

Low-grade multi-metal sulfide mineral selective bioleaching technology

ActiveCN103184335ALow impurity contentReduce the amount of sedimentProcess efficiency improvementSulfide mineralsContamination

The invention provides a low-grade multi-metal sulfide mineral selective bioleaching technology. The process is as follows: pile building is performed on the raw mineral materials, dilute acid solution is adopted for presoaking, and efficient mineral leaching bacteria are led in for leaching after the acidity of the mineral pile is basically stable; pile unloading is performed when the leaching of nickel reaches more than 80 wt%, then pile building is performed again on the leaching residue, and thermophilic bacteria are led in for leaching; and when the concentration of nickel in the leaching agent is more than 2.0 g / L, open-cycle is performed on the partial leaching agent, sodium sulfide is added into the leaching agent for fractional precipitation, so as to obtain copper sulphide, zinc sulphide and nickel and cobalt sulphide products, after precipitation is completed, lime is added into the leaching agent for neutralization, wherein concentration of iron in the neutralized leaching agent is less than 1.0 g / L, and the neutralized leaching agent can be reused at the leaching stage. According to the invention, technological process is short, equipment is simple, investment conservation and zero contamination are realized, cost is low, recovery rate of valuable metal is improved, the purpose of comprehensively utilizing low-grade multi-metal sulfide mineral resources is realized, and greater economic benefits can be achieved.

Owner:有研资源环境技术研究院(北京)有限公司

Method for purifying crude product heparin sodium

The invention discloses a method for purifying a crude product heparin sodium. The method comprises the following steps of: adjusting the pH value of the heparin sodium solution containing alcohol to remove most impurities; oxidizing the heparin sodium solution containing alcohol by using hydrogen peroxide for decoloring and impurity removing; and performing fractional precipitation of organic solvent to obtain the heparin sodium meeting pharmacopoeia standard. In the method, the heparin sodium solution containing low concentrate alcohol is selected in the steps of pH adjustment, impurity removal, oxidization and the like for operation, so that the method can not only effectively improve the product quality (ensuring impurities can be better separated from the heparin sodium and can be easily flocculated), but also ensure the product yield, the structure of the heparin sodium cannot be changed in the whole process, and the alcohol can be recycled. Therefore, the method has the advantages of low production cost, short production period, stable quality, suitability for mass production, and product quality in accordance with the quality requirement of injection heparin sodium raw material.

Owner:江苏麦德森制药有限公司

Preparation method of dogwood polysaccharides

The invention relates to a preparation method of dogwood polysaccharides. The process comprises the following steps of: taking dry residues obtained after extracting total glucoside from dogwood pulp alcohol as a raw material, adding 5-10 (V / W) times of warm water, ultrasonically extracting for 1-2 h, combining the extracting solutions, concentrating, adding 30% of H2O2 and 3% trichloroacetic acid, centrifuging, taking the supernate, ultrafiltering, firstly adding a right amount of water into entrapped matter, then adding different concentrations of alcohol for fractional precipitation, filtering out high concentration alcohol precipitates and drying to obtain the product. The process has the advantages of simple operation, lower cost and higher purity and is beneficial to large production operation.

Owner:NANJING ZELANG MEDICAL TECH

Method for separating and purifying heparin sodium and heparan sulfate from heparin byproducts

ActiveCN102911290AHigh purityEfficient removalOrganic active ingredientsBlood disorderMaterial resourcesIon-exchange resin

The invention discloses a method for separating and purifying heparin sodium and heparan sulfate from heparin byproducts. The method comprises the steps of dissolving raw heparin byproducts, adding potassium acetate to precipitate and separate heparin sodium, adding potassium acetate to precipitate heparin sodium after precipitating and dissolving heparin sodium, collecting a precipitate, dissolving and then conducting fractional precipitation repeatedly with anhydrous alcohol to prepare the heparin sodium with a higher purity, adding a benedict reagent and a saturated sodium hydroxide solution to supernate, centrifuging to obtain a solution containing the heparan sulfate, removing copper ions with a decoppering agent, adding active carbon to absorb the precipitate, decolorizing and filtering, and then absorbing and eluting with anion exchange resin to obtain the high-purity heparan sulfate by separation. According to the method, the high-purity heparin sodium and heparan sulfate can be separated again from the byproducts used for producing the heparin sodium, so that financial resources and material resources required for storing or discarding a large number of heparin byproducts can be saved, wastes can be changed into valuables, the byproducts are recycled, the cost is saved greatly, and a value is created.

