Patents

Literature

158results about How to "The generation of solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Additive with dual lithium dendrite inhibition effect and application of additive

InactiveCN106252722AThe generation of solutionOvercome the problem that the inhibitory effect is not obviousFinal product manufactureElectrolyte accumulators manufactureLithiumSURFACTANT BLEND

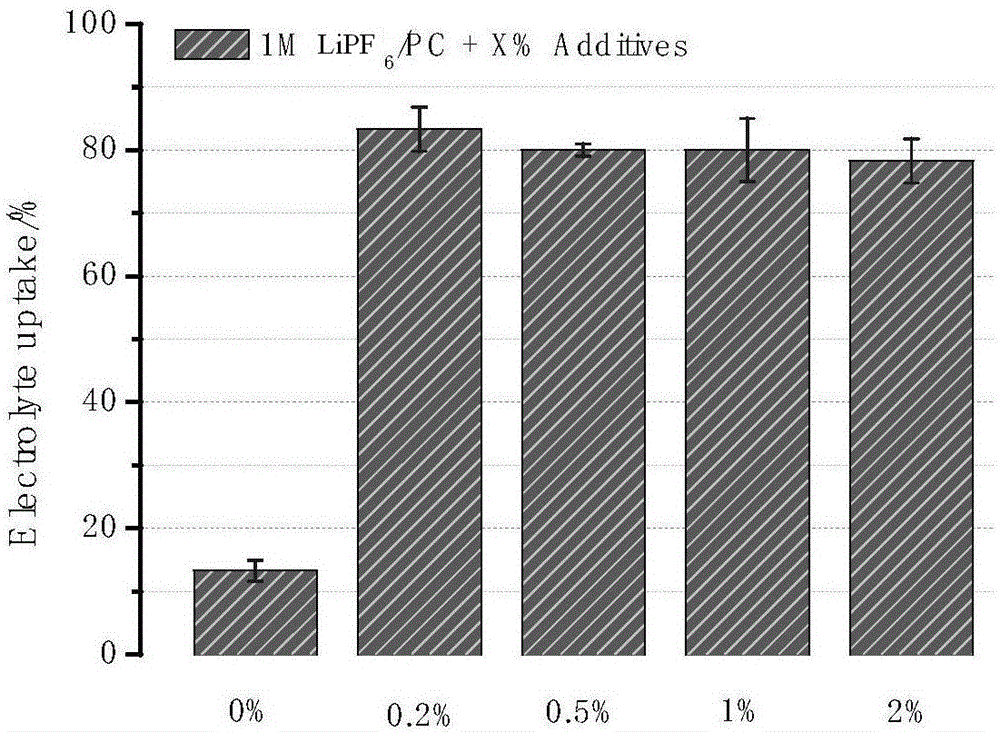

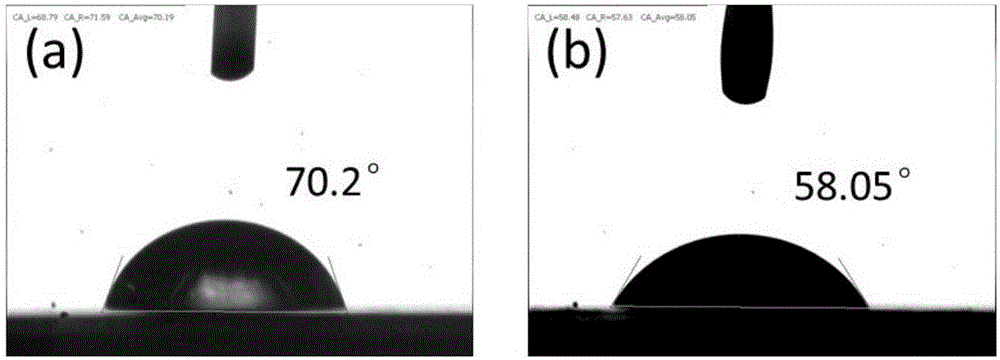

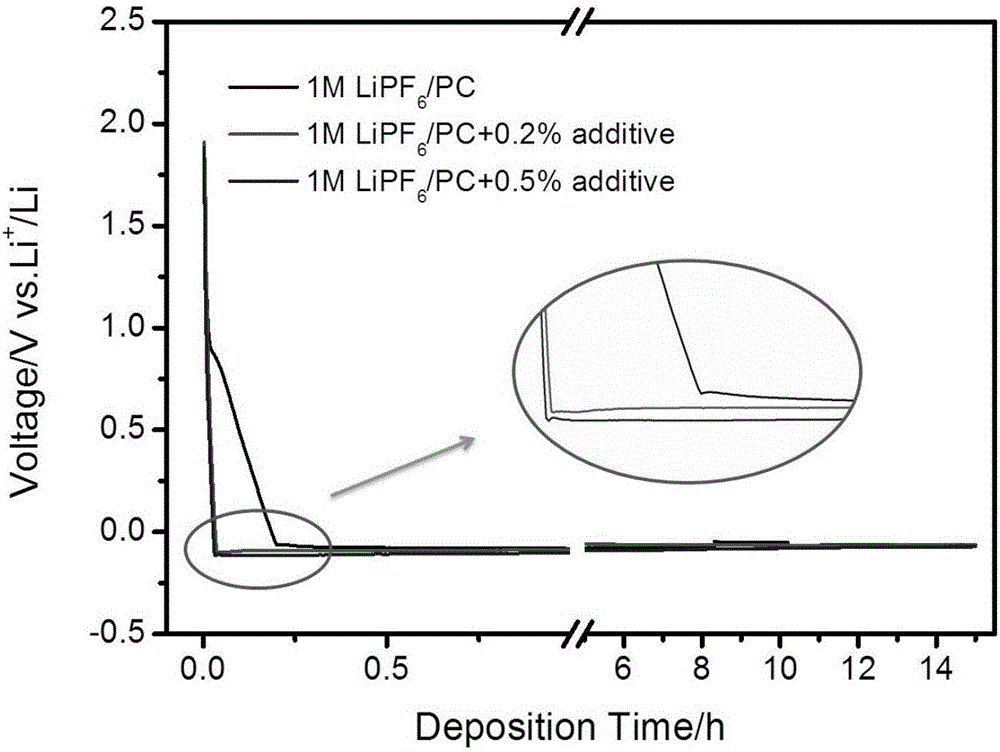

The invention discloses an additive with a dual lithium dendrite inhibition effect and an application of the additive, an electrolyte containing the additive, a battery and a preparation method of the battery. The additive is a typical non-ionic surfactant and the mass fraction of the additive in the electrolyte is 0.05%-5%. Through a simple method of adding an organic additive to the electrolyte, formation of lithium dendrites on the surface of an electrode is inhibited from two aspects as follows: (1) the wettability of the electrolyte and a membrane is improved by reducing the surface tension of the electrolyte and transmission channels of lithium ions in the membrane are increased, so that lithium ion flow is uniformly distributed on the surface of the electrode to finally achieve the target of inhibiting formation of the lithium dendrites; and (2) deposition sites of the lithium ions on the surface of the electrode are further improved through adsorption of the additive on the surface of the electrode, thereby inhibiting formation of the lithium dendrites. The safety and the cycle performance of a lithium secondary battery are greatly improved by adding the additive to the electrolyte.

Owner:HEFEI UNIV OF TECH

Method of preparing nanometer magnesium oxide using uniform precipitation-supercritical carbon dioxide drying method

InactiveCN1597520AReduced operating temperature and pressureReduce energy consumptionMagnesiaEnvironmental chemistryAqueous solution

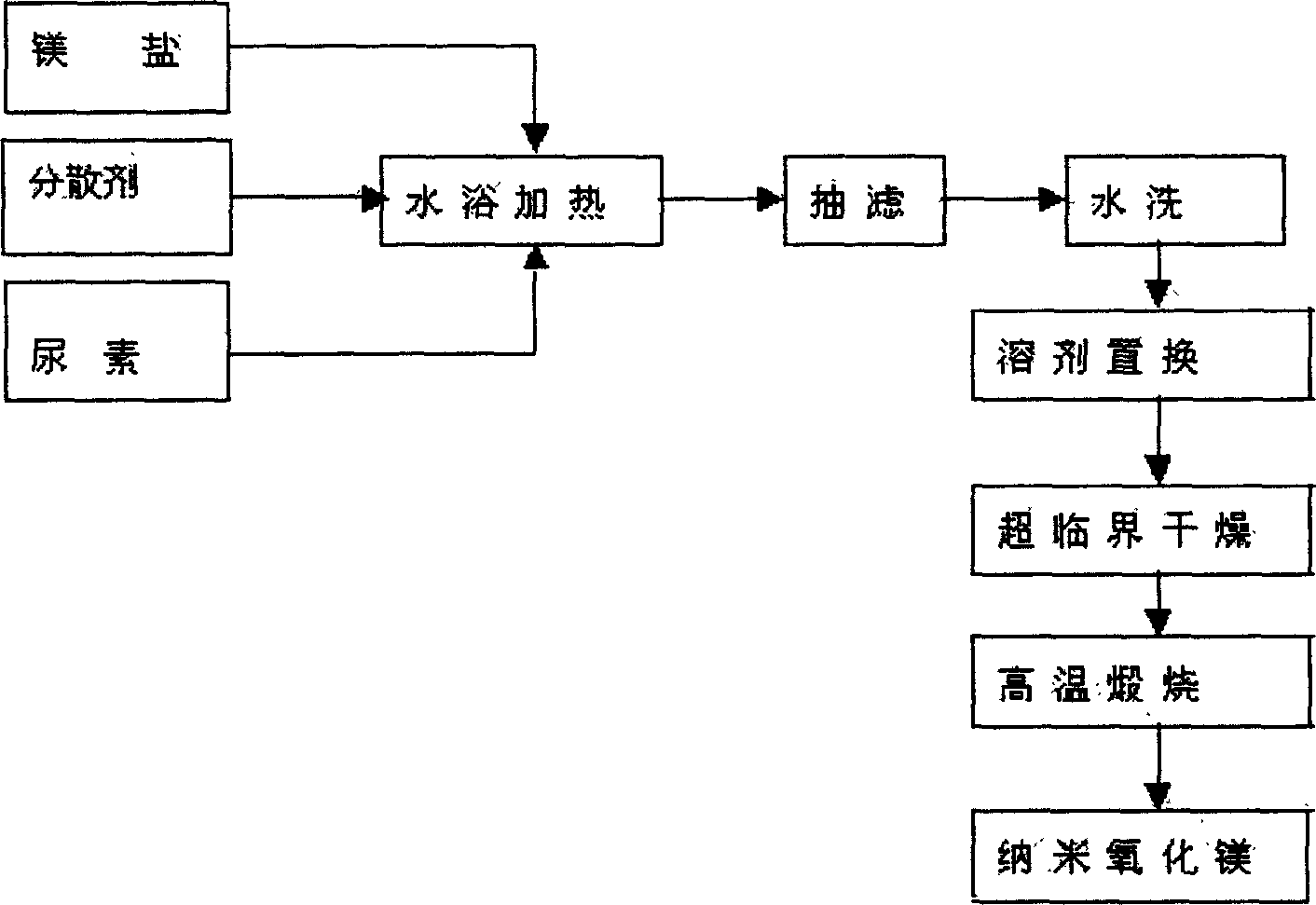

A process for preparing nano-magnesium oxide by uniform deposition-supercritical CO2 drying method includes such steps as preparing magnesium hydroxide deposit in aqueous solution by uniform deposition method, displacing water from the deposit by alcohol, removing alcohol from deposit by supercritical CO2 drying method, separating alcohol for recovering it, cyclic use of CO2, and calcining the dried magnesium hydroxide.

Owner:DALIAN UNIV OF TECH

Glue-free PVC (polyvinyl chloride) floor board and preparation method thereof

The invention relates to a glue-free PVC (poly vinyl chloride) floor board, comprising a surface wear-resistant layer, a fabric layer and a bottom layer, wherein the bottom layer comprises an upper layer, a middle layer and a lower layer, the upper layer is prepared from the following raw materials in parts by weight: 140-170 parts of PVC powder, 700-900 parts of plasticizer and 5-7 parts of stabilizer, the middle layer is prepared from the following raw materials in parts by weight: 400-600 parts of PVC powder, 300-400 parts of plasticizer, 800-1000 parts of mountain flour and 9-13 parts of stabilizer, and the lower layer is prepared from the following raw materials in parts by weight: 800-1000 parts of PVC powder, 600-750 parts of plasticizer, 200-300 parts of mountain flour and 20-30 parts of stabilizer. The glue-free PVC floor board provided by the invention has skid resistance and good elasticity, is easy to construct and has low construction cost, and no glue is used. The invention also discloses a preparation method of the glue-free PVC floor board.

Owner:HUIZHOU WEIKANG NEW BUILDING MATERIALS CO LTD

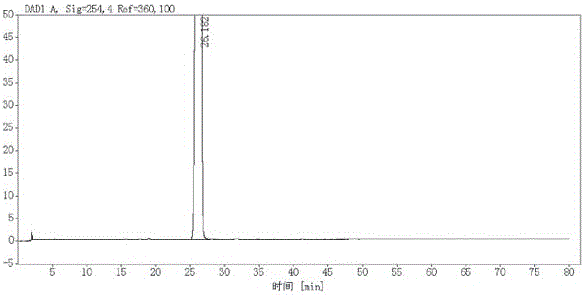

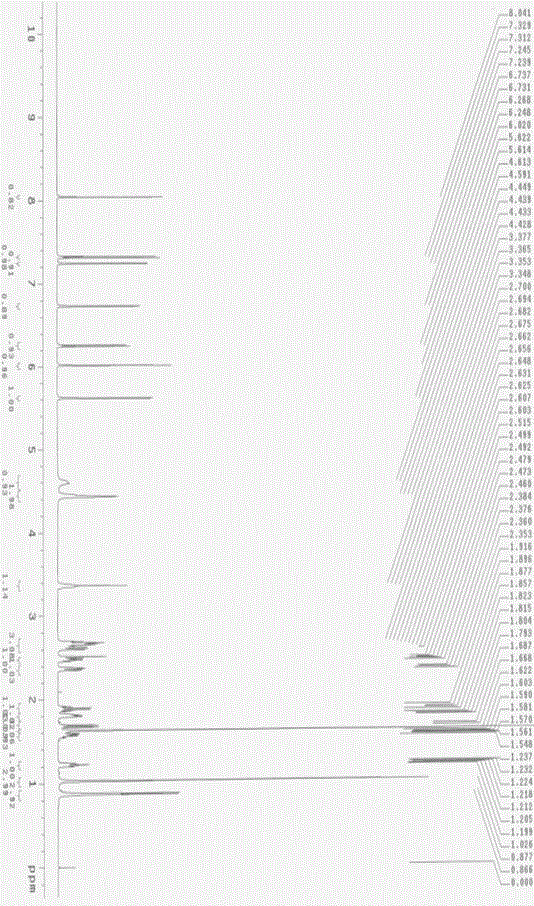

Method for synthesizing mometasone furoate or monohydrate of mometasone furoate

ActiveCN106279340AThe generation of solutionNo generationSteroidsAfter treatmentMometasone furoate monohydrate

The invention belongs to a synthesizing method for medicine, and particularly relates to a method for synthesizing mometasone furoate or a monohydrate of the mometasone furoate. The method includes the steps that 8-DM serving as a first compound is used as an initial material, and the first compound and paratoluensulfonyl chloride are subjected to a sulfonylation reaction to generate a second compound; the second compound is not subjected to after-treatment and is subjected to a chlorination reaction with RCl (R is Li, Na, K and Et3N) to generate a third compound; the third compound is not subjected to after-treatment, a part of organic alkali is replenished, and the mixture and furoyl chloride are subjected to an esterification reaction to generate a fourth compound; the fourth compound is not subjected to after-treatment, acid adjustment is carried out, a large quantity of chlorine elements existing in a reaction system are used for a ring-opening reaction, and the mometasone furoate or the mometasone-furoate monohydrate is obtained. The method is simple in technology, mild in reaction condition, high in yield, low in cost, high in quality and raw-auxiliary-material using rate, free of genetic toxicity impurity generation and suitable for industrial production.

