Patents

Literature

262 results about "Lanthanoid Series Elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Elements of the lanthanoid series including atomic number 57 (LANTHANUM) through atomic number 71 (LUTETIUM).

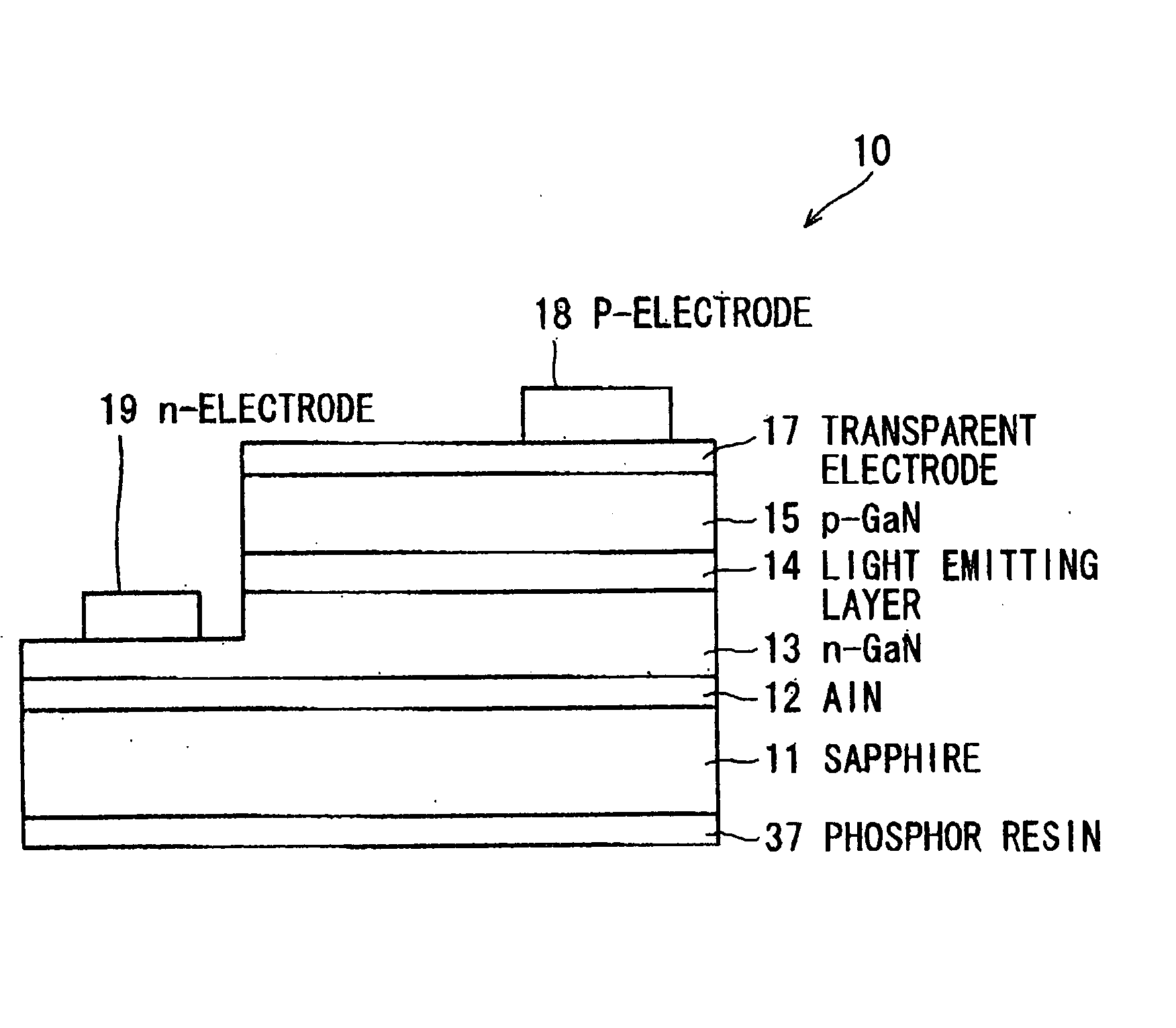

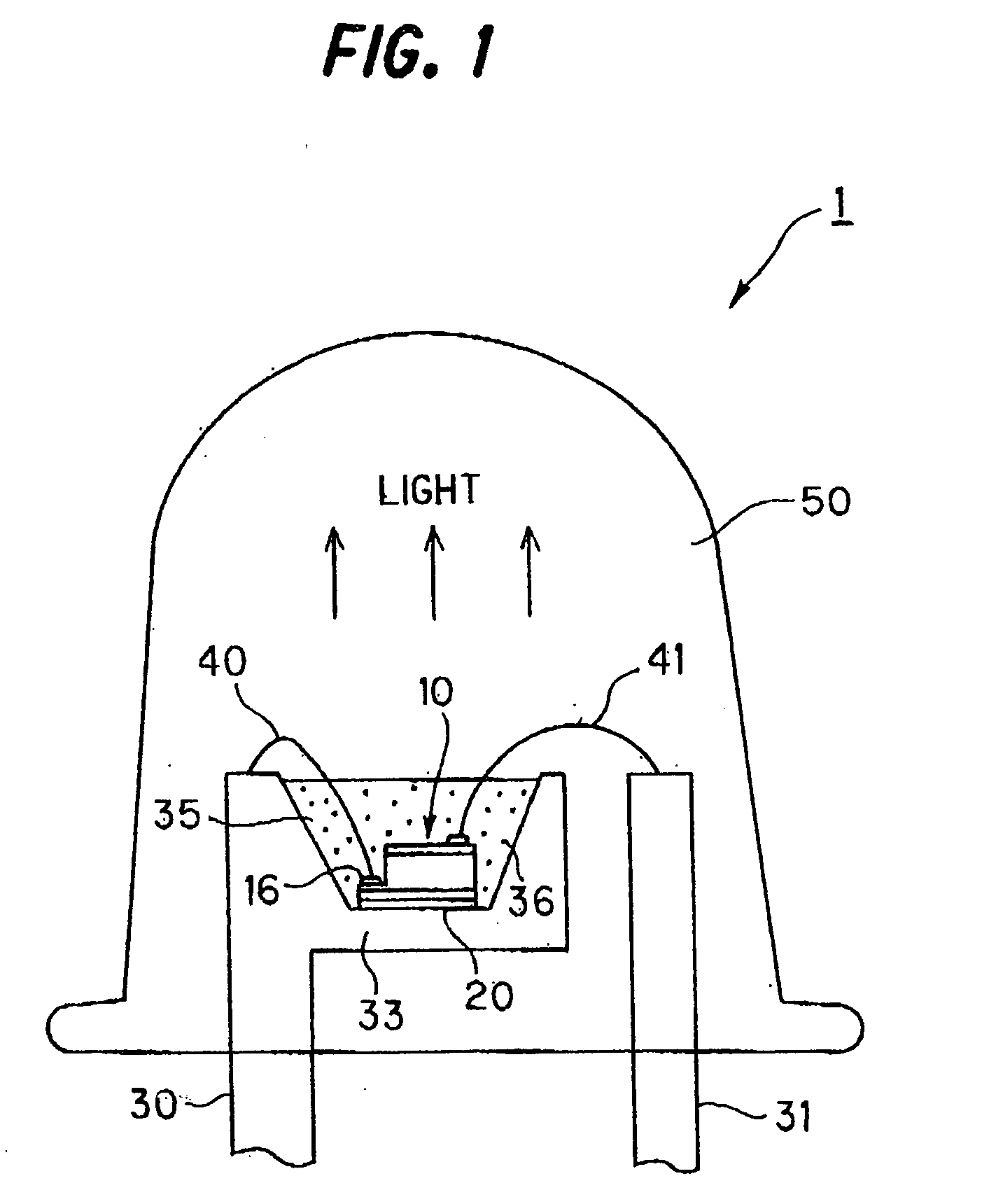

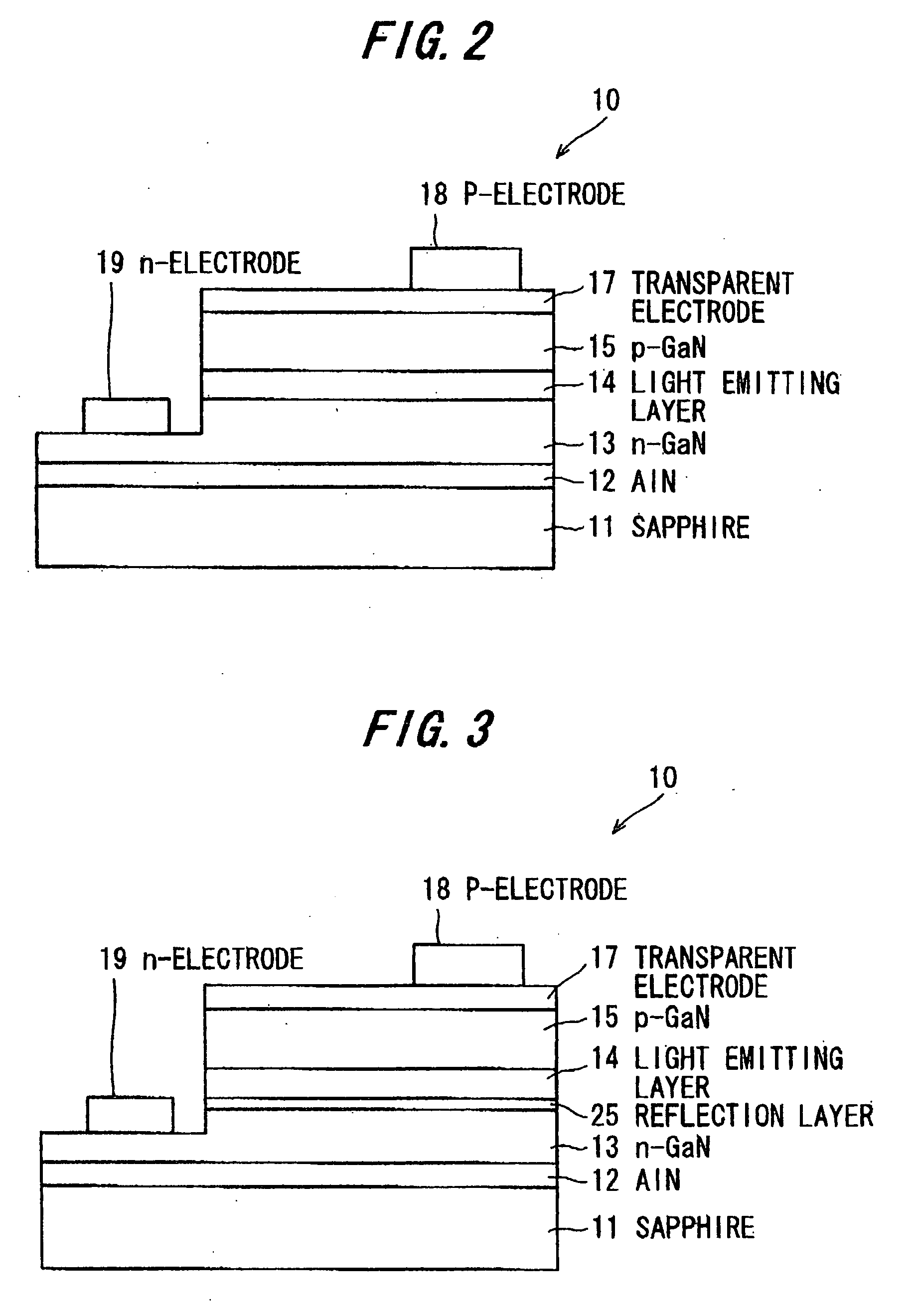

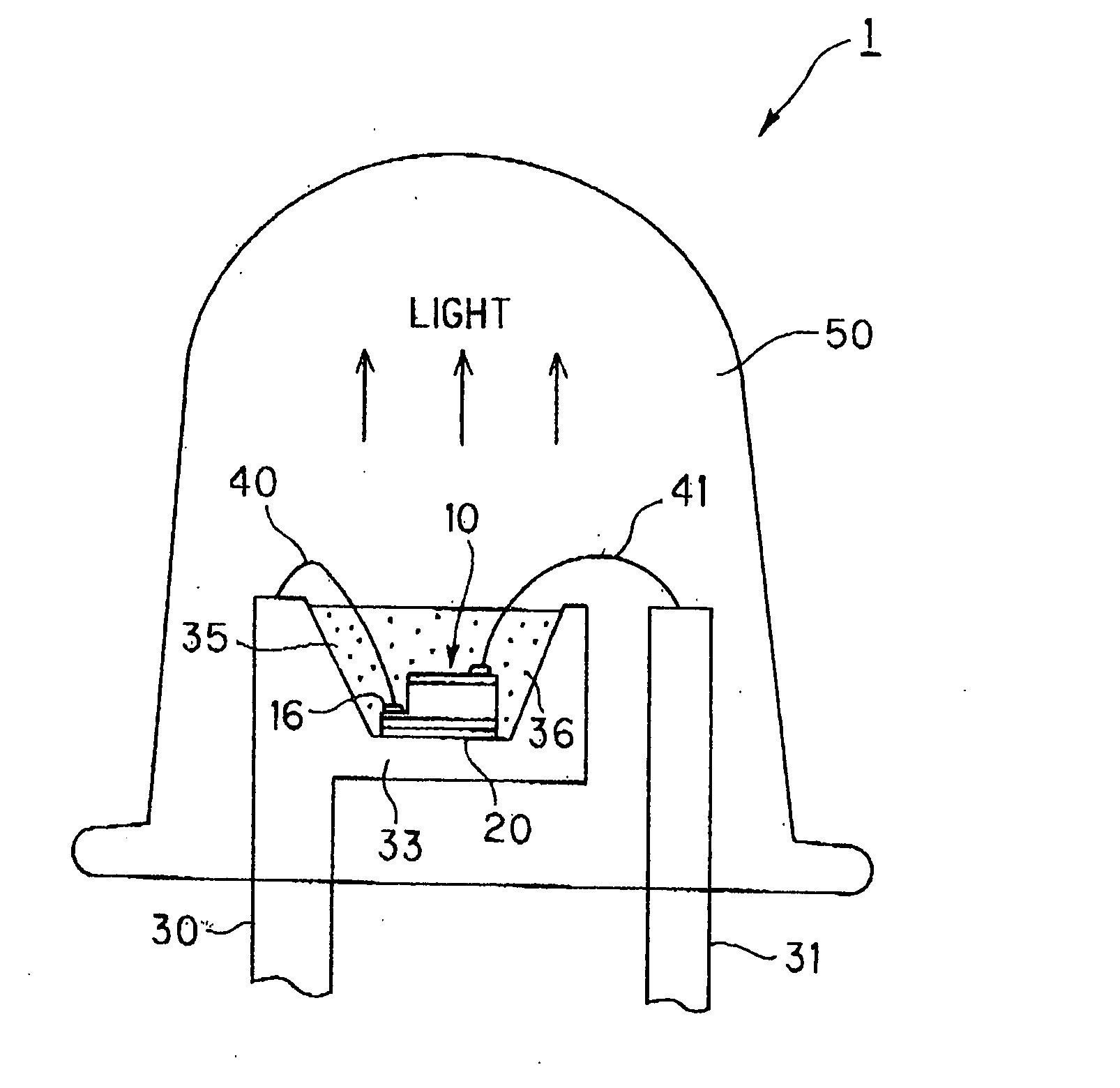

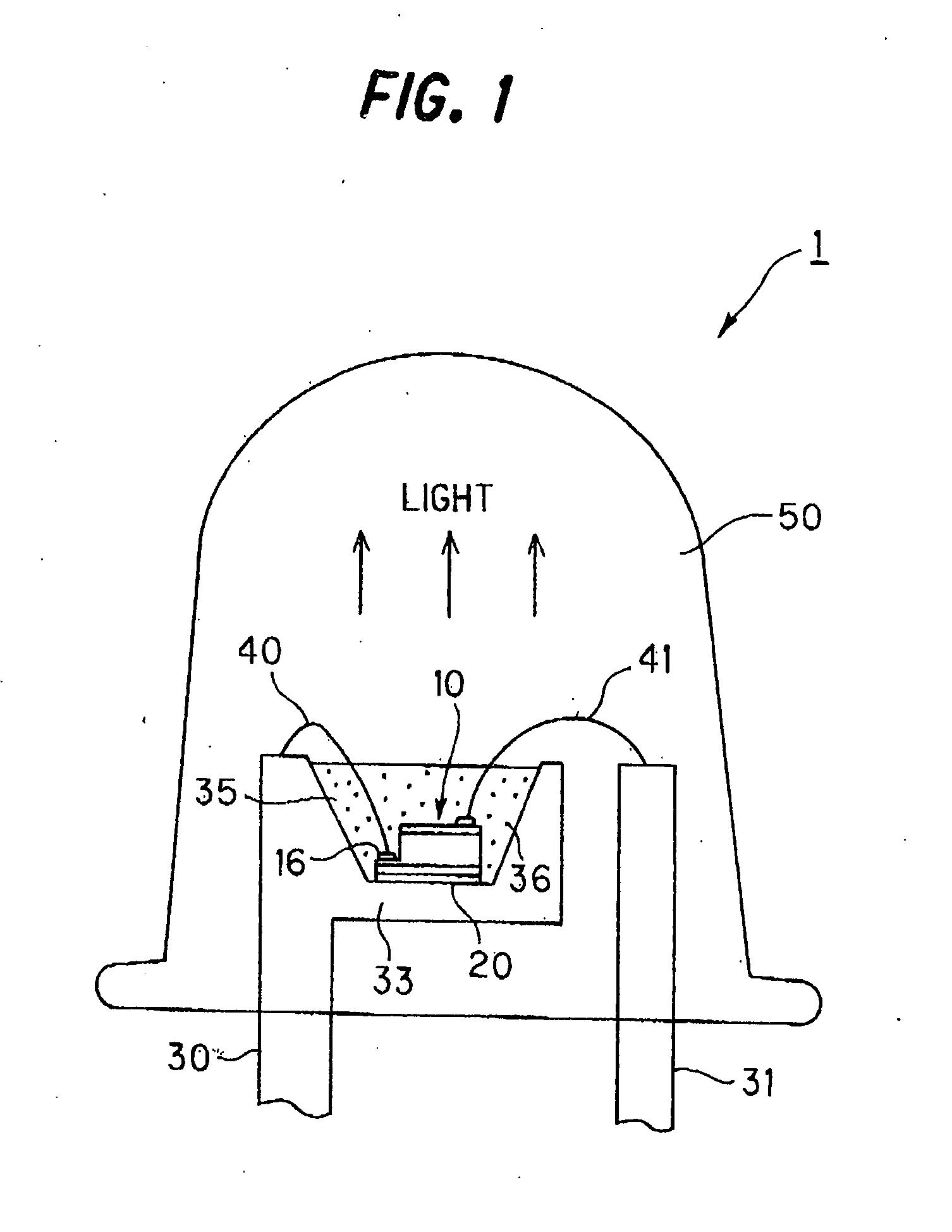

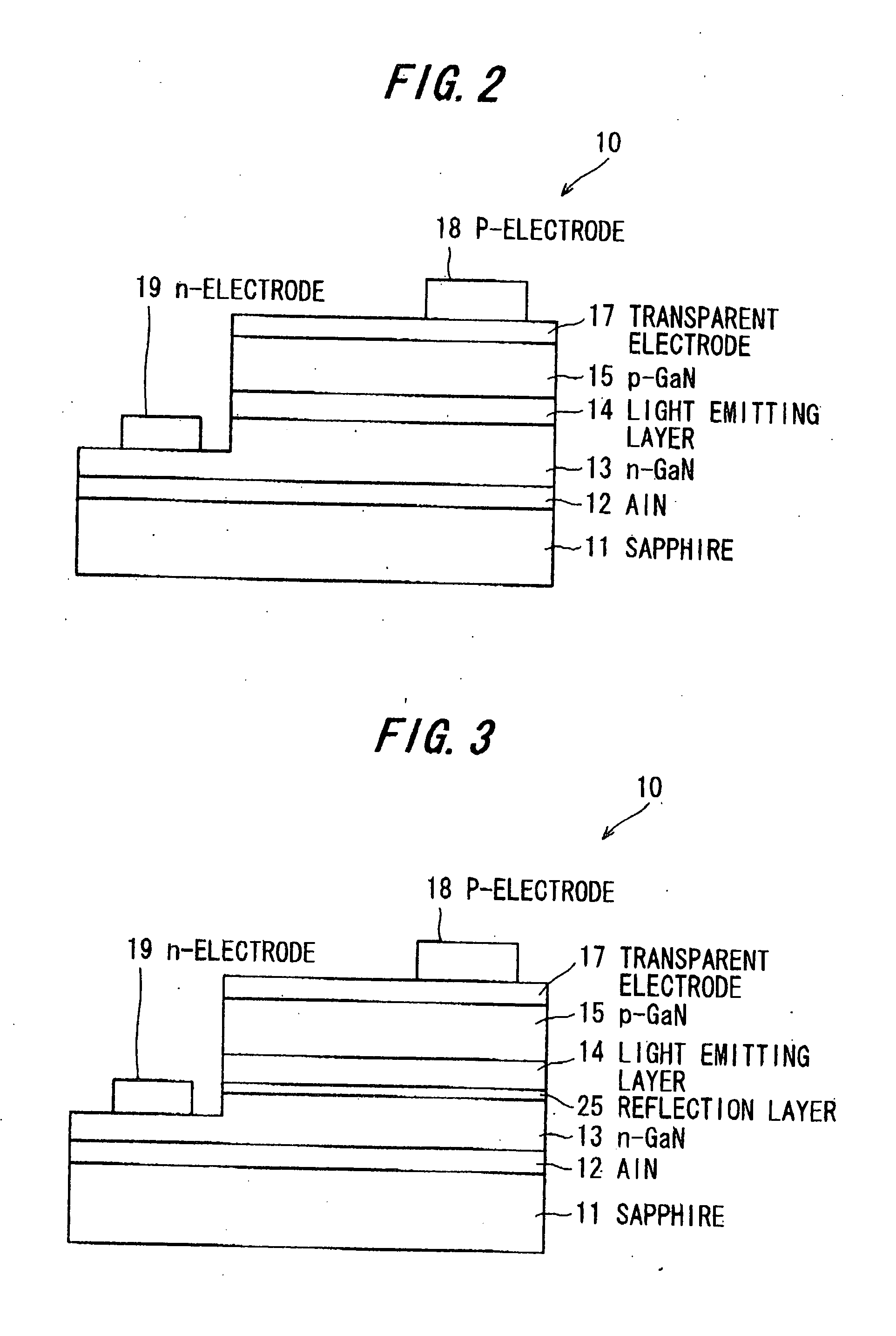

Light emitting apparatus and light emitting method

InactiveUS20050001225A1Improve propertiesIncrease brightnessSolid-state devicesBulk negative resistance effect devicesRare-earth elementSilicon nitride

A light emitting apparatus has a light emitting element with an emission wavelength in the range of 360 to 550 nm and a rare-earth element doped oxide nitride phosphor or cerium ion doped lanthanum silicon nitride phosphor. Part of light radiated from the light emitting element is wavelength-converted by the phosphor. The light emitting apparatus radiates white light generated by a mixture of the wavelength-converted light and the other part of light radiated from the light emitting element.

Owner:TOYODA GOSEI CO LTD +1

High performance lithium ion battery anode material lithium manganate and preparation method thereof

The invention provides a high performance lithium ion battery anode material lithium manganate and a preparation method of the material. The lithium manganate is a doped lithium manganate LiMn2-yXy04 which is doped with one kind or a plurality of other metal elements X, wherein X element is at least one kind selected form the group of aluminium, lithium, fluorine, silver, copper, chromium, zinc, titanium, bismuth, germanium, gallium, zirconium, stannum, silicon, cobalt, nickel, vanadium, magnesium, calcium, strontium, barium and rare earth elements lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium and lutetium, and y is larger than 0 but less than or equal to 0.11. The lithium ion battery anode material lithium manganate provided in the invention has extraordinary charge and discharge cycle performance both in the environments of normal temperature and high temperature. According to the invention, the preparation method of the material is a solid phase method, the operation is simple and controllable and the cost is low so that it is easy to realize large-scale productions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Light emitting apparatus and light emitting method

ActiveUS20070164308A1Improve propertiesIncrease brightnessDischarge tube luminescnet screensLamp detailsFluorescenceDoped oxide

A light emitting apparatus has a light emitting element with an emission wavelength in the range of 360 to 550 nm and a rare-earth element doped oxide nitride phosphor or cerium ion doped lanthanum silicon nitride phosphor. Part of light radiated from the light emitting element is wavelength-converted by the phosphor. The light emitting apparatus radiates white light generated by a mixture of the wavelength-converted light and the other part of light radiated from the light emitting element.

