Patents

Literature

69results about How to "Solve the problem of low purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-purity vanadium pentoxide through sodium polyvanadate

InactiveCN104004926ASolve the problem of low purityNo pollution in the processAmmonium carbonateHydrolysis

The invention discloses a method for preparing high-purity vanadium pentoxide through sodium polyvanadate. The method includes the following steps that a, a sodium removal agent aqueous solution is prepared, wherein a sodium removal agent is at least one of ammonium carbonate, ammonium bicarbonate and ammonium oxalate; b, the finely grinded sodium polyvanadate is added to the sodium removal agent aqueous solution, filtering, washing and drying are carried out after the stirring reaction, and sodium-free sodium polyvanadate is obtained; c, the high-purity vanadium pentoxide is obtained after the sodium-free sodium polyvanadate is calcinated. The process of removing sodium through one step is adopted, the removal rate of sodion in the sodium polyvanadate reaches about 99%, sodion content of vanadium pentoxide obtained through later preparation is very low, yield of vanadium also reaches more than 99%, and the problem that prepared vanadium pentoxide is not high in purity due to the fact that the sodium content in sodium polyvanadate obtained after hydrolysis of vanadium precipitation exceeds the standard is solved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

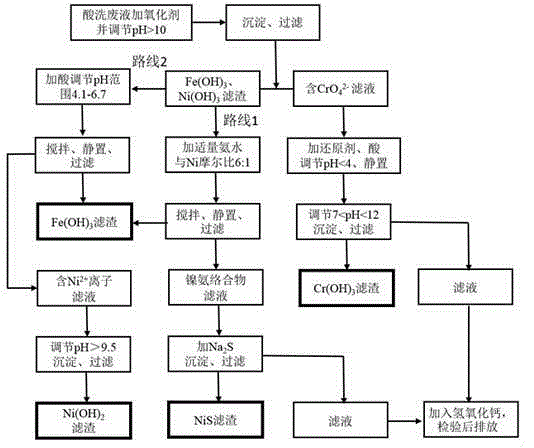

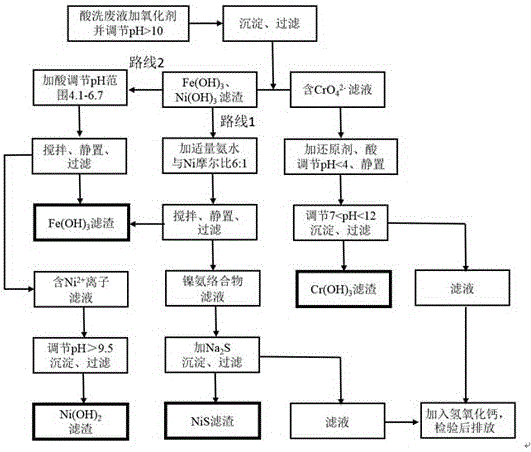

Recovery processing method of stainless steel acid pickling waste liquid containing iron, chromium and nickel

InactiveCN104787928AEasy to separateSolve the problem of low purityIron oxides/hydroxidesMultistage water/sewage treatmentFractional PrecipitationSS - Stainless steel

The invention discloses a recovery processing method of stainless steel acid pickling waste liquid containing iron, chromium and nickel. The recovery processing method comprises the following steps: (1) oxidizing chrome (III) ions in an alkaline condition, and separating the oxidized chrome (III) ions from iron and nickel; (2) reducing chrome in an acidic condition to trivalent chrome, and precipitating the trivalent chrome in the form of hydroxide; (3) separating nickel and iron elements through the ammonia leaching or fractional precipitation method, separating the iron elements in the form of Fe (OH)3, and obtaining the final product of the nickel element in the form of NiS or Ni(OH)2. According to the invention, the technological universality is high, the stainless steel acid pickling waste liquid with different concentrations can be separated, the characteristics of low cost, easiness in control of technological conditions, simple equipment and high recycling rate of valuable metal elements are realized, the problem about the sewage pollution of a stainless steel production enterprise can be effectively solved, the recycled metal elements can be reutilized, the economic benefit of the enterprise can be increased, and the dual significances of environmental protection and resource utilization are realized.

Owner:NANYANG NORMAL UNIV

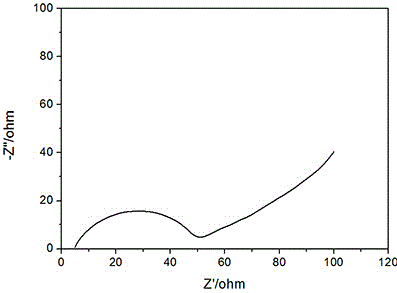

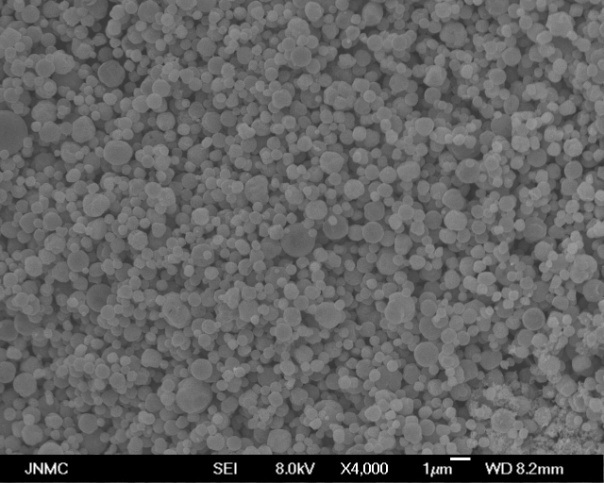

Preparation method of amorphous sulfide solid electrolyte

InactiveCN105609870APrecise control ratioSolve the problem of low puritySolid electrolytesSecondary cellsMetallic lithiumPhosphorus pentasulfide

The invention relates to the field of lithium ion batteries, in particular to a preparation method of an amorphous sulfide solid electrolyte. The preparation method of the amorphous sulfide solid electrolyte is characterized by mainly comprising the following steps: (1) putting metallic lithium, elemental sulfur, germanium sulfide and phosphorus pentasulfide in a certain proportion into a water-free and oxygen-free sealed container for mixing; and (2) mechanically grinding the raw materials mixed in the step (1) so as to prepare the amorphous sulfide solid electrolyte. According to the preparation method, the proportion of lithium, sulfur to phosphorus can be accurately controlled, and the problem that raw material volatilization in a high-temperature solid-phase method causes relatively low product purity is solved; and meanwhile, the resources of the raw materials are abundant, the process is simple, and the high-purity amorphous sulfide solid electrolyte can be obtained through a ball-milling one-step method.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

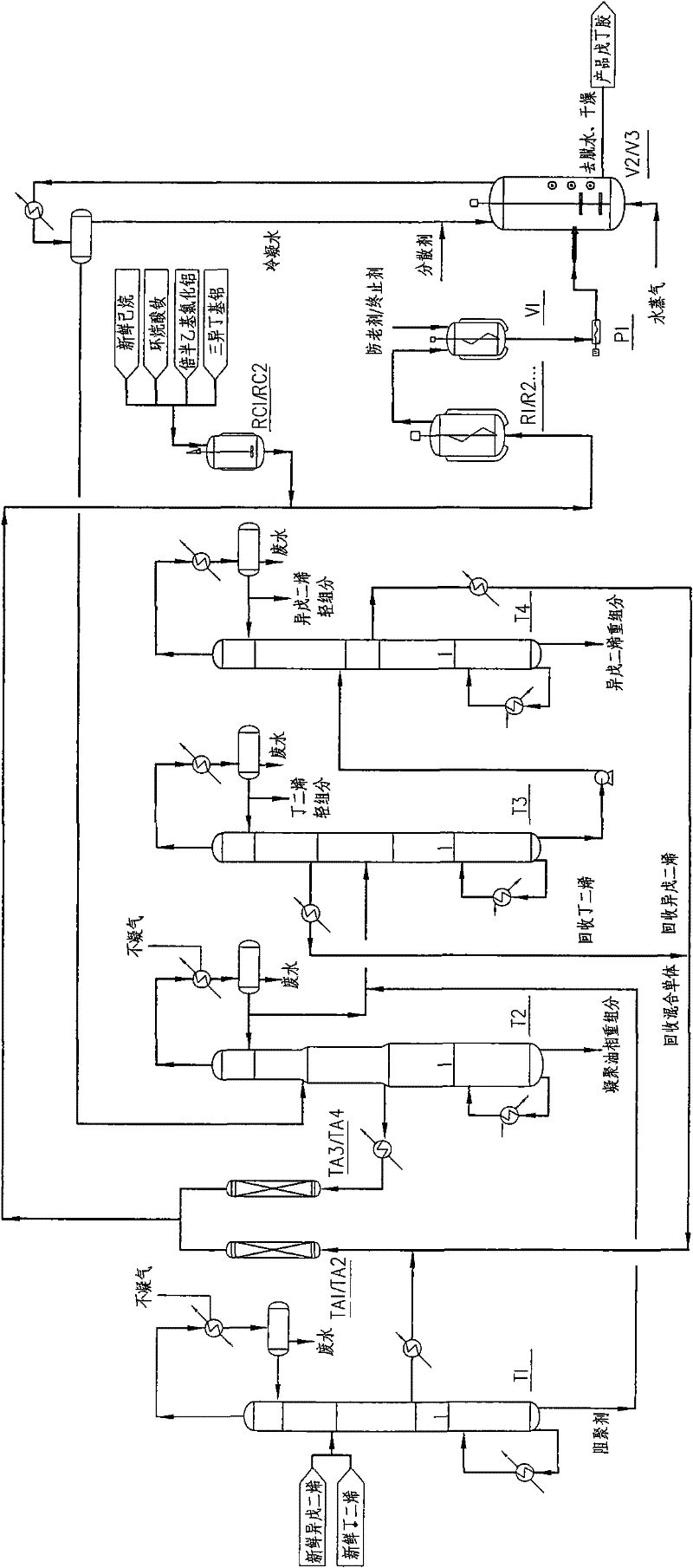

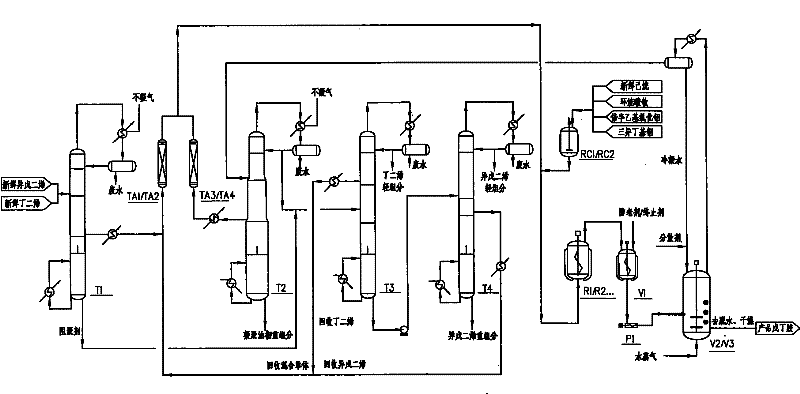

Method for producing rare-earth isoprene butadiene rubber

ActiveCN102234356AIncrease production energy consumptionReduce production energy consumptionSpecial tyresPolymer scienceRare earth

The invention discloses a method for producing rare-earth isoprene butadiene rubber. Two refined monomers, namely isoprene and 1, 3-butadiene are proportioned and mixed, and subjected to polymerization reaction in the presence of a rare earth catalyst to form random copolymer rubber. A multi-tower circular preparation process flow is adopted, and the problem of low purity of recovered monomers and solvents caused by crossed boiling points of various monomers and impurities thereof is solved, so that the production efficiency and molecular weight of the rare-earth isoprene butadiene rubber areimproved and the whole production cost is reduced. In the rare-earth isoprene butadiene rubber, the molar content of polyisoprene units is 40 to 90 percent, the cis-content in the polyisoprene units is more than 95 percent, the cis-content in polybutadiene units is more than 99 percent, the weight-average molecular weight is 2,000,000 to 3,000,000, the molecular weight distribution is 3 to 7, andthe anti-ageing agent content is 1 to 2 percent. The rare-earth isoprene butadiene rubber copolymer can replace a binary blend of natural rubber (or high cis-isoprene rubber) and butadiene rubber, and has the characteristics of capacity of being easily mixed, low themogenesis, wear resistance, crack growth resistance and the like.

Owner:FUSHUN YIKESI NEW MATERIAL

Method for preparing environment-friendly high-purity isomaltooligosaccharide

ActiveCN103952452ASimple production processAvoid wastingFermentationChromatographic separationIsomaltooligosaccharide

The invention relates to a method for preparing environment-friendly high-purity isomaltooligosaccharide. The method comprises the following steps of (1) adding starch into deionized water, mixing and pulping to obtain pulp; (2) liquefying the pulp with alpha-high temperature amylase to obtain a liquefied solution; (3) saccharifying the liquefied solution to obtain a crude saccharified solution; (4) adsorbing the crude saccharified solution and filtering to obtain a saccharified solution; (5) carrying out ion exchange on the saccharified solution by an ion exchange system to obtain a refined saccharified solution; (6) concentrating the refined saccharified solution to obtain a concentrated solution and then enabling the concentrated solution to pass through a molecular exclusion chromatographic separation system to obtain isomaltooligosaccharide liquid and isomaltooligosaccharide separation mother liquor; (7) concentrating the isomaltooligosaccharide liquid and drying. According to the invention, the isomaltooligosaccharide is separated from the glucose successfully, and impurity molecules such as macromolecular protein are removed at the same time. The existing production process is simplified, the full use of the raw material is made, high-purity glucose solution is obtained, and the economic benefits are obvious.

