Patents

Literature

73results about How to "Good molding precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mineral/long glass fiber reinforced polypropylene composite material and preparation method thereof

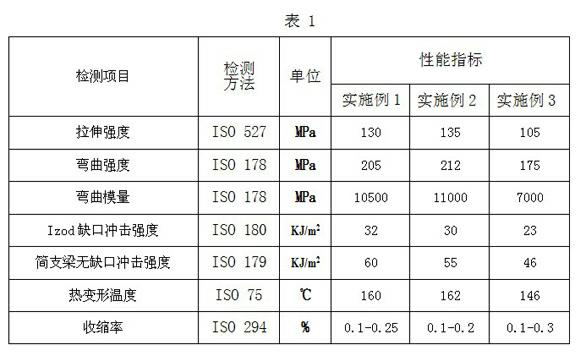

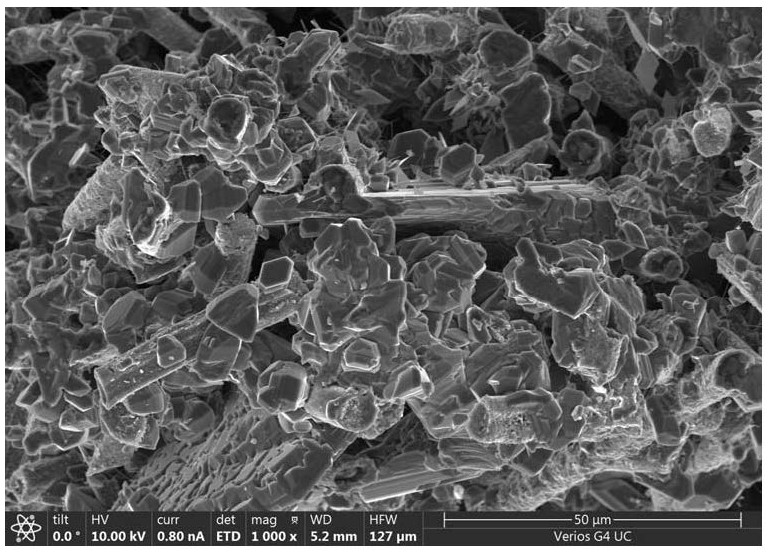

The invention belongs to the field of high molecular materials and molding thereof, and relates to a mineral / long glass fiber reinforced polypropylene composite material and a preparation method thereof. The mineral / long glass fiber reinforced polypropylene composite material comprises the following components in percentage by weight: 40-60% of long glass fiber reinforced polypropylene master batch, 20-50% of mineral master batch and 0-30% of polypropylene resin. The preparation method comprises the following steps: proportionally weighing long glass fiber reinforced polypropylene master batch, mineral master batch and polypropylene resin, and mixing; and drying the mixture at 90 DEG C for 3 hours, and carrying out injection molding, wherein the conditions of the injection molding machine are as follows: the temperature of a first region is 200-220 DEG C, the temperature of a second region is 230-240 DEG C, the temperature of a third region is 240-250 DEG C, the temperature of a fourth region is 245-255 DEG C, the pressure is 60-90 MPa, and the speed is 30-50 mm / s. The product has the advantages of excellent comprehensive performance, high dimensional stability and favorable mechanical properties.

Owner:NANJING JULONG SCI&TECH CO LTD

Three-dimensional printing method

ActiveCN105711094ABroaden your optionsAchieve stabilityAdditive manufacturing apparatusResin matrixEngineering

The invention discloses a three-dimensional printing method, wherein a melt enters a three-dimensional printing device to print a finished product. The three-dimension printing device comprises a three-dimensional moving mechanism, a working platform mechanism and a computer control and driving system; the melt is made from a modified nylon material formed by a nylon resin matrix and a tackifying nucleating agent; the tackifying nucleating agent is prepared by compounding of ion liquid and nano carbon filler; and the ion liquid is formed by anions and cations, wherein the anions are alkyl imidazole ions. The device disclosed by the invention has the advantages of being simple and compact in structure, high in automation degree, easy to control, high in precision, high in efficiency and high in adaptability; the modified nylon material provided by the invention can effectively avoid edge warping during 3D printing; and a finally printed product has the advantages of being excellent in mechanical property, good in dimension stability, smooth in surface, low in cost and the like.

Owner:DONGHUA UNIV

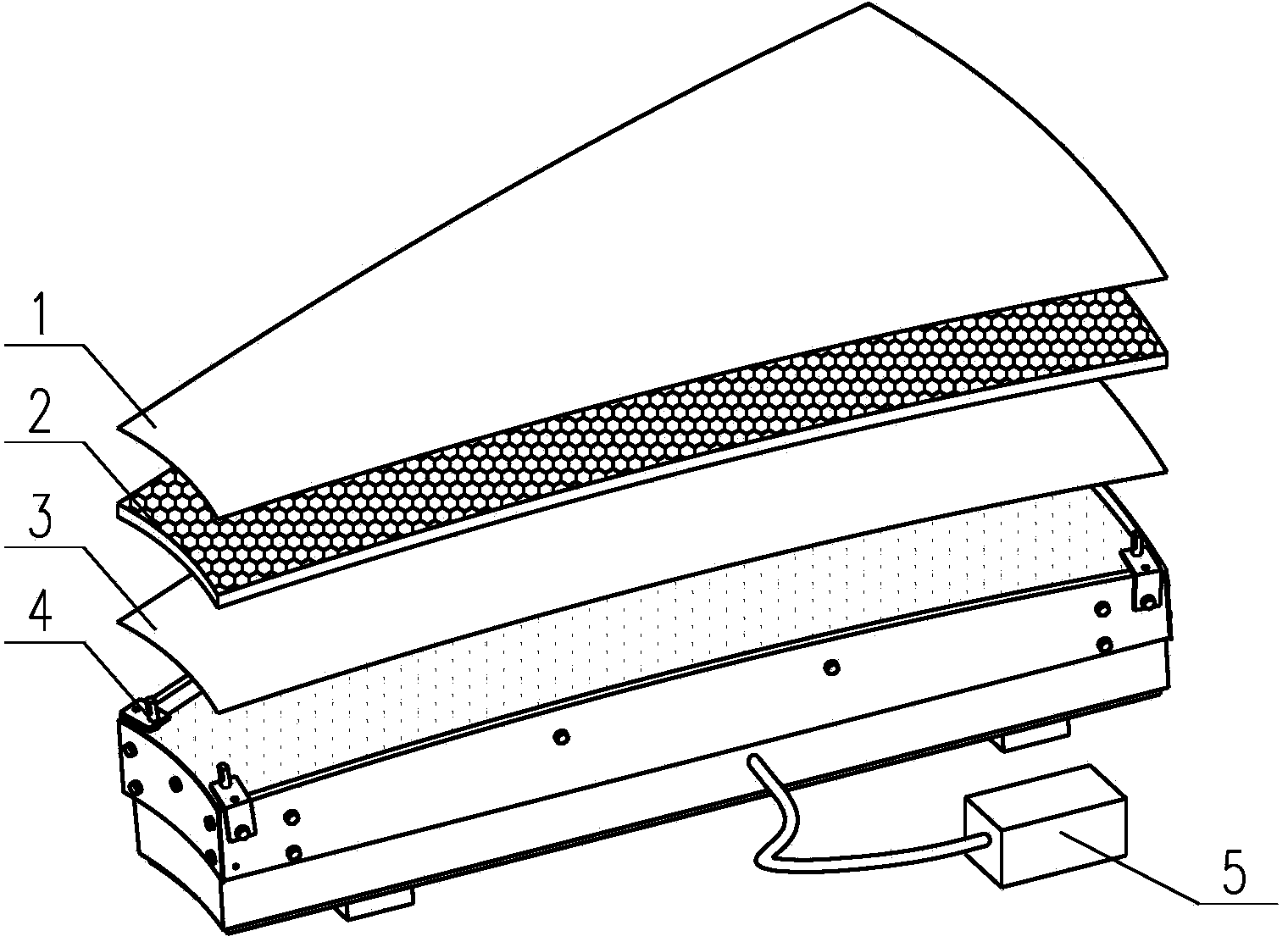

Manufacture method of high-precision carbon fiber composite antenna panel

The invention discloses a manufacture method of a high-precision carbon fiber composite antenna panel. According to the manufacture method, the high-precision carbon fiber composite antenna panel is manufactured by the steps of manufacturing with a die, forming a skin, forming a panel, assembling and protecting and the like. Compared with an existing panel manufacture technology, the manufacture technology of the high-precision carbon fiber composite antenna panel has the characteristics that a negative-pressure forming technology is used; by changing the panel material, the disadvantage of poor precision in manufacture of an aluminum alloy tensile skin is avoided, and the advantages of easy film adhesion and good forming precision of the carbon fiber material are brought into full play. Meanwhile, the antenna panel manufactured by the method is high in precision and light in weight.

Owner:CHINA ELECTRONICS TECH GRP NO 39 RES INST

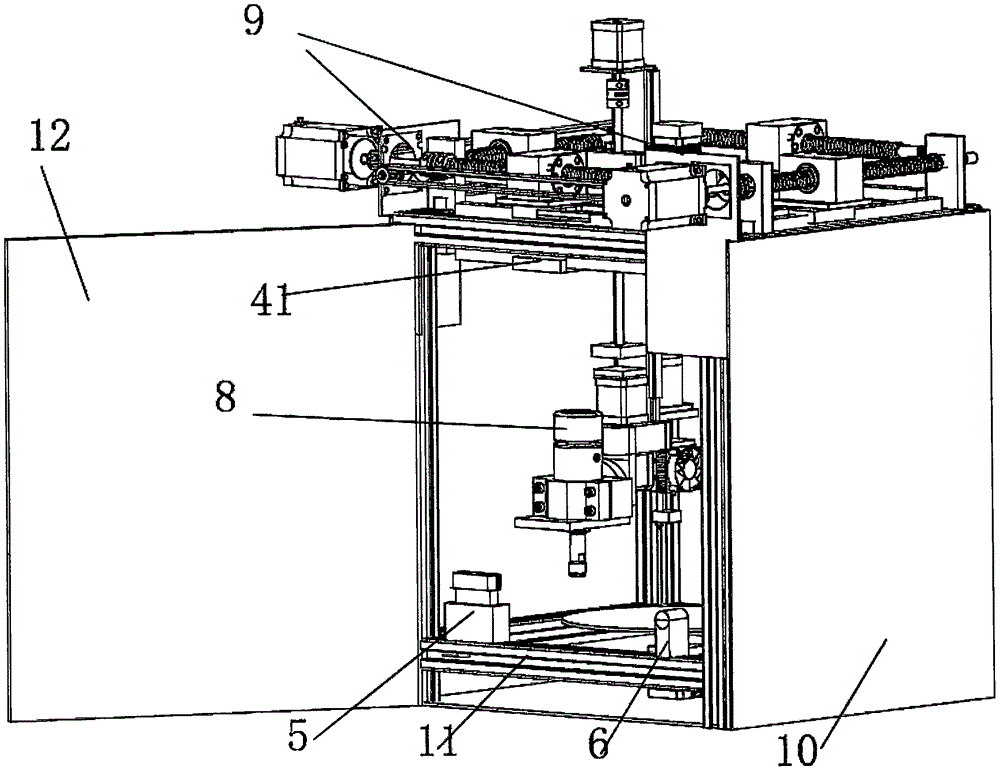

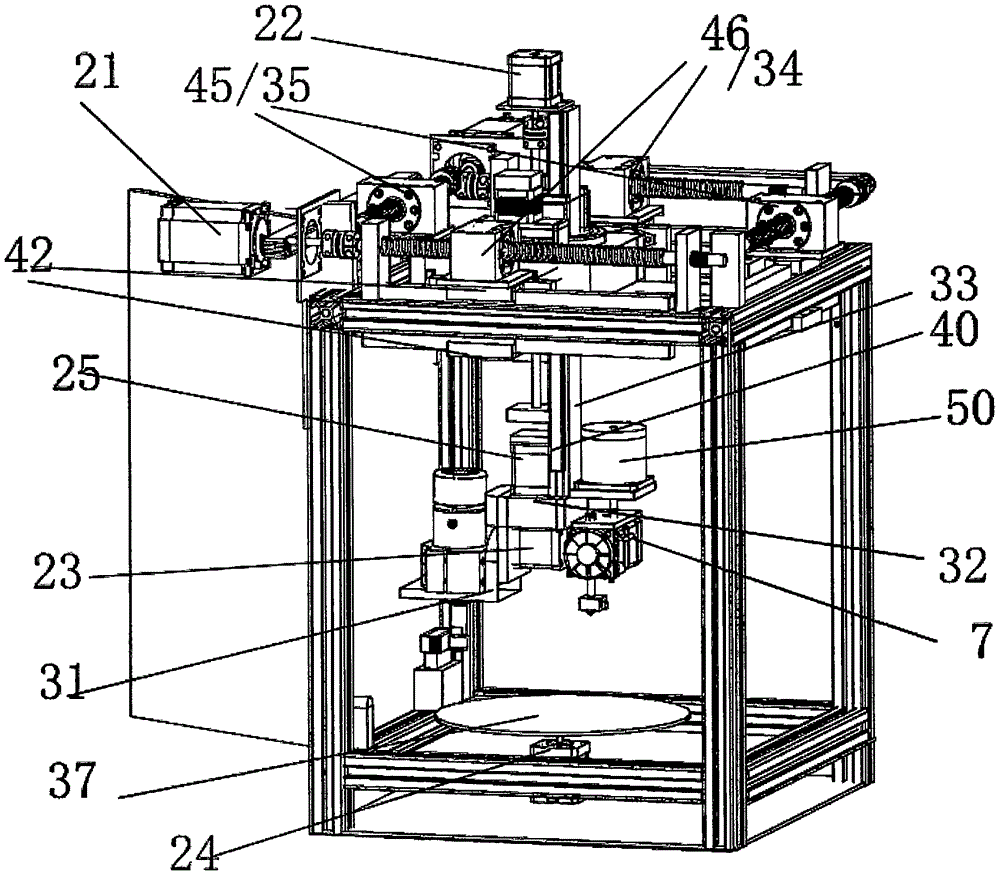

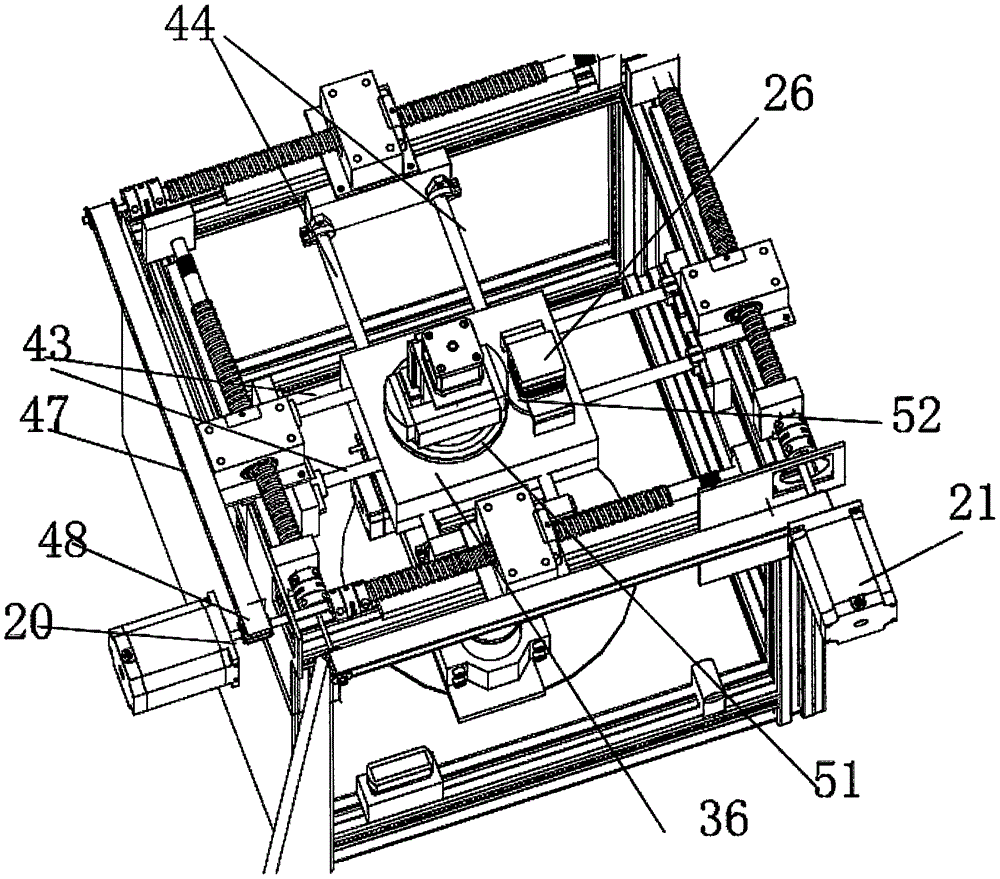

Desktop type multifunctional five-axis machining equipment

InactiveCN106042385AAvoid pollutionUndisturbedAdditive manufacturing apparatusLaser beam welding apparatusNumerical controlEngineering

The invention discloses desktop type multifunctional five-axis machining equipment, relates to the field of mechanical machining equipment, and provides a multifunctional machining center of a semi-closed cube frame structure. By means of the mechanical structure, the problem that a traditional movable gantry numerical control carving machine is heavy in structure and low in speed is solved, and the problem that a traditional fixed gantry is large in practical occupied area under the same machining area is solved. Three-dimensional printing and tasks capable of being completed by the traditional numerical control carving machine can be simultaneously completed. The desktop type multifunctional five-axis machining equipment comprises a system for automatically switching tools, the system can automatically switch a three-dimensional printing spray head and an electric main shaft during machining, two processes are continuously carried out, and manual intervention is not needed in the whole process. In addition, more possibilities are provided for machining of complex parts due to five-axis design. The equipment also has a three-dimensional scanning function, a large space utilization rate is achieved under the condition that functions are guaranteed, the desktop type is promoted, and general requirements of individual makers or small worm rooms can be met.