Owner:TOYODA GOSEI CO LTD

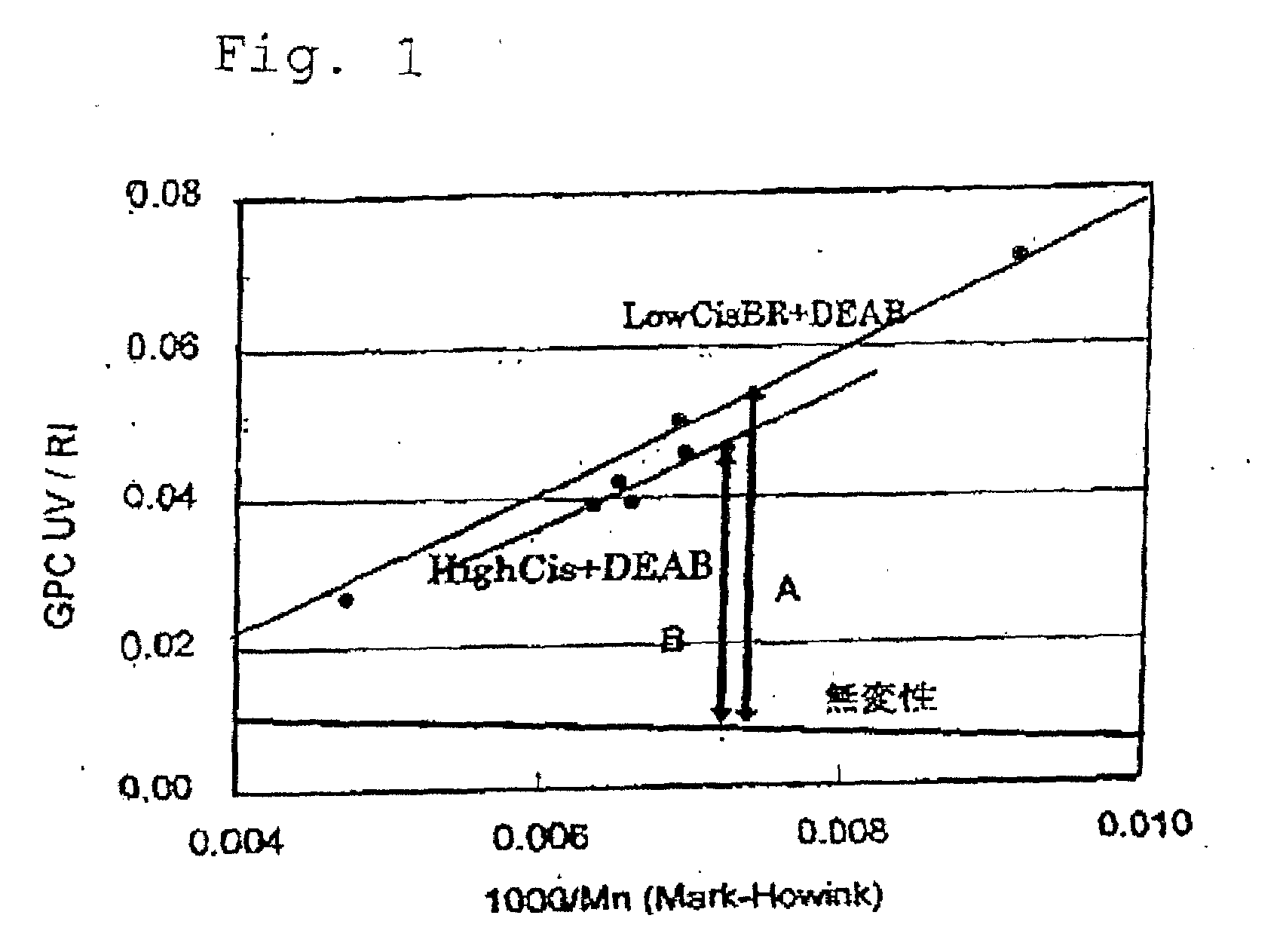

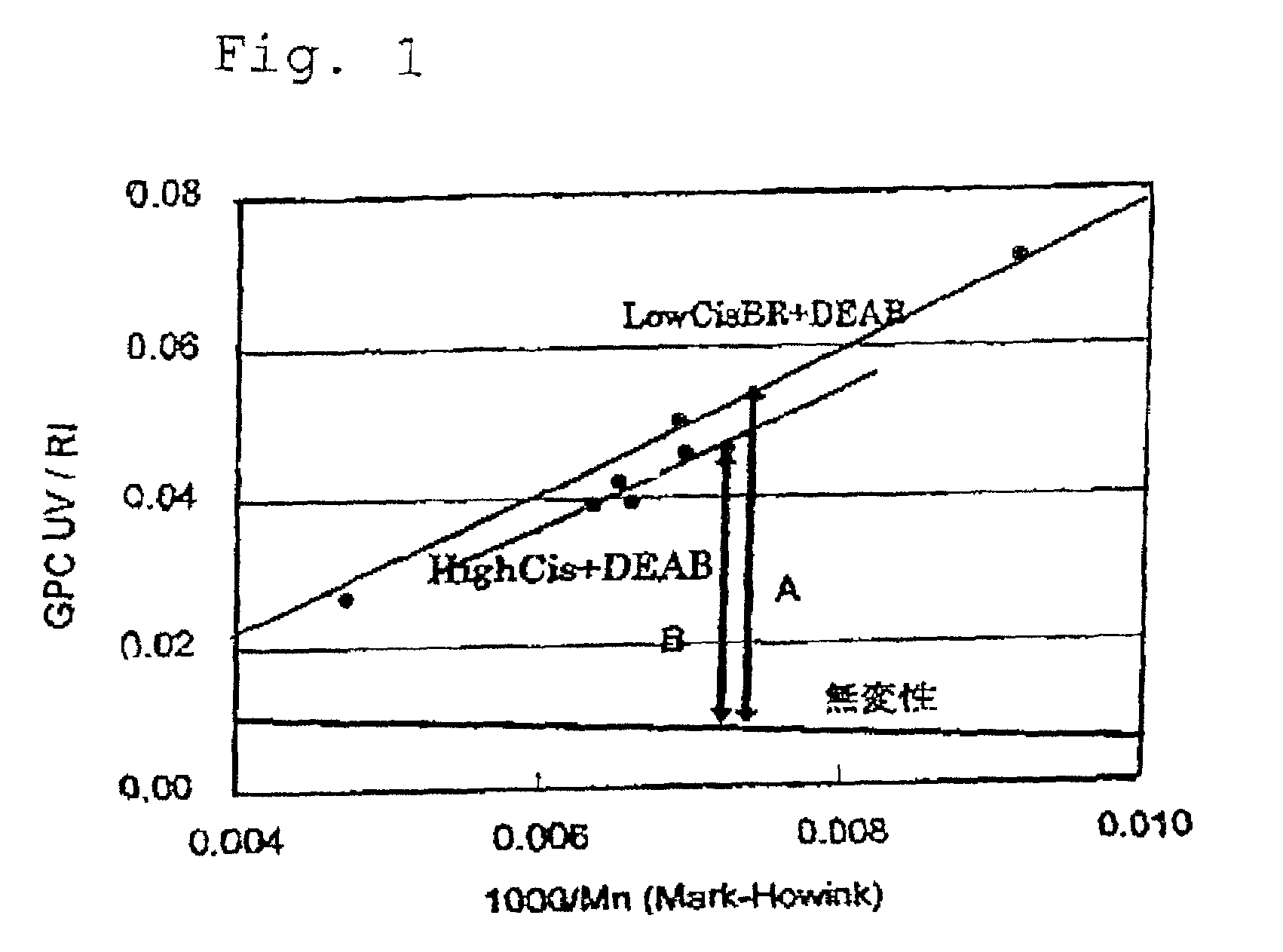

Modified conjugated diene copolymer, rubber compositions and tires

The present invention provides a modified conjugated diene polymer that is prepared by polymerization of a conjugated diene compound using a catalyst containing a lanthanoid rare earth element compound in an organic solvent and then modifying the resulting polymer having an active organic metal site with a modifier, wherein the modification efficiency is not less than 15% and the cis-1,4 bond content in the conjugated diene moiety measured by Fourier transform infrared spectroscopy satisfies the relationship (I):cis-1,4 bond content≧98.00(%) (I),or the modification efficiency is not less than 75% and the cis-1,4 bond content in the conjugated diene moiety measured by Fourier transform infrared spectroscopy satisfies the relationship (II):94.00(%)≦cis-1,4 bond content<98.00(%) (II).The invention further provides a rubber composition containing the modified conjugated diene polymer and giving a tire exhibiting low heat build-up, satisfactory failure characteristics, and high abrasion resistance, and a tire composed of the rubber composition and exhibiting these characteristics.

Owner:BRIDGESTONE CORP

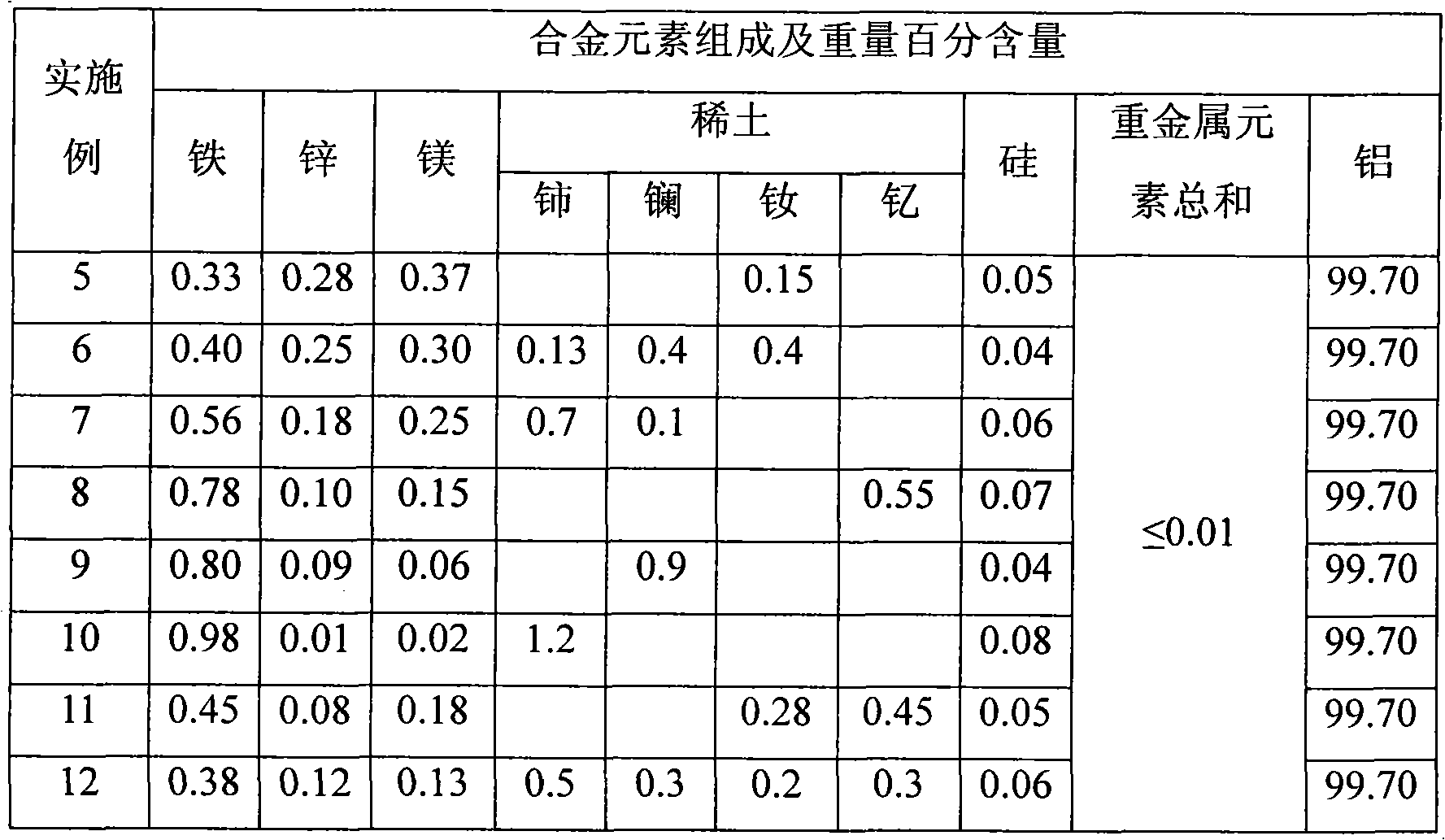

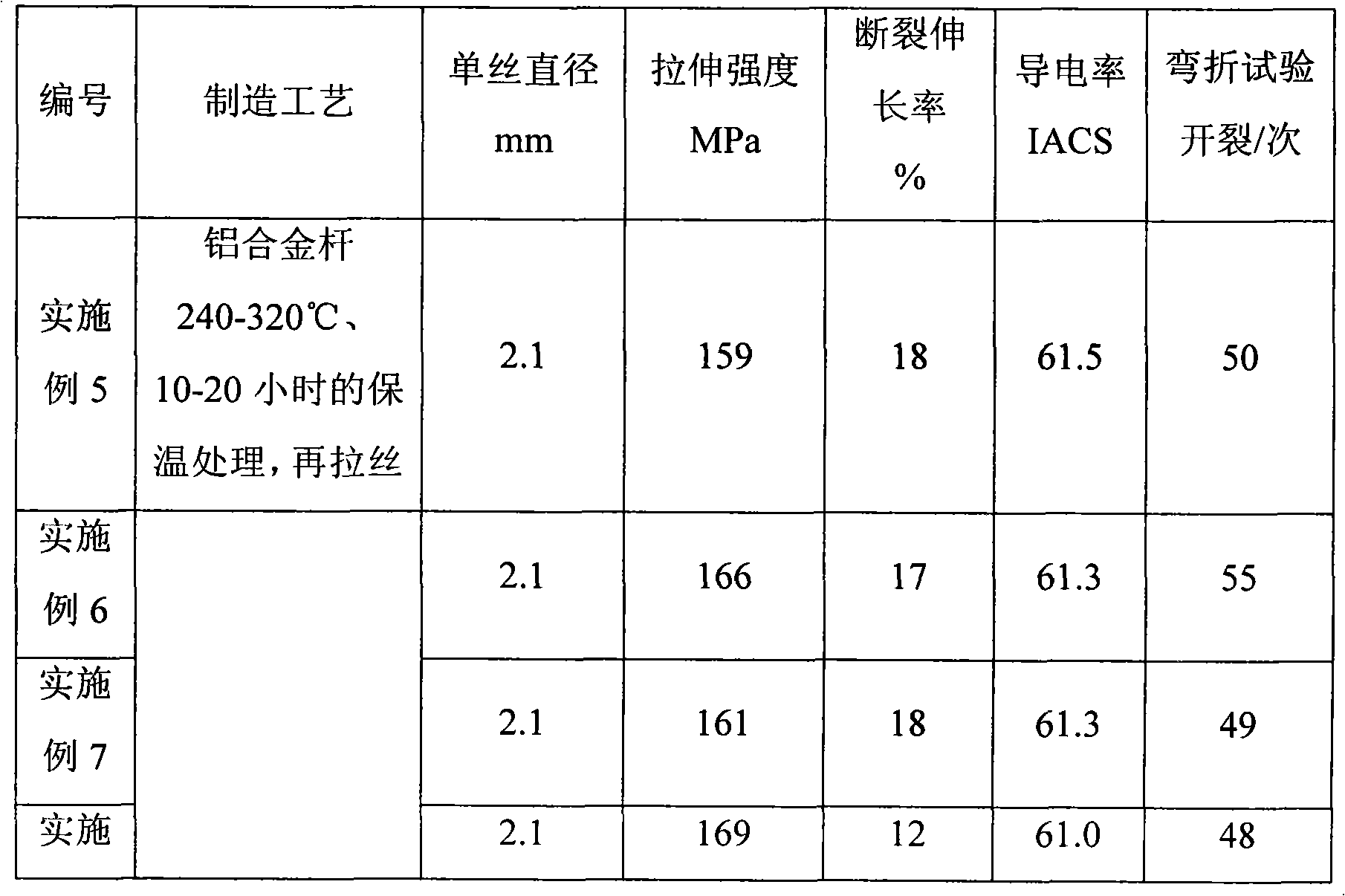

Al-Fe-Zn-Mg rare earth alloy wire and preparation method thereof

InactiveCN101880799AReduce defect densityGood match of strength and toughnessSingle bars/rods/wires/strips conductorsMetal/alloy conductorsAlloy elementRare-earth element

The invention discloses an Al-Fe-Zn-Mg rare earth alloy wire and a preparation method thereof. The aluminum alloy comprises the following elements: 0.3-1.2wt% of Fe, 0.01-0.3wt% of Zn, 0.01-0.4wt% of Mg, 0.1-1.5wt% of rare earth element and the balance of Al and inevitable impurities, wherein the rare earth element is composed of one or more of cerium, lanthanum, neodymium and yttrium. The preparation method of the aluminum alloy wire comprises the following steps: preparing an aluminum alloy rod through smelting, casting and rolling, performing insulation treatment in a heat holding cover at 240-320 DEG C for 10-20 hours, wiredrawing and extruding insulating material on the wire; or preparing an aluminum alloy rod through smelting, casting and rolling, drawing the aluminum alloy rod to prepare the aluminum alloy wire, performing semi-annealing treatment in an annealing furnace at 340-380 DEG C for 5-10 hours, and finally extruding insulating material on the wire. The aluminum alloy wire prepared by the method of the invention has excellent electrical property, mechanical property and corrosion resistance and can be used in the wire and cable conductors.