Owner:NANJING KING FRIEND BIOCHEM PHARMA CO LTD +1

Method and device for treating and recycling copper-containing acid wastewater of mines

ActiveCN107601779AReduce adverse effectsHigh technical feasibilityWaste water treatment from quariesWater contaminantsSludgeSulfate-reducing bacteria

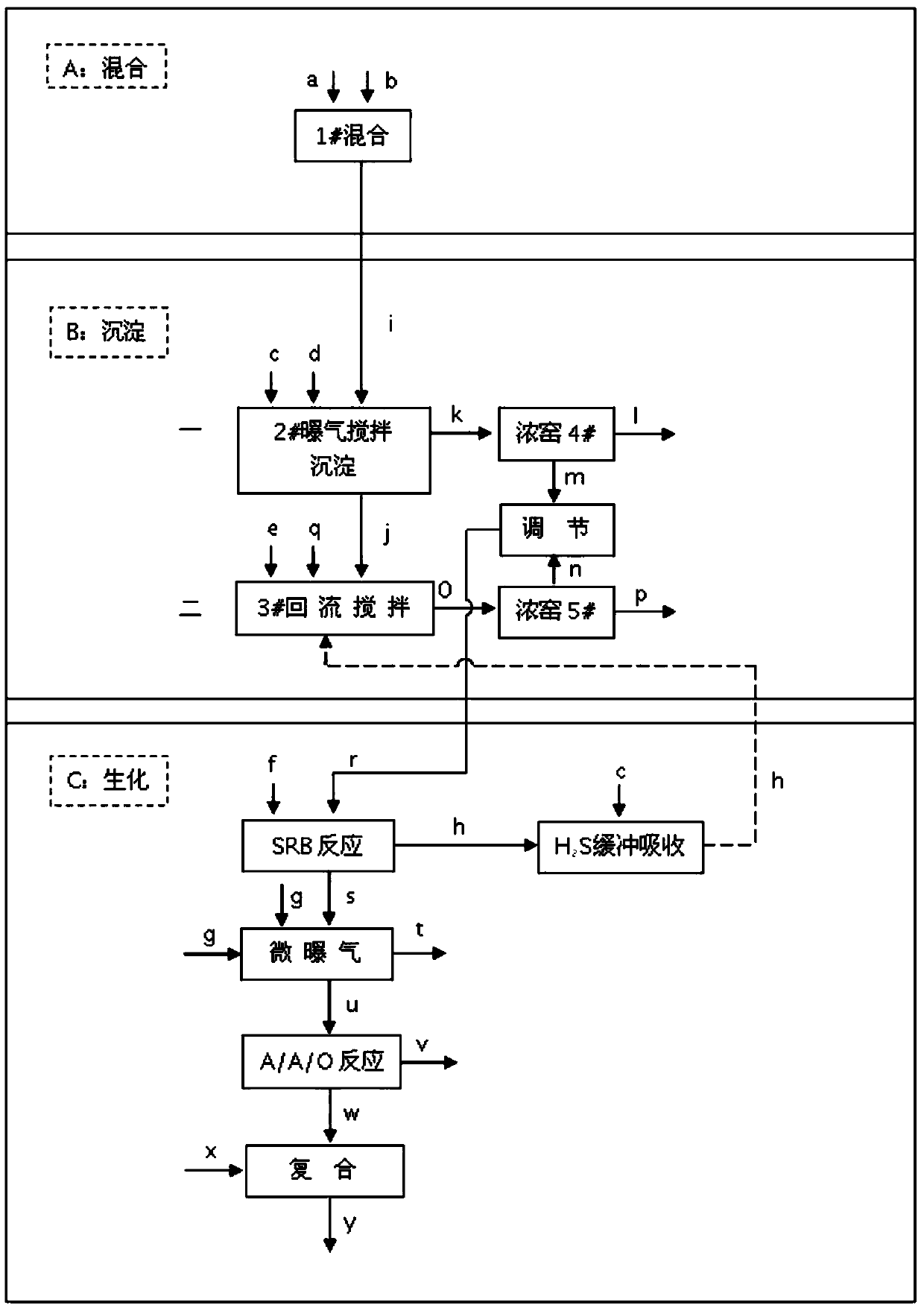

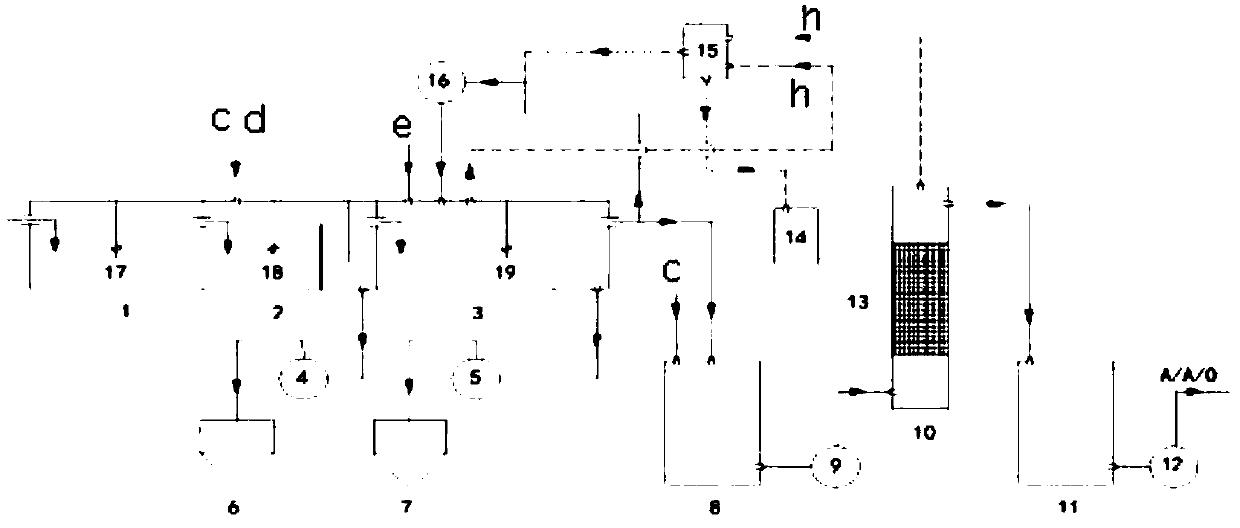

The invention relates to a method and a device for treating and recycling copper-containing acid wastewater of mines. The method comprises the following steps: mixing two wastewaters, namely copper pit water and raffinate, in a certain volume proportion, so as to form mixed acid wastewater; carrying out fractional precipitation on valuable heavy metals in the mixed acid wastewater by virtue of a combined medicament, so as to reduce neutralizing residue and recycle copper; recycling copper in the acid wastewater through the synergic effect generated in a metabolic process of chemical precipitates and sulfate reducing bacteria; and preparing a compound fertilizer from organic sludge generated by virtue of a biochemical method, and reusing the compound fertilizer in the rehabilitation and afforesting of the mines. According to the device for implementing the method, hydrogen sulfide circulating and absorbing equipment is additionally arranged, a reaction device is optimized, and combinedfillers of a bioreactor are optimized, so that the conversion efficiency of sulfate reducing bacteria to SO4<2-> is increased, and the repeated cyclic utilization of hydrogen sulfide is realized. A process adopted in the method is environment-friendly and has good universality to working conditions of the mines, so that the method has the advantages that the recycling rate of copper in the acid wastewater is more than or equal to 92%, the reduction amount of the neutralizing residue is more than or equal to 70%, the storage capacity pressure of tailings can be effectively reduced, and the like.

Owner:ZIJIN MINING GROUP +1