Owner:山东锐顺药业有限公司

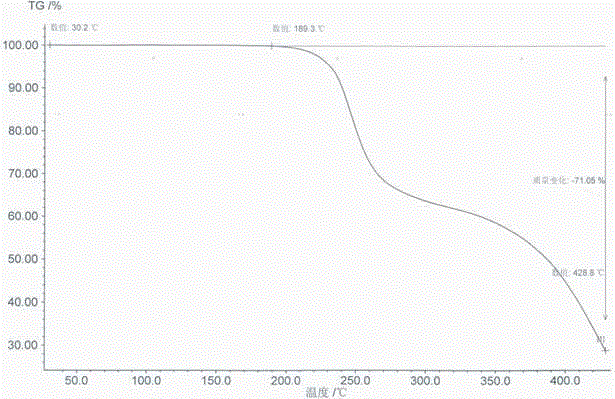

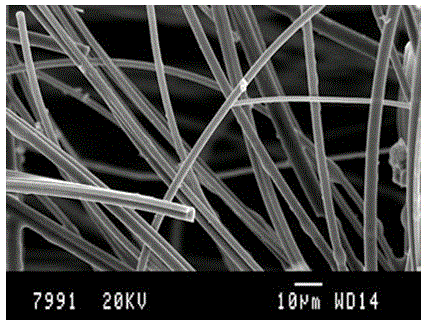

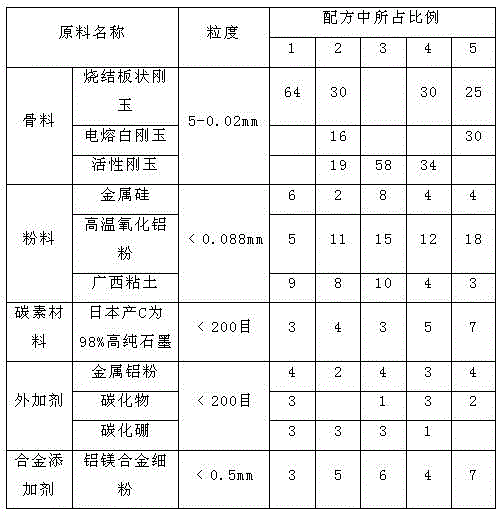

Alloy combined unfired sliding plate

The invention belongs to the technical field of steelmaking refractory materials, specifically relates to a refractory material product for controlling the flow rate of molten steel in a steelmaking process, namely a sliding plate brick, and in particular relates to an alloy combined unfired sliding plate brick. The alloy combined unfired sliding plate brick consists of 55-70% of aggregate, 20-35% of powder, 3-8% of carbon material, 2-7% of alloy additive and 4-15% of admixture. The sliding plate brick is prepared by adopting an unfiring process; the aluminum-magnesium alloy additive is added in the sliding plate brick, so that the sliding plate brick has a super strong anti-oxidation effect and the toughness of a sliding plate is enhanced; and the thermal shock resistance of the sliding plate brick is improved by introducing a nano high-purity graphite material. The produced alloy combined unfired sliding plate has a good use effect, the procedures are simple, the firing cost is saved, and the harm to the environment is reduced.

Owner:济南新峨嵋实业有限公司

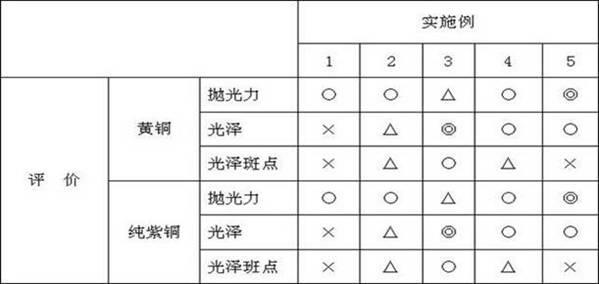

Polishing solution for processing surfaces of copper and copper alloy by replacing copper pickling process

The invention relates to a polishing solution for processing surfaces of copper and copper alloy by replacing a copper pickling process. The polishing solution consists of the following components in percentage by volume: 10 to 40 percent of hydrogen peroxide, 2 to 5 percent of organic brightening agent, 0.8 to 2.4 percent of concentrated sulfuric acid, 3 to 8 percent of hydrogen peroxide stabilizing agent and the balance of water. The polishing solution does not comprise chromic acid, nitric acid or hydrochloric acid, smoothens the surface of the copper or the copper alloy through chemical polishing, and ensures complete luster on the surface subjected to chemical polishing.

Owner:WENZHOU AOYANG METAL SURFACE TREATMENT

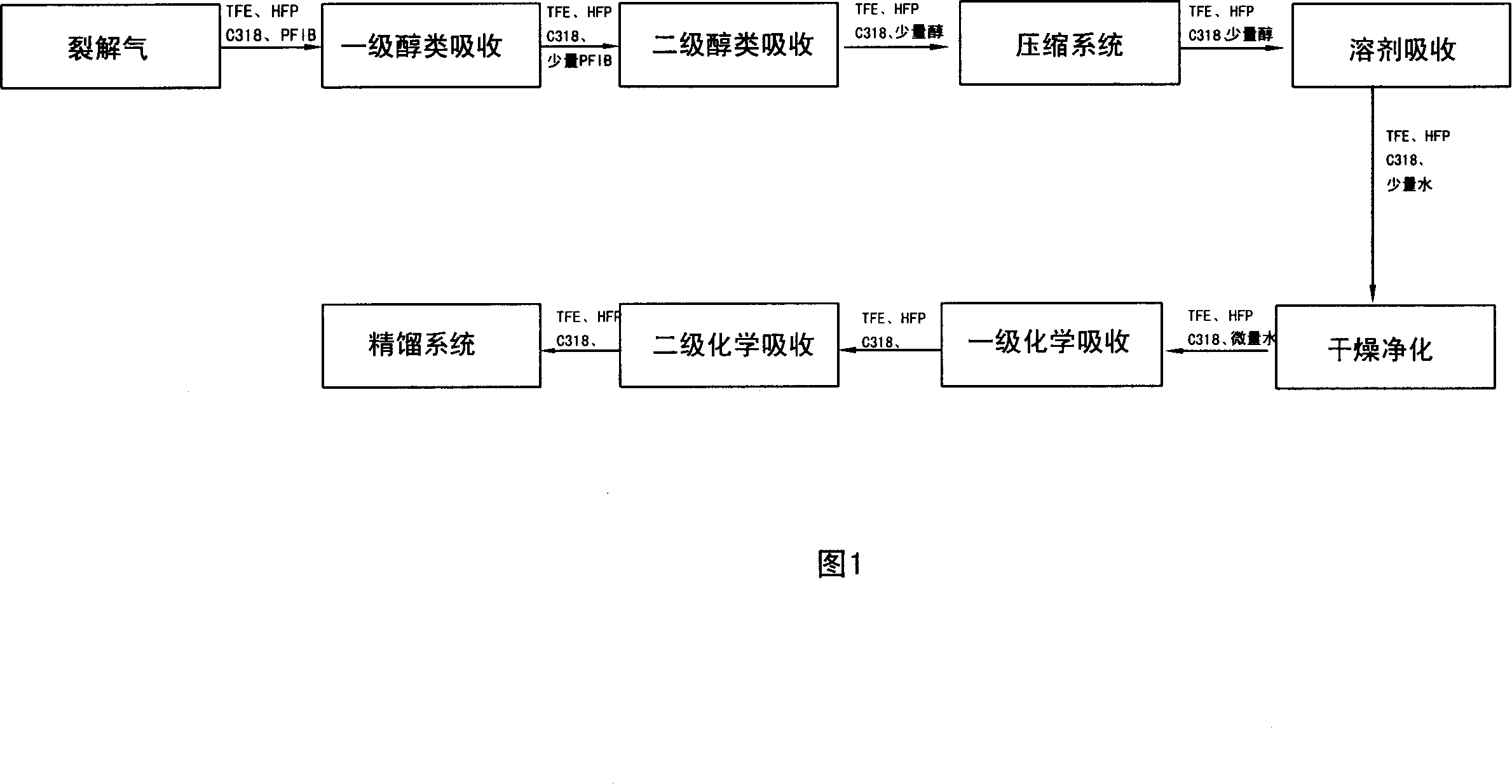

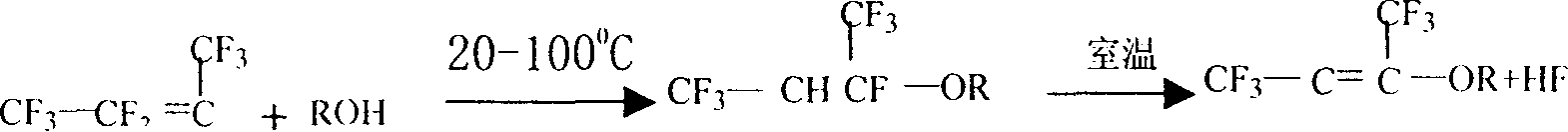

Removed method for poisonous component of cleaved product in hexafluoropropylene manufacturing technique

ActiveCN1923775AGuaranteed smooth productionEasy to separateHalogenated hydrocarbon preparationAlcoholManufacturing technology

The invention discloses a removing method of toxic component in the hexafluoropropylene manufacturing technology, which comprises the following steps: adopting cracking gas in the manufacturing course to enter into distilling system before adsorbed by alcohol material to remove toxic component; proceeding solvent adsorption; purifying; proceeding chemical adsorption; adopting alcohol material as adsorbant; detoxifying octafluoroisobutylene in the cracking gas.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

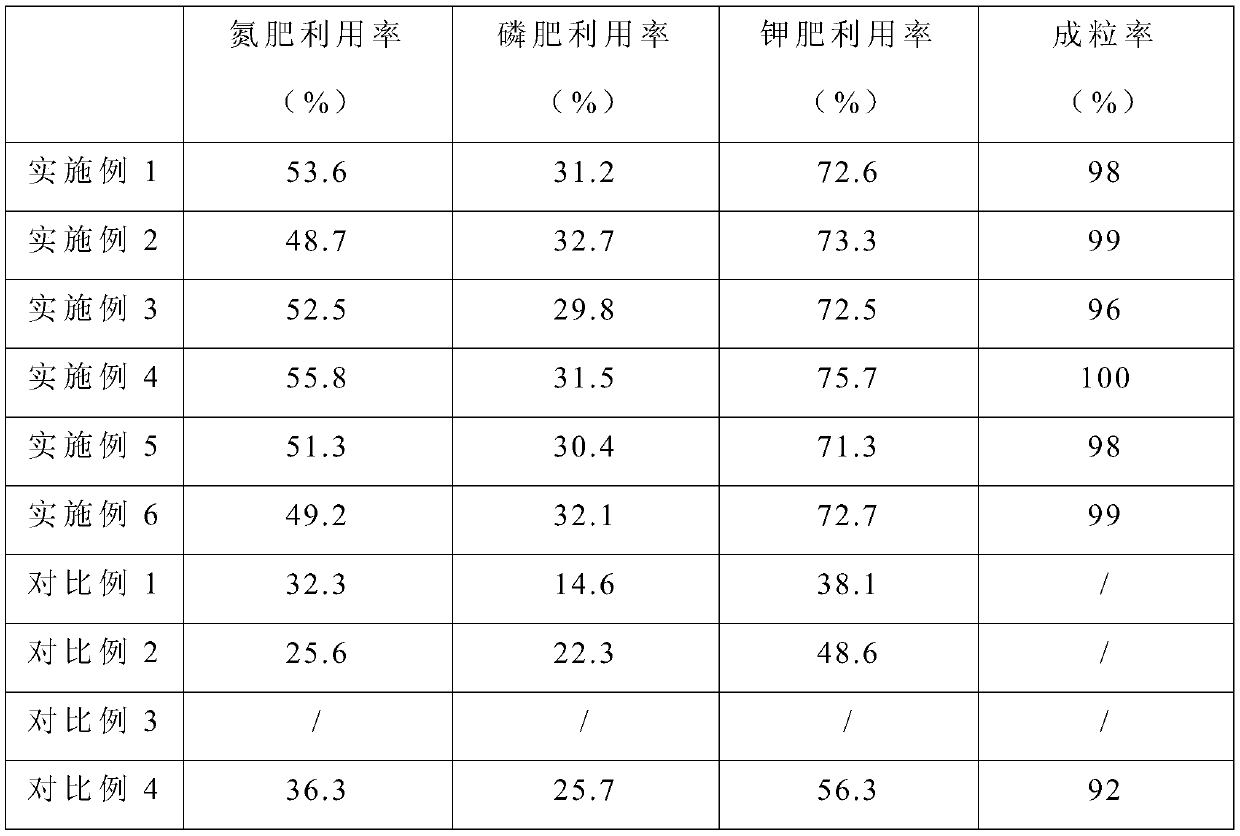

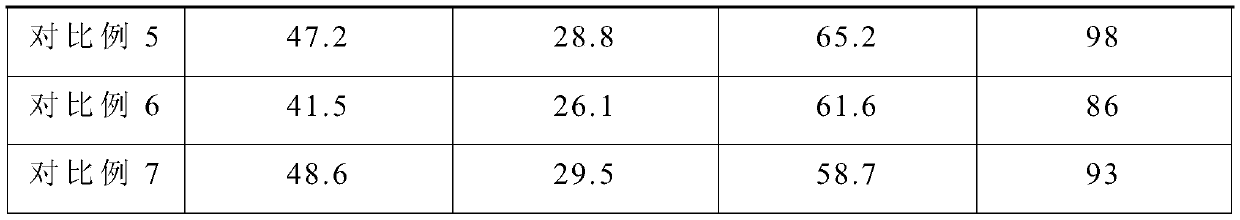

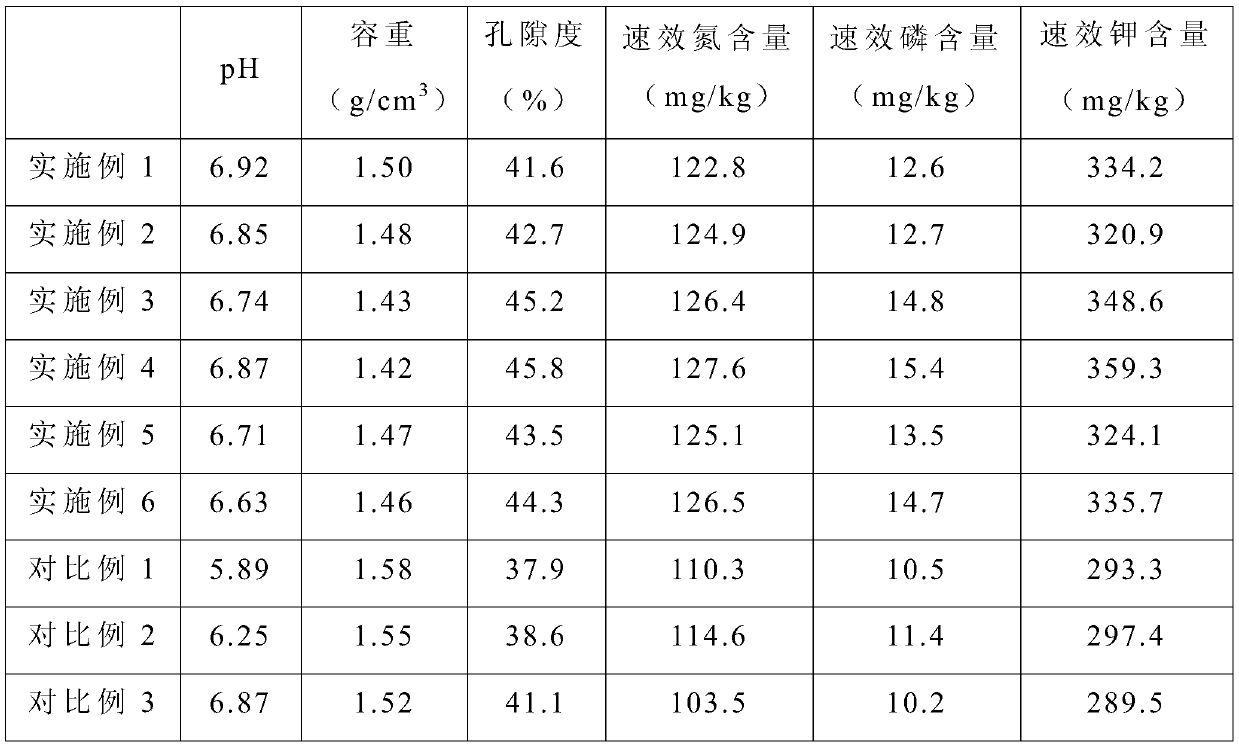

Tobacco special-purpose charcoal-based compound fertilizer, and preparation method and application method thereof

InactiveCN109879693AReduce environmental pollutionEasy to drawBio-organic fraction processingFertilising methodsChemistryNitrogen fertilizer

The invention belongs to the technical field of fertilizer, and more specifically relates to a tobacco special-purpose charcoal-based compound fertilizer, and a preparation method and an application method thereof. The tobacco special-purpose charcoal-based compound fertilizer comprises, by weight, tobacco straw, waste tobacco, pig manure, earthworm manure, vegetable waste, domestic garbage, nitrogen fertilizer, phosphate fertilizer, potassium fertilizer, trace element liquid fertilizer, a compound microbial agent, and an adhesive, and is prepared through a plurality of technologies. The tobacco special-purpose charcoal-based compound fertilizer is high in granulation rate, is capable of obviously improving fertilizer utilization rate, and is capable of improving soil acidifying and hardening after being applied to tobacco field, and increasing soil available nutrient content; the quality of the harvested tobacco leaves is improved obviously, the proportion of middle and upper-grade tobacco leaves is increased, the yield per mu and the output value per mu are obviously increased; and the tobacco special-purpose charcoal-based compound fertilizer is taken as a base fertilizer, onlyone time of application is capable of satisfying all the requirements of tobacco on nutrients in the tobacco growth period, reducing the using amount and the application frequency of traditional fertilizers; using is convenient; and labor is saved.