Owner:ANHUI JOY SENSE CABLE

Petroleum hydrocarbon catalytic pyrolysis catalyst and its application

ActiveCN1955255AIncrease throughputHigh airspeedHydrocarbonsNaphtha reformingCatalytic pyrolysisAlkaline earth metal

This invention provides a petroleum hydrocarbon catalytic decomposition accelerant and its application. This accelerant includes following components: (1) lanthanide, its weight amount is 0.1-25%; (2) phosphorus or boron, its weight amount is 0.1-10%; (3) base metal, alkali metal and transition metal, their weight amount is 0.1-15%; (4) The others are ZSM-5,ZRP used as carrier. This accelerant used for production of low carbon alkenes by cracking heavy magnesium alkanes, with space velocity of gas 1-25hr-1, such as naphtha, diesel oil, educed pressure diesel and so on. The yield of ethylene, propylene, butylenes and butadiene will improve by 5%.

Owner:CHINA PETROLEUM & CHEM CORP +1

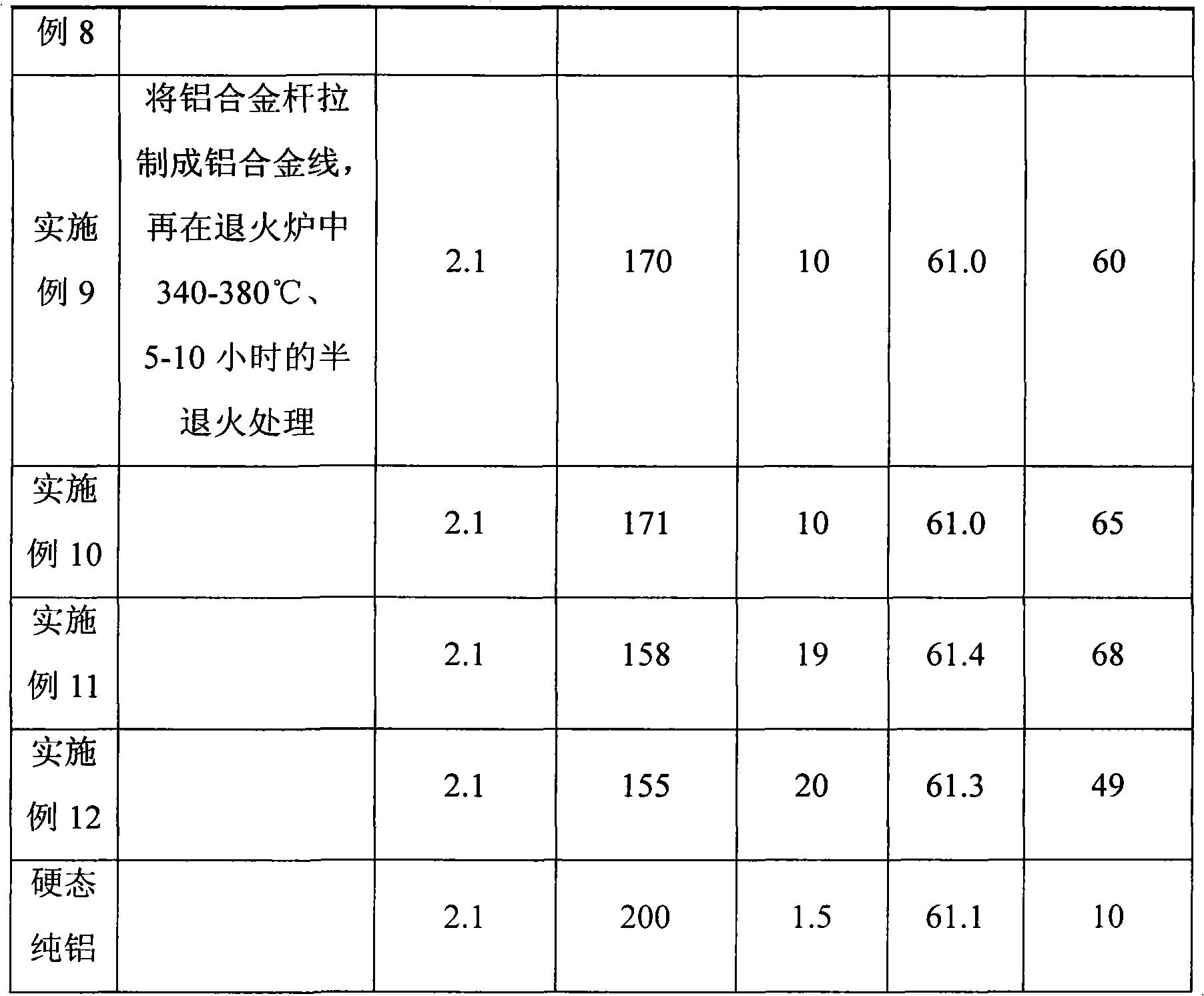

Y reinforced Mg-Zn-Y-Zr system magnesium alloy with effective utilization of rare earth element and production method

The invention relates to a lanthanon Y which is utilized to strengthen magnesium alloy effectively and a preparation technology thereof, in particular to a quasicrystal phase which is utilized to strengthen Mg-Zn-Y-Zr magnesium alloy and a preparation method thereof, and the problems such as magnesium alloy strengthening, etc. are solved. On the premise of definite Y contents, the volume percentage of the quasicrystal phase which is led into a magnesium alloy matrix to reach the maximum through reasonably choosing the rate between Zn and Y in the alloy (the rate between Zn and Y ranges from 6 to 15), so as to prepare the Mg-Zn-Y-Zr magnesium alloy with low density, high strength and better plasticity. The magnesium alloy material has the components and the contents thereof as follows: the content of zinc (Zn) ranges from 5 to 30 percent; the content of yttrium (Y) ranges from 0.5 to 5 percent; the content of zirconium (Zr) ranges from 0.3 to 0.8 percent, and the others are magnesium (Mg); all the percentage are weight percentage. The magnesium alloy material are processed through alloy melting and subsequent hot extrusion processing and deformed into products, and the operation of the processing technology is simple and convenient. The tensile strength of the material satisfies that Sigma (b) ranges from 290 to 360MPa, the yield stress delta0.2 ranges from 175 to 260MPa, the unit extension Delta ranges from 10 to 18 percent, and the density is 1.84 to 2.73g / cm<3>.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Leadless and free-cutting phosphorus-brass alloy and manufacturing method thereof

The invention provides a lead-free cutting-free alloy and a preparation method thereof. The components (weight percentage) of the alloy are: more than 97.0 but not equal to 99.5 of (copper + zinc), more than 35.0 of zinc, 0.4-1.6 of phosphor and 0.005-0.6 of at least two other elements selected from aluminum, silicon, antimony, stannum, lanthanon, titanium and boron, the balance being zinc and impurities, wherein, the zinc content is more than 35.0 (weight percentage). The invention also provides a preparation method for the lead-free cutting-free high phosphor brass alloy. The alloy of the invention has excellent machinability, castibility, welding property, dezincification corrosion resisting property, formability and mechanical property, and is particularly suitable for forged pieces and low-pressure cast castings needing cutting processing, grinding processing (polish), welding and plating, such as hydrants, valve bodies and bushings in a water supply system.

Owner:XIAMEN LAVIDA HI TECH MATERIAL CO LTD

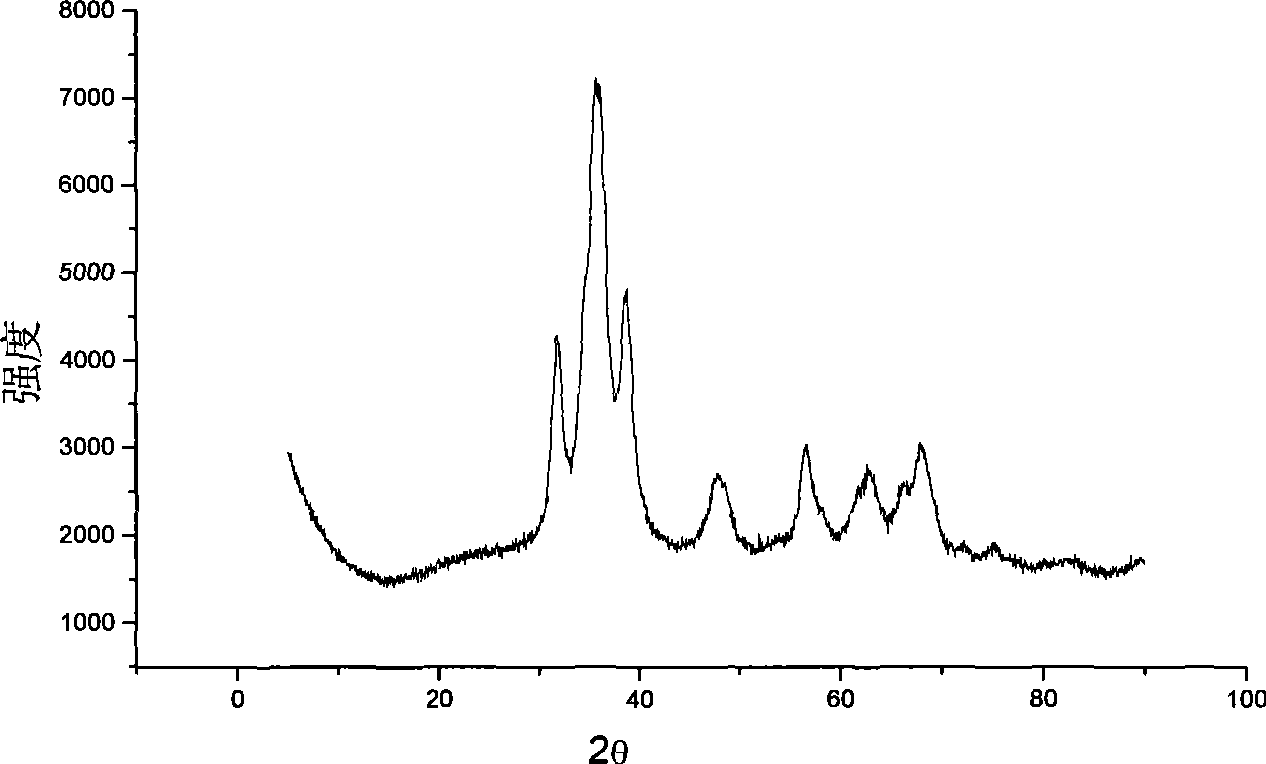

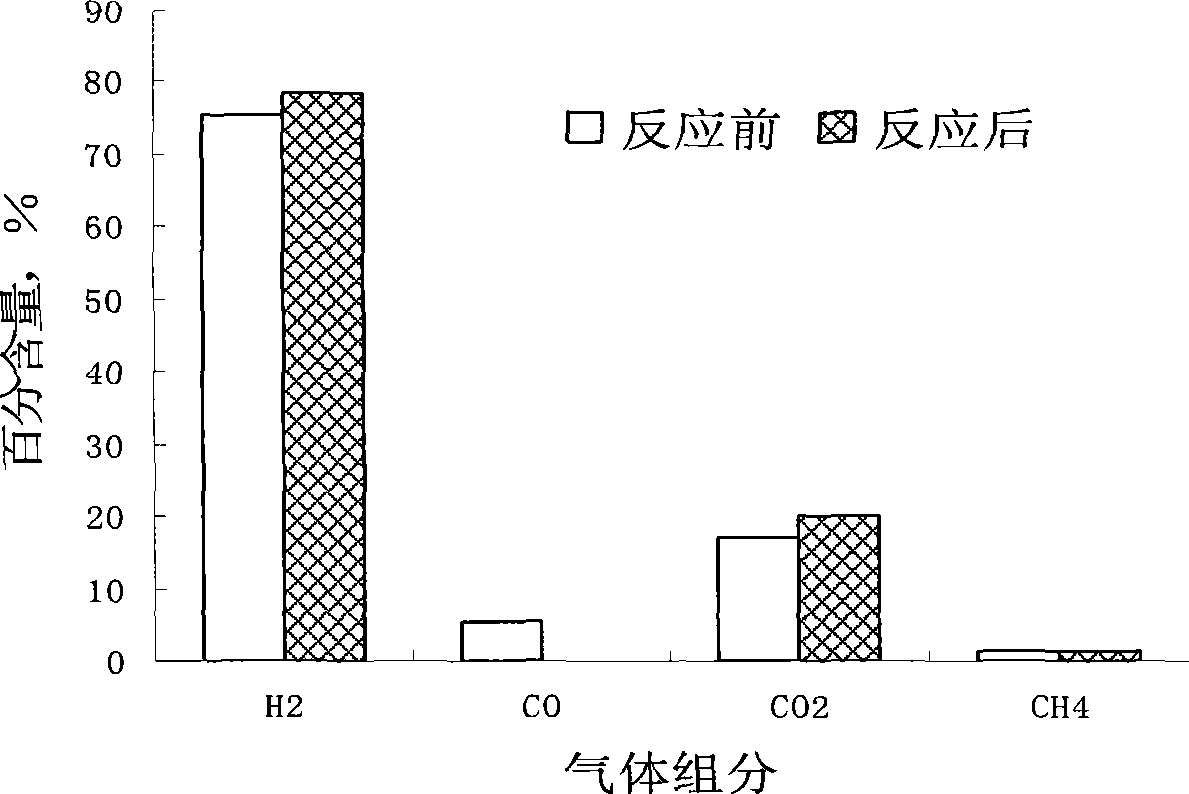

Catalyst for shifting carbon monoxide by water gas reaction in hydrogen-rich fuel gas and preparation method thereof

InactiveCN101518737AHigh reactivitySimple processHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementIndium

The invention relates to a catalyst for changing and transforming carbon monoxide in hydrogen-rich fuel gas of coke-oven gas according to a water gas shift reaction and a preparation method thereof, which belong to the technical field of water gas shift processes and catalysts. The catalyst takes copper or iron as an active component, takes zinc, rare earth element cerium or lanthanum and one of boron, aluminum or indium as auxiliary agents, and is prepared by adopting a solution precipitation method. A mixed salt solution of metal nitrates or sulfates is subjected to processes such as homogenization treatment by ultrasonic wave, co-precipitation, constant-temperature aging, drying, baking and the like to finally obtain the mixed metal solid catalyst. The catalyst prepared by the method has the advantages of higher activity, good dispersivity, and large specific surface area, and has high water gas shift activity in the hydrogen-rich fuel gas (VH2 is more than 75 percent), and the transformation ratio of carbon monoxide of the catalyst can approach 100 percent.

