Patents

Literature

69 results about "Cold hardening" patented technology

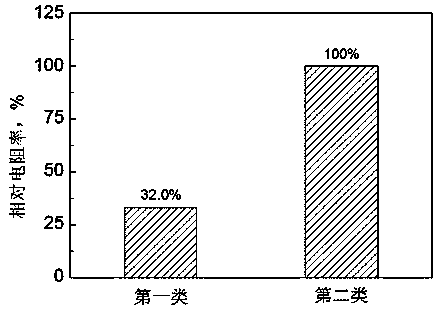

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold hardening is the physiological and biochemical process by which an organism prepares for cold weather.

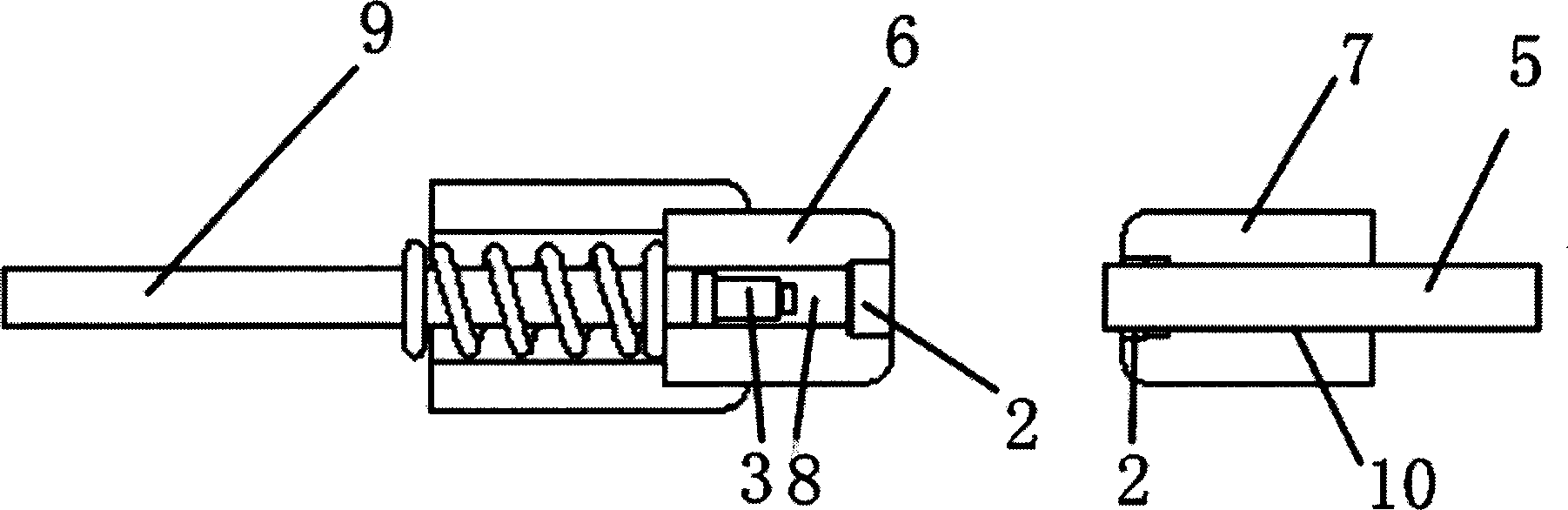

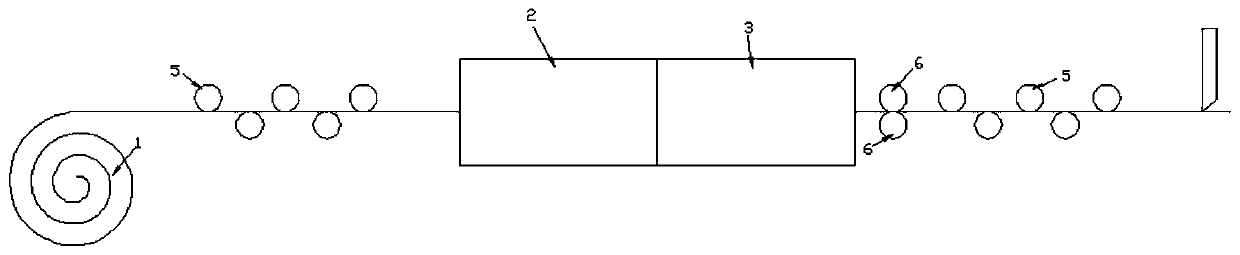

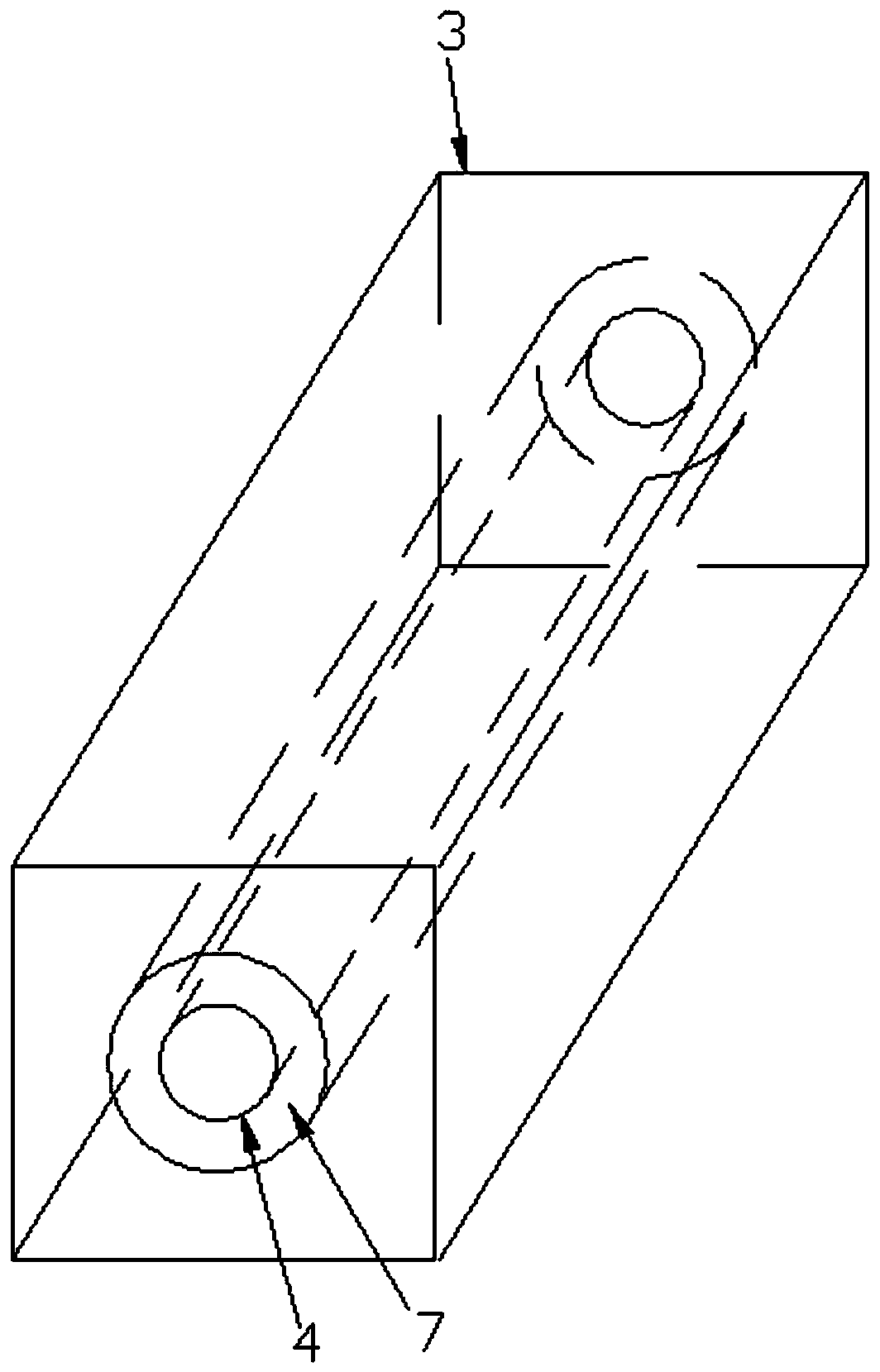

Apparatus and process for securing, analyzing and sorting materials, and sorted products

InactiveUS7067834B2Improve efficiencyUniform strengthPreparing sample for investigationInvestigating moving fluids/granular solidsAdhesiveCold hardening

