Combined production of alkali by using waste water

A combined alkali and wastewater production technology, applied in chemical instruments and methods, carbonate preparations, alkali metal compounds, etc., can solve the problems of difficult treatment, long process route, low efficiency, etc., to protect the ecological environment, reduce manufacturing costs, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

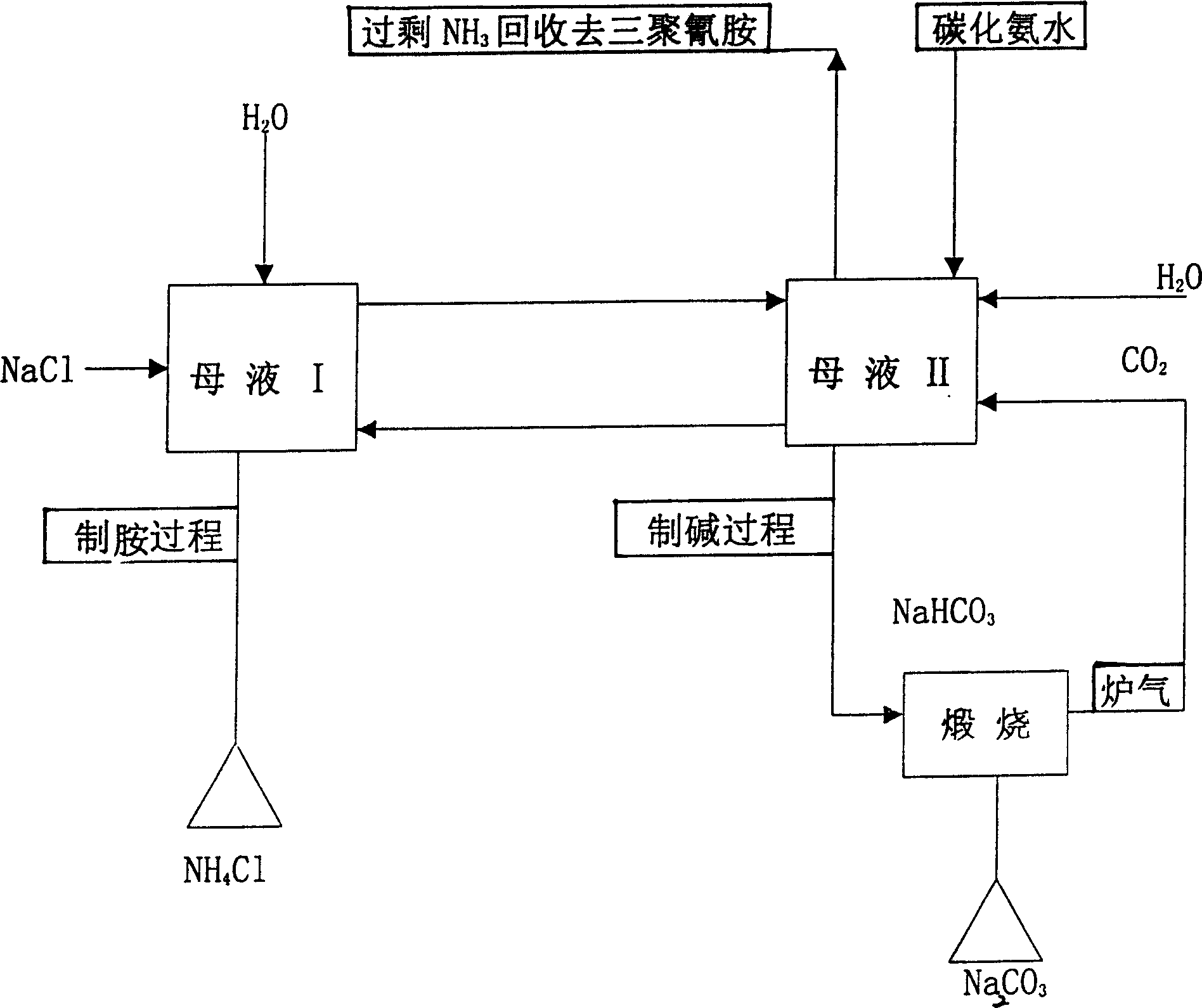

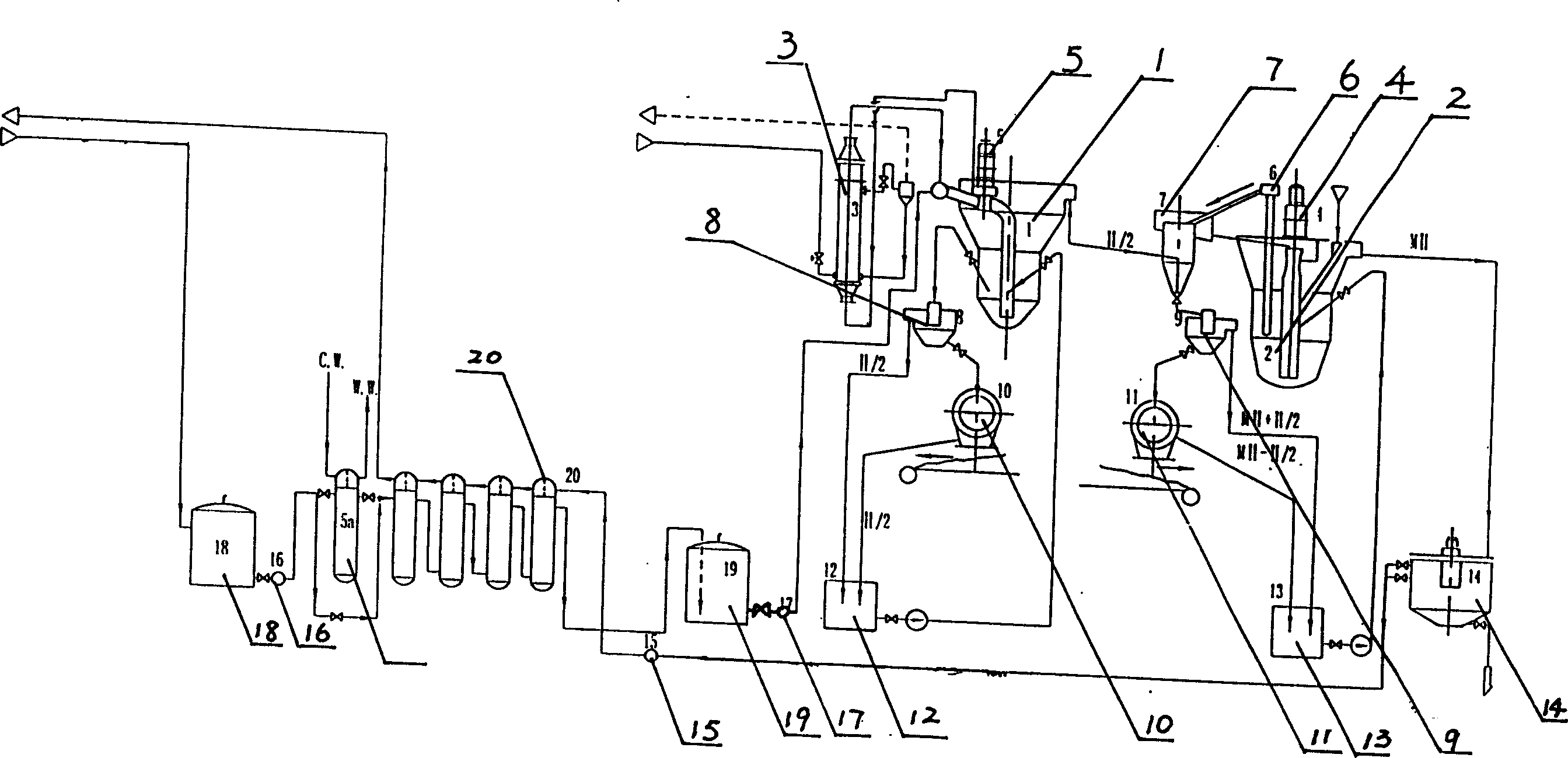

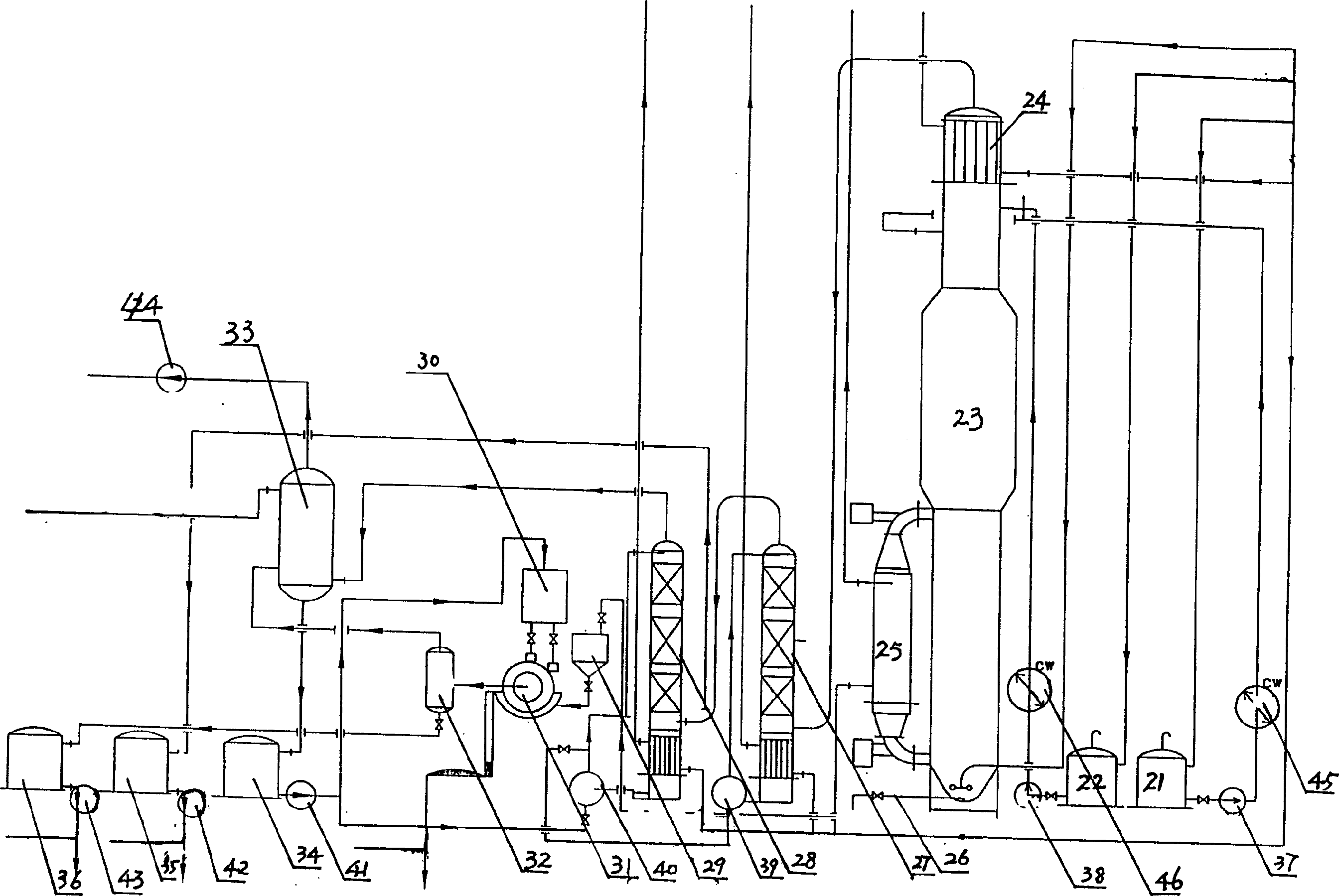

[0020] Example 1 as Figure 1-5 Shown: the manufacturing process technology of the present invention mainly contains the following steps: 1. Collect the waste carbonized ammonia water produced by normal pressure full ammonia catalytic circulation method melamine in a concentrated manner, and require the index of carbonized ammonia water to meet ammonia content 27.3%-29%, carbon dioxide content 32.3%-35%, the water content is less than 40% (theoretical calculation is based on the actual measurement results of ammonia in the production of carbonized ammonia: ammonia: 27.37%, carbon dioxide 32.26%, water 40.37% This index is because there was no requirement for carbonized ammonia in the past, as long as the melamine device It is allowed for efflux, but now comprehensive utilization must consider the stable and normal operation of downstream devices.

[0021] 2. Prepare standard mother liquor II according to the production of combined alkali

[0022] 3. Pump the mother liquor II ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com