Thermal state copper and sulfur blowing device

A copper matte and supporting device technology, applied in crucible furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problem of low-altitude pollution hot copper matte purity, low, etc., and achieve the effect of improving purity and solving low-altitude pollution.

Active Publication Date: 2016-10-05

CHINA ENFI ENGINEERING CORPORATION

View PDF8 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The main purpose of the present invention is to provide a hot copper matte blowing device to solve the problems of low-altitude poll

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

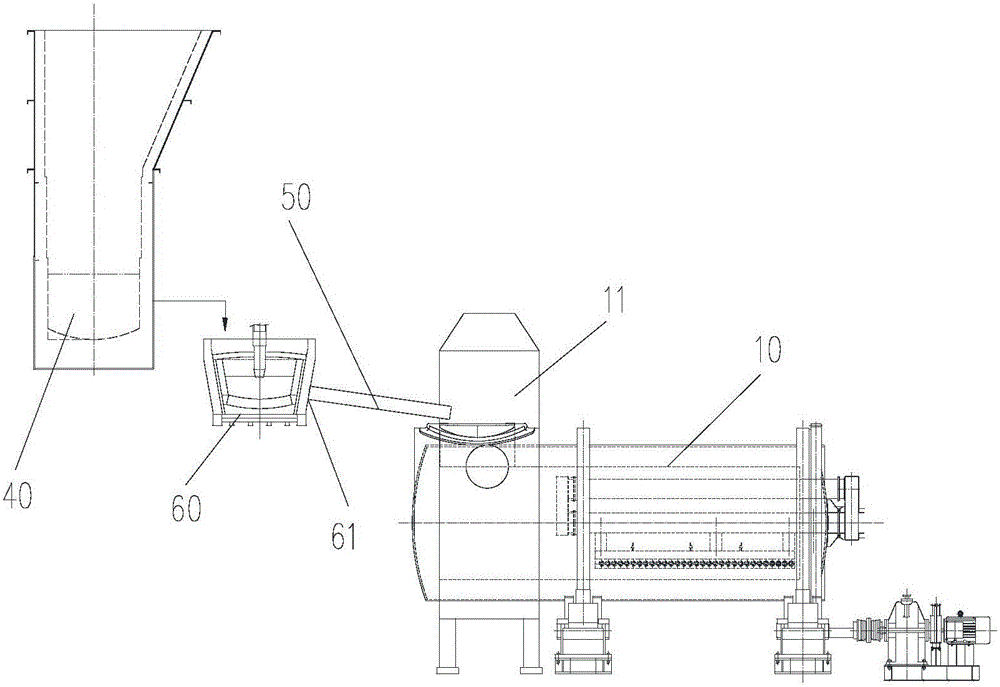

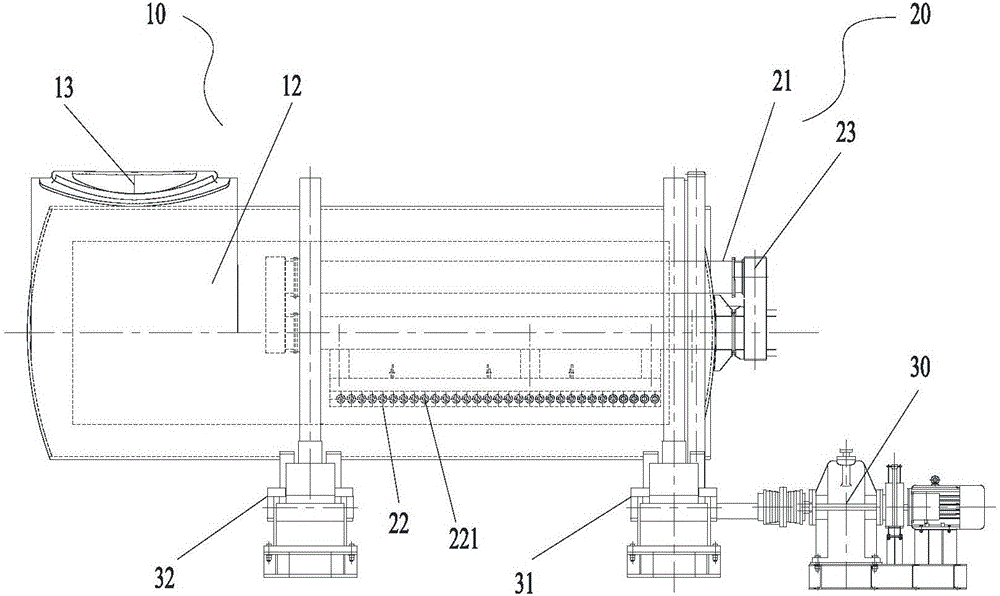

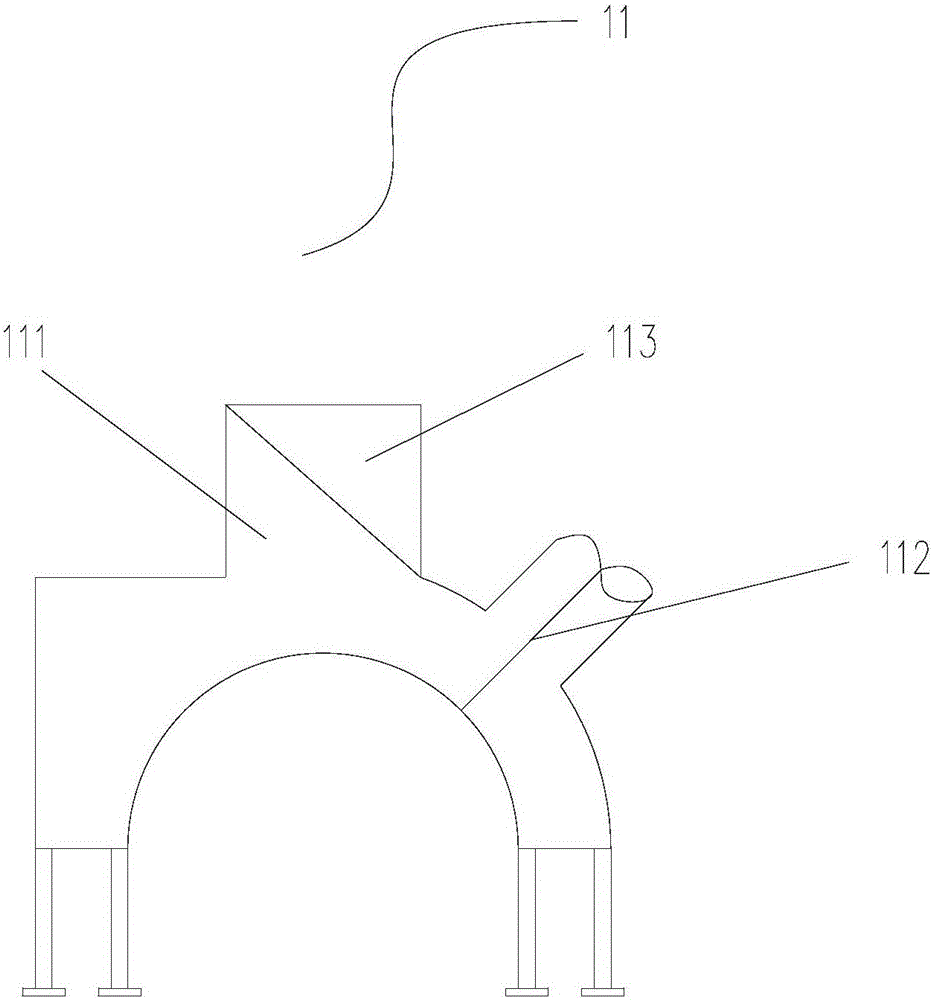

The invention provides a thermal state copper and sulfur blowing device which comprises a smelting furnace, a sedimentation electric furnace, a converter and a fluid channel. Melt in the smelting furnace enters the sedimentation electric furnace, and the sedimentation electric furnace is provided with a first communication opening. The converter is provided with a second communication opening. The first communication opening communicates with the second communication opening through the fluid channel so as to make the melt in the smelting furnace flow into the converter. By means of the technical scheme of the thermal state copper and sulfur blowing device, the problems that low-altitude pollution exists, and the purity of thermal state copper and sulfur entering the converter is not high during thermal state copper and sulfur transshipping of a crane in the prior art are effectively solved.

Description

technical field [0001] The invention relates to the technical field of mineral smelting, in particular to a hot copper matte blowing device. Background technique [0002] Copper matte blowing is an important intermediate link in the process of copper pyrometallurgy. At present, there are two ways of copper matte blowing at home and abroad: hot copper matte P-S converter blowing and cold copper matte blowing. In contrast, hot copper matte P-S converter converting is the most widely used and mature, with low investment and low energy consumption. On the one hand, the traditional P-S converter blowing process needs to use a crane to transport the copper matte, so there will be problems of low-altitude pollution and poor environmental protection conditions; on the other hand, when the molten liquid in the melting furnace directly enters the converter, the melting There are both hot copper matte and smelting slag in the liquid in the state, which reduces the purity of the hot co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B15/00

CPCC22B15/0028

Inventor 吴玲唐续龙陆金忠

Owner CHINA ENFI ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com