Owner:陈天润

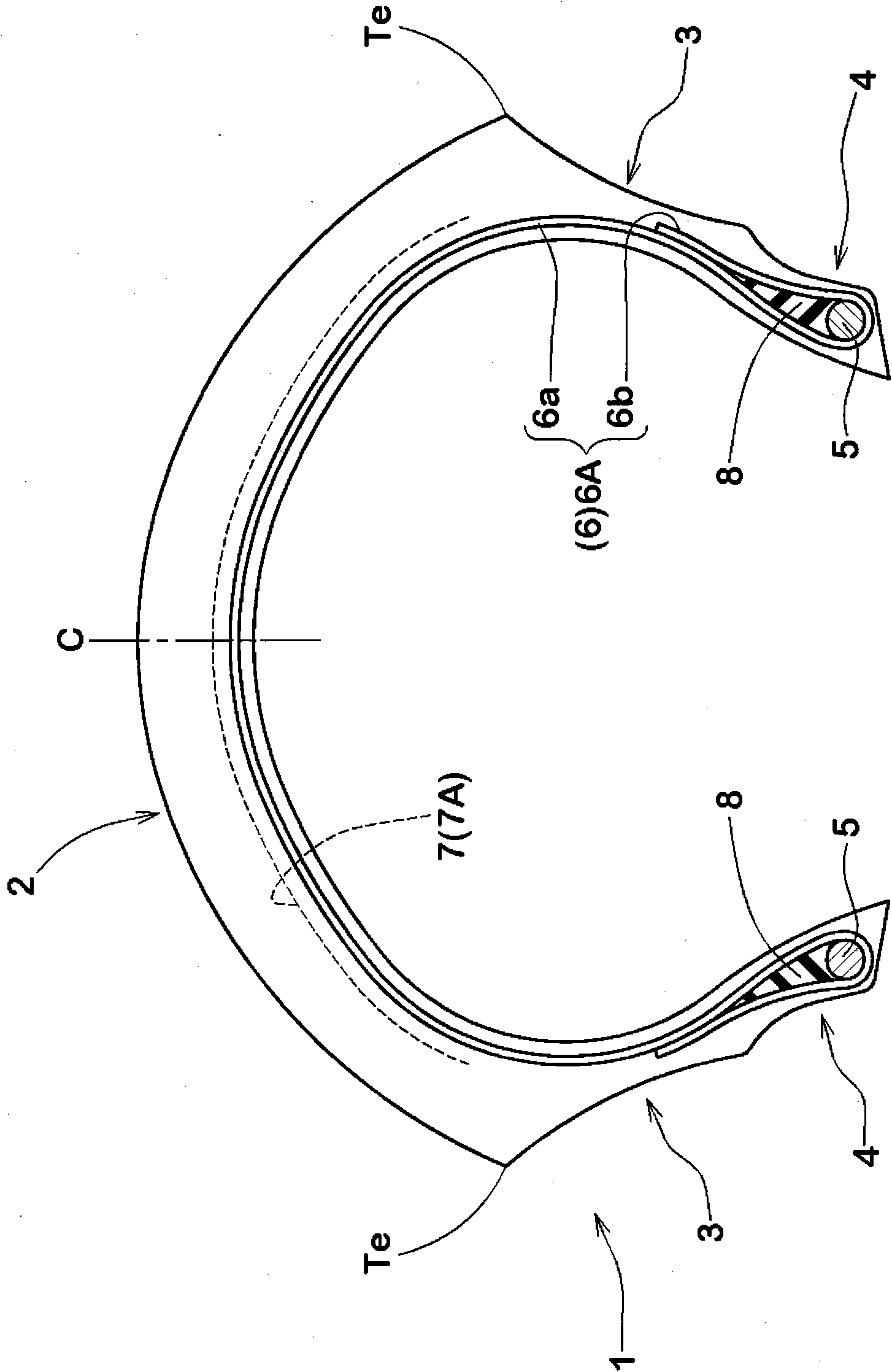

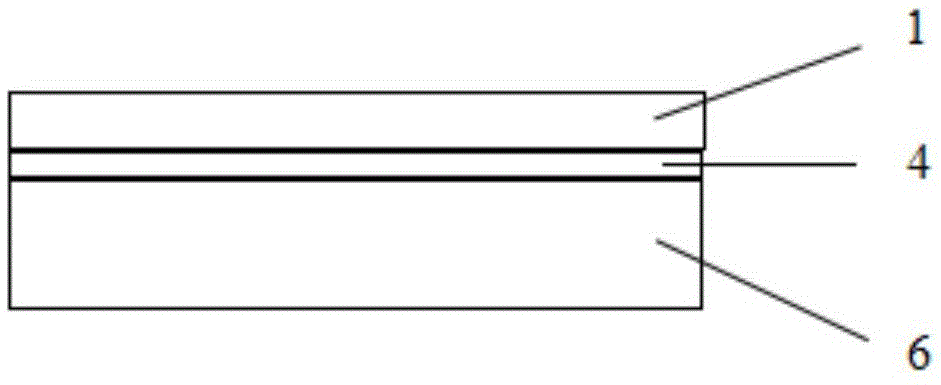

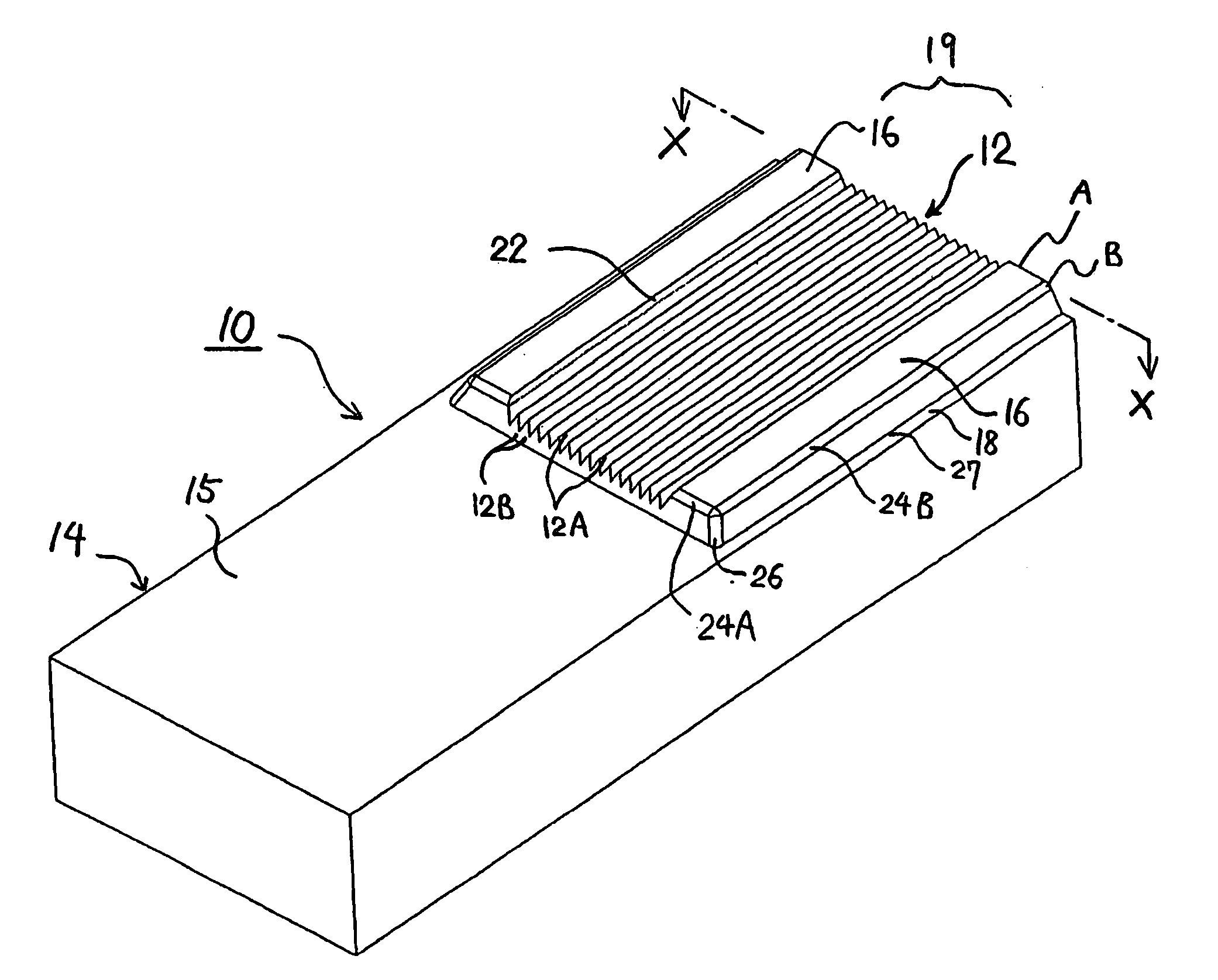

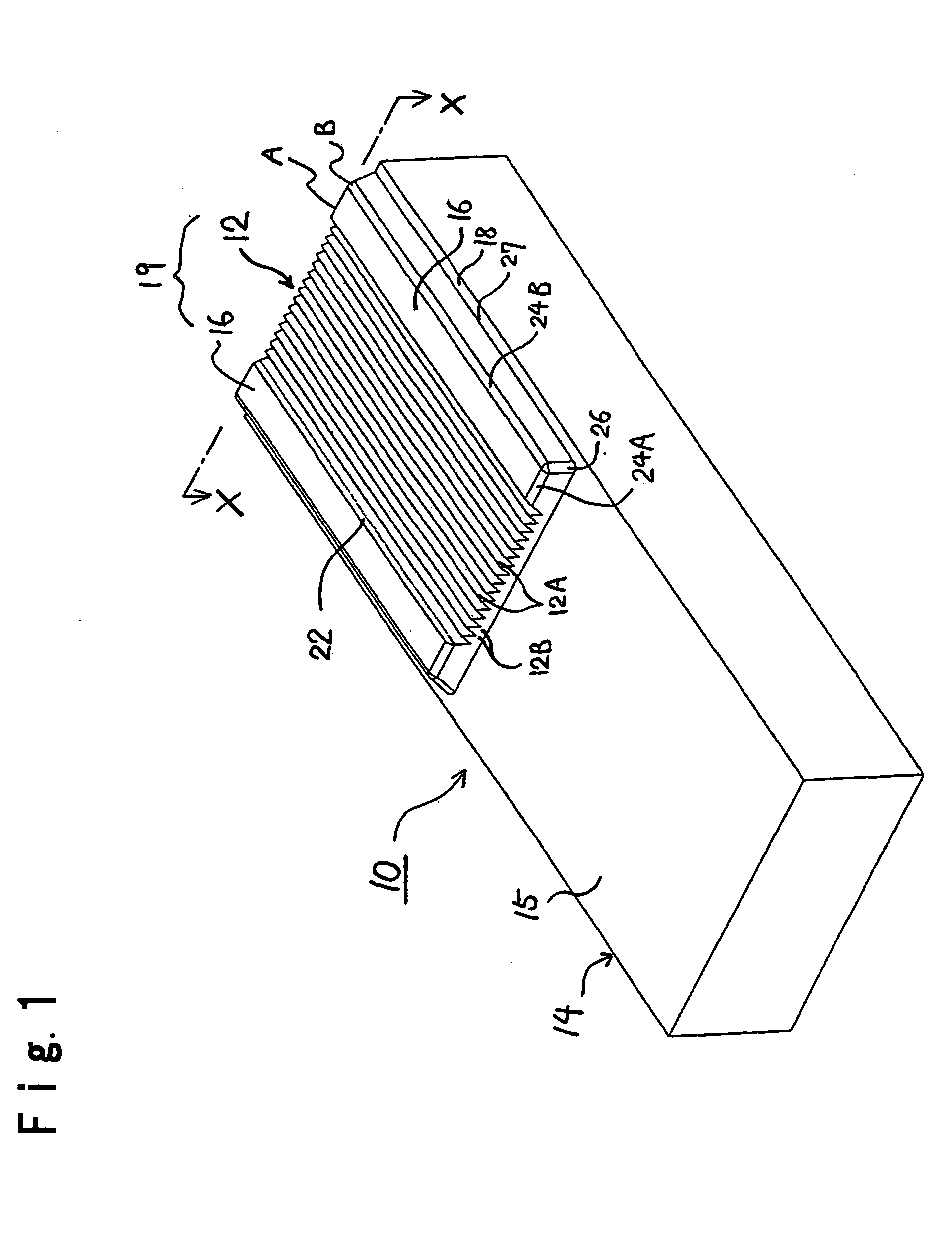

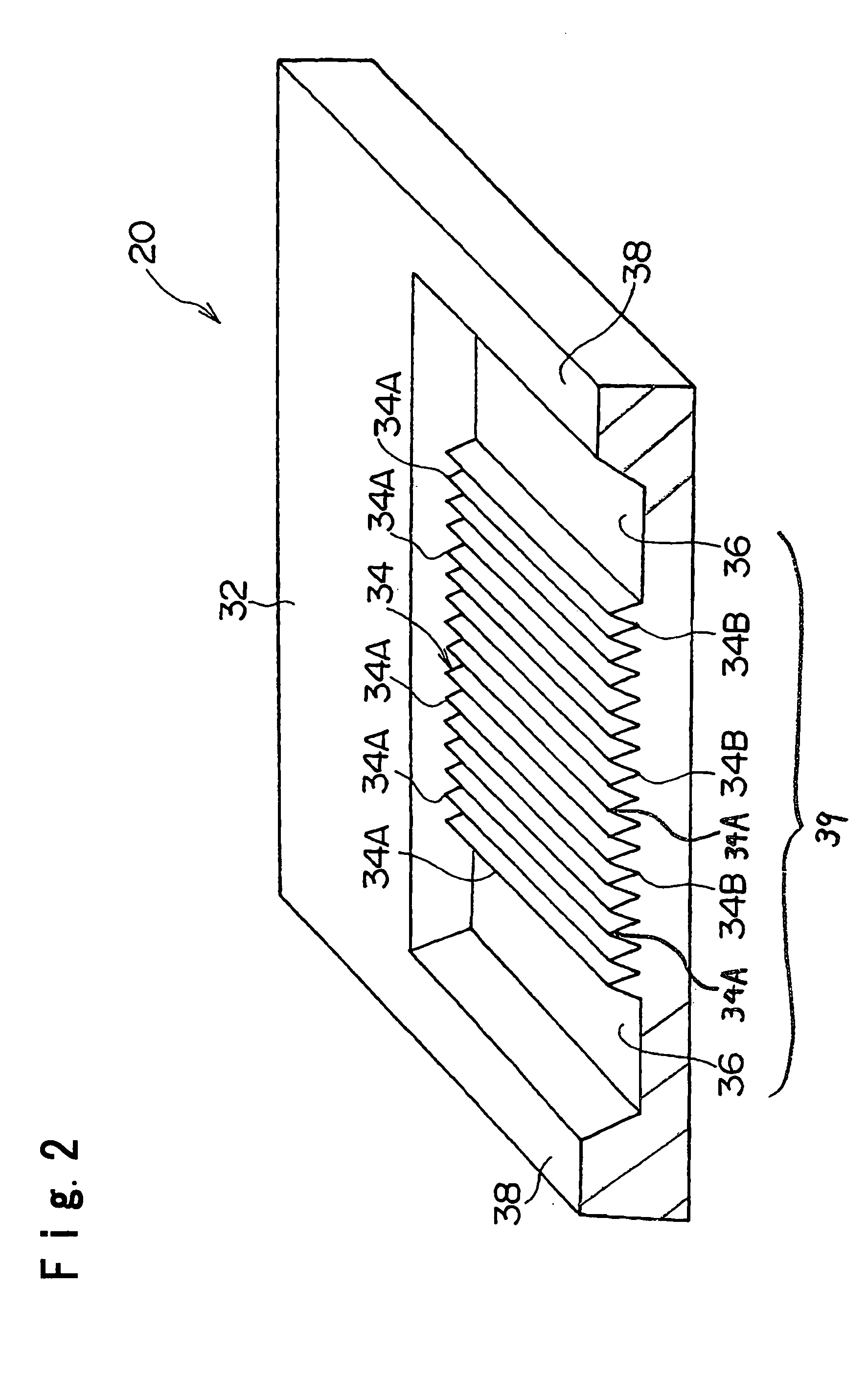

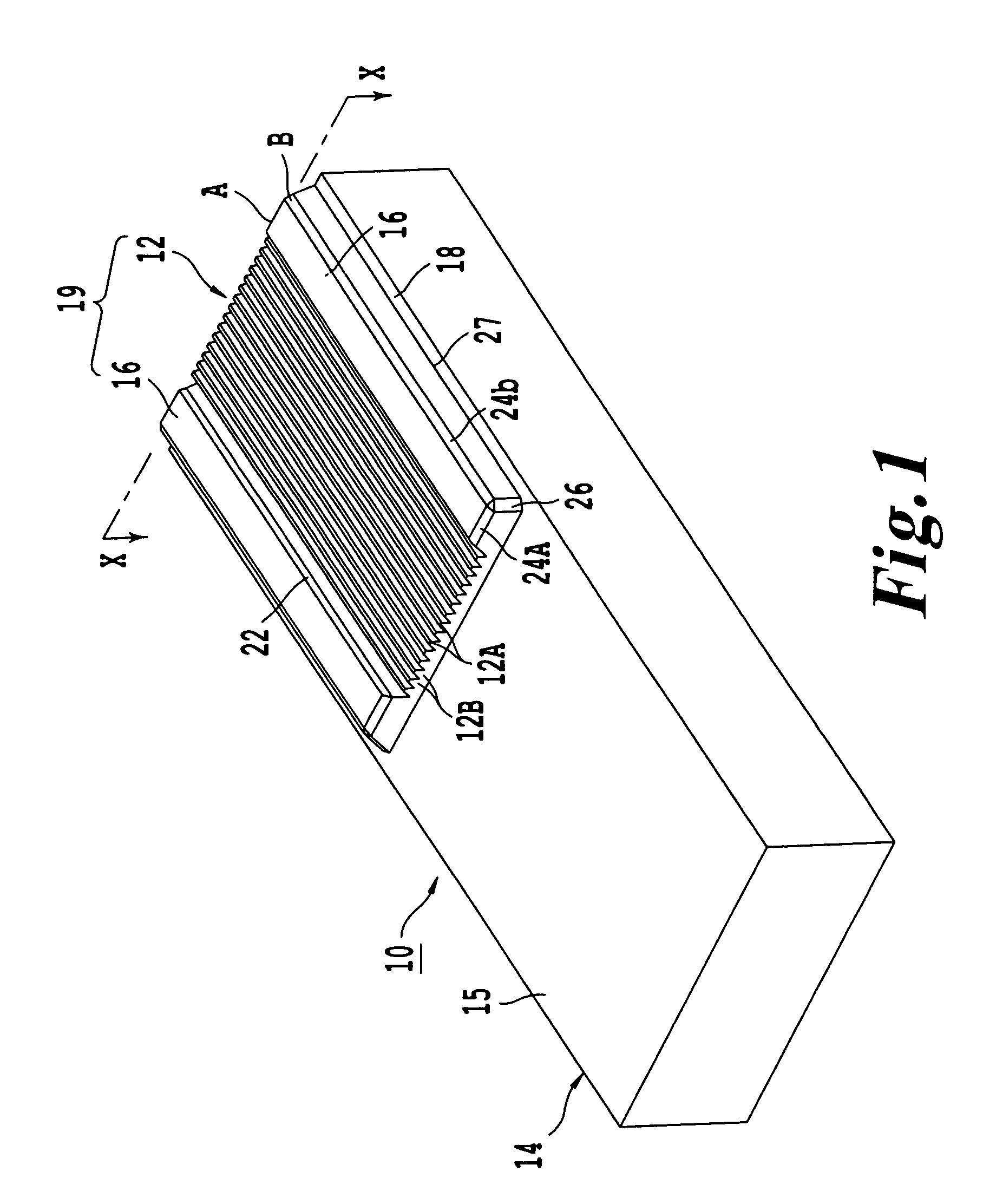

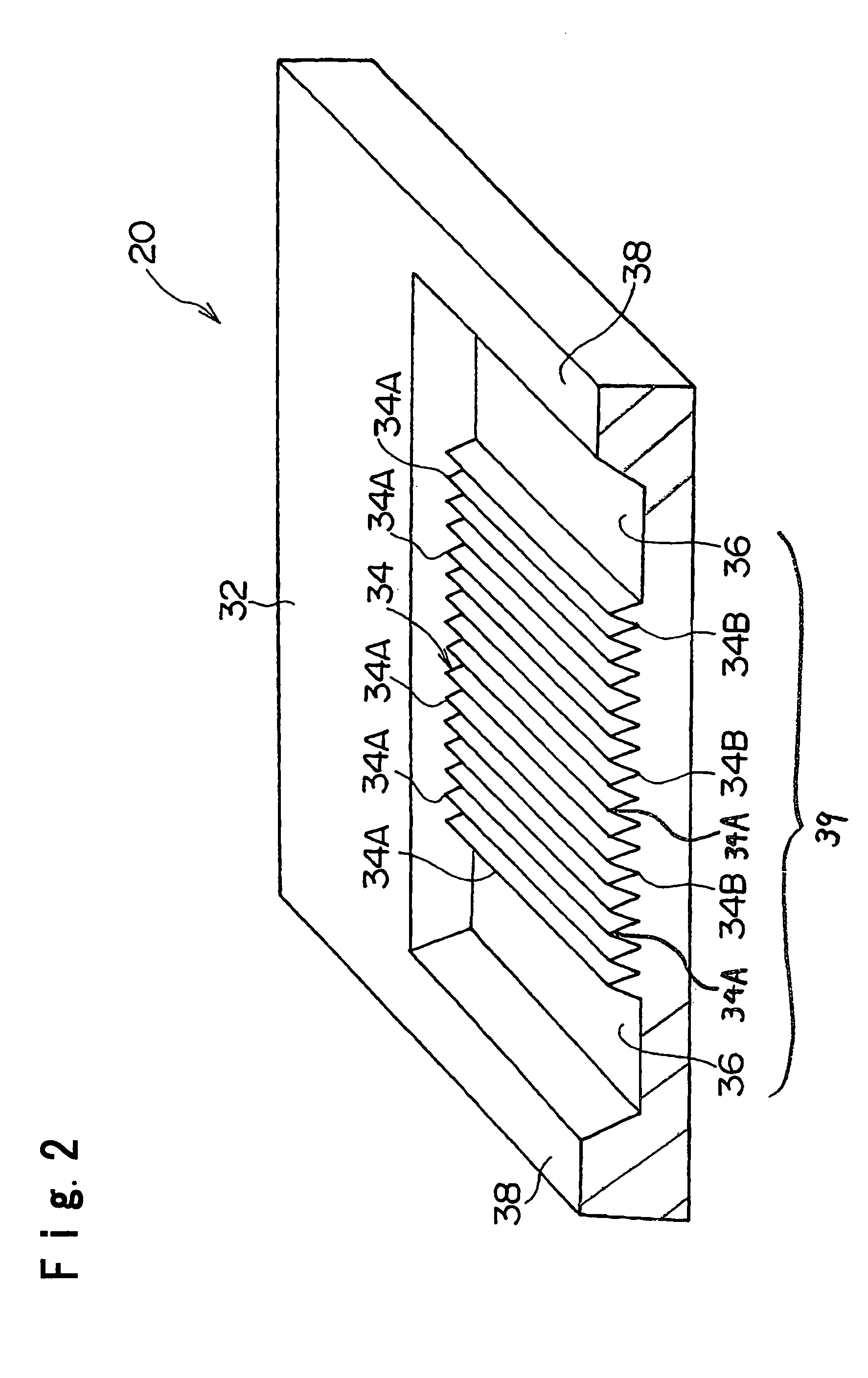

Tire cord and pneumatic tire including the same

InactiveCN101922071AGood molding precisionTensile modulus changeMotorcycle tyresPneumatic tyre reinforcementsAramidesEngineering

Owner:SUMITOMO RUBBER IND LTD

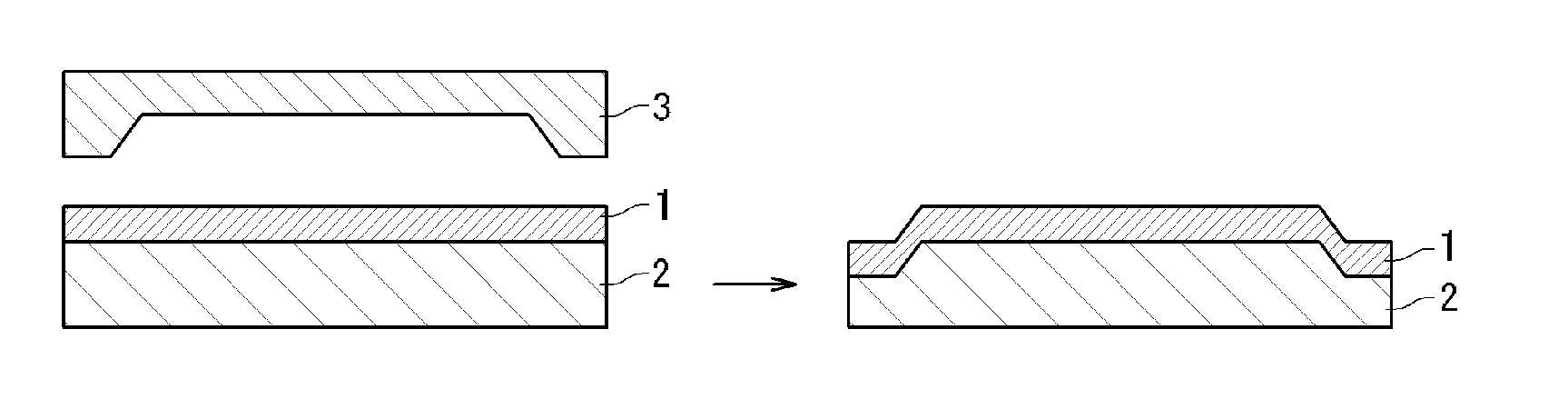

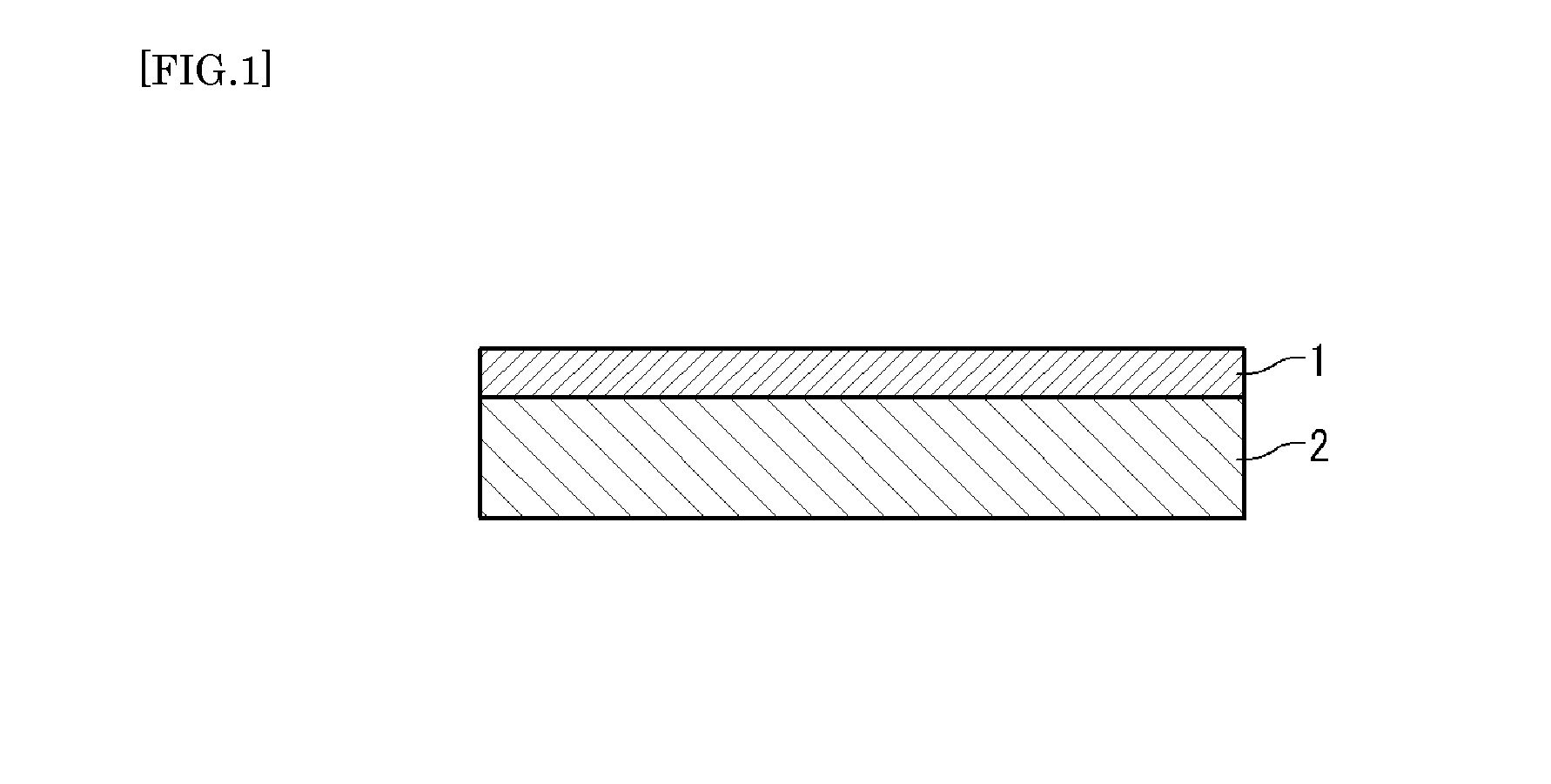

Molding material

InactiveUS20140221568A1Good molding precisionSuitable for useSynthetic resin layered productsOptical elementsEmulsionAcrylic resin

Provision of a molding material excellent in molding accuracy without using a silicone resin and suitable for use in producing a molded body having high hardness and excellent appearance; a resin film formed from the molding material; a molded body obtained by using the molding material as a starting material; and a method for producing the molded body. A molding material used as a starting material in producing a molded body, containing a (meth)acrylic resin emulsion, a polyfunctional (meth)acrylic acid ester and a polymerization initiator; a resin film formed from the molding material; a molded body including a substrate and a molding material layer formed on the substrate wherein the molding material layer is formed from the molding material; and a method for producing the molded body.