Owner:BAOLINGBAO BIOLOGY

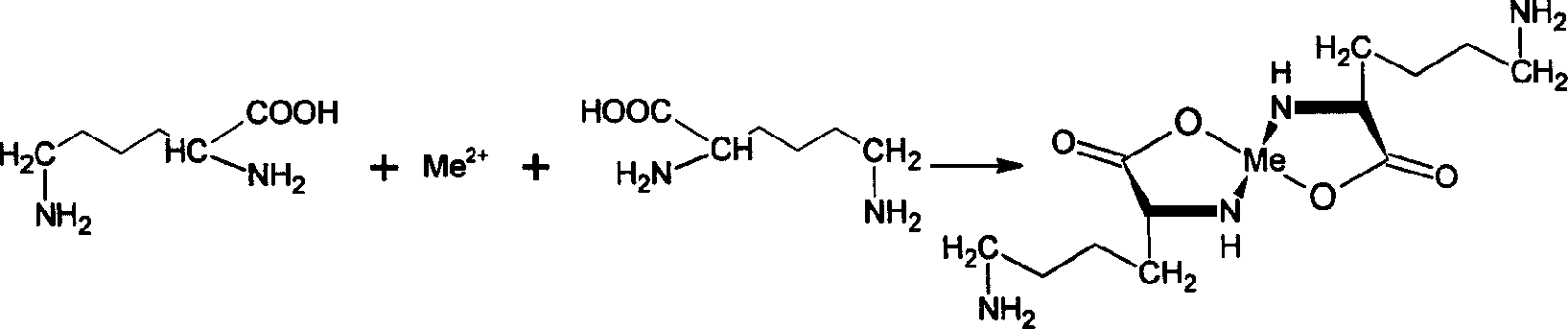

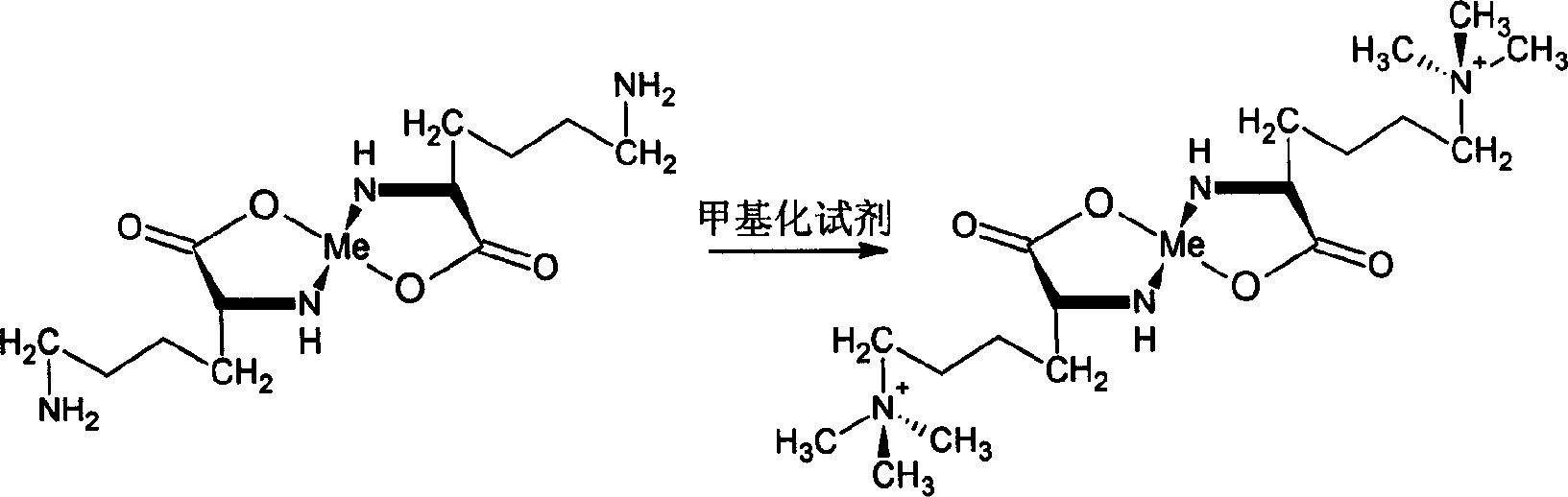

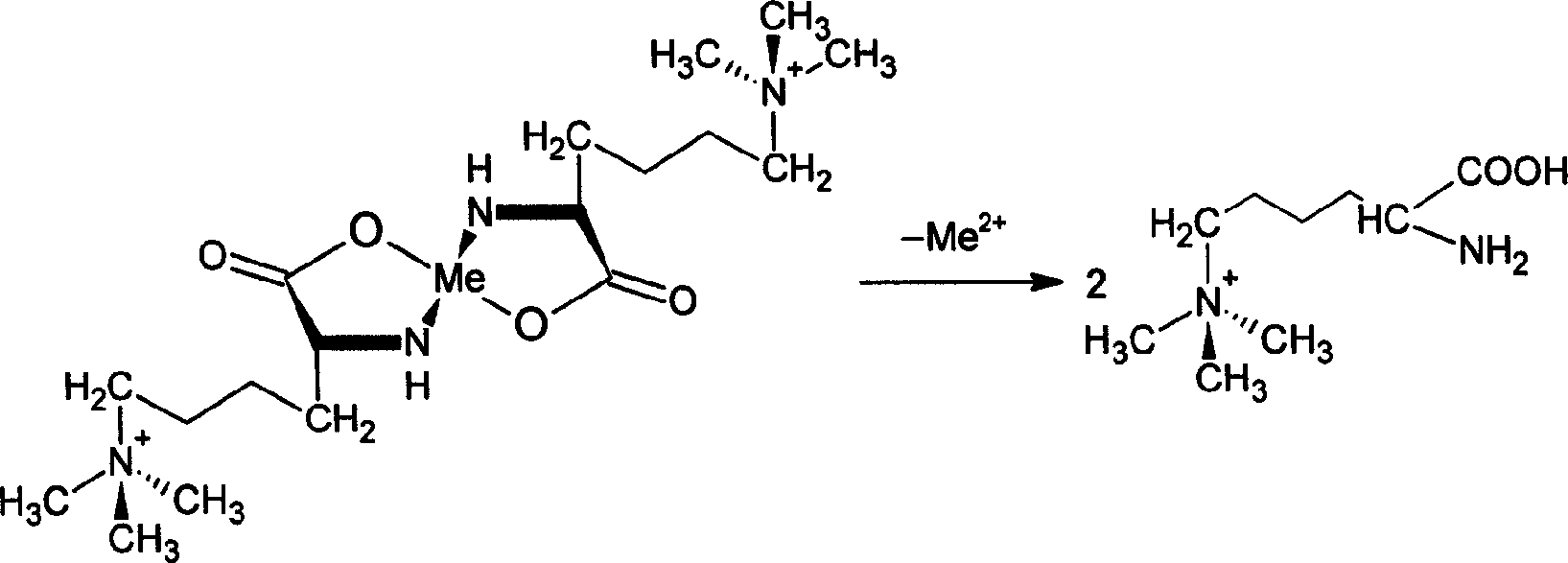

Clean method for producing high-purity laminine

InactiveCN1951905ANo precipitationSolve the problem of low purityOrganic compound preparationAmino-carboxyl compound preparationIon exchangeMethyllysine

The invention discloses a cleaning manufacturing method of high-purity laminine, which is characterized by the following: adopting lysine as raw material; reacting lysine with metal salt under alkaline condition (pH =7-11) to do alpha-amino shelter reaction to generate intermediate product; reacting with methylating agent to produce quaternised lysine derivant on the yimxilong-amino; generating metal ionic demasking reaction with complexing agent to obtain rough product of N-trimethyl lysine; adsorbing through cationic resin exchange column; washing; purifying to obtain the product; making ammonia as adjuster of pH value.

Owner:QINGDAO UNIV

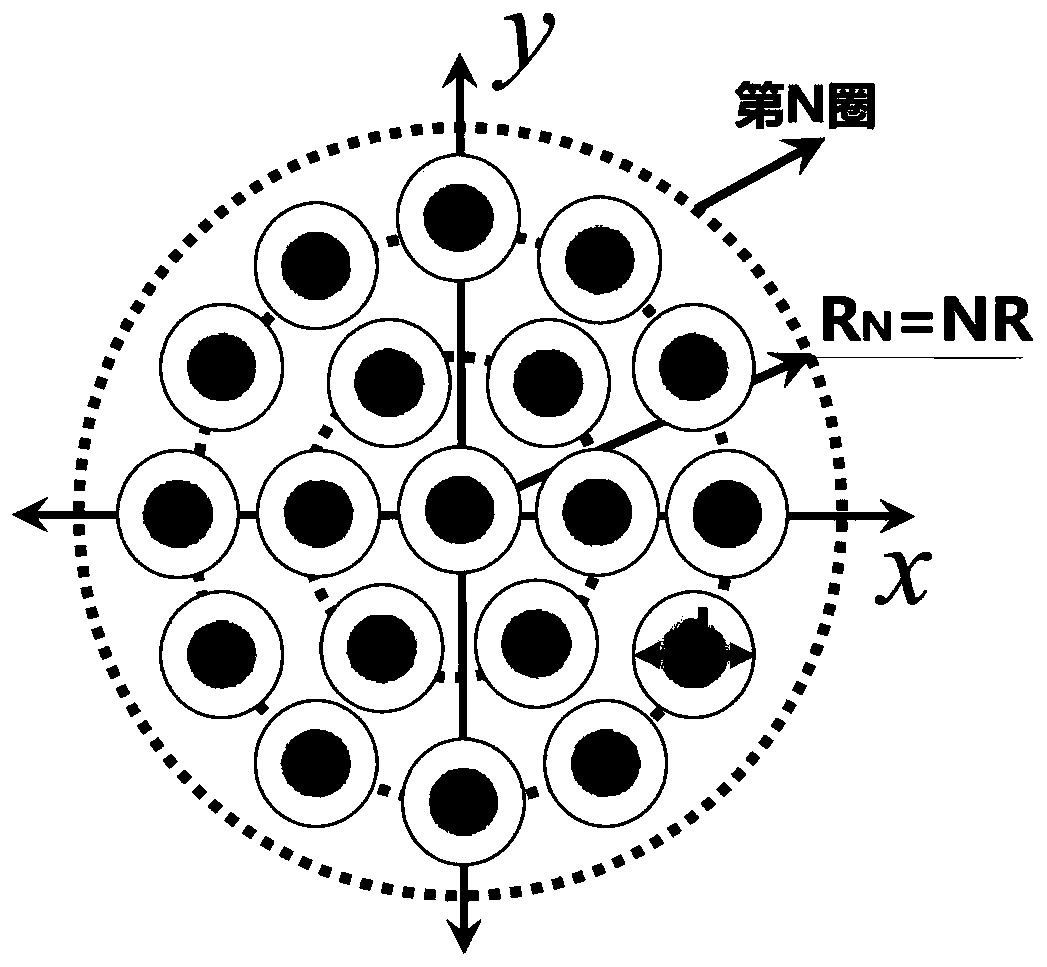

Fractal-based coherent optical fiber laser array and generation system thereof

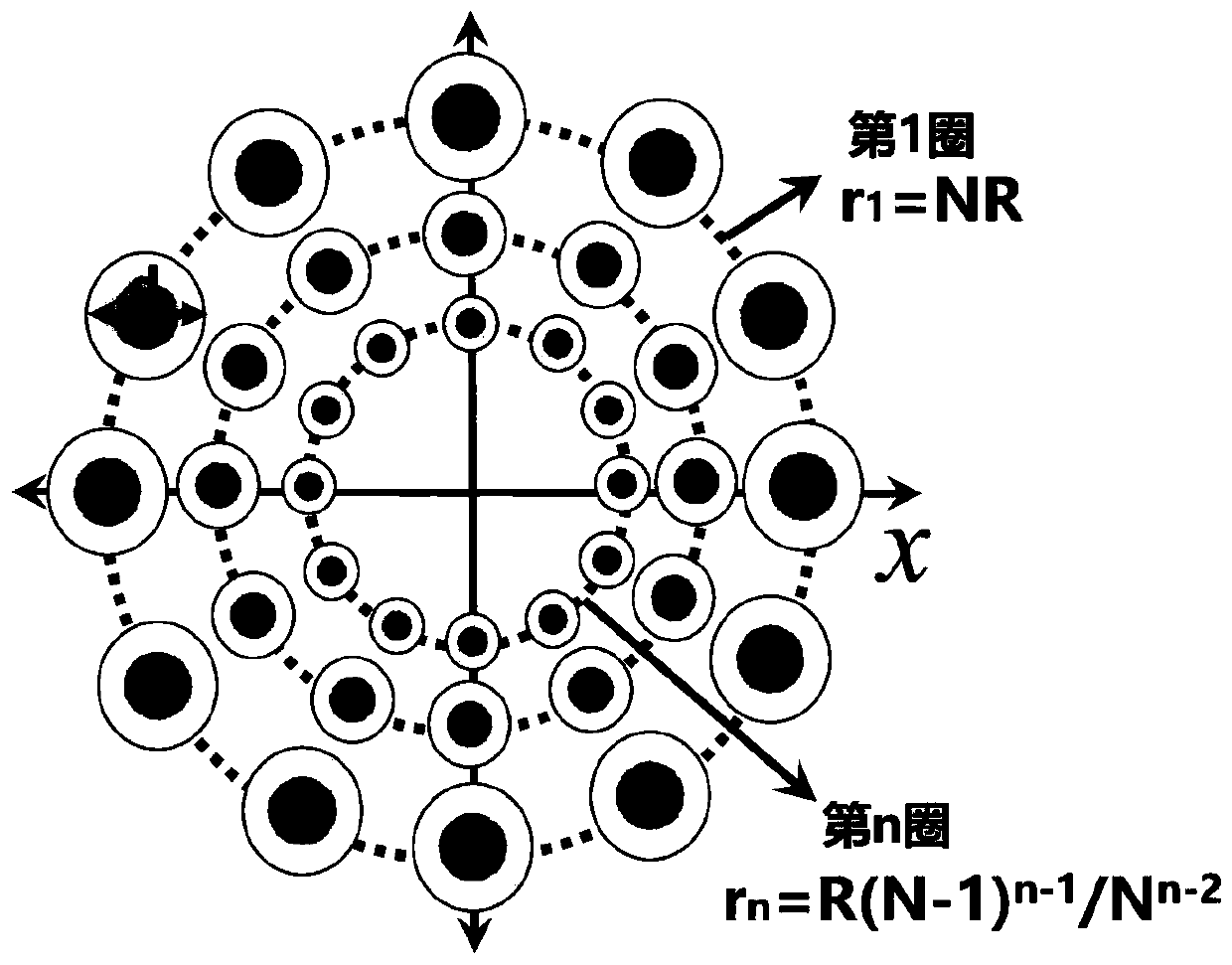

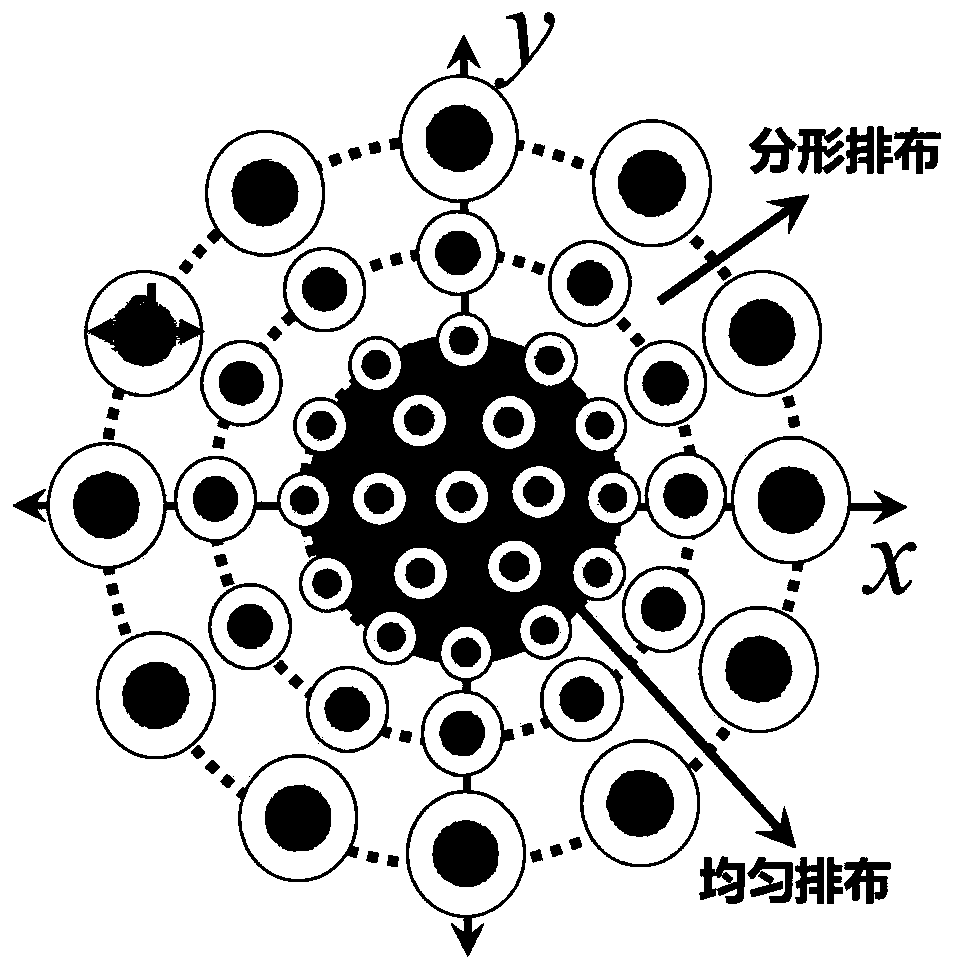

PendingCN111193167ASame quantitySolve the problem of low purityLaser arrangementsOptical devices for laserLaser arrayLight beam

Disclosed are a fractal-based coherent optical fiber laser array and a generation system thereof. The coherent optical fiber laser array comprises N circles of light beams annularly arranged around the center of an array optical fiber from inside to outside, each circle of light beams comprises the same number of sub-light beams, and the sub-light beams in the same circle of light beams have the same optical parameters and are uniformly arranged in the angular direction. At least two or more continuous circles of light beams in the N circles of light beams form a fractal arrangement laser array; any two adjacent circles of light beams in the fractal arrangement laser array are separated from each other; and the beam waist radius, the beam caliber and the distance between the beam center and the center of the array optical fiber of each sub-beam in the circle of light beams close to the inner side are reduced in an equal ratio relative to the beam waist radius, the beam caliber and thedistance between the beam center and the center of the array optical fiber of each sub-beam in the circle of light beams close to the outer side. According to the invention, the array filling mode ofthe system can be expanded, and the optical parameter regulation and control capability of the laser array is improved, so that the synthesis efficiency and mode purity of structured light generated by the coherent optical fiber laser array are improved.