Comprehensive preparation and purification method for polysaccharides with different properties in hericium erinaceus

InactiveCN106883304AHigh extraction rateIncrease viscosityPurification methodsWater soluble polysaccharides

The invention provides a comprehensive preparation and purification method for polysaccharides with different properties in hericium erinaceus. The comprehensive preparation and purification method comprises the following steps: (1) crushing dried hericium erinaceus sporophores, degreasing and drying; (2) extracting with hot water and carrying out ethanol precipitation; (3) washing sediment with absolute ethyl alcohol, acetone and absolute ethyl ether; removing protein by a Sevag method; dialyzing and removing small molecular substances to obtain hericium erinaceus water extracted water-soluble polysaccharides; (4) re-dissolving; carrying out ethanol fractional precipitation to obtain hericium erinaceus water-soluble purified polysaccharide components with different properties; (5) drying filter residue generated after extracting with the hot water; extracting with NaOH / NaBH4, and carrying out the ethanol precipitation; washing with the absolute ethyl alcohol, the acetone and the absolute ethyl ether; removing protein by the Sevag method; dialyzing and removing small molecular substances to obtain hericium erinaceus alkali extracted water-soluble polysaccharides. According to the comprehensive preparation and purification method, the water extracted water-soluble polysaccharides and high-stickiness alkali extracted water-soluble polysaccharides of the hericium erinaceus are prepared from the hericium erinaceus sporophores, and the utilization rate is high; the water extracted water-soluble polysaccharides of the hericium erinaceus are subjected to fractionation purification through the ethanol to obtain the hericium erinaceus water-soluble purified polysaccharide components with different properties; a process is simple, and the cost is low.

