Method for processing V-shaped groove of stainless steel composite plate

A processing method, stainless steel technology, applied in the field of metal cutting, can solve problems such as tool damage, poor austenite stability, and low work efficiency, and achieve the effects of high milling precision, low planing resistance, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

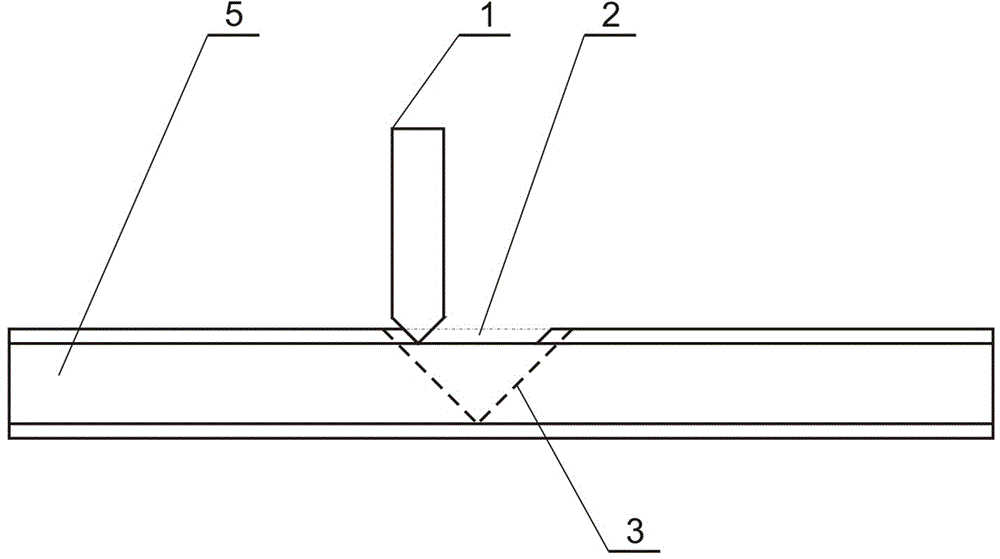

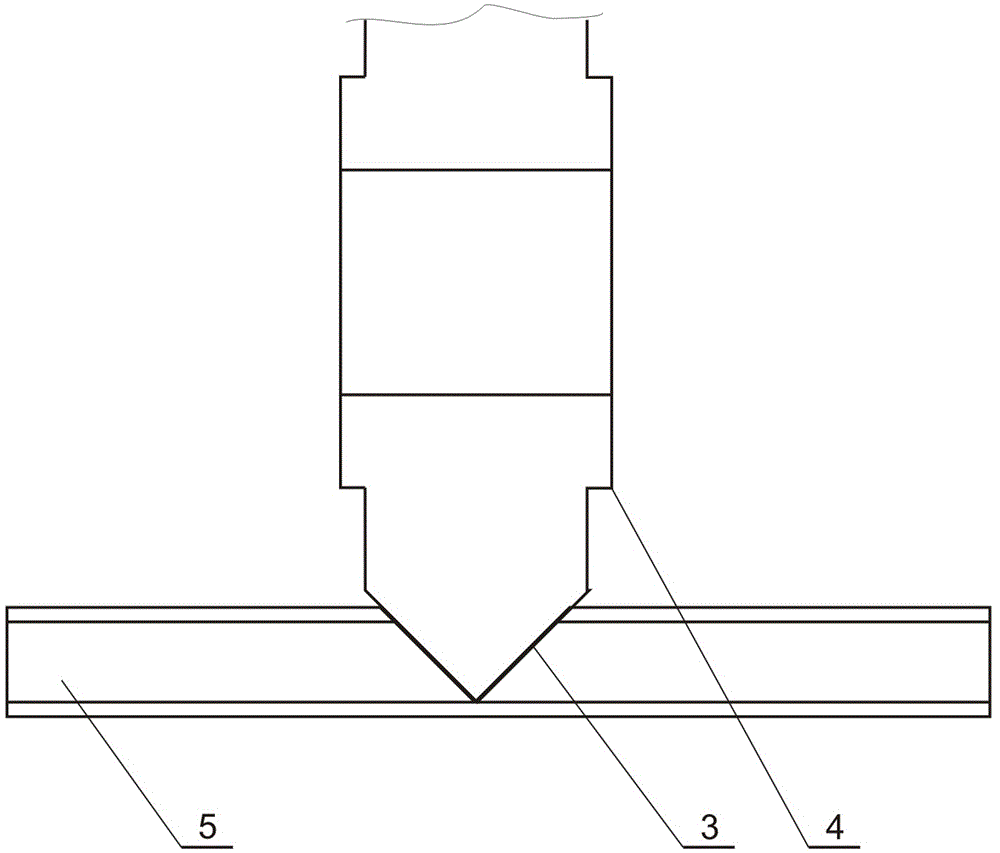

[0011] refer to figure 1 , figure 2 , the stainless steel composite board 5 is clamped on a planer equipped with a milling power head, a V-shaped planer 1 with a large rake angle is selected, and a flat groove 2 is planed on the surface of the stainless steel composite board 5, and the position of the flat groove 2 is centered on the V shaped groove 3, and the width is smaller than the boundary of the V-shaped groove 3, and the depth of the flat groove 2 is to cut off the stainless steel surface until the composite layer is exposed;

[0012] Start the milling power head, implement milling, and implement milling in the flat groove 2 with a V-shaped horizontal milling cutter until the V-shaped groove 5 on the stainless steel composite plate is formed.

[0013] The present invention uses planing technology to plan a flat groove on the surface of the stainless steel composite board, and cuts off the stainless steel part to be processed into a V-shaped groove. Due to the use of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com