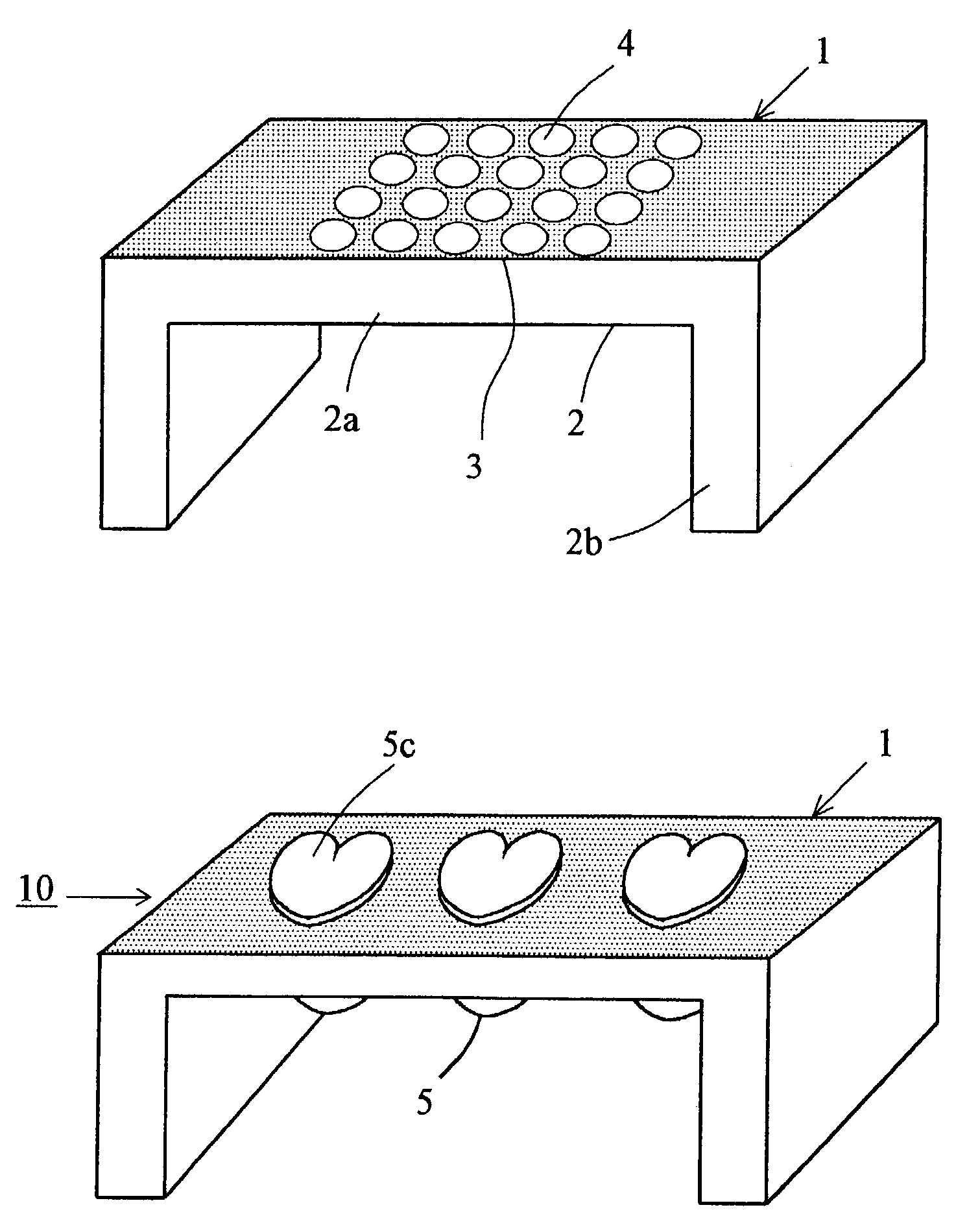

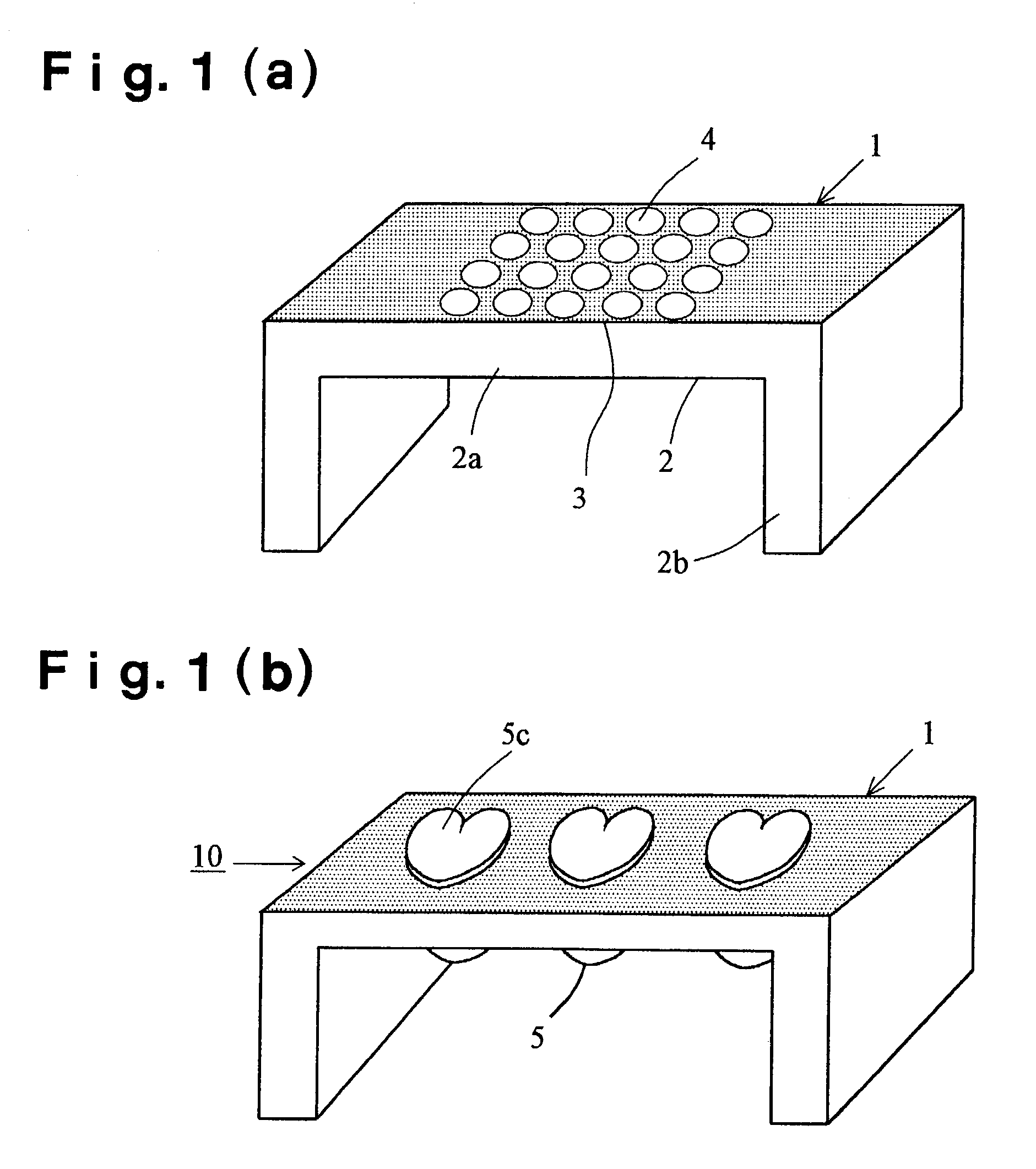

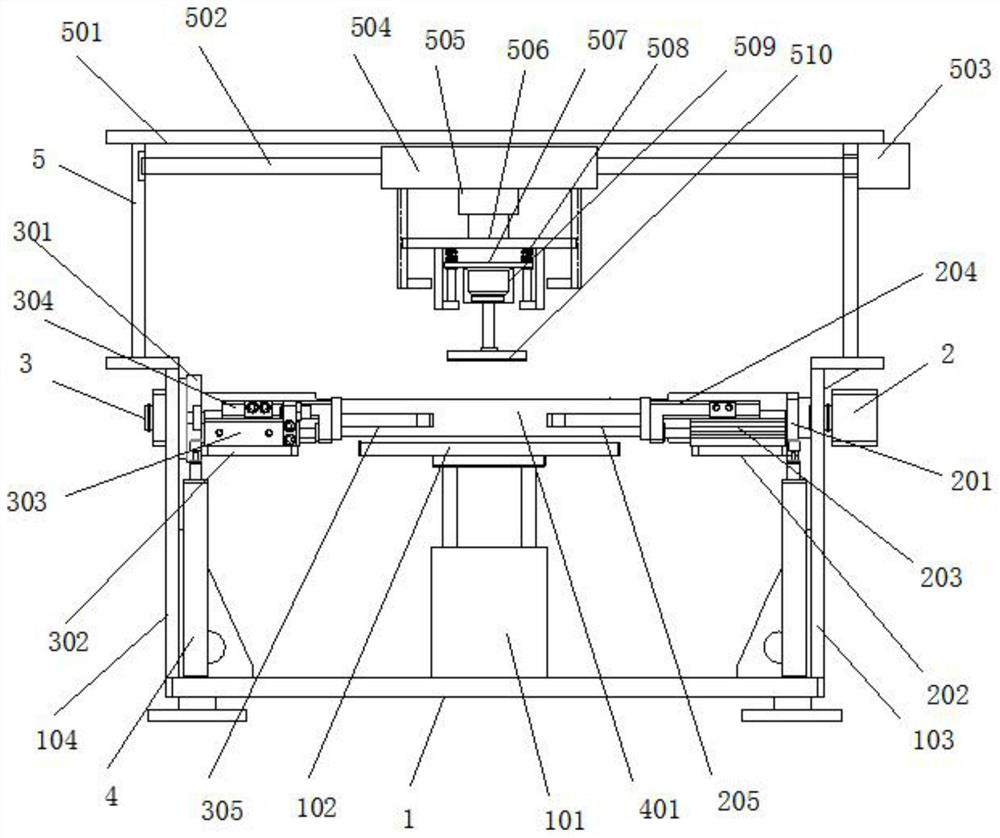

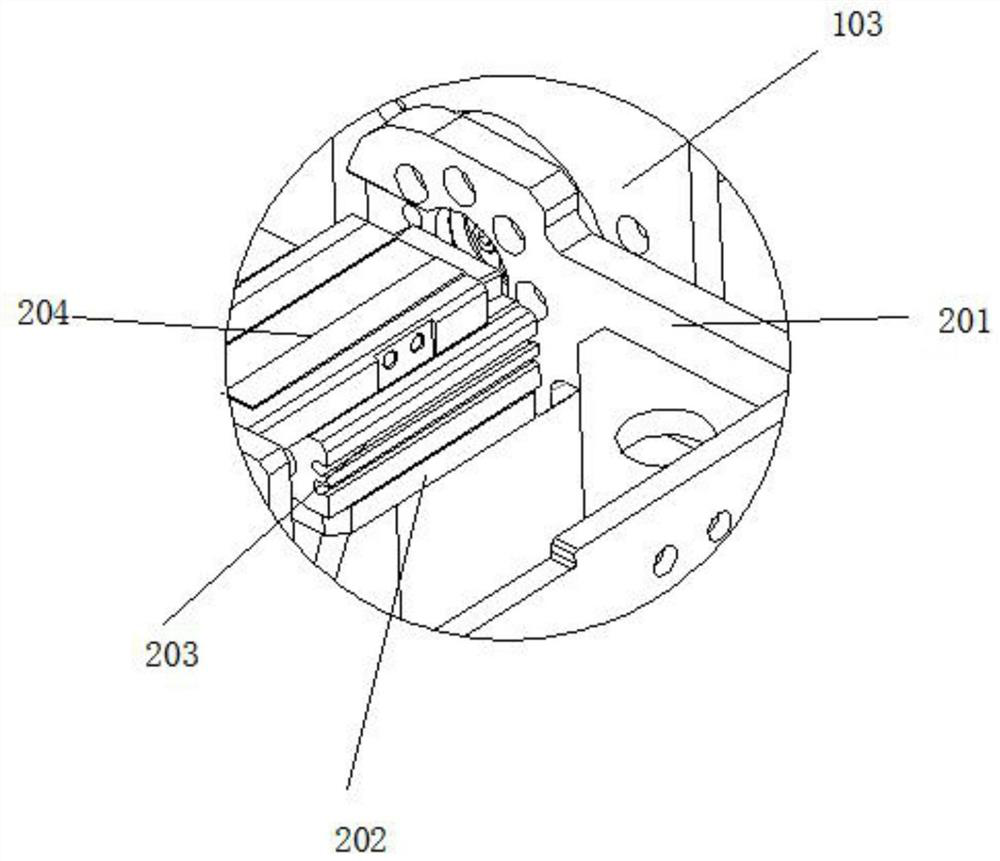

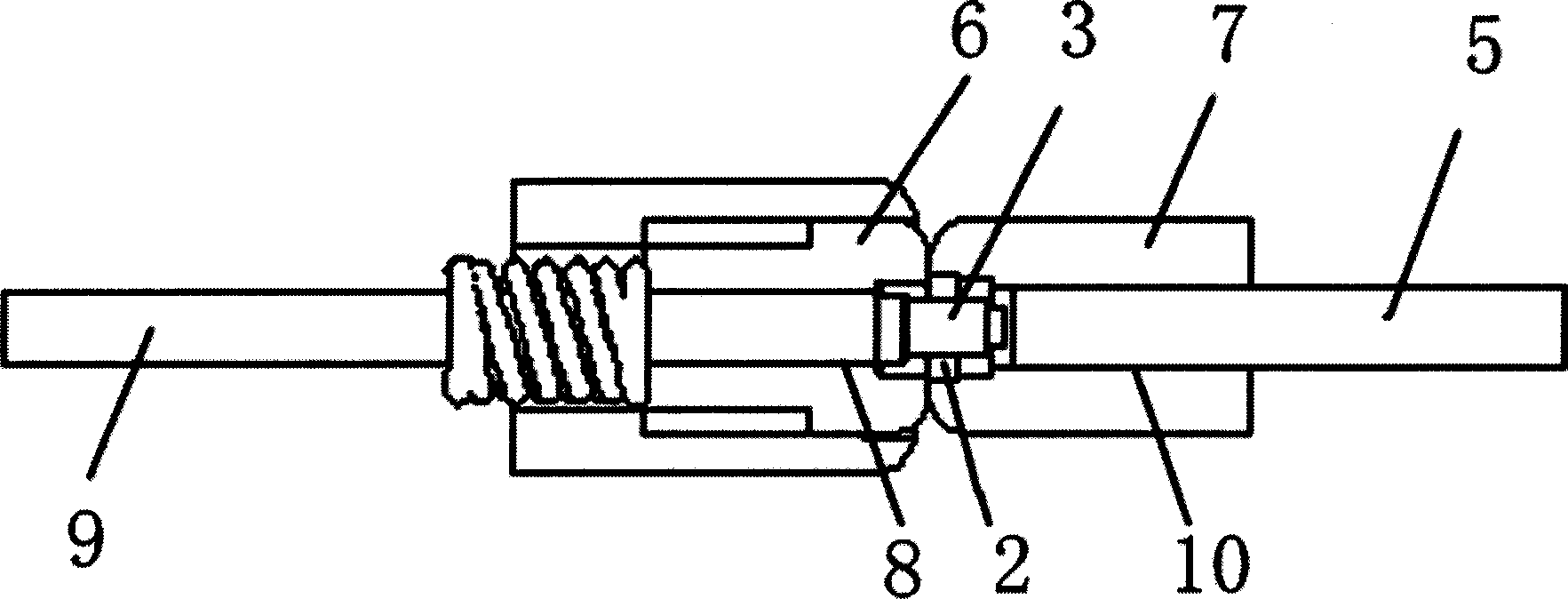

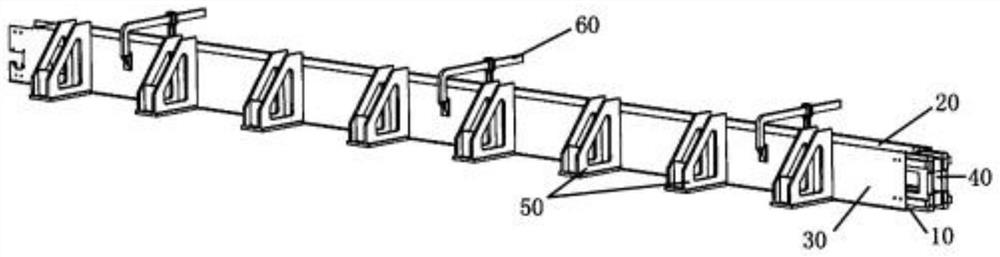

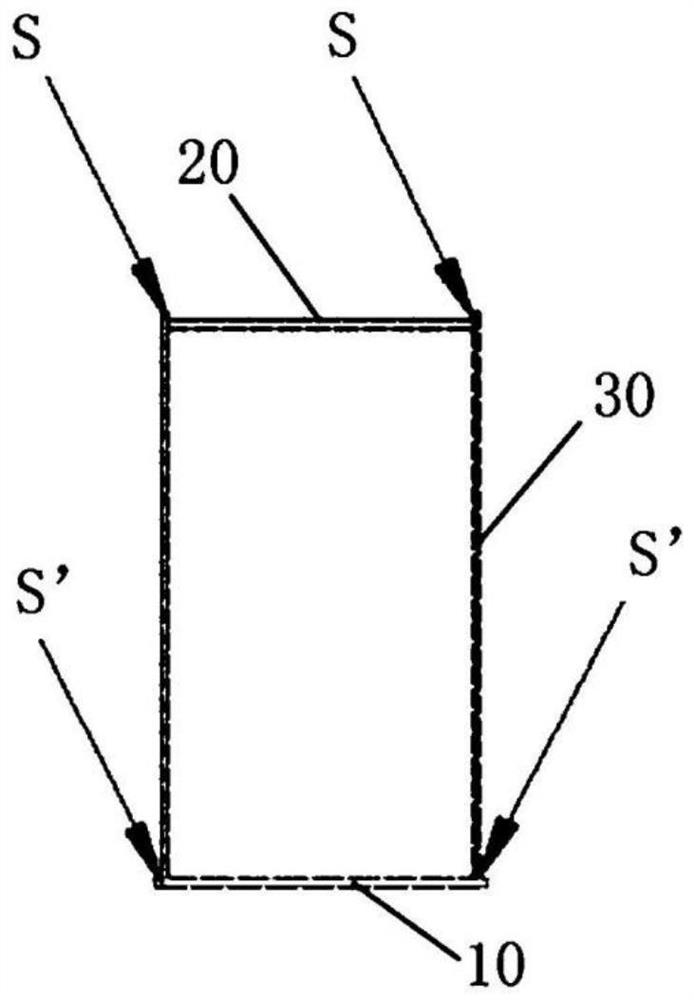

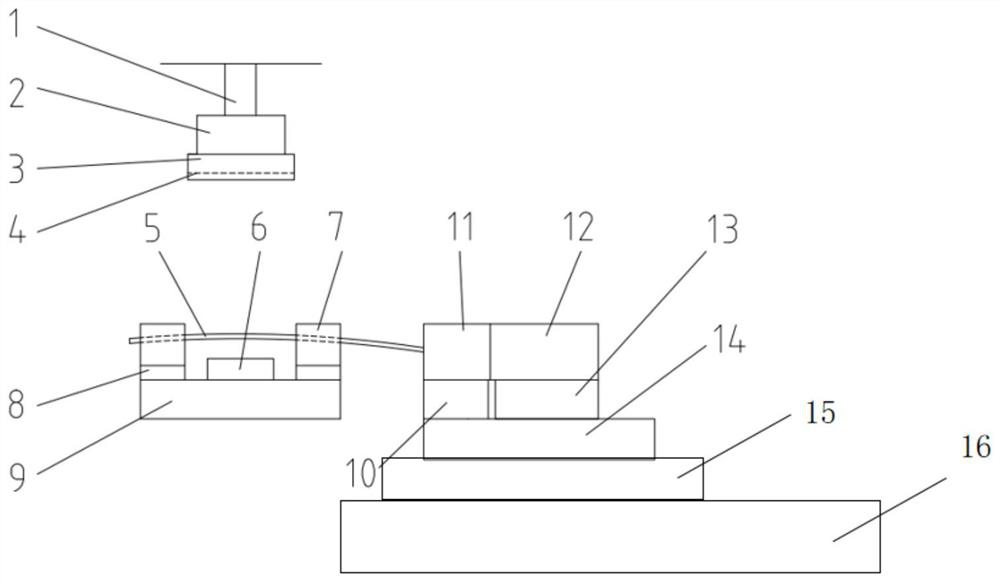

An apparatus for securing, analyzing and sorting materials, which allows such procedures as analysis and sorting of materials present as independent pieces at a high efficiency and a high accuracy, by securing individual pieces 5 of materials in receptacles 4 of a holder 1 at a definite posture using a light-hardenable adhesive at a uniform hardening strength and a uniform but brief hardening time by cold hardening under identical hardening conditions without causing denaturation of the material, wherein the receptacles 4 are arranged on the holder 1 in a definite arrangement and a definite posture, whereby it is able to process each individual material piece after the hardening of the adhesive, by, for example, cutting and so on, to uniformly form on each material piece an analyzing surface for which the analysis is performed. Each material piece 5 is bonded and fixed onto an inner wall of the receptacle 4 using a light ray-hardenable adhesive 7 by irradiating a light ray 8 thereonto to effect hardening of the adhesive at normal temperatures. The resulting holder 1 having the fixed material pieces is mounted on an analyzing unit 12 to subject each material piece to a spectrometric analysis by irradiating it with an electromagnetic ray 15. Then, the holder 1 having the analyzed material pieces is set on a sorting device 22 to sort the analyzed material pieces, in which the material pieces are dispensed by operating dispenser rods 24 based on the analysis results.