Owner:NAT UNIV OF DEFENSE TECH

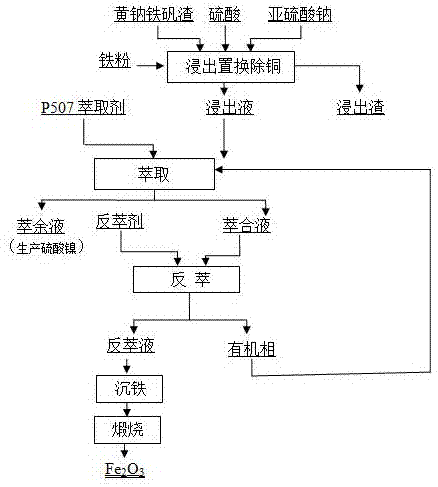

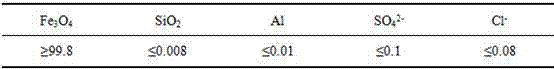

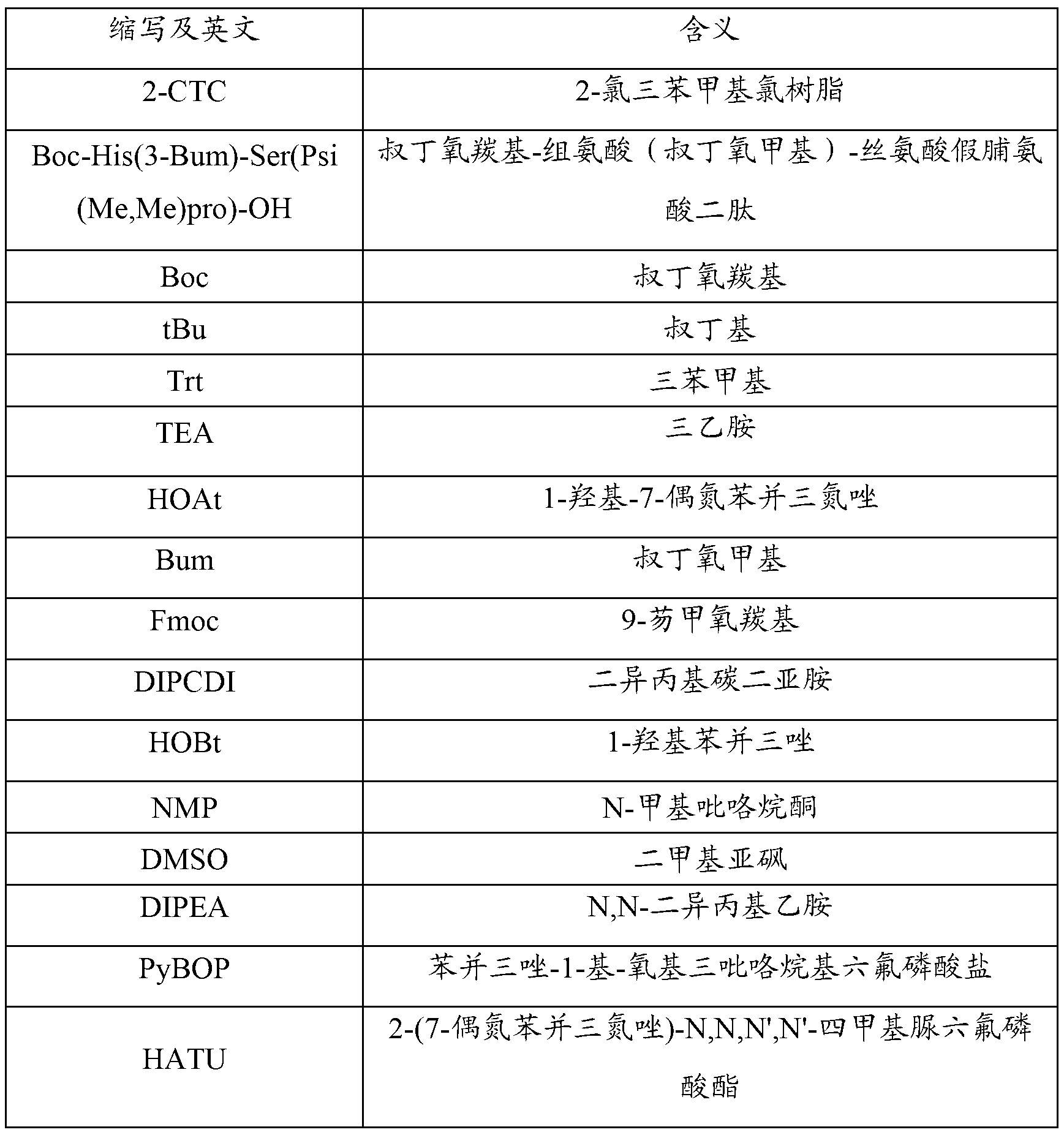

Preparation method of iron oxide product

InactiveCN106957965AEfficient recyclingShorten the purification processProcess efficiency improvementBrown iron oxidePyrometallurgy

The invention relates to the technical field of hydrometallurgical and pyrometallurgical processes of non-ferrous smelting, and discloses a preparation method of an iron oxide product. The method comprises the following steps: carrying out leaching treatment of iron vitriol dreg of yellow sodium by using industrial sulfuric acid; carrying out extraction and impurity removal of a leaching solution with P507 to ensure that an extraction solution meets a quality requirement on production of a nickel sulfate product and contents of impurities of a re-extraction solution can meet a quality requirement on production of the iron oxide product; carrying out an oxidation neutralization hydrolysis method and a goethite process of the re-extraction solution to precipitate iron; calcining the iron precipitant at high temperature to produce the qualified iron oxide product. With iron vitriol dreg of yellow sodium as a raw material, the iron oxide is prepared, so that the iron vitriol dreg of yellow sodium is recycled, and a raw material for producing the iron oxide is found to ensure that the iron vitriol dreg of yellow sodium is recycled, and the category of the raw materials for producing the iron oxide products can be widened.

Owner:甘肃有色冶金职业技术学院

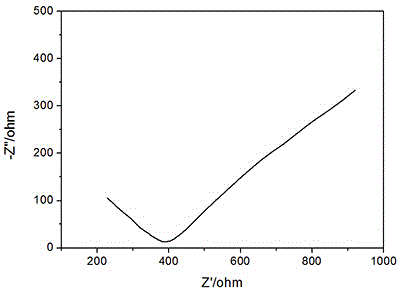

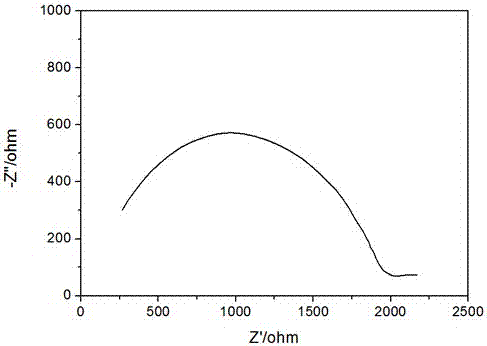

Electrochemical preparation method of solid electrolyte lithium aluminum titanium phosphate

ActiveCN105304938APrecise control ratioSolve the problem of low puritySecondary cellsElectrolyte immobilisation/gelificationLithium-ion batteryMaterials science

The invention relates to the technical field of lithium ion batteries, in particular to an electrochemical preparation method of solid electrolyte lithium aluminum titanium phosphate. The electrochemical preparation method comprises the following steps of firstly, preparing a mixture of aluminum oxide and titanium dioxide according to the ratio of aluminum to titanium; secondly, embedding the titanium dioxide into lithium ions through an electrochemical method; thirdly, adding phosphor salts according to the ratio of lithium to aluminum to titanium to phosphorus to form a uniform mixture, and annealing to obtain an LATP solid electrolyte. The electrochemical preparation method disclosed by the invention is low-priced in raw materials and is simple in process; high-purity lithium aluminum titanium phosphate can be obtained by an electrochemical step and a high-temperature treatment step; the ratio of the lithium to the aluminum to the titanium to the phosphorus can be accurately controlled, and the problem that the purity of products is lower caused by volatilization of lithium salts at high temperature in a general solid-phase method is solved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

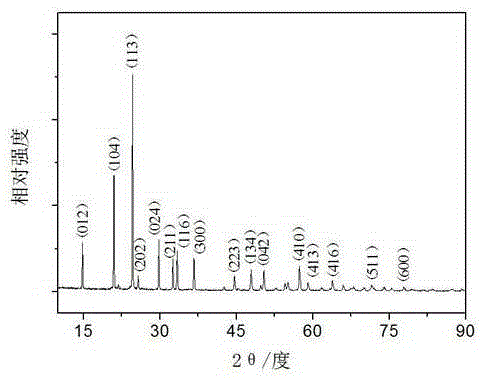

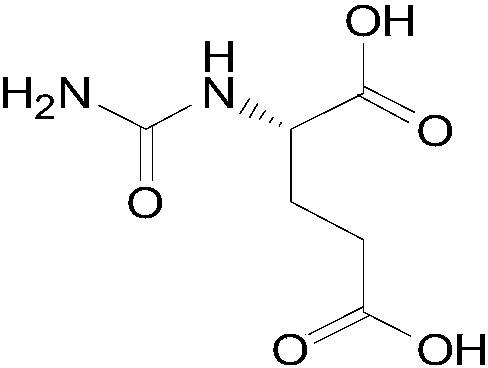

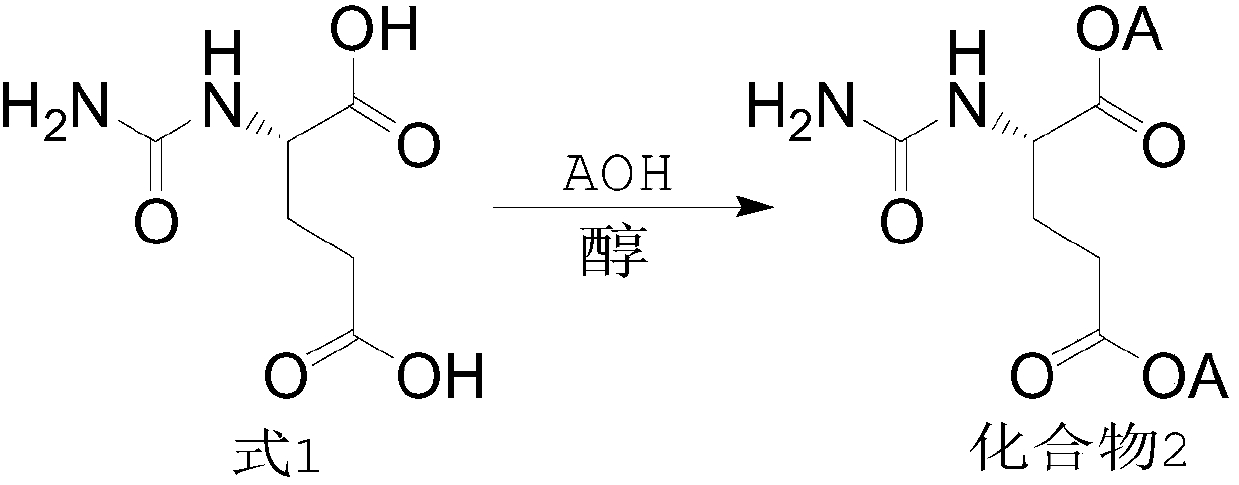

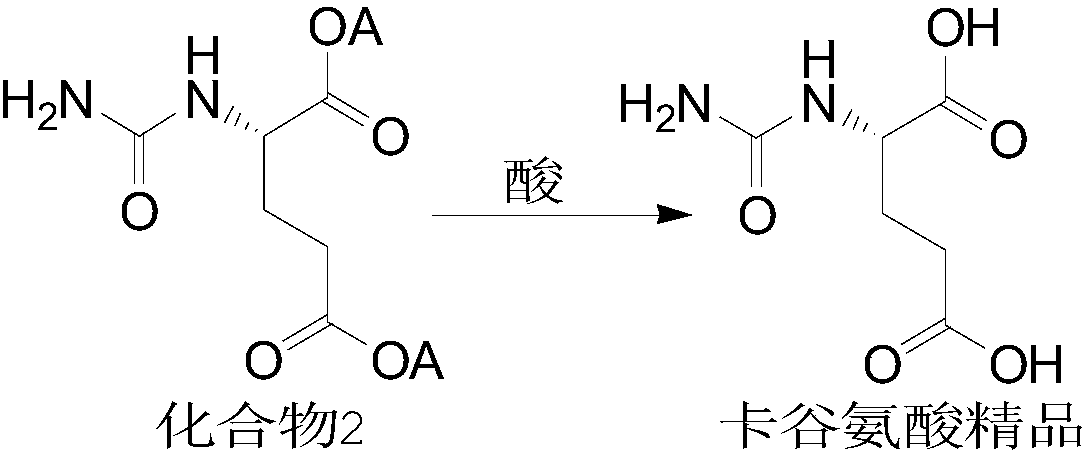

Method for refining carglumic acid

ActiveCN108017561ASolve the problem of low purityPost-refining process improvementUrea derivatives preparationOrganic compound preparationCarglumic acidAlcohol

The invention relates to a method for refining carglumic acid. The method comprises the following steps: (1-1) reacting crude carglumic acid with an alkali in a C1-5 alcohol solvent to obtain carglutamate; and (2-1) reacting the carglutamate obtained in step (1-1) with an acid to obtain the carglumic acid. The method solves the problem of low product purity of traditional technologies, and improves the product quality of the carglumic acid; and the content of the product refined through the method reaches 99.5% or more, the impurity content is less than 0.1%, and the product quality of a bulkdrug is met.