Owner:GUIZHOU TOBACCO CORP QIANXINAN CORP

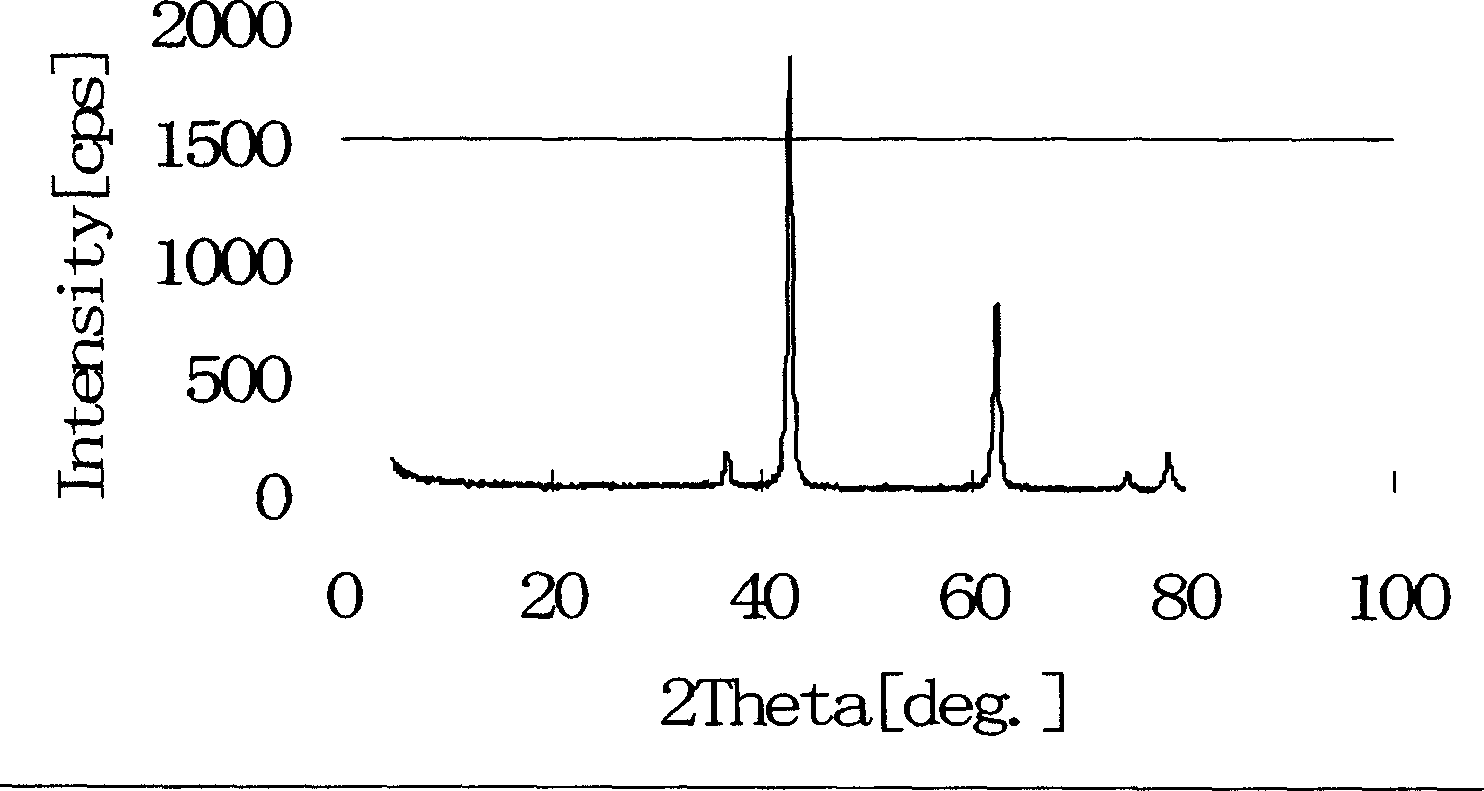

Preparation method of machine tool slider by powder metallurgy

ActiveCN103252497AEnhance the effect of mixing and pressingHigh bulk densityPolyethylene vinyl acetateCerium

The invention discloses a preparation method of a machine tool slider by powder metallurgy. The method includes that the machine tool slider is made of, by weight percentage, 0.6-0.8% of graphite, 0.2-0.4% of silicon carbide powder, 0.4-0.6% of manganese, 0.2-0.4% of nickle, 0.2-0.4% of cerium, 0.2-0.4% of titanium, 0.4-0.6% of aluminum, 1-2% of zinc, 5-8% of copper, 1-2% of performance additive and the rest iron. By the added performance additive, superfine powder is provided in mixed raw materials and can fill gaps among large particles, so that apparent density of a mixture is improved; the superfine powder is mainly composed of nanoscale iron powder and calcium stearate, and the novel performance additive is obtained through auxiliaries like silane coupling agent, so that various physical characteristics like abrasive resistance of the machine tool slider is further improved; and polyethylene vinyl acetate and liquid paraffin serving as lubricant are added into the performance additive, so that effects, in mixing and pressing, of the performance additive are enhanced, compacting strength of a powder metallurgy structural member is substantially improved under same pressing pressure, particle combining forms and pore shapes of the raw materials are changed, and generation of cracks is avoided fundamentally.

Owner:HAIAN YINGQIU POWDER METALLURGY CO LTD

Preparation method for powder metallurgy for automotive brake valve block

InactiveCN103252492AEnhance the effect of mixing and pressingHigh bulk densityTurbinesOther manufacturing equipments/toolsPolyethylene vinyl acetateManganese

The invention discloses a preparation method for powder metallurgy for an automotive brake valve block. The preparation method includes that the automotive brake valve slice is made from raw materials, by weight percentage, 0.2-0.4% of nickel, 0.2-0.4% of cerium, 0.2-0.4% of chromium, 0.4-0.6% of emery powder, 0.6-0.8% of zinc, 0.8-1% of manganese, 0.8-1% of graphite powder, 1-2% of copper, 1-2% of performance additives and the balance ferrum. By adding the performance additives, superfine powder in mixed materials can be filled in gaps between large particles, so that apparent density of the mixed materials is improved; since main ingredients of the superfine powder are nano ferrum powder and calcium stearate and novel performance additives obtained from additives of silane coupling agent and the like further improves various physical properties of wear resistance and the like of products; and polyethylene vinyl acetate and liquid paraffin are added into the performance additives as lubricant, so that efficiency of the performance additives in mixed suppression is enhanced, pressing intensity of powder metallurgical parts under the same pressing pressure is greatly improved, particle combination forms and pore configurations of the raw materials are changed, and the problem caused by cracks is totally solved.

Owner:XUZHOU DALT MECHANICAL EQUIP MFG CO LTD

Method for producing bone essence, bone protein, bone meal, meat bone meal, meat meal and refined oil by animal fresh bone

InactiveCN102342529AShorten production timeImprove economic efficiencyAnimal feeding stuffEdible oils/fatsActivated carbonActive carbon

A method for producing bone essence, bone protein, bone meal, meat bone meal, meat meal and refined oil by animal fresh bones. The invention solves the problems of environment pollution, low extraction yield, and addition of preservatives and mould inhibitors in the production of bone essence, bone protein, bone meal, meat bone meal, meat meal and refined oil. The method comprises the following steps: boiling fresh bones and water at a high pressure, separately storing bone oil, separately storing bone residue wastes, adding an enzyme, stirring, allowing the mixture to stand; performing high-pressure boiling after standing, adding a compound enzyme, stirring, allowing the mixture to stand, and freeze-drying the mixture into powder so as to obtain bone essence and bone protein; decoloring the bone oil with active carbon to obtain the refined oil, recovering wastes after decoloration by active carbon; sterilizing the bone residue wastes and the wastes after decoloration by active carbon, performing pulverization to obtain bone meal, meat bone meal, meat meal. The invention does not need the addition of additives of preservatives and mould inhibitors; the product can be stored for above three years at normal temperature; the invention prevents the problem of environment pollution; and the extraction yield of bone essence, bone protein, and refined oil is increased by 40% when compared with original yield.

Owner:施建春 +1

Method for concrete impermeability test adopting rubber sleeve seal

InactiveCN104977235AThe generation of solutionEasy to operatePermeability/surface area analysisWater leakagePetroleum engineering

Disclosed is a concrete impermeability test adopting rubber sleeve seal, which comprises an impervious instrument, impervious test pieces, rubber sleeves, and test piece sleeves. Each impervious test piece is sleeved by a sealing sleeve prepared by the rubber sleeve; the impervious test pieces sleeved by the rubber sleeves are pressed into the test piece sleeves; the test piece sleeves are in fastening connection with an operating table on the impervious instrument with nuts to protect the bottoms of the test pieces from water leakage to affect a test effect during a test process. The rubber sleeves are taken as sealing materials, and heating of test pieces and test moulds aren't needed. The rubber sleeves are simple and convenient to operate and high in work efficiency, and can be used repeatedly. The method is saved in cost, can protect the environment, and has a wide popularization value.