Owner:TSUKUBA FOOD SCI

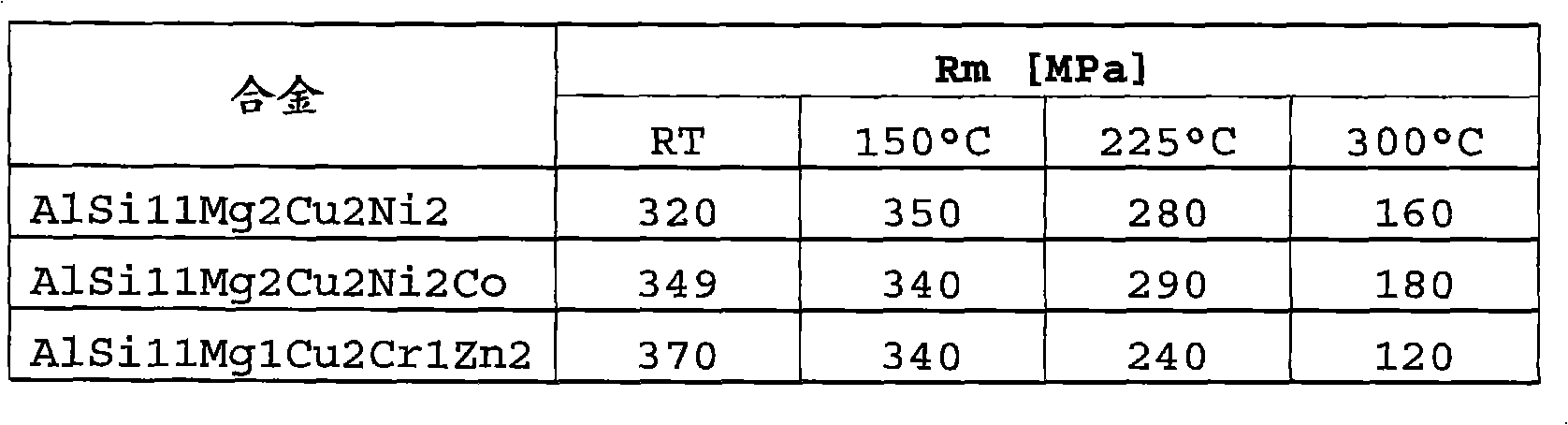

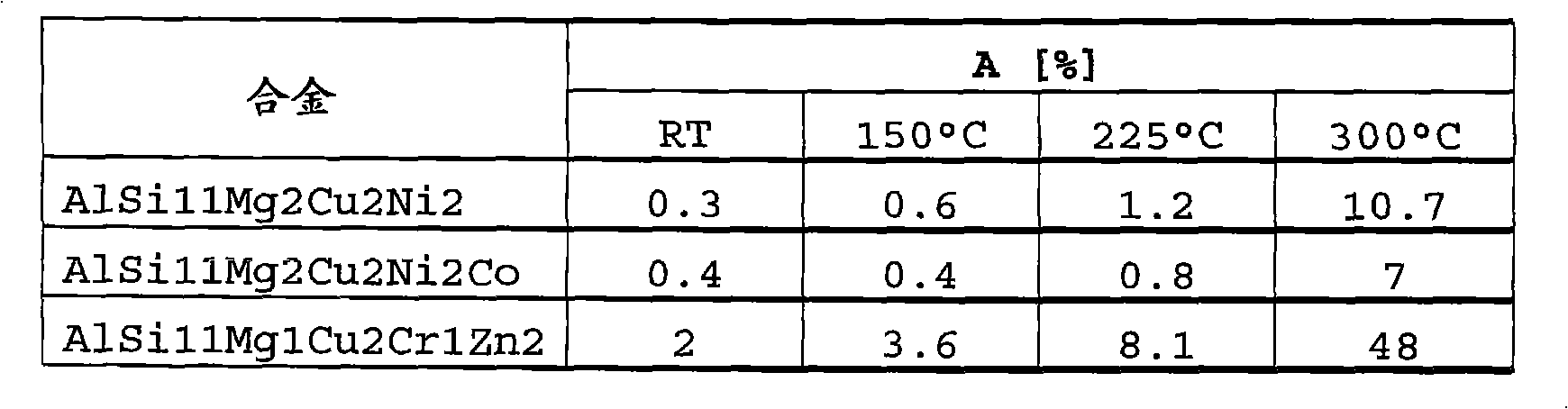

High-temperature aluminium alloy

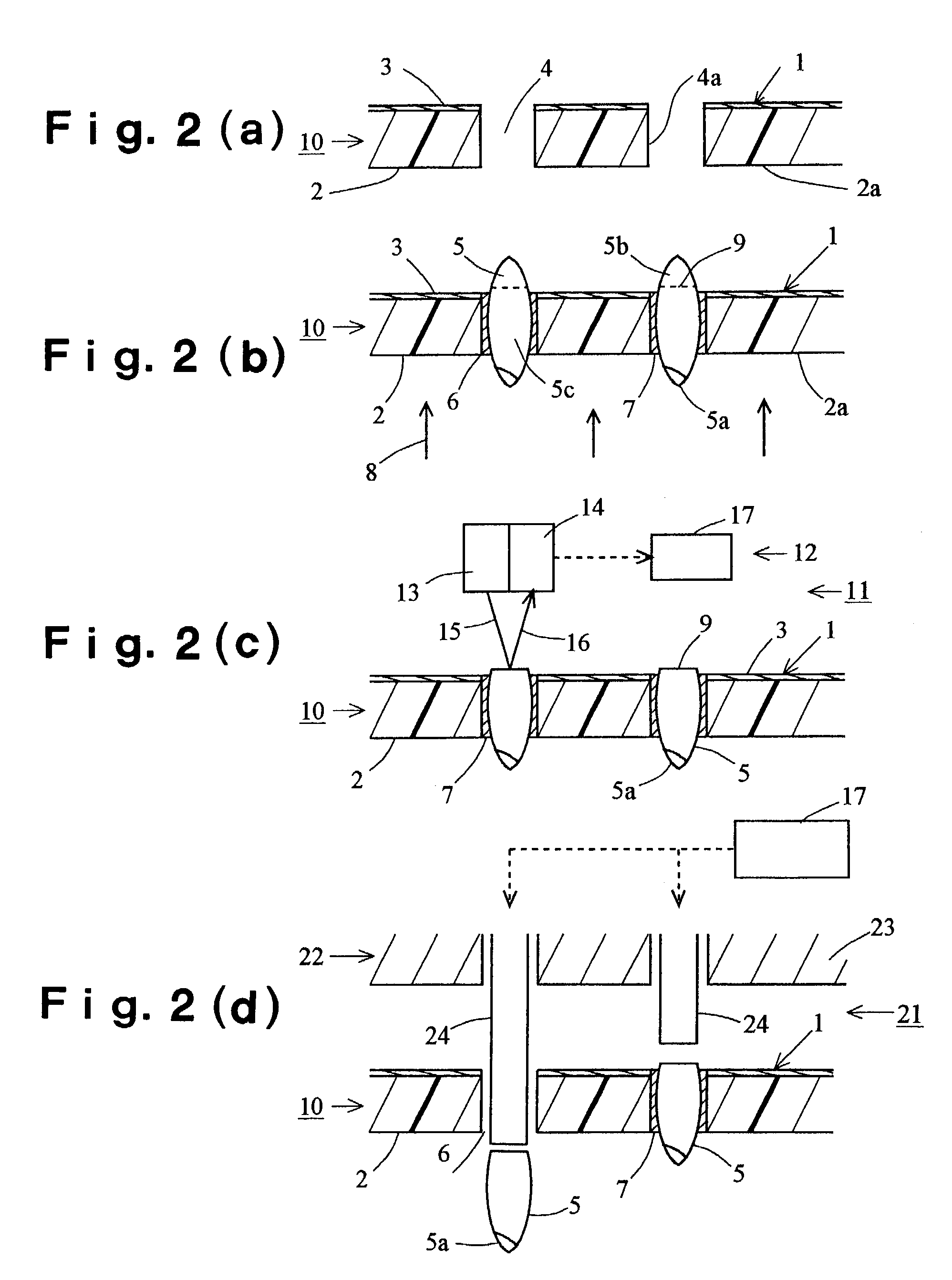

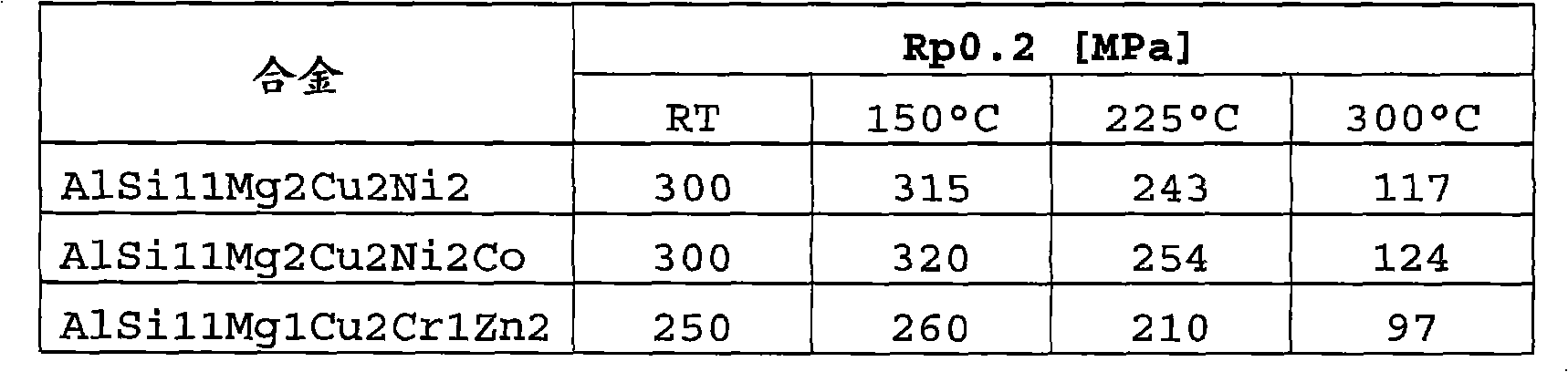

A cold hardening ceralumin used for manufacturing a casting component for bearing heat and mechanical load with excellent thermal stability, comprises: 11.0-12.0 wt% Silicon; 0.7-2.0 wt% Magnesium; 0.1-1 wt% manganese, at most 1 wt% iron; at most 2 wt% copper; at most 2 wt% nickel; at most 1 wt% chromium; at most 1 wt% co; at most 2 wt5 zinc; at most 0.25 wt% Ti; at most 40 ppm boron; optional 80-300 ppm sr and the balance aluminium, and other elements and impurities with respectively at most 0.05 wt% and in total 0.2 wt%. The alloy is particularly suitable to manufacturing a cylinder crankcase through a die manufacturing method.

Owner:АЛЮМИНИУМ РАЙНФЕЛЬДЕН ГМБХ

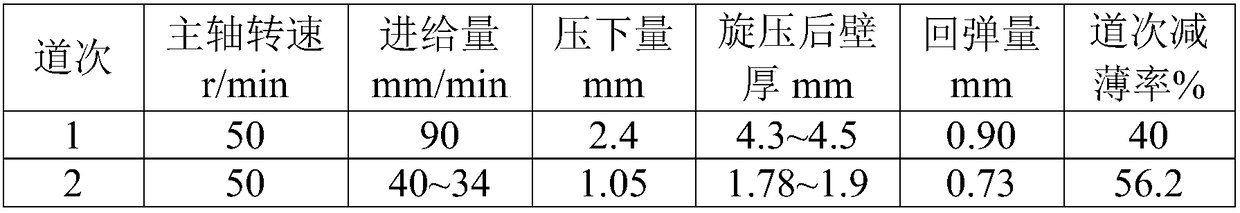

Welding and forming method for shell of solid rocket engine

ActiveCN109014790AImprove the assembly environmentReliable strengthWelding/cutting auxillary devicesAuxillary welding devicesHeat-affected zoneStructure property

The invention discloses a welding and forming method for a shell of a solid rocket engine. The shell is made of 30Cr3 ultrahigh-strength steel in material; a cylindrical section is tempered in advance, and then, a way of power-spinning cold hardening is employed to guarantee that the cylindrical section reaches 48 to 52 HRC (Rockwell hardness) and is not less than 1620 MPa in strength before beingwelded; a front joint and a rear joint are tempered after being roughly turned, and then a butting part and a butting part of the cylindrical section are turned, thus creating a good assembly environment for welding and forming a circumferential weld by an electron beam; the circumferential weld among the front joint, the rear joint and the cylindrical section is welded by adopting a vacuum electron beam, so that a heat affected zone is small, the weld width is narrow, the weld in a tempered state and an overheated zone can be respectively prevented from generating a cold crack and from beingembrittled and softened, and stable and reliable welded joint strength is guaranteed; and after the shell is welded by adopting the vacuum electron beam in the tempered state, structure property doesnot need to be improved through high-temperature quenching, and welding stress is removed only by low-temperature tempering, so that the shell is little in deformation and can be effectively guaranteed in geometric tolerance.

