Patents

Literature

97results about How to "Single component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

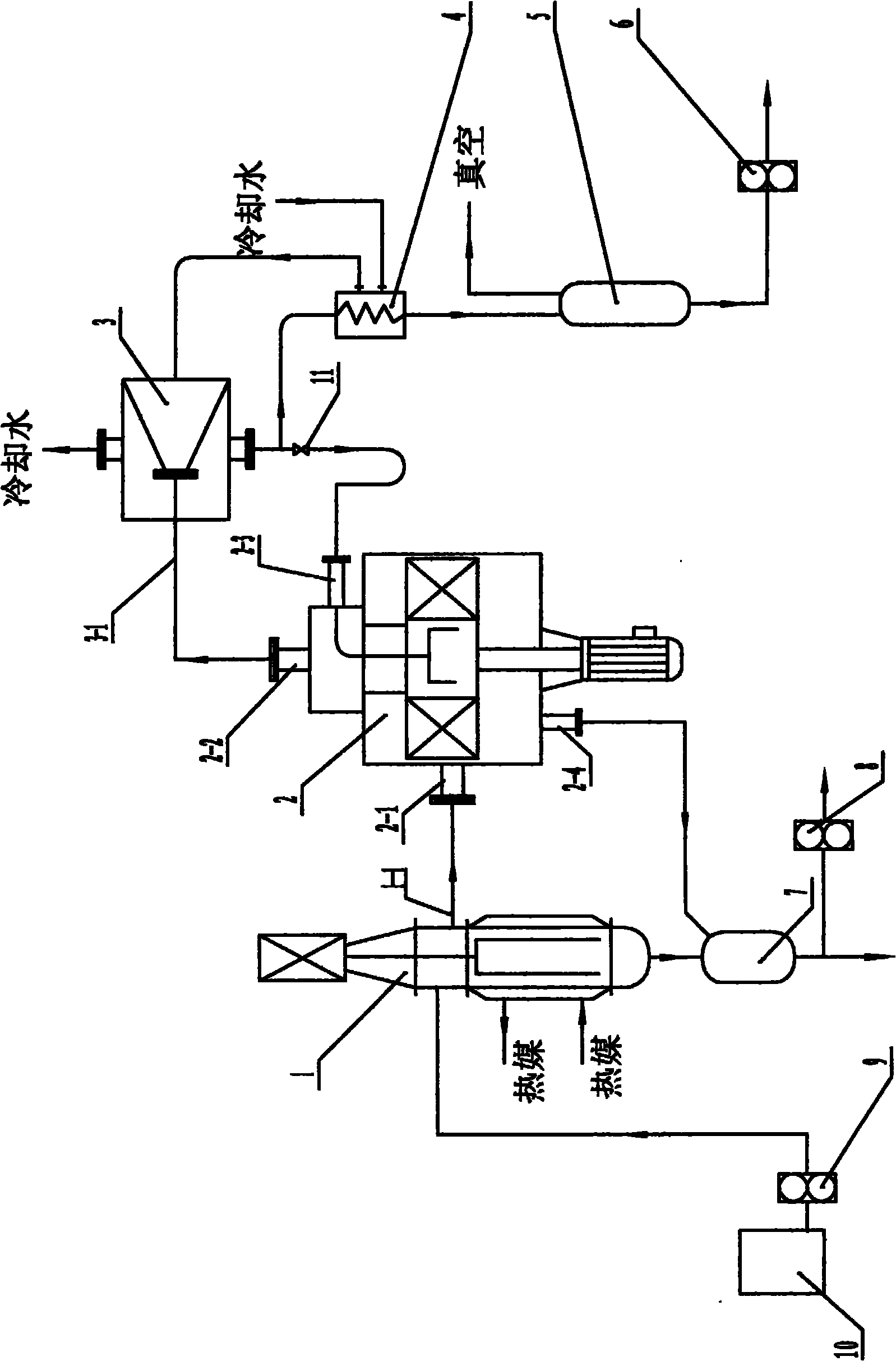