Owner:中震(北京)工程检测股份有限公司

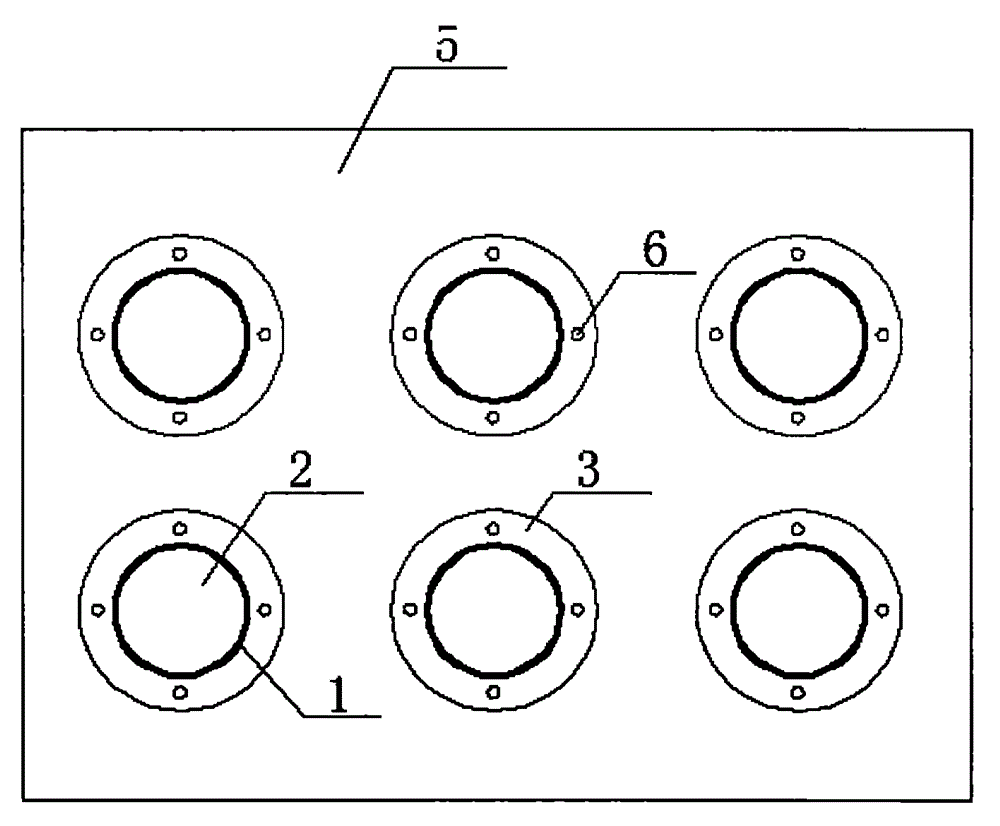

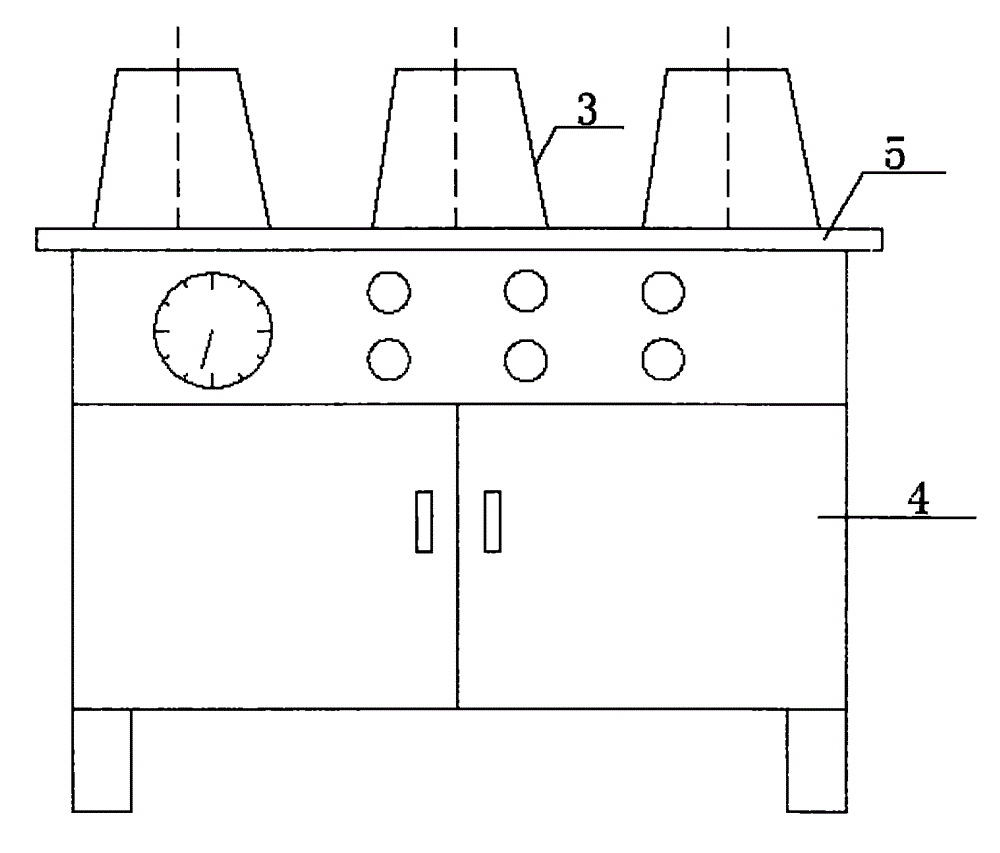

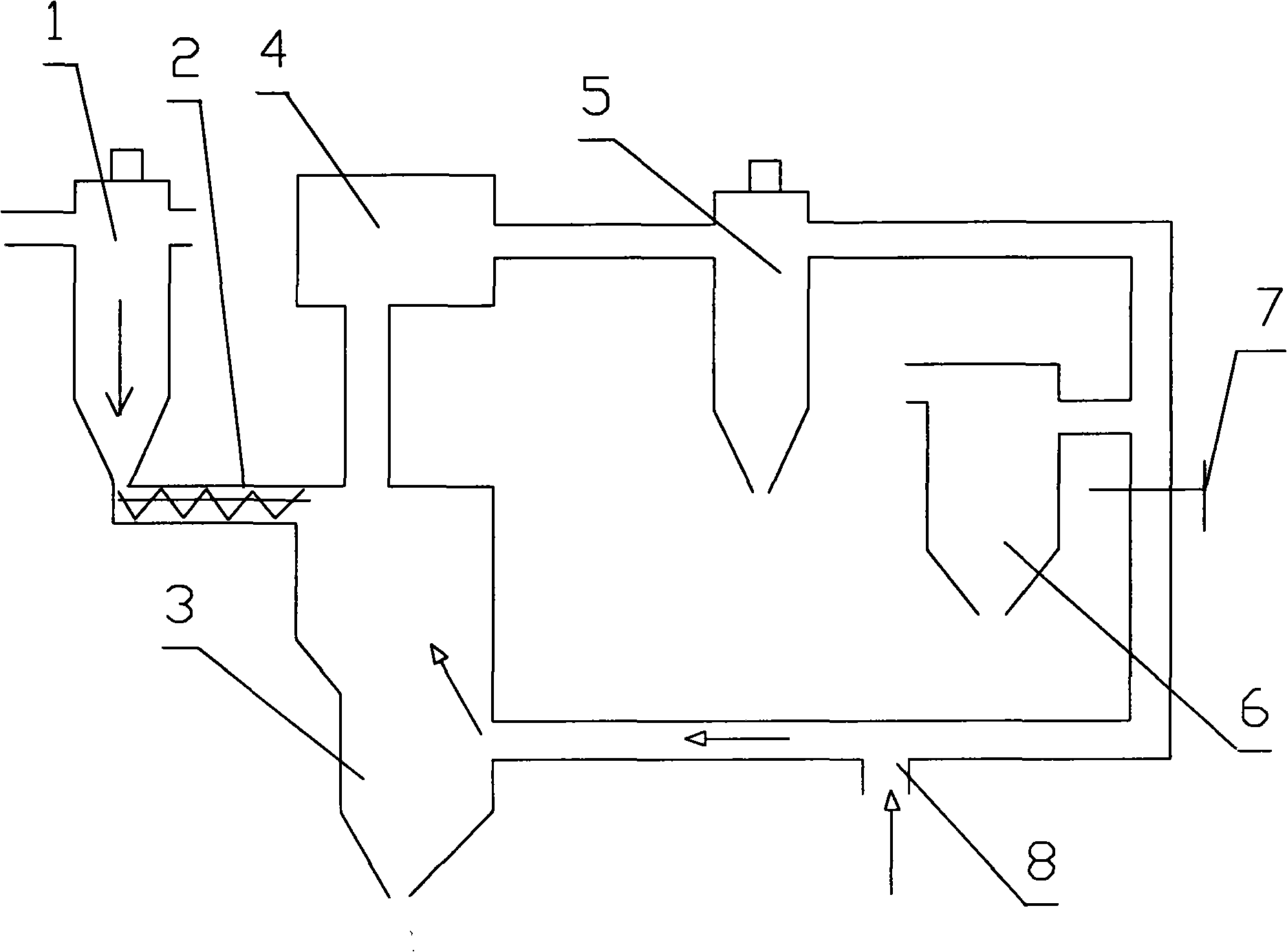

Pure pine beaverboard preparation

InactiveCN101254607AEasy to shapeReduce dustGas current separationWood working apparatusFiberParaffin wax

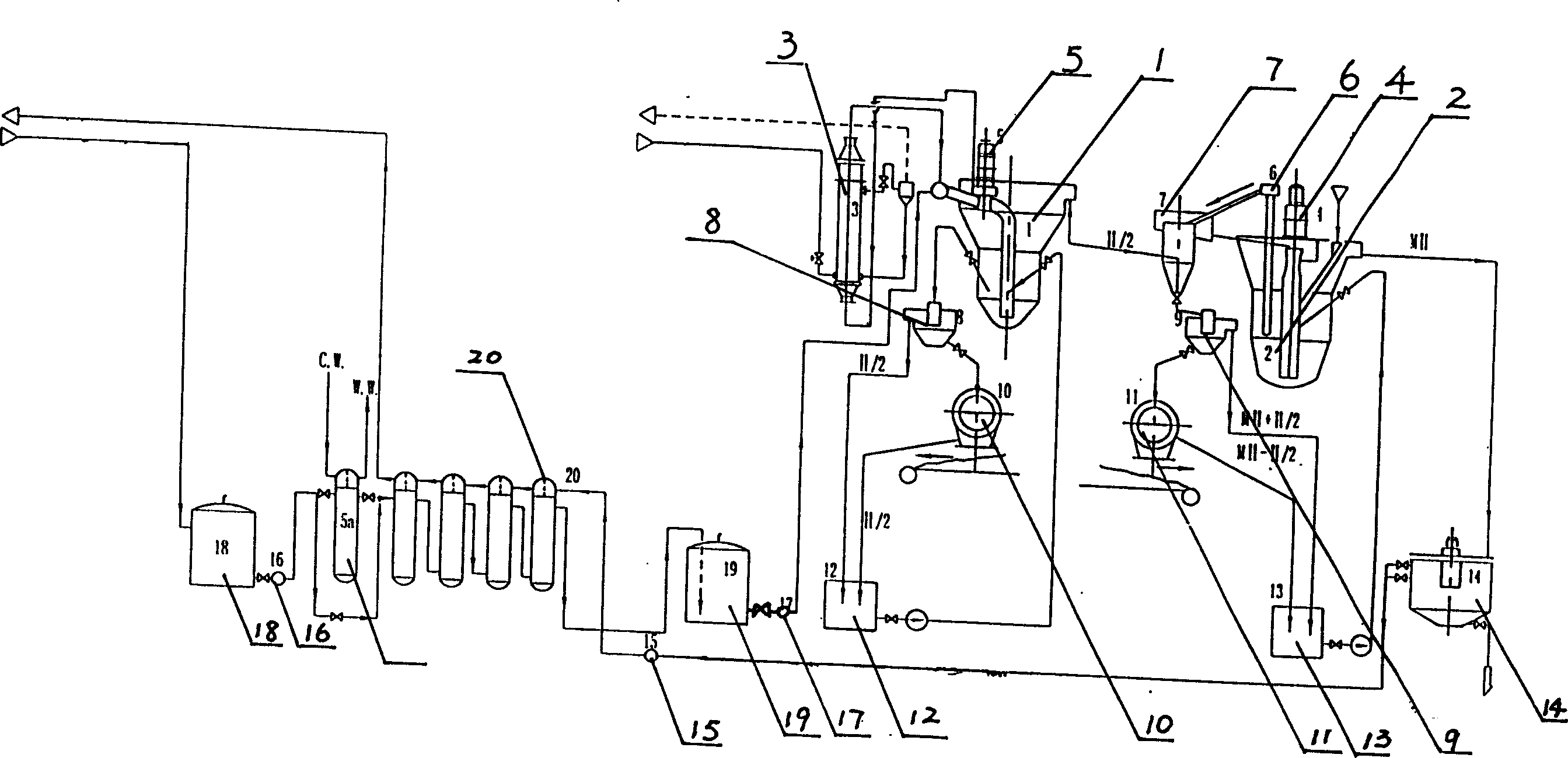

The manufacture method of pure pine fiber board comprises the following steps: (A) pre-steaming; (B) steaming; (C) hot-grinding; (D) drying; (E) applying adhesive, paraffin wax and white paste; (F) winnowing; (G) cold-pressing; and (H) hot-pressing and cutting to obtain final product. A wind feeding device comprises a cyclone separator (1), a feed pipe (2), a winnower (3), an exhauster (4), a cyclone separator (5) and wind pipes, a dust collector (6) and a valve (7), wherein the duct collector (6) is arranged on the wind pipe between the cyclone separator (5) and the winnower (3); the valve (7) is arranged on the wind pipe between the dust collector (6) and a winnower (3); and a cold wind inlet (8) is formed on the wind pipe between the valve (7) and the winnower (3). The pure pine fiber board manufactured by the method has the advantages of greatly improved strength and waterproof performance, pleasant smell of rosin and improved appearance quality. The wind feeding device is reconstructed to remarkably improve the product quality.

Owner:湖北宝源木业有限公司

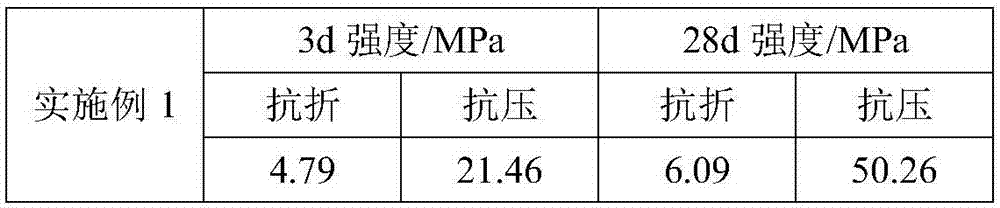

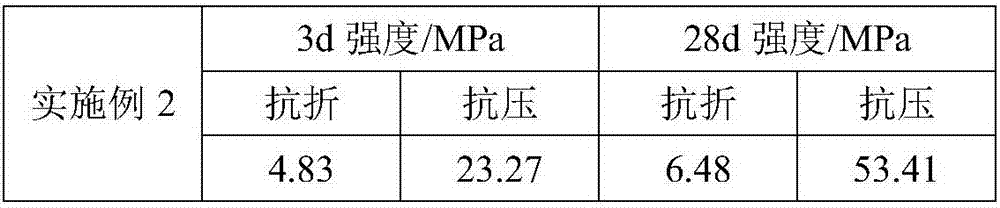

Method for sintering belite-calcium sulphoaluminate-calcium sulphosilicate cement at low temperature and product thereof

ActiveCN106904848ALow firing temperatureImprove performanceClinker productionSlurryToxic industrial waste

The invention discloses a method for sintering belite-calcium sulphoaluminate-calcium sulphosilicate cement at low temperature. The method comprises the following steps: a) mixing industrial waste residue and industrial gypsum, adding water according to water cement ratio of 0.3-0.41 and mixing the materials, grinding a mixture for 15-60 min and dumping the slurry in a die, demoulding after moulding to obtain a sample; b) performing constant temperature maintenance on the above sample at the temperature of 60-150 DEG C for 3-9 hours; preferably at the temperature of 80-130 DEG C for 3-4 hours; and c) calcining the material at the temperature of 750-1150 DEG C for 60-120 min; taking the calcined sample from a high temperature furnace, rapidly cooling the material; and grinding the material to obtain the product. According to the invention, limestone is not used, a lot of carbon dioxide is not generated, environment pressure is increased, on the other hand, calcining temperature is low, and the energy consumption is low. The method has the advantages of low carbon and environment protection.

Owner:YANCHENG INST OF TECH

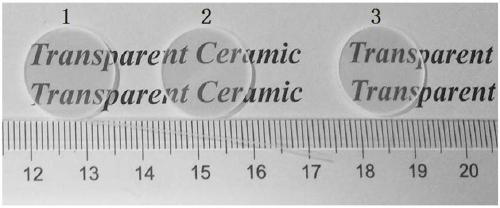

Warm-white high-color-rendering-index fluorescent ceramic for high-power LED/LD illumination, as well as preparation method and application thereof