Owner:湖北三江航天江北机械工程有限公司

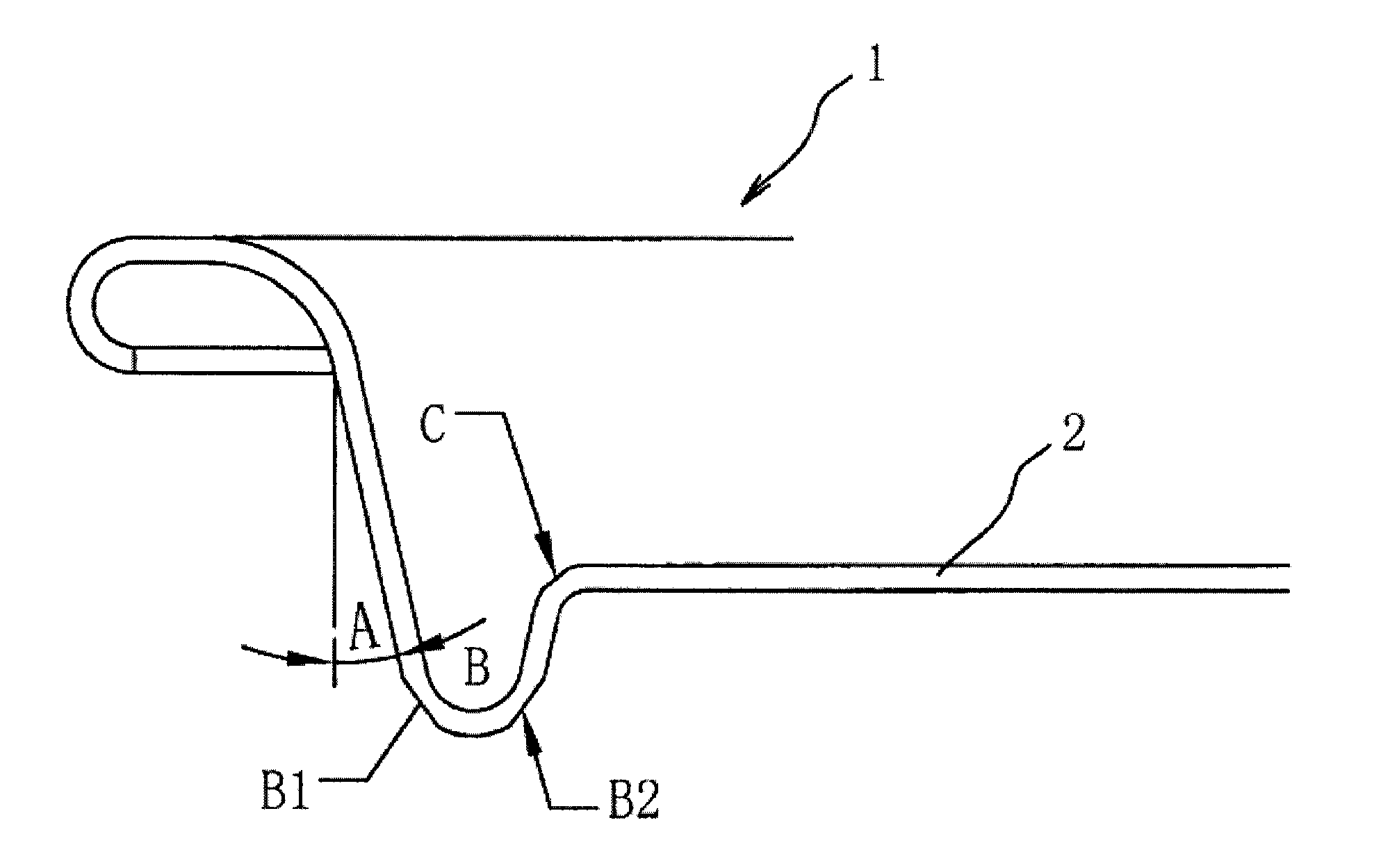

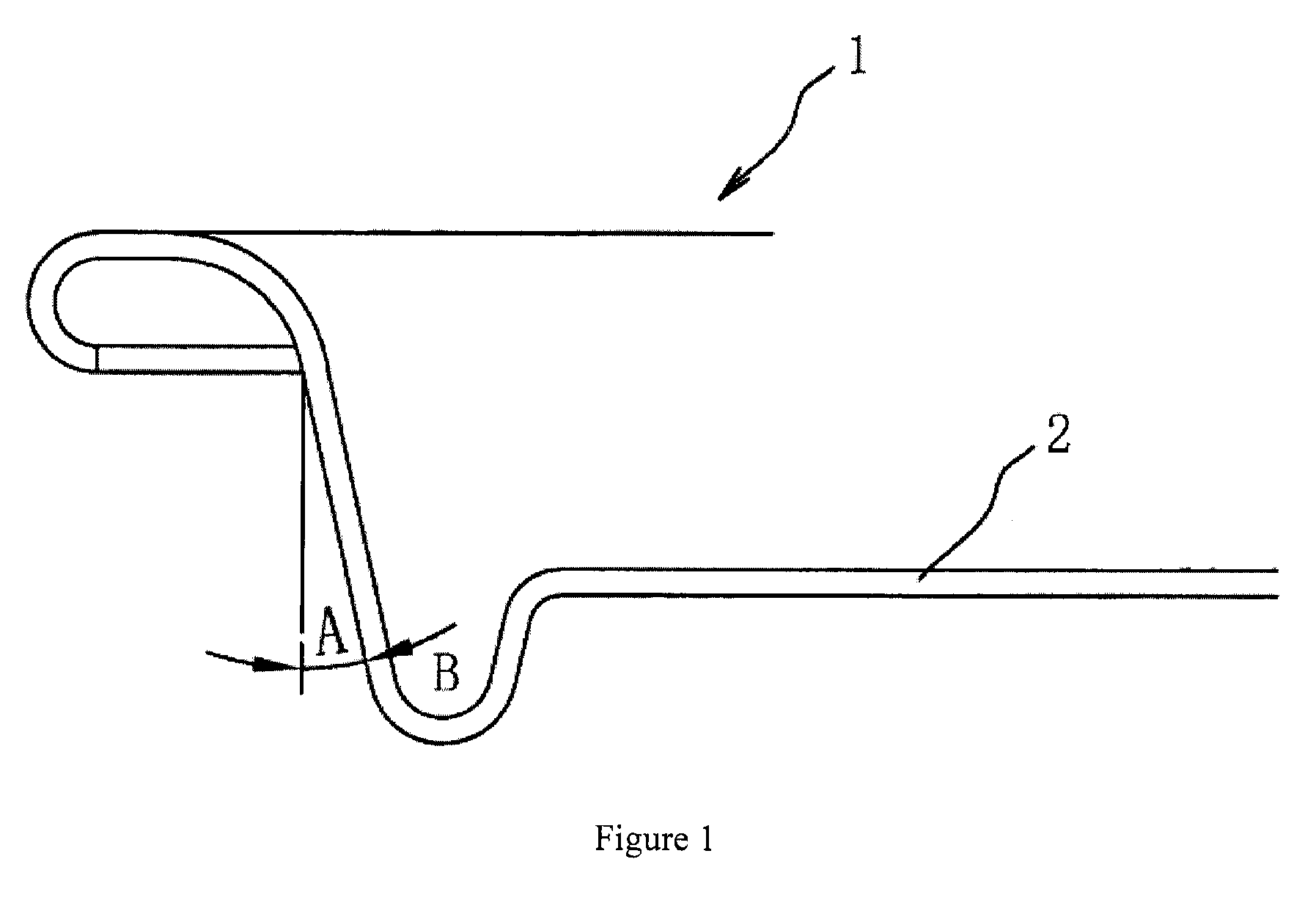

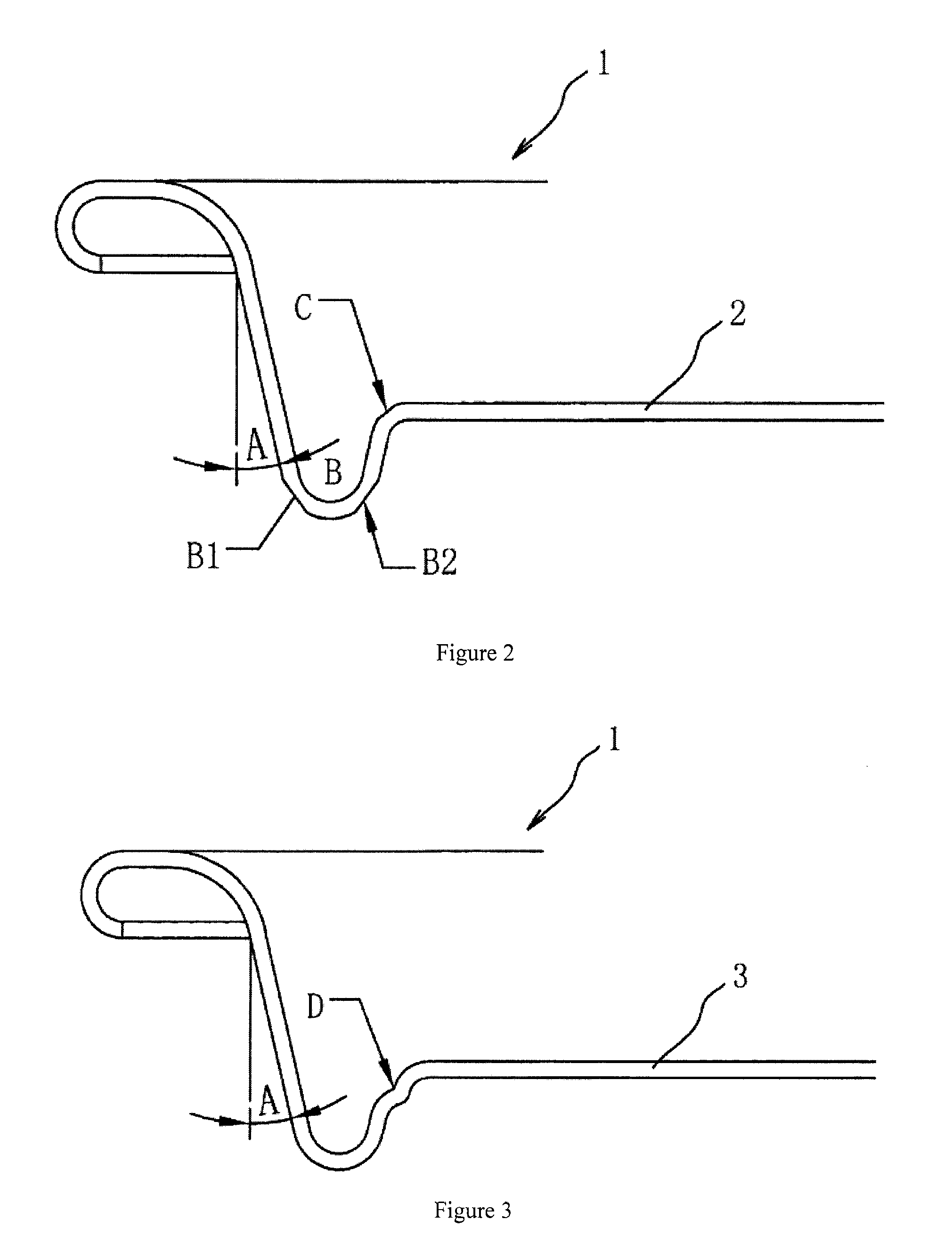

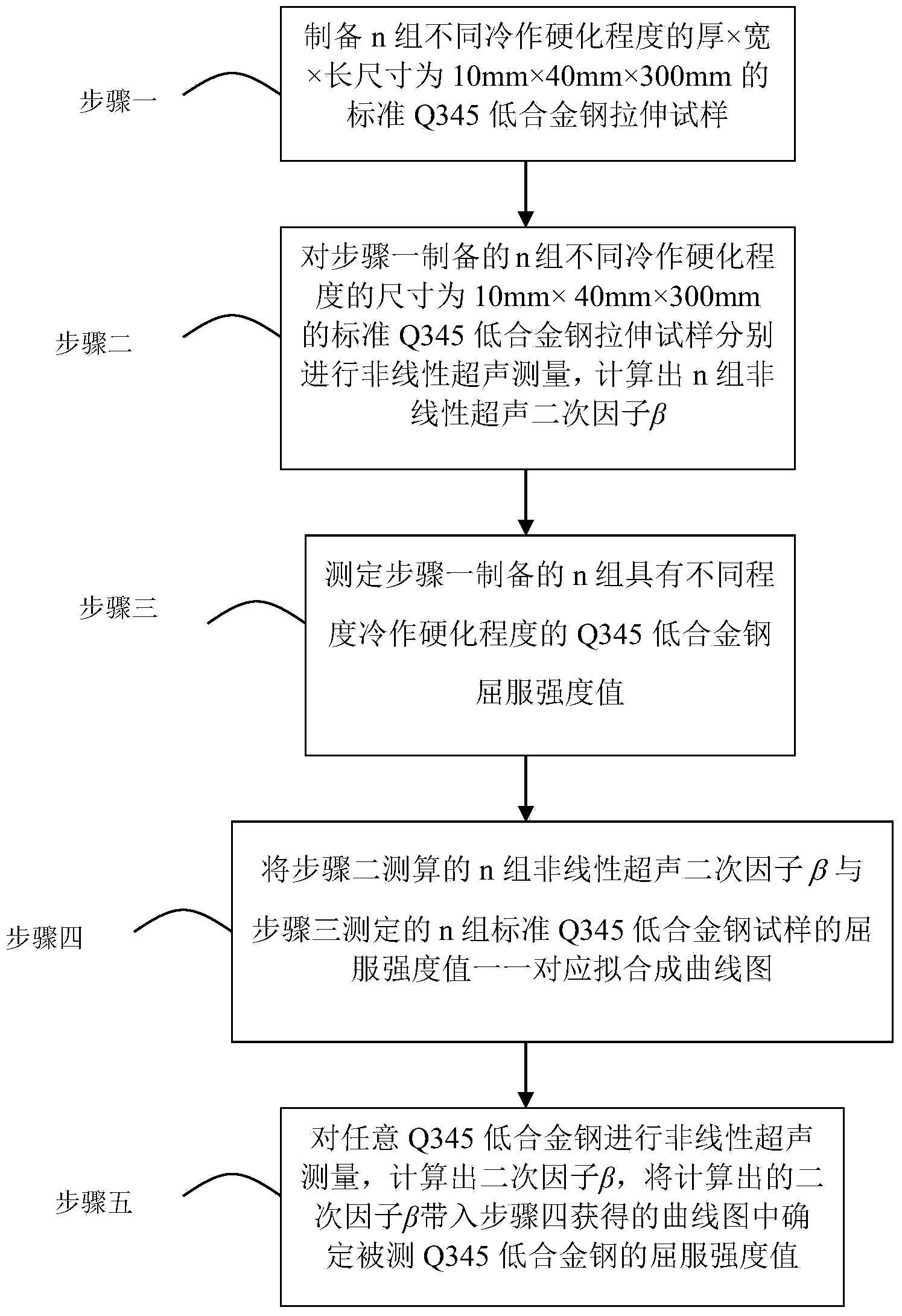

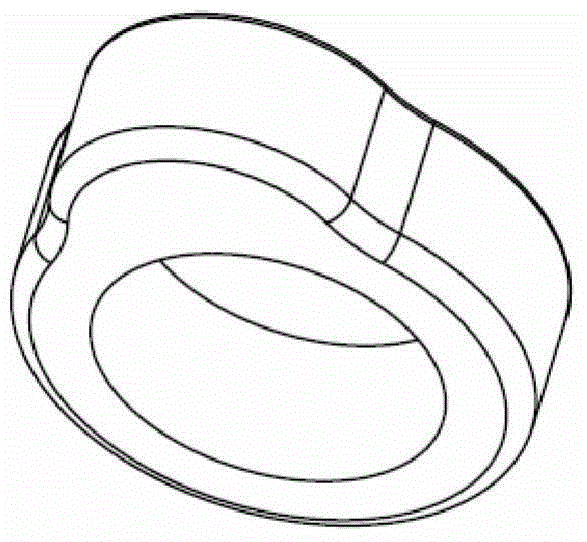

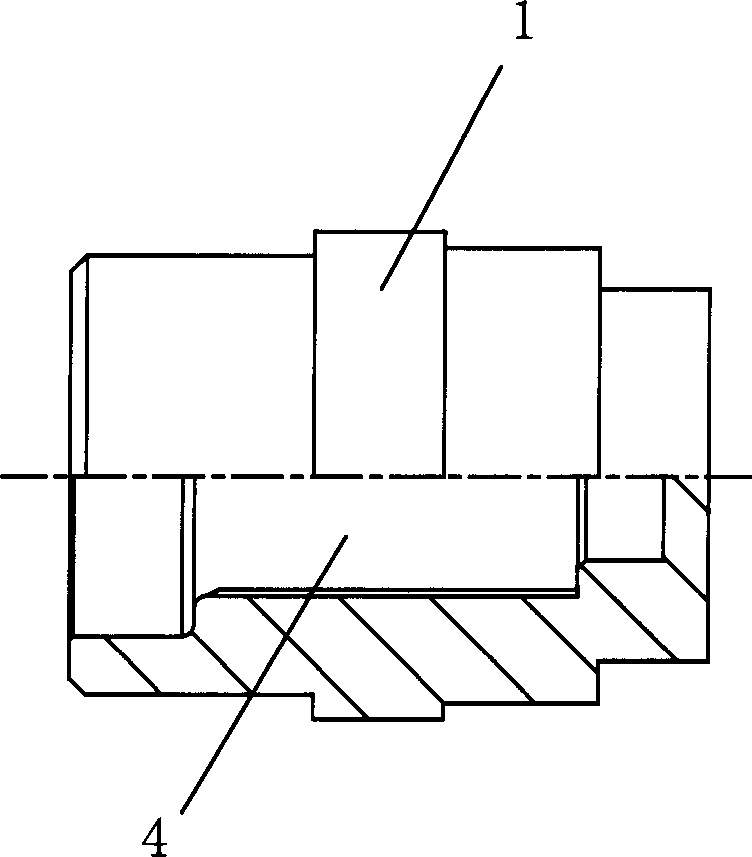

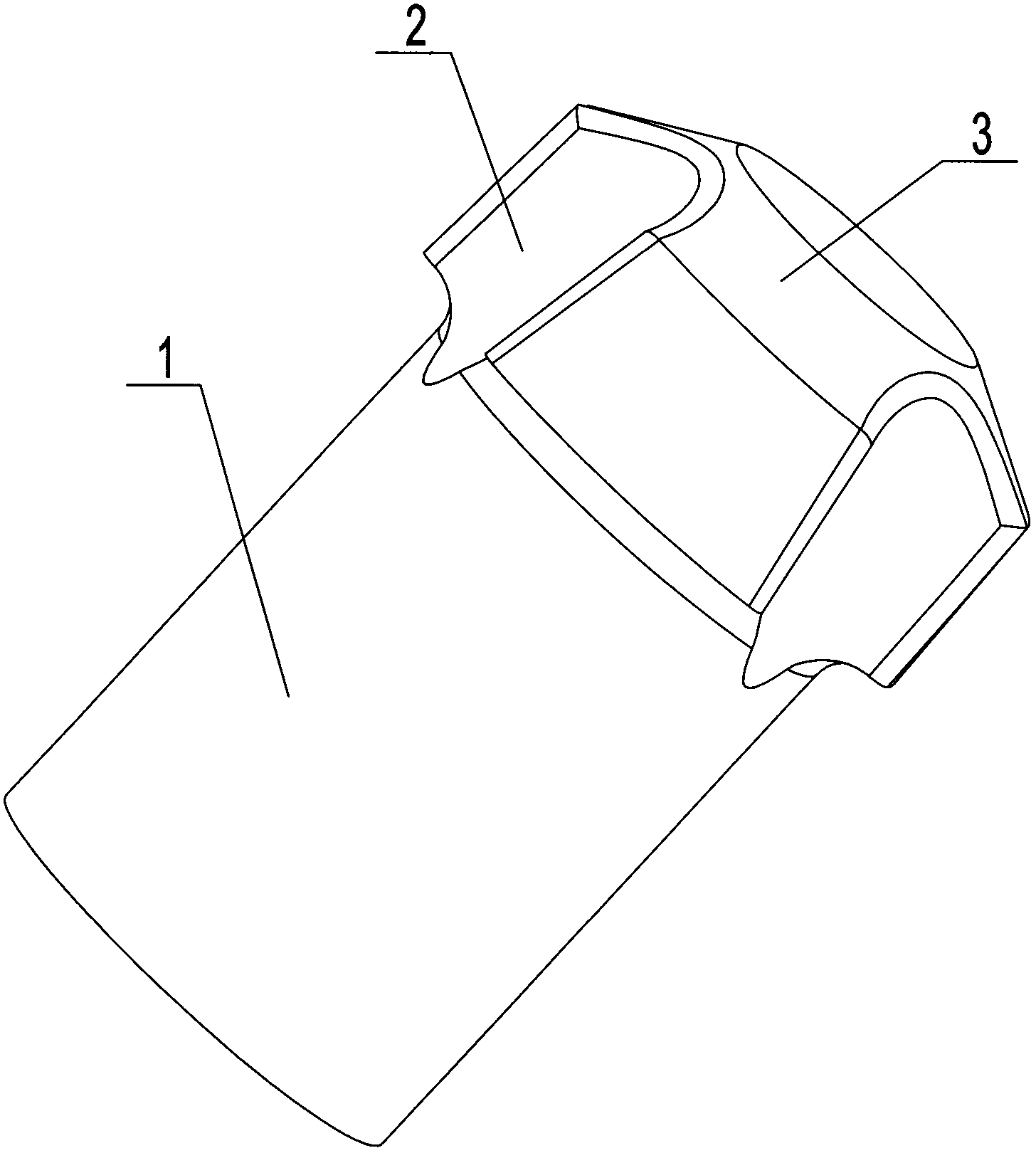

Internal Gas Pressure Resistant Metal Pop-Top Cover and Method of Making

ActiveUS20100059517A1Reduce the overall diameterSave materialRigid containersHollow articlesCold hardeningEngineering

A gas pressure-resistant metal pop-top cover comprised of two parts, a lid (1) and a pull-ring, the pull-ring being riveted to the lid (1), there being a concave countersink that begins at the circumferential edge of the lid (1) and extends toward its center, and at the center of the concave countersink there being a round convex platform (2), wherein the angle of inclination A of the countersink is 15-60°, and the arc-shaped segments B1 and B2 of the bottom part of the convex platform and the corner portion of the rise segment C rotate around the center of the lid (1) and are subjected to cold hardening treatment through forging and pressing. Through a new design, the conflict between material-saving and maintaining pressure resistance in a pop-top cover has been solved, with the result that greater resistance to high pressure is provided as the notch diameter and thickness of materials in the pop-top cover are decreased.