Owner:NIPPON SHOKUBAI CO LTD

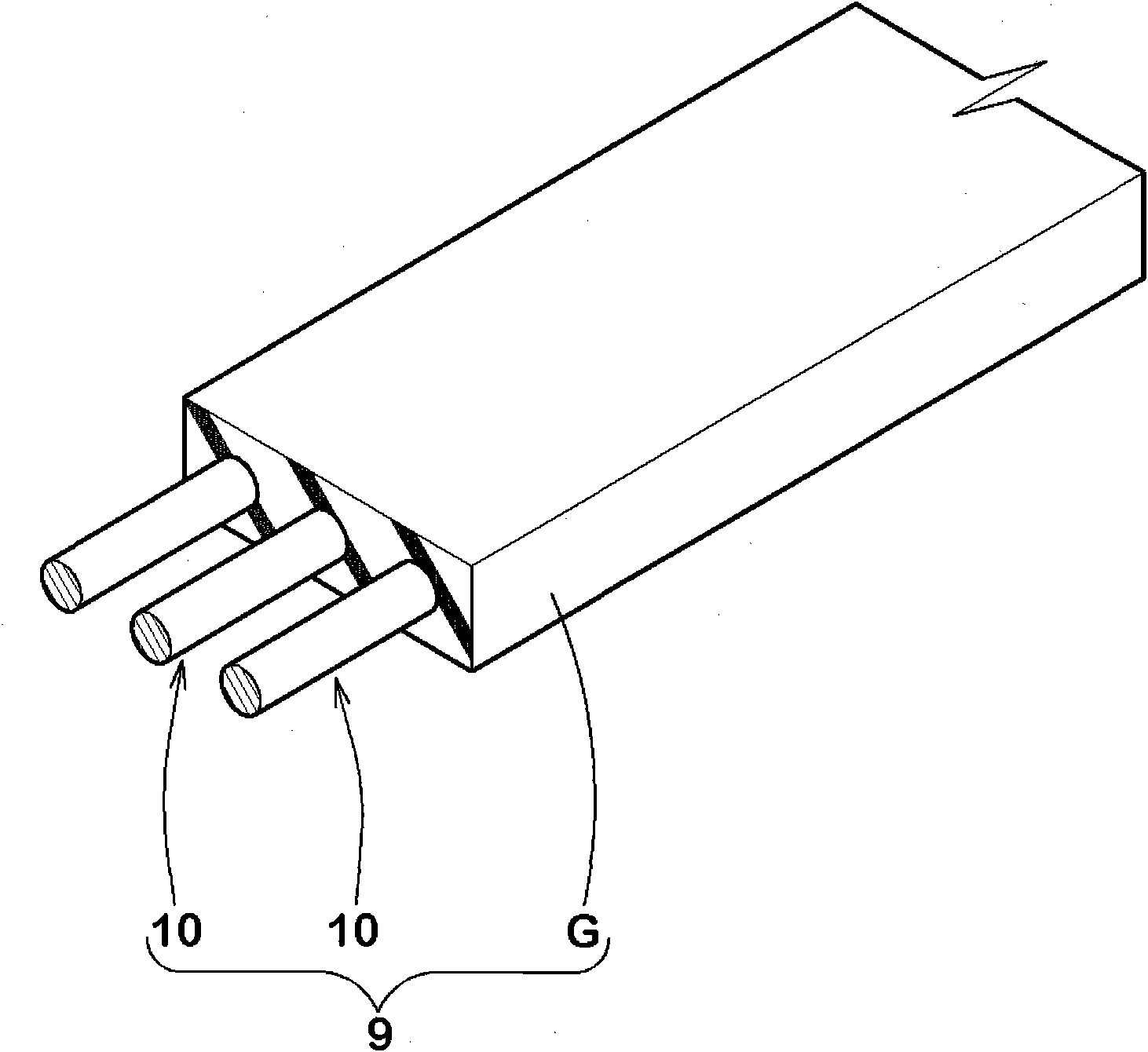

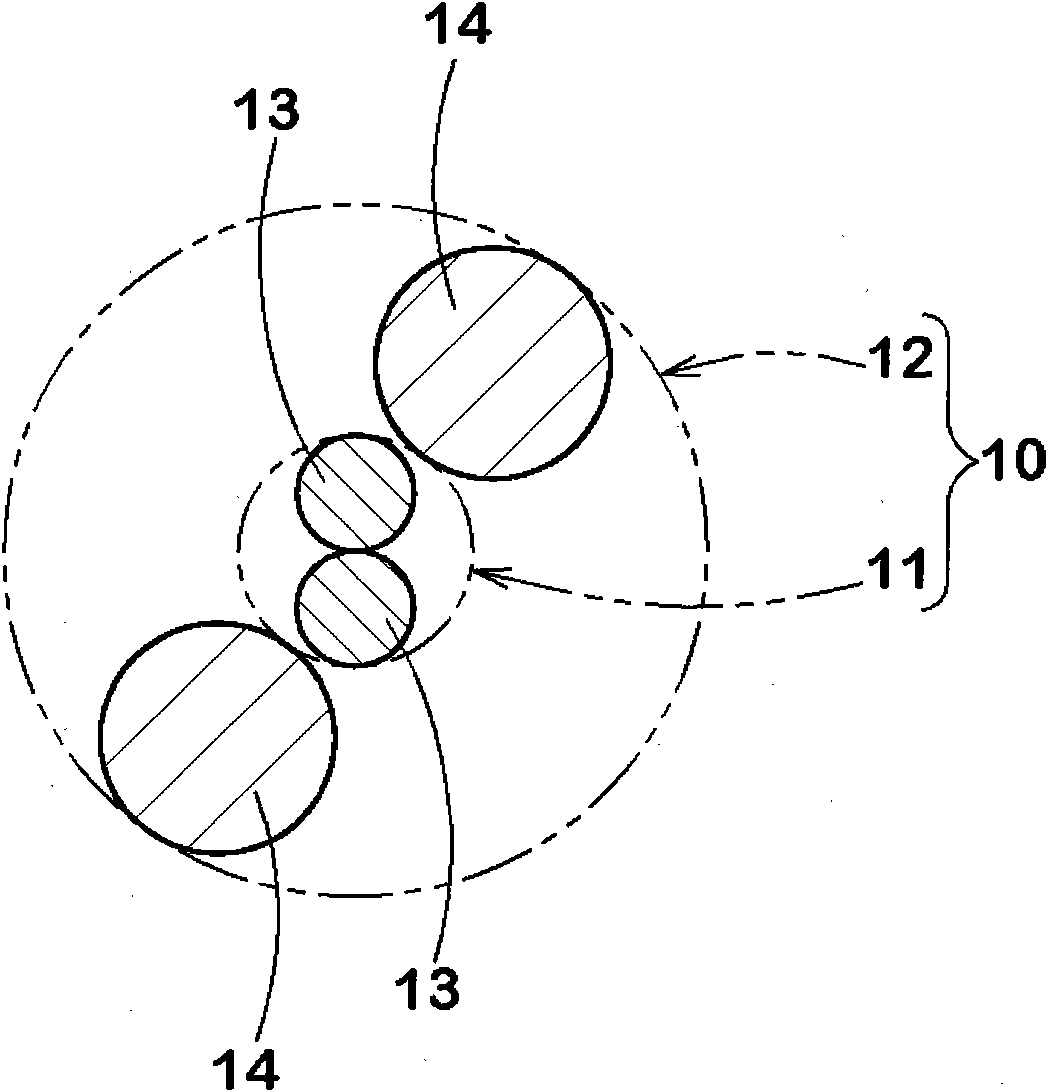

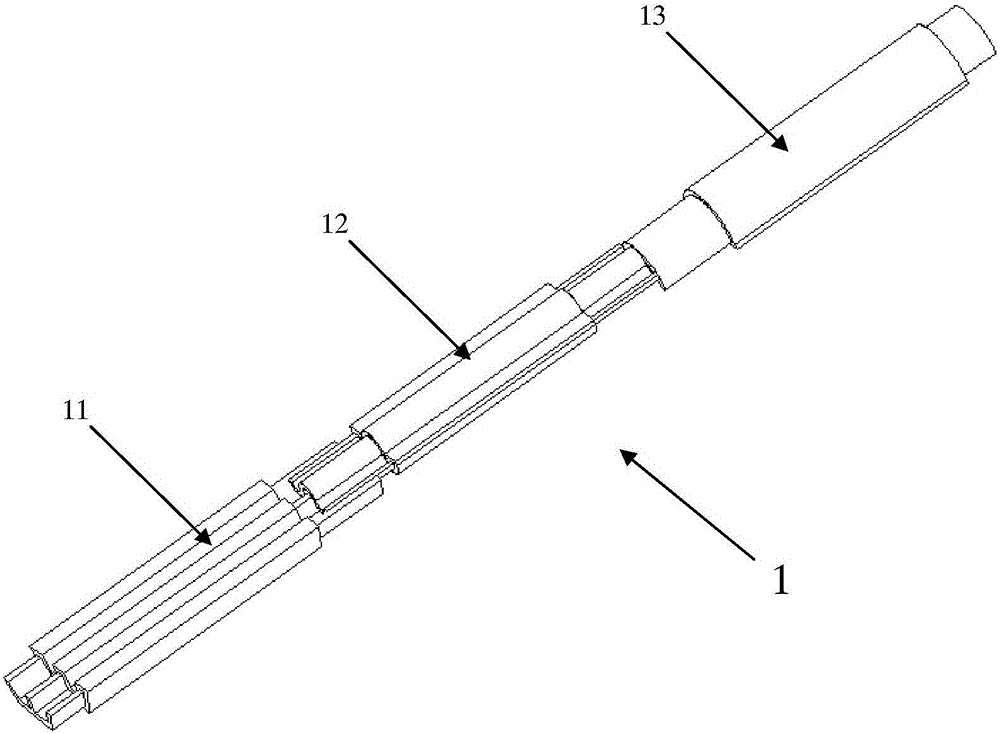

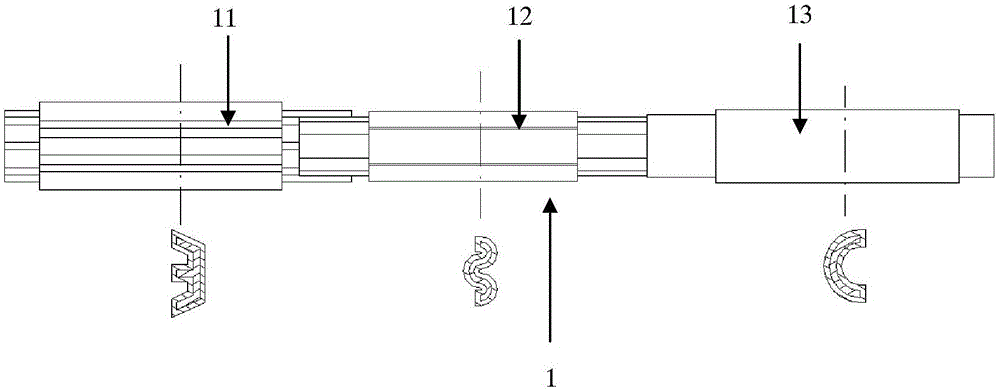

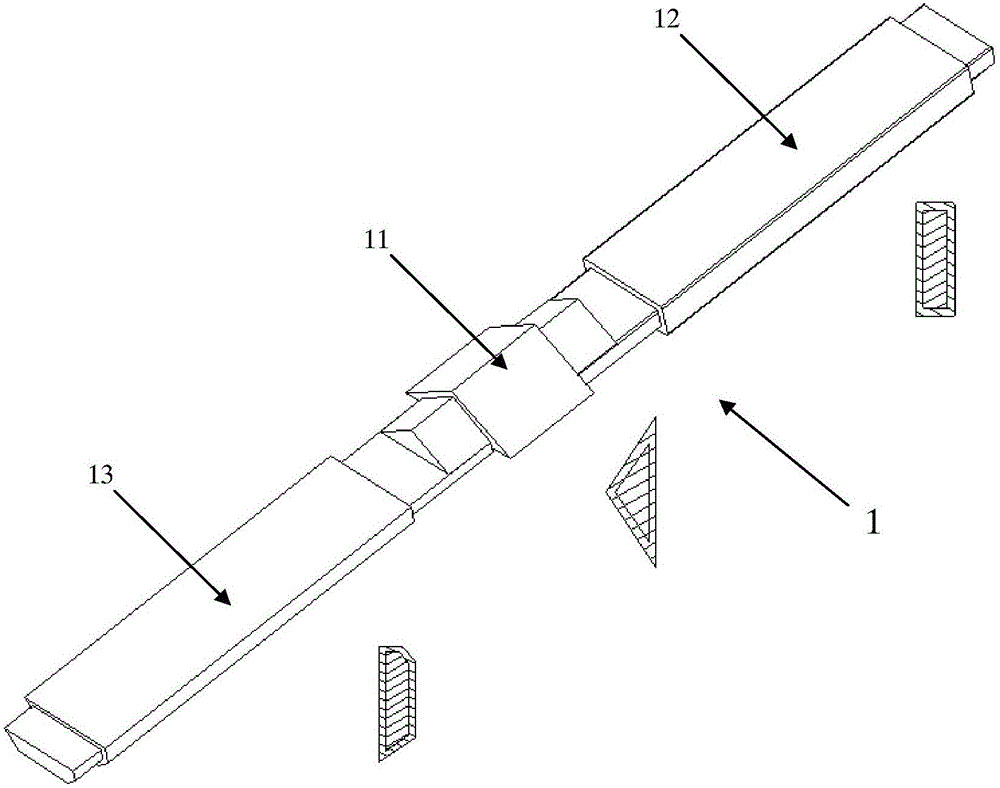

Special-shaped cable and preparation method thereof

ActiveCN106653163ADoes not affect operationReduced eddy current effectDetails of conductive coresManufacturing wire harnessesAbnormal shapedConsumables

The invention discloses a special-shaped cable and a preparation method thereof. The conductive core of the special-shaped cable is composed of at least two conductive core segments in an end-to-end way, wherein the cross sections of the conductive core segments are different in shape. The conductive core segments are externally wrapped by an insulating layer. The contour of the insulating layer is fit with the conductive core segments. The cable has great bending performance and can also be greatly fit with a vehicle body so that consumables can be saved and the safety performance can be greatly enhanced. The cable is made of the aluminum or aluminum alloy conductive cores so that the vehicle body is enabled to be light-weighted, and the production cost of the motor vehicle can be reduced. The preparation method of the special-shaped cable comprises the steps of manufacturing the conductive core segments, connection of the conductive core segments and manufacturing of the insulating layer so that the production efficiency and the productivity can be effectively enhanced according to different production requirements and the production cost can be reduced.

Owner:长春捷翼汽车科技股份有限公司

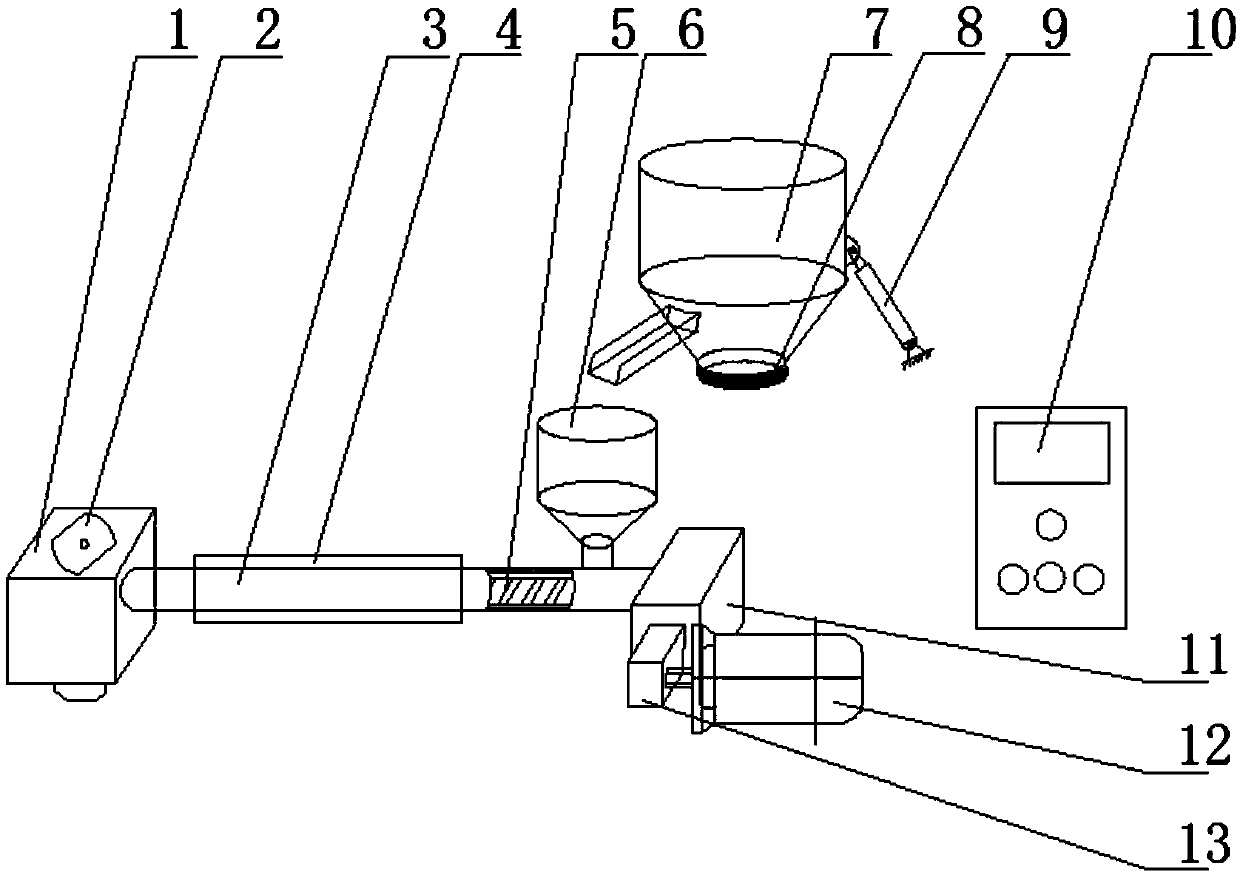

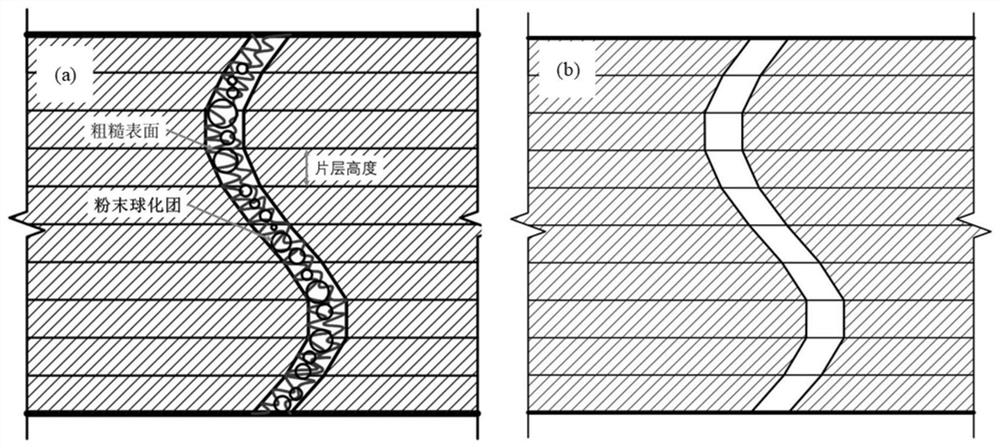

Fiber enhanced composite material annularly coated printing nozzle

ActiveCN109551762AStable quantitative deliveryMonitor quality in real timeManufacturing data aquisition/processingAdditive mnaufacturing with solid and fluidPorosityFiber-reinforced composite

The invention relates to the technical field of 3D printing and provides a fiber enhanced composite material annularly coated printing nozzle. The fiber enhanced composite material annularly coated printing nozzle comprises a feeding part, an extruding mechanism, an impregnating cavity, an annularly coated nozzle and a measuring and controlling part, wherein the feeding part is primarily used forproviding a resin material quantitively at a constant speed and the lower end of the feeding part is connected to the extruding mechanism; the resin is extruded at the constant speed under the actionof a heating ring and a screw to enter the impregnating cavity; in the impregnating cavity, the resin and the fibers are mixed and are extruded and formed through the annularly coated nozzle. The bottom end of the annularly coated nozzle is of a planar structure. The formed surface can be compacted after the composite material is formed, so that the inner porosity is reduced, and the laminar bonding effect is improved. In the printing process, a plurality of temperature and pressure parameters need to be collected and controlled. The printing nozzle mixes the resin and the fibers quickly and efficiently on the one hand, and compacts and prints the resin and the fibers on the other hand, so that the mechanical property of a formed part can be improved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Method of preparing high-temperature nickel-based alloy porous material by 3DP (three-dimensional printing) and aftertreatment process

ActiveCN109807320AMeet the needs of different purposesLow costAdditive manufacturing apparatusPore distributionPolyvinyl alcohol

The invention discloses a method of preparing a high-temperature nickel-based alloy porous material by 3DP (three-dimensional printing) and an aftertreatment process. The method comprises the following steps of: step A. mixing powder, to be specific, fully mixing a certain proportion of metal powder such as Ni, Cr, and Fe with polyvinyl alcohol powder; step B. carrying out macroscopic direct pore-forming, to be specific, designing a three-dimensional model being of a porous structure by three-dimensional design software according to the appearance feature, porosity, pore distribution law and pore shape and size design requirements of the porous material; step C. preparing the porous material by 3DP, to be specific, 3DP equipment receives a printing program, and sets printing parameters tostart printing; step D. removing residual powder, to be specific, firstly taking out a rough blank from a powder stack, and then removing the residual powder on the rough blank; step E. debonding andatmosphere sintering treatment, to be specific, sending the rough blank to a muffle surface for debonding and atmosphere sintering; step F. carrying out electrochemical corrosion, to be specific, carrying out electrochemical corrosion treatment on the sintered nickel-based porous material; step G. carrying out cryogenic treatment, to be specific, putting a workpiece in a cryogenic device for cryogenic treatment; and step H. completing the preparation and aftertreatment of the high-temperature nickel-based alloy porous material.