Owner:WUHAN WUYAO SCI & TECH

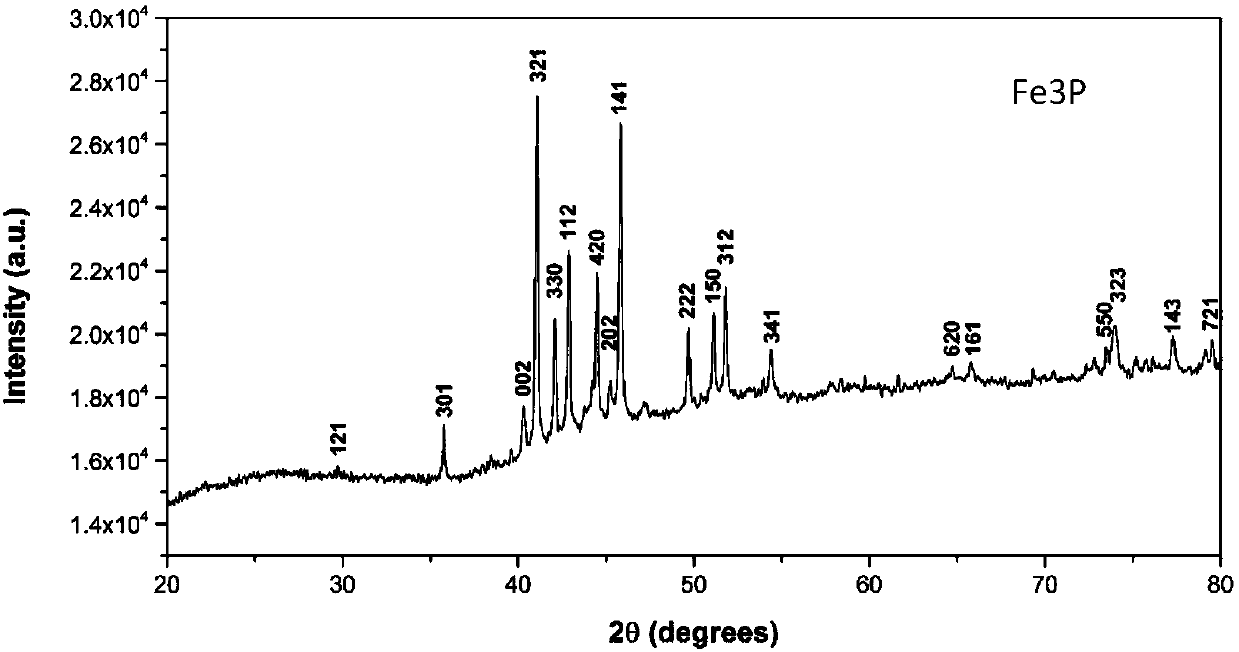

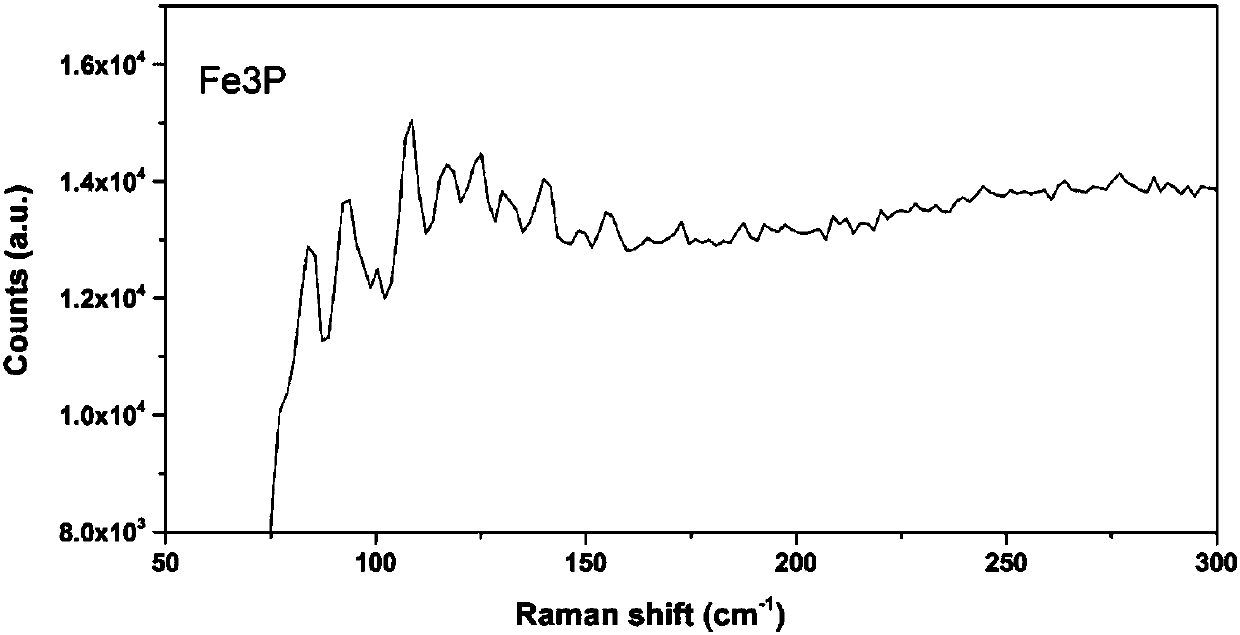

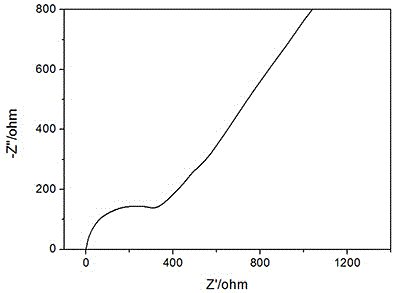

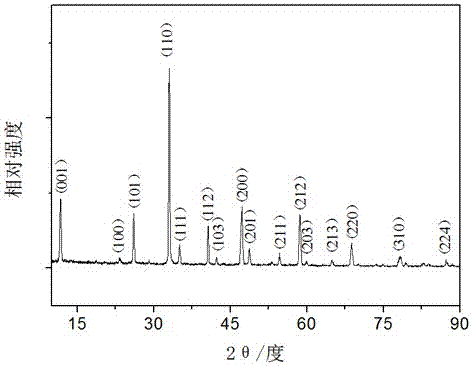

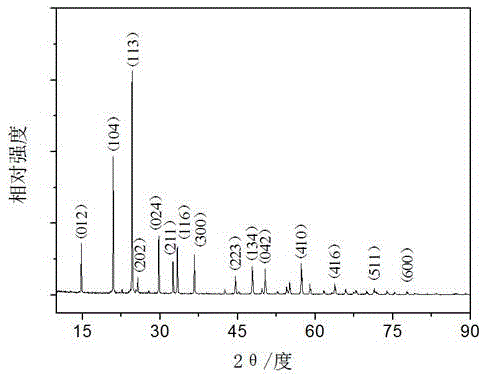

Method for preparing ferrous phosphide Fe3P at high temperature and high pressure

The invention discloses a method for preparing ferrous phosphide at high temperature and high pressure. The method comprises the following steps of using analytically pure ferrous nanometer powder andred phosphorus powder as starting raw materials; performing sufficient grinding and mixing on the analysis pure ferrous nanometer powder and the red phosphorus powder according to a mol ratio of 3:1in an agate mortar by using alcohol; using a tabletting machine for pressing the ground mixed powder into a cylindrical sample; processing a boron nitride ceramic rod into a round tube; putting the round tube into a baking oven to be baked; putting the cylindrical sample into the boron nitride round tube; sealing the upper and lower sides by using boron nitride ceramic sheets; then, putting a whole into a six-surface-top big pressing machine to be subjected to high-temperature and high-pressure reaction; taking out the reacted samples; clearing away boron nitride outside the sample to obtain apure Fe3P blocky sample. The technical problems that in the prior art, the reaction variable cannot be easily controlled, the quartz tube is corroded, the reaction time is long, the product purity islow, the crystallinity degree is low, the product is powder and cannot realize the later-stage processing, and the like are solved.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

Preparation method for amorphous state sulfide solid electrolyte

InactiveCN105552433ASolve the low purity of the productAbundant sources of raw materialsSecondary cellsElectrolyte immobilisation/gelificationChemistrySolid-state

The invention relates to the field of a lithium ion battery and specifically to a preparation method for an amorphous state sulfide solid electrolyte. The preparation method for the amorphous state sulfide solid electrolyte is characterized by comprising the following steps of (1) putting metal lithium, elemental sulfur and phosphorus pentasulfide into an anhydrous and oxygen-free sealed container for mixing; and (2) performing mechanical grinding on the mixed raw materials obtained in the step (1) to obtain the amorphous state sulfide solid electrolyte. According to the preparation method, the proportion of lithium to sulfur to phosphorus can be accurately controlled; the problem of a relatively low purity of the product caused by raw material volatilization existing in a high-temperature solid state method is solved; and meanwhile, the preparation method is rich in raw material sources and simple in process; and the high-purity amorphous state sulfide solid electrolyte can be obtained in one step by a ball milling method.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

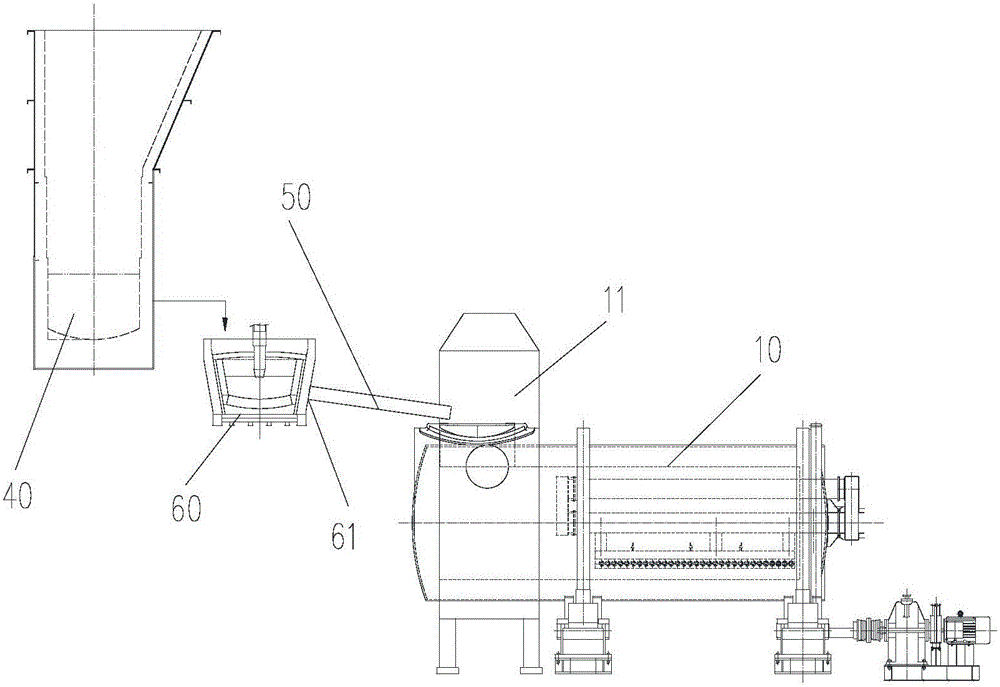

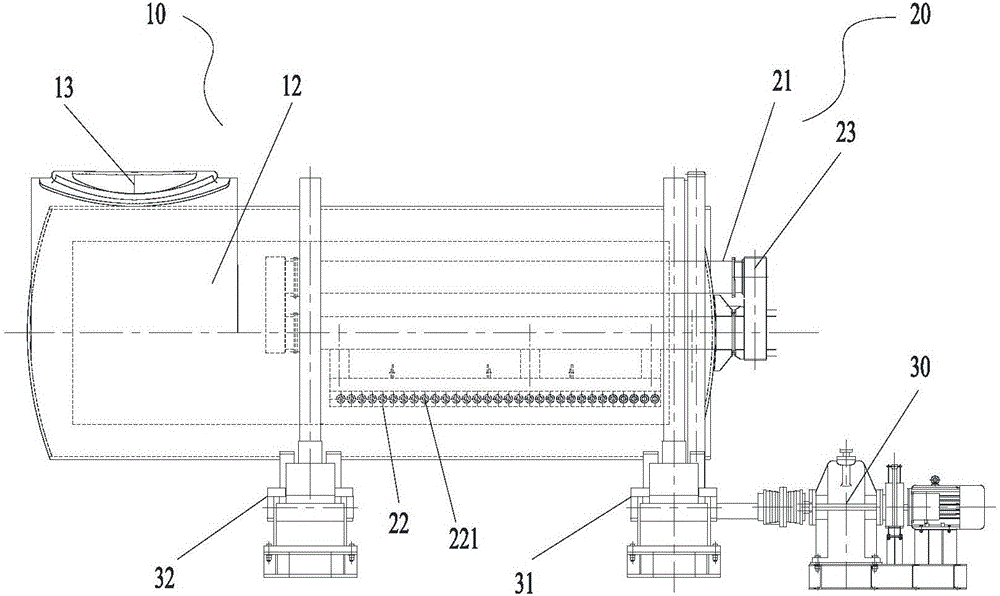

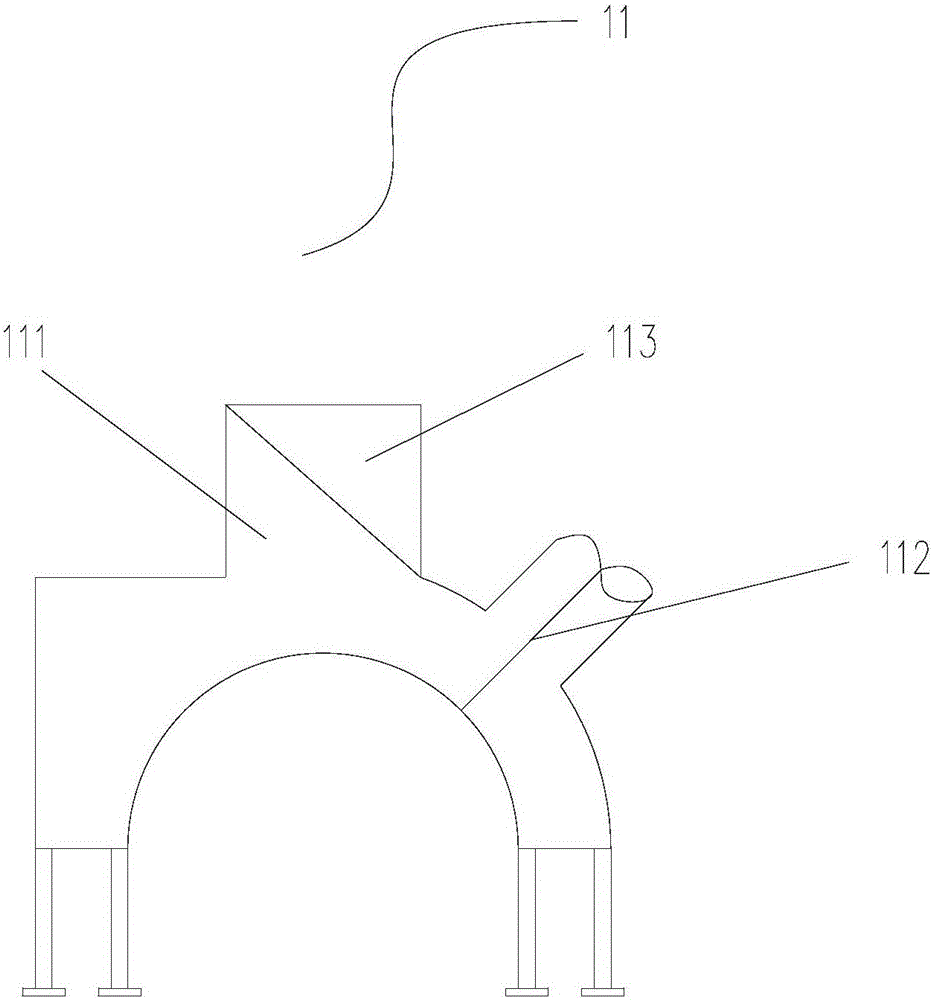

Thermal state copper and sulfur blowing device

ActiveCN105986128AHigh puritySolve low-altitude pollutionRotary drum furnacesCrucible furnacesThermal stateLow altitude

Owner:CHINA ENFI ENGINEERING CORPORATION

Purifying method of rimsulfuron original medicine

The invention relates to the technical field of pesticide production, in particular to a purifying method of rimsulfuron original medicine. The purifying method comprises the following steps: (1) adding a rimsulfuron original medicine crude product into a solvent, and heating under a stirring condition; (2) adding or not adding a solvent, slowly cooling, filtering after completely separating out aproduct, and taking filter cake; (3) adding the filter cake in the solvent, and stirring and pulping; (4) filtering and drying, thus obtaining a purified rimsulfuron original medicine product. According to the purifying method disclosed by the invention, through selection of a new purifying method, proportions of main purities can be reduced, the purity of original medicine can be increased, thepurity of the rimsulfuron original medicine purified by utilizing the technology of the invention is not lower than 98.5 percent, the content of purities is reduced to a large extent, and the problemof low purity generally existing in the industry is solved; meanwhile, the technical scheme of the invention is very easy to operate, the purification cost is relatively low, and the purifying methodis beneficial for being adopted in industrial production.