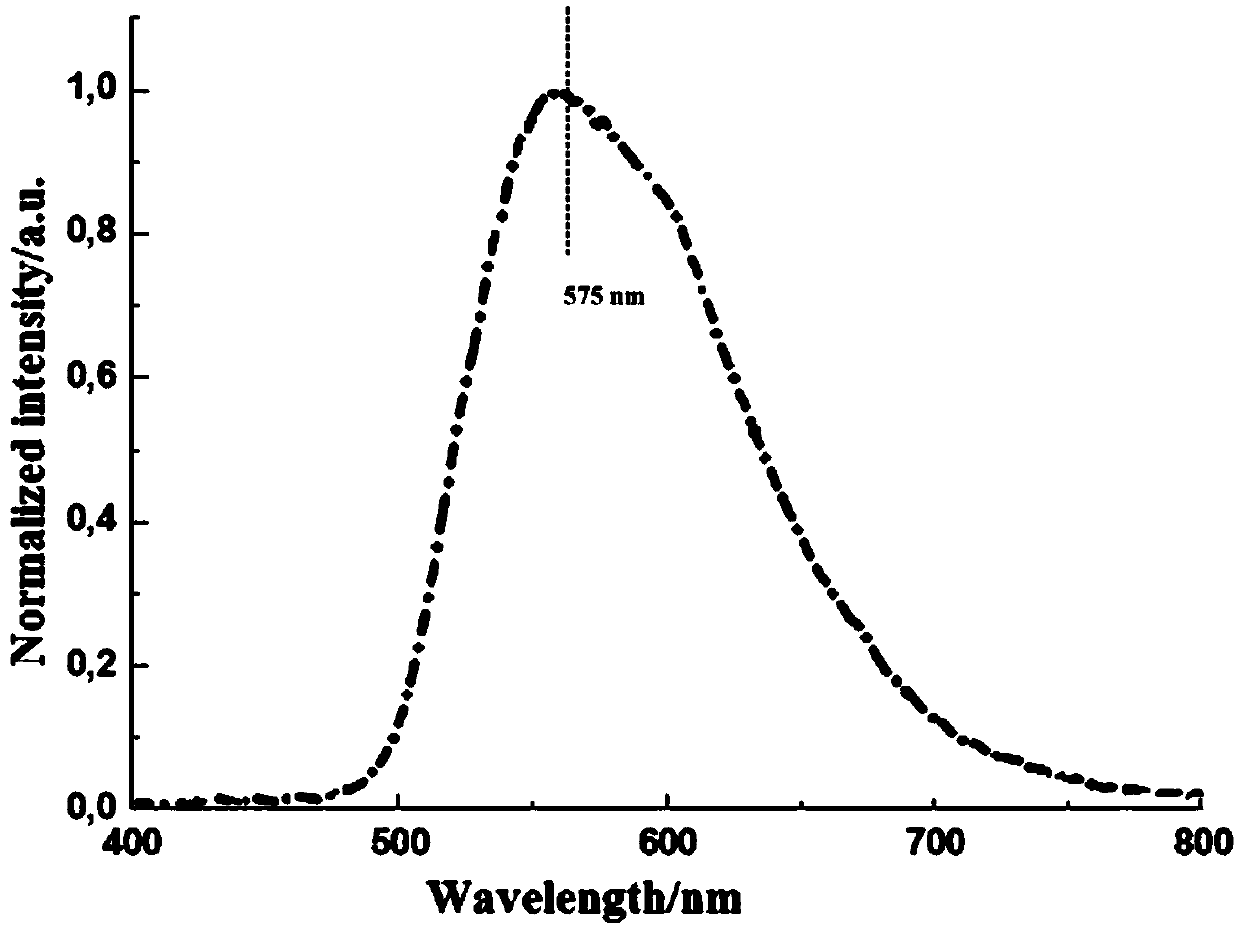

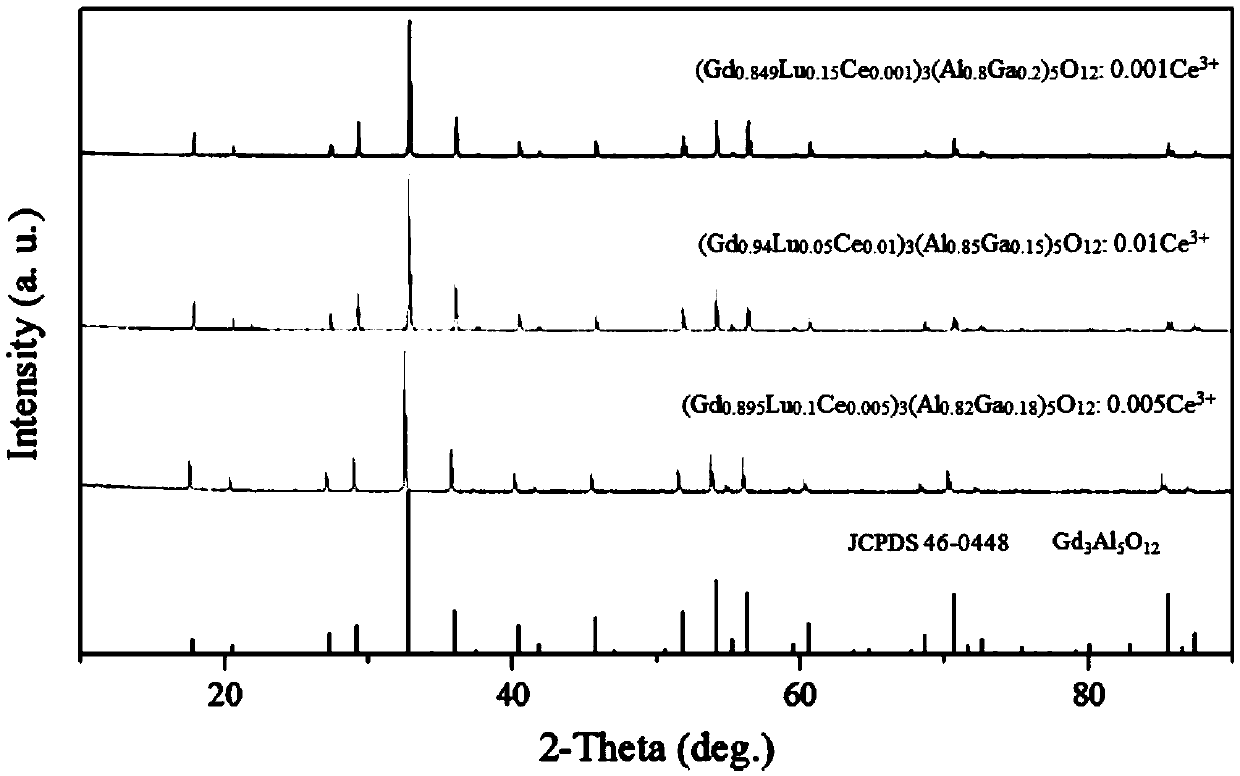

ActiveCN109592978AStable structureHigh strengthEnergy efficient lightingLuminescent compositionsColor rendering indexFluorescence

The invention discloses a warm-white high-color-rendering-index fluorescent ceramic for high-power LED / LD illumination, as well as a preparation method and application thereof. The fluorescent ceramichas a chemical formula of (Gd(1-x-z)LuxCez)3(Al(1-y)Gay)5O12:zCe<3+>, wherein x is the molar percentage of crystal structure stable ion Lu<3+> doped Gd<3+>, y is the molar percentage of crystal structure stable ion Ga<3+> doped Al<3+>, z is the molar percentage of Ce<3+> doped Gd<3+>, x is more than or equal to 0.05 and less than or equal to 0.15, y is more than or equal to 0.15 and less than orequal to 0.2, and z is more than or equal to 0.001 and less than or equal to 0.01; and a ceramic biscuit is molded and sintered by adopting tape casting and high-temperature solid phase reaction sintering. The transparent fluorescent ceramic material has an emission spectrum main peak of 575-580nm and half-width of 140-145nm, and realizes warm-white emission under excitation of high-power LED (350-500mA) or LD (4-10W), and has a color temperature of 2800-3000K and a color rendering index of 80-84; and the preparation process is simple, and the process is controllable.

Owner:XUZHOU NORMAL UNIVERSITY

Method for recycling organic tin in sucralose production

ActiveCN105111246AThe generation of solutionImprove the on-site environmentEsterified saccharide compoundsSugar derivativesRecovery methodSucrose

The invention relates to a method for recycling organic tin in sucralose production. The method includes sucralose esterification reaction, dibutyltin oxide serves as a catalyst to take participate in the reaction to generate a sucrose-6-ester midbody, after a midbody solution is extracted through cyclohexane, organic tin acetic ester is dissolved in an extractant cyclohexane phase, a cyclohexane phase is extracted out, and cyclohexane is obtained through evaporation by means of a distillation still. The method is characterized by including the following steps that a, boiled cooling water is cooled to 50 DEG C, then pure water is added for stirring and washing, and stirring is carried out for one hour; b, bottom water is separated out, residues in the still are recycled organic tin acetic ester, and the residues are returned to an esterification reactor to take participate in the esterification reaction and be used repeatedly. The method has the advantages that the organic tin acetic ester is not degreased or dried and can be directly recycled and used repeatedly, so that zero emission is achieved, production cost is reduced, waste water generated in the organic tin recycling process is eliminated to the largest extent, production efficiency is greatly improved, and economic benefits are remarkable.

Owner:ANHUI JINGHE IND

Method for preparing N-(9-fluorenylmethoxy carbony)-O-tertiary butyl-L-tyrosine

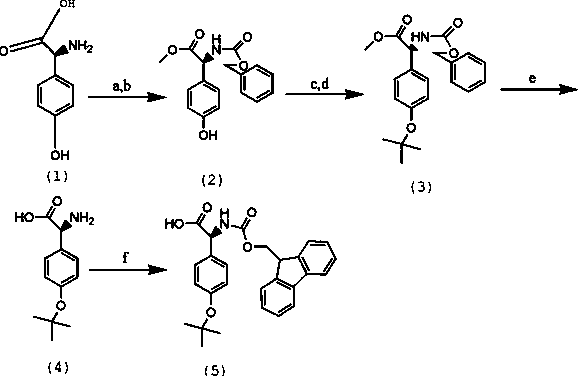

InactiveCN103833593AAvoid generatingLow priceCarbamic acid derivatives preparationOrganic compound preparationHydrogenEnantiomer

The invention relates to a method for preparing N-(9-fluorenylmethoxy carbony)-O-tertiary butyl-L-tyrosine. The problem that an enantiomer is easily generated is solved. The method comprises the following synthetic steps: (1) dissolving L-Tyr into a methanol solution, adding SOCl2 and then carrying out reflux reaction, so as to obtain Tyr-OMe.HCl; (2) dissolving the Tyr-OMe.HCl into a water solution, adding AcOEt and Na2CO3 and then reacting with Z-Cl, and controlling the pH of the system at 7-10, so as to obtain Z-L-Tyr-OMe; (3) dissolving the Z-L-Tyr-OMe into a CH2Cl2 solution, adding H2SO4 and isobutene, reacting at normal temperature for 1-10 days, so as to obtain Z-L-Tyr(tBu)-OMe; (4) adding the NaOH solution to the Z-L-Tyr(tBu)-OMe to react, so as to obtain Z-L-Tyr(tBu); (5) dissolving the Z-L-Tyr(tBu) into methanol, adding Pd / C, and leading in hydrogen to react, so as to obtain L-Tyr(tBu); (6) dissolving Z-L-Tyr(tBu) into the water solution, adding the Na2CO3 and THF and then reacting with Fmoc-osu, and controlling the pH of the system at 8-10, so as to obtain Fmoc-Tyr(tBu). By adopting the method, generation of the enantiomer is avoided, and the citric acid is taken as an acidifier, so that the product is more stable, and the reaction processes do not relate to high-temperature and high-pressure reaction, and the method is applicable to large-scale production.

Owner:四川什邡市三高生化实业有限公司

Wujingxiang moxibustion and preparation method thereof

InactiveCN101455734AThe generation of solutionExempt from chokingDevices for heating/cooling reflex pointsMammal material medical ingredientsRadix AconitiWarm water

The invention relates to a fragrant moxibustion with tungsten colour and a preparation method thereof. Firstly, putting Chinese mugwort leaves in a container at 150-200 DEG C, covering the container to isolate oxygen until the Chinese mugwort leaves emit smoke, exhausting the smoke to obtain Chinese mugwort leaf ash, crushing the ash into powder; mixing food gums with warm water to make liquid gum, cooling the liquid gum, adding muskiness to obtain muskiness gum; adding the Chinese mugwort leaves carbon powder, powdered radix aconiti, powdered dahurian angelica, powdered common fennel, powdered cinnamon and powdered radix clematidis into the muskiness gum, uniformly stirring, putting into a mould to mould by stamping, taking out, putting at a shady place to dry, thus obtaining the fragrant moxibustion with tungsten colour. Because the Chinese mugwort leaves are made into Chinese mugwort leaf carbons with smoke exhausted and then made into the fragrant moxibustion with tungsten colour with other Chinese herbal medicines, the fragrant moxibustion with tungsten colour has no smoke after being ignited. The problem that acceptors and operators are choked by smoke generated when the moxibustion is used is solved, and health care and curative effect are improved.

Owner:郭宝玉

Plush roller brush manufacture process

InactiveCN1962241AThe generation of solutionSolve the problem of producing toxic gasLiquid surface applicatorsBristleAdhesiveEngineering

The invention relates to a method for producing plush roller brush, wherein said method comprises heating PP corn tube to fuse its outer surface, coiling the plush on the corn tube. The invention directly heats PP tube without adhesive, to fuse the outer layer with plush naturally, which will be fixed in cooled condition. The invention can avoid harmful gas and the solvent problem that drops plush. And the product has long service life and low cost.

Owner:扬州光和毛刷有限公司

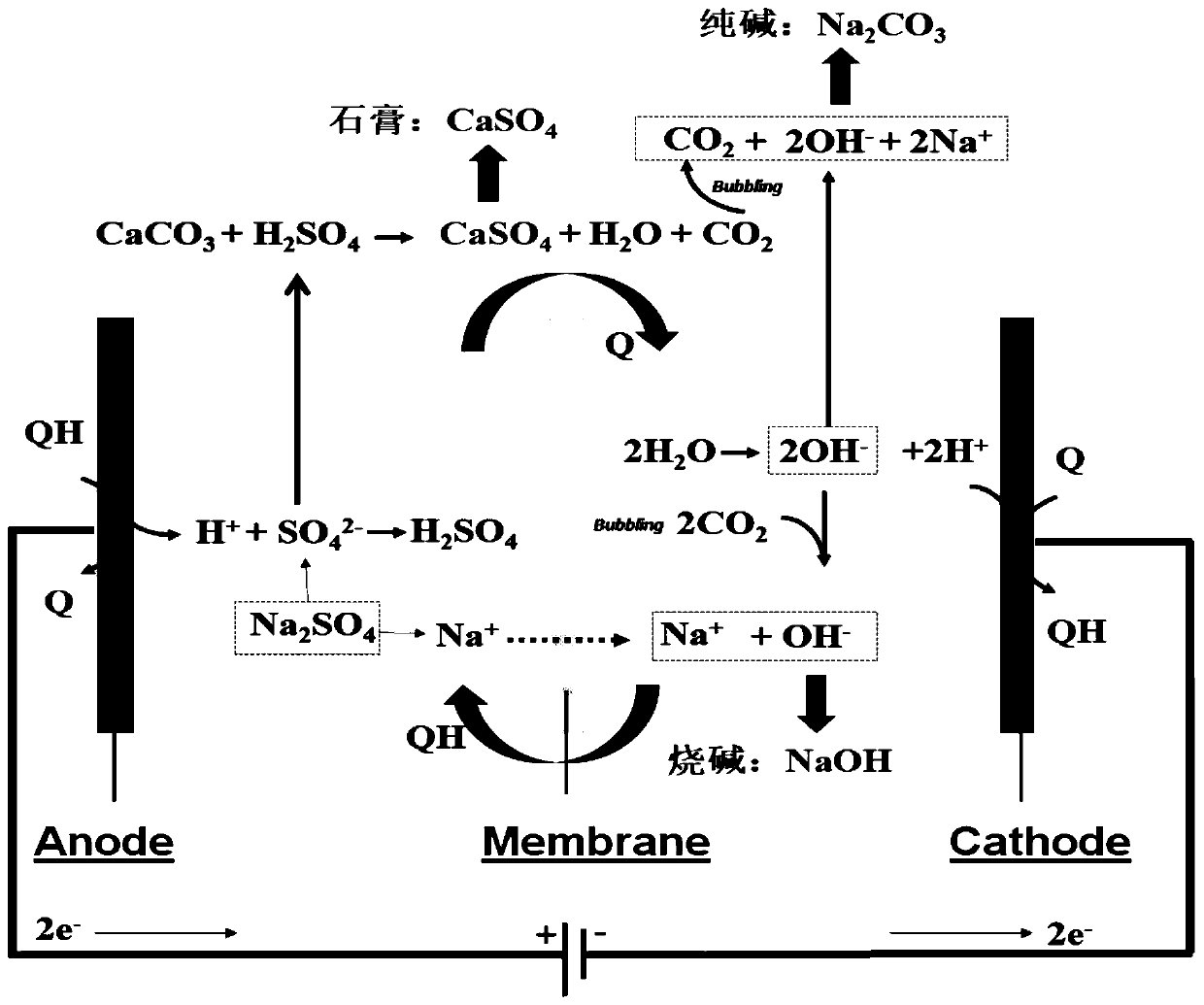

Method for preparing two alkalis and co-producing high-purity gypsum from mirabilite and limestone through PCET reaction

ActiveCN110656343AReduce preparation energy consumptionReduce manufacturing costCalcium/strontium/barium sulfatesElectrodesPtru catalystDissolution reaction

The invention provides a method for preparing two alkalis and co-producing high-purity gypsum from mirabilite and limestone through a PCET reaction, belonging to the technical field of low-energy-consumption production of two alkalis. According to the invention, a cation exchange membrane is putted into an electrolytic cell; a weakly acidic sodium salt solution and a compound QH are added into ananode region to serve as an anode electrocatalyst; sodium carbonate or sodium hydroxide is added into a cathode region, and a compound Q is added as a cathode electrocatalyst; a direct-current power supply is applied between a negative electrode and a positive electrode; in the process of electrolysis, QH is oxidized into Q, H<+> is released, and Na<+> in an anolyte permeates the cation exchange membrane, reaches the cathode region and is combined with OH<-> in a catholyte to generate NaOH, or NaOH further absorbs CO2 to realize conversion into Na2CO3; and an anolyte containing a large amountof H<+> is generated through electrolysis and undergoes a dissolution reaction with limestone, H<+> is consumed to generate Ca<2+>, and SO4<2-> and Ca<2+> are combined to generate a high-purity CaSO4precipitate. A compound with PCET reactivity is used as an electrocatalyst, Q is the oxidation state of the compound, QH is the reduction state of the compound, mirabilite and limestone are used as raw materials, and preparation of sodium carbonate, caustic soda and gypsum is realized.

