Preparation method of high-purity nickel protoxide

A nickel oxide, high-purity technology, applied in nickel oxide/nickel hydroxide and other directions, can solve the problems that the fineness cannot reach high-end manufacturing, the thermal decomposition temperature of nickel chloride is high, and the purity of nickel oxide is not high. The effect of short preparation time, low cost and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

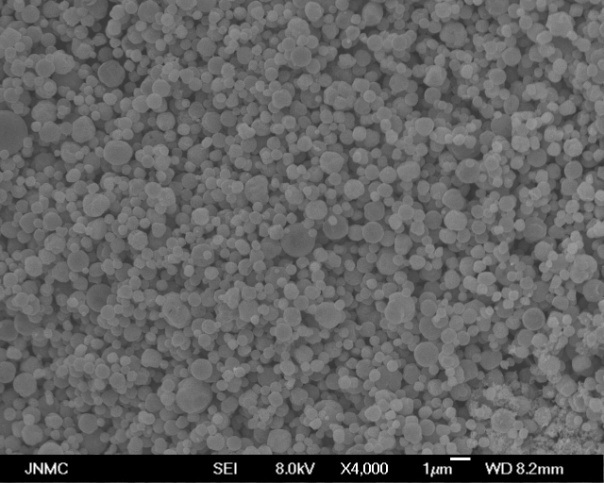

[0033] A preparation method of high-purity nickelous oxide is realized through the following steps:

[0034] Step 1, select nickel nitrate as raw material, add pure water to prepare the nickel nitrate solution of 1.7~2.5mol / L;

[0035] Step 2, the nickel nitrate solution in step 1 is purified, and the purification process uses P507 as an extractant to extract and remove cobalt, remove the cobalt to below 0.005g / L, adjust the pH to 4.0, remove iron impurities, and obtain iron low Nickel salt solution at 0.005g / L;

[0036] Step 3, adding the nickel nitrate solution into the spray pyrolysis device, and then adding 0.2% polyethylene glycol of the total mass of the solution;

[0037] Step 4: Set the spray pressure of the spray pyrolysis device to 0.2MPa, the pyrolysis temperature to 600°C, and the pyrolysis atmosphere to be air atmosphere, start the spray pyrolysis device to prepare nickel oxide, and the tail gas produced by spray pyrolysis is sprayed An acidic solution is obtain...

Embodiment 2

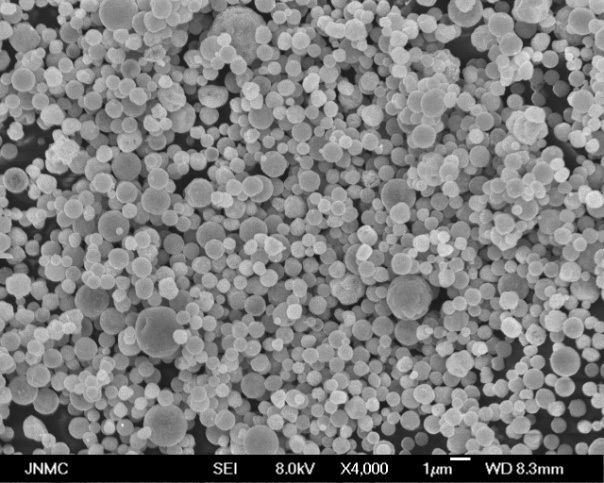

[0041] A preparation method of high-purity nickelous oxide is realized through the following steps:

[0042] Step 1, select nickel chloride as raw material, add pure water to prepare the nickel chloride solution of 2.5mol / L;

[0043] Step 2, purify the nickel chloride solution in step 1, use Cyanex272 as the extractant to extract and remove cobalt in the purification treatment, remove the cobalt to below 0.005g / L, adjust the pH to 4.6, remove iron impurities, and obtain iron after filtration Nickel salt solution lower than 0.005g / L;

[0044] Step 3, adding the nickel chloride solution to the spray pyrolysis device, and then adding polyacrylamide with a total mass of 2.0% of the solution;

[0045]Step 4: Set the spray pressure of the spray pyrolysis device to 1.0MPa, the pyrolysis temperature to 950°C, and the pyrolysis atmosphere to be an oxygen atmosphere, start the spray pyrolysis device to prepare nickel oxide, and the tail gas produced by spray pyrolysis is sprayed An ac...

Embodiment 3

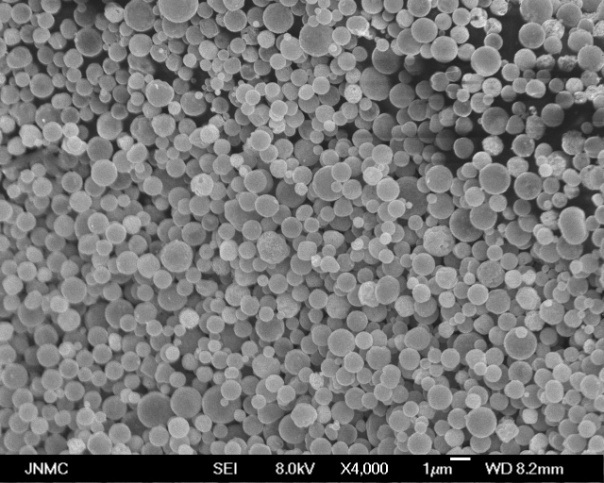

[0049] A preparation method of high-purity nickelous oxide is realized through the following steps:

[0050] Step 1, select nickel acetate soluble salt as raw material, add pure water to prepare the nickel acetate solution of 2.0mol / L;

[0051] Step 2, purify the nickel acetate solution in step 1, use Cyanex272 as the extractant to extract and remove cobalt in the purification treatment, remove the cobalt to below 0.005g / L, adjust the pH to 4.3, remove iron impurities, and obtain iron low Nickel salt solution at 0.005g / L;

[0052] Step 3, nickel acetate solution is added in the spray pyrolysis device, then add the sodium lauryl sulfate of solution gross mass 1.0%;

[0053] Step 4: Set the spray pressure of the spray pyrolysis device to 0.6MPa, the pyrolysis temperature to 780°C, and the pyrolysis atmosphere to be air atmosphere, start the spray pyrolysis device to prepare nickel oxide, and the tail gas produced by spray pyrolysis is sprayed An acidic solution is obtained aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com