Owner:SUZHOU SLAC PRECISION EQUIP CO LTD

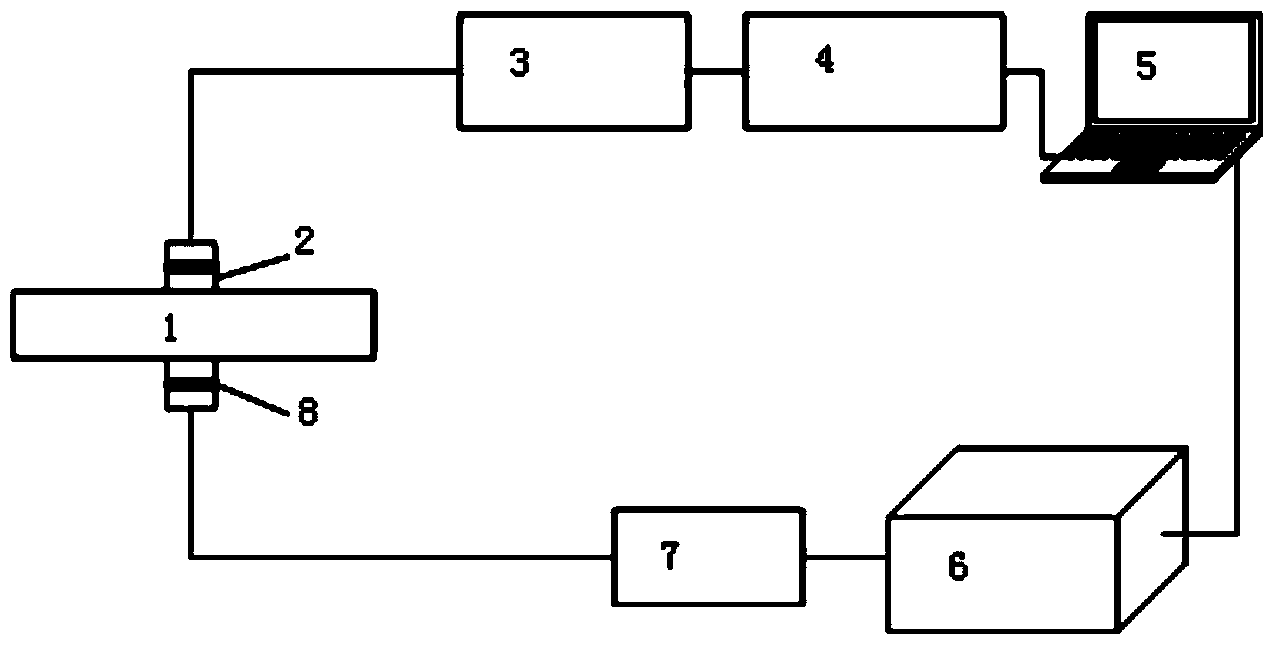

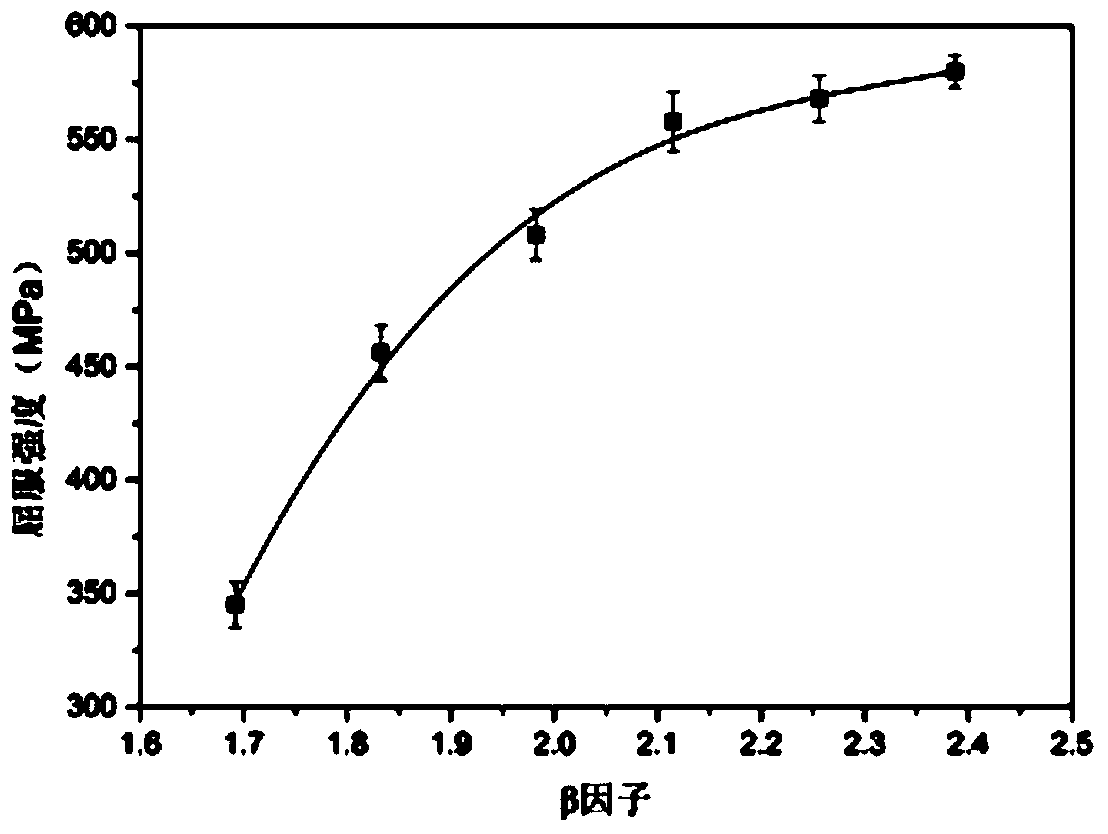

Method for measuring yield strength of Q345 low alloy steel by using nonlinear ultrasonic technique

InactiveCN103713052AYield strength reflectsFast measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesMetallurgyCold hardening

The invention discloses a method for measuring yield strength of Q345 low alloy steel by using a nonlinear ultrasonic technique, which relates to methods for measuring yield strength of Q345 low alloy steel. The method for measuring yield strength of Q345 low alloy steel by using nonlinear ultrasonic technique provided by the invention is used for solving the problems that a traditional steel yield strength measurement method is destructive and the measurement speed is low. The method comprises the following steps: 1. preparing n groups of standard Q345 low alloy steel tensile samples with different cold hardening degrees and with thickness*width*length sizes of 10mm *40mm*300mm; 2. calculating n groups of nonlinear ultrasonic secondary factors beta; 3. measuring the yield strength values of n groups of Q345 low alloy steel; 4. fitting a curve graph; 5. measuring the yield strength value of any Q345 low alloy steel; and the method disclosed by the invention is applied to the field of measurement of yield strength of Q345 low alloy steel.

Owner:STATE GRID CORP OF CHINA +1

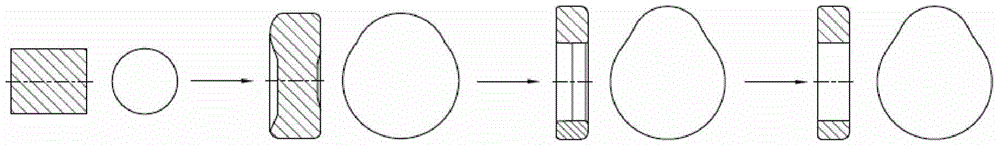

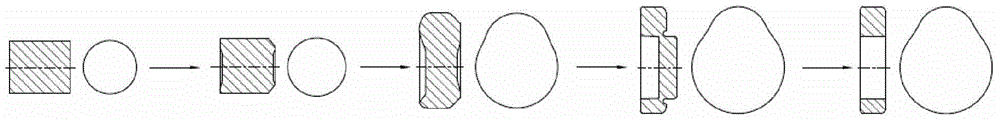

Precise cold forging formed cam sheet manufacturing method

ActiveCN104148574AReduce tensile stressReduce the expansion rateMetal-working apparatusEngine componentsWire rodBall bearing

The invention relates to a precise cold forging formed cam sheet manufacturing method. The manufacturing method includes the steps of A, pretreatment, B, cold forging forming and C, thermal treatment, wherein in the step A, a steel wire rod or a steel bar is annealed, drawn and lubricated, so that a first blank suitable for cold upsetting forming is obtained; in the step B, a cam sheet is forged through a horizontal or vertical forging machine, and the cold forging forming step includes an expansion and extrusion procedure. Due to the adoption of the expansion and extrusion technology, acquisition of a ball bearing steel cold forging cam is possible for the first time; compared with the traditional upsetting technology, forging force is greatly reduced, the cold hardening speed is low, cracks are not likely to generate, the service life of a die is greatly prolonged, a metallographic structure can not be changed in the cold forging process, and a surface structure is free of the carbon insufficiency risk; due to the fact that a finally-used outline is obtained through precise extrusion or finishing directly, the outline of the cam does not need to be ground, and equipment investment and part cost are greatly reduced.

Owner:HANGZHOU XZB TECH

Method for improving winter resistance of turf by adopting garbage compost filtrate

InactiveCN102172147AAchieve annual productionClimate change adaptationOrganic fertilisersLitterCold hardening

The invention discloses a method for improving winter resistance of turf in Tianjin by adopting municipal garbage compost filtrate. The method mainly comprises the following steps: (1) preparing compost eluent, (2) cultivating lawn plants, and (3) carrying out cold hardening and sampling. The final technical effect shows that cold-hardened turf can fully resist winter in the winter environment ofnot less than 10 DEG C below zero in the outdoor balcony without being provided with a heating facility in the house of Tianjin, and the aim of storing the turf in winter is achieved. Compared with the peripheral turfgrass, the ryegrass seedlings turned green in spring next year has obvious advantages, which means that the garbage compost filtrate plays an important role in lawn plant growing andwinter resisting and plays a guiding role in applying the garbage compost filtrate to the growth of the turf in winter. The technology lays a foundation for the production of the turf all year around.

Owner:TIANJIN NORMAL UNIVERSITY

Flux-cored wire for remanufacturing cold hardening resisting supporting roll through bead welding

InactiveCN105290644AImprove toughnessHigh strengthFurnace typesWelding/cutting media/materialsCold hardeningUltimate tensile strength

The invention provides a flux-cored wire for remanufacturing a cold hardening resisting supporting roll through bead welding. A flux core of the flux-cored wire comprises, by mass, 0.35-0.40% of C, 0.5-1.0% of Si, 2.0-3.0% of Mn, 8.0-12.0% of Cr, 0.8-1.2% of Ni, 1.5-2.0% of Mo, 0.3-0.6% of V, 0.05-0.15% of Nb, 1.3-1.9% of La2O3, and the balance Fe. Tempering treatment is conducted on the supporting roll subjected to bead welding and is kept at the temperature of 560 DEG C for 40-48 hours. The flux-cored wire is used for conducting bead welding remanufacturing on the large supporting roll, so that the toughness of metal of a bead weld layer is improved, the high anti-crack property of the supporting roll is guaranteed, the strength and corrosion resistance of the metal of the bead weld layer are further improved, and the cold hardening phenomenon generated in the metal of the bead weld layer is prevented.

Owner:ZHENJIANG HUAYING ROLLER CO LTD

Method for manufacturing spring of derrick centralizer

InactiveCN101543947AGuaranteed Characteristic RequirementsHigh yield strengthFurnace typesHeat treatment process controlSolution treatmentCold hardening

The invention relates to a method for manufacturing a spring of a derrick centralizer, which comprises the following processing steps: (1) selecting an austenitic stainless steel wire as a material of the spring; (2) performing solution treatment, namely heating the steel wire to between 1,050 and 1,100 DEG C under the protection of atmosphere, preserving the temperature for 25 to 35min, and cooling the steel wire by water to normal temperature; (3) performing cold drawing on the steel wire to make the steel wire have a required diameter; (4) coiling the steel wire on a spring coiling machine; (5) performing relief annealing, namely heating the coiled spring to between 390 and 410 DEG C in a tempering furnace under the protection of atmosphere, and preserving the temperature for 25 to 30 minutes; (6) combining end rings of the spring, and correcting the spring; (7) performing treatment of removing residual stress, namely pressing two ends of the spring tightly to make the rings of the spring combined and formed, heating the spring at a temperature of between 240 and 270 DEG C, preserving the temperature for more than or equal to 3h, and cooling the spring by air to room temperature; and (8) performing one-stage or multi-stage shot cold hardening on the spring. The spring of the derrick centralizer manufactured by the method can strengthen corrosion resistance and fatigue resistance under severe working conditions in oil field, while meeting the requirement on the characteristics of the spring, and.

Owner:RG PETRO MACHINERY GROUP

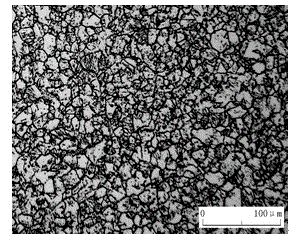

Production method of pure copper stranded wire

InactiveCN105499302AImprove the strength of pure copperIncrease productionRotary drum furnacesCable/conductor manufactureResource utilizationCold hardening

The invention relates to a production method of a pure copper stranded wire. The method comprises the following steps of melting and refining, hot rolling, cooling, pickling, taking-up, wire drawing and wire stranding. After welding, refining and hot rolling processes are conducted on scrap copper, horizontal rolling and vertical rolling are conducted alternatively on a copper rod by adopting rollers of rough rolling and finish rolling with larger rolling reduction in the hot rolling process, and a tiny and even metallographic structure is formed inside the copper rod. In the drawing process, by means of friction calendaring between the copper rod and a mold, the strength of pure copper is improved through cold hardening. All performance indexes of a produced pure copper load-bearing rope can meet standard requirements; compared with a traditional technology, the production method of the pure copper stranded wire has the advantages that the yield is high, the resource utilization rate is high, energy conservation and environmental protection are achieved, and the production cost is low.