Owner:SHANGHAI UNIV

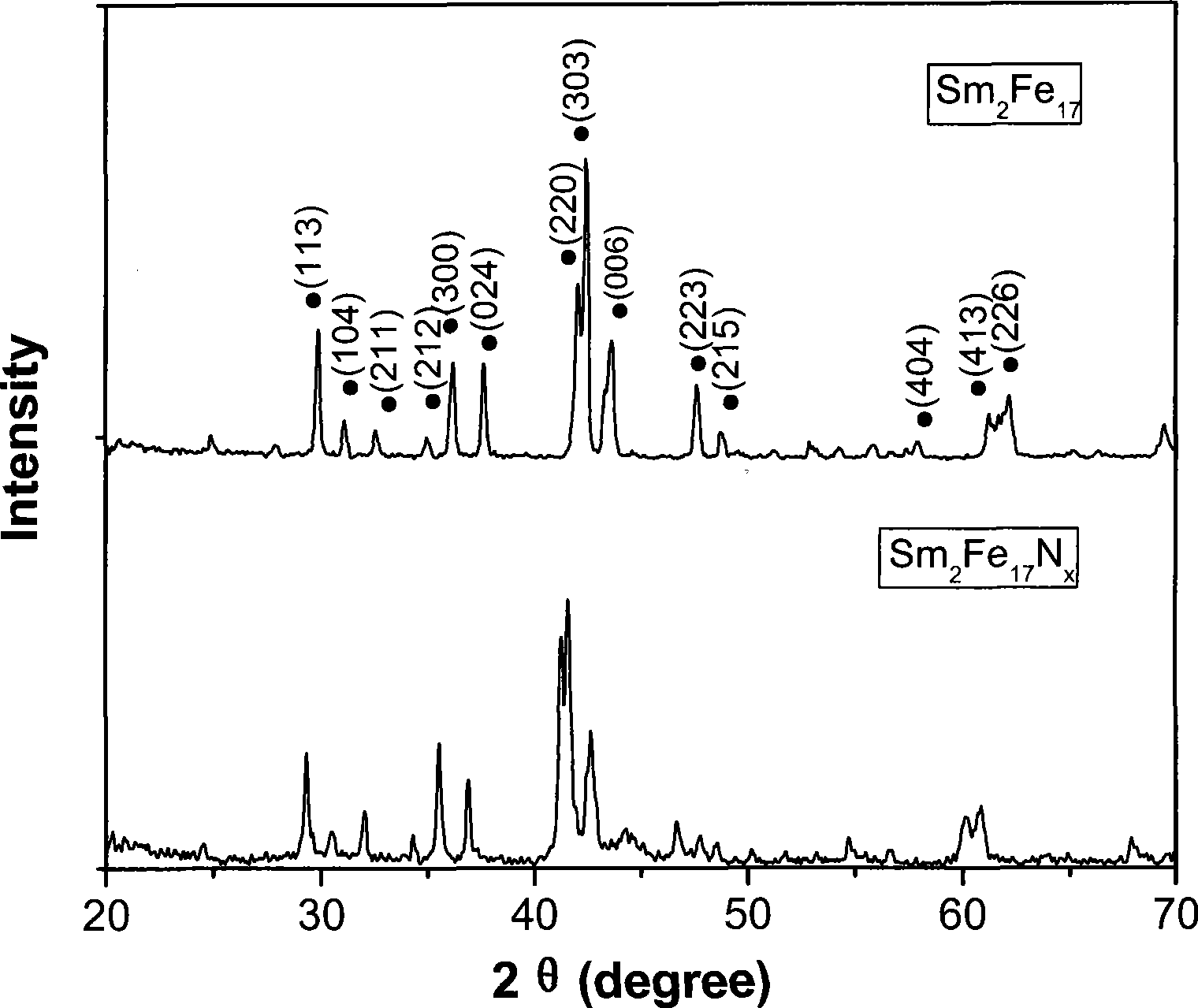

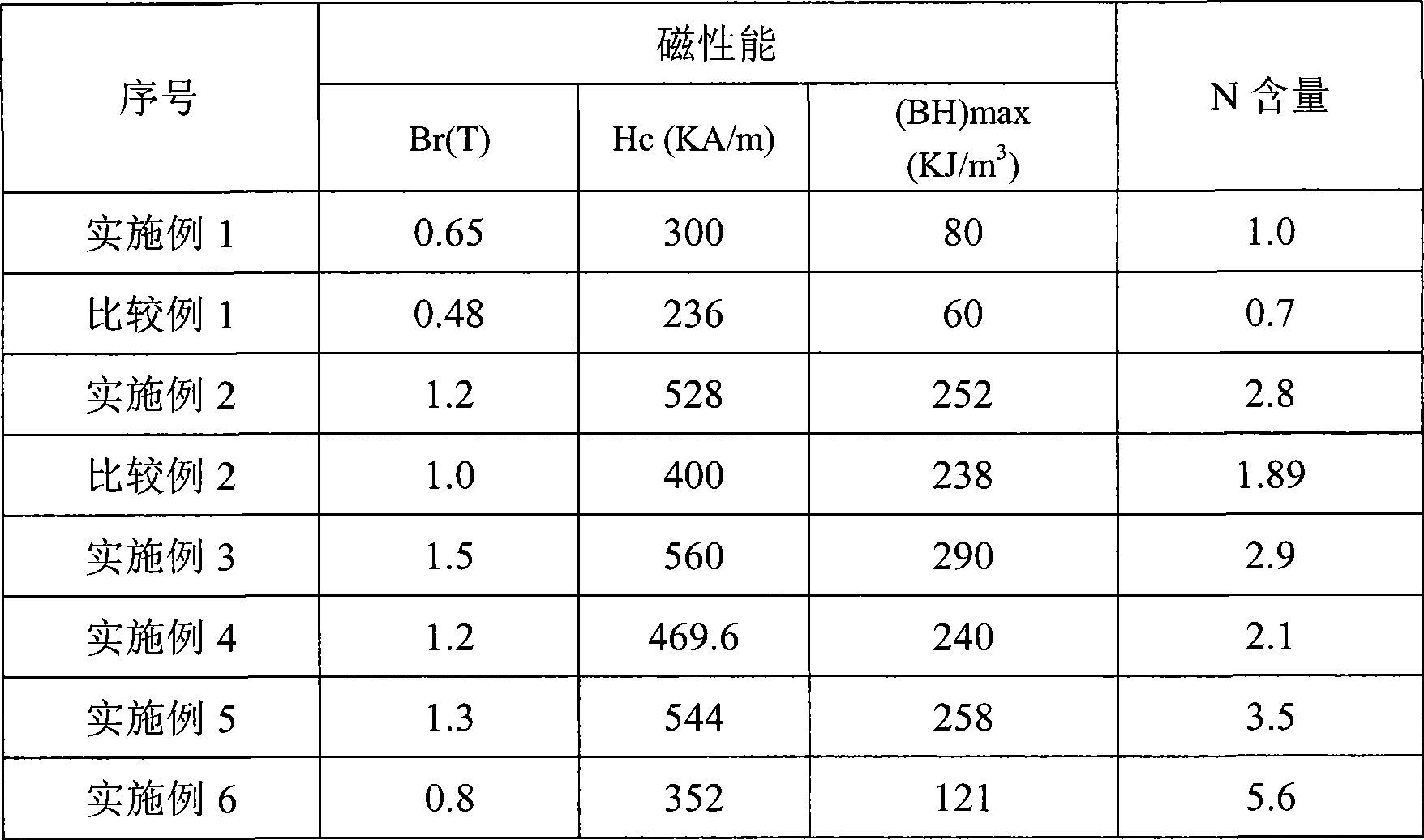

Nitrogen-containing rare-earth magnetic powder and preparation method thereof

ActiveCN101546642AIncrease the speed of diffusionPromote decompositionInorganic material magnetismRare-earth elementLanthanide

The invention discloses a nitrogen-containing rare-earth magnetic powder prepared by taking ferrocene, cyclopentadienyl lanthanide, metallic iron and rare earth as the main raw materials. The nitrogen-containing rare-earth magnetic powder comprises the following component of R2Fe17-xMxNy, wherein the R is one or more kinds of 17 kinds of rare earth elements including Sc and Y, the M includes transitional elements except for Fe and is one or more kinds of Al, Ga, In, Si, Ge, Sn, Pb, Mg and Ca, the x is equal to 0 to 5, and the y is equal to 1 to 6; and the preparation method comprises the following steps: working procedure of preparation of the R2Fe17-xMx compound powder; working procedure of nitridation; and working procedure of magnetic powder refining and nitriding.

Owner:GUOKE RE ADVANCED MATERIALS CO LTD

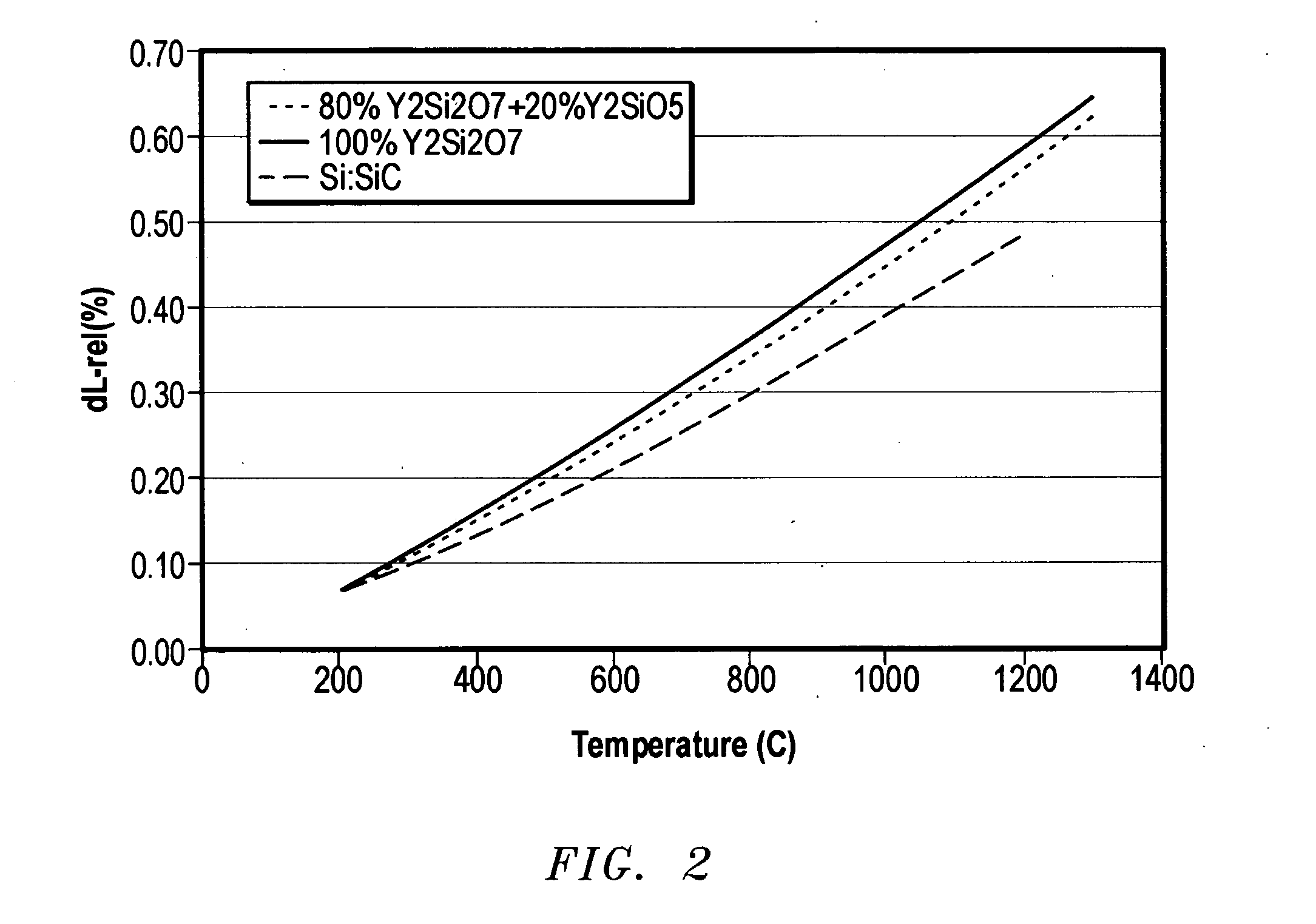

Semiconductor processing components and semiconductor processing utilizing same

ActiveUS20060046450A1Vacuum evaporation coatingSputtering coatingLanthanoid Series ElementsSemiconductor

A semiconductor processing component includes a substrate and a layer overlying the substrate. The layer has a composition ReAyO1.5+2y, wherein Re is Y, La, a Lanthanoid series element, or a combination thereof, A is (Si1−aGea), 0.25≦y≦1.2, and 0≦a≦1.

Owner:COORSTEK INC

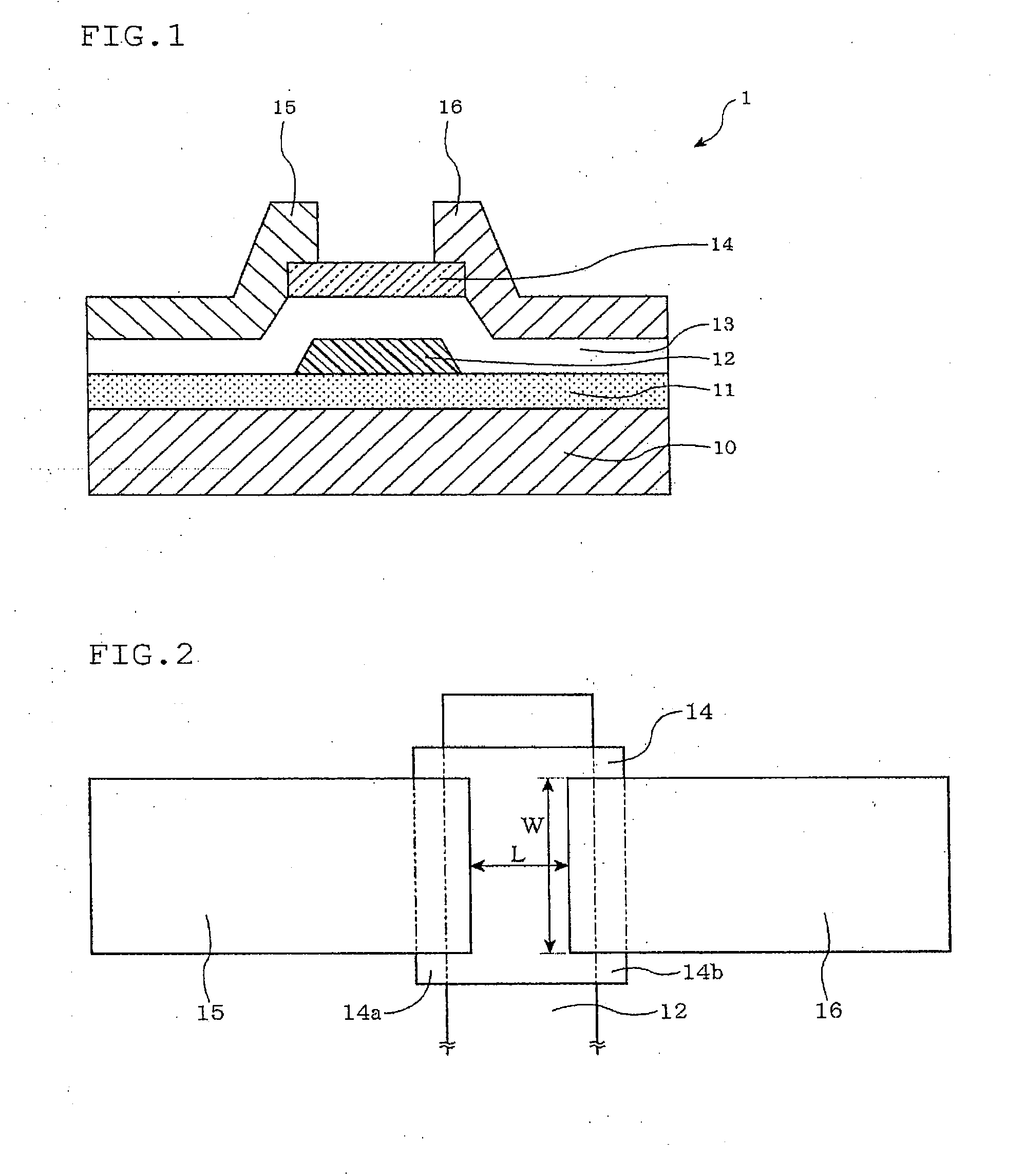

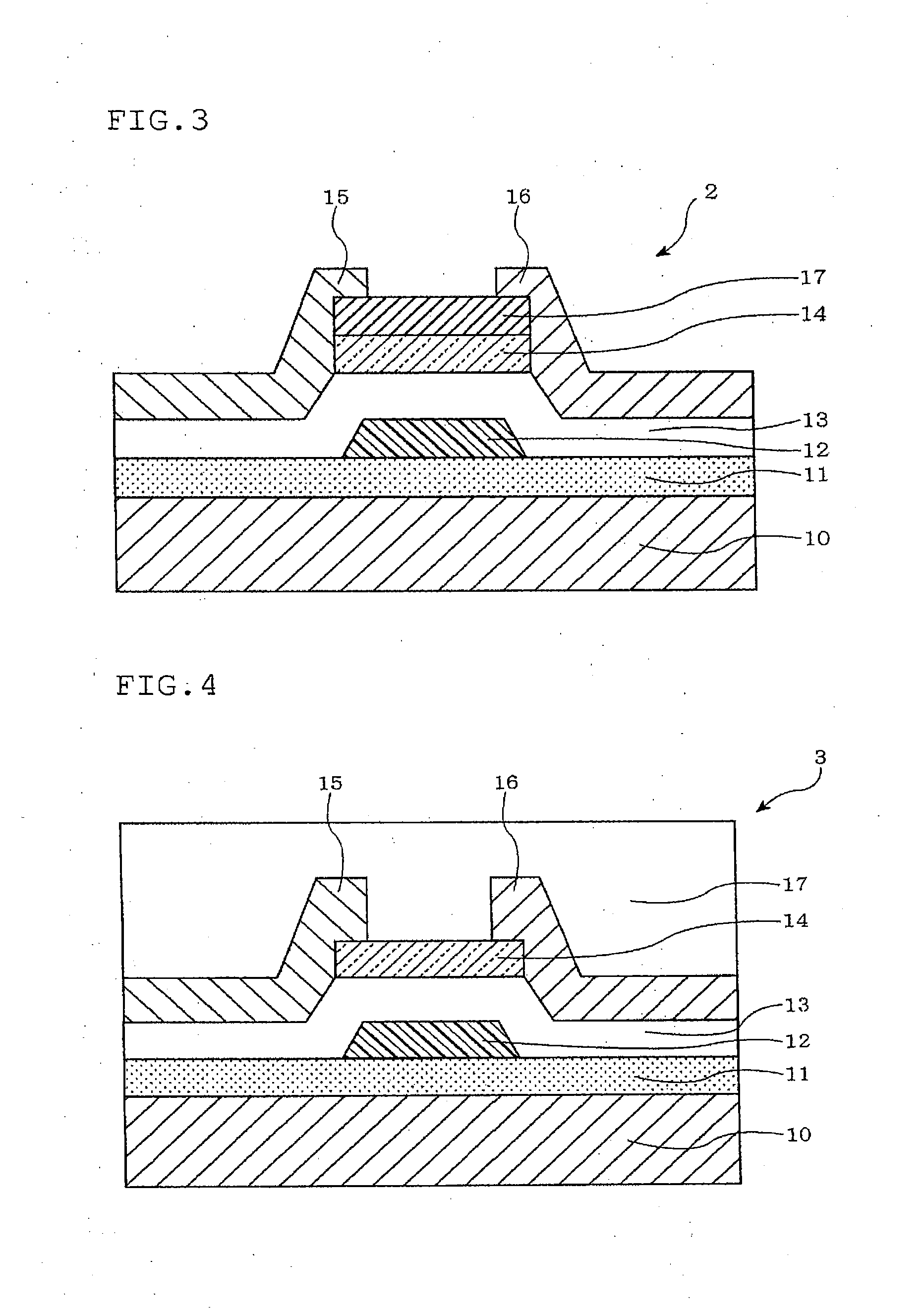

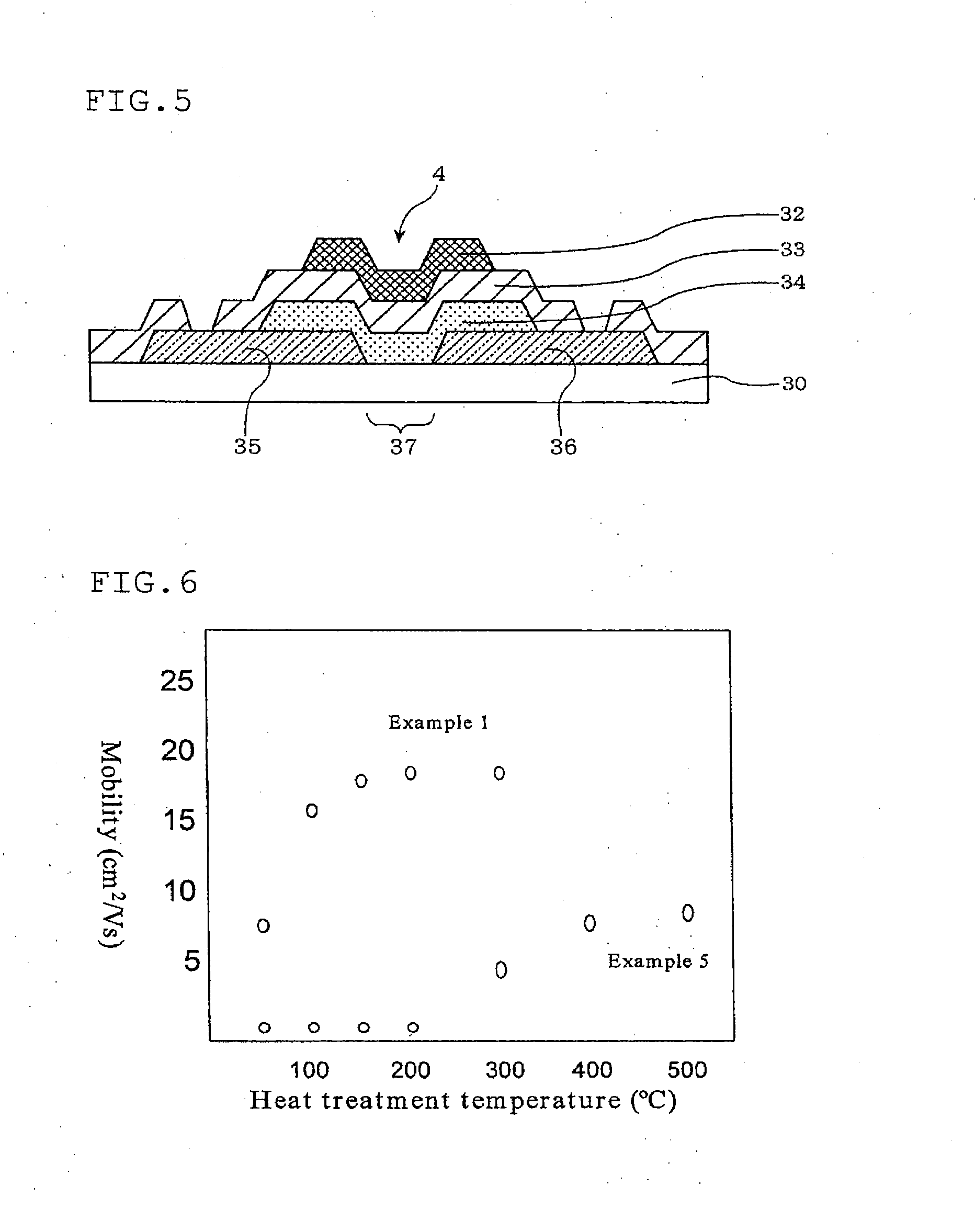

Oxide semiconductor field effect transistor and method for manufacturing the same

InactiveUS20130140175A1Easy to produceCellsVacuum evaporation coatingField-effect transistorLanthanoid Series Elements

A field effect transistor including a semiconductor layer including a composite oxide which contains In, Zn, and one or more elements X selected from the group consisting of Zr, Hf, Ge, Si, Ti, Mn, W, Mo, V, Cu, Ni, Co, Fe, Cr, Nb, Al, B, Sc, Y and lanthanoids in the following atomic ratios (1) to (3):In / (In+Zn)=0.2 to 0.8 (1)In / (In+X)=0.29 to 0.99 (2)Zn / (X+Zn)=0.29 to 0.99 (3).

