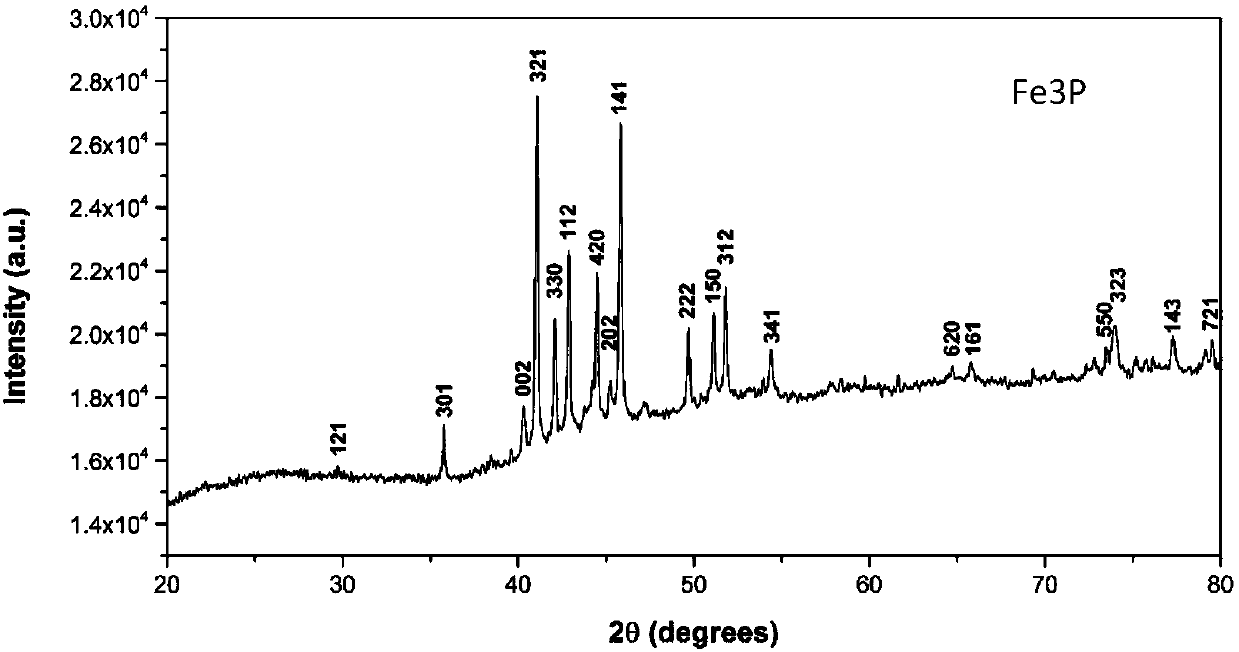

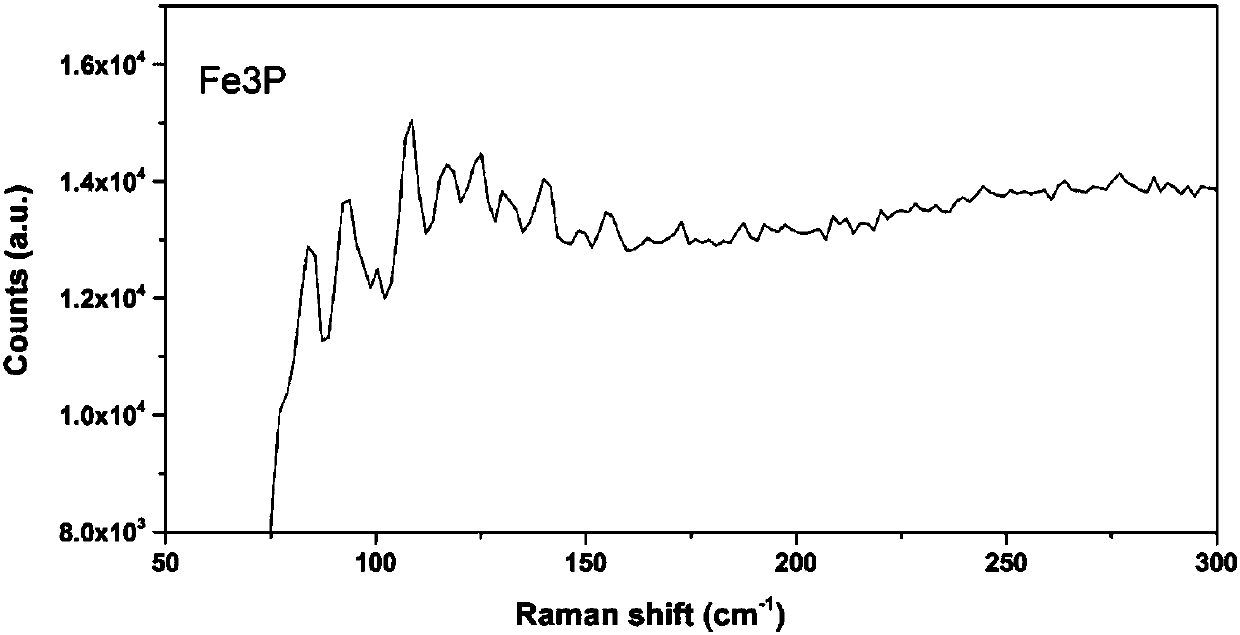

Method for preparing ferrous phosphide Fe3P at high temperature and high pressure

A high-temperature, high-pressure, phosphating technology, which is applied in the field of functional material synthesis, can solve problems such as long reaction time, difficult processing, and low cleanliness, and achieve the effects of improving synthesis efficiency, avoiding volatilization loss, and improving the degree of crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0035] Use analytically pure iron nanopowder (Fe) and red phosphorus powder (P) as starting materials, grind and mix them thoroughly in an agate mortar with alcohol at a molar ratio of 3:1, and take about 0.30 g of iron-phosphorus mixed powder for use The powder tablet press will be pressed into a cylinder of φ6mm×6mm, and the boron nitride ceramic rod will be processed into a boron nitride ceramic tube with a length of 10mm, an outer diameter of 10mm, and an inner diameter of 6mm, and placed in an oven at 150°C for 2 hours. , and then put the powder cylinder sample in a boron nitride ceramic tube, and seal it with 2mm boron nitride ceramic sheets up and down to complete the high-voltage assembly block. High voltage assembly block assembly method:

[0036] ① Drill a circular through hole with a diameter of 12mm in the center of the pyrophyllite cube of 32mm×32mm×32mm;

[0037] ②The circular through hole of the pyrophyllite block is covered with a graphite sleeve heating furna...

Embodiment example 2