Owner:NANCHANG UNIV

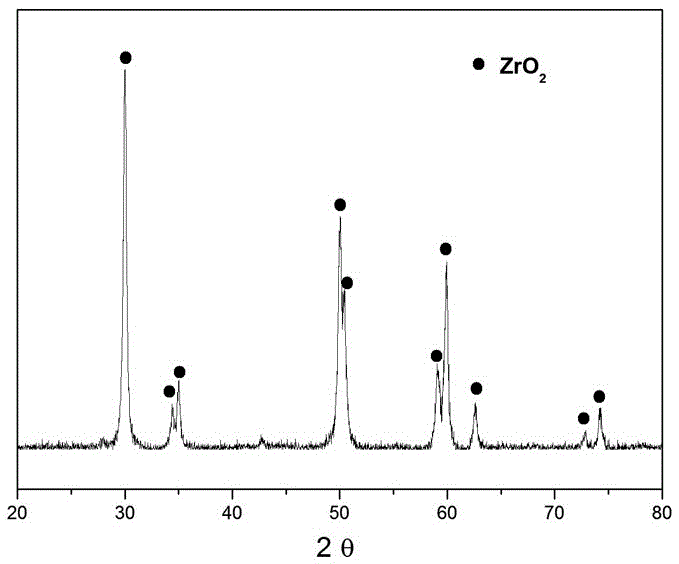

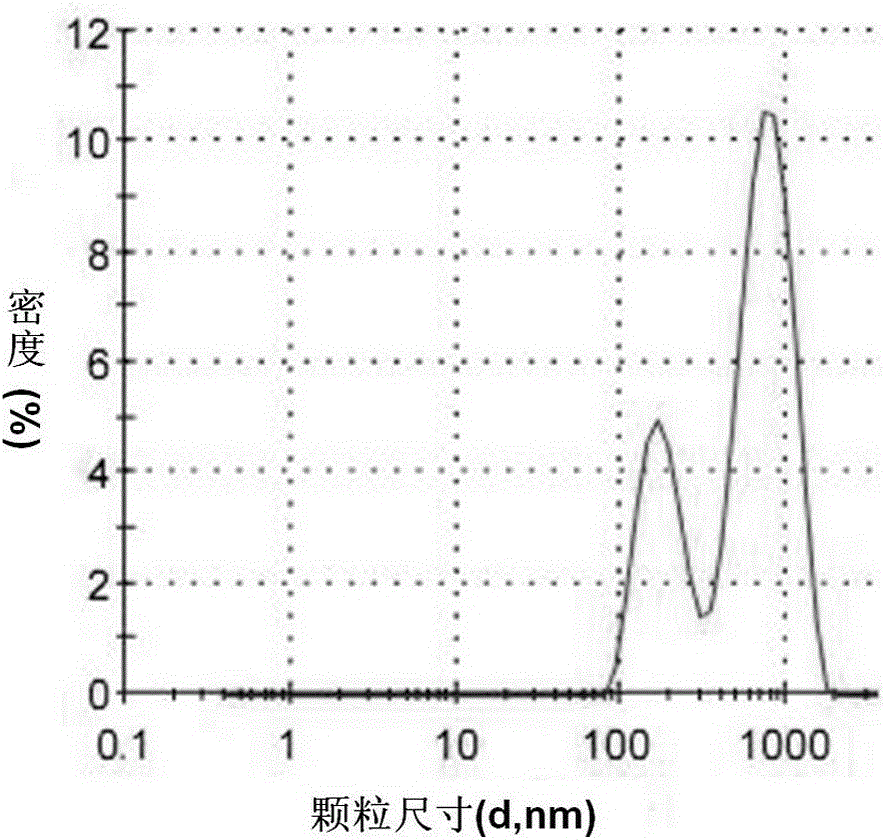

Grain-composition zirconia powder preparation and ceramic sintering method

The invention discloses a grain-composition zirconia powder preparation and ceramic sintering method. The method comprises the following steps: by adopting a co-precipitation method and taking water as a solvent under a weakly alkaline condition, synthesizing nano-scale and submicron-scale mixed particles with specific size distribution by one step at relatively low temperature; adding a fractional precipitation agent into the system, and controlling the proportions of the submicron particles and nanoparticles; drying and calcining the precipitate to obtain grain-composition zirconia powder with high crystallinity; adding a sintering aid; performing mixing, drying and dry pressing; and then sintering at 1,400-1,700 DEG C to obtain dense zirconia ceramic. The method disclosed by the invention is applicable to the grain composition of superfine powder and obtains close packing; and the biscuit density is increased, the sintering shrinkage is reduced, and the production technology is improved. The powder prepared by the method can be applied to the field of high-density zirconia preparation.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