Owner:IDEMITSU KOSAN CO LTD

Cerium oxide and zirconium oxide based sosoloid catalyst, preparation method and application thereof

InactiveCN101607195AImprove catalytic performanceImprove thermal stabilityDispersed particle separationCatalyst activation/preparationZirconium hydrideCerium(IV) oxide

The invention relates to a catalytic material for purifying tail gas of an automobile, in particular to a cerium oxide and zirconium oxide based sosoloid catalyst, a preparation method and application thereof. The cerium oxide and zirconium oxide based sosoloid catalyst comprises 50-79.5wt% of zirconium oxide, 20-49.5wt% of cerium oxide and 0.5-25wt% of oxides of other elements, wherein the zirconium oxide, the cerium oxide and the oxides of other elements is present in a sosoloid form, and the oxides of other elements are one or more oxides of lanthanons except cerium. The preparation method is as follows: continuous coprecipitation is carried out on zirconium oxychloride, saline solution of cerium and saline solution of lanthanons except cerium to obtain the cerium oxide and zirconium oxide based sosoloid catalyst. In the invention, by adding the zirconium oxide and the oxides of the lanthanons except cerium, the prepared cerium oxide and zirconium oxide based sosoloid catalyst has favorable catalytic performance and greatly improved thermal stability. The preparation method can prepare the cerium oxide and zirconium oxide based sosoloid catalyst under relatively lower temperature and normal pressure.

Owner:顾冬萍

Chromium-free passivation solution for tin plate and method for using same

InactiveCN101638804ALow costSimple processSurface reaction electrolytic coatingChromium freeRare-earth element

The invention relates to an acid metal passivation solution and a method for using the same, in particular to a chromium-free passivation solution for a tin plate and a method for using the same. Thepassivation solution comprises the following components in portion by weight: 5 to 30 portions of inorganic salt of a rare earth element Ce or La, 5 to 40 portions of inorganic salt of ammonium and 1,000 portions of water; the pH value of the passivation solution is between 2 and 7 and can be adjusted by dilute nitric acid or dilute sulfuric acid; the inorganic salt of the rare earth element Ce orLa may be cerous nitrate, cerous sulfate, lanthanum nitrate or lanthanum sulfate; and the inorganic salt of ammonium may be ammonium nitrate or ammonium sulfate. The method for using the passivationsolution comprises that: the tin plate is soaked in the passivation solution for electrochemical processing, and during the processing, the cathodic current density is between 0.1 and 20A / dm<2>, the processing time is between 0.1 and 10s, and the temperature is between 30 and 65 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

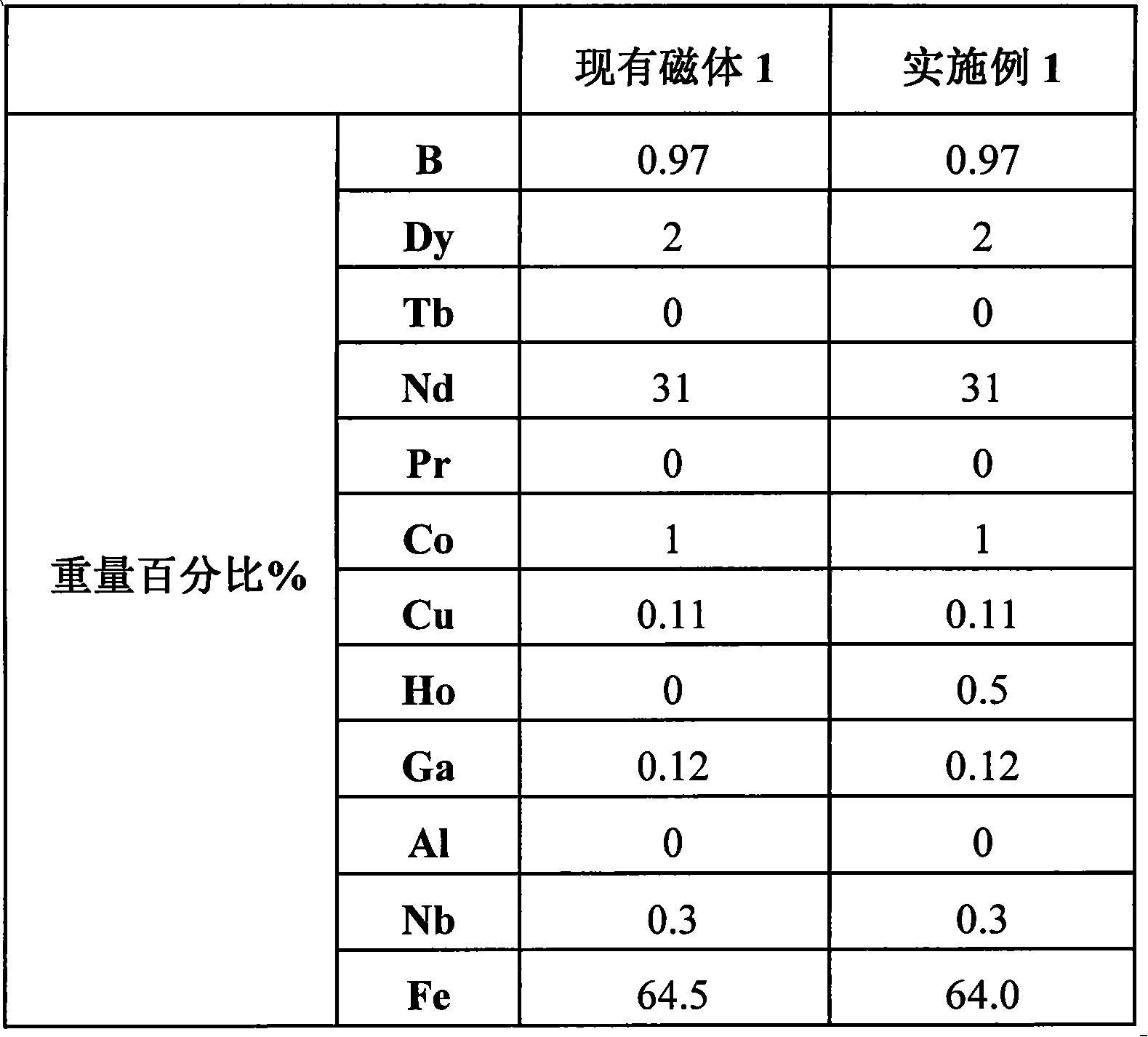

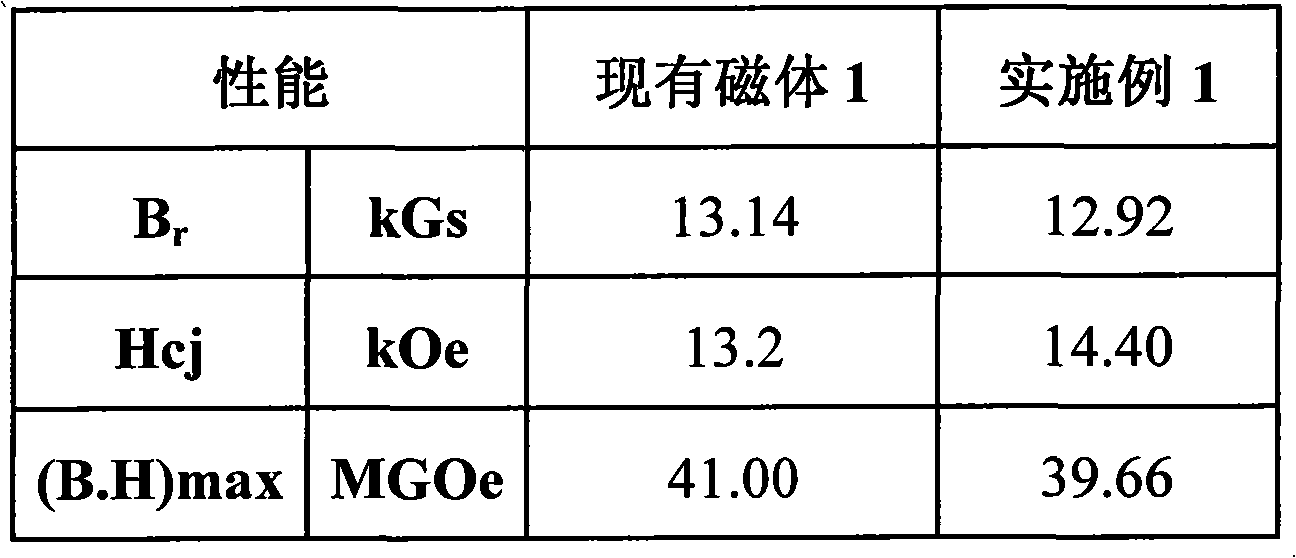

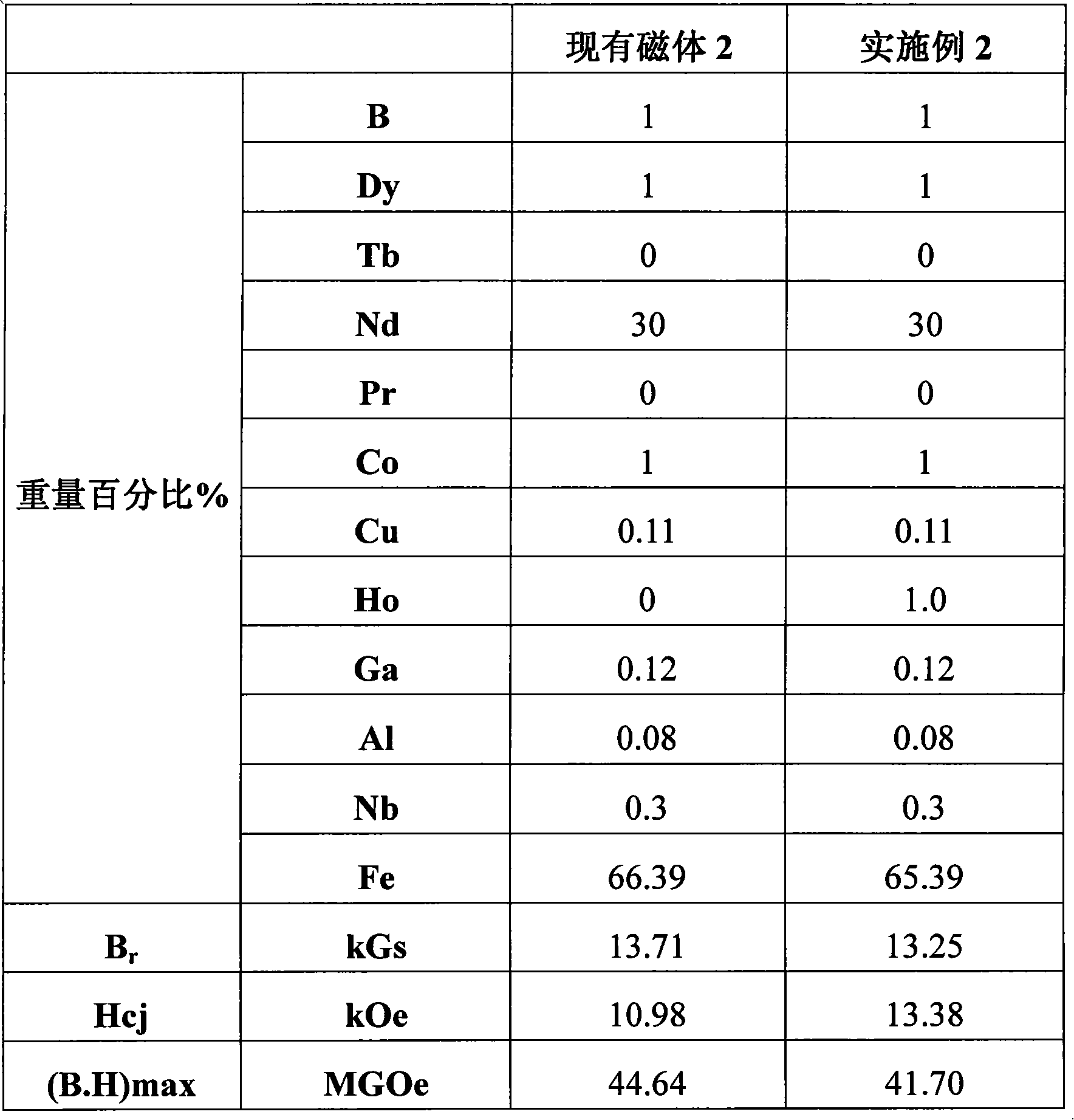

Novel sintered neodymium-iron-boron permanent-magnet material and manufacture method thereof

ActiveCN101582317ALow costSave heavy rare earth resourcesInorganic material magnetismInductances/transformers/magnets manufactureHolmiumMetallurgy

The invention provides a novel sintered neodymium-iron-boron permanent-magnet material containing holmium and a manufacture method thereof. The novel sintered neodymium-iron-boron permanent-magnet material has the structural formula as follows: LnAlphaHoBetaBGammaMxNyFe100-Alpha-Beta-Gamma-x-y, wherein Ln is lanthanon comprising Nd and one or more selected from Pr, Dy and Tb; M is an additive element comprising Co and Cu; N is an additive element comprising one or more selected from Al, Ga, Nb, Zr and Ti; Alpha, Beta, Gamma, x and y are weight percentages of each element; Fe is an Fe element or unavoidable impurities; and Alpha is mare than or equal to 29 and less than or equal to 33, Beta is more than or equal to 0.5 and less than or equal to 4, Gamma is more than or equal to 0.95 and less than or equal to 1.20, x is more than or equal to 0 and less than or equal to 3.5, and y is more than or equal to 0 and less than or equal to 1.50. In the invention, the addition of Ho has a remarkable function in improving the Hcj of a magnet.

Owner:SANVAC BEIJING MAGNETICS +1

Aluminium alloy foil material for heat exchanger fin and mfg. process thereof

This invention discloses a fin heat-exchanger made of aluminum alloy foil and its preparation method. The ingredient and ratio of the alloy are as follows: iron is 0.15-0.40%, silicon is 0.05-0.30%, copper is 0-0.10%, manganese is 0.05-0.30%, the element of rare-earth is 0.05-0.4%, titanium is 0.010-0.060%, the other is aluminum. The ingredient and ratio of rare-earth is as follows: lanthanum is 20-40%, cerium is 45-65%, praseodymium is 5-15%, neodymium is 1-9%, samarium is 0-0.05%, yttrium is 0-0.05%,the other is impurities. The preparation method includes four processes: the preparation of rare-earth aluminum alloy, the casting of blank, cold-rolling of slat and heat treating. Contrasting to the existing aluminum alloy material, the product has the better extension and toughness, the smaller aeolotropism at the same thickness and hardness, and it can be suitable to punch at high flanged fill heat-exchanger and could not crack.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

Luminophore and core-shell luminophore precursors

InactiveCN101490211ASmall particlesLess quantityLamp incadescent bodiesLuminescent compositionsMean diameterCerium phosphate

The present invention relates to a new type of green luminophore composed of mixed rare-earth phosphates, and a method of preparation of these new luminophores from precursors comprising particles having a mean diameter of between 1.5 and 15 microns, these particles comprising an inorganic core and a shell composed of a mixed lanthanum and / or cerium phosphate, optionally doped with terbium, evenly covering the inorganic core with a thickness greater than or equal to 300 nm.

Owner:RHODIA OPERATIONS SAS

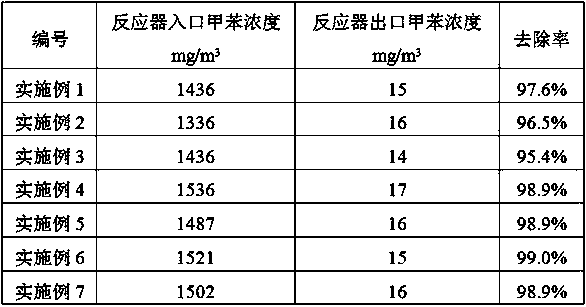

Manganese-copper based composite oxide doped rare earth element catalyst for catalyzing VOCs as well as preparation method and application of catalyst

ActiveCN108325536AHigh activityExpensive to fixGas treatmentHeterogenous catalyst chemical elementsRare-earth elementComposite oxide

The invention provides a manganese-copper based composite oxide doped rare earth element catalyst for catalyzing volatile organic compounds (VOCs) as well as a preparation method and application of the catalyst. The catalyst disclosed by the invention adopts a high-pore-volume cordierite honeycomb ceramic material as a carrier, and the carrier is sequentially coated with a first metal oxide coating layer, a second metal oxide coating layer and a third metal oxide coating layer from the inside to the outside, wherein the first metal oxide coating layer is active aluminum oxide, the second metaloxide coating layer is a hafnium-lanthanum-cerium oxide, and the third metal oxide coating layer is a manganese-copper based oxide. The catalyst provided by the invention adopts a non-precious metalinstead of a precious metal; and the catalyst provided by the invention has uniformly-dispersed coating layers, binding force between an active component and a matrix is strong, the coating layers arenot easy to fall or crack, and the catalyst can maintain higher activity under high-speed airflow and thermal shock, has stable activity when being used repeatedly, strong catalytic activity to the VOCs, a simple preparation process and low costs, and is suitable for large-scale production.