Owner:王昱飞

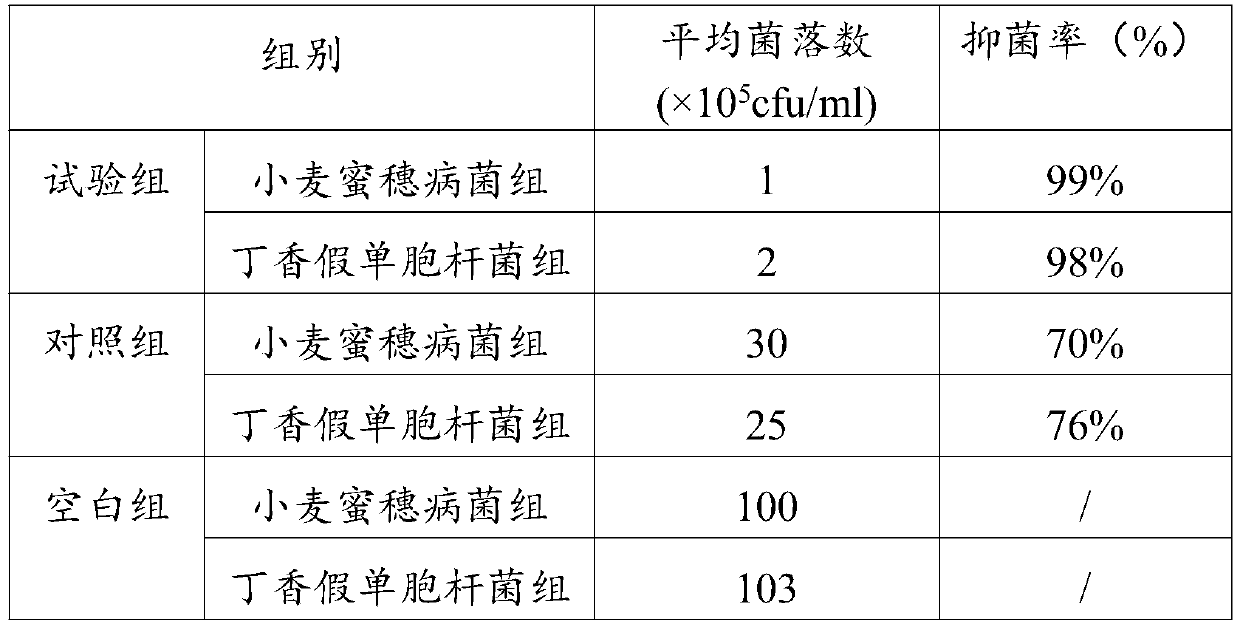

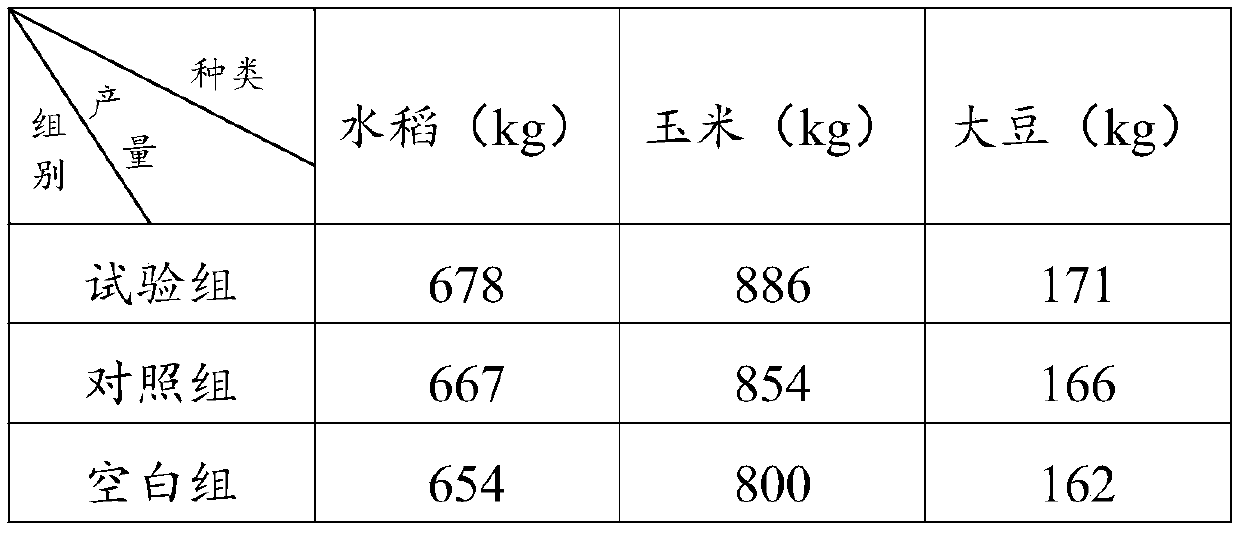

Biologically fermented bacteriostatic agent, and preparation method and application thereof

InactiveCN110432294AInhibit harmful bacteriaImprove yield and qualityBiocideFungicidesFertilizerMacromolecular Substances

A biologically fermented bacteriostatic agent provided by the invention adopts food materials as raw materials rich in source. A probiotic mixture and residues of ecological tofu production are added.Through a fermentation manner, effective bacteriostatic substances in the raw materials are fully released, and macromolecular substances in the raw materials are decomposed into small molecular substances and inorganic salts that are easily absorbed and utilized by plants, so that the bacteriostatic agent can effectively inhibit the growth and reproduction of harmful bacteria, and the small molecular substances and inorganic salts thereof can be used as biological fertilizers to provide nutrients required for crop growth. The bacteriostatic agent is prepared only from plants and is preparedthrough fermentation without addition of chemicals; the bacteriostatic agent is nontoxic and harmless, allows drug resistance of harmful bacteria to be not liable to generate, can improve environment,can balance microorganisms in the environment, and does not increase environmental burden. The raw materials are abundant, the cost is low, and the bacteriostatic effect is outstanding.

Owner:厦门市民安创享实业有限公司

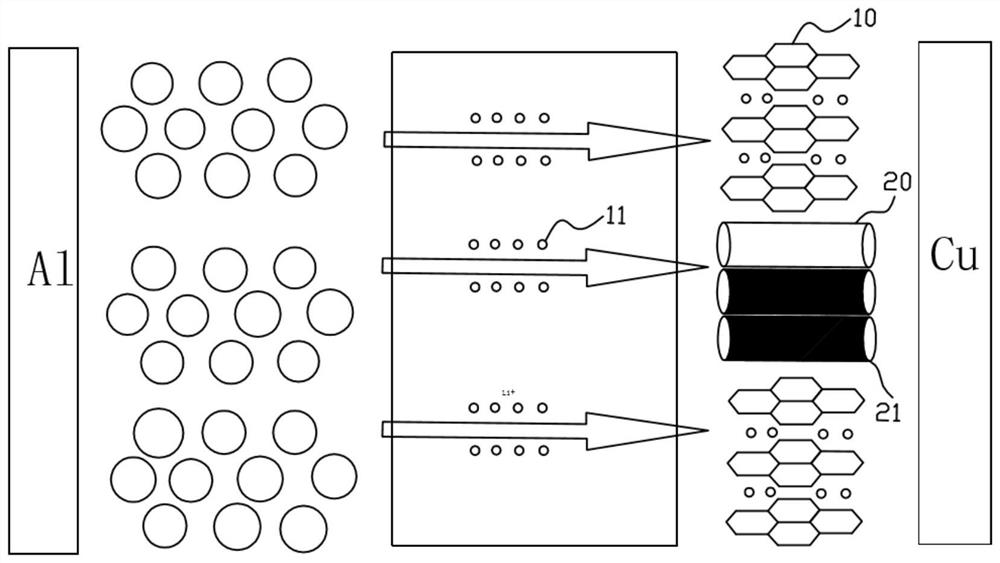

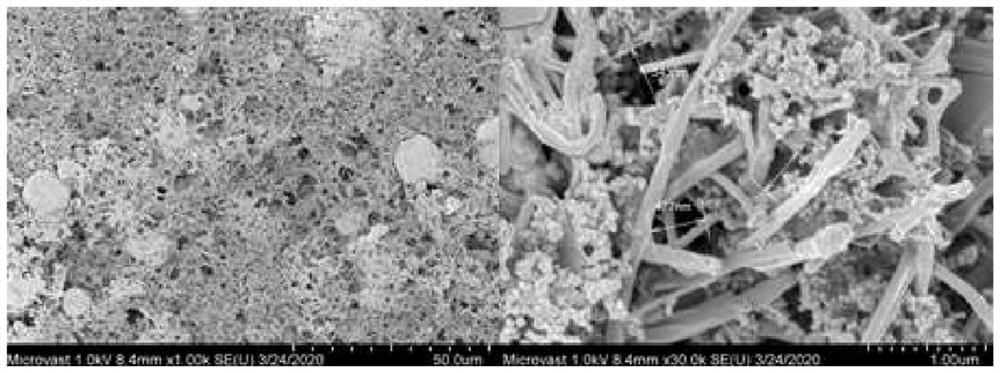

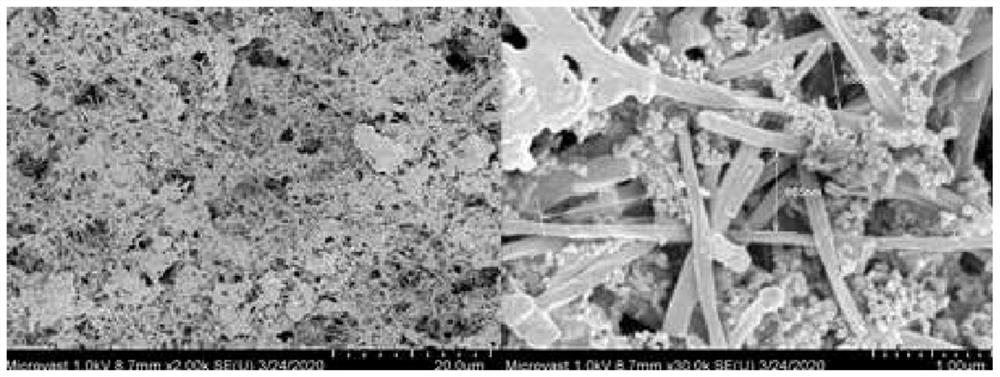

Negative electrode, lithium ion secondary battery and preparation method of lithium ion secondary battery

InactiveCN112397686AThe generation of solutionAchieve mass productionSecondary cellsNegative electrodesPhysicsLithium dendrite

The invention provides a negative electrode. The negative electrode comprises a first negative electrode active material, a conductive network structure with holes and a second negative electrode active material positioned in the holes, the second negative electrode active material is lithium metal, and the lithium metal is deposited in the conductive network structure and is not separated out from the surface of the negative electrode. The invention further provides a lithium ion secondary battery comprising the negative electrode and a preparation method of the lithium ion secondary battery,excessive lithium ions of the positive electrode are separated out and deposited in holes of the negative electrode through a charging process, so that lithium metal and a negative electrode active material jointly form the negative electrode, and the problem of lithium separation on the surface of the negative electrode in a battery circulation process is solved; the formation of lithium dendrites is avoided, so that the safety of the battery is improved; meanwhile, the negative electrode has two charging and discharging forms of lithium metal and graphite with different mechanisms, so thatthe energy density and the cycle performance of the battery are improved.

Owner:MICROVAST POWER SYST CO LTD +1

Tanning production technology

InactiveCN105671219AThe generation of solutionSolve the emission problemTanning treatmentPre-tanning chemical treatmentAmmoniacal nitrogenProcess engineering

The invention relates to a tanning production technology. The tanning production technology includes the following sequential steps of soaking, fleshing, depilating, hair shoveling, alkali expanding, splitting, dealkalizing, softening, pickling and tanning; then production is conducted according to a conventional chrome tanning follow-up technology; in the preparing process, a novel ash-free and sulfur-free technology is adopted, generation of sulfides is avoided, sludge generated when lime powder is used is avoided, and the sludge discharging problem of an enterprise is solved; and an ammonia-free dealkalizing and subsalt technology is adopted in the tanning process, so that ammonia nitrogen discharging and industrial salt discharging pollution is greatly reduced. By means of the novel sulfur-free, ash-free, ammonia-free and subsalt technology, produced leather is soft in hand feel and good in fullness, all indexes of the produced leather reach EU standards, and the produced leather is exported to Europe and receives consistent praise from users.

Owner:HAINING SHANGYUAN LEATHER

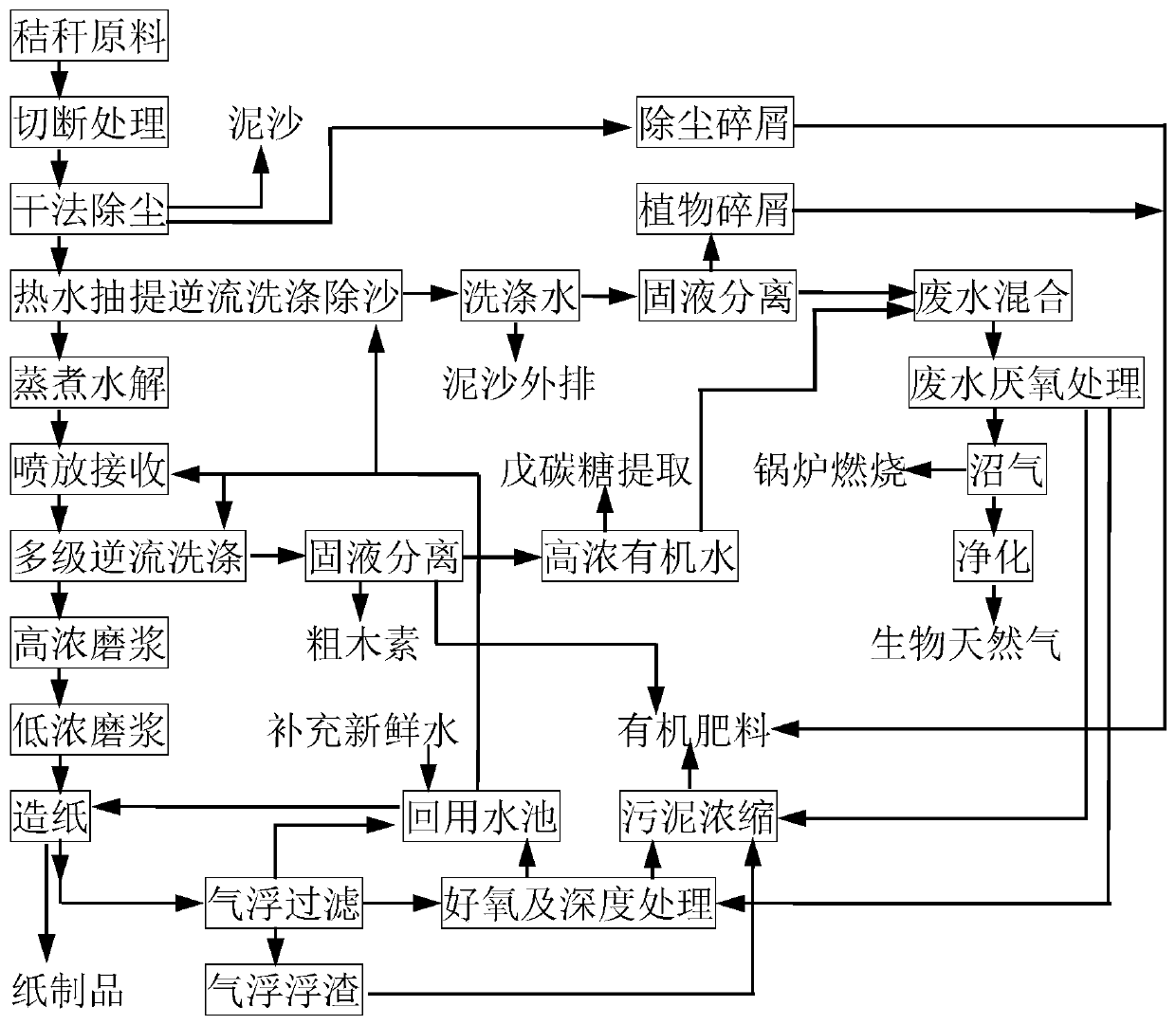

Straw comprehensive utilization method

InactiveCN110791990AImprove porosity and drainageReduced steam and power consumptionPretreatment with water/steamClimate change adaptationBiogasAgricultural crops

The invention discloses a straw comprehensive utilization method comprising the following steps: 1, paper product production: (1) straw cutting off; (2) dry dedusting; (3) hot water extraction, countercurrent washing and sand removal; (4) cooking and hydrolyzing; (5) spraying and receiving; (6) multistage countercurrent washing; (7) high-concentration pulping; (8) low-concentration pulping; and (9) papermaking; 2, natural gas production: (1) anaerobic treatment; (2) aerobic treatment; and (3) biogas purification; 3, production of an organic fertilizer: (1) extracting chippings generated by drydedusting in the step 1, plant chippings filtered by hot water extraction countercurrent washing water in the step 1, and solids obtained by solid-liquid separation of multi-stage countercurrent washing water for fermentation production of the organic fertilizer; and (2) mixing the concentrated sludge produced by anaerobic treatment and aerobic treatment in the step 2 with air flotation dross andplant debris, and fermenting to produce the organic fertilizer. The straw comprehensive utilization method provided by the invention is environment-friendly, realizes process wastewater resource utilization, can improve the slurry self-production capability in China, alleviates the problem of lack of fiber raw materials in China, can effectively utilize crop straws, and increases agricultural income.