[0042] Use analytically pure iron nanopowder (Fe) and red phosphorus powder (P) as starting materials, grind and mix them thoroughly in an agate mortar with alcohol at a molar ratio of 3:1, and take about 0.30 g of iron-phosphorus mixed powder for use The powder tablet press will be pressed into a cylinder of φ6mm×6mm, and the boron nitride ceramic rod will be processed into a boron nitride ceramic tube with a length of 10mm, an outer diameter of 10mm, and an inner diameter of 6mm, and placed in an oven at 150°C for 2 hours. , and then put the powder cylinder sample in a boron nitride ceramic tube, and seal it with 2mm boron nitride ceramic sheets up and down to complete the high-voltage assembly block. High voltage assembly block assembly method:

[0043] ① Drill a circular through hole with a diameter of 12mm in the center of the pyrophyllite cube of 32mm×32mm×32mm;

[0044] ②The circular through hole of the pyrophyllite block is covered with a graphite sleeve heating furna...

Embodiment example 3

[0049] Use analytically pure iron nanopowder (Fe) and red phosphorus powder (P) as starting materials, grind and mix them thoroughly in an agate mortar with alcohol at a molar ratio of 3:1, and take about 0.30 g of iron-phosphorus mixed powder for use The powder tablet press will be pressed into a cylinder of φ6mm×6mm, and the boron nitride ceramic rod will be processed into a boron nitride ceramic tube with a length of 10mm, an outer diameter of 10mm, and an inner diameter of 6mm, and placed in an oven at 150°C for 2 hours. , and then put the powder cylinder sample in a boron nitride ceramic tube, and seal it with 2mm boron nitride ceramic sheets up and down to complete the high-voltage assembly block. High voltage assembly block assembly method:

[0050] ① Drill a circular through hole with a diameter of 12mm in the center of the pyrophyllite cube of 32mm×32mm×32mm;

[0051] ②The circular through hole of the pyrophyllite block is covered with a graphite sleeve heating furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com