Owner:普利飞尔环保科技(上海)有限公司

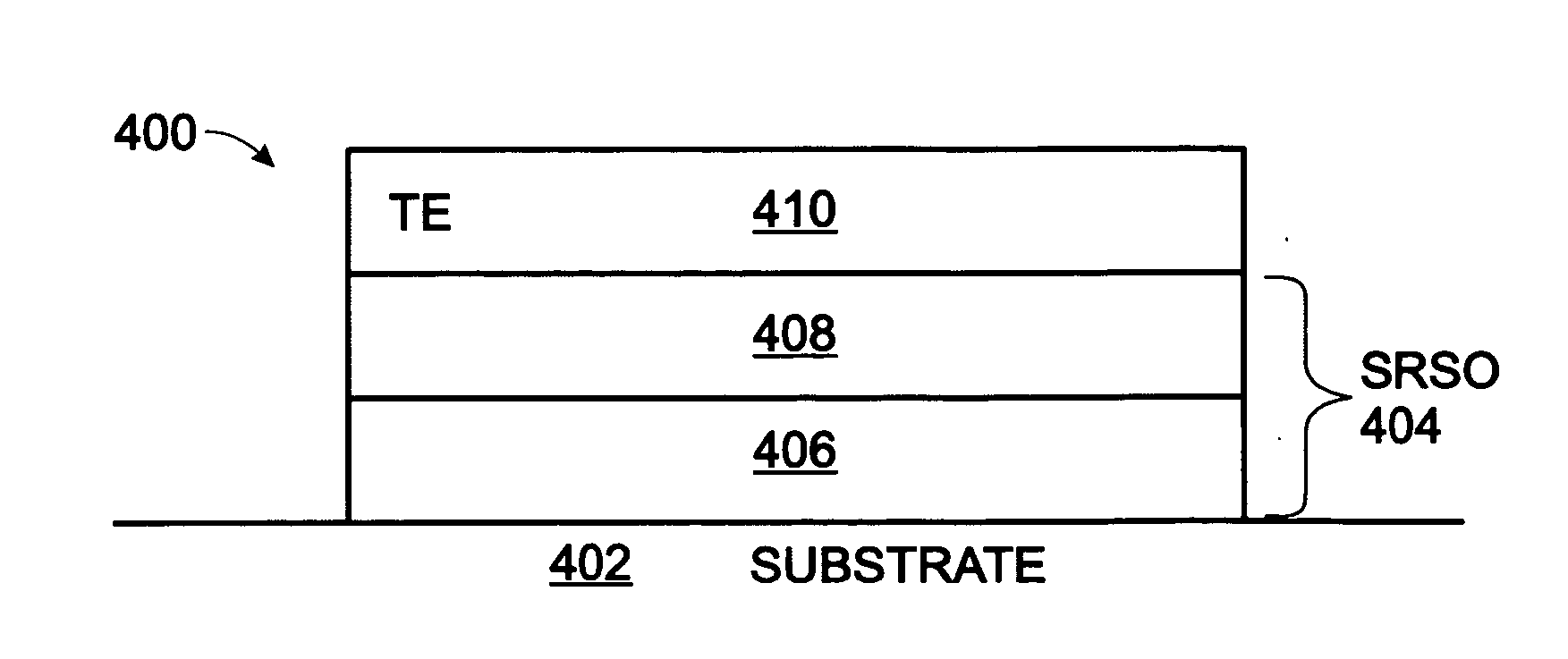

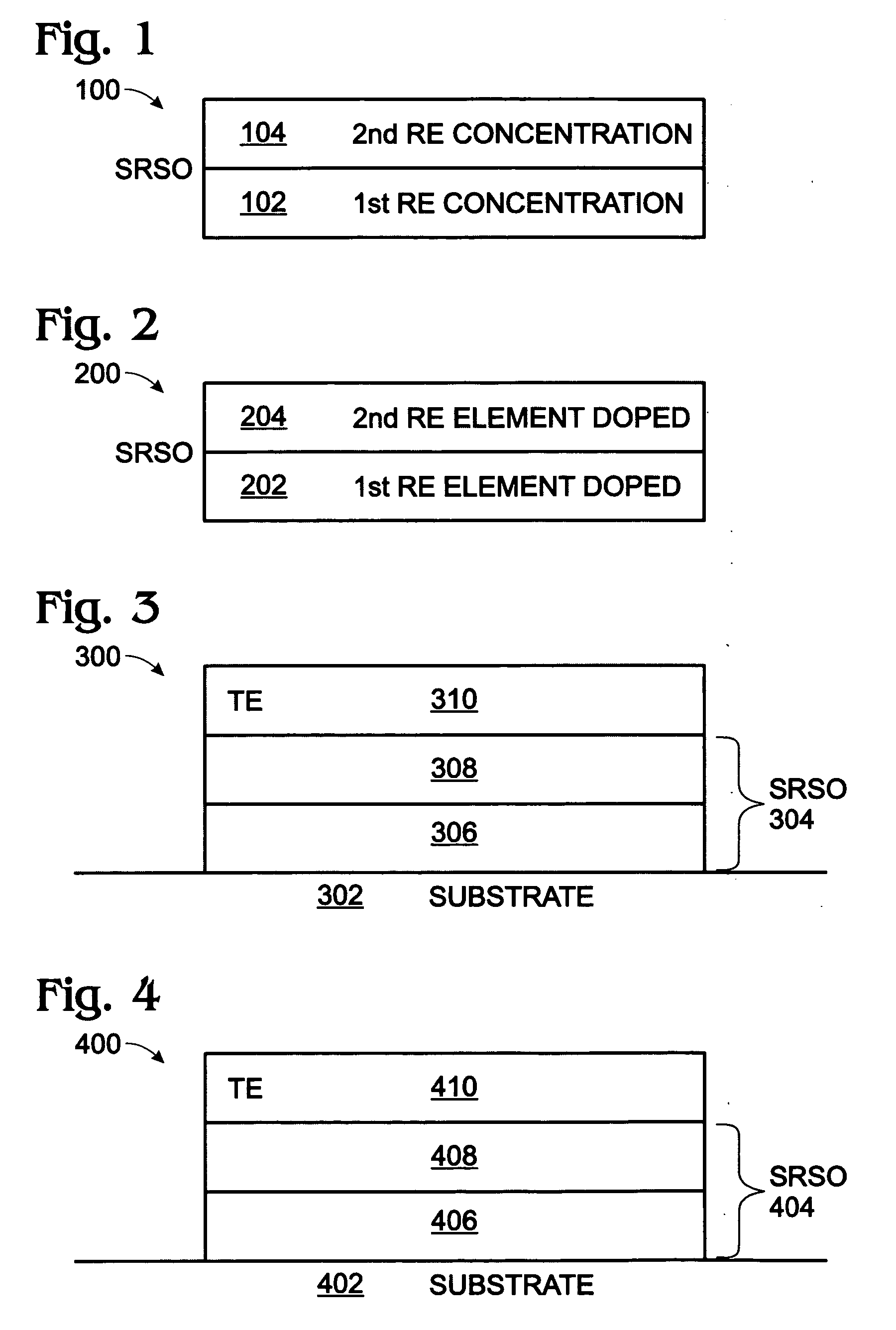

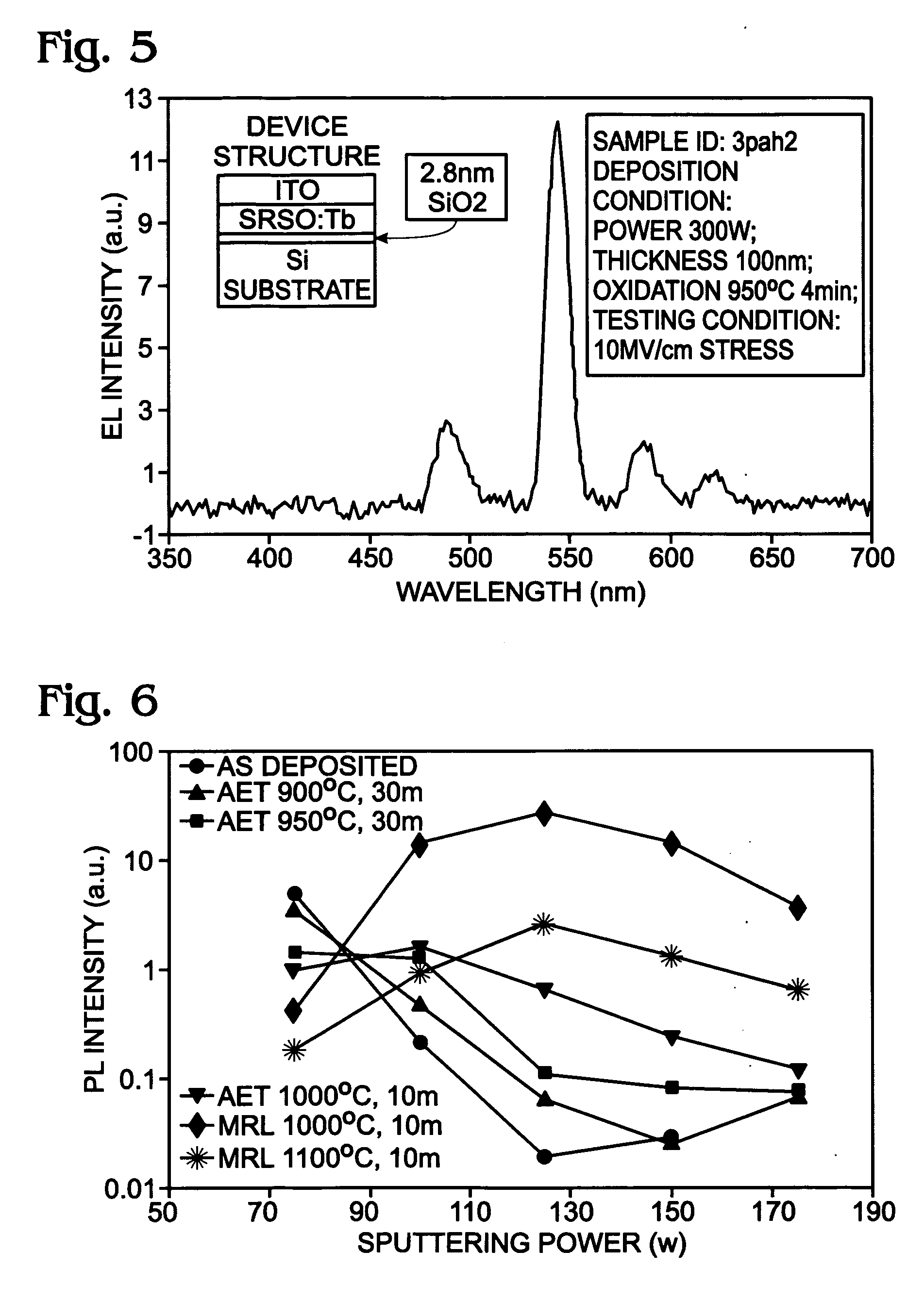

Sputter-deposited rare earth element-doped silicon oxide film with silicon nanocrystals for electroluminescence applications

InactiveUS20060183305A1Electroluminescent light sourcesSemiconductor/solid-state device manufacturingSilicon nanocrystalsCerium

A method is provided for forming a rare earth (RE) element-doped silicon (Si) oxide film with nanocrystalline (nc) Si particles. The method comprises: providing a first target of Si, embedded with a first rare earth element; providing a second target of Si; co-sputtering the first and second targets; forming a Si-rich Si oxide (SRSO) film on a substrate, doped with the first rare earth element; and, annealing the rare earth element-doped SRSO film. The first target is doped with a rare earth element such as erbium (Er), ytterbium (Yb), cerium (Ce), praseodymium (Pr), or terbium (Tb). The sputtering power is in the range of about 75 to 300 watts (W). Different sputtering powers are applied to the two targets. Also, deposition can be controlled by varying the effective areas of the two targets. For example, one of the targets can be partially covered.

Owner:SHARP KK

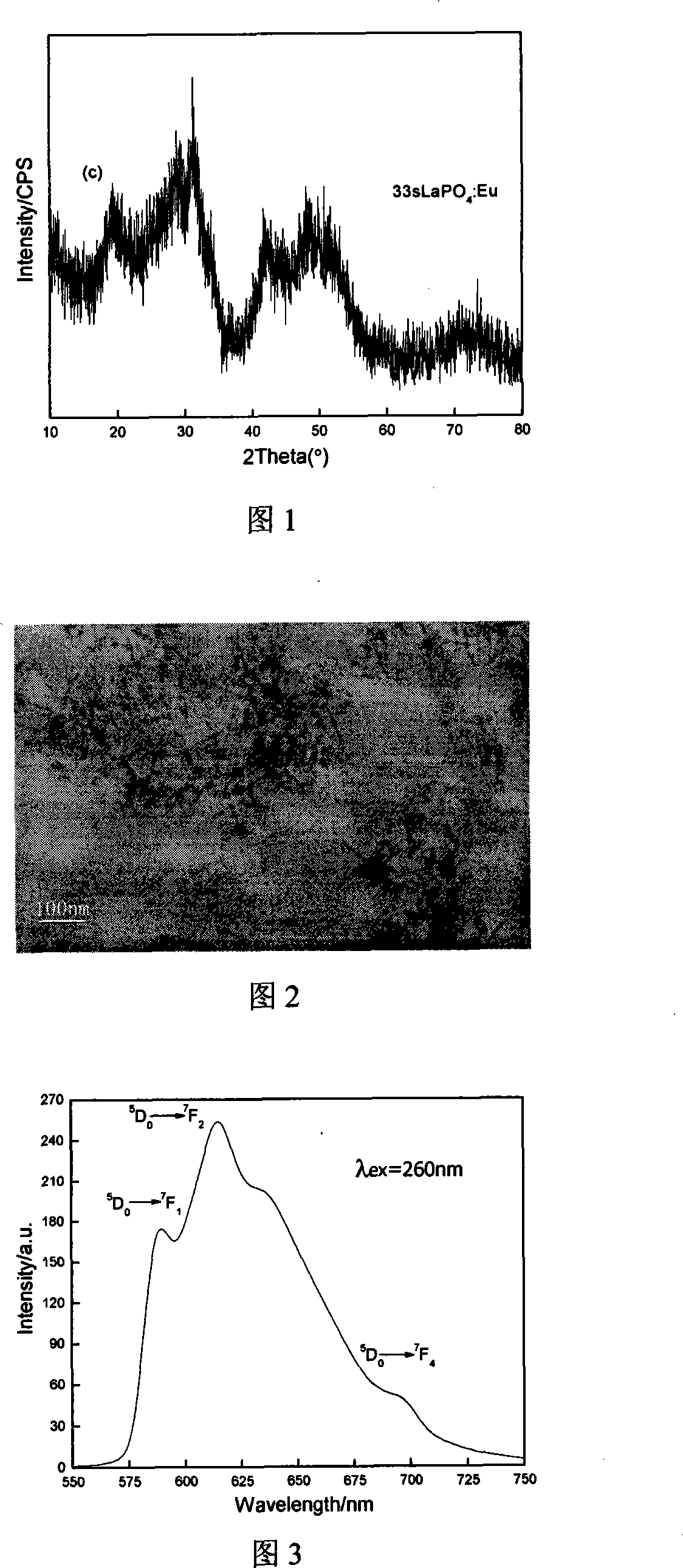

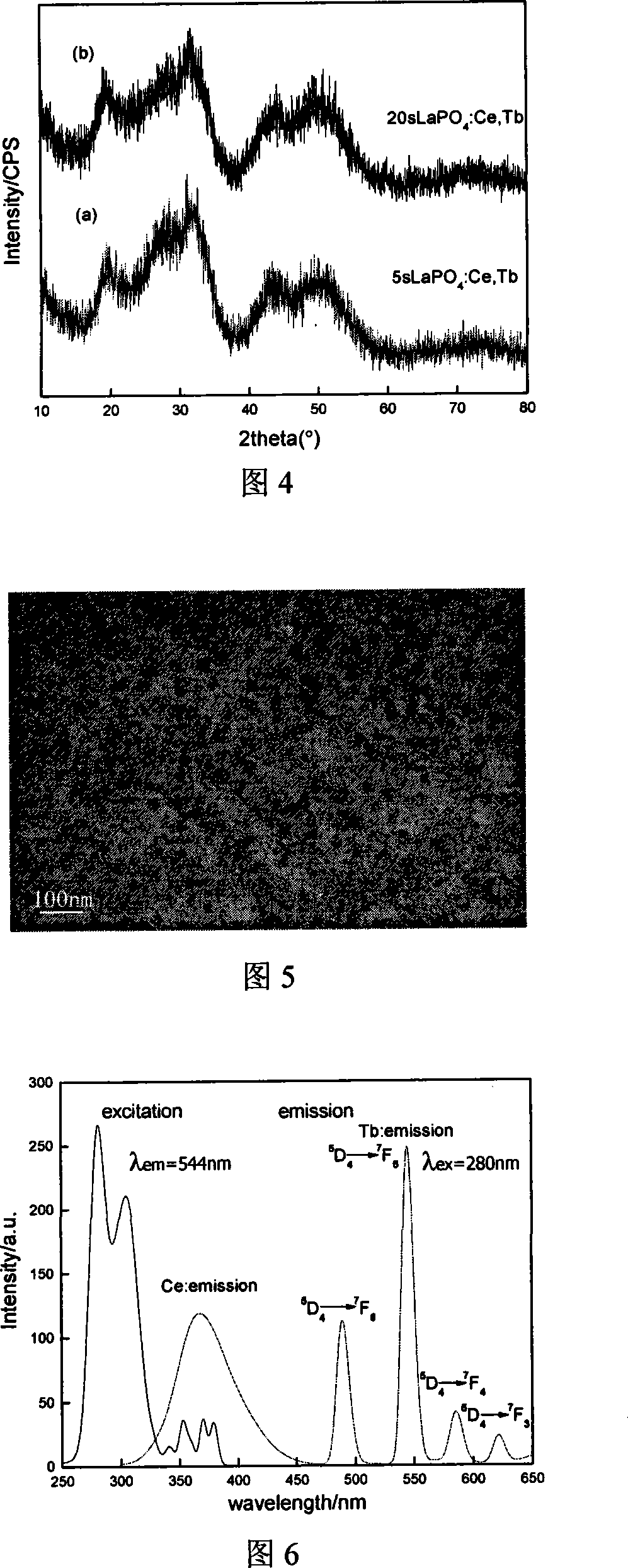

Method for preparing rare-earth doped lanthanum phosphate nano luminous particles

The invention relates to a method for preparing luminescent nano-particles of rare earth doped with lanthanum phosphate, comprising the following steps: preparing stock solutions including lanthanum nitrate polyol solution doped with rare earth element of Ln and polyol solution of NaH2PO4-2H2O; mixing the stock solutions in a micro mixer and heating the mixture in oil under constant temperature after the mixture enters the micro-channels, after which the mixture will react to produce polyol solution of luminescent nano-particles of rare earth doped with lanthanum phosphate; obtaining luminescence nano-particles of rare earth doped with lanthanum phosphate by extracting, washing and centrifugal separation. With simple technology and easy for batch production, the obtained nano-particles are provided with small particles, good dispersibility and fluorescence.