Owner:吴学军 +5

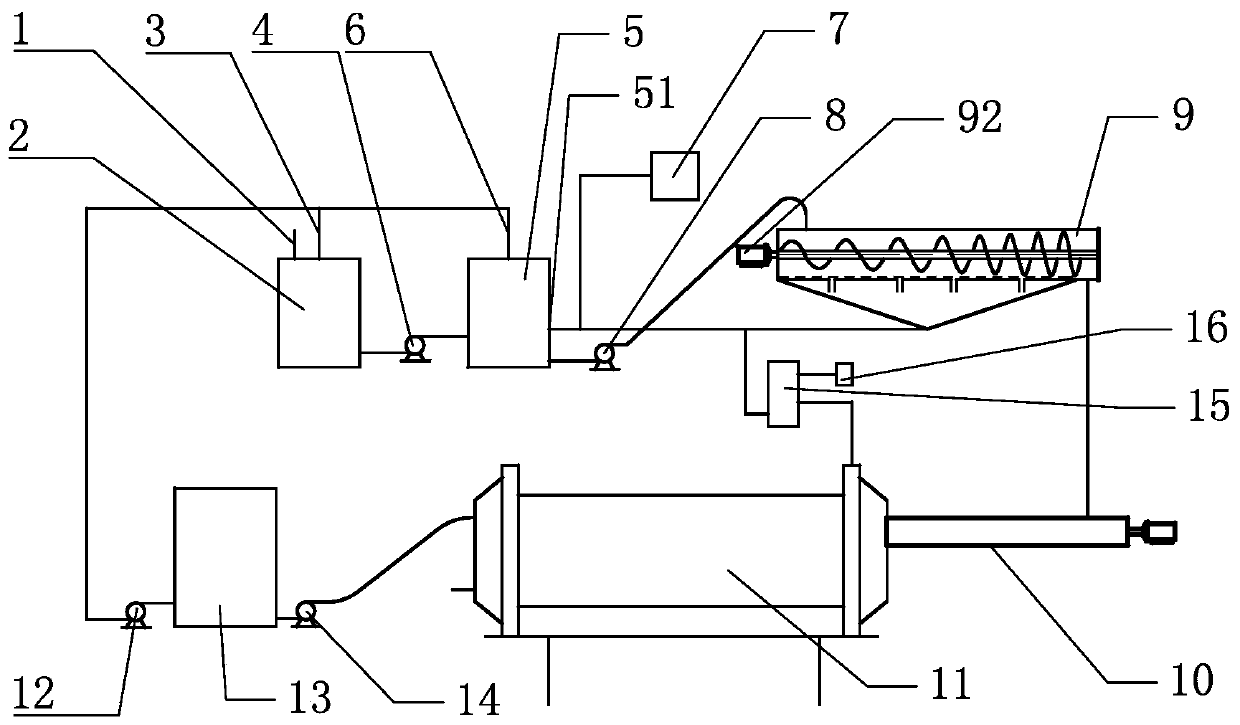

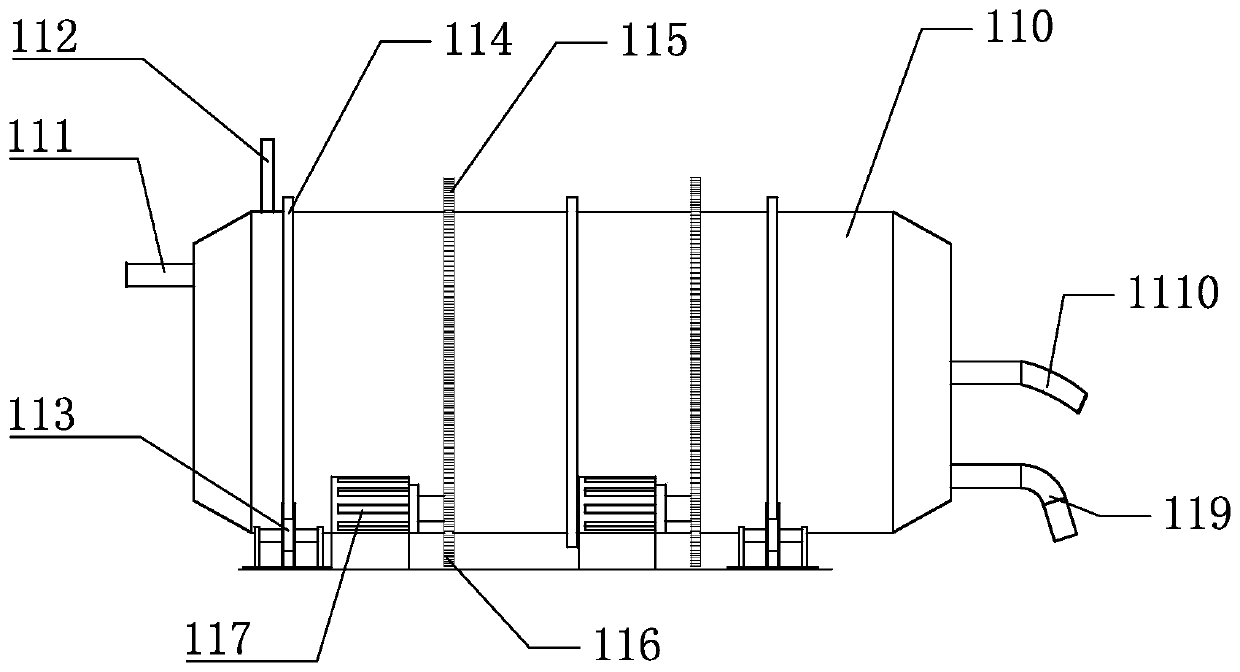

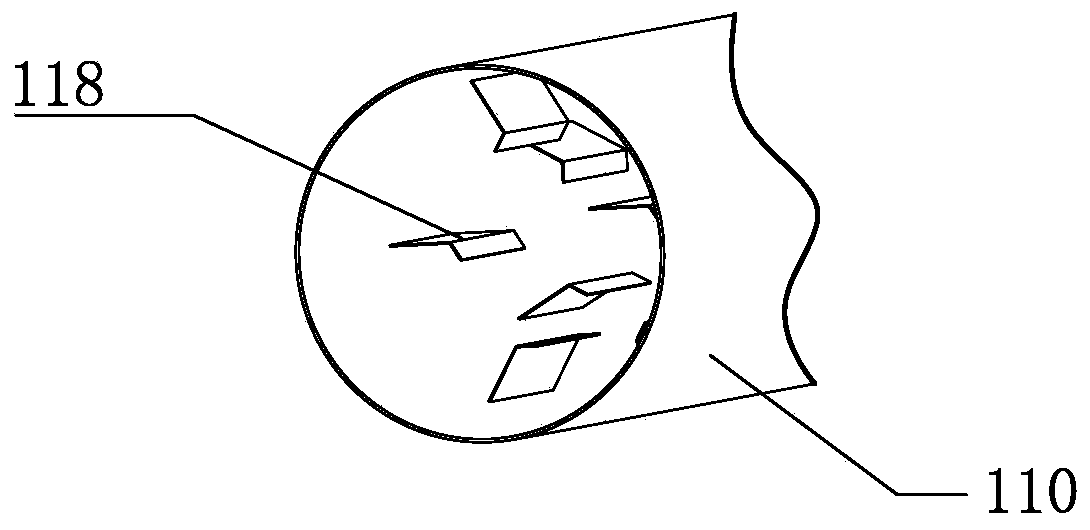

Sludge drying system based on biomass energy

InactiveCN110436731AOptimize process flowEasy to dehydrateSludge treatment by de-watering/drying/thickeningSludgePulp and paper industry

The invention relates to the technical field of sludge treatment, in particular to a sludge drying system based on biomass energy. The sludge drying system includes a precipitation device, a dehydration device and a drying device which are successively arranged, the precipitation device, the dehydration device and the drying device are connected in series by a conveying device, and the drying device is connected with a hot air device. The sludge drying system is optimized in technological process, sludge drying is carried out by adopting a mode of drying after mechanical dehydration, and gooddehydration effect can be realized; and clean energy is used, the hot air device does not pollute the environment in the process of heat production, at the same time, smelly gas generated in other processes is also solved, harmless treatment of sludge and recycling of resources are realized, and the purposes of energy saving, emission reduction and environmental protection are achieved.

Owner:SHANDONG UNIV OF TECH

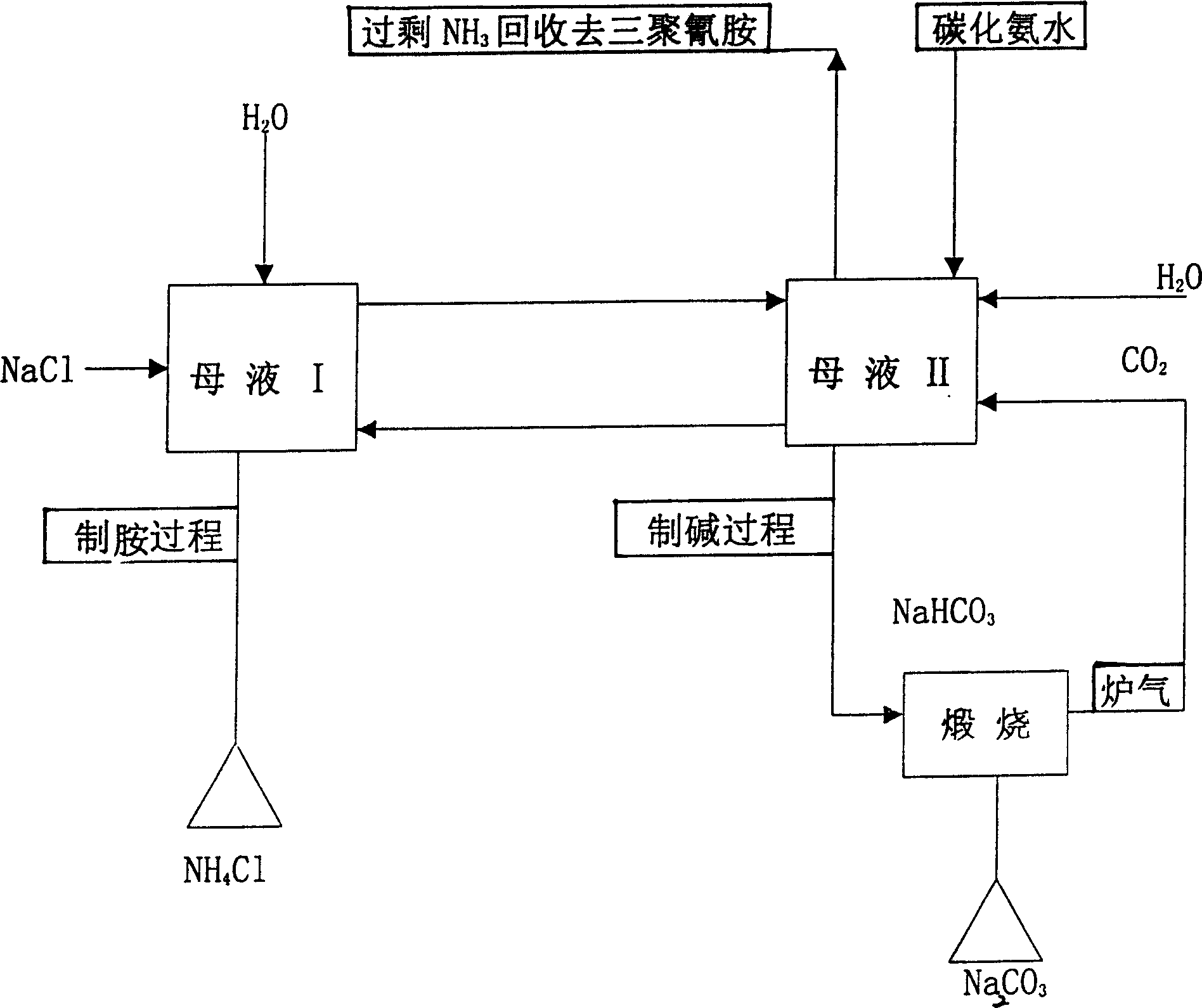

Combined production of alkali by using waste water

InactiveCN1613769AReduce manufacturing costThe generation of solutionProductsReagentsSodium bicarbonateDicarbonate

A combined soda production with waste water is carried out by: 1) totally collecting waste carbureted ammonia water produced by melamine with constant pressure ammonium catalytic circulating method, ammonia content of carbureted ammonia water > 27%, carbon dioxide content > 33%, and water content < 40%; 2) separating dicarbonate to obtain mother liquor, making mother liquor I heat exchange with mother liquor II , and cold crystallizing separating out industrial ammonium chloride; 2) salting out semi-mother liquor II , adding sodium chloride, and salting out crystallizing separating to obtain agricultural ammonium chloride. It achieves low cost and no pollution.