Owner:NANTONG INST OF TECH

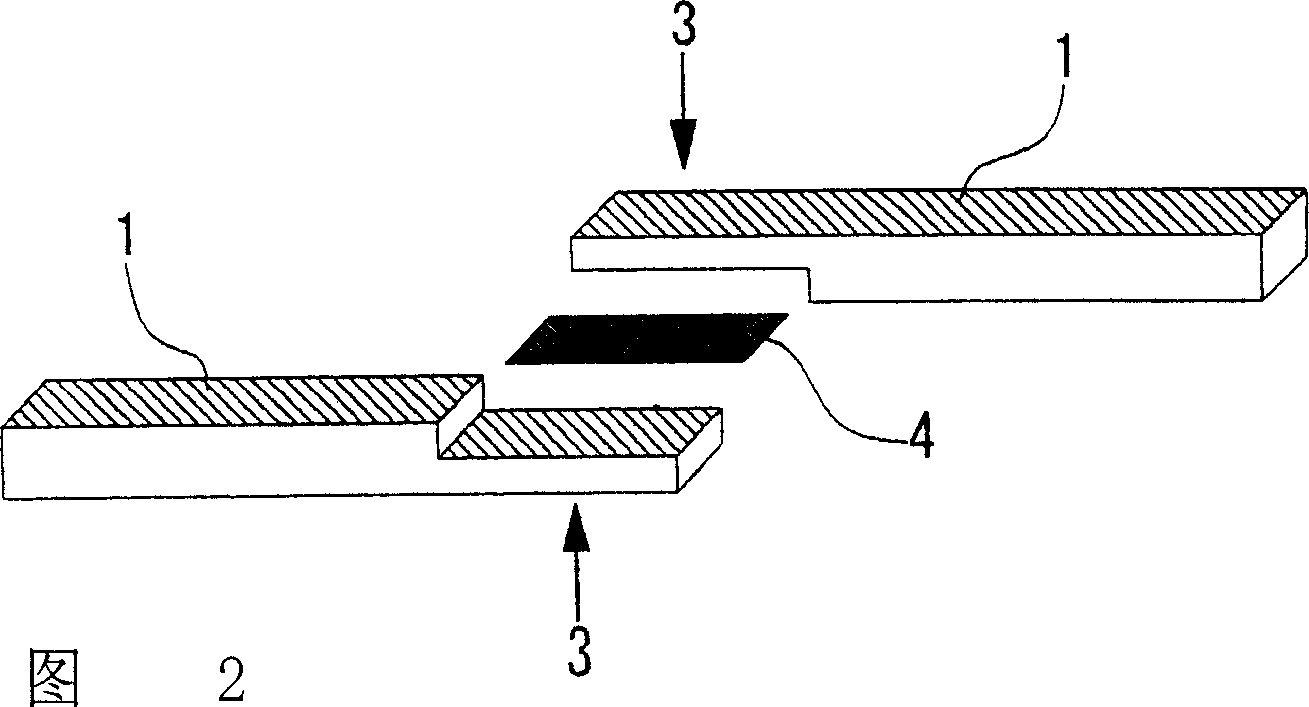

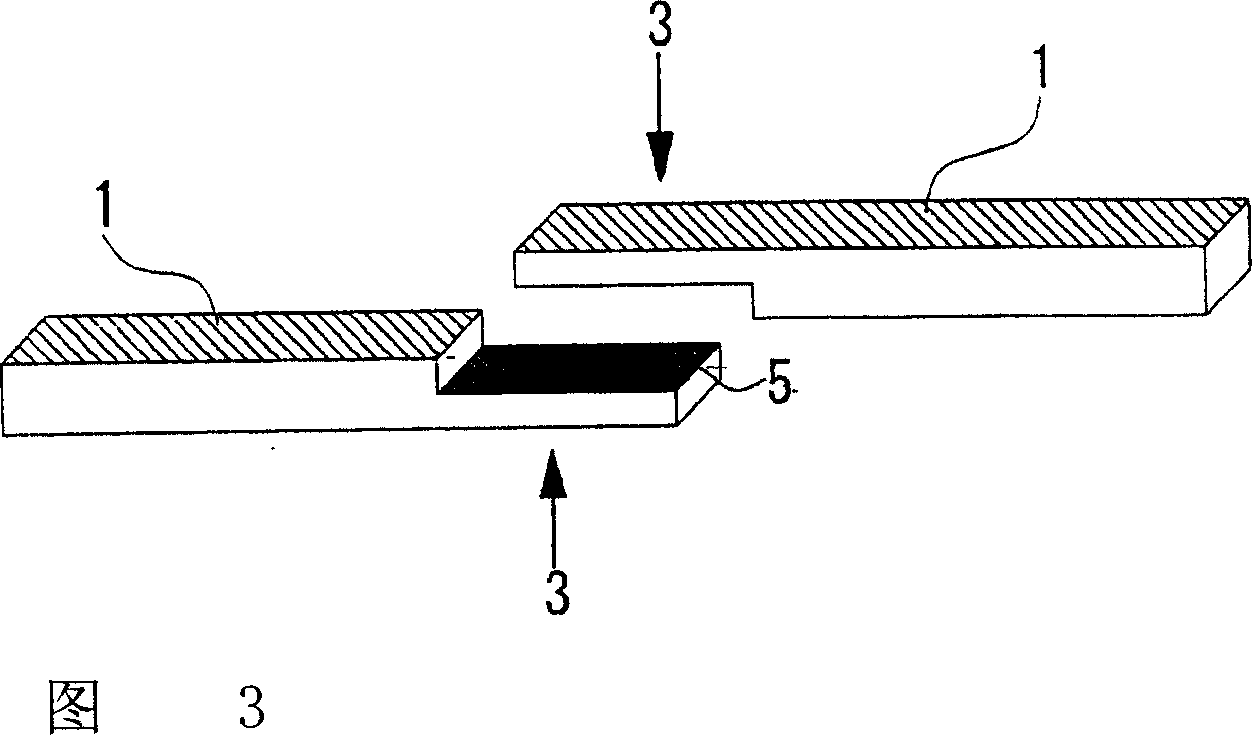

Laser ray transmitting colored resin composition and related art

InactiveUS20070044907A1Good molding precisionGood lookingLamination ancillary operationsLaminationHeat resistanceLaser

A laser ray transmitting colored resin composition is formed of polyphenylene sulfide resin and a colorant having an endothermic peak between 200° C. and 300° C. as determined by TG / DTA thermal analysis. The difference TC-TN between the crystallization point TC of the laser ray transmitting colored resin composition and the crystallization point TN of the same composition as the composition except for not containing the aforementioned colorant, is not less than 0° C. as determined by DSC thermal analysis. The laser ray transmitting material is made of the laser ray transmitting colored resin composition, and has one exothermic energy peak and one endothermic energy peak as determined by DSC thermal analysis. The laser ray transmitting colored resin composition is excellent in molding accuracy, good in molded product appearance and gloss, capable of preventing or effectively reducing the gap between the materials to be welded in the case of a molded product used for laser welding, and good in heat resistance and fastness. The laser ray transmitting material is excellent in dimension stability and shape stability and capable of preventing or effectively reducing the gap between the materials to be welded when used for laser welding.

Owner:ORIENT CHEM INDS

Preparation method of laser 3D-printed complex-configuration silicon carbide composite part

ActiveCN112624777AImprove performanceSave on high costsAdditive manufacturing apparatusCarbide siliconFiber

The invention discloses a preparation method of a laser 3D-printed complex-configuration silicon carbide composite part. The preparation method comprises the following steps that (1) preparing composite raw powder for laser 3D printing, wherein the composite raw powder comprises, by volume percent, 10-70% of chopped carbon fibers, 20-70% of silicon carbide, 20-50% of organic resin with a carbon residue rate larger than 35%, and 5-20% of carbon black; (2) molding the composite raw powder into a silicon carbide composite biscuit with a complex configuration by adopting a laser 3D printing method; (3) degreasing the biscuit in a vacuum atmosphere to crack and carbonize the organic resin and form a degreased biscuit completely composed of inorganic matters; and (4) carrying out liquid-phase reaction siliconizing on the degreased biscuit in a vacuum environment to obtain the laser 3D-printed complex-configuration silicon carbide composite part.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

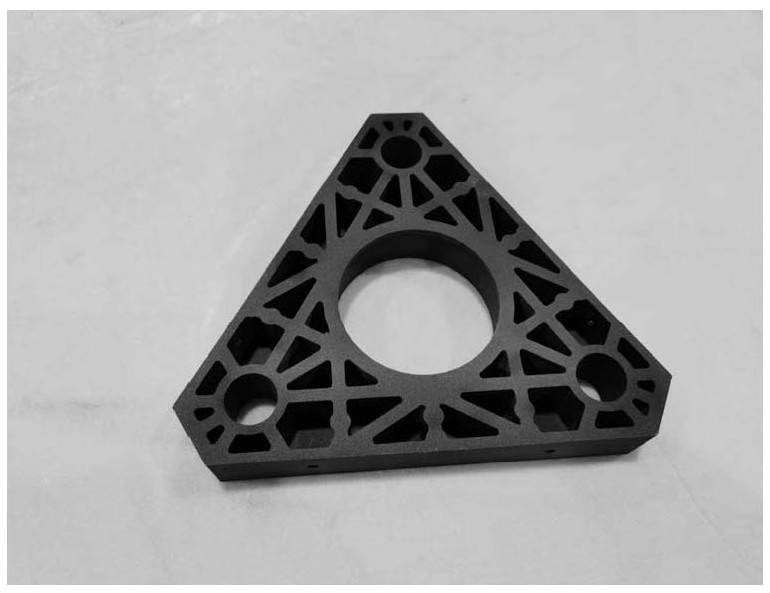

Bracket for Protecting Liquid Crystal Display (LCD) of Portable Display Device

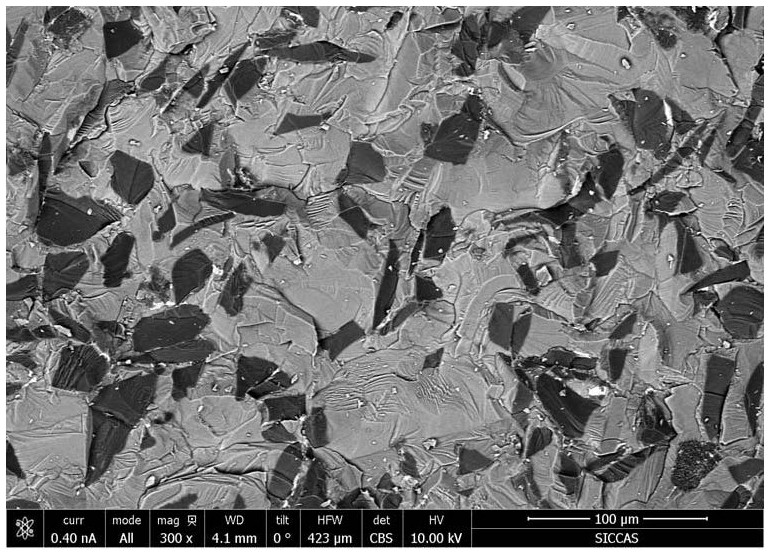

InactiveUS20130165576A1High modulusLow moisture absorptionSpecial tyresCeramic shaping apparatusFiberLiquid-crystal display

A bracket for protecting the liquid crystal display (LCD) of a portable display device comprises (A) a polyamide resin, and (B) a carbon fiber, wherein the ratio of (A):(B) of the (A) polyamide resin and the (B) carbon fiber is about 20 to about 40 wt %: about 60 to about 80 wt %, and the (A) polyamide resin comprises (a1) an aromatic polyamide and (a2) an aliphatic polyamide including a C10 to C20 aliphatic group.

Owner:CHEIL IND INC

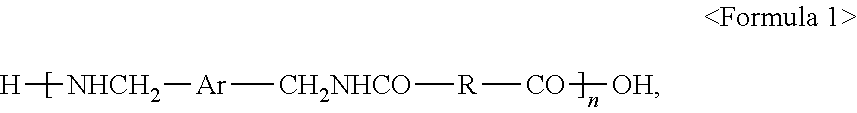

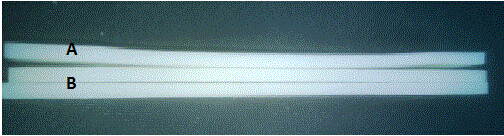

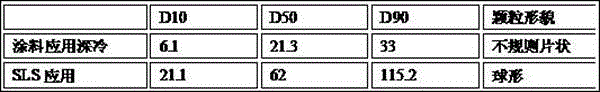

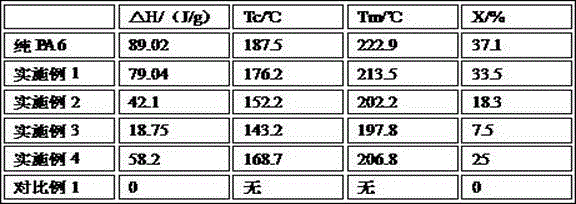

Low-melting-point and low-crystallinity nylon 6 powder for SLS (Selective Laser Sintering) and preparation method of nylon 6 powder

The invention relates to the technical field of nylon materials for SLS (Selective Laser Sintering), in particular to low-melting-point and low-crystallinity nylon 6 powder for SLS and a preparation method of the nylon 6 powder. The nylon 6 powder is prepared from the following raw materials in parts by weight: 93-98 parts of nylon 6 granules, 7-2 parts of metal ion salt and 0.4-1 part of aids. The preparation method comprises steps as follows: step one, the nylon 6 granules and the metal ion salt powder are weighed in parts by weight, dried, mixed uniformly and extruded and granulated with a double-screw extruder, the rotating speed of screws is 150-170 r / min, and the temperature is controlled to be 200-250 DEG C; step two, the granules obtained in the step one are smashed and sieved, and powdery granules with diameter being 20-120 mu m are obtained; step three, the powdery granules obtained in the step two and the aids are uniformly mixed in proportion and sieved , and the nylon 6 powder with diameter being 20-120 mu m is obtained. The nylon 6 powder has lower melting point and lower crystallinity, and a product obtained through SLS has a good overall forming effect and high size precision.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD +1

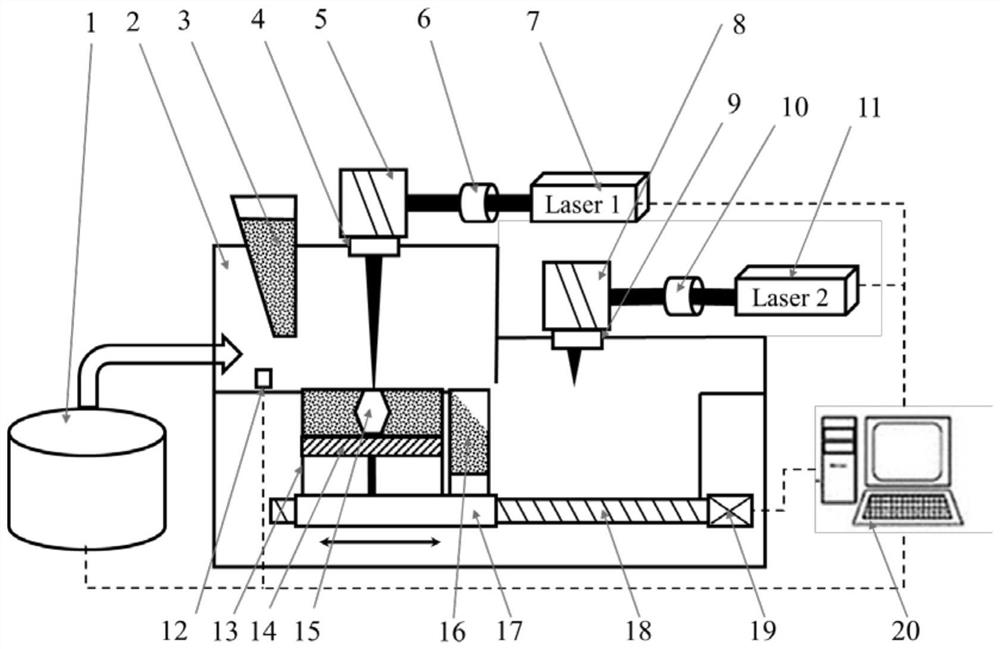

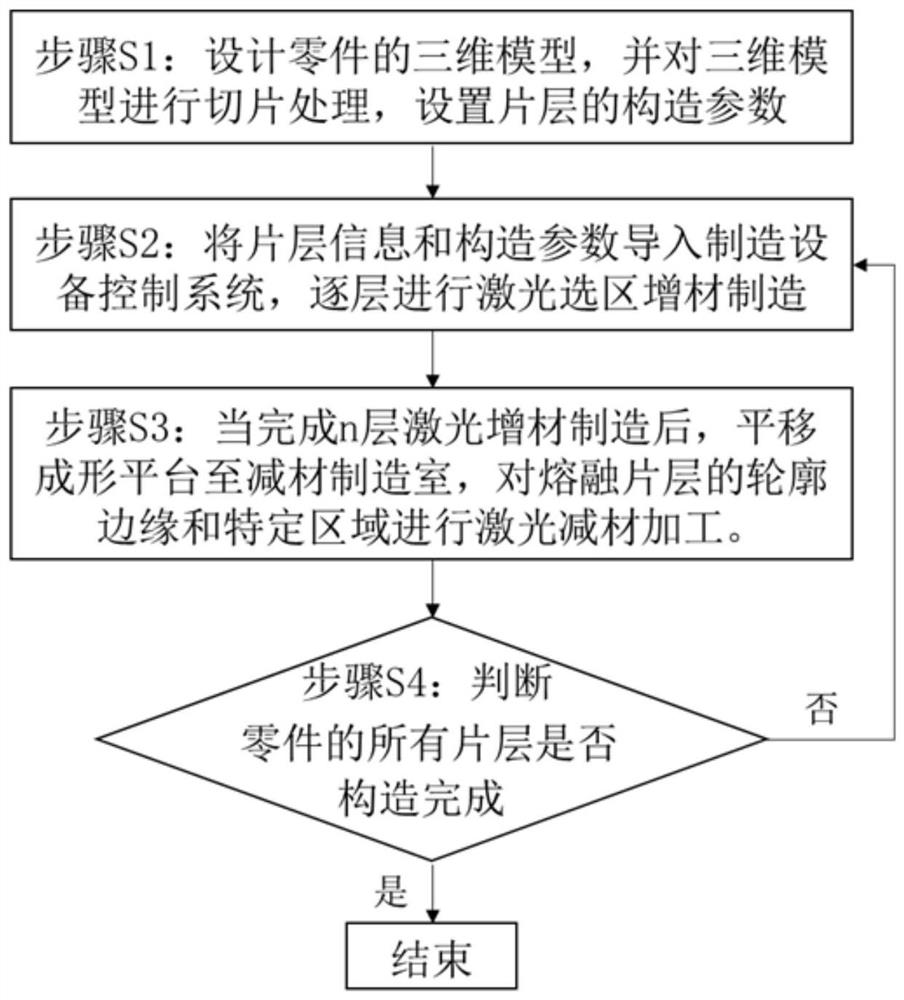

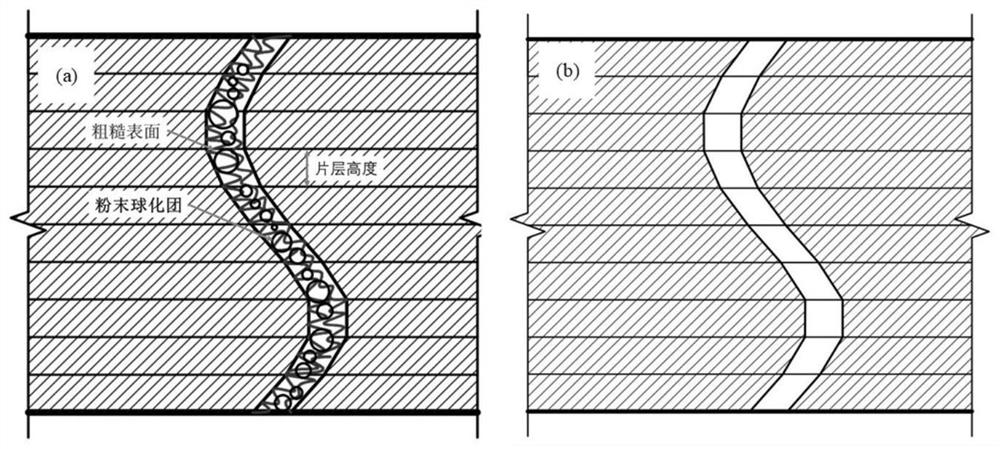

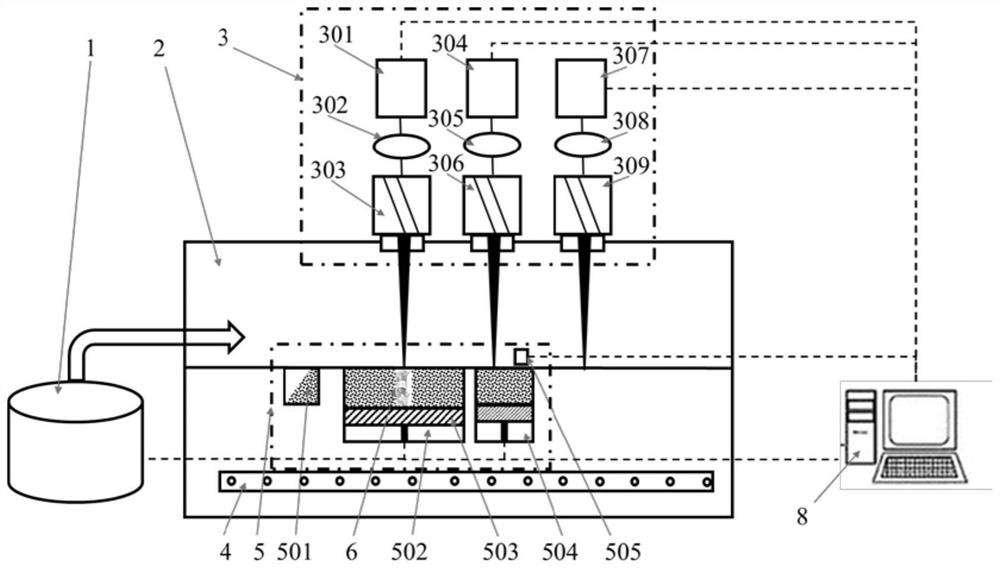

High-precision laser additive and subtractive material combined manufacturing device

PendingCN111992877AEfficient removalEliminate the step effectAdditive manufacturing apparatusIncreasing energy efficiencyElectric machineryLaser light

The invention discloses a high-precision laser additive and subtractive material combined manufacturing device. The device comprises a sealed forming chamber, an inert protective gas source and a machining forming platform. The inert protective gas source is connected with the sealed forming chamber. The machining forming platform is arranged in the sealed forming chamber, and a light path selection system is arranged over the machining forming platform. A machining station is arranged on the machining forming platform, a lead screw is arranged at the bottom of the machining forming platform,the machining forming platform is fixed to a sliding block of the lead screw, the lead screw is connected with a lead screw motor, and the machining forming platform can be driven by the lead screw motor to slide forwards and backwards on the lead screw. The light path selection system comprises an additive material independent laser light path and a subtractive material independent laser light path. The additive material independent laser light path and the subtractive material independent laser light path are parallel to each other, are arranged in the direction of the lead screw and do notshare equipment. According to the device, the laser additive and subtractive material technology is integrated, the forming precision, the surface quality, the structure performance and the residual stress state of a complex fine additive workpiece are improved, and one-stop high-efficiency high-precision and high-performance additive workpiece manufacturing operation is achieved.