Owner:DONGHUA UNIV

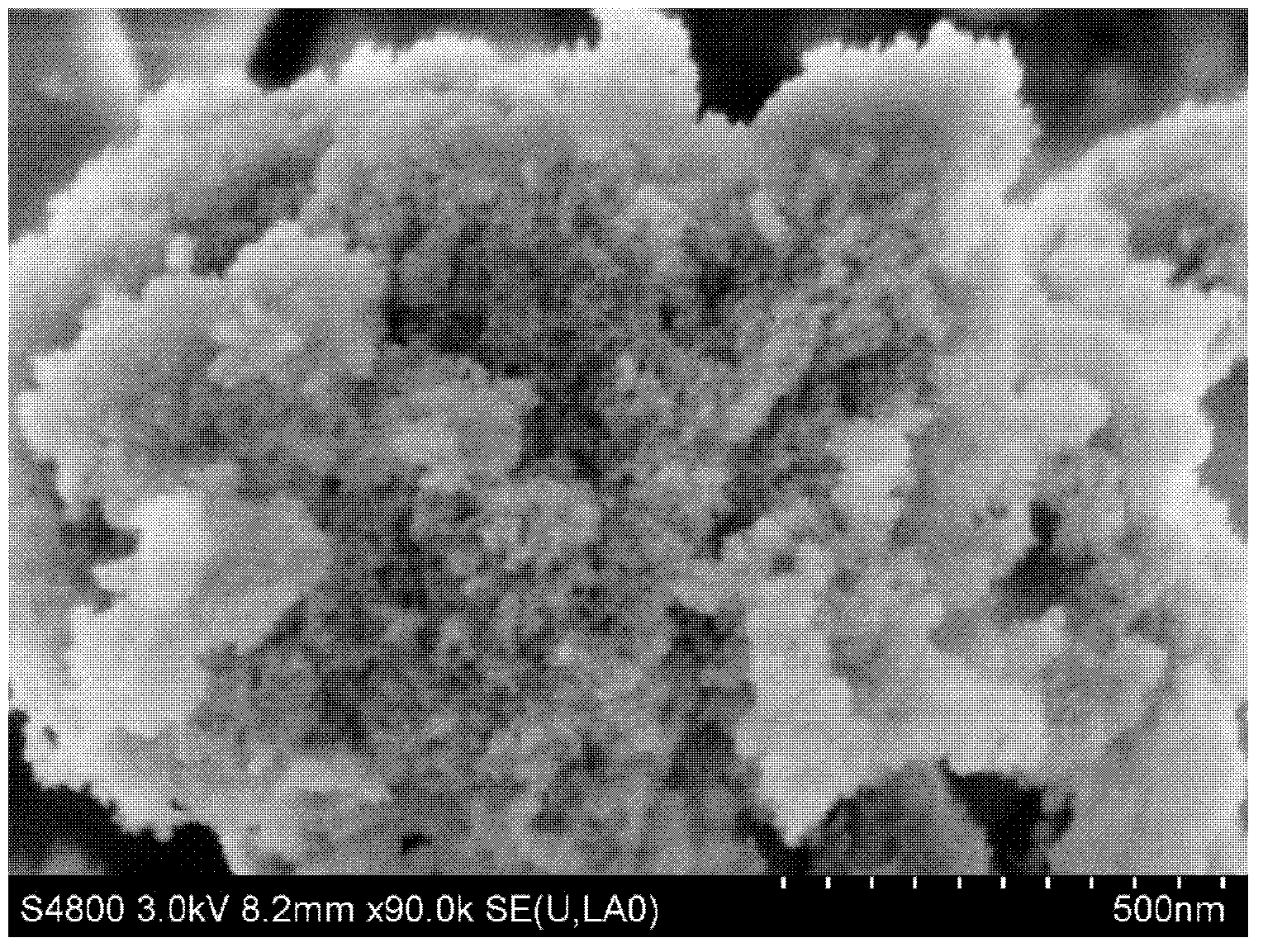

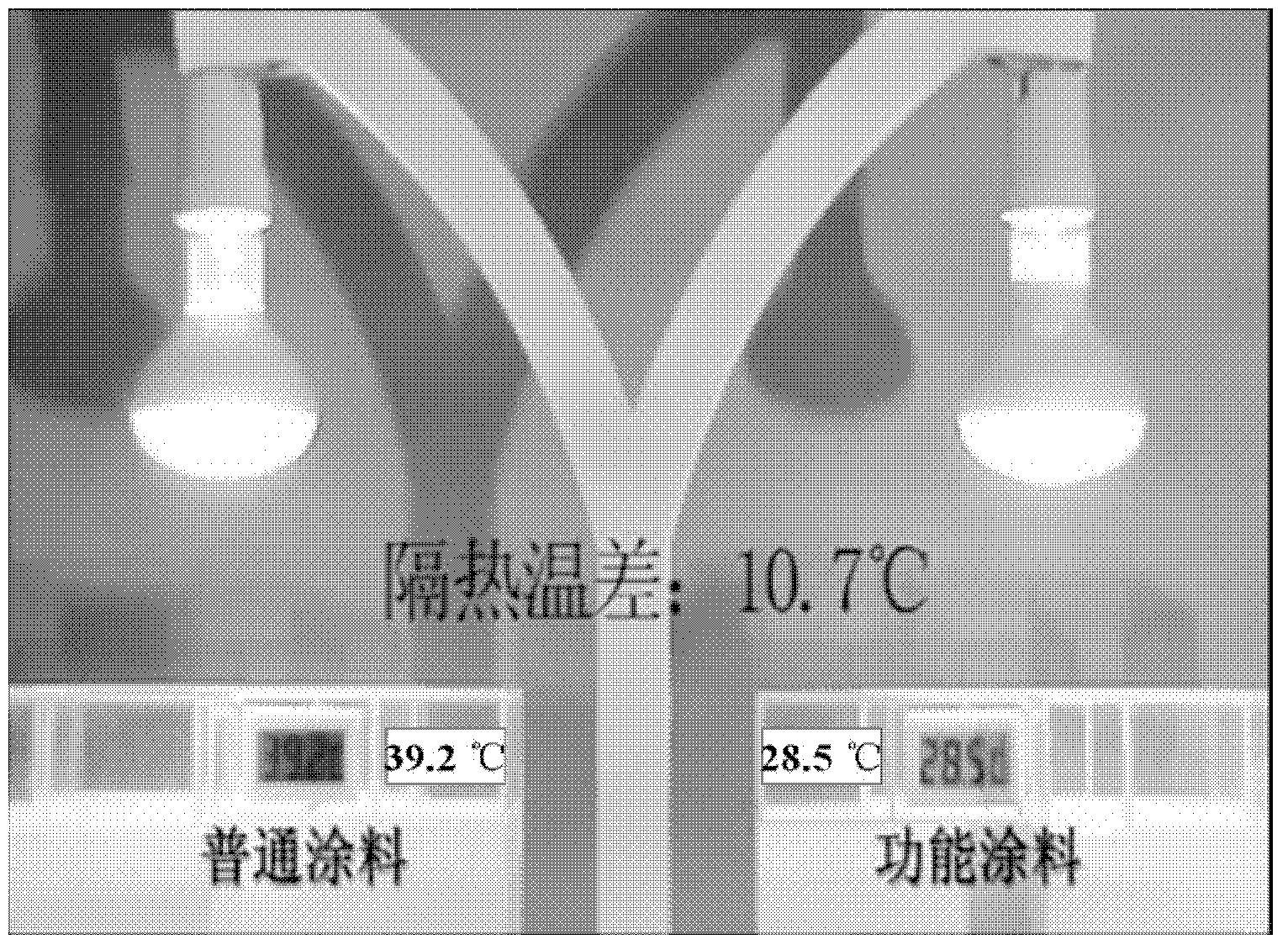

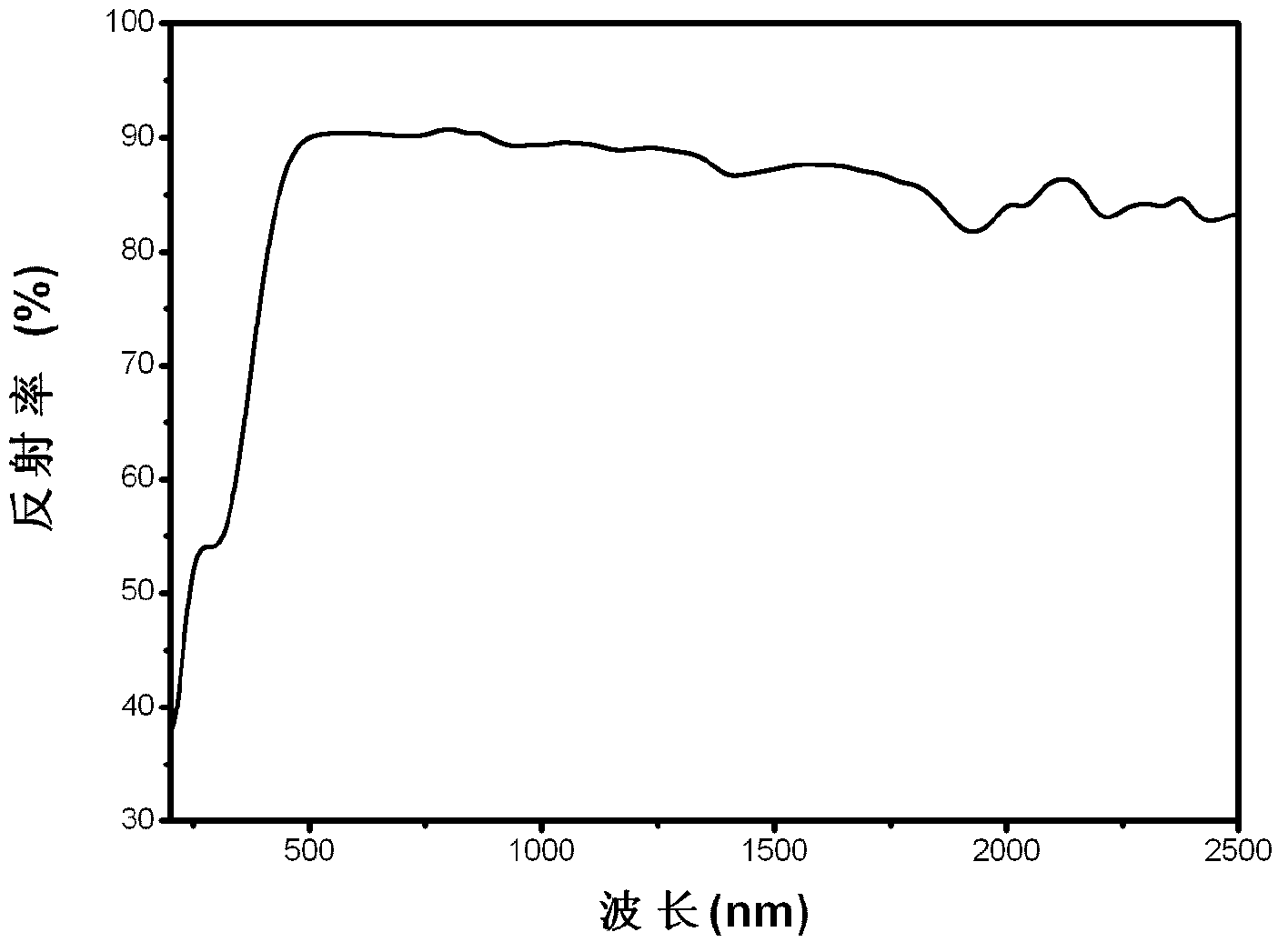

Heat-reflecting heat-insulation inorganic composite material as well preparation method and application thereof

InactiveCN102585572APrevent heat radiationHas anti-ultraviolet damage functionFibre treatmentRadiation-absorbing paintsMicro nanoThermal insulation

The invention discloses a heat-reflecting heat-insulation inorganic composite material as well a preparation method and an application thereof. The heat-reflecting heat-insulation inorganic composite material is a micron / nano composite material which takes alumina, titanium oxide and silicon oxide as substrates and is doped with one or a plurality of rare-earth elements such as yttrium, cerium and lanthanum. The inorganic composite material prepared by using a liquid phase method, a liquid phase coating method and a solid phase mixing method can be used for preparing a heat-reflecting thermal-insulation heat-insulation coating. The heat-reflecting heat-insulation inorganic composite material has the beneficial effects that 1) the reflectivity of the heat-reflecting heat-insulation inorganic composite material on a heat ray can be above 90%, the thermal radiation of sun and thermal radiation of other thermal radiation sources can be effectively prevented, ultraviolet ray can be absorbed, and the heat-reflecting heat-insulation inorganic composite material has an ultraviolet ray harm resistant function; 2) the heat-reflecting heat-insulation inorganic composite material is an inorganic solid material which does not contain an organic solvent and has the beneficial effects that is the material is safe and non-toxic, has stable chemical property and stable heat reflecting thermal insulation performance, is easy to store for a long term, and the like; and 3) the preparation technology is simple and easy to operate, the raw material is easy to obtain and cheap, the reaction process is almost free from industrial three wastes, thus the preparation technology has the characteristics of green production and environment-friendly application and is suitable for industrial production.

Owner:SHANGHAI NORMAL UNIVERSITY

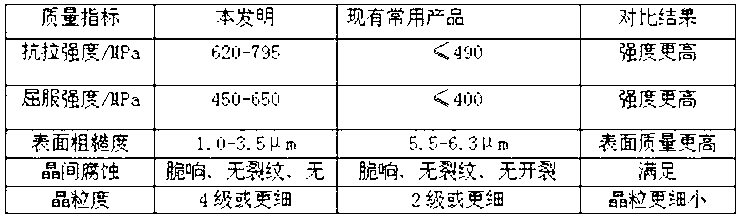

Nuclear power pipe fittings material forging and manufacture process

ActiveCN103103453APrevent precipitationGuaranteed corrosion resistanceManufacturing technologyNuclear power

The invention relates to a nuclear power pipe fittings material forging and a manufacture process, the manufacture process comprises the following steps: selecting materials, blanking, heating, forging, performing thermal treatment after forging, machining, performing physical and chemical inspection and ultrasonic flaw detection, performing thermal treatment, performing finish machining and ultrasonic flaw detection or magnetic powder inspection, cleaning the package and packaging. According to the limitation of components and technological parameters, a proper amount of lanthanide series rare earth element is added, the thermal treatment process with twice normalizing and twice tempering can avoid the intergranular precipitation of a carbide, carburization and nitridation during the thermal treatment process can be avoided, and the corrosion resistance of the material can be avoided.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

Modified conjugated diene copolymer, rubber compositions and tires

The present invention provides a modified conjugated diene polymer that is prepared by polymerization of a conjugated diene compound using a catalyst containing a lanthanoid rare earth element compound in an organic solvent and then modifying the resulting polymer having an active organic metal site with a modifier, wherein the modification efficiency is not less than 15% and the cis-1,4 bond content in the conjugated diene moiety measured by Fourier transform infrared spectroscopy satisfies the relationship (I):cis-1,4 bond content≧98.00(%) (I),or the modification efficiency is not less than 75% and the cis-1,4 bond content in the conjugated diene moiety measured by Fourier transform infrared spectroscopy satisfies the relationship (II):94.00(%)≦cis-1,4 bond content<98.00(%) (II).The invention further provides a rubber composition containing the modified conjugated diene polymer and giving a tire exhibiting low heat build-up, satisfactory failure characteristics, and high abrasion resistance, and a tire composed of the rubber composition and exhibiting these characteristics.

Owner:BRIDGESTONE CORP

High-melt-strength polypropylene material, and preparation method and application thereof

The invention discloses a high-melt-strength polypropylene material, and a preparation method and application thereof. The polypropylene material is prepared from 65-99.79 parts of polypropylene, 0.01-10 parts of initiator, 0.1-10 parts of polyfunctional group monomer, 0.1-5 parts of free radical stabilizer and 0-10 parts of inert processing assistant, wherein the free radical stabilizer is a lanthanide rare-earth oxide, carboxylate of lanthanide rare-earth element, naphthenate complex of lanthanide rare-earth element or dithiocarbamic acid rare-earth compound. The lanthanide rare-earth element does not include promethium. The proportion of the polypropylene, initiator and polyfunctional group monomer is controlled, the grafting reaction time is prolonged, and the rare-earth substances are utilized to inhibit the degradation of the polypropylene and prolong the service life of the free radical, thereby obtaining long-branched-chain high-melt-strength polypropylene with stable performance and enhancing the service performance of the conventional polypropylene. The method disclosed by the invention is easy to operate and convenient to control, and can easily implement industrial production.

Owner:KINGFA SCI & TECH CO LTD +2

Chemical coprecipitation preparation of nano-rave-earth blend AgSnO2 electric contacting alloy and its process

InactiveCN1652268AImproved ability to disperse the arcImprove welding resistanceContact materialsRare-earth elementNanoparticle

The invention is relates to components of electric contact material and fabricating technique. Weight percentage of each component is a following: 70-95% Ag, 2.5-20% stannic oxide, 0.025-1% magnesia and 0.025-9% lanthanum or cerium. Compound powder of Ag, SnO2, MgO, La or Ce in Nano amorphous or crystalloid is prepared through high-octane ball milling. Structure, decentrality and dimensional stability of Nano granules are improved by adding lanthanide series into material. Thus, formability and electrical property of electric contact alloy are improved as well as ablation rate of contact is reduced and service life is increased.