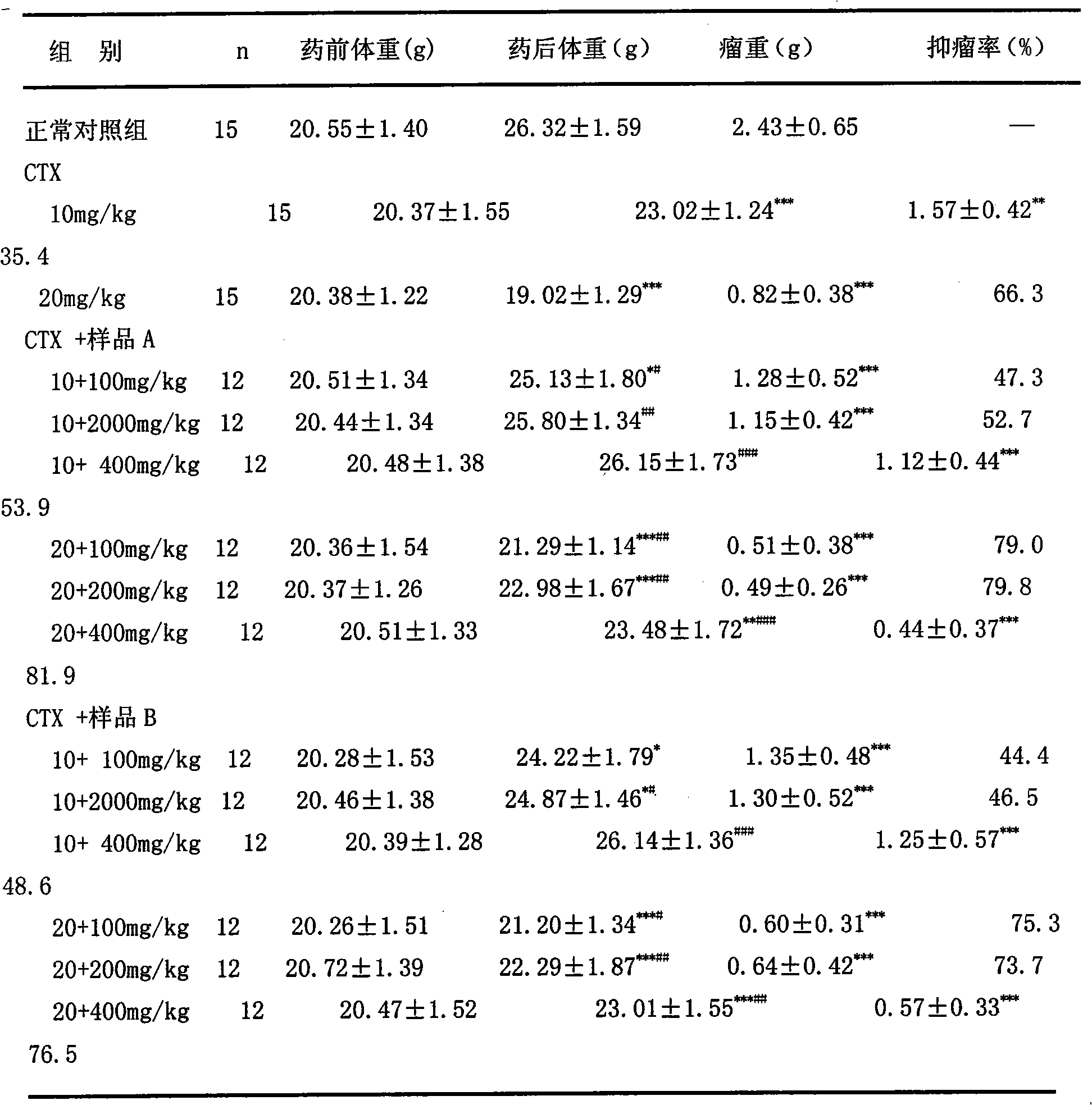

Clam polypeptide and preparation method thereof

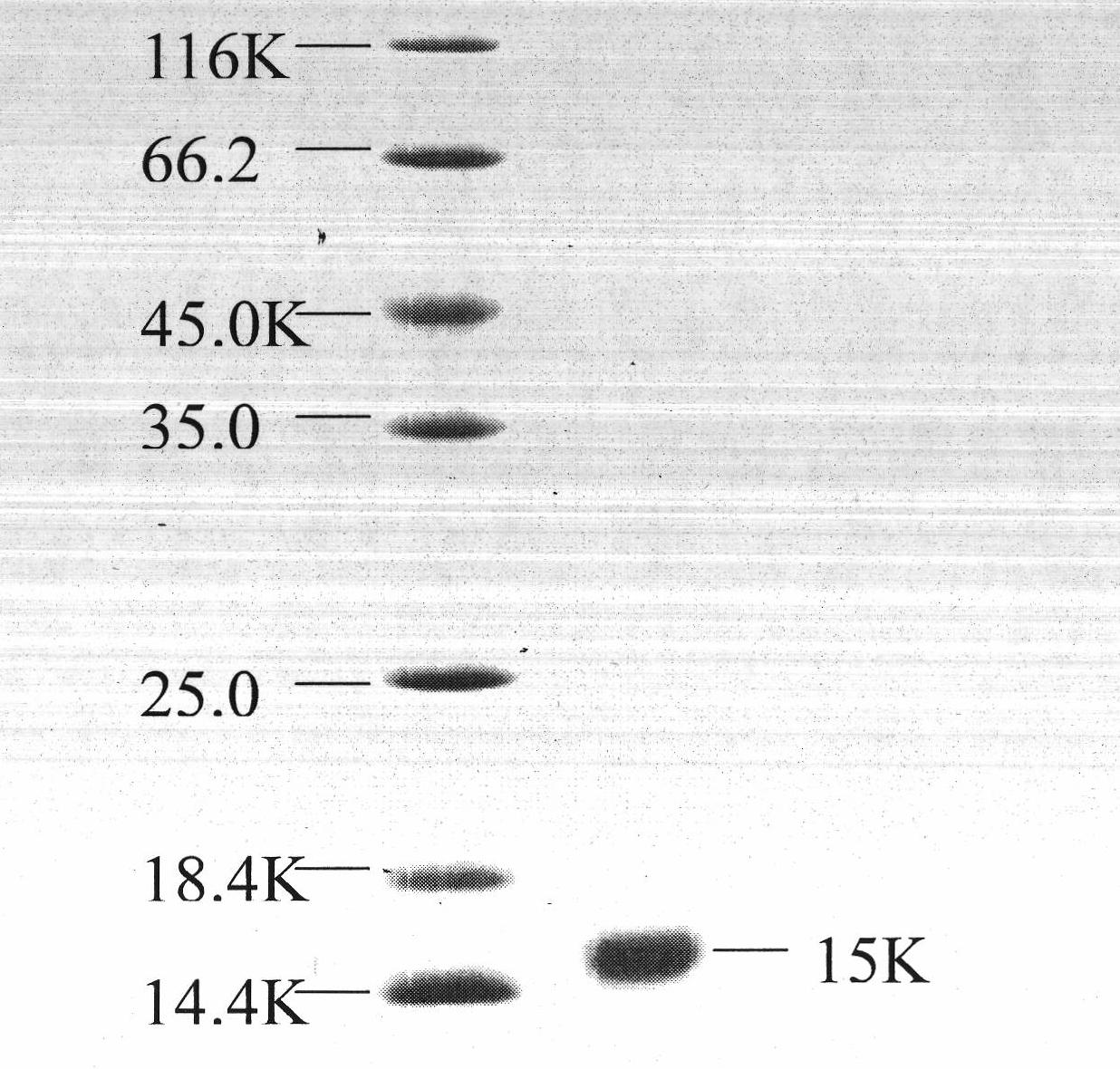

ActiveCN102161699ASmall molecular weightNon-immunogenicPeptide preparation methodsAnimals/human peptidesUltrafiltrationIon exchange

The invention belongs to the field of biological pharmacy, particularly relating to a clam polypeptide and a preparation method thereof. The N-tail end sequence of the clam polypeptide is IDEIQNTGGGTNFR, and the molecular weight of the clam polypeptide is 15KDa. The preparation method comprises the following steps: carrying out fractional precipitation, ultrafiltration, ion-exchange column chromatography, hydrophobic chromatography and opposite phase chromatography on a clam liquid by ammonium sulphate to obtain the polypeptide of which the molecular weight is 15KDa. The invention also relates to an application of the polypeptide in preventing and / or treating malignant tumors. The preparation method is characterized in that the polypeptide is extracted from the clam and has higher inhibitory activity on various tumor cells. The polypeptide is continuously optimized into a polypeptide substance of which the molecular weight is 15KDa. The antitumor activity of the clam polypeptide is detected with an MTT (3-(4,5-Dimethylthiazol-2-yl)-2, 5-diphenyltetrazolium bromide) colorimetric method, and the compound can obviously inhibit the growth of various tumor cells but does not have an inhibition action on normal cells. The characteristic that the polypeptide can selectively inhibit the proliferation of tumor cells enables the polypeptide to have the potential to become a new anti-cancer drug.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