Owner:赣州江钨拉法格高铁铜材有限公司

Machining technology prolonging service life of bearing

ActiveCN111633386ADense surfaceHas cold work hardening effectPositioning apparatusMetal-working holdersPunchingCold hardening

The invention discloses a machining technology prolonging the service life of a bearing. Through a series of machining processes such as pipe blank machining, coarse material cutting, end surface grinding, punching, inner and outer surface processing, grinding extrusion and surface grinding, in the bearing coarse material machining process, a raw blank of the bearing is better in hardness throughmultiple times of heat treatment, meanwhile, a mandrel is extruded into the inner diameter of the bearing and passes through the bearing, and thus, the bearing is expanded in the radial direction; thecircumferential stretching effect on the bearing in the extrusion process is achieved, accordingly, the surface of the bearing has a cold hardening effect, the surface is more compact, the comprehensive performance is further improved, and the usage period of the bearing is prolonged to a great extent.

Owner:ANHUI RZN BEARING

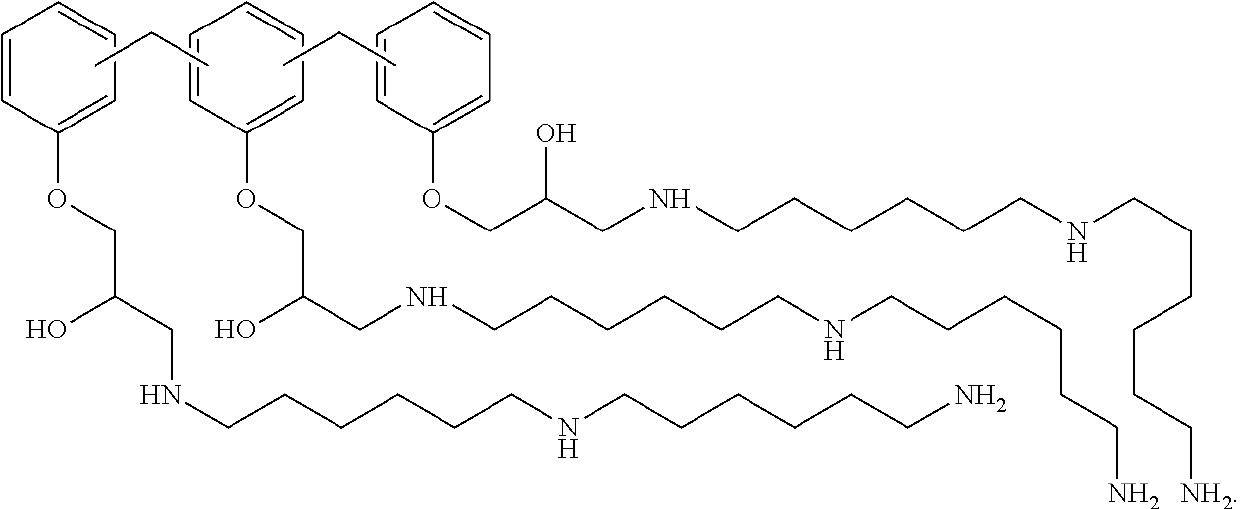

Hardener for cold hardening epoxy resin adhesives having fast hardening

ActiveUS20190382524A1Inexpensively preparableReduce the smellEpoxy resin adhesivesEpoxy resin coatingsGlycidyl ethersCold hardening

An adduct AD obtained from the reaction of at least one novolak glycidyl ether containing an average of 2.5 to 4 epoxy groups per molecule with an amine mixture including bis(6-aminohexyl)amine and at least one amine A1 other than bis(6-aminohexyl)amine that has at least one primary amino group. Preferably, the amine mixture is a technical grade quality of bis(6-aminohexyl)amine that contains 25% to 82% by weight of bis(6-aminohexyl)amine. The adduct AD is preparable in a simple manner and without the use of solvents, and enables low-odor, low-toxicity and low-viscosity hardeners that can be processed and stored even under cold conditions. Epoxy resin compositions cured therewith very rapidly build up high binding forces and high strengths under ambient outdoor temperatures, even on substrates that are difficult to bond.

Owner:SIKA TECH AG

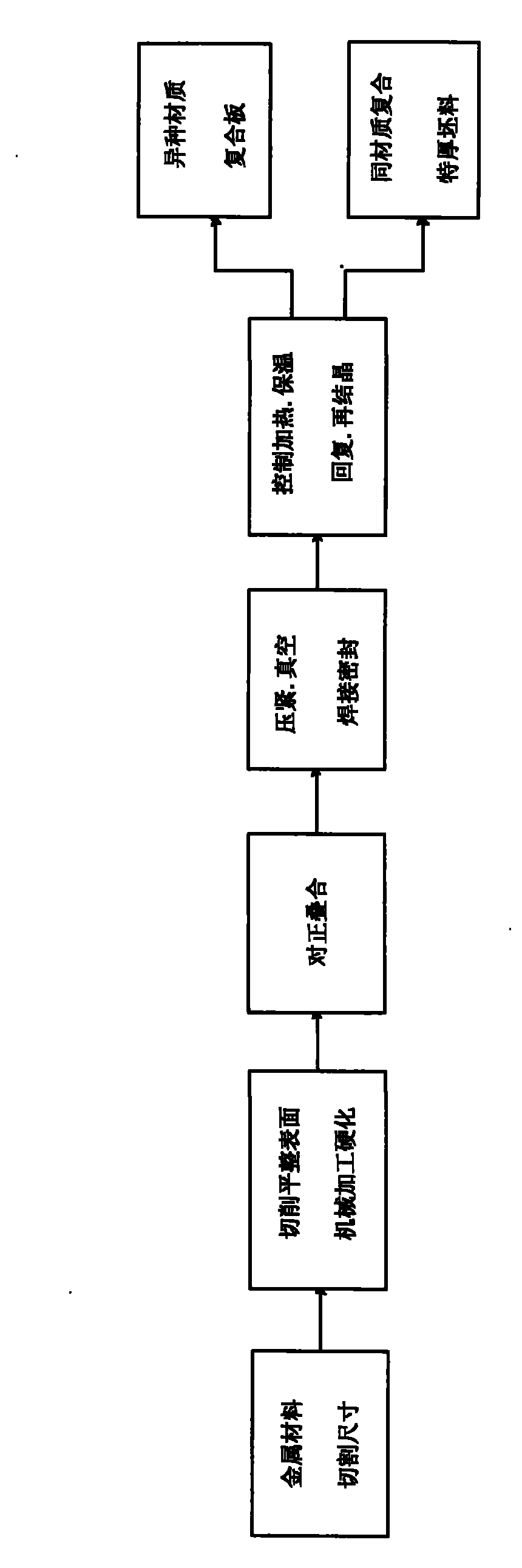

Cold deformation recrystallization course-based process method for producing metal composite material

ActiveCN102000960AEconomical and convenient productionQuality improvementWelding/soldering/cutting articlesMetal layered productsCompound aSurface layer

The invention discloses a cold deformation recrystallization course-based process method for producing a metal composite material, which aims to compound two or more metal materials with different material qualities or the same material quality. The process method comprises the main steps of: firstly, removing surface layers of the two metal materials by utilizing a mechanical processing method, mainly forming the cold hardening on processing surfaces to ensure that the surfaces are flat and clean; then, ensuring that the processing surfaces of the metal materials face towards each other and are aligned and superposed and completely adhered, and welding the peripheries of joint surfaces of the two metal materials under the condition of pressure compaction and / or vacuum; and gradually heating the welded combining block until the restoring and recrystallization temperature of the material T is more than 0.4T so as to ensure that the tissues of the two metal materials are integrated into a whole. The invention can be used for compounding a stainless steel plate and a straight carbon steel plate, compounding the metals of nickel and titanium and the straight carbon steel plate, and compounding multilayer thin materials of the same material into thick materials.

Owner:辽宁孚胜金属复合板有限公司

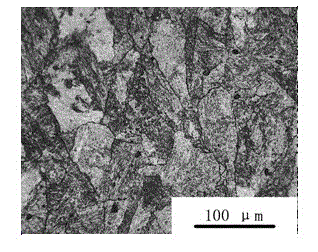

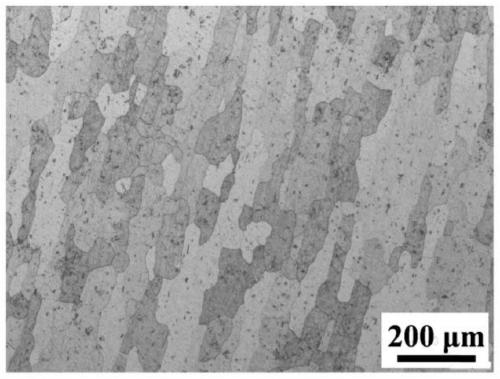

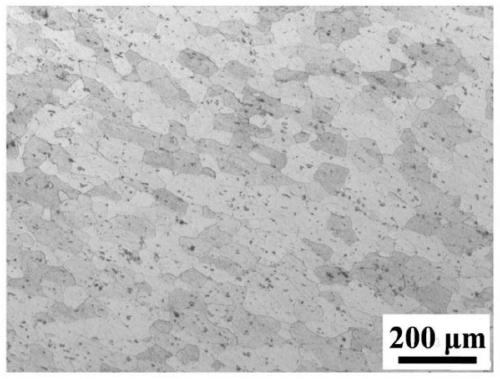

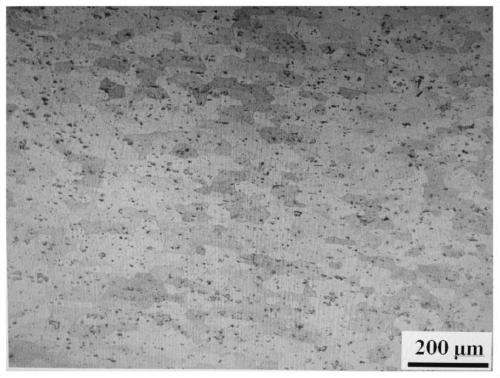

Variable-temperature circular treatment method of ultrafine C250 maraging steel grains

The invention discloses a variable-temperature circular treatment method of ultrafine C250 maraging steel grains, which comprises the following steps: heating C250 maraging steel to 700-780 DEG C, keeping the temperature for 1-10 minutes, and carrying out water quenching to room temperature, thereby implementing primary circular treatment; and heating the material subjected to primary circular treatment to 900-960 DEG C, keeping the temperature for 1-10 minutes, and carrying out water quenching to room temperature, thereby implementing secondary circular treatment. The variable-temperature circular treatment twice simultaneously implements refinement and homogenization of the C250 maraging steel grains. By utilizing the characteristic of phase-change cold hardening recrystallization in the reverse change process from martensitic structure to austenite by heating, the variable-temperature circular treatment twice effectively and sufficiently refines and homogenizes the austenite grains without plastic deformation. The invention can effectively enhance the toughness and fatigue life of the part.

Owner:GUIZHOU UNIV

Method and device for working bearing fixing sleeve using cold extrusion process

This invention discloses a method of processing gearing fixation cover using cold extrusion technique and its equipment. Materials' plasticity is used to forming through linear to-and-fro in cold extrusion mould. It can improve output and reduce cost, prolong quality period. Gearing fixation cover with axial sinew flute can be processed, and cold hardening phenomenon in the processing of cold extrusion is fully used to improve product hardness.

Owner:HENGJI HARDWARE ELECTRONICS

Stainless steel material and manufacturing methods thereof

ActiveCN105296869ANo allergiesHigh strengthOther manufacturing equipments/toolsPunchingCold hardening

The invention discloses a stainless steel material and manufacturing methods thereof. The stainless steel material is Cr-Mn-N austenitic stainless steel with nickel replaced with nitrogen. The manufacturing methods comprise a smelting method, a blank punching method and a machining method. The smelting method mainly comprises the step of smelting high-nitrogen steel through two alloying nitrogen-increasing methods, namely using nitrogen-containing materials and gaseous nitrogen. The blank punching method mainly comprises the steps of conducting circulative blank punching, conducting heat treatment, conducting solid solution treatment, and controlling the heat retention temperature and heat retention time, wherein hardness values and impact toughness values serve as the main reference for die selection. The machining method mainly comprises the steps of controlling appropriate machining parameters of milling and turning. The stainless steel material and the manufacturing methods thereof have the advantages that the stainless steel material is the novel austenitic stainless steel; the smelting method is applicable to batch smelting of the high-nitrogen steel with the nitrogen content ranging from 0.4 wt% to 0.75 wt%; the blank punching method inhibits cold hardening phenomena in the high-nitrogen steel machining process, and blank punching is facilitated; through the machining method, the problem that machining difficulty is large due to high hardness of the high-nitrogen steel is solved.

Owner:CENT IRON & STEEL RES INST +1

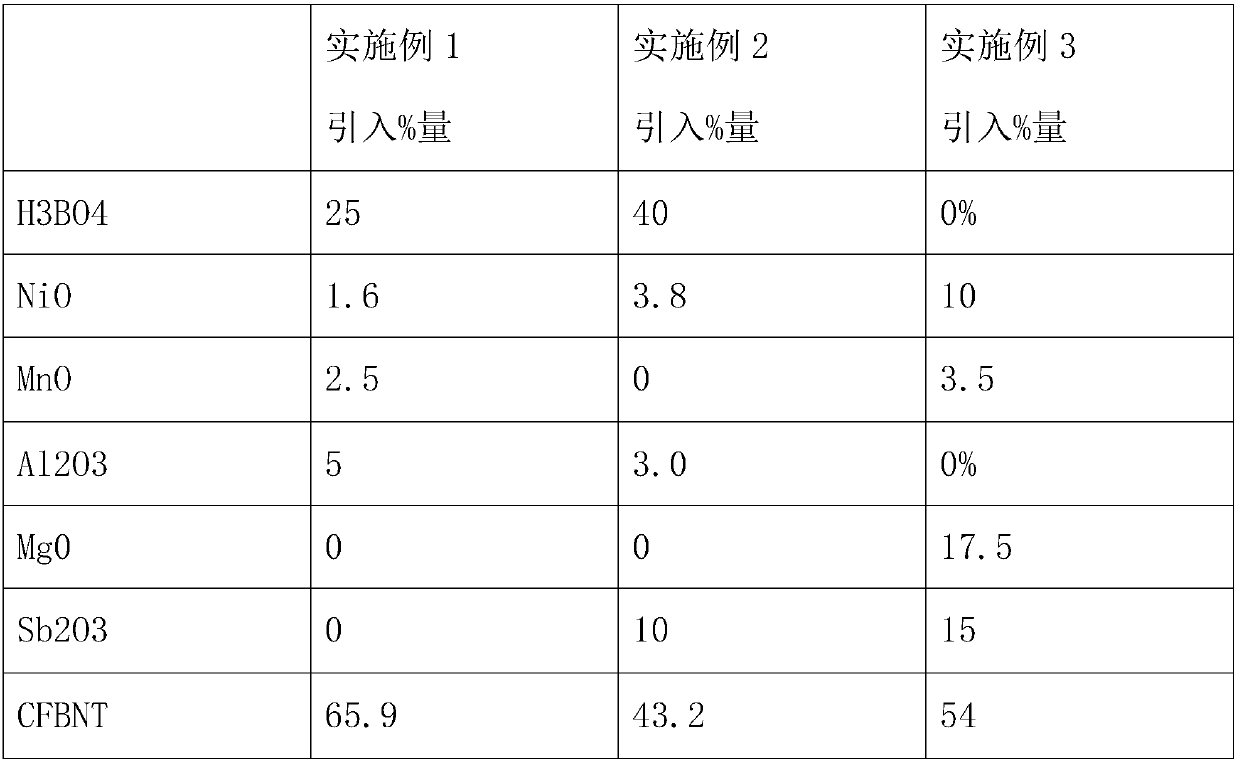

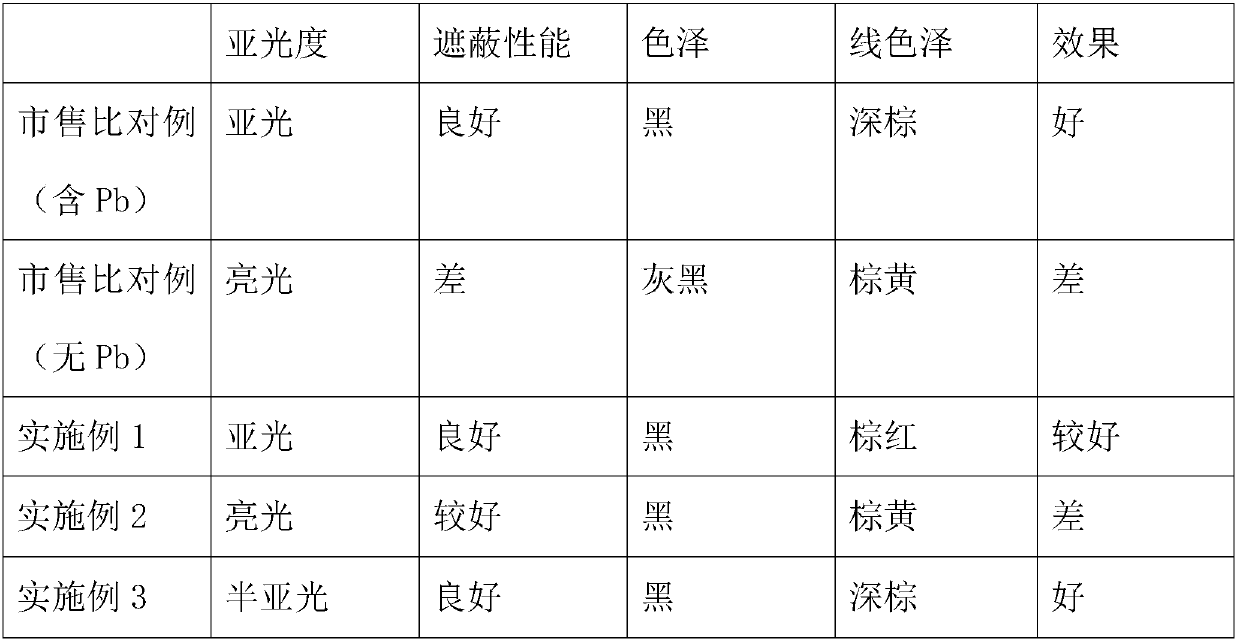

Semi-matt lead-free glass powder for automobile backstop glass and preparation method of glass powder