Owner:绍兴上虞银邦化工有限公司

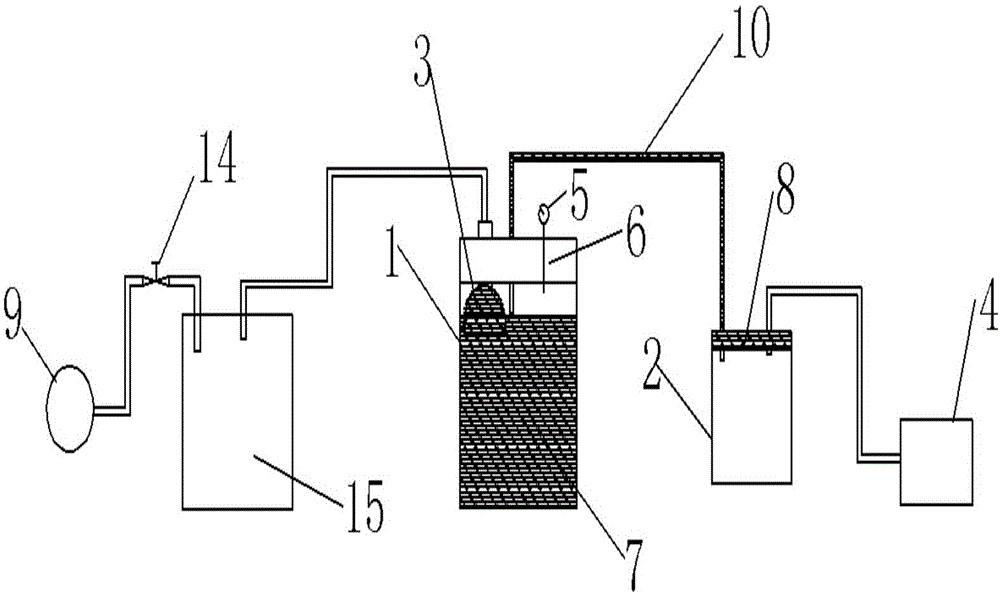

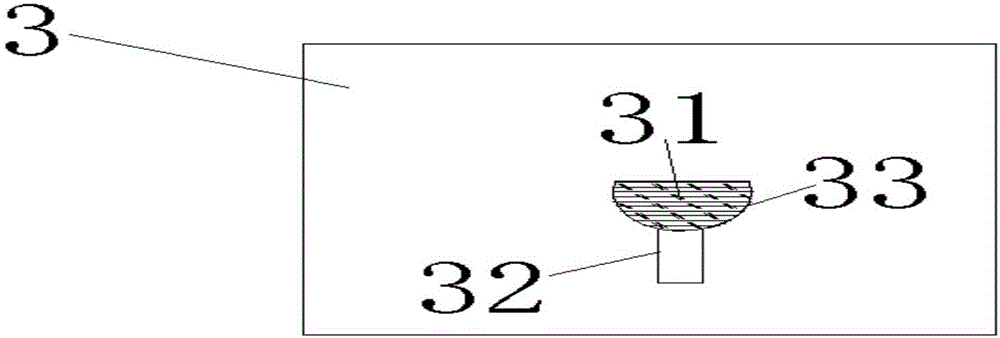

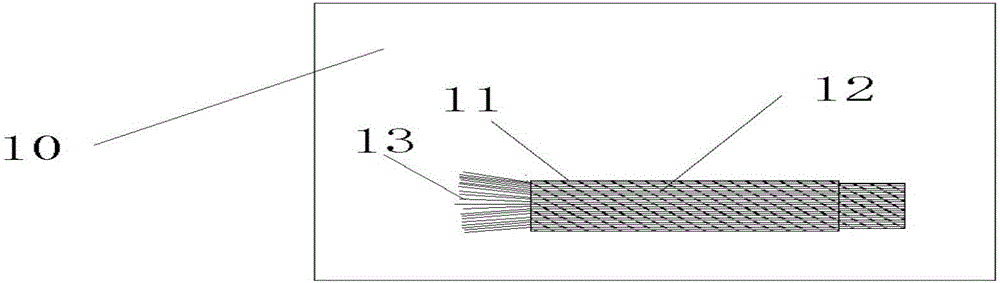

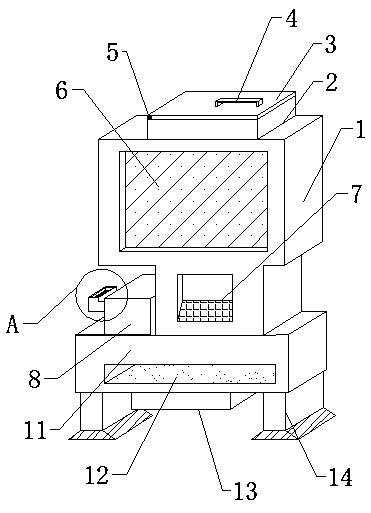

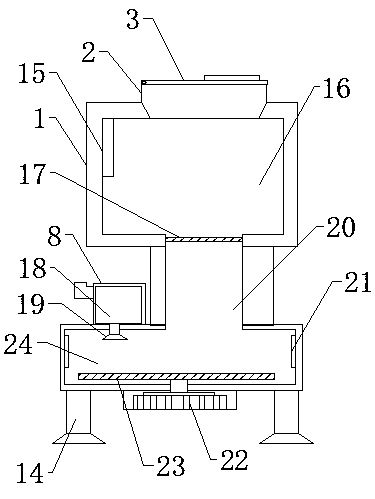

Organic matter filtrate separating and filtering device

The invention discloses an organic matter filtrate separating and filtering device. The organic matter filtrate separating and filtering device comprises a big suction filtration flask (1), a small suction filtration flask (2), a filter plate device (3), a nitrogen bag (4) and a suction filtration pipe (10), wherein the nitrogen bag (4) is connected with the small suction filtration flask (2) through a gas pipe; the small suction filtration flask (2) is connected with the big suction filtration flask (1) through the suction filtration pipe (10); one end of the filter plate device (3) is completely immersed into a filter solution (7) in the big suction filtration flask (1), and the other end is connected with a suction filtration pump (9) through a pipeline by penetrating through a big suction filtration flask plug (6) of the big suction filtration flask (1). According to the organic matter filtrate separating and filtering device disclosed by the invention, the problems that filtering of a centrifugal machine or filtering and separating of a filter press is used as a traditional filter mode, the solid-liquid separation effect is poorer by adopting the filtering of the centrifugal machine, a self-sucking pump is required for leading in a filter material by adopting the filtering and separating of the filter press, massive volatilization of organic matters is caused, filter cloth is seriously blocked, the separation effect is not good, ammonium chloride can be brought into a separation solution along with a solution, and the purity of a separated solution is not high are solved.

Owner:GUIZHOU MINZU UNIV

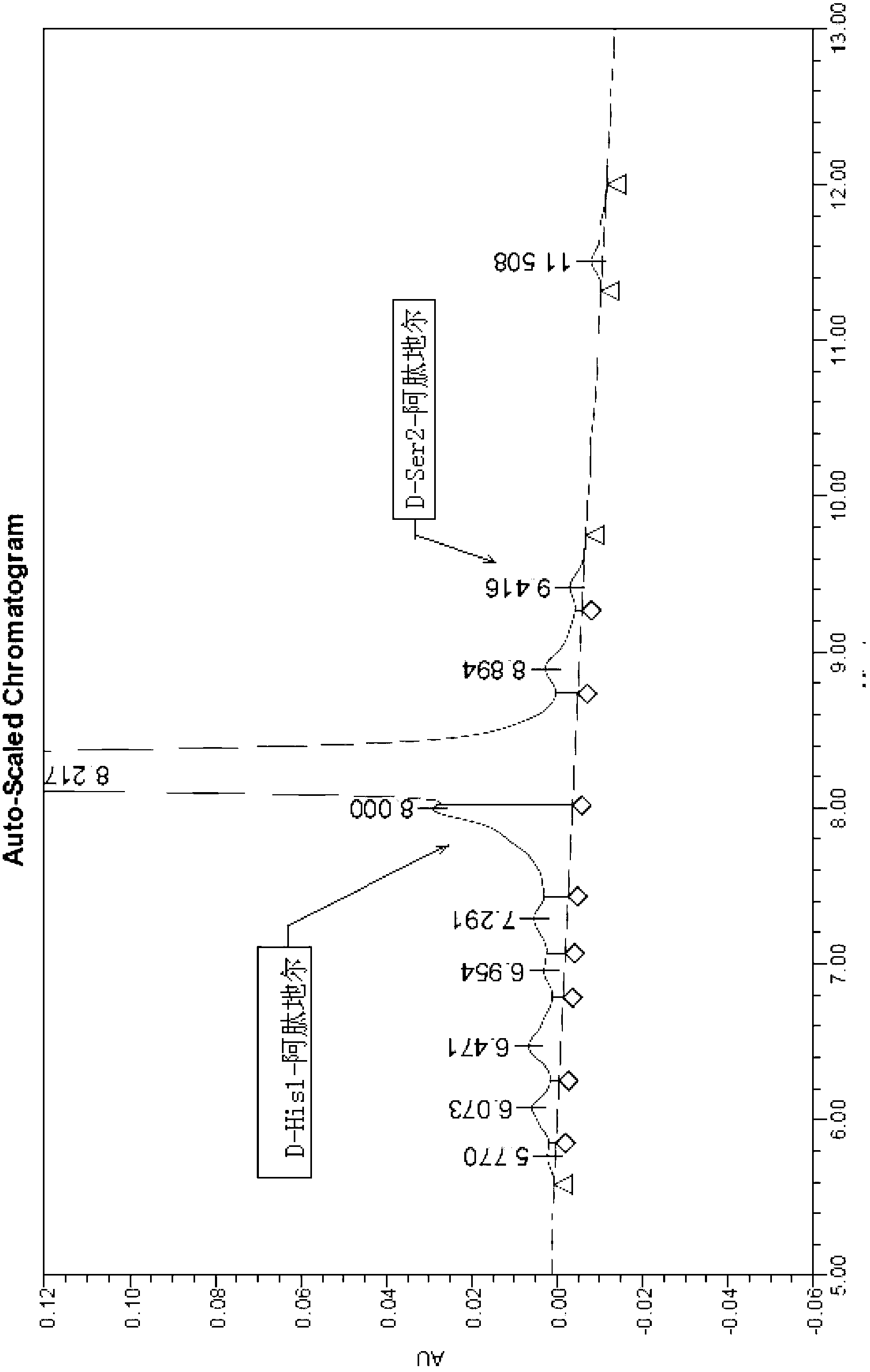

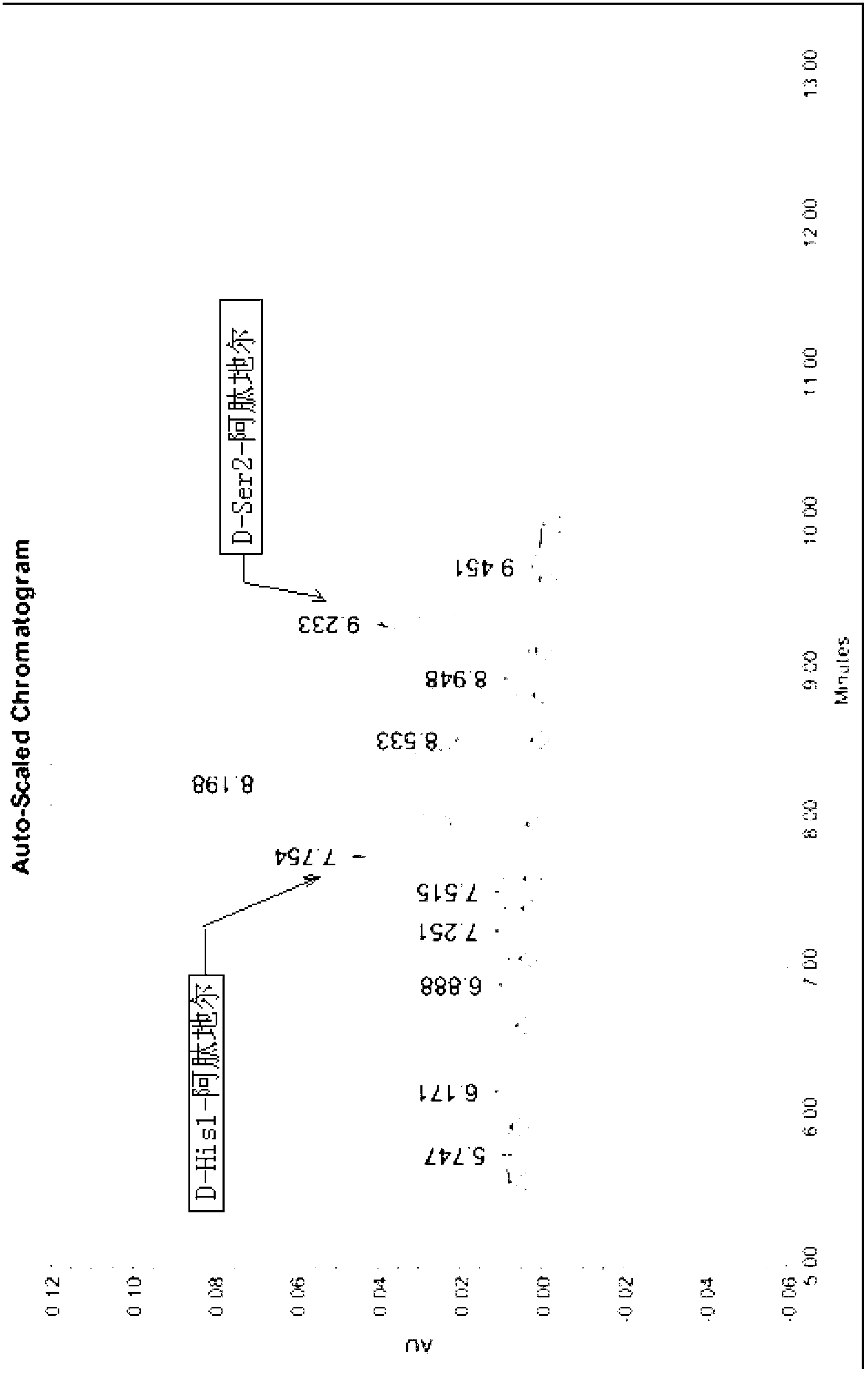

Method for synthetizing aviptadil

InactiveCN103159845ASolve the problem of low purityHormone peptidesPeptide preparation methodsSynthetic materialsCoupling

The invention relates to the field of medicine synthesis and discloses a method for synthetizing aviptadil. The method comprises the steps of according to the amino acid sequence of aviptadil peptide chain from N terminal to C terminal, synthetizing a 1-9 fragment by using Boc-His(3-Bum)-Ser(Psi(Me, Me)pro)-OH, synthetizing 10-18 and 19-28 fragments simultaneously, coupling the three polypeptide fragments to obtain the aviptadil. By adopting the method, the problems that in the conventional synthetic methods, the content of racemic impurities D-Hisl- aviptadil and D-Ser2-aviptadil is higher and the aviptadil purity is lower due to the inappropriate synthetic materials and coupling methods are solved.