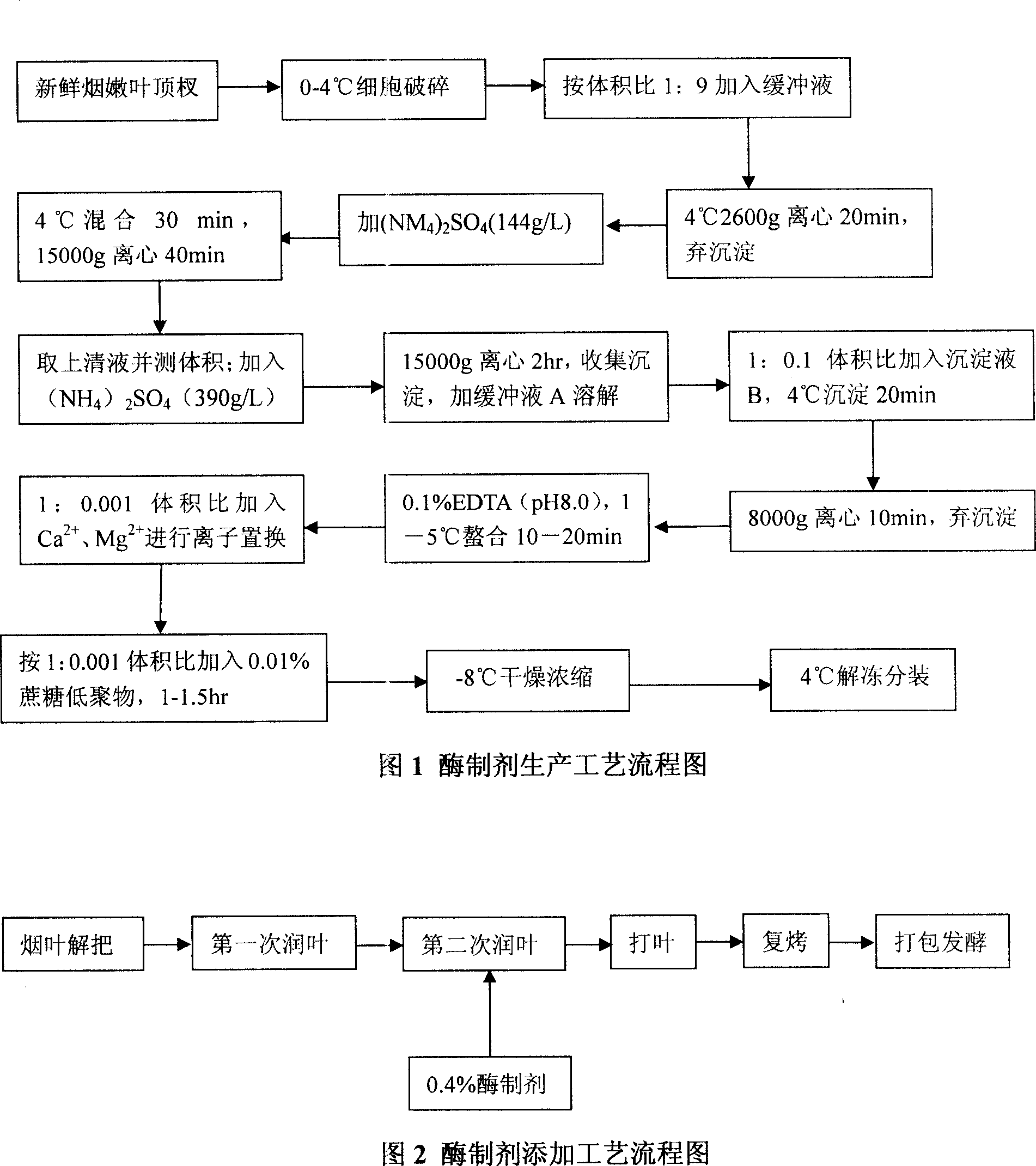

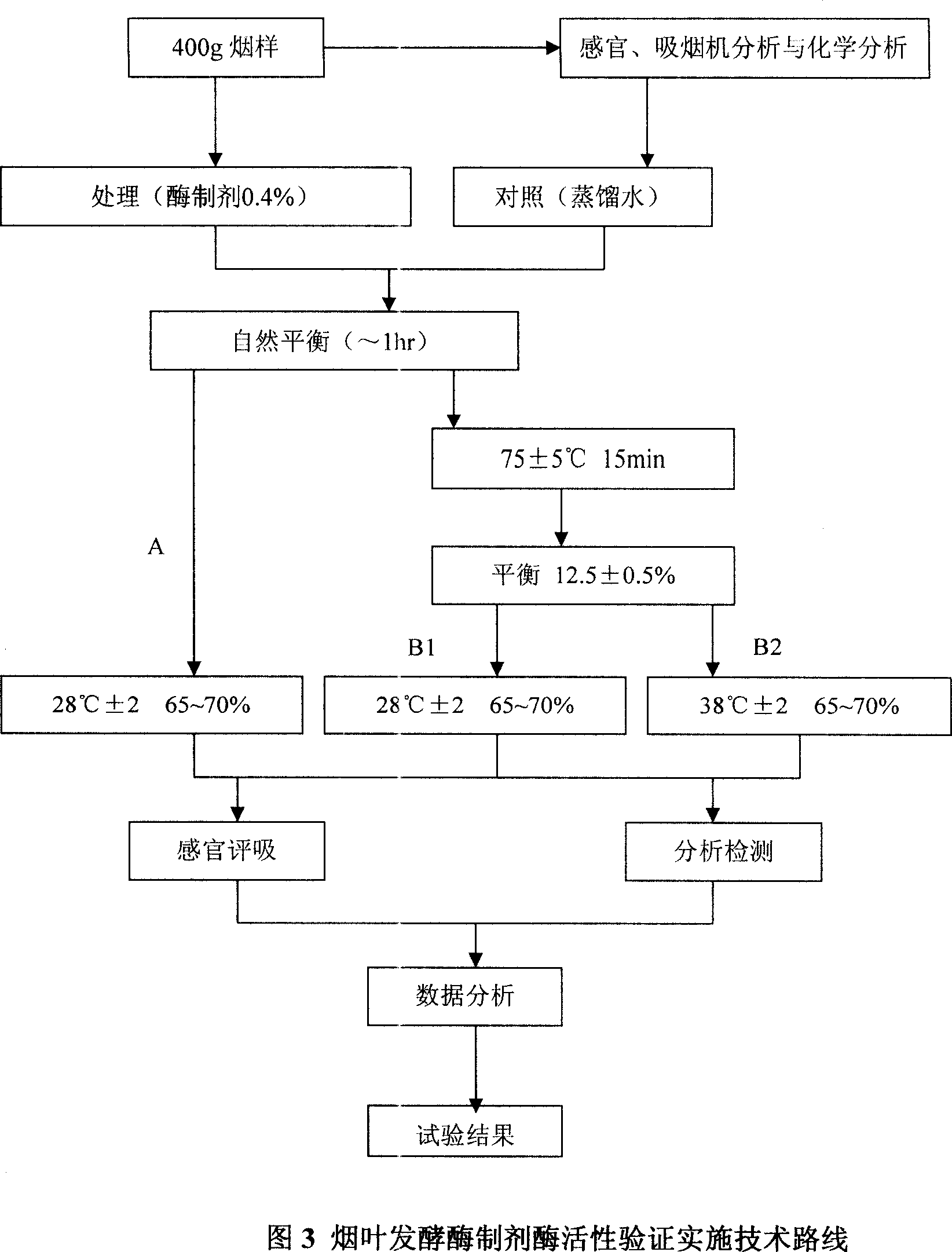

Method for producing tobacco leaf fermenting enzyme preparation

InactiveCN101144073AGood application effectIt has the characteristics of high temperature resistance of rebaking lineTobacco treatmentEnzymesBiotechnologySaccharum

The present invention relates to a novel tobacco leaf fermenting enzyme preparation production method which aims to solve the technical problems that how the quality of the tobacco leaf fermenting product is improved and how the reactivity protection of the tobacco leaf fermenting enzyme preparation is realized in the natural fermenting field of the tobacco leaf. The enzyme preparation consists of glucoseoxidase, chlorophyl oxidase, carotenoid oxidase, protease, and nicotine-degradation enzyme. Through the cell disruption of fresh leaves, (NH 4) 2 SO 4 is utilized to operate the second fractional precipitation to obtain crude enzyme fluid, an enzyme molecule adopts Ca 2 + and Mg 2 + to operate the metal ion exchange, to accomplish the molecule modification; a macro molecule combination modification is accomplished through adopting 0.01 percent of cane sugar low molecular polymer, thereby prolonging the half life period of an enzyme preparation, and obviously improving the high temperature resistant ability. The experimental result employed by the enzyme preparation indicates that the nicotine is decreased by 9.3 percent, the total nitrogen is decreased by 5.7 percent, the protein is decreased by 7.1 percent; cigarette smoke condensates are decreased