Method and device for working bearing fixing sleeve using cold extrusion process

A technology for processing and fixing sleeves, applied in the direction of metal extrusion dies, etc., can solve the problems of short quality cycle, reduced output, and increased cost, and achieve the effect of longer quality cycle, higher hardness and lower cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

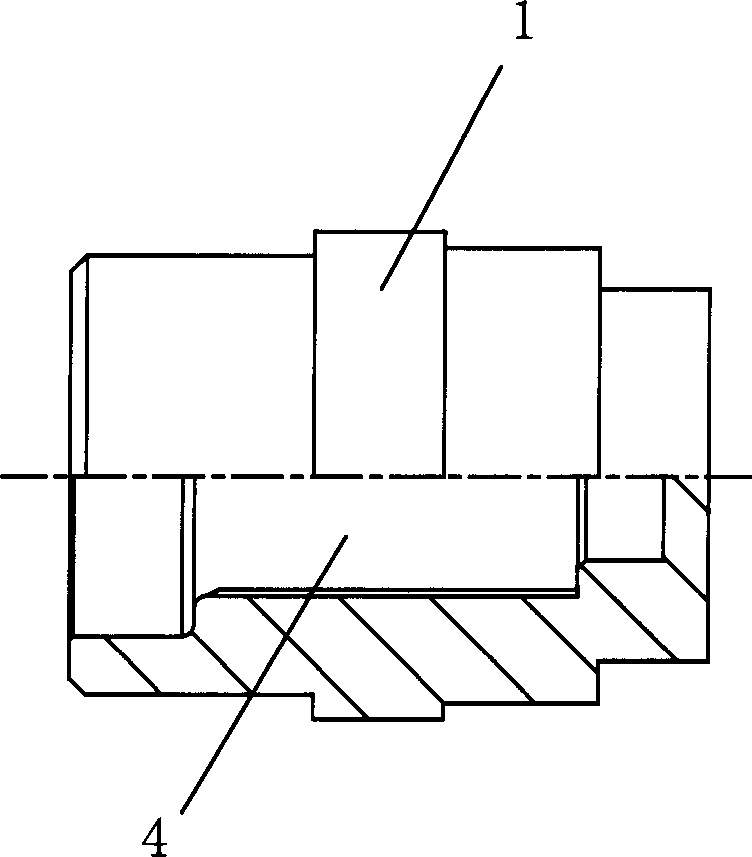

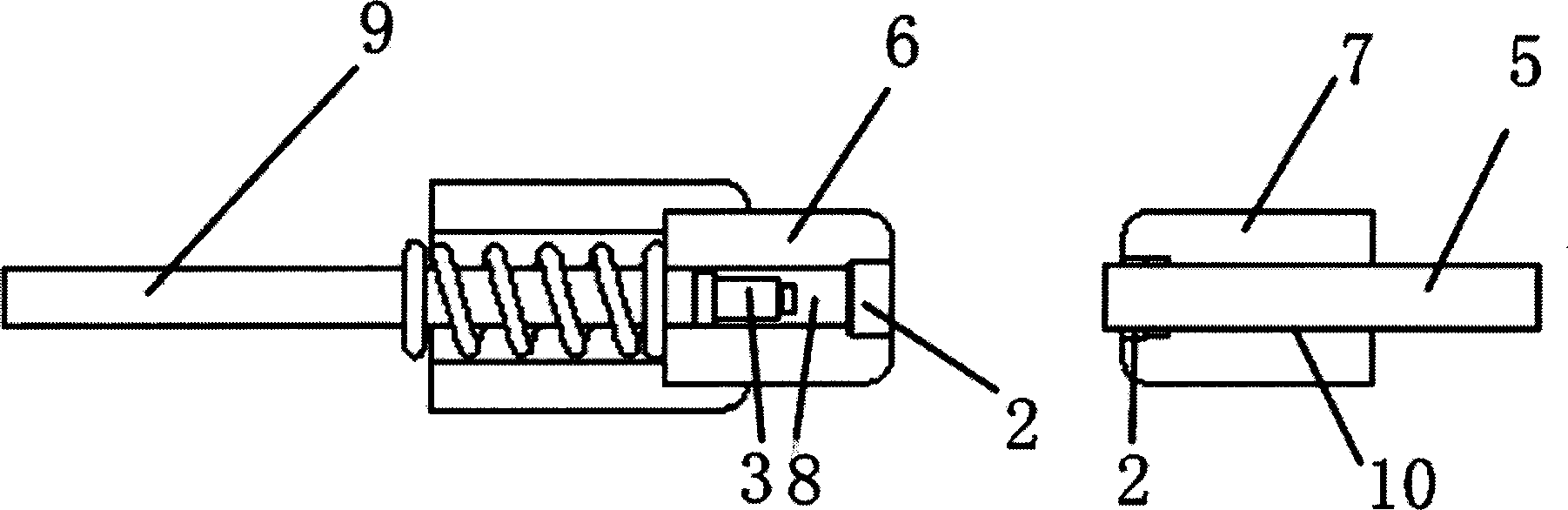

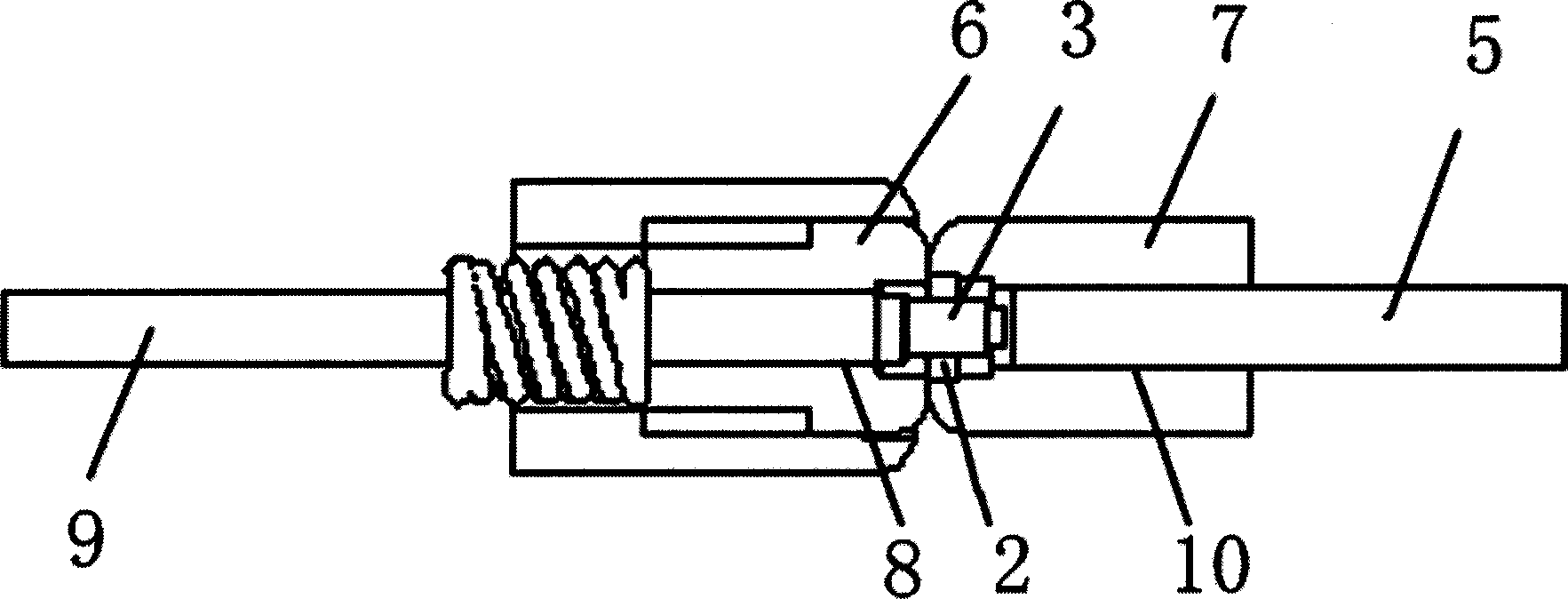

[0019] Example: such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a method for processing a bearing fixed sleeve with a cold extrusion process includes the following steps:

[0020] A. Place the blank of the bearing fixing sleeve 1 into the cavity 2 of the cold extrusion die;

[0021] B. Clamp the mold to form the shape of the bearing fixed sleeve 1, and stamp the inner cavity 4 of the bearing fixed sleeve 1 with the punch 3;

[0022] C. Open the mold, and eject the formed bearing fixing sleeve 1 with the ejector pin 5 .

[0023] A device for processing a bearing fixed sleeve with a cold extrusion process, including a cold extrusion die, the cold extrusion die includes a front die 6 and a rear die 7, the rear part of the front die 6 and the front part of the rear die 7 are molded Cavity 2, when the front mold 6 and the rear mold 7 are closed, the mold cavity 2 has the same shape as the bearing fixed sleeve 1, and the front part of the front mold 6 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com