PendingCN109574502ASolve the problems of particles, pinholes, etc.Has the characteristics of non-secondary reunionSurface layerCold hardening

The invention discloses impact-resistant toughened glass prepared from a semi-matt lead-free glass powder and a preparation method of the toughened glass. The preparation method includes the steps: weighing NiO, MnO, MgO and Sb2O3 according to the ratio, mixing the NiO, the MnO, the MgO, Sb2O3 and a certain H3BO4 for standby application, melting mixture at the high temperature of the 1000-1250 DEGC, rapidly pouring the mixture into purified water after discharging, weighing Cr2O3, Fe2O3, Bi2O3, NaF and TiO2 according to ratio, and mixing the Cr2O3, the Fe2O3, the Bi2O3, the NaF and the TiO2 for standby application; melting mixture at the high temperature of the 1000-1250 DEG C, rapidly pouring the mixture into purified water after discharging to form cold hardening particles, and drying the particles; mixing the particles and the mixture for standby application; weighing materials without being matched according to the ratio, performing secondary mixing on the materials without beingmatched and the mixture, crushing and pretreating mixture, melting screened mixture at the high temperature, and rapidly pouring the mixture into purified water to perform cold quenching; collecting and drying the mixture, and finely grinding the mixture to obtain glass powder. The impact-resistant toughened glass solves the problems that a glaze layer reflects light and a surface layer is matte in the secondary melting process of a glass body.

Owner:咸阳盈和电子材料有限公司

Method for increasing stress corrosion resistance of Fe-Ni-based anticorrosion alloy oil well pipe

ActiveCN109234500AReduce development costsImproved resistance to stress corrosion crackingFurnace typesHeat treatment furnacesCrack resistanceCold hardening

A method for increasing the stress corrosion resistance of a Fe-Ni-based anticorrosion alloy oil well pipe comprises the following steps: I, preparing a blank pierced billet for a cold hardening typeFe-Ni-based anti-corrosion alloy oil well pipe through hot working modes such as hot extrusion or hot rolling; II, preparing the cold hardening type Fe-Ni-based anti-corrosion alloy oil well by adopting a two-pass or multi-pass Pilger cold rolling mode; III, carrying out solid-solution annealing among all passes of cold working, and removing a cold hardening effect of a pipe; IV, enabling the deformation rate of final-pass cold rolling to be 56.5 percent or more; V, enabling the feeding amount of the final-pass cold rolling to be 5mm every time or more and the rolling frequency to be 20 per minute or more; VI, slowly cooling an oil well pipe prepared through the final-pass cold rolling to room temperature through an asbestos covering or sand covering mode. According to the method disclosedby the invention, the stress corrosion cracking resistance of the cold hardening type Fe-Ni-based anti-corrosion alloy oil well in H2S medium environment can be remarkably increased.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

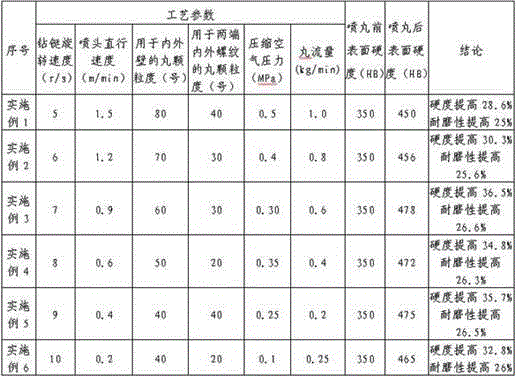

Process for strengthening surfaces of inner and outer walls of non-magnetic drill collar and internal and external threads of joints at two ends

The invention discloses a process for strengthening the inner and outer walls of a non-magnetic drill collar and the internal and external threads of joints at two ends, wherein the horizontal non-magnetic drill collar rotates around a fixed axis; the spray head of a shot-blasting machine is aligned to the start ends of the inner and outer walls of the non-magnetic drill collar respectively so as to spray pills; the spray head axially moves towards the other end; then, the spray head of the shot-blasting machine is aligned to the start ends of the internal and external threads of the joints at two ends respectively so as to spray pills; and then, the spray head axially moves towards the other end. Aiming at the characteristics of the non-magnetic material, ZIRPRO ceramic ultra-fine pills are selected; shot blasting is driven by compression air; work pieces have very obvious cold hardening effect under collision of dense and high-speed pills; in the event that the non-magnetic characteristics of the work-pieces are not changed, besides obviously increased hardness, the erosion resistance of a formed surface compact metal layer is also increased; and the process disclosed by the invention is used for reducing the cracking rate caused by stress corrosion while drilling a well, also increasing the wear-resisting property simultaneously, and being beneficial to increasing the service life of the non-magnetic drill collar.

Owner:JIANGSU SHUGUANG HUAYANG DRILLING TOOL

Precise forming process of deep-hole button bit

The invention discloses a precise forming process of a deep-hole button bit, which is low in processing cost. The forming process comprises technological processes as follows: material sawing, spheroidizing annealing, shot blasting, phosphating, saponifying, backward extruding, low-temperature annealing, shot blasting, phosphating, saponifying, outer diameter reducing, low-temperature annealing, shot blasting, phosphating, saponifying and head upsetting and forming. The precise forming process has the advantages as follows: with the adoption of a precise cold forging forming method, metal flow lines of parts are continuously and uniformly distributed in the direction of metal flowing, and particularly the inner cavity part which bears impact doesn't have the problem of cut-off flow lines, and the strength is improved greatly; and meanwhile, due to the specific cold hardening effect produced during plastic forming of metal, the whole strength of the parts is improved.

Owner:盐城中德精锻股份有限公司

Carbon fiber reinforced resin powder material

The invention discloses a carbon fiber reinforced resin powder material. The material comprises main raw materials and auxiliary materials; the main raw materials comprise, by mass, 50-60 parts of polyacrylonitrile carbon fibers, 40-50 parts of asphalt-based carbon fibers, 30-40 parts of IM8 carbon fibers, 10-15 parts of phenolic resin, 12-15 of epoxy resin and 13-15 parts of thermoplastic resin;and the auxiliary materials comprise, by mass, 5-8 parts of an antioxidant and 3-5 parts of a catalyst. The epoxy resin has strong adhesion, normal temperature operability, simple constructability andother good workability, and the thermoplastic resin has heat softening and cold hardening performances, so the main raw materials can improve the high temperature resistance and the corrosion resistance, and make the powder material have excellent thermodynamic performances; and the raw materials have low prices, so the powder material can be massively produced, thereby the practicality of the carbon fiber reinforced resin powder material is improved.

Owner:珠海诚然科技服务有限公司

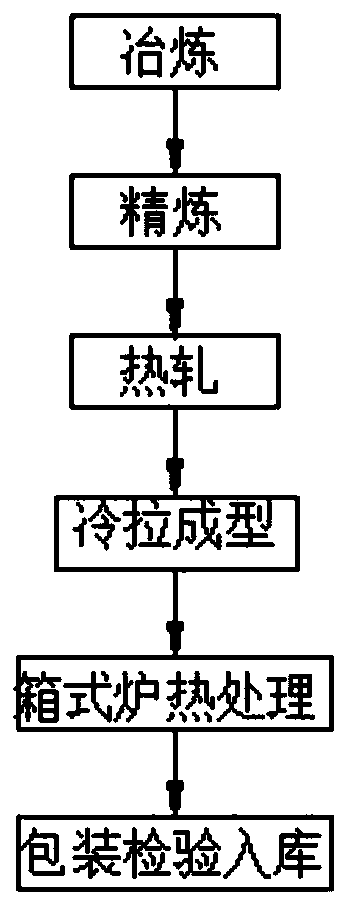

Heat-resistant steel for automobile fasteners and production method of heat-resistant steel

The invention discloses a heat-resistant steel for automobile fasteners and a production method of the heat-resistant steel. The heat-resistant steel is produced by adopting the production method of smelting, refining, hot-rolling, cold-drawing forming, box furnace heat treatment and inspection, packaging and storage. A trace amount of copper and lanthanum-cerium rare earth elements are speciallyadded into heat-resistant steel raw materials, cold hardening can be delayed, the purification of metal grain boundaries can be strengthened, the cold forging performance of the heat-resistant steel is improved, the heat-resistant steel can meet national requirements, the performance is good, the quality is high, producing of the automobile fasteners is facilitated, and the heat-resistant steel isbeneficial to prolonging the service life of the automobile fasteners.

Owner:SUZHOU DOUBLE GOLD IND

Material processing stress online removing and straightening cutting-off process

ActiveCN110894570APrevents the problem of excessive cold work hardeningShorten working hoursTemperingCold hardening

The invention discloses a material processing stress online removing and straightening cutting-off process. The process sequentially comprises the following process steps of stainless steel wire rod unwinding, straightening, heat treatment, cooling, secondary straightening and shearing. Heat treatment adopts a tubular furnace for tempering treatment, the length of the tubular furnace is 8 m, the heat treatment temperature is 900 DEG C, and the wire inlet speed of the stainless steel wire rod is 4-5 m / min. Online machining stress removing can be achieved, the working time is saved, the workingefficiency is improved, cooling is not pure air cooling or water cooling any more, the mode between air cooling and water cooling is adopted, the problem that the air cooling efficiency is not high issolved, and the problem that due to water cooling, the cold hardening degree of materials is too high is solved; the technological mode can be well matched with a continuous mode of online rolling and online heat treatment of stainless steel products, the machining time is short, and the machining efficiency is high.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

Machining method for reducing deformation of elongated thin-wall rocket combustion chamber shell

The invention discloses a machining method for reducing deformation of an elongated thin-wall rocket combustion chamber shell. The machining method avoids the defects of large deformation and difficult correction of an elongated thin-wall shell caused by quenching and tempering heat treatment after welding of a traditional shell by adopting cylinder heat treatment strengthening, power spinning cold hardening strengthening, laser welding or electron beam welding and stress tempering after welding. By the adoption of the machining method, the size diameter difference and straightness of the shell are remarkably reduced, and design requirements are met without shape correction; for the a shell with the diameter phi of 300 mm, the wall thickness of 2.2 mm and the length of 3,000 mm, the size diameter difference is 1.5 mm and the straightness is 1.0 mm; and for a shell with the diameter phi of 200 mm, the wall thickness of 1 mm and the length of greater than 800 mm, the size diameter difference is 1 mm, and the straightness is 0.8 mm.

Owner:湖北三江航天江北机械工程有限公司

Manufacturing method of metal spinning part

The invention provides a manufacturing method of a metal spinning part. The manufacturing method of metal spinning parts comprises the following steps of 1, prestretching a metal raw material into a pie blank; 2, conducting first-pass spinning on the blank and then conducting complete annealing treatment on the blank to obtain a primary treated product; 3, conducting second-pass spinning on the primary treated product and then conducting incomplete annealing and quenching treatment to obtain a secondary treated product; and 4, conducting third-pass spinning on the secondary treated product andthen conducting quenching and aging treatment to obtain the metal spinning part. Through the manufacturing method, the crack sensitive rate of products can be eliminated or substantially reduced; thephenomena of surface cracking of spinning products manufactured through the method can be reduced by 90% or more; and the situation that the products are subjected to cold hardening in the spinning process badly, the crack depth of the outer surface of the spinning part is increased and the spinning part gets cracked and is scrapped is avoided.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