Owner:HYBIO PHARMA

Lithium aluminum titanium phosphate preparation method

ActiveCN105336948APrecise control ratioSolve the problem of low purityMaterial nanotechnologyCell electrodesPhosphorTitanium phosphate

The present invention belongs to the technical field of lithium-ion batteries, and specifically discloses a lithium aluminum titanium phosphate preparation method. First, titanium dioxide is embedded into an appropriate amount of lithium ions by electrochemical method, according to the ratio of lithium aluminum titanium phosphate, aluminum and phosphor salts are added to form a homogeneous mixture, and the homogeneous mixture is annealed to obtain a LATP (lithium aluminum titanium phosphate) solid electrolyte. The raw materials are cheaper, the process is simple, high purity lithium aluminum titanium phosphate can be obtained by two steps of electrochemical and high temperature treatment, the ratio of lithium aluminum titanium phosphate can be precisely controlled, and the lower product purity problem caused by volatilization of a lithium salt at high temperature in general solid-phase method can be solved.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

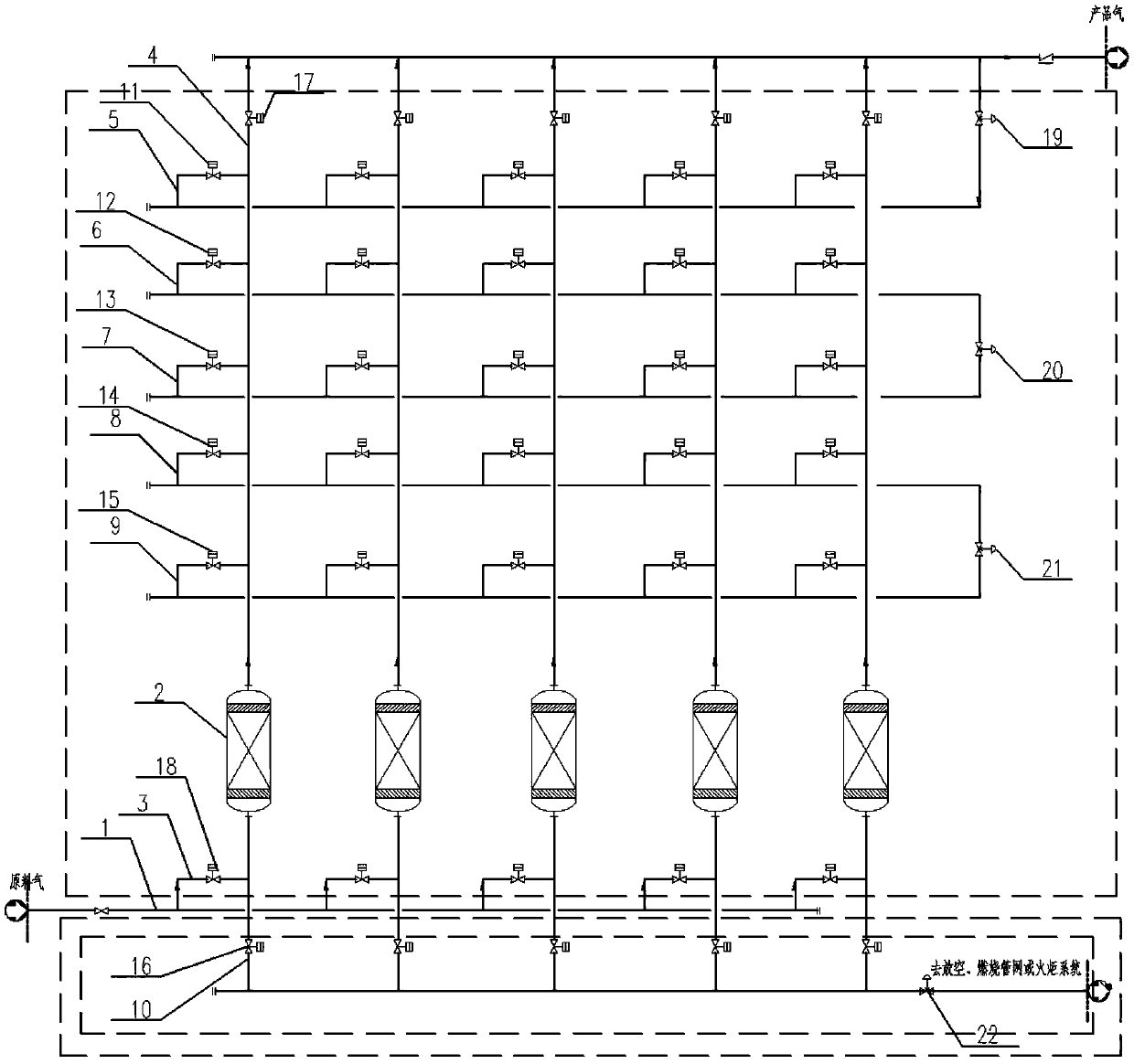

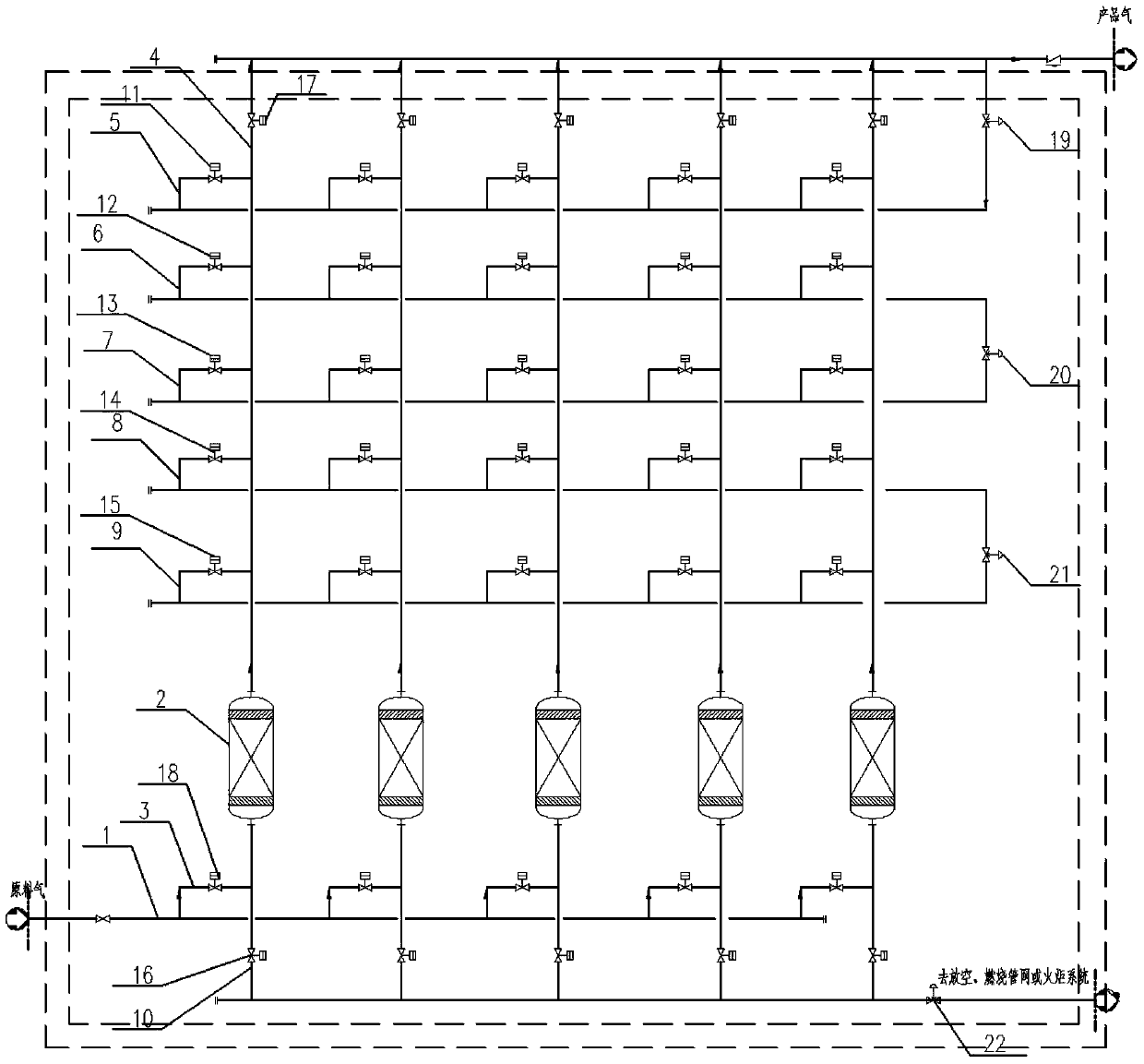

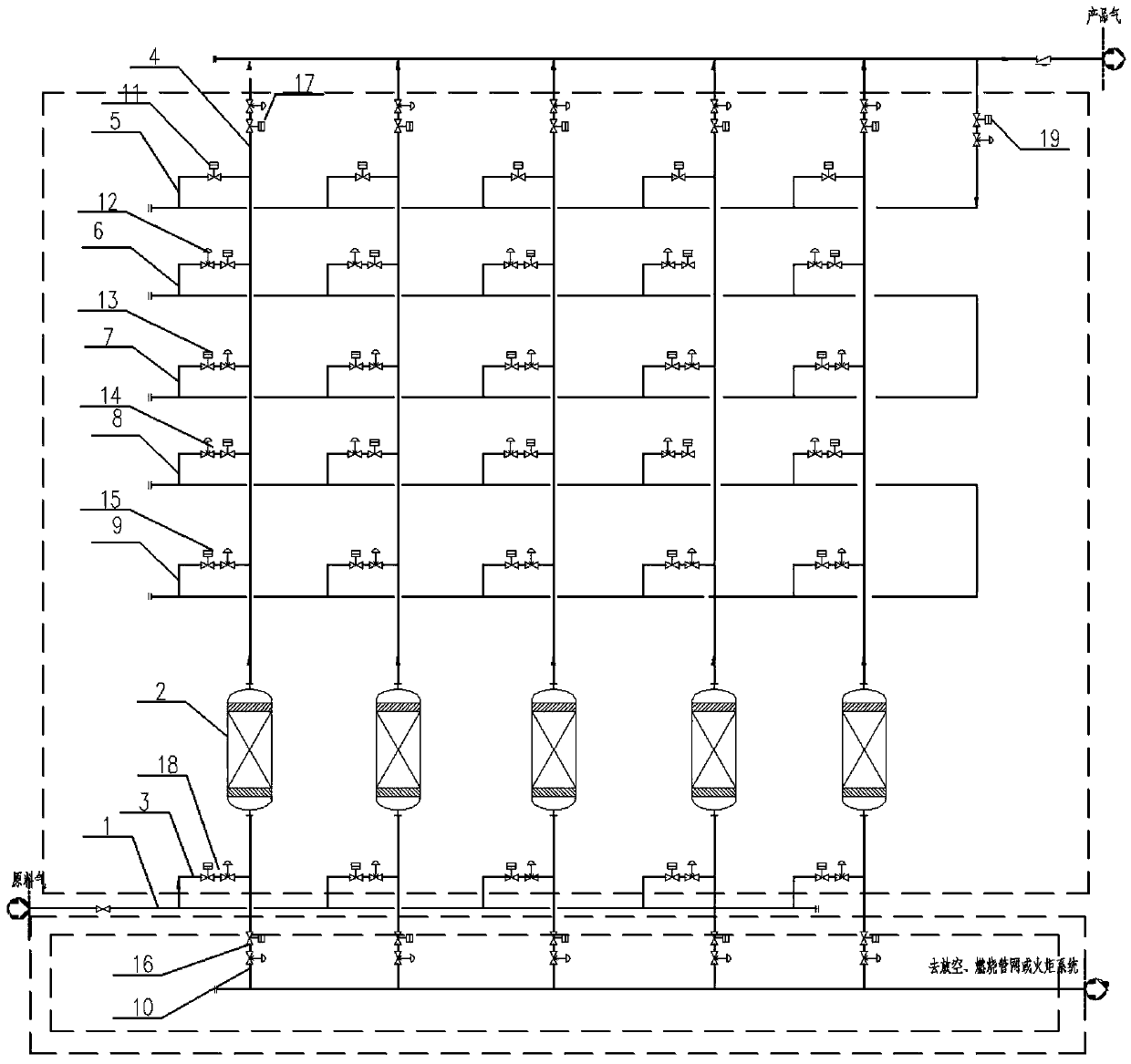

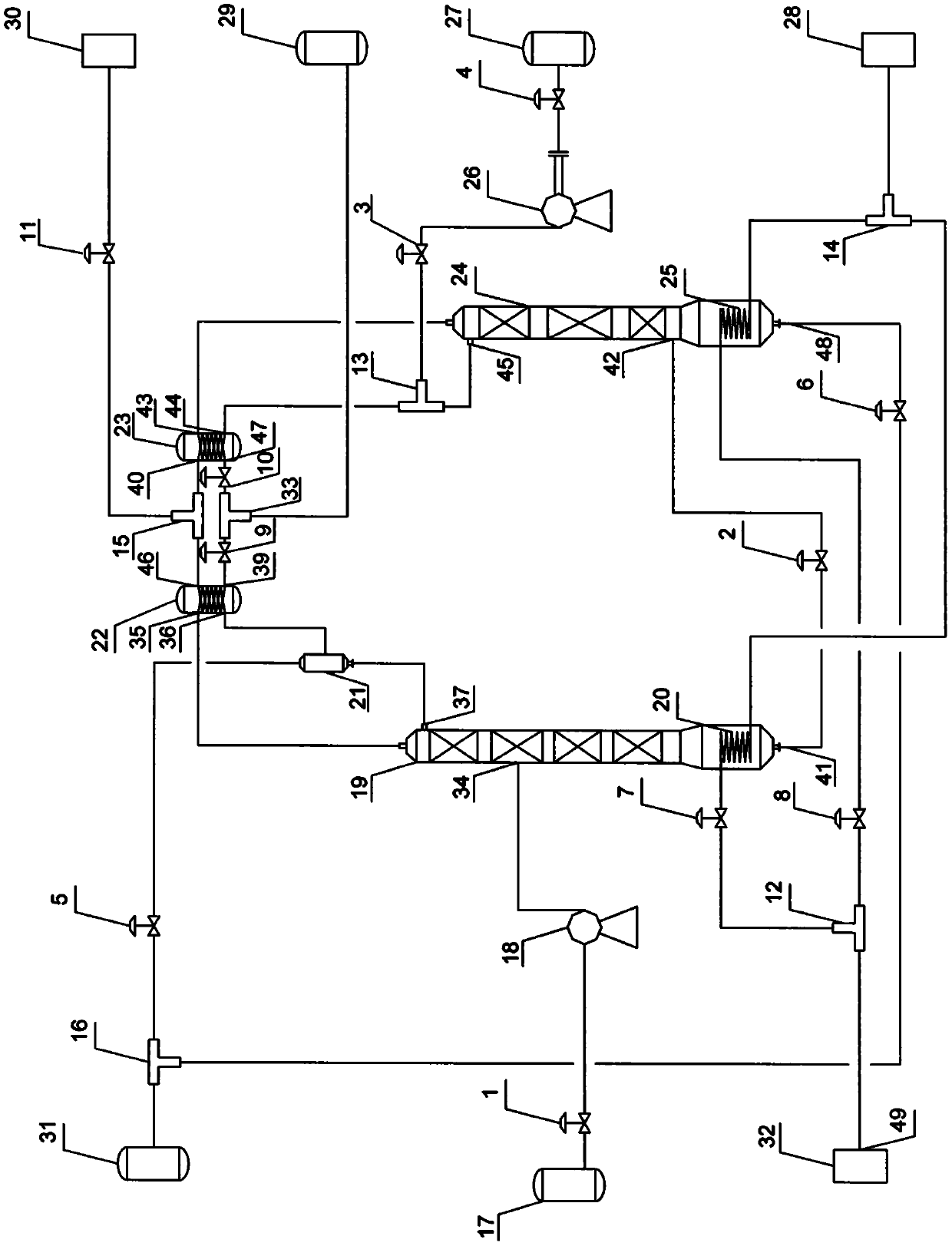

A pressure swing adsorption method for pressure change linkage control in cycle operation

ActiveCN107349746BImprove fault toleranceGuaranteed uptimeDispersed particle separationFault toleranceDesorption

The invention discloses a pressure-swing adsorption method for coupling control of pressure change in cyclic operation and relates to the technical field of pressure-swing adsorption gas-separation technologies. The pressure-swing adsorption method comprises the following steps: carrying out simulation on the cyclic operation process of adsorption and desorption of a pressure-swing adsorption system to determine a mechanical designation mode, an autonomous judgment mode and a mechanical-autonomous combining mode by boundary conditions of an inlet and an outlet of an adsorbing tower in simulation, wherein the pressure-swing adsorption system consists of one or more groups of adsorbing tower sections consisting of at least two adsorbing towers; and carrying out coupling control on the determined control mode and combination of a program control valve and an adjusting valve, by adopting instantaneous pressure in two or more target adsorption towers as basis, adjusting opening and closing as well as opening degree of valve combination, carrying out instantaneous coupling control on gas flowing speed and pressure change trend in the target adsorption tower and the inlet and outlet so as to increase the composition and pressure of raw gas of a pressure-swing adsorption device and the fault tolerance of pressure change of each step in the cyclic operation process of adsorption and desorption of pressure-swing adsorption.