Owner:王禄宏

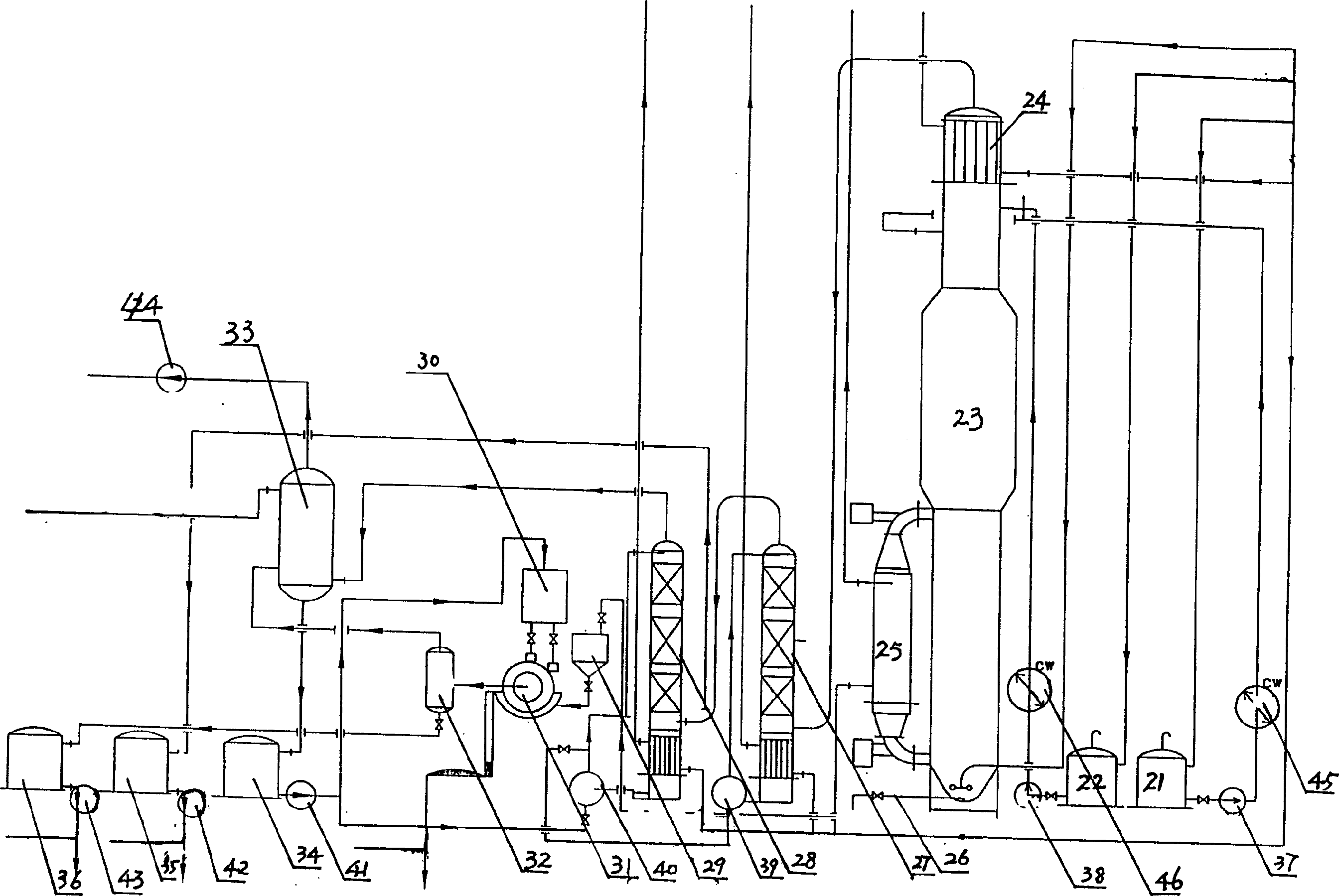

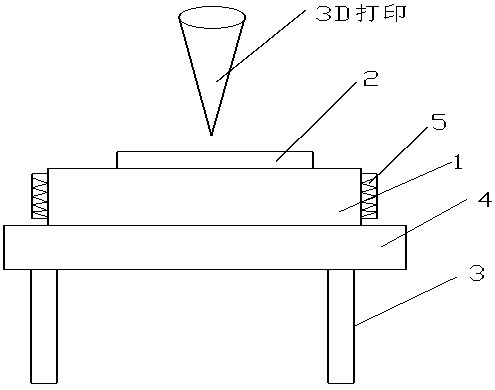

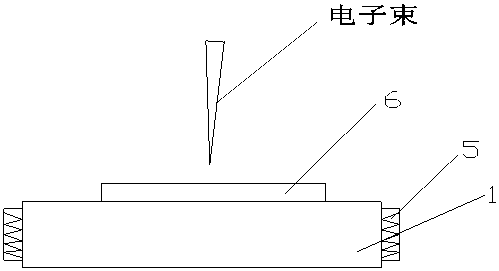

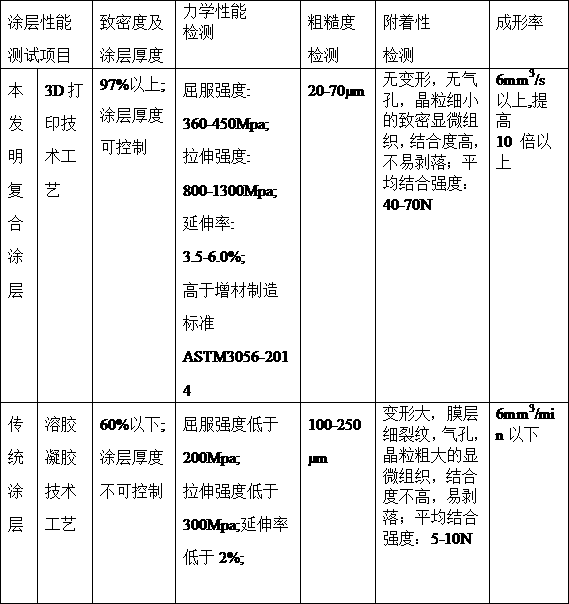

Method for preparing coating by 3D printing overlapping electron beam

InactiveCN110714199AGood molding precisionAvoid low powder utilizationAdditive manufacturing apparatusIncreasing energy efficiencyCermetCeramic composite

The invention relates to a method for preparing a coating by 3D printing overlapping an electron beam. Metal or ceramic powder and metal / ceramic powder are printed on the surface of a base material layer by layer through 3D printing, layer-by-layer printing is carried out by a three-dimensional model according to the set layer thickness, and then the metal or ceramic powder and metal / ceramic powder on the surface of the base material are preheated to form a fusion layer. A heating device used for the preheating includes a high-frequency vibrator and an induction heating coil which are placed on a workbench, the high-frequency vibrator acts on the bottoms of the fusion layer and the base material, the induction heating coil is arranged around the base material for preheating, after preheating is carried out, the fusion layer is melted with the electron beam to form a metal / ceramic. composite coating, and finally the metal / ceramic composite coating is subjected to post-heat treatment through the induction heating coil. The product development cycle is greatly shortened, production rate is improved, and the production cost is reduced.

Owner:FUJIAN UNIV OF TECH

Method for producing ferrovanadium nitride by use of vanadium nitride powder

The invention discloses a method for producing ferrovanadium nitride by use of vanadium nitride powder. The method comprises the following steps: performing batch-grouping on the vanadium nitride powder according to 1-2 tons per batch, and then mixing; testing to obtain the contents of vanadium and carbon in each batch of the vanadium nitride powder; determining the ratio of the vanadium nitride powder, ferrous powder and vanadium oxide in raw materials according to test results of the vanadium nitride powder and requirements on target products, and then compounding according to the ratio of the raw materials; after compounding, continually performing secondary mixing; grinding materials subjected to secondary uniform mixing into 150 meshes or below, then canning, and placing into a pushed slab kiln; and firing to obtain target ferrovanadium nitride. Starting from the properties of the vanadium nitride powder, the method fires the vanadium nitride powder into the new product ferrovanadium nitride through combination reaction between vanadium, nitrogen and ferrum, meanwhile, the problem that qualified ferrovanadium nitride cannot be produced by the vanadium nitride powder with high carbon content, the finally obtained ferrovanadium nitride product conforms to the GB / T30896-2014 ferrovanadium nitride national standard requirements, and the difficult problem of redundancy of the vanadium nitride powder is solved.

Owner:HEBEI IRON AND STEEL

Ink for thin-paper waterborne intaglio printing of furniture and preparation method of ink

The invention relates to ink for thin-paper waterborne intaglio printing of furniture. The ink is prepared from the following components: 13 percent to 38 percent of waterborne acrylic resin emulsion,12 percent to 38 percent of ethanol, 7 percent to 25 percent of pure water, 1 percent to 6 percent of waterborne dispersant, 0.1 percent to 1.5 percent of waterborne de-foaming agent, 0.1 percent to0.8 percent of ammonia water, 2 percent to 18 percent of filling agent and 5 percent to 50 percent of pigment. The improved waterborne acrylic resin emulsion is used as a main connecting material andthe waterborne de-foaming agent, the waterborne dispersant, the filling agent and the pigment are added; after a mixture is ground, the ink has relatively good fineness and color developing performance; furthermore, the water and the edible ethanol are used as a diluting gent so that the cost of printing raw materials is reduced; the VOC (Volatile Organic Compounds) content of the prepared waterborne ink is extremely low and a working environment of ink producers and printing operators is improved; potential safety hazards are solved and emission and pollution problems of a furniture paper intaglio printing industry are solved.

Owner:东莞市世丰油墨有限公司

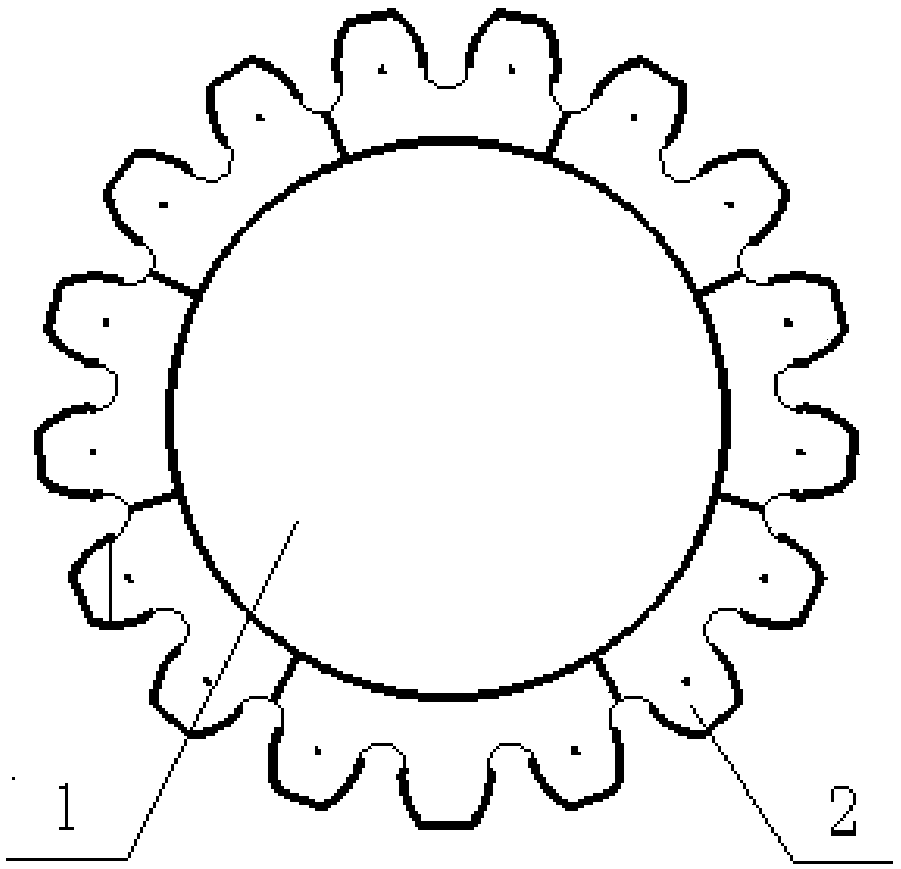

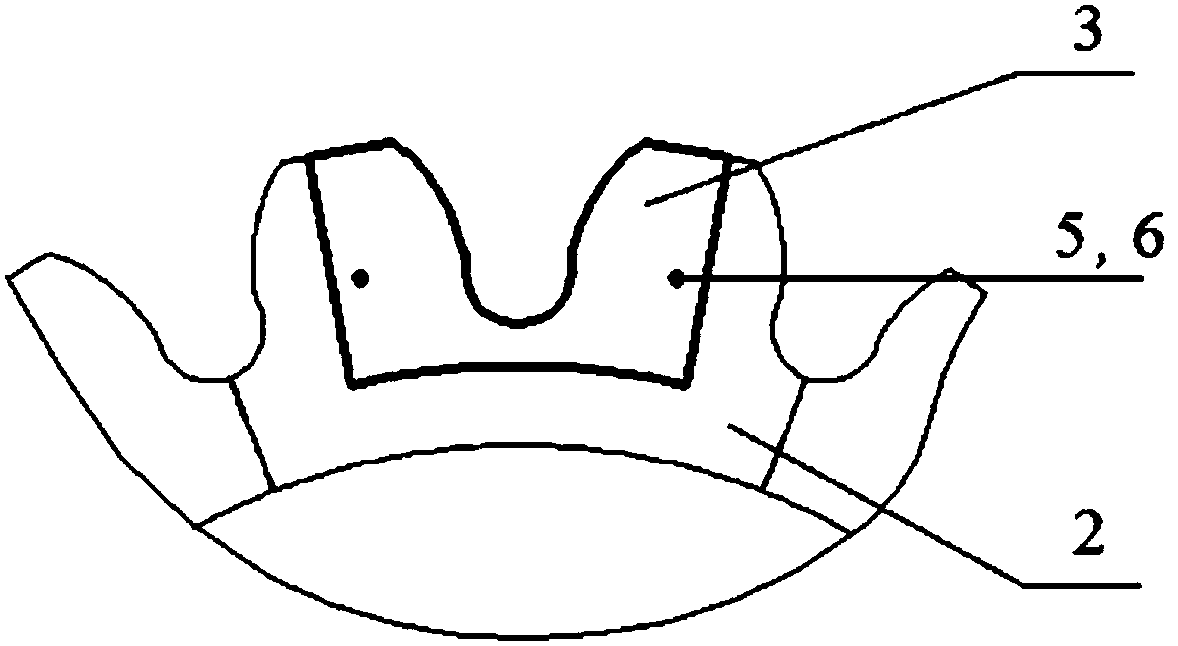

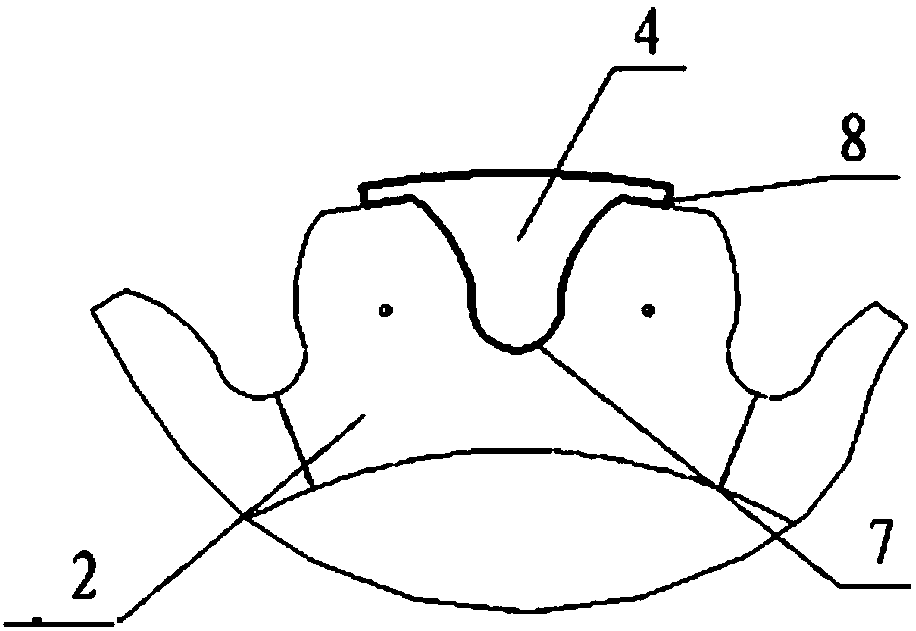

Sample plate combination for online overlaying of star wheel tooth plate, and online overlaying method

ActiveCN108406150ASolve the technical problems that the installation is not easy to guarantee the qualityAvoid Mating Installation DifficultiesWelding/cutting auxillary devicesAuxillary welding devicesEngineeringInstallation Problem

The invention discloses a sample plate combination for online overlaying of a star wheel tooth plate. The sample plate combination for online overlaying of the star wheel tooth plate comprises outer sample plates and an inner sample plate, wherein the two outer sample plates are fixedly arranged on two sides of the star wheel tooth plate, and are used for comparing and molding when overlaying is carried out on the star wheel tooth plate; and the inner sampling plate is inserted into a tooth groove of the star wheel tooth plate, and is used for inspecting a tooth profile outline of the star wheel tooth plate before and after welding. The invention further discloses an online overlaying method of the star wheel tooth plate. According to the sample plate combination for online overlaying of the star wheel tooth plate, and the online overlaying method provided by the invention, the size restoration of the worn tooth plate can be realized without disassembling the star wheel tooth plate, the installation problem during a tooth plate disassembling and assembling process is avoided, and the overhaul time is saved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com