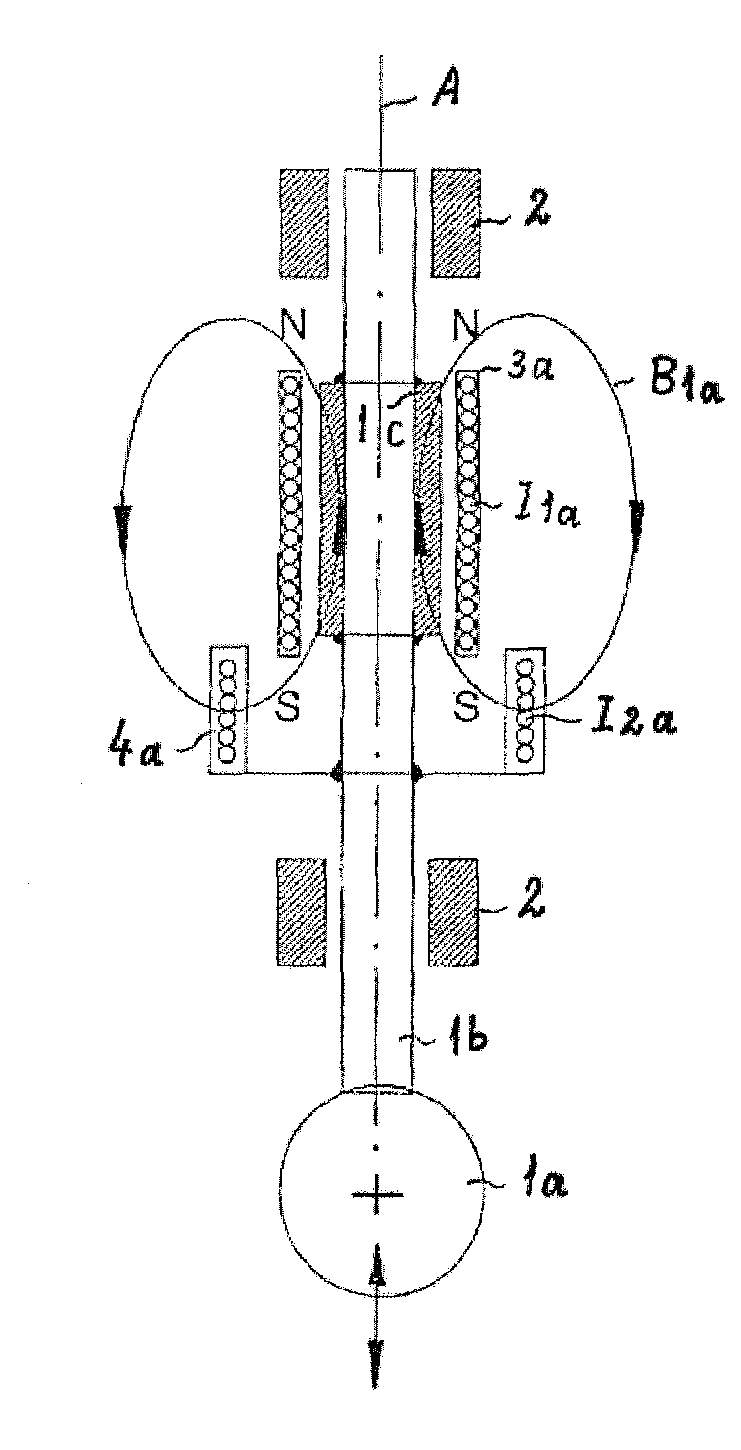

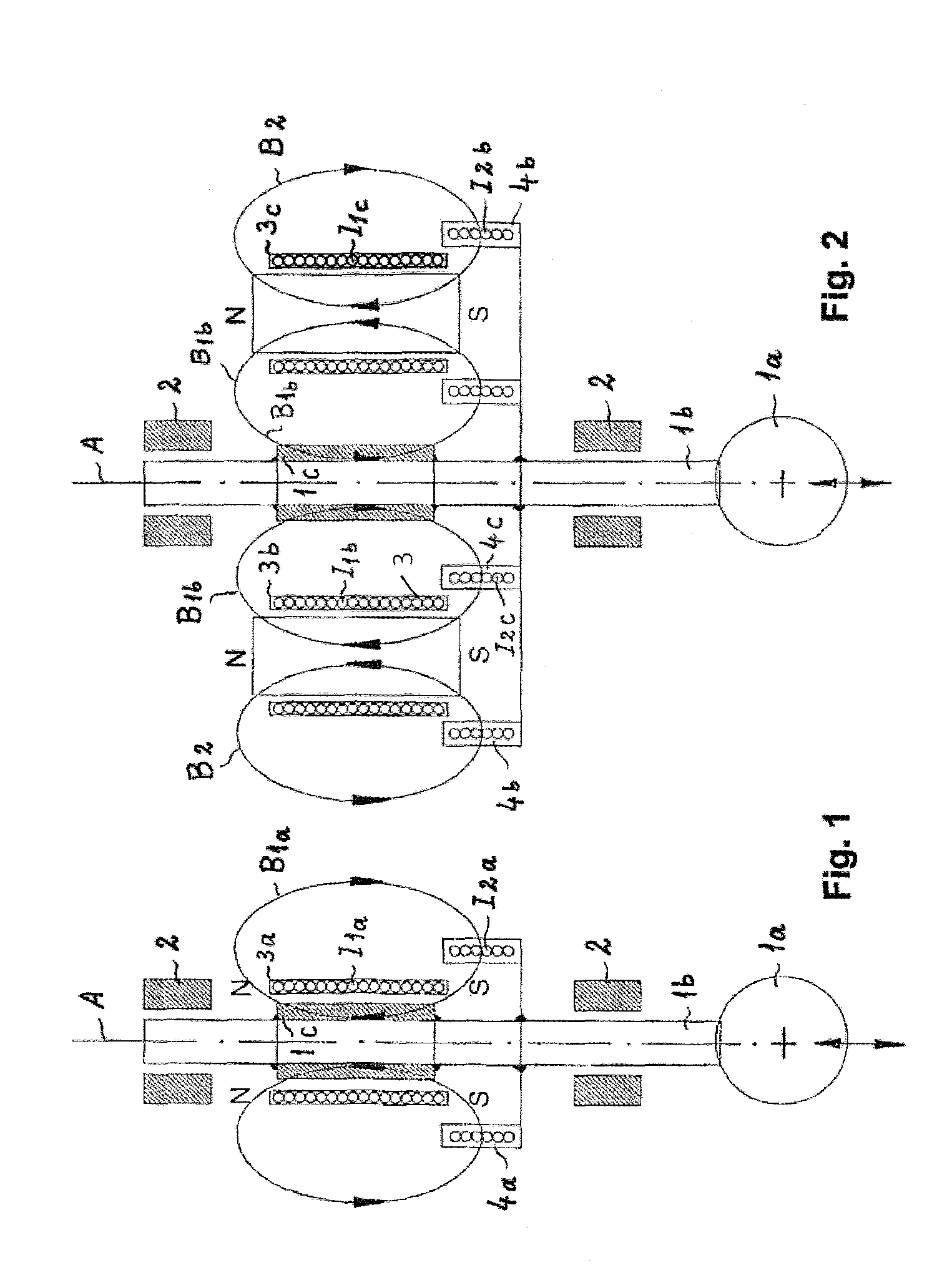

Method and device for the technique of cold microforging any freely formed 3-D surfaces

ActiveUS8166793B2Minimum of wearMinimum of abrasionAC motor controlMetal-working feeding devicesCold hardeningCombined use

An electromechanical knocking activated device and method for working and cold-hardening the surface of tools, machine parts, etc. is disclosed. The electromechanical apparatus may include: an impact head which is secured to a support, wherein at least one part of the support is composed of a ferromagnetic material; and at least one coil which is also secured to the support. A magnetic field holds the impact head in a defined position of rest. The coil is may be positioned in the same magnetic field or a second magnetic field, through which an alternating or pulsed current may flow. As a result, the impact head is made to oscillate with a defined impact frequency, impact altitude and zero crossing. The device may be used in combination with a computer aided manufacturing system.

Owner:LOECKER CHRISTIAN

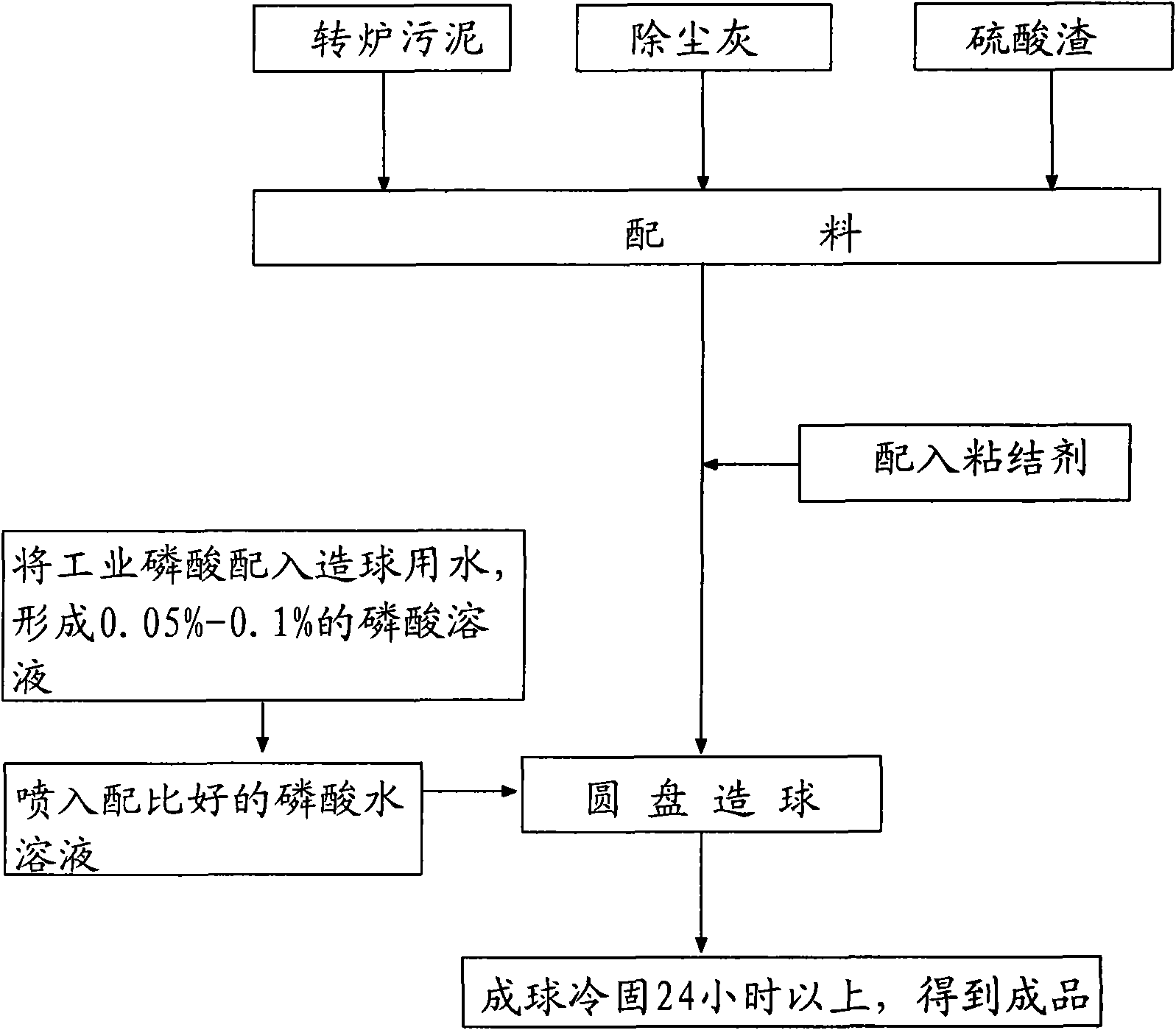

Fast-setting water-hardening sludge cold hardened pellet and preparation method thereof

InactiveCN101549530AHow to solve difficult problemsReduce occupancyMixing operation control apparatusCeramic shaping apparatusSludgePhosphoric acid

The invention discloses a fast-setting water-hardening sludge cold hardened pellet which is formed mainly by mixing converter sludge, settled dust, sulfuric acid residue and binder, and then adding 0.05-0.1 percent (in concentration) of phosphoric acid, then finally conducting disc pellet fabrication and cold hardening; the pellet is quite suitable to be served as the sintering materials of a belt-type sintering machine; in addition, the invention also provides a preparation method for the fast-setting water-hardening sludge cold hardened pellet; and the method ensures the integrity of particles when the cold hardened pellet enters the mixing materials, maintains the permeability of a sintered material layer, and can obtain stable economic indicators of sintering production technology.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

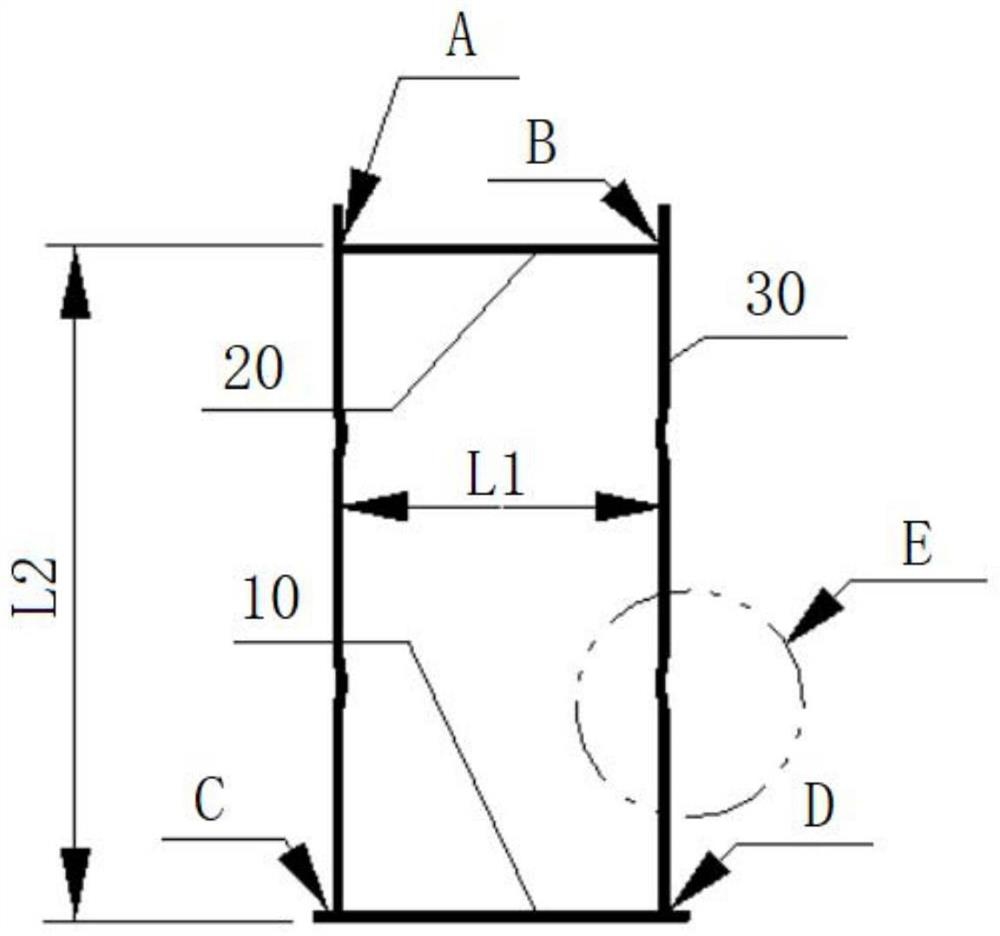

Box-shaped cantilever crane and welding deformation control method thereof

The invention belongs to the technical field of engineering machinery, and discloses a box-shaped cantilever crane and a welding deformation control method thereof.The box-shaped cantilever crane comprises a single boom section, the single boom section comprises a bottom plate, side plates and an upper cover plate, the bottom plate, the left side plate, the right side plate and the upper cover plate are spliced into a box-shaped structure, and bending parts are arranged on the side plates. And the left side plate and the right side plate are placed on a bending machine to be longitudinally bent, the bending force is controlled, the left side plate and the right side plate are deformed with the deformation amount being P1, P1 ranges from 2 mm to 3 mm, the number of bending channels is 2-3, and the left side plate and the right side plate have the cold hardening effect. The method has the beneficial effects that the welding deformation of the box-shaped arm support can be effectively reduced, the planeness, straightness and other form and location tolerances are ensured to meet the design and process requirements, and the bearing capacity of the box-shaped structure is improved.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD +1

Material bar single-side clamping type straightening device and straightening method

ActiveCN113145691AAvoid deformationReduce distortionMetal-working feeding devicesPositioning devicesCold hardeningEngineering

The invention discloses a material bar single-side clamping type straightening device and straightening method, and belongs to the technical field of straightening equipment. The material bar single-side clamping type straightening device comprises a hydraulic / pneumatic cylinder driving device connected with an upper pressing plate and used for driving the upper pressing plate to downwards press a material bar, the upper pressing plate used for pressing the material bar downwards, a base fixedly arranged and used for supporting a lower pressing plate; the lower pressing plate fixedly supported on the base and used for being matched with the upper pressing plate when the upper pressing plate downwards presses the material bar, a clamp assembly and a clamp assembly supporting platform; one set of clamp assembly is arranged at one side, and the clamp assembly is used for clamping the clamping end of the material bar; and the clamp assembly supporting platform is driven by a driving mechanism and can achieve linear stepping movement. The material bar can be prevented from being subjected to extra force or repeated force to cause extra deformation, cold hardening is reduced, only slight oxide skin falls on the appearance of a steel bar in the whole straightening process, extrusion deformation is avoided, and the integrity of the steel bar is obviously protected.

Owner:SGIS SONGSHAN CO LTD

A Method for Improving Stress Corrosion Resistance of Iron-Nickel-Based Corrosion-Resistant Alloy Oil Well Pipe

ActiveCN109234500BReduce development costsImproved resistance to stress corrosion crackingFurnace typesHeat treatment furnacesFernicoCold hardening

A method for increasing the stress corrosion resistance of a Fe-Ni-based anticorrosion alloy oil well pipe comprises the following steps: I, preparing a blank pierced billet for a cold hardening typeFe-Ni-based anti-corrosion alloy oil well pipe through hot working modes such as hot extrusion or hot rolling; II, preparing the cold hardening type Fe-Ni-based anti-corrosion alloy oil well by adopting a two-pass or multi-pass Pilger cold rolling mode; III, carrying out solid-solution annealing among all passes of cold working, and removing a cold hardening effect of a pipe; IV, enabling the deformation rate of final-pass cold rolling to be 56.5 percent or more; V, enabling the feeding amount of the final-pass cold rolling to be 5mm every time or more and the rolling frequency to be 20 per minute or more; VI, slowly cooling an oil well pipe prepared through the final-pass cold rolling to room temperature through an asbestos covering or sand covering mode. According to the method disclosedby the invention, the stress corrosion cracking resistance of the cold hardening type Fe-Ni-based anti-corrosion alloy oil well in H2S medium environment can be remarkably increased.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com