Owner:SICHUAN TECHAIRS

A kind of electrochemical preparation method of solid electrolyte lithium lanthanum titanium oxide compound

ActiveCN105206870BPrecise control ratioSolve the problem of low puritySecondary cellsTwo stepLanthanum

The invention belongs to the field of lithium ion batteries, in particular to an electrochemical preparation method of a solid electrolyte lithium lanthanum titanium oxide compound. In the present invention, firstly, lanthanum oxide is intercalated with an appropriate amount of lithium ions by an electrochemical method, and then titanium salt is added according to the ratio of lithium, lanthanum and titanium to form a uniform mixture, and annealed to obtain perovskite-type LLTO. The invention can precisely control the content of lithium by controlling the discharge electric quantity, so as to obtain high-purity lithium lanthanum titanium oxide compound. The invention can accurately control the ratio of lithium lanthanum to titanium, and solves the problem of low product purity due to the volatilization of lithium salt at high temperature in the usual solid-phase method. At the same time, the raw material is cheap and the process is simple. It can be achieved by two steps of electrochemical and high temperature treatment. Obtain high-purity lithium lanthanum titanium oxide compound.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

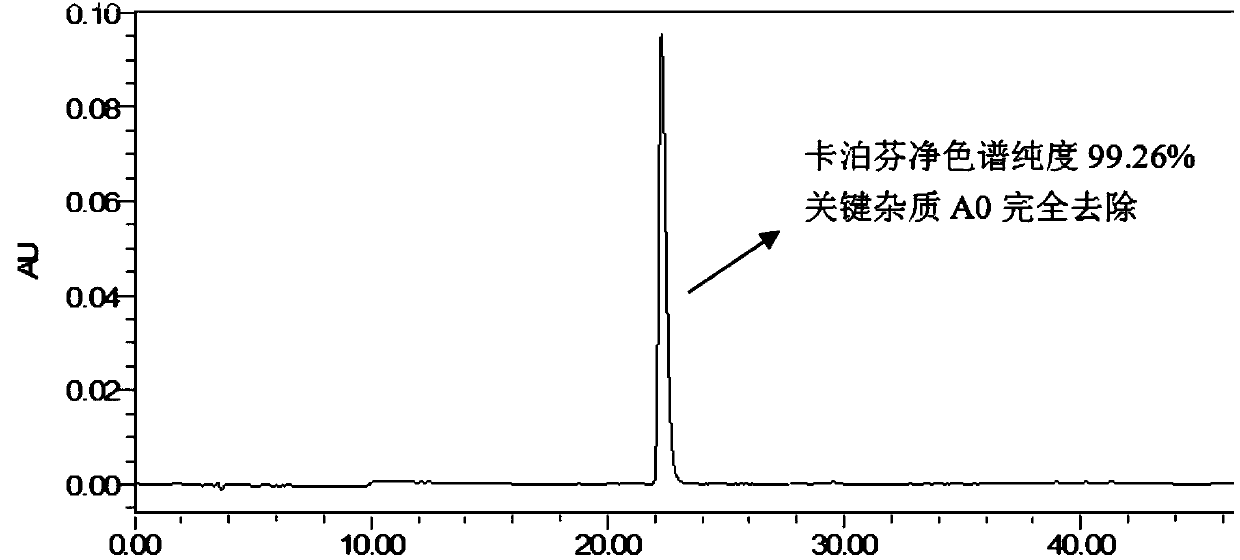

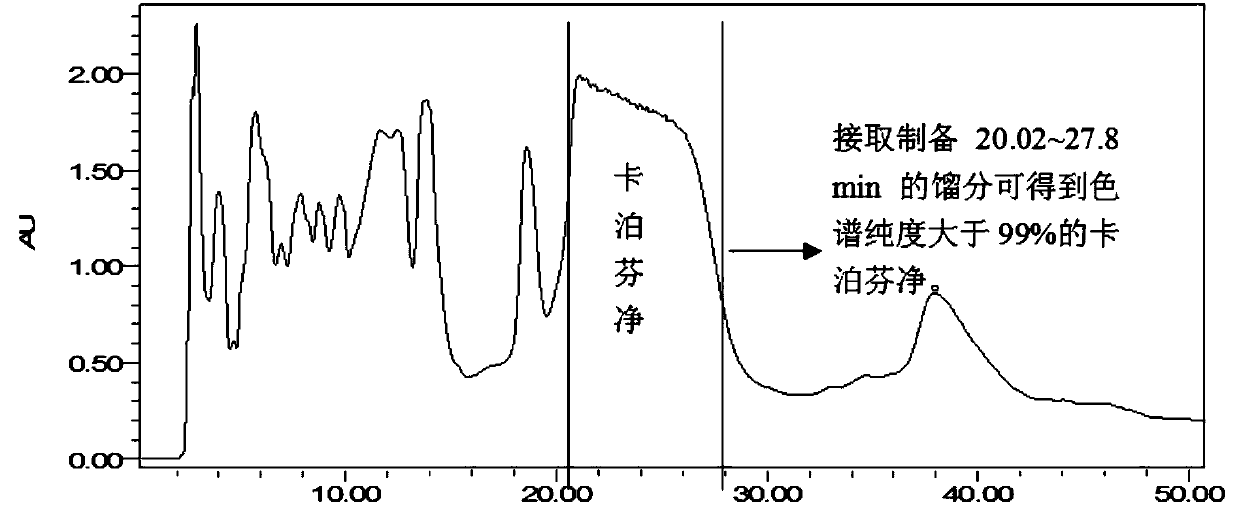

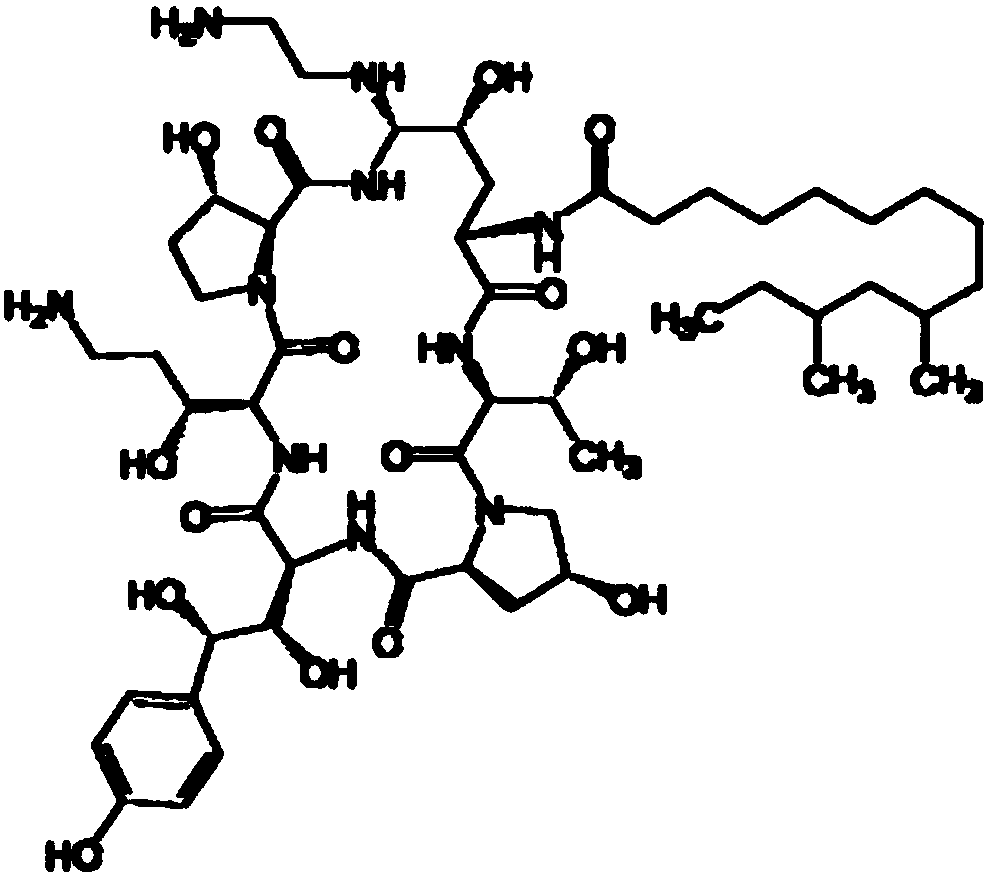

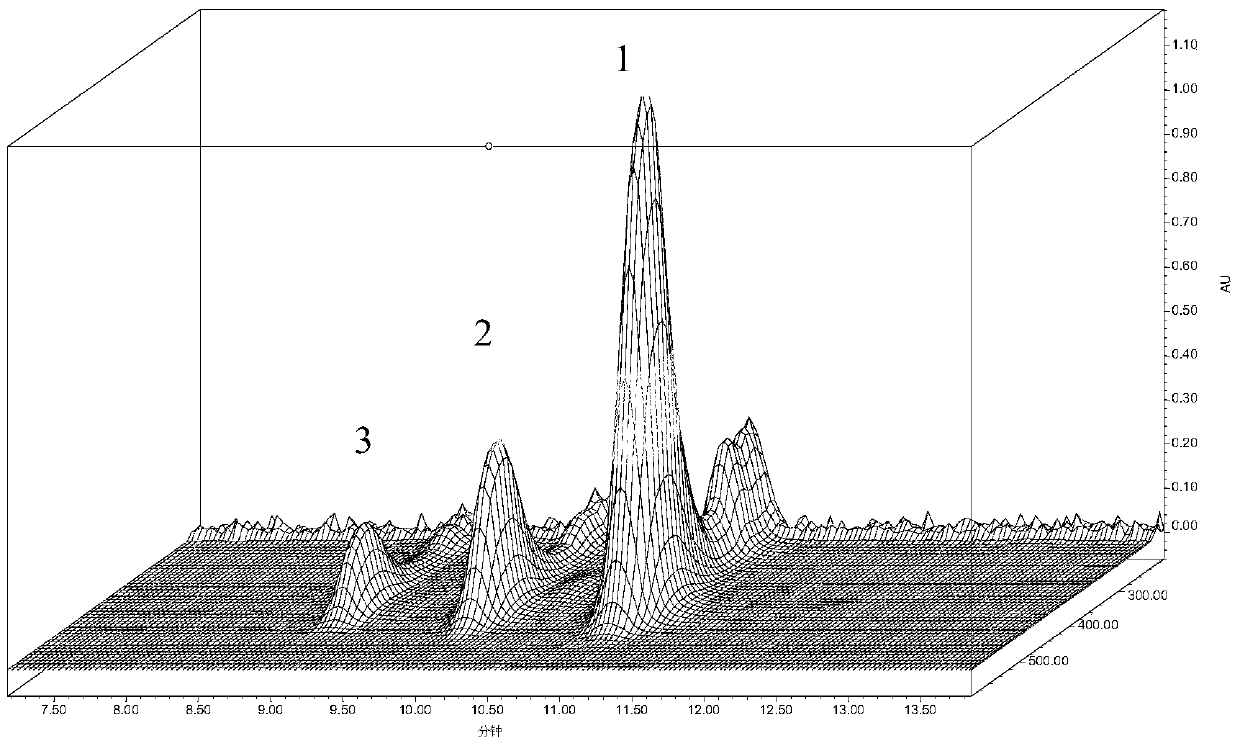

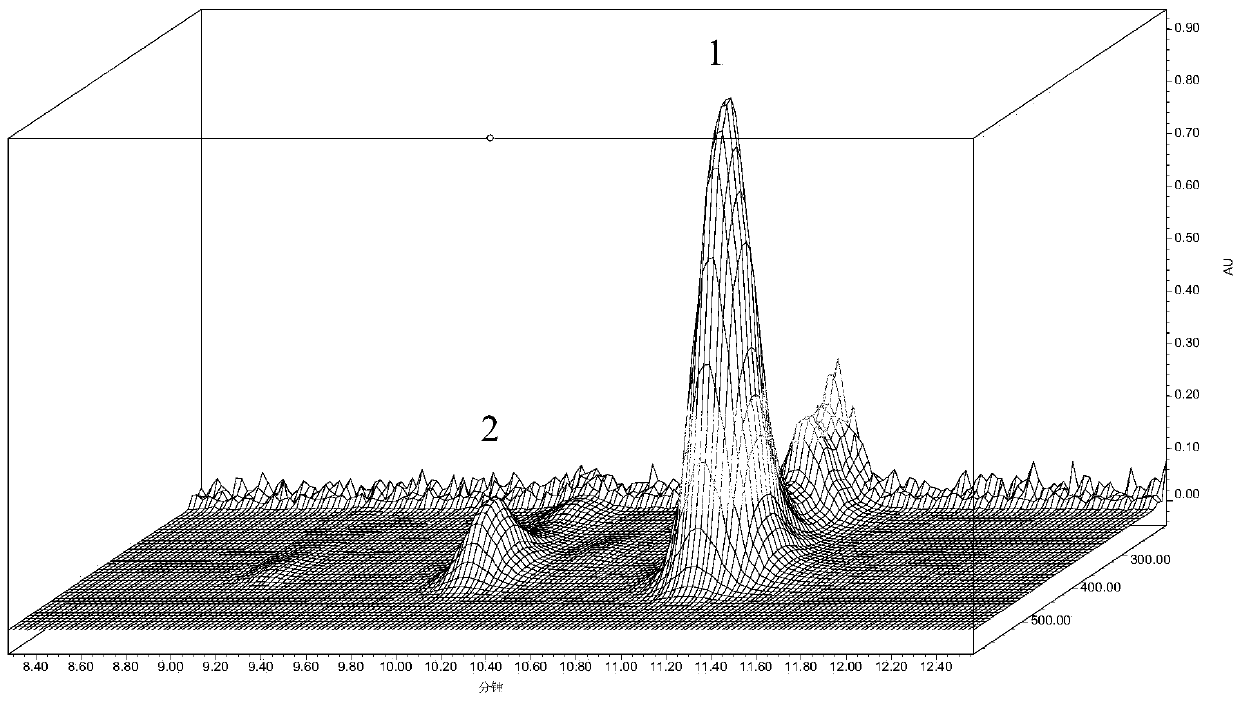

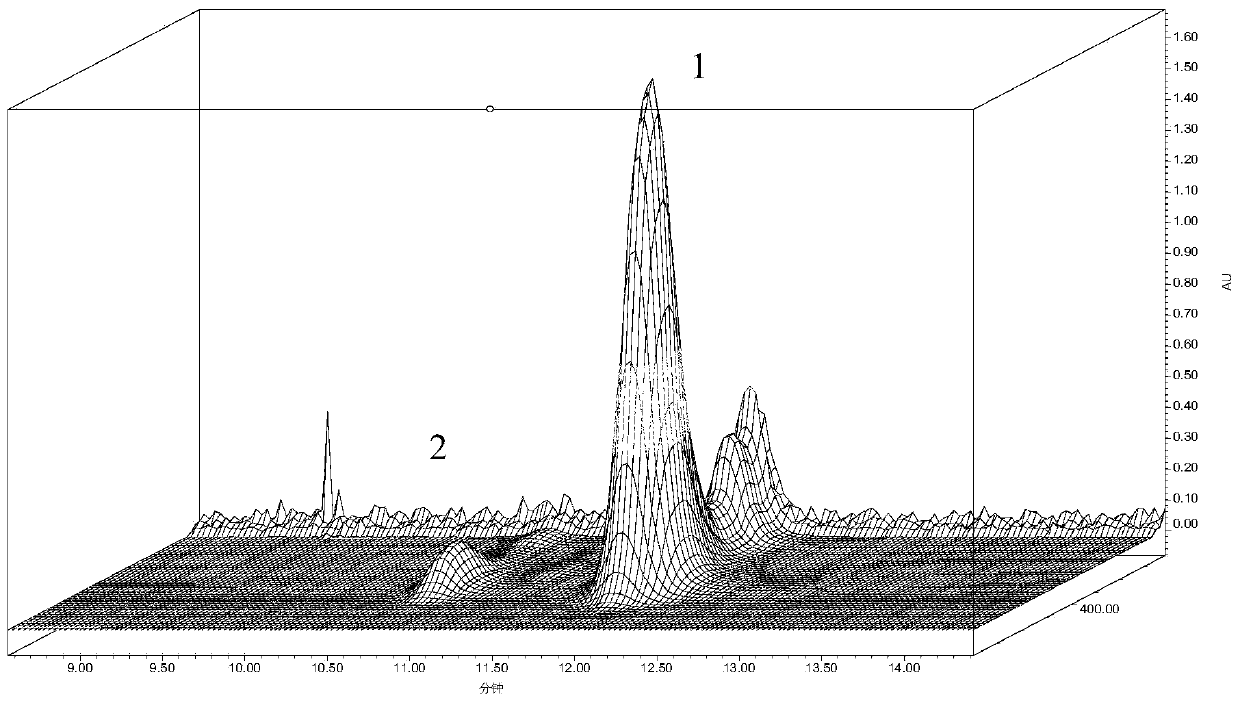

Method for efficiently separating and purifying caspofungin

InactiveCN108250272AEasy to separateSolve the problem of low sample loading and low purity after purificationPeptide preparation methodsOrganic solventElution

A purpose of the present invention is to provide a method for separating and purifying caspofungin. The method is characterized in a silica gel hydrophilic material with a polar group modified on thesurface is used, a caspofungin crude product is dissolved with a certain proportion of an organic solvent-buffer salt solution, the obtained sample is injected, elution is performed with a certain proportion of an organic solvent-buffer salt solution, purification is performed, and desalting is performed to obtain the caspofungin with a chromatographic purity of greater than 99% and a key impurityA0 of less than 0.1%. With the method of the present invention, the efficient separation purification and preparation of caspofungin is achieved, and the method has advantages of good stability, highsample injection amount, easy operation, controllability and the like, and is suitable for the separation and purification in the production.