Owner:SHANGHAI UNIV OF ENG SCI

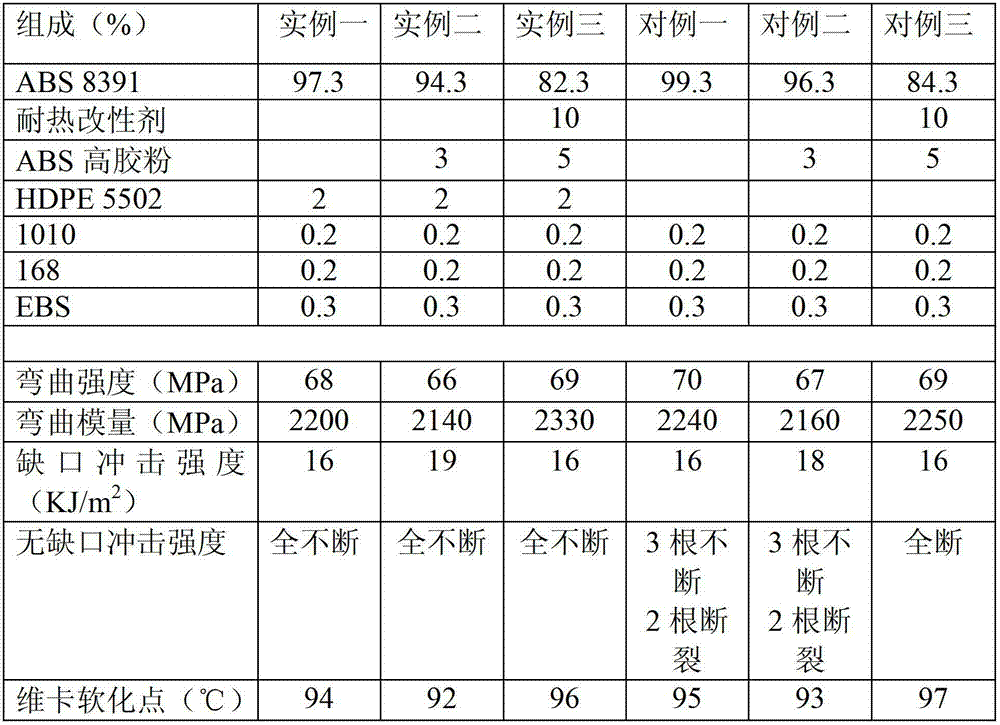

ABS (acrylonitrile butadiene styrene) composite material for automobile and preparation method thereof

InactiveCN102863733AGood heat resistance and unnotched impact performanceSimple processing technologyHigh-density polyethyleneAcrylonitrile butadiene styrene

The invention relates to the technical field of composite materials for automobiles, in particular to an ABS (acrylonitrile butadiene styrene) composite material for an automobile and a preparation method thereof. By using ABS as a base material and HDPE (high-density polyethylene) as toughening synergist and by adding heat-resistant modifier, ABS high-rubber powder, antioxidant and lubricant, the obtained ABS composite material for the automobile has the advantages of heat resistance, better non-notched impact performance, simple processing technology and high product molding accuracy. Since components such as the heat-resistant modifier, the ABS high-rubber powder, the HDPE, the antioxidant and the lubricant which are used for preparing the ABS composite material for the automobile are commercially available products which are low in cost and easy to obtain, the production cost of the ABS composite material is lower, the market prospect is better and the ABS composite material has a very wide market in fields such as automobile interior and exterior decoration, electronic products and electric appliances.

Owner:江苏安格特新材料科技有限公司 +1

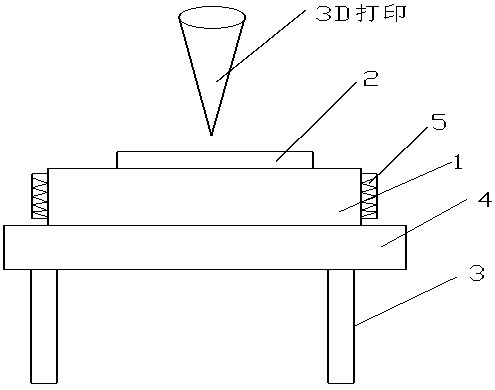

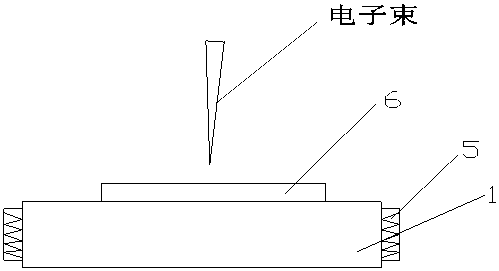

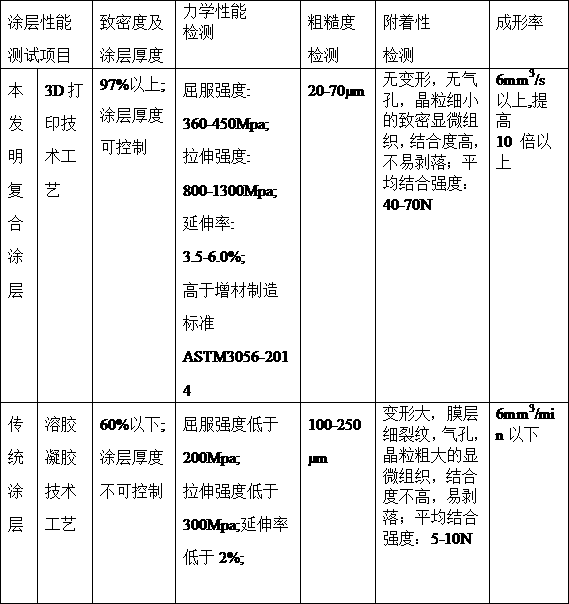

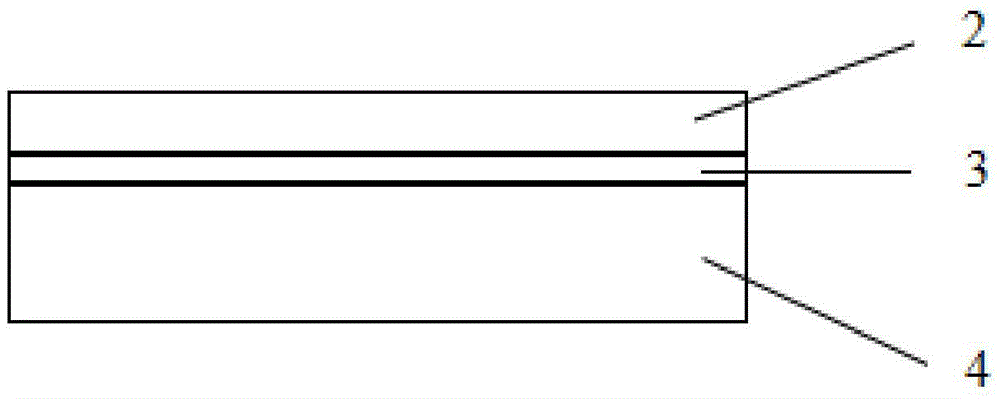

Method for preparing coating by 3D printing overlapping electron beam

InactiveCN110714199AGood molding precisionAvoid low powder utilizationAdditive manufacturing apparatusIncreasing energy efficiencyCermetCeramic composite

The invention relates to a method for preparing a coating by 3D printing overlapping an electron beam. Metal or ceramic powder and metal / ceramic powder are printed on the surface of a base material layer by layer through 3D printing, layer-by-layer printing is carried out by a three-dimensional model according to the set layer thickness, and then the metal or ceramic powder and metal / ceramic powder on the surface of the base material are preheated to form a fusion layer. A heating device used for the preheating includes a high-frequency vibrator and an induction heating coil which are placed on a workbench, the high-frequency vibrator acts on the bottoms of the fusion layer and the base material, the induction heating coil is arranged around the base material for preheating, after preheating is carried out, the fusion layer is melted with the electron beam to form a metal / ceramic. composite coating, and finally the metal / ceramic composite coating is subjected to post-heat treatment through the induction heating coil. The product development cycle is greatly shortened, production rate is improved, and the production cost is reduced.

Owner:FUJIAN UNIV OF TECH

3D printing method of fiber-grade flame retardant product based on reactive extrusion

InactiveCN105818384ABroaden your optionsAchieve stabilityAdditive manufacturing apparatusPolyesterFiber

The invention relates to a 3D printing method of a fiber-grade flame retardant product based on reactive extrusion. According to the 3D printing method, polymerization reaction is performed on a lactam monomer and / or a lactone monomer and an assistant and a plasticizer after fusing under the action of a catalyst, and a flame retardant is added before polymerization or during polymerization to obtain a target polymer; then the target polymer is subjected to fused deposition 3D printing, and then is subjected to thermal treatment, thus obtaining a final product. According to the invention, a high-precision high-adaptation 3D printer is adopted, the forming precision is high, the efficiency is high, the mechanical property of a product is good, and the dispersibility of a functional component is good; and a process of preparing a product directly from a polymeric monomer is adopted, and therefore, the production flexibility is improved, and the conditions of edge warping of nylon, polyester and other semi-crystalline polymers caused by crystallization and large temperature difference, and even failure in printing can be avoided. The method can widen the species of fused deposition 3D printing materials, can improve the quality of products, and is wide in application in the fields of automotive materials, engineering plastics, building materials and the like.