Owner:XI'AN POLYTECHNIC UNIVERSITY

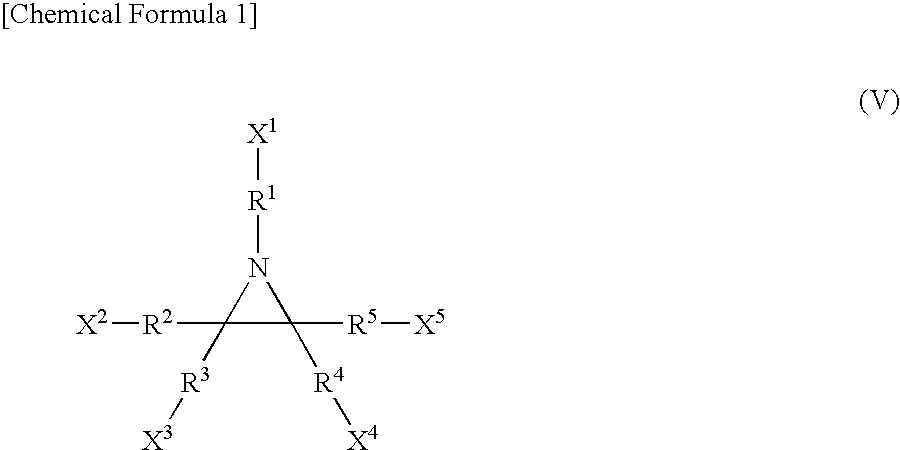

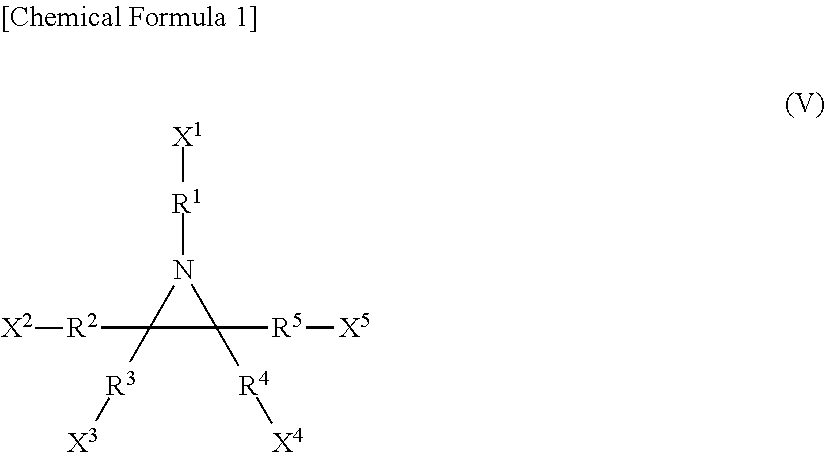

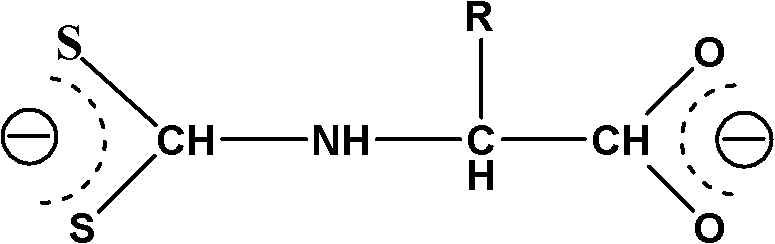

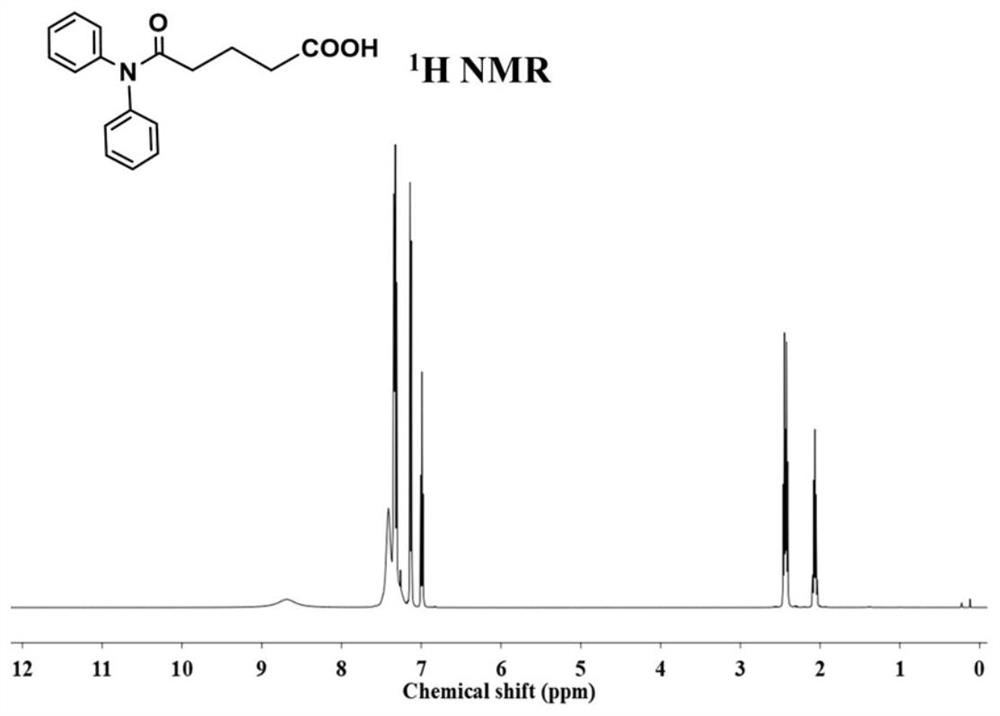

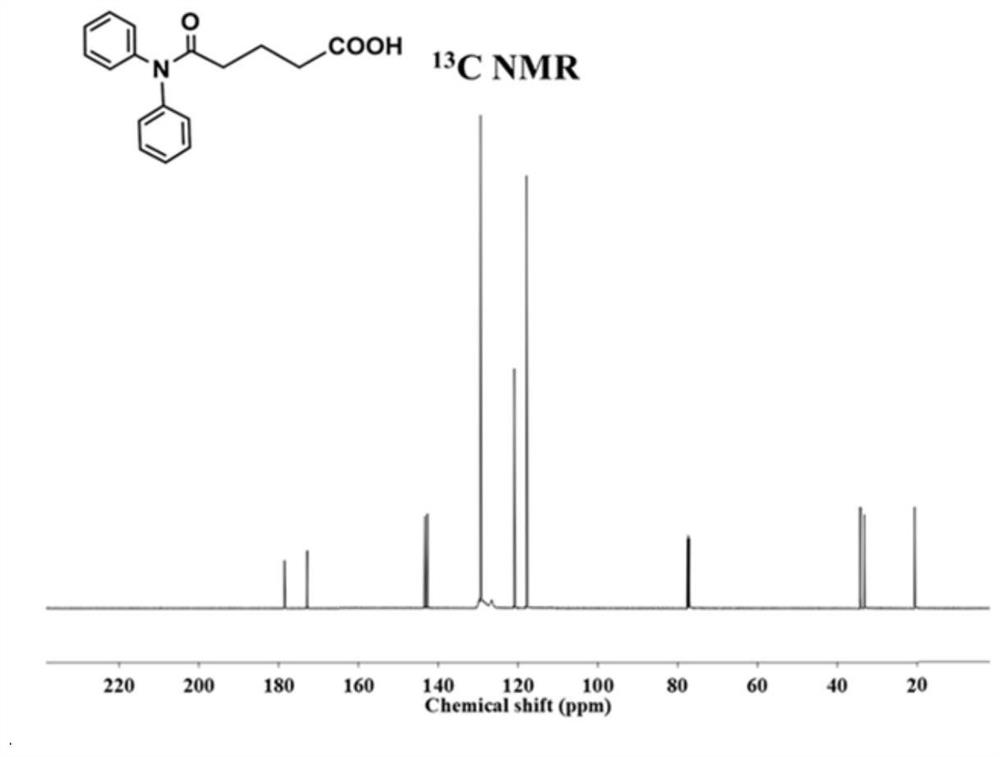

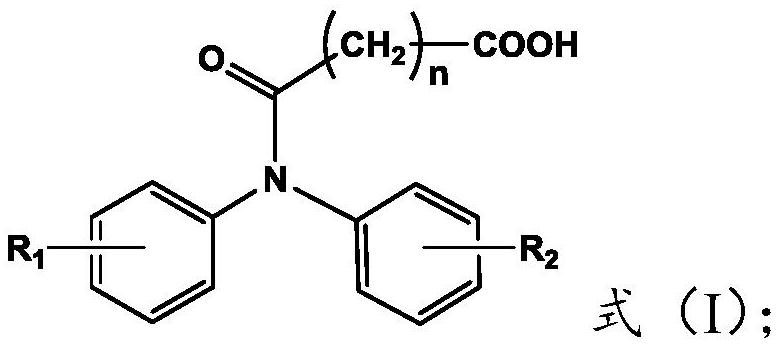

Diphenylamino oxocarboxylic acid extraction agent and preparation method and application thereof

InactiveCN112760481ASingle componentStable chemical structureProcess efficiency improvementCombinatorial chemistryCarboxylic acid

The invention relates to the technical field of rare earth resource recovery, in particular to a diphenylamino oxocarboxylic acid extraction agent and a preparation method and application thereof. The diphenylamino oxocarboxylic acid extraction agent has a structure shown in a formula (I); and in the formula (I), R1 and R2 are independently selected from H or C1-C9 alkyl groups, and n is a natural number from 1 to 6. The diphenylamino oxocarboxylic acid extraction agent provided by the invention can be used for effectively separating yttrium from lanthanide, and compared with an industrially applied naphthenic acid extraction agent, the extraction agent provided by the invention has the advantages of simplex component, stable chemical structure, no reduction of the concentration of an extracted organic phase and stable extraction performance; and moreover, the coefficient of the diphenylamino oxocarboxylic acid extraction agent for separating yttrium from light rare earth elements is obviously higher than that of the naphthenic acid extraction agent, the coefficient of the diphenylamino oxocarboxylic acid extraction agent for separating yttrium from heavy rare earth elements is also higher than that of the naphthenic acid extraction agent, and the diphenylamino oxocarboxylic acid extraction agent can completely replace the naphthenic acid extraction agent in the aspect of separation efficiency and has quite good application prospects.

Owner:XIAMEN TUNGSTEN

Corrosion-resistant copper alloy

The invention discloses a corrosion-resistant copper alloy, which comprises the following compositions by weight percent: 1.0-1.2% of Mn, 0.5-0.7% of Si, 0.05-0.15% of Fe, 0.8-1.2% of Mg, 2-4% of Zn, 11-13% of Al, 1.2-1.4% of Ti, 0.3-0.5% of Sc, 5.5-6.5% of Ni and 0.2-0.3% of composite mischmetal, wherein the composite mischmetal contains La and Ce mischmetal elements, the percentage of Ce is 30-50%, and the balance is Cu.

Owner:NINGBO SUNLIGHT MOTOR PARTS

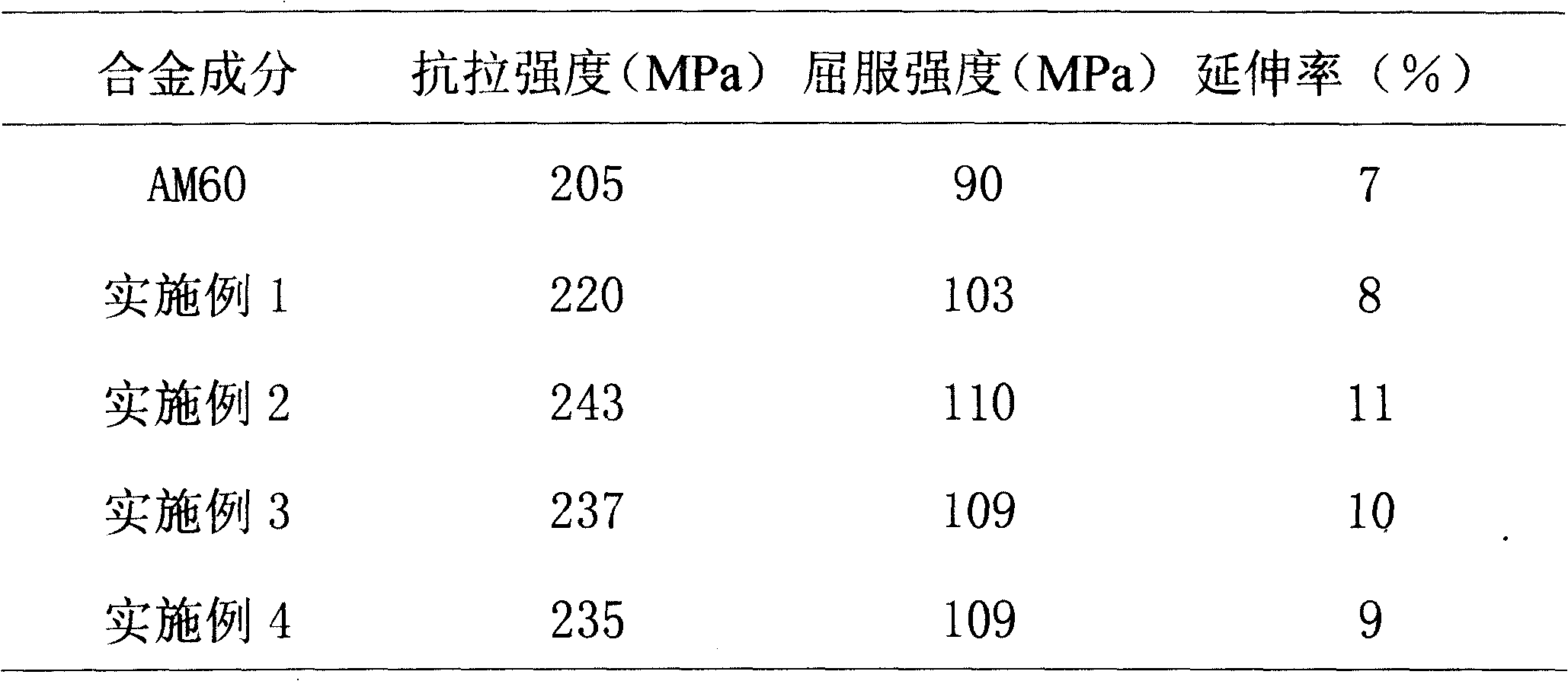

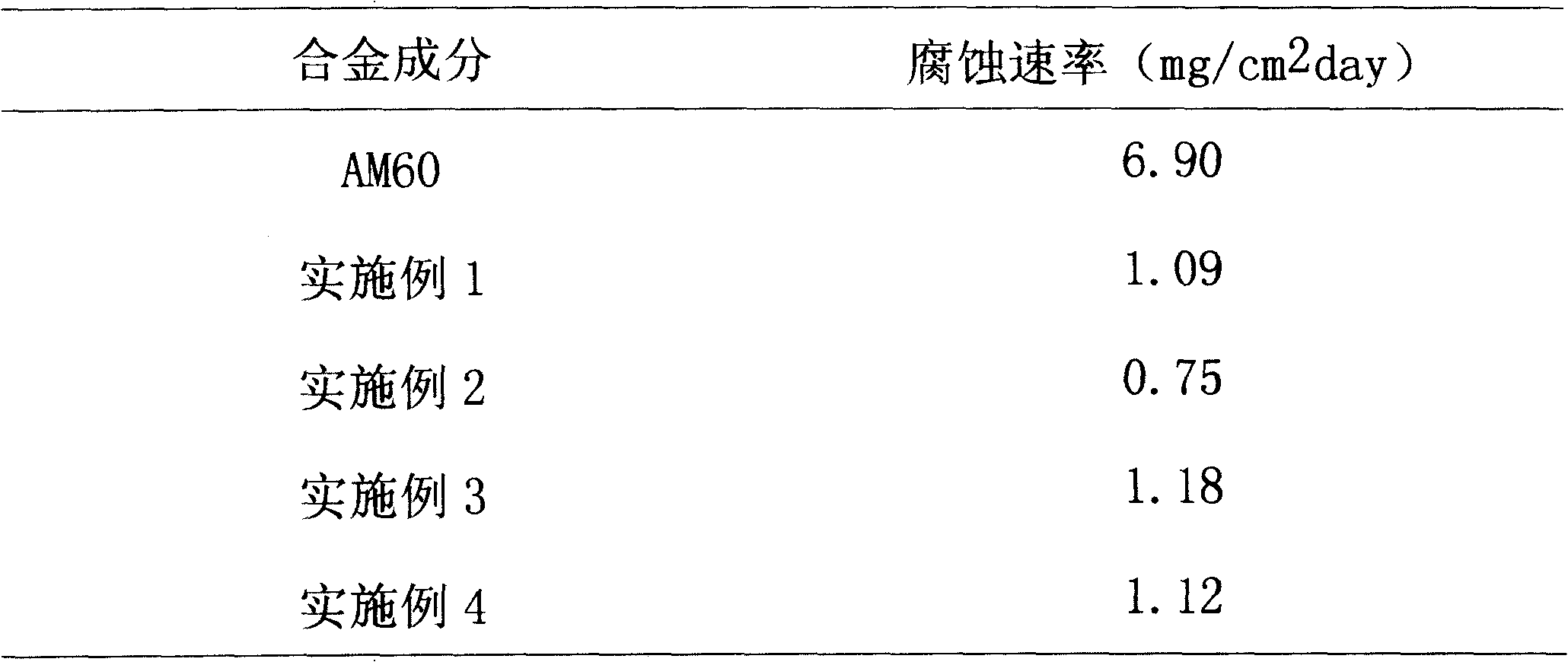

High-strength high-ductility Mg-Al-Mn die-casting magnesium alloy containing lanthanum-cerium mixed rear earth

The invention provides a high-strength high-toughness Mg-Al-Mn die cast magnesium alloy containing lanthanum-cerium rare earth compound, which is composed of 97% to 90% by mass of AM60 magnesium alloy and 3% to 10% by mass of magnesium-lanthanum cerium interalloy in a proportion of 3% to 10%. The magnesium-lanthanum cerium interalloy is prepared by 80% by mass of magnesium ingot and 20% by weight of lanthanum-cerium rare earth compound; the lanthanum-cerium rare earth compound is the residual lanthanum-cerium rare earth compound after Pr and Nd are separated from cerium-rich rare earth compound, composed of 20% to 80% by mass of Ce, 80% to 20% by mass of La and no more than 1% of other rare earth elements. Comparing the preparing method with that of traditional magnesium alloy, the differences lies in: magnesium-lanthanum cerium interalloy is first prepared, and then magnesium-lanthanum cerium interalloy is added during smelting process. The rare earth has small lose, is easy to control its compositions, the smelting time is shorted, thus to improve the alloy quality.

Owner:白山市天安金属镁矿业有限公司

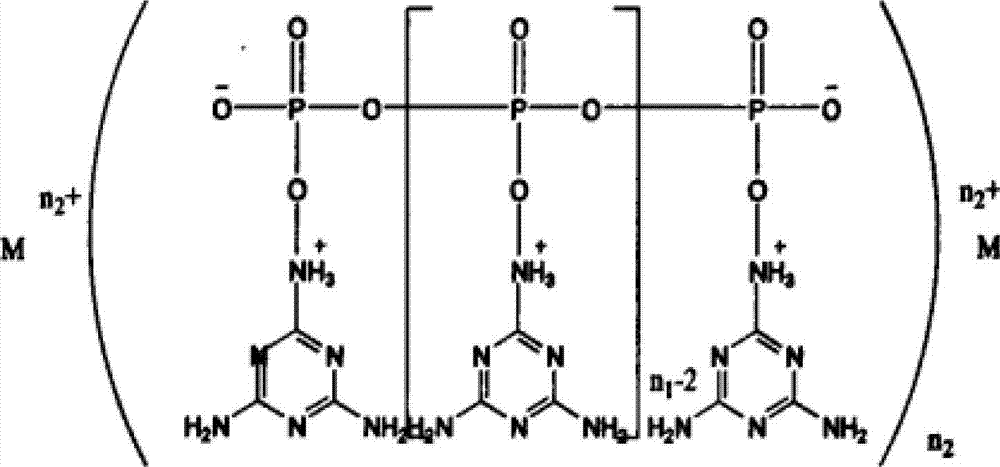

Halogen-free flame retardant and method for preparing same

InactiveCN102964629AImprove thermal stabilityNot easy to produceOrganic chemistryChemical LinkageRare-earth element

The invention discloses a halogen-free flame retardant. The halogen-free flame retardant has a structural formula as follows, wherein M is rare earth element series of lanthanum, cerium or praseodymium; and n2 is an integer from 1 to 4. A method for preparing the halogen-free flame retardant comprises the following steps: 1, synthesizing melamine phosphate; 2, carrying out polycondensation on the melamine phosphate (MP) to form melamine pyrophosphate (MPP); and 3, carrying out end sealing reaction to synthesize metal melamine pyrophosphate (MMPP). A rear earth metal chloride end sealing group is added during the polycondensation of the product, as rare earth elements have unique valence shell structures and physicochemical properties, coordination bonding is realized except chemical bonding, the thermal stability of MMPP is increased, and after the MMPP is mixed with polyvinyl plastics, the flame retardant property of the polyvinyl plastics can be greatly improved. The MMPP does not contain halogen, has high thermal stability and does not generate toxic hydrogen halide gas easily.

Owner:ZHANGJIAGANG SHUNCHANG CHEM

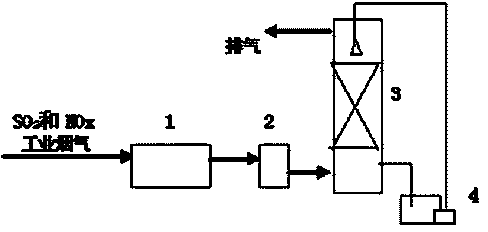

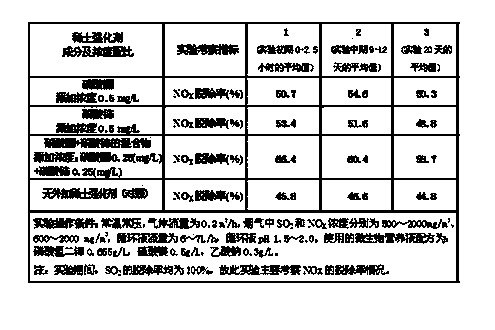

Method for improving denitrification efficiency of biological membrane packed tower for simultaneously removing sulfur and nitrogen from smoke by externally adding rare earth enhancer

The invention discloses a method for improving the denitrification efficiency of a biological membrane packed tower for simultaneously removing sulfur and nitrogen from smoke by externally adding a rare earth enhancer. The method comprises the steps of adding the mixture of low-concentration rare earth elements include lanthanum (La) and cerium (Ce) into circulating liquid of a circulating liquid storage tank of a biological membrane packed tower system to be as a biological activity enhancer, uniformly mixing, spraying the biological activity enhancer to a biological membrane in the tower along with the circulating liquid to stimulate and improve the adaptability of denitriding flora in a microbial flora based on autotrophic bacteria to a low-pH strong-acidity growing environment condition, so as to accelerate the rapid growth and reproduction of the microbial flora, thus achieving the effect of improving the denitrification efficiency of the biological membrane packed tower for simultaneously removing the sulfur and nitrogen of the smoke. According to an experiment, the rare earth enhancer including 0.25mg / L lanthanum nitrate and 0.25mg / L of cerous nitrate in the additive concentration ratio is screened out. Due to the application of the technical method disclosed by the invention, the NOx removal efficiency of the biological membrane packed tower is improved by 20.6% and 13.9% respectively, and an application effect of a simultaneous smoke desulfurization and denitrification technique by virtue of a biological method is remarkably improved.

Owner:YUNNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com