Owner:浙江华谱新创科技有限公司

A method of extracting curcumin from turmeric

ActiveCN105669410BHigh purityReduce extraction costsCarbonyl compound separation/purificationEthyl acetateCurcuma

The invention provides a method for extracting curcumin from turmeric. The method comprises the following steps: weighing a certain amount of turmeric powder, adding 70-85% acetone according to the liquid-solid ratio of 1: 8-10, extracting for three times, decompressing and recovering acetone to obtain a dark brown oily extract, carrying out liquid-liquid extraction by the use of petroleum ether, water and ethyl acetate, carrying out crude separation, crystallizing and recrystallizing by the use of ethanol-water to obtain needle curcumin crystal, and measuring mass fraction by HPLC. Through calculation, purity detected by HPLC after crystallization can reach 88% and above, and purity detected by HPLC after recrystallization can reach 95% and above.

Owner:BEIJING UNION UNIVERSITY

A method for recycling and treating waste pickling liquid of stainless steel containing iron, chromium and nickel

InactiveCN104787928BEasy to separateSolve the problem of low purityIron oxides/hydroxidesMultistage water/sewage treatmentFractional PrecipitationSS - Stainless steel

Owner:NANYANG NORMAL UNIV

A kind of recovery purification method of high-purity rhodium

InactiveCN104860358BReduce acidityImprove adsorption capacityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsPurification methodsPotassium hydroxide

The invention discloses a high purity rhodium recovery purification method, relates to precious metal recovery purification field, and especially relates to a method for separation and purification of rhodium from other precious metals and base metals in a rhodium-containing waste leachate. According to the method, tetramethylammonium chloride is used as a precipitant, the rhodium solution concentration is controlled to 30-80 g / L, firstly, a small amount of precipitant is added for reaction to remove platinum, iron and other high valence impurities, excessive precipitant is added into the obtained filtrate for boiling and reflux at 110-120 DEG C for 24 h-48 h to obtain a rhodium salt precipitate. High purity rhodium hydroxide is obtained by full washing, dissolving, passing through resin, and potassium hydroxide precipitation carried out on the rhodium salt precipitate. The high purity rhodium recovery purification method is strong in process applicability, simple in operation, low in cost, high in product purity, and free of emission, and may not cause environmental pollution.

Owner:兰州金川贵金属材料股份有限公司

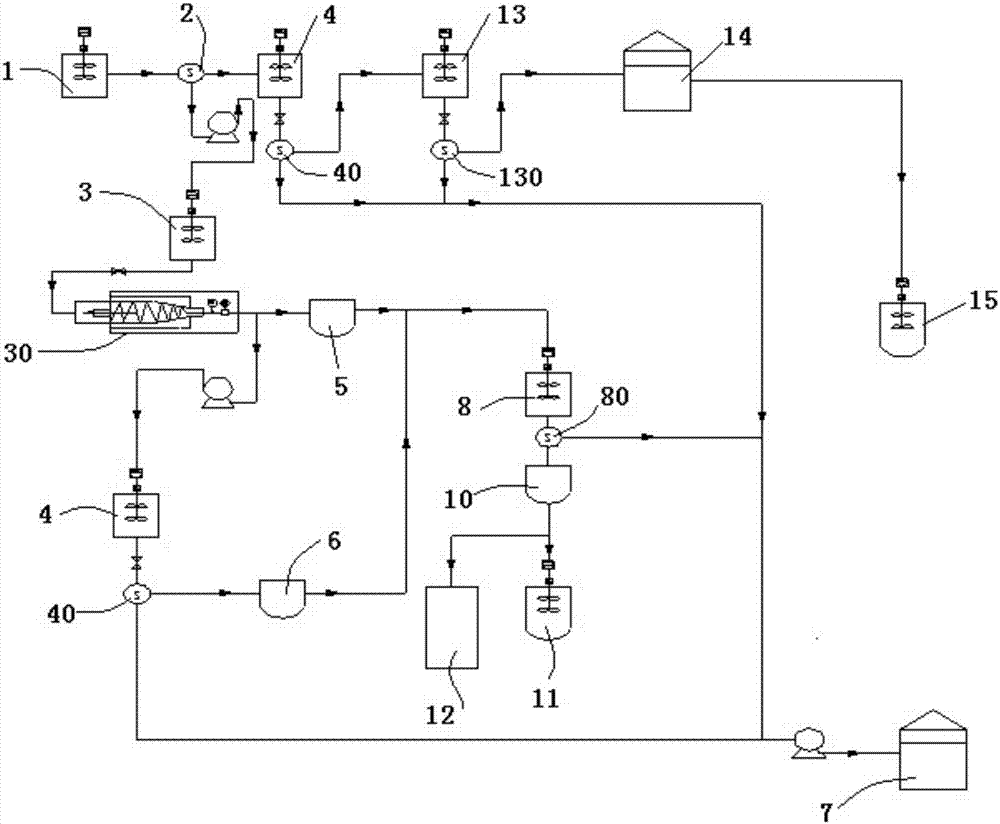

Device for producing high-purity boron trichloride and production method of device

PendingCN110065951ALow priceReduce manufacturing costBoron halidesFractional distillationBoron trichlorideMethods of production

The invention belongs to a device for producing high-purity boron trichloride and a production method of the device. The device comprises a raw material liquid buffering tank, a product tank, a liquidammonia storage tank and a circulating water recycling pool. The raw material liquid buffering tank is connected with a first raw material liquid inlet in the upper middle portion of a first rectification tower through a raw material liquid pump, a liquid phase outlet in the bottom of the first rectification tower is connected with a first raw material liquid inlet of a second rectification tower, and a top gas phase outlet of the second rectification tower is sequentially connected with a product tank through a first tube pass inlet of a second heat exchanger, a first tube pass outlet of a second heat exchanger, a first tee joint and a product pump in sequence. The device has the advantages that the automation degree is high, operation is stable, and the product purity reaches the high-purity grade of 99.9995%. Study of special gas of the electron industry and development of the field of semiconductors are guaranteed, and good economic and social benefits are achieved.

Owner:HENAN XINLIANXIN SHENLENG ENERGY

A kind of meropenem compound and its preparation method

InactiveCN102267997AGuarantee product qualitySolve the problem of low purityAntibacterial agentsOrganic chemistryMeropenemSaline solutions

The invention relates to a meropenem compound and a preparation method thereof. In the method, crude meropenem prepared with the prior art is prepared into a relatively pure meropenem compound by adopting the following steps of: adding aqueous alkali into a crude meropenem raw material and fully reacting to clear to obtain a meropenem saline solution; adding active carbon for adsorbing, filteringand collecting filtrate, adding acid into a filtrating solution, and filtering and collecting precipitates; and separating and purifying by using a preparation type neutral aluminum oxide chromatographic column, collecting eluent, concentrating under reduced pressure, and drying in vacuum at the temperature 25-30 DEG C to obtain refined meropenem. The method has the advantages of simple process, convenience for operation and low cost, and is suitable for scale production. According to the invention, the purity is increased, the security of the meropenem compound in an anti-sensitive bacterialinfection medicament is ensured, the product quality of a preparation is improved, and toxic or side effect is reduced.

Owner:HAINAN MEILAN SMITH KLINE PHARMA

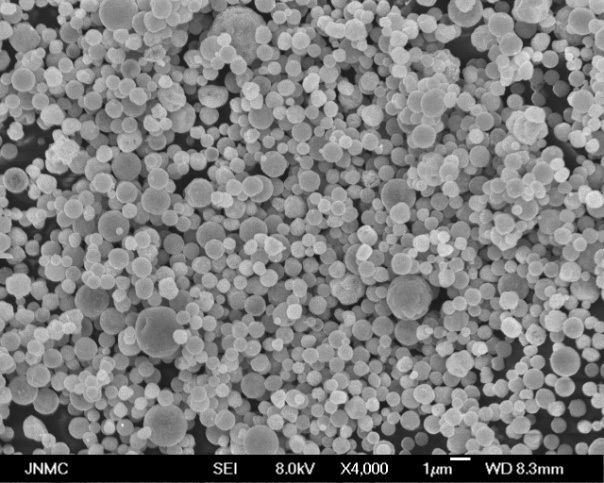

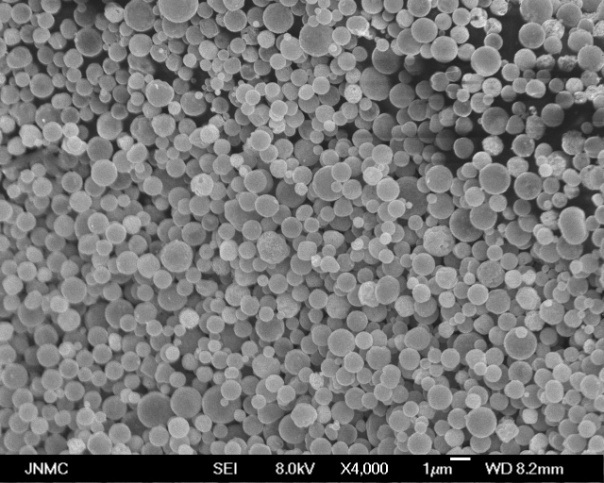

Preparation method of high-purity nickel protoxide

PendingCN112573592AHigh puritySolve the problem of low purityNickel oxides/hydroxidesPhysical chemistrySpray pyrolysis

The invention relates to a preparation method of high-purity nickel protoxide. The preparation method comprises the following steps: dechlorinating nickel oxide obtained by spray pyrolysis, and condcuting calcining at high temperature to obtain nickel protoxide powder with higher purity. The preparation method does not generate wastewater, has the advantages of stable technique and high product purity, and can prepare a high-purity nickel protoxide product with a nickel content of 77% or more, a cobalt content of 0.004% or less, an iron content of 0.004% or less, a calcium content of 0.004% orless and a chlorine content of 0.01% or less.

Owner:浙江博瓦德新材料科技有限公司

Device for cultivation of photosynthetic bacteria

PendingCN109762723AQuick killGuaranteed purityBioreactor/fermenter combinationsBiological substance pretreatmentsMicroorganismEngineering

The invention discloses a device for cultivation of photosynthetic bacteria. The device comprises a device main body, a feeding inlet runs through the top of the device main body, a feeding inlet cover is connected to one side of the feeding inlet through a movable shaft, and a handle is fixed to the top of the feeding inlet cover; an observation window is arranged on the upper portion of the external surface of the device main body, an operation desk is arranged on the lower portion of the external surface of the device main body, and a purifying chamber is formed in the device main body; a user can start an ultraviolet sterilizer through the operating desk to kill miscellaneous bacteria for a culture medium in the purifying chamber so as to ensure the purity of the culture medium needingto be processed, the culture medium subjected to killing enters a culture room through an impurity filter net, and the purity of the culture medium is ensured; the photosynthetic bacteria needing tobe cultured are filtered and guided into a liquid storage box from a bacteria solution opening, and uniformly sprayed to the culture medium in the culture room through a spray head; stirring is conducted under the constant temperature, and pure photosynthetic bacteria microorganisms grow out and are output from a discharge hole formed in the bottom of the device.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Recovery method of nylon acid

InactiveCN108003013AIncrease the crystallization potentialRealize development and utilizationCarboxylic compound separation/purificationPolyesterRecovery method

The invention relates to a recovery method of nylon acid. The recovery method of nylon acid comprises following steps: 1, nylon acid is dissolved in water, an obtained solution is cooled to 20 to 35 DEG C for crystallization, and separation is carried out so as to obtain a primary mother liquor; 2, the primary mother liquor is subjected to condensation, is subjected to crystallization at 10 to 25DEG C, and is subjected to separation so as to obtain crude glutaric acid. The obtained crude glutaric acid is subjected to recrystallization, and then is reacted with hexylenediamine so as to preparenylon 65, and crystals obtained via primary crystallization can be reacted with butylene glycol to prepare mixed polyester polyols. According to the recovery method, only one time of crystallizationis adopted in preparation of crude glutaric acid, the content of glutaric acid in obtained primary crystals is low, the glutaric acid concentration in obtained primary mother liquor is high; condensation of primary mother liquor is capable of breaking the dissolving-crystallization balance of the primary mother liquor, and increase the crystallization potential energy of glutaric acid; then cooling crystallization is adopted to prepare crude glutaric acid with a purity ranging from 93 to 98%; and then recrystallization of the obtained crude glutaric acid is carried out so as to obtain high purity glutaric acid with a purity of 99.9% or higher.

Owner:中国平煤神马控股集团有限公司 +1

Method for extracting and culturing amniotic stem cells

ActiveCN110218697AImprove extraction efficiencyHigh purityCell dissociation methodsSkeletal/connective tissue cellsMicrobiologyDigestion

The invention discloses a method for extracting and culturing amniotic stem cells. The method comprises the steps of soaking a cleaned healthy amnion mechanically separated from a placenta into a first mixed solution for 0.5-1 hour, cleaning the healthy amnion with a trimethylolaminomethane buffer solution, scraping the surface of the amnion slightly with a cell scraper to remove epithelial cells,flushing the amnion with PBS 3-5 times, and mechanically shearing the amnion; adding amnion fragments into a second mixed solution, and digesting the amnion fragments until the amnion fragments basically disappear; superposing 1 / 2X ml of an amnion digestion suspension on a separated solution, performing centrifuging for 30 minutes at the speed of 1,500-2,000 rpm, and sucking a second suspension layer; finally, putting the second suspension layer into a culture medium for resuspension, and inoculating an obtained suspension into a cell culture dish for culturing at the constant temperature. According to the method, the efficiency of extracting the amniotic stem cells is higher, and the purity is higher.

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

Electrochemical preparation method for LTP (LiTi2(PO4)3)

ActiveCN105460911APrecise control ratioSolve the problem of low purityPhosphatesCell electrodesLithiumElectrochemistry

The invention discloses an electrochemical preparation method for LTP (LiTi2(PO4)3). According to the method, firstly, a proper quantity of Li ions are inserted into TiO2 with an electrochemical method, then P salt is added according to proportion of Li, Ti and P, a uniform mixture is formed, and an LTP solid electrolyte is obtained through annealing. The content of Li can be controlled accurately through control of the discharge electric quantity, and high-purity LTP can be obtained accordingly.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com