Owner:DONGHUA UNIV

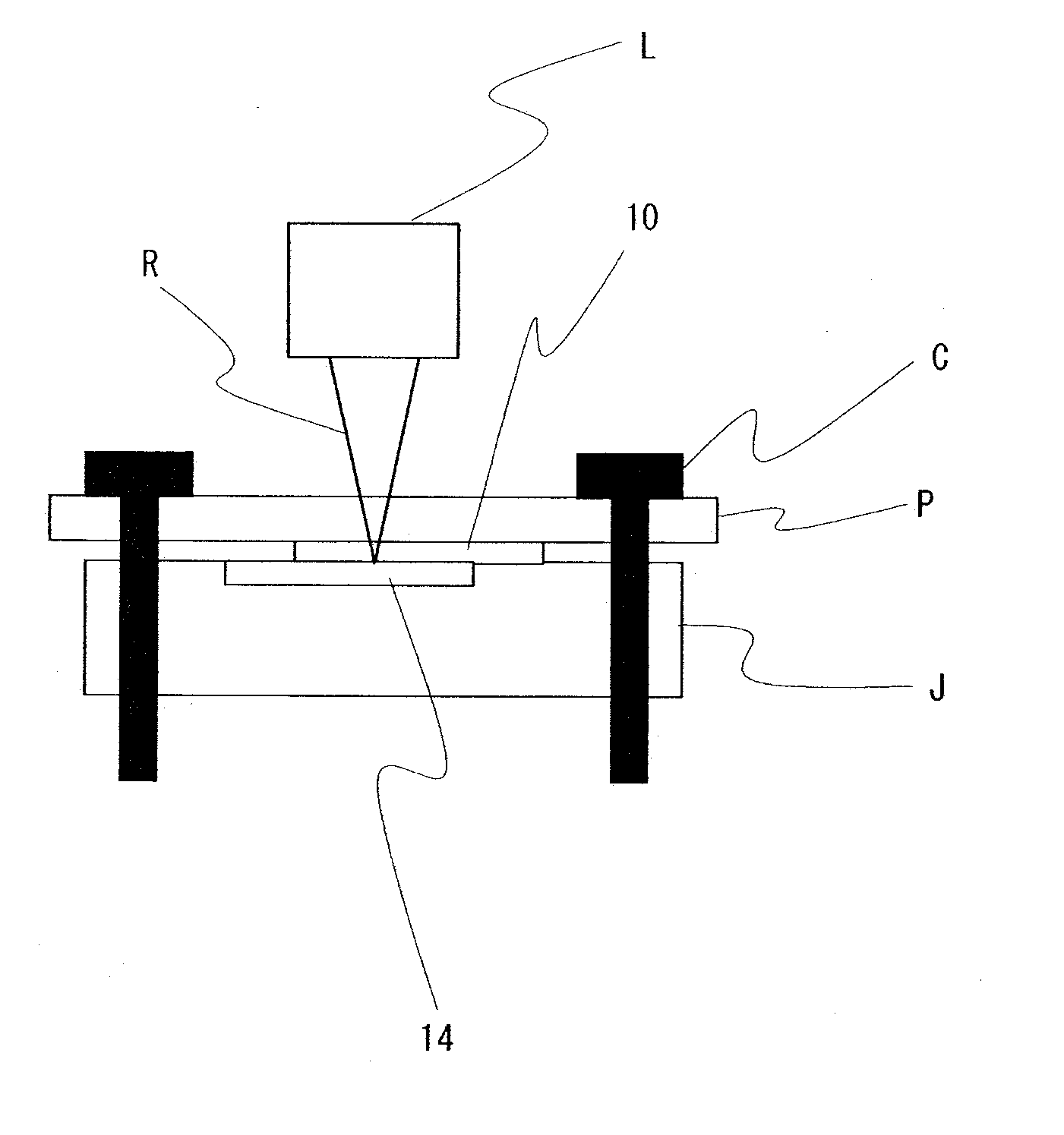

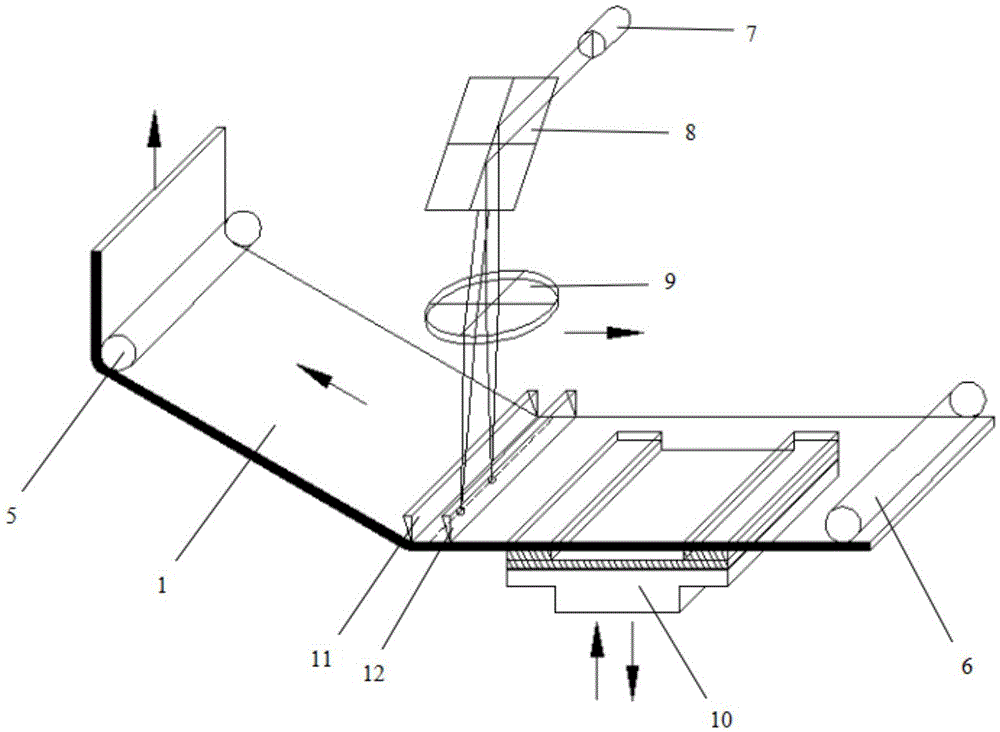

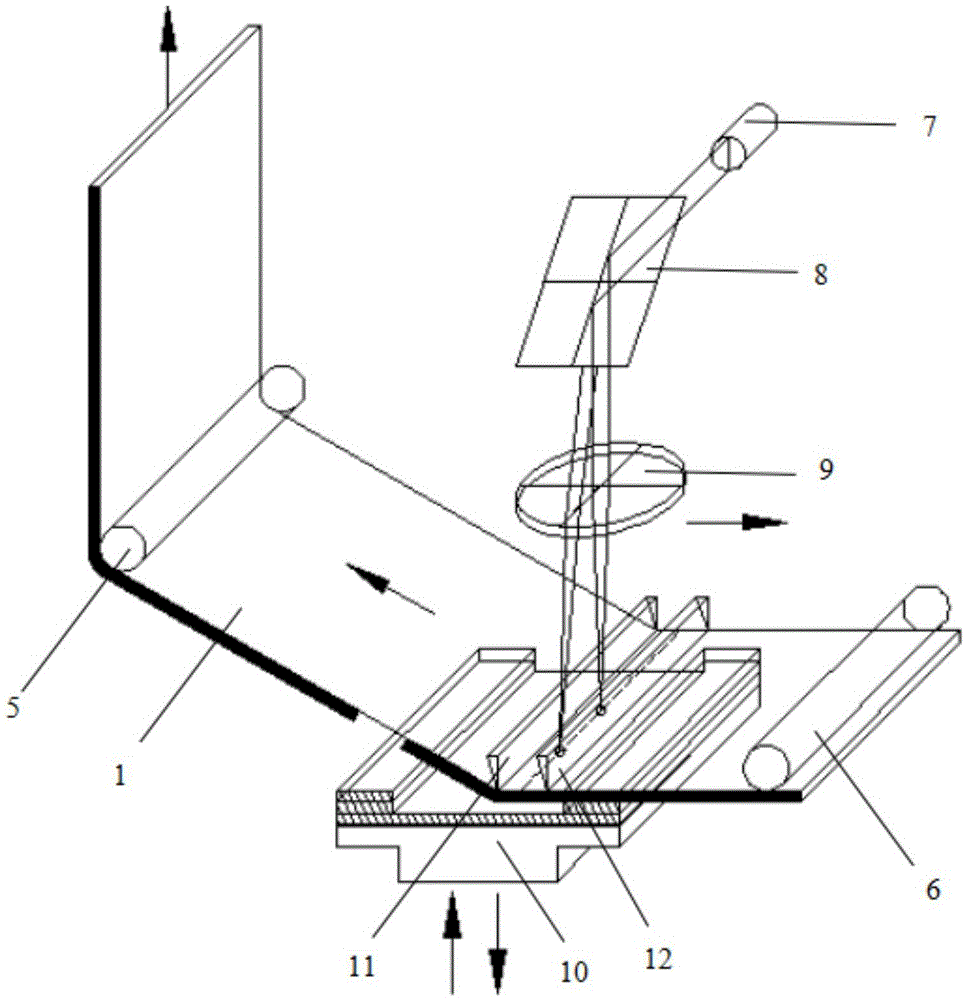

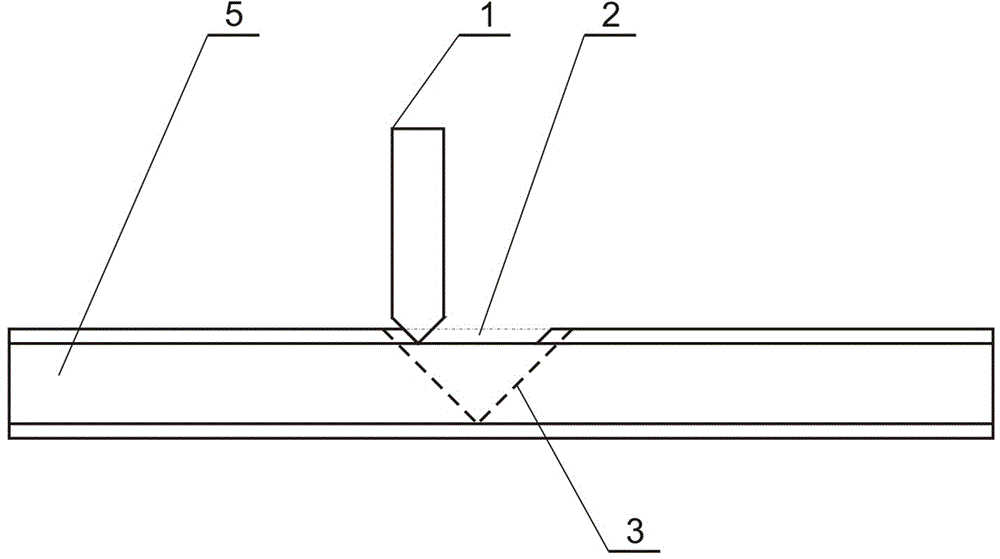

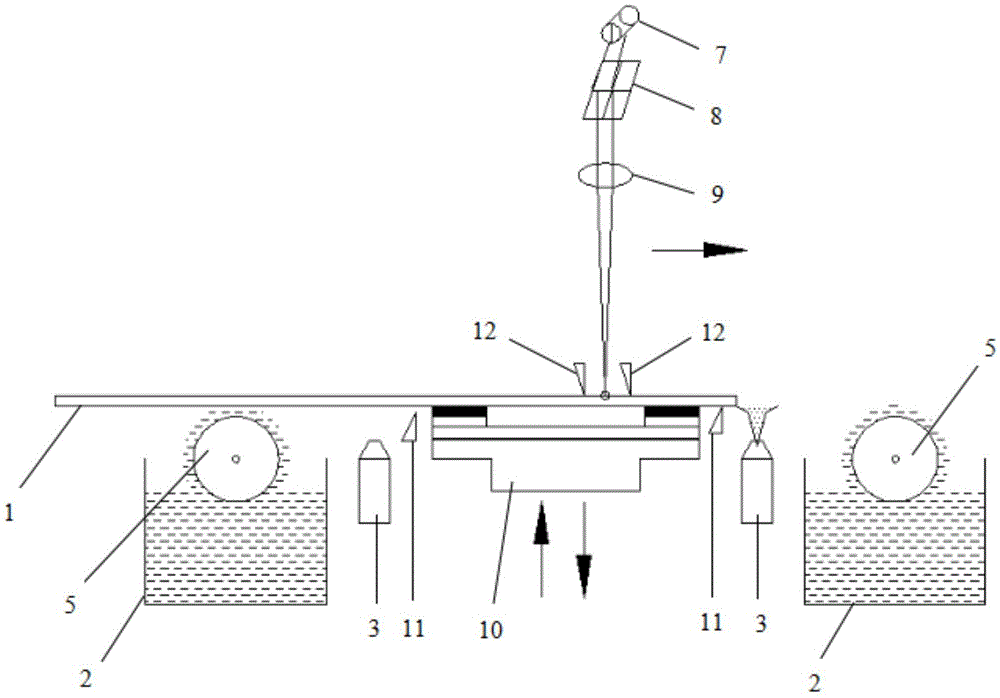

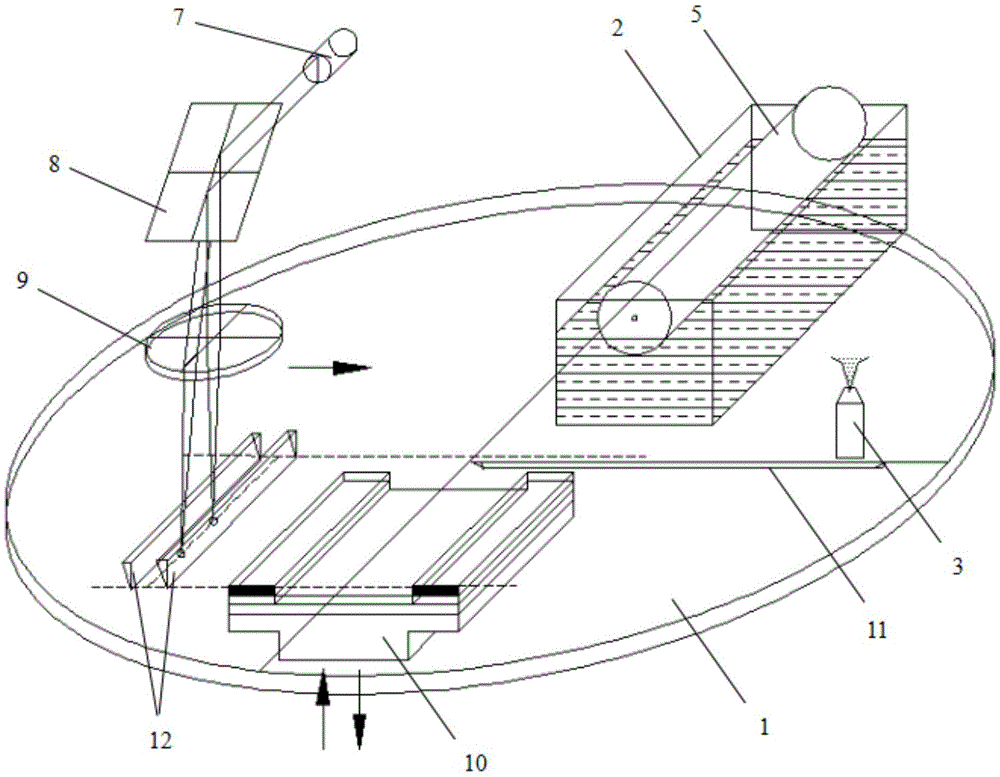

Three-dimensional molding device and method based on film substrate

The invention discloses a three-dimensional molding device and method based on a film substrate. The device comprises a feeding mechanism, an exposure mechanism, a supporting mechanism and a separating mechanism, wherein photosensitive material layers are sent to corresponding exposure areas through the feeding mechanism and then are exposed through the exposure mechanism so that solidification generation of each layer of specific pattern can be achieved, and the patterns on all layers are stacked to form a required part on the supporting mechanism; separation and exposure are conducted synchronously, a film substrate material layer is gradually separated from the top surface of the formed part on the supporting mechanism as the separating mechanism moves rightwards under the action of tension, and unexposed photosensitive material layers are stripped off to the space outside the supporting mechanism at the same time. By conducting exposure and separation synchronously, working efficiency can be improved, and requirements for large breadth, high efficiency, high precision and low cost during three-dimensional entity manufacturing are met.

Owner:SVG TECH GRP CO LTD +1

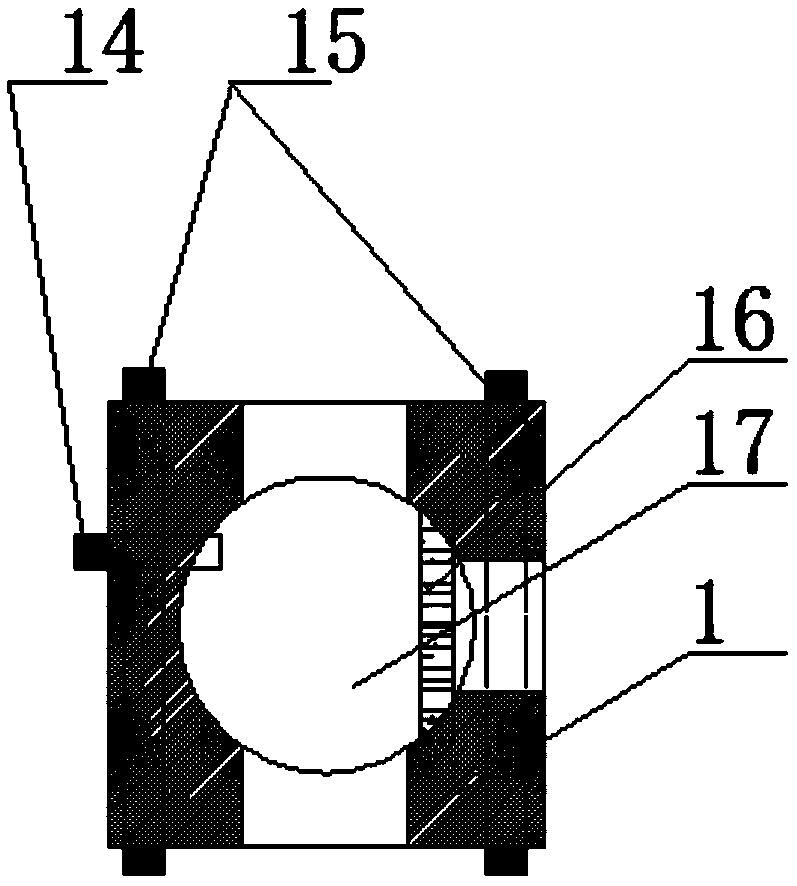

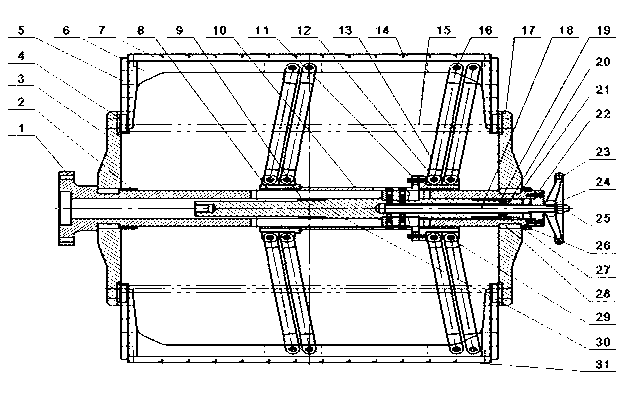

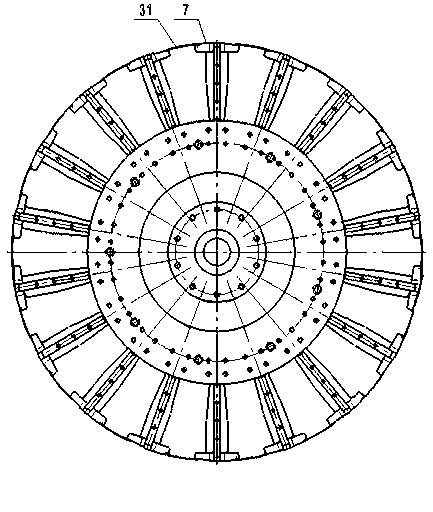

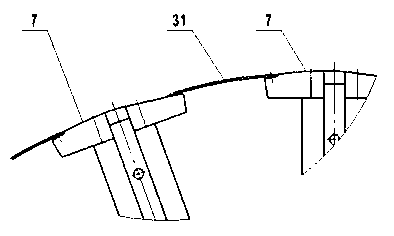

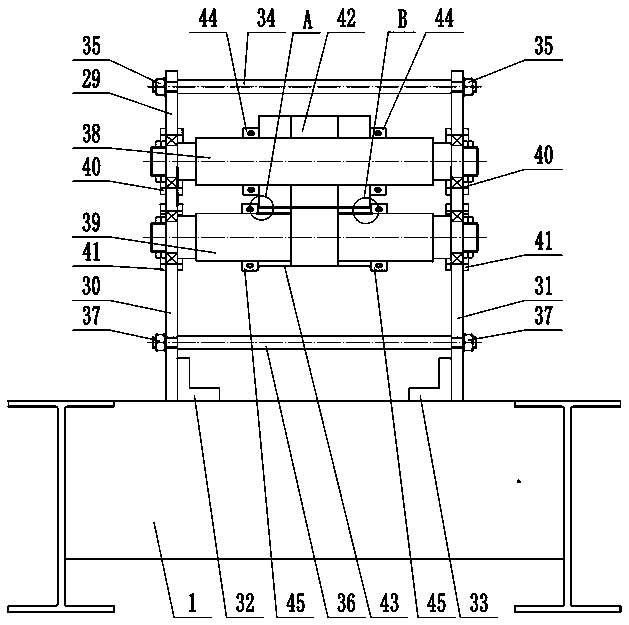

Tire pasting drum with ultra-large expansion and shrinkage ratio

ActiveCN103302881ALarge expansion and contraction ratioWide range of manufacturing specificationsTyresOperations securityEngineering

The invention relates to a tire pasting drum with an ultra-large expansion and shrinkage ratio, which is used for forming a radial tire blank. The pasting drum comprises a power transmission mechanism, a drum tile expansion and shrinkage mechanism and an expanded drum diameter adjustment mechanism, and is characterized in that the drum tile expansion and shrinkage mechanism comprises a driving seat, long connection rods, sliding blocks, main tiles and auxiliary tiles; the driving seat is connected with an inner shaft through connection blocks; the long connection rods are respectively hinged with the driving seat and the sliding blocks through pin shafts; the main tiles are arranged on the sliding blocks; one edge of each auxiliary tile is fixed on the corresponding main tile, and the other edge of each auxiliary tile is hasped onto the adjacent main tile, so that the ultra-large expansion and shrinkage ratio can be obtained, and slits among drum tiles during drum expansion are eliminated; and therefore, the tire manufacturing specification range of equipment is greatly expanded, and the tire blank forming quality is improved; the expanded drum diameter adjustment mechanism is adjusted by a built-in screw; a handwheel rotation screw moves a nut to limit the travel of the inner shaft, so that the aim of adjusting the diameter of an expanded drum is fulfilled; the specification of the pasting drum is convenient to adjust, and the pasting drum is high in operation safety.

Owner:福建建阳龙翔科技开发有限公司

Device conducting composite manufacturing on basis of laser technology

PendingCN111992712AImprove mechanical propertiesImprove the finishAdditive manufacturing apparatusIncreasing energy efficiencyLaser technologyEngineering

The invention discloses a device conducting composite manufacturing on the basis of a laser technology. The device comprises a sealed forming chamber, an inert protective gas source and a machining forming platform. The inert protective gas source is connected with the sealed forming chamber. The machining forming platform is arranged in the sealed forming chamber, and a light path selection system is arranged over the machining forming platform. A machining station is arranged on the machining forming platform, and the machining forming platform is arranged on a guide rail and can slide forwards and backwards through the guide rail. The light path selection system comprises a shock reinforcing independent laser light path, an additive independent laser light path and a subtractive independent laser light path. The light paths are arranged in the direction of the guide rail, and all the independent laser light paths do not share equipment and are arranged over the machining forming platform. According to the device, the laser shock reinforcing technology and the laser additive and subtractive technology are integrated, the forming precision, the surface quality, the organization performance and the residual stress state of a complex fine additive workpiece are improved, and one-stop high-efficiency high-precision and high-performance additive workpiece preparation is achieved.

Owner:SHANGHAI UNIV OF ENG SCI

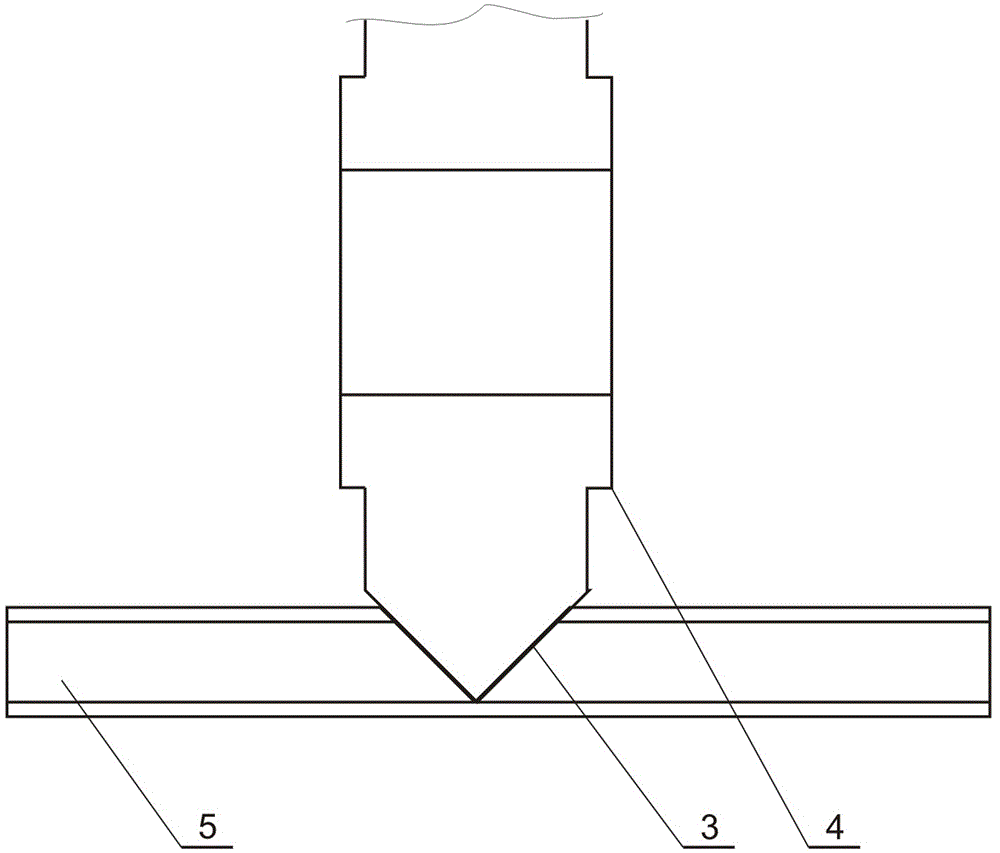

Method for processing V-shaped groove of stainless steel composite plate

The invention discloses a method for processing a V-shaped groove of a stainless steel composite plate. The method comprises planing processing and milling processing. The planing processing means the operation of cutting a flat groove on the surface of the tainless steel composite plate, the position of the flat groove is at the middle of the V-shaped groove, the width of the flat groove is smaller than the edge of the V-shaped groove, and the depth of the flat groove is obtained by cutting off a stainless steel surface layer until a composite layer is exposed. The milling processing means the operation of utilizing a V-shaped milling cutter to perform milling in the flat groove until the V-shaped groove in the stainless steel composite plate is formed. According to the method, a processing mode of first performing planing and then performing milling is adopted, the V-shaped groove is processed in the stainless steel composite plate by utilizing the characteristics of small planing resistance and high milling forming accuracy, and the method has the advantages of easiness in cutting, high working efficiency and good forming accuracy.

