Heat-resistant steel for automobile fasteners and production method of heat-resistant steel

A production method and technology of heat-resistant steel, which are applied in the fields of material smelting and metal pressure extension processing, can solve the problems that the performance of ordinary steel wire materials cannot meet the requirements, and achieve the effects of delaying cold work hardening, high quality and improving the performance of cold piers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

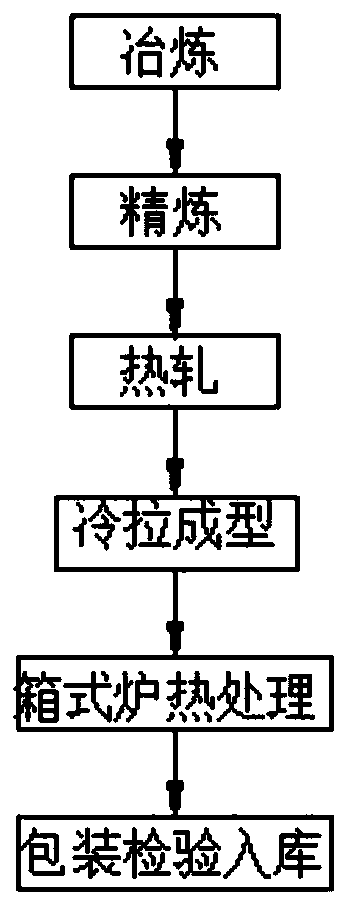

[0027] Such as figure 1 As shown, the chemical composition wt% of the heat-resistant steel of the present invention includes: nickel Ni: 25.00, chromium Cr: 14.00, titanium Ti: 2.25, molybdenum Mo: 1.15, manganese Mn: 0.7, copper Cu: 0.4, aluminum AL: 0.25 , silicon Si: 0.4, lanthanum cerium rare earth La: 0.20, vanadium V: 0.15, carbon C: 0.040, boron B: 0.005, phosphorus P: ≤0.015, sulfur S: ≤0.005, nitrogen N: ≤300ppm, oxygen O: ≤ 20ppm, hydrogen H: ≤2ppm, the rest is iron Fe;

[0028] And the specific production steps of the heat-resistant steel of the present embodiment are as follows:

[0029] (1) Smelting: batching is carried out according to the above weight percentages, then smelted in a vacuum furnace, poured into steel ingots after smelting, and used in the next step;

[0030] (2) Refining: put the ingot into the electroslag remelting furnace for electroslag remelting, and then use RH cycle degassing equipment for vacuum degassing and removal of inclusions to ensu...

Embodiment 2

[0038] Such as figure 1 As shown, the chemical composition wt% of the heat-resistant steel of the present invention includes: nickel Ni: 25.00, chromium Cr: 14.00, titanium Ti: 2.30, molybdenum Mo: 1.25, manganese Mn: 0.8, copper Cu: 0.45, aluminum AL: 0.27 , silicon Si: 0.3, lanthanum cerium rare earth La: 0.20, vanadium V: 0.15, carbon C: 0.040, boron B: 0.005, phosphorus P: ≤0.015, sulfur S: ≤0.005, nitrogen N: ≤300ppm, oxygen O: ≤ 20ppm, hydrogen H: ≤2ppm, the rest is iron Fe;

[0039] And the specific production steps of the heat-resistant steel of the present embodiment are as follows:

[0040] (1) Smelting: batching is carried out according to the above weight percentages, then smelted in a vacuum furnace, poured into steel ingots after smelting, and used in the next step;

[0041] (2) Refining: put the ingot into the electroslag remelting furnace for electroslag remelting, and then use RH cycle degassing equipment for vacuum degassing and removal of inclusions to ens...

Embodiment 3

[0049] Such as figure 1As shown, the chemical composition wt% of the heat-resistant steel of the present invention includes: nickel Ni: 25.00, chromium Cr: 14.50, titanium Ti: 2.20, molybdenum Mo: 1.40, manganese Mn: 0.95, copper Cu: 0.35, aluminum AL: 0.30 , silicon Si: 0.25, lanthanum cerium rare earth La: 0.18, vanadium V: 0.20, carbon C: 0.040, boron B: 0.005, phosphorus P: ≤0.015, sulfur S: ≤0.005, nitrogen N: ≤300ppm, oxygen O: ≤ 20ppm, hydrogen H: ≤2ppm, the rest is iron Fe;

[0050] And the specific production steps of the heat-resistant steel of the present embodiment are as follows:

[0051] (1) Smelting: batching is carried out according to the above weight percentages, then smelted in a vacuum furnace, poured into steel ingots after smelting, and used in the next step;

[0052] (2) Refining: put the ingot into the electroslag remelting furnace for electroslag remelting, and then use RH cycle degassing equipment for vacuum degassing and removal of inclusions to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com