by 8.4 percent, the tar content is decreased by 5.1 percent, cigarette smoke nicotine content is decreased by 28.0 percent, and the carbon is decreased monoxide by 1.6 percent. The enzyme preparation is employed when the tobacco is wet for the second time before defolat and redrying.

Owner:谢勇 +2

Extraction method for joint production of coptis chinensis with coptis chinensis fibrous root as raw material

The invention relates to an extraction process technology for the combined production of coptis alkaloid by taking coptis roots as a raw material, which comprises the following process flow: the coptis roots, adding of proper amount of 0.05 to 1 percent sulfuric acid for soaking, precipitate neutralization and impurity removal, entrance to an anion separation column, stepwise elution, separation decolorization of components, recovery of a solvent, fractional precipitation and crystallization, drying, and a jateorrhizine monomer, a jamaicin monomer, and a coptis composite alkaloid. In the process, the contents of the jateorrhizine monomer and the jamaicin monomer are more than 90 percent, and the total alkali content of the composite alkaloid is more than 50 percent. In the extraction process, the efficiency of separation on the column is improved through the operation step of neutralization and impurity removal; the stepwise elution realizes the separation of an alkaloid monomer; and a product realizes the separation of alkaloid through the fractional separation on the column.

Owner:SOUTHWEST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com