Owner:上海斯诺博建筑科技有限公司

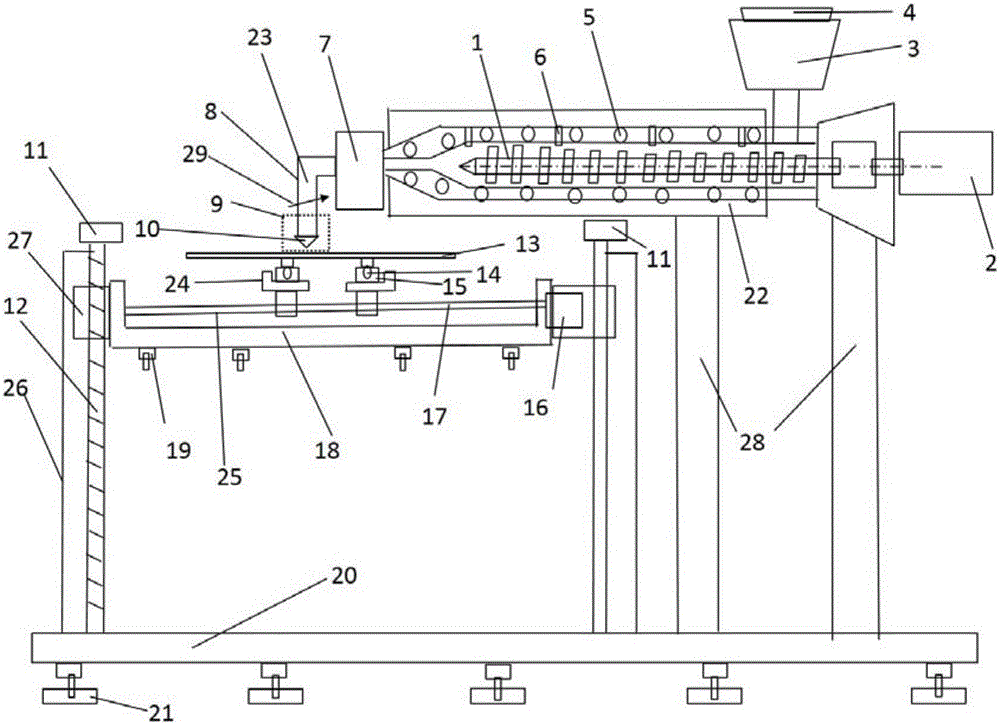

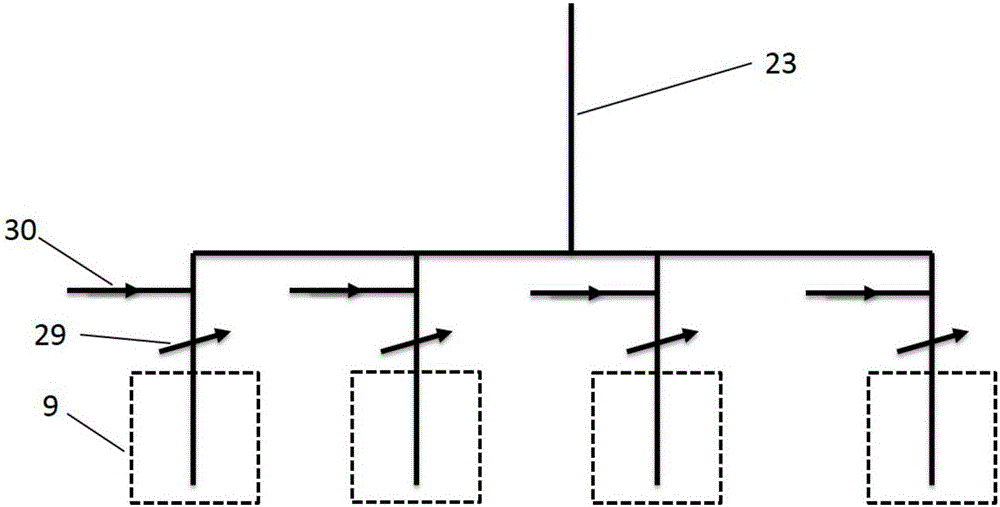

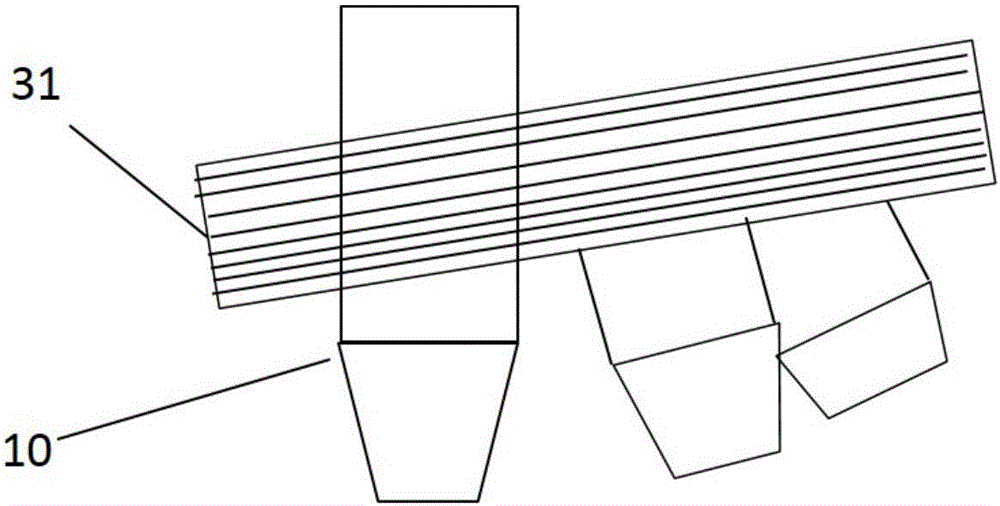

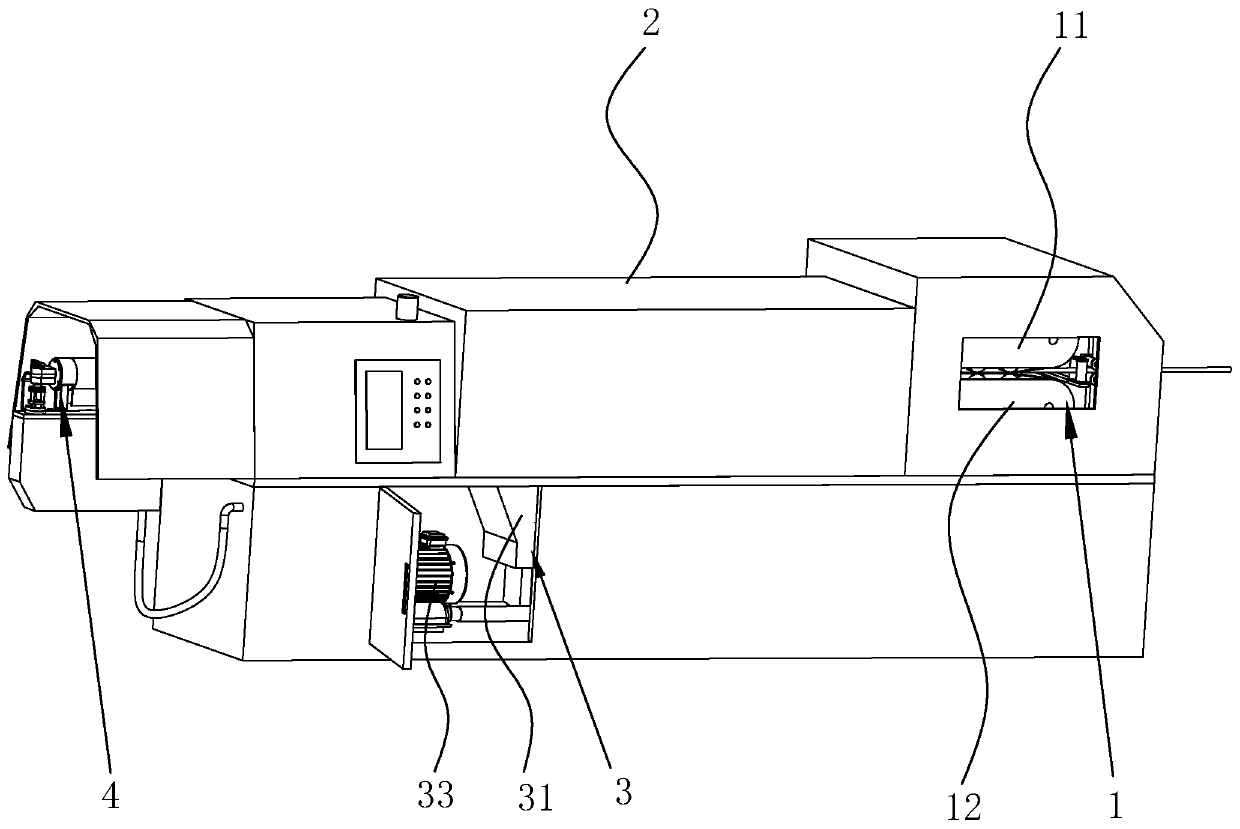

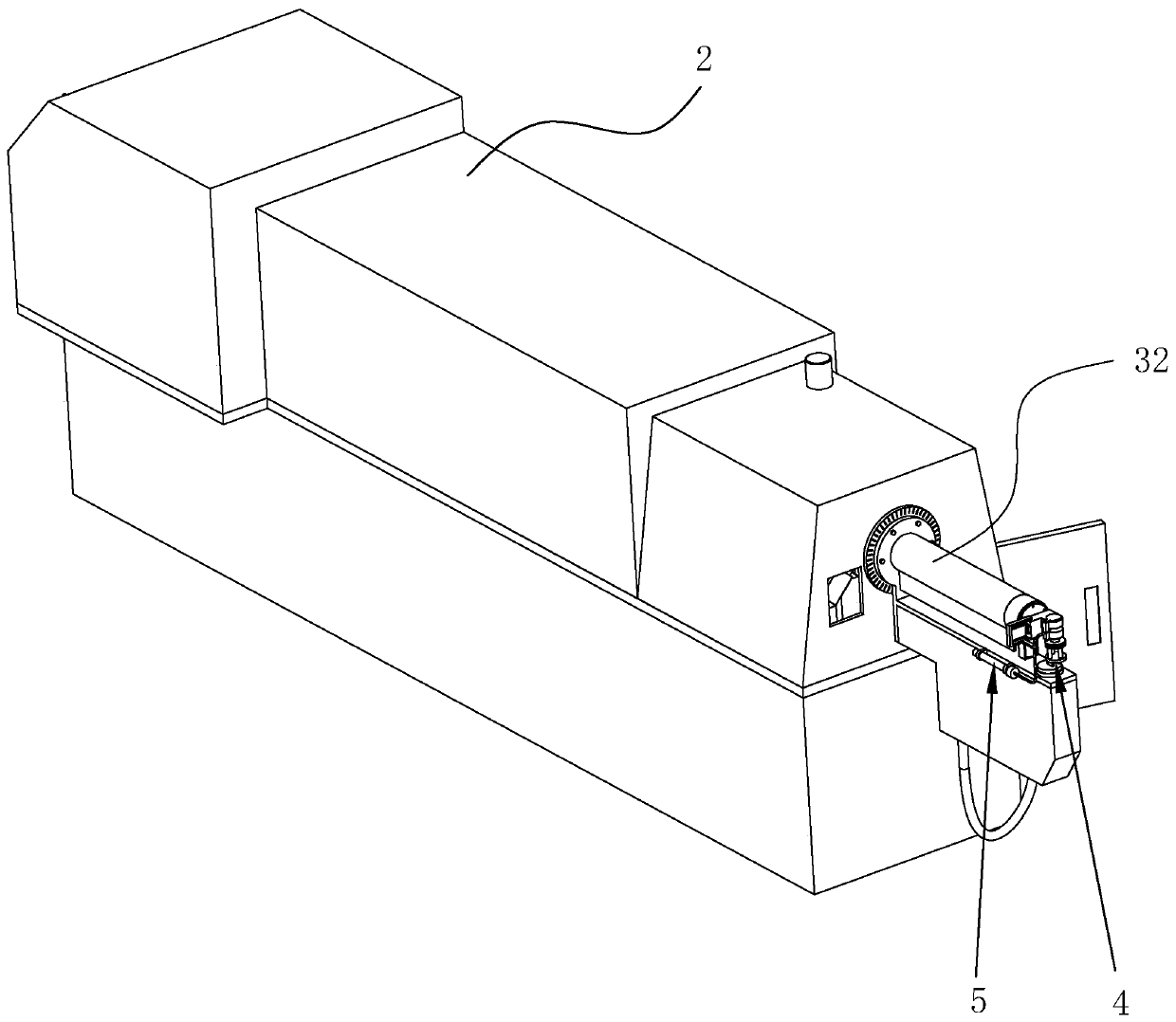

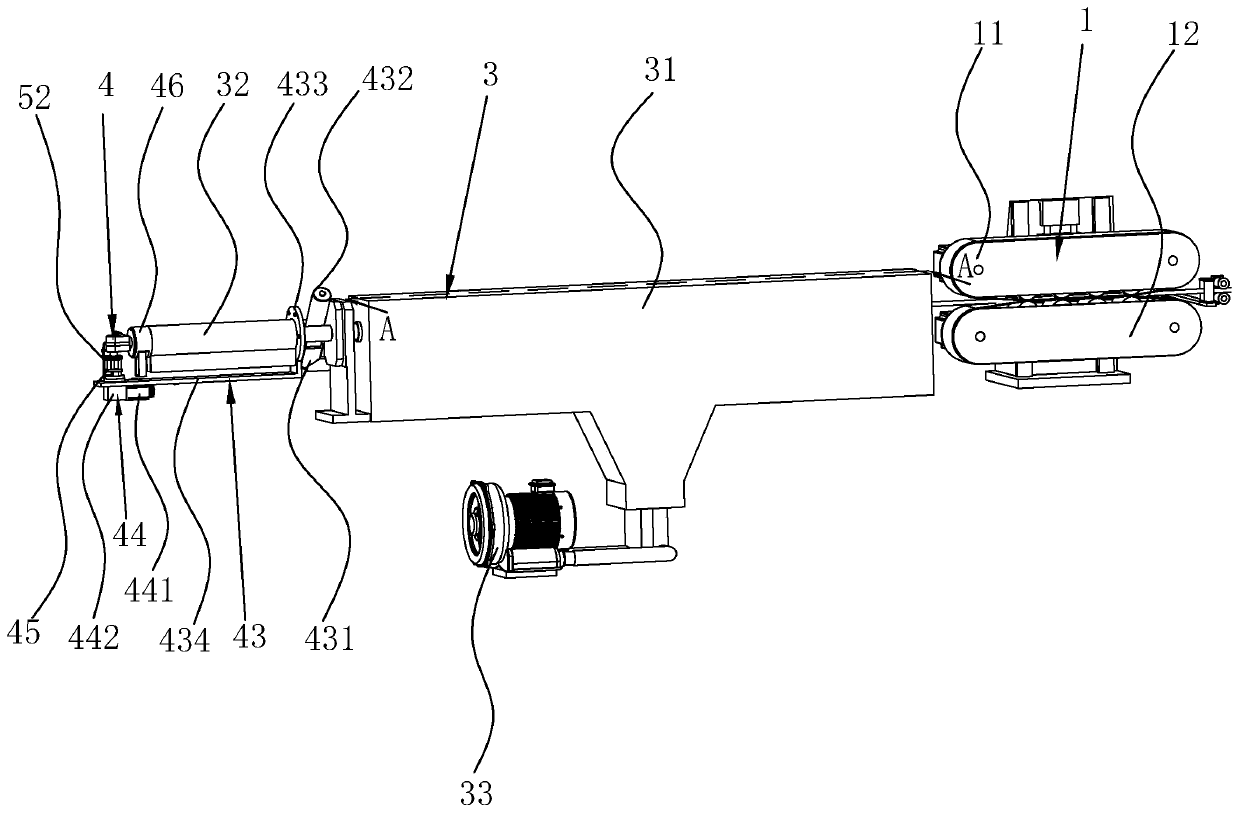

Automatic nylon tube hot forming apparatus and process

The invention discloses an automatic nylon tube hot forming apparatus and process, and relates to the technical field of nylon tube forming. The automatic nylon tube hot forming apparatus comprises abody, a feeding assembly, a heating assembly and a bending assembly, wherein the heating assembly comprises a baking oven in communication with the feeding assembly and an electric heating cylinder arranged between the baking oven and the bending assembly; a heating ring is arranged in the electric heating cylinder; a nylon tube is fed from the feeding assembly and enters the bending assembly through the baking oven and the heating ring; the electric heating cylinder and the bending assembly are arranged outside the body; and an air cooling system and a cutting device are arranged outside thebending assembly. The nylon tube forming process comprises the following steps: pulling; heating in the body; heating outside the body; bending; staying; feeding; angle adjusting; repeating the previous steps until the length and the bending degree of the nylon tube meet the requirements; and cutting off. The apparatus and process have the beneficial effects of improving the forming precision of the nylon tube, ensuring the product quality and improving the machining efficiency.

Owner:ZHEJIANG BOSHITE MECHANICAL CO LTD

Three-dimensional forming device and method

ActiveCN105619819AImprove work efficiencyGood molding precisionAdditive manufacturing apparatusLiquid jetBiomedical engineering

The invention discloses a three-dimensional forming device based on a base layer. The three-dimensional forming device comprises the base layer, a base material forming mechanism, an exposure mechanism, a supporting mechanism and a stripping mechanism. The base material forming mechanism comprises a separating liquid jetting device and a containing groove used for containing a photosensitive material. The separating liquid jetting device jets separating liquid to the lower surface of the base layer so that a separated type coating can be formed; afterwards, coating of a photosensitive material layer is conducted; and the base layer, the separated type coating and the photosensitive material layer are sequentially formed to form a base material. The base material is repeatedly and sequentially transferred to the base material forming mechanism, the supporting mechanism and the stripping mechanism, the corresponding positions of the base material forming mechanism, the exposure mechanism and the stripping mechanism are controlled, two or three steps of base material forming, exposure and stripping can be conducted at the same time through the three-dimensional forming device, and the actions of base material forming, exposure and stripping are conducted repeatedly at the same time. The working efficiency is improved, and the three-dimensional forming device is suitable for meeting the manufacturing requirements of three-dimensional entities for the large range, high efficiency, high precision, low cost and the like.

Owner:SVG TECH GRP CO LTD +1

Laser ray transmitting colored resin composition and related technique

Laser ray transmitting colored resin composition comprising a polyphenylene sulfide resin and a colorant having an endothermic peak between 200°C and 300°C as determined by TG / DTA thermal analysis, wherein the difference T C -T N between the crystallization point T C of the laser ray transmitting colored resin composition and the crystallization point T N of the same composition as said composition except for not containing the aforementioned colorant, is not less than 0°C as determined by DSC thermal analysis. Laser ray transmitting material made of the laser ray transmitting colored resin composition, and having one exothermic energy peak and one endothermic energy peak as determined by DSC thermal analysis. The laser ray transmitting colored resin composition excellent in molding accuracy, good in molded product appearance and gloss, capable of preventing or effectively reducing the gap between the materials to be welded in the case of a molded product used for laser welding, and good in heat resistance and fastness, and the laser ray transmitting material excellent in dimension stability and shape stability and capable of preventing or effectively reducing the gap between the materials to be welded when used for laser welding.

Owner:ORIENT CHEM INDS

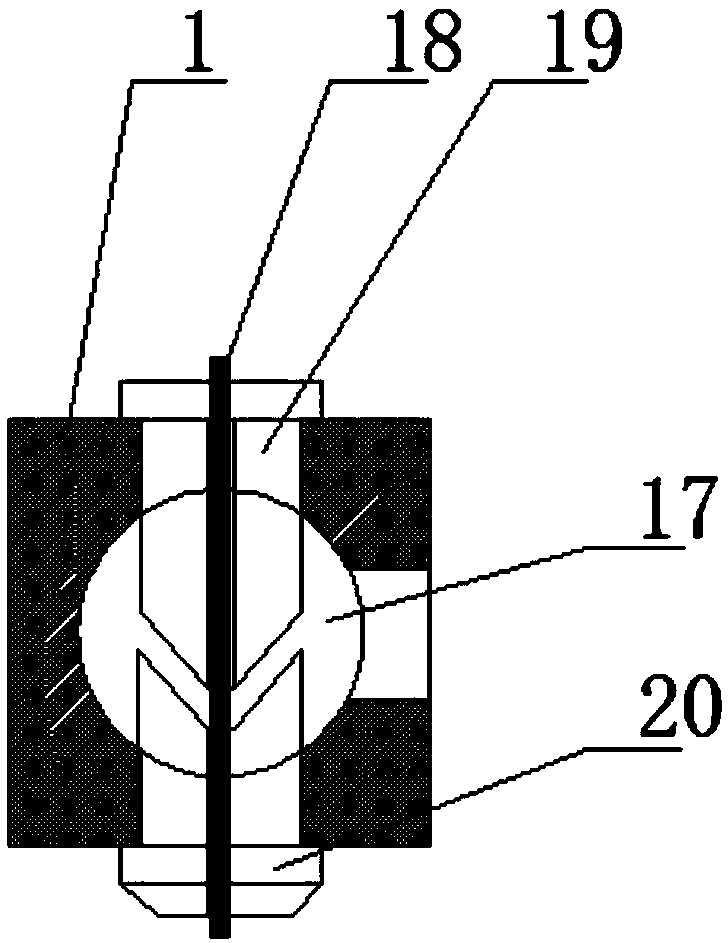

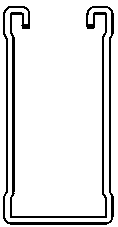

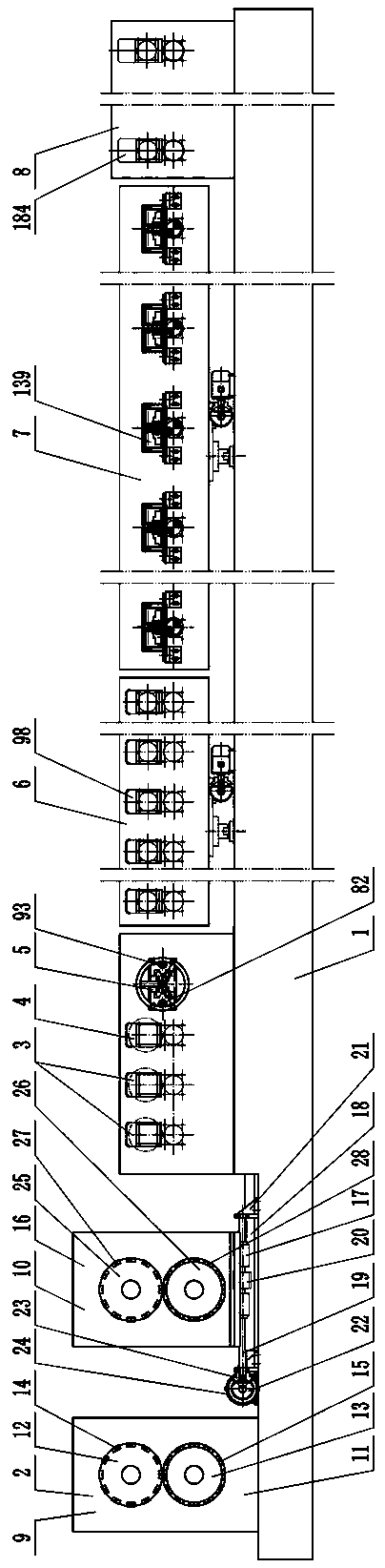

Molding equipment for anti-seismic bracket

ActiveCN108972004AAchieve regulationGood hole making accuracyOther manufacturing equipments/toolsHobbingVertical edge

The invention provides molding equipment for an anti-seismic bracket, and belongs to the technical field of seismic resistance of building electromechanical engineering. The molding equipment comprises a rack base, a hole making device, calendering devices, a rib pressing device, a gear hobbing device, a first small edge molding device, a second small edge molding device and a vertical edge molding device; the hole making device, the calendering devices, the rib pressing device, the gear hobbing device, the first small edge molding device, the second small edge molding device and the verticaledge molding device are arranged side by side in sequence. According to the molding equipment, the molding process of the anti-seismic bracket can be achieved quickly, and the anti-seismic bracket hasthe advantages of high molding accuracy, the rational structure and high degree of automation.

Owner:ZHEJIANG WILLING TECH

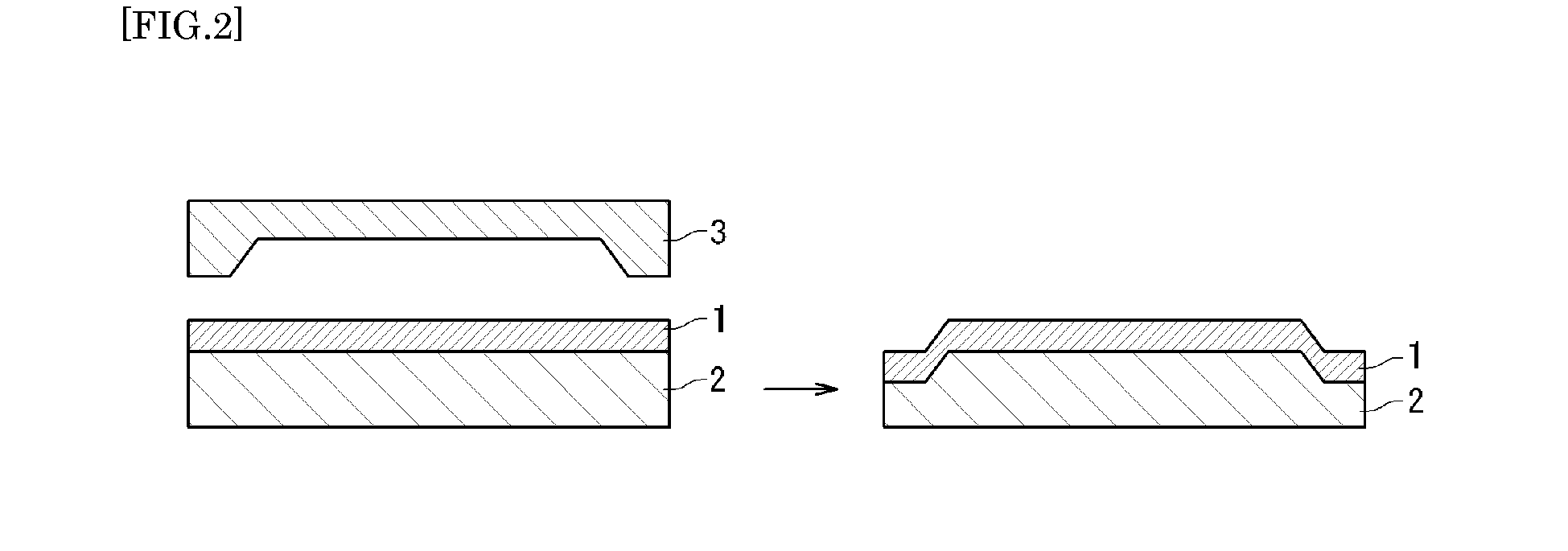

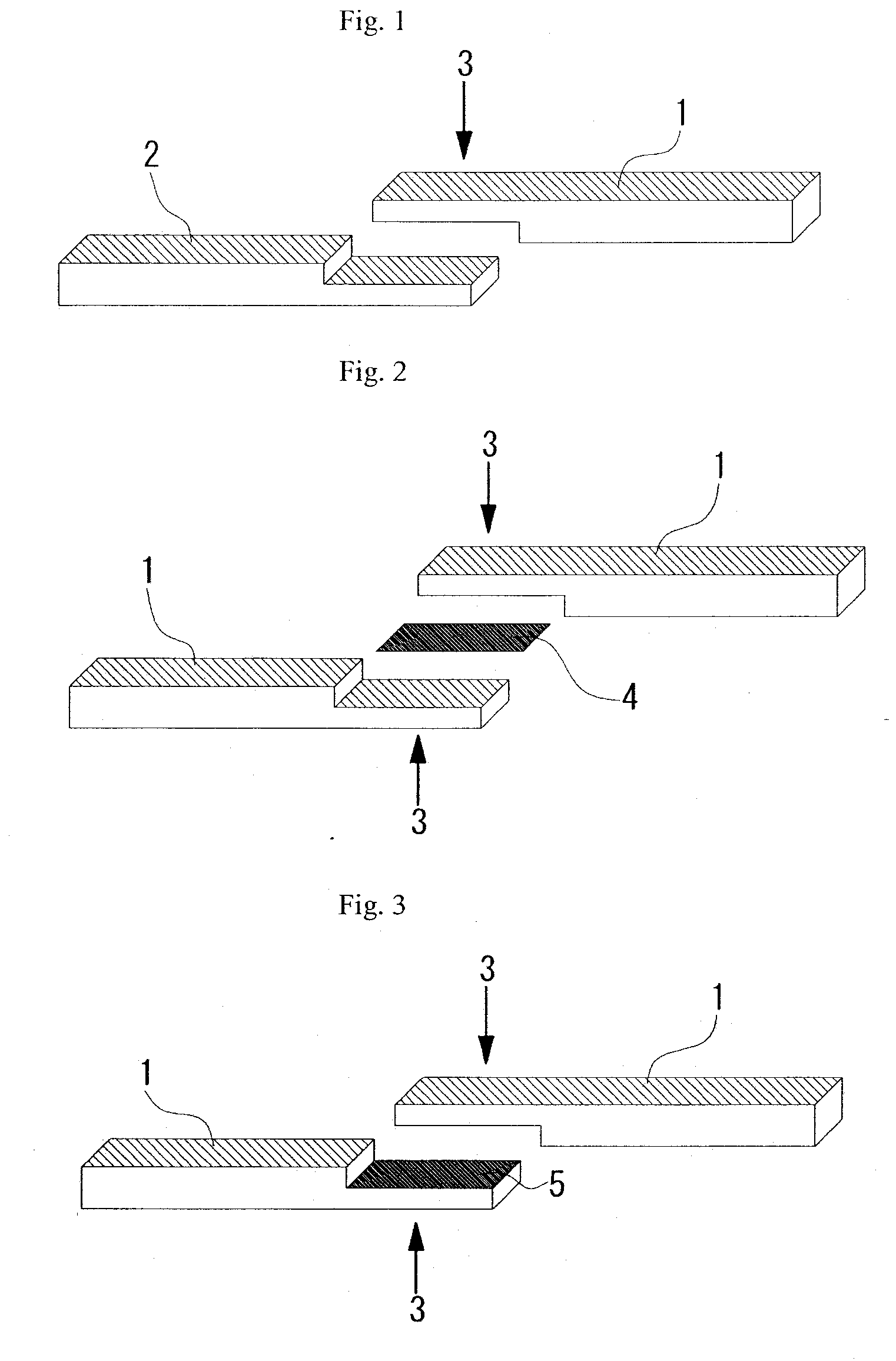

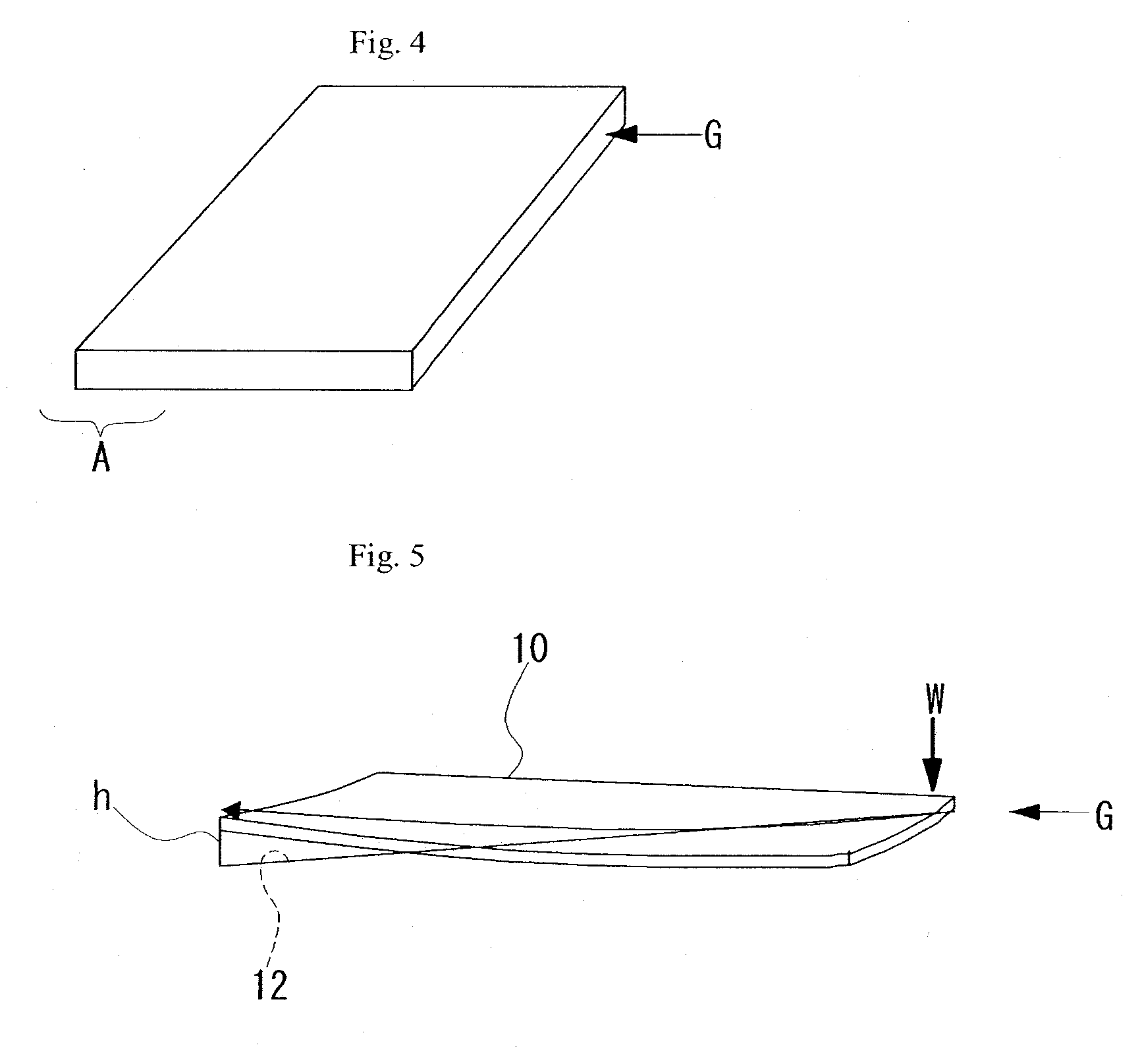

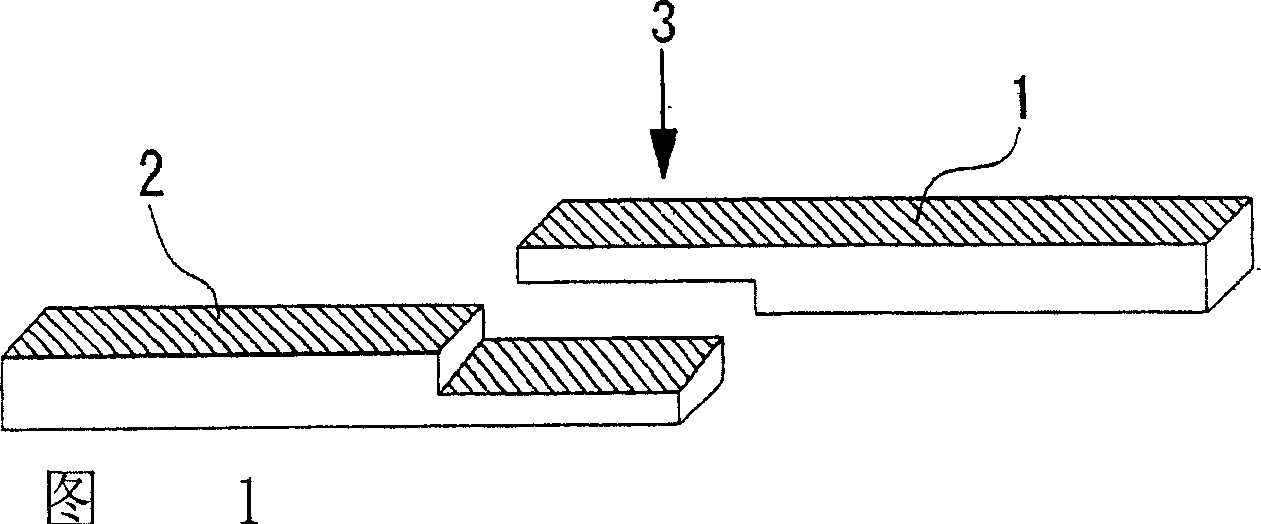

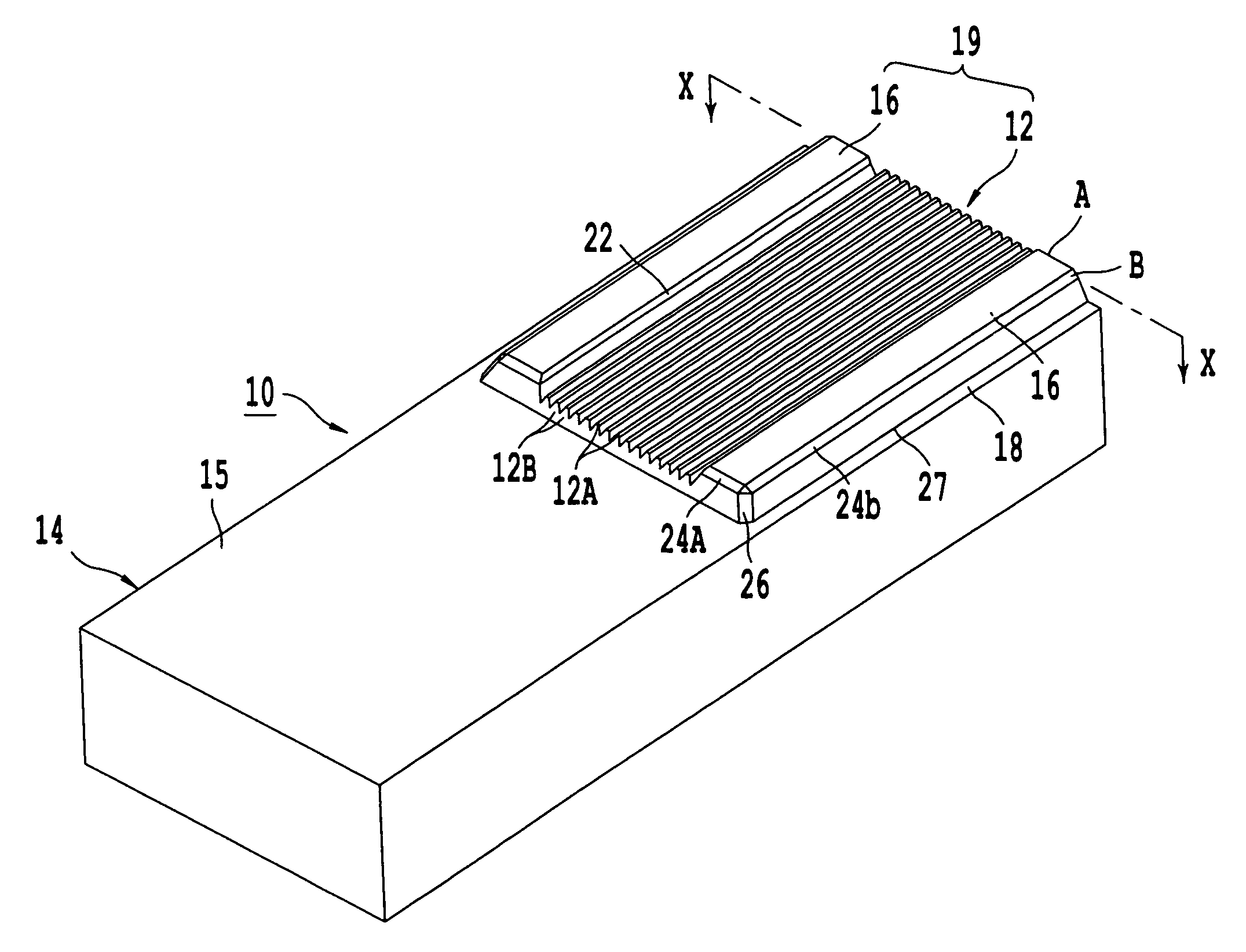

Glass substrate having a grooved portion, method for fabricating the same, and press mold for fabricating the glass substrate

InactiveUS20060022349A1Avoid damageEasy to makeSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsReference surface

A press mold for fabricating a glass substrate, the glass substrate comprising a substrate; and a terrace-shaped flat portion formed on the substrate and having a grooved portion formed therein, is characterized in that the press mold comprises a top mold and a bottom mold; at least one of the top mold and the bottom mold having an indented portion formed therein so as to correspond to the terrace-shaped flat portion, the indented portion having an entire periphery surrounded by a mold reference surface.

Owner:ASAHI GLASS CO LTD

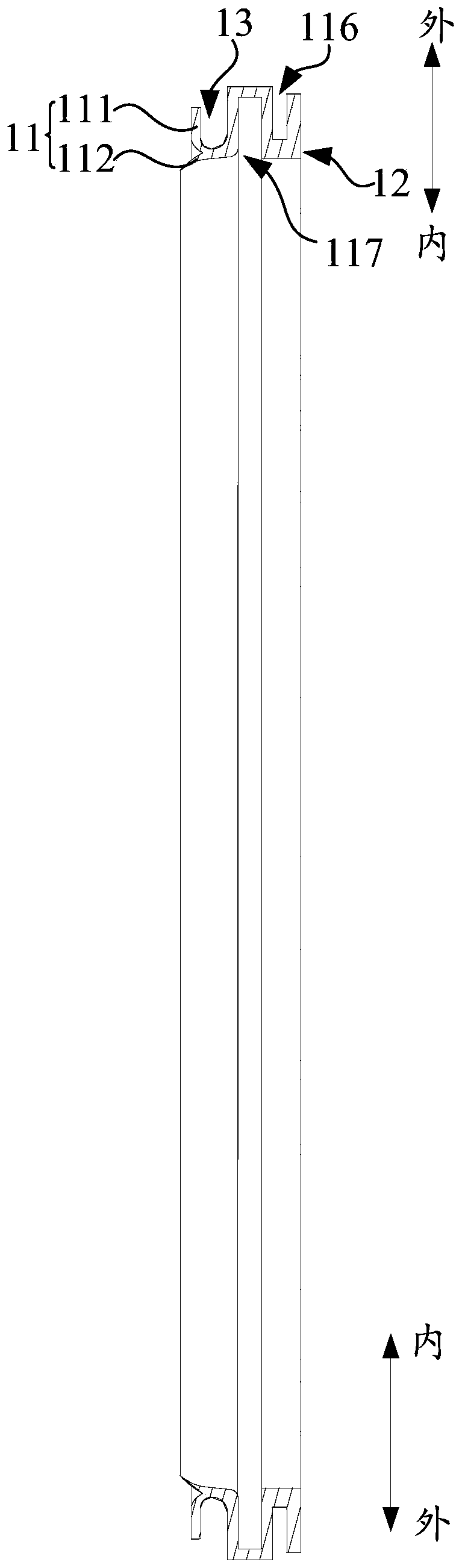

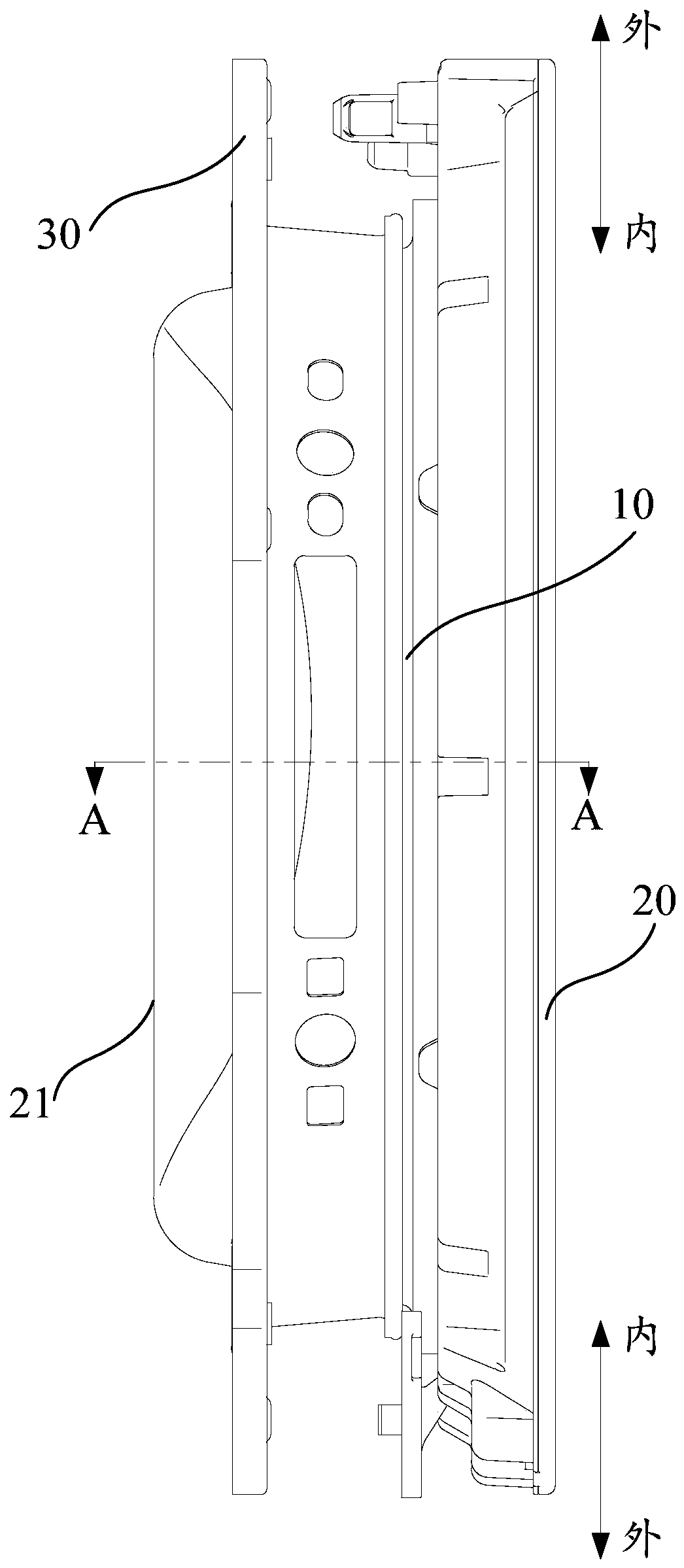

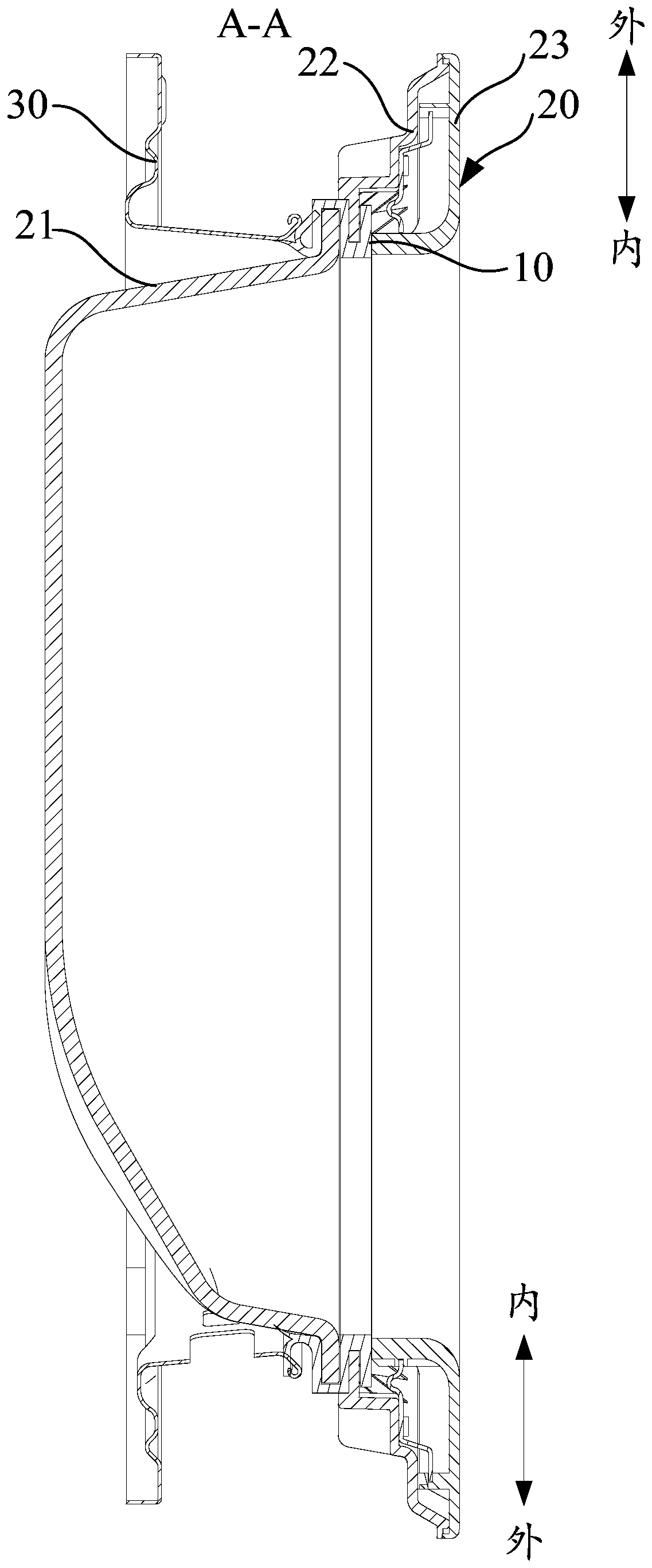

Door seal ring, door assembly and clothes processing equipment

ActiveCN110656472ASealed movablePrevent water leakageOther washing machinesWashing machine with receptaclesWater leakMechanical engineering

The invention provides a door seal ring, a door assembly and clothes processing equipment. The door seal ring is provided with a matching body and an abutting seal part which are connected with each other; the abutting seal part comprises a first lip and a second lip connected with each other. According to the technical scheme, the abutting seal part is separated from a tub assembly when a door body is opened, and the abutting seal part is abutted against the tub assembly when the tub assembly is covered with the door body; thus, the sealing between the movable door body and the tub assembly is realized, water leakage of the tub assembly is prevented effectively, and seal reliability and safety of the product are guaranteed; further, since the abutting seal part and the tub assembly are inabutting fit, and the door seal ring keeps in abutting against the tub assembly through its elasticity and can move synchronously with the tub assembly, the leakage between the door body and the tubassembly can be avoided, and the seal reliability of the door body can be improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Fiber-scale reactive extrusion 3D printing method

InactiveCN105904728ABroaden your optionsAchieve stabilityAdditive manufacturing apparatusFiberPolyester

The invention relates to a fiber-scale reactive extrusion 3D printing method including the steps of: a) fusing a lactam monomer and / or a lactone monomer, and an additive and an ionic liquid, and performing a polymerization reaction under the effect of a catalyst to prepare a target polymer; and b) performing fused deposition 3D printing to the target polymer and performing thermal treatment to obtain a finish product, wherein the thermal treatment is carried out at 100-180 DEG C for 3-60 min. In the invention, a high-precision high-adaptability 3D printer is employed, so that the method has high shaping precision and efficiency and the finish product has good mechanical performance. A process, in which the polymerization monomers are directly processed to obtain the finish product, is employed, so that the method is improved in production flexibility and also avoids the problems of edge warping and even printing failure since semi-crystallized polymers, such as nylon, polyester and the like, are crystallized and are large in temperature difference, thereby avoiding reduction of performance of the finish product due to degradation of the polymers. The method increases the types of fused deposition 3D printing materials, improves quality of the finish product, and has wide applications in the fields of crafts, machines, chemical engineering, instruments, automobiles and the like.

Owner:DONGHUA UNIV

Glass substrate having a grooved portion, method for fabricating the same, and press mold for fabricating the glass substrate

InactiveUS7332809B2Good molding precisionEasy to makeSemiconductor/solid-state device detailsSolid-state devicesOptoelectronicsReference surface

A press mold for fabricating a glass substrate, the glass substrate comprising a substrate; and a terrace-shaped flat portion formed on the substrate and having a grooved portion formed therein, is characterized in that the press mold comprises a top mold and a bottom mold; at least one of the top mold and the bottom mold having an indented portion formed therein so as to correspond to the terrace-shaped flat portion, the indented portion having an entire periphery surrounded by a mold reference surface.

Owner:AGC INC

Great drop mountain directional drilling crossing construction method

InactiveCN107605401AGood molding precisionDirectional drillingFlushingComing outDirectional drilling

The invention discloses a great drop mountain directional drilling crossing construction method, comprising the following process steps: 1) determining a soil coming-in position and a soil coming-outposition, through a drilling tool, drilling along the direction from the soil coming-in position to the soil coming-out position, to realize construction processing of a guide hole; 2) withdrawing thedrilling tool along the direction from the soil coming-out position to the soil coming-in position, after the drilling tool is changed to a hole expanding device, through the hole expanding device, drilling along the direction from the soil coming-in position to the soil coming-out position, to realize hole expanding construction processing; 3) in the hole in which hole expanding construction processing is completed, placing a pipe which is to be laid in the hole along a drag direction from the soil coming-out position to the soil coming-in position, the pipe being dragged by the hole expanding device. Compared with a conventional directional drilling process, in the great drop mountain directional drilling crossing construction method using the above technical scheme, pushing processingof the hole expanding device from the soil coming-in position to the soil coming-out position is used in a hole expanding stage, control of a guide curve in an operation process can be effectively improved, so that a hole expanding path tends to be a line, and hole expanding precision is improved.

Owner:CHINA NAT CHEM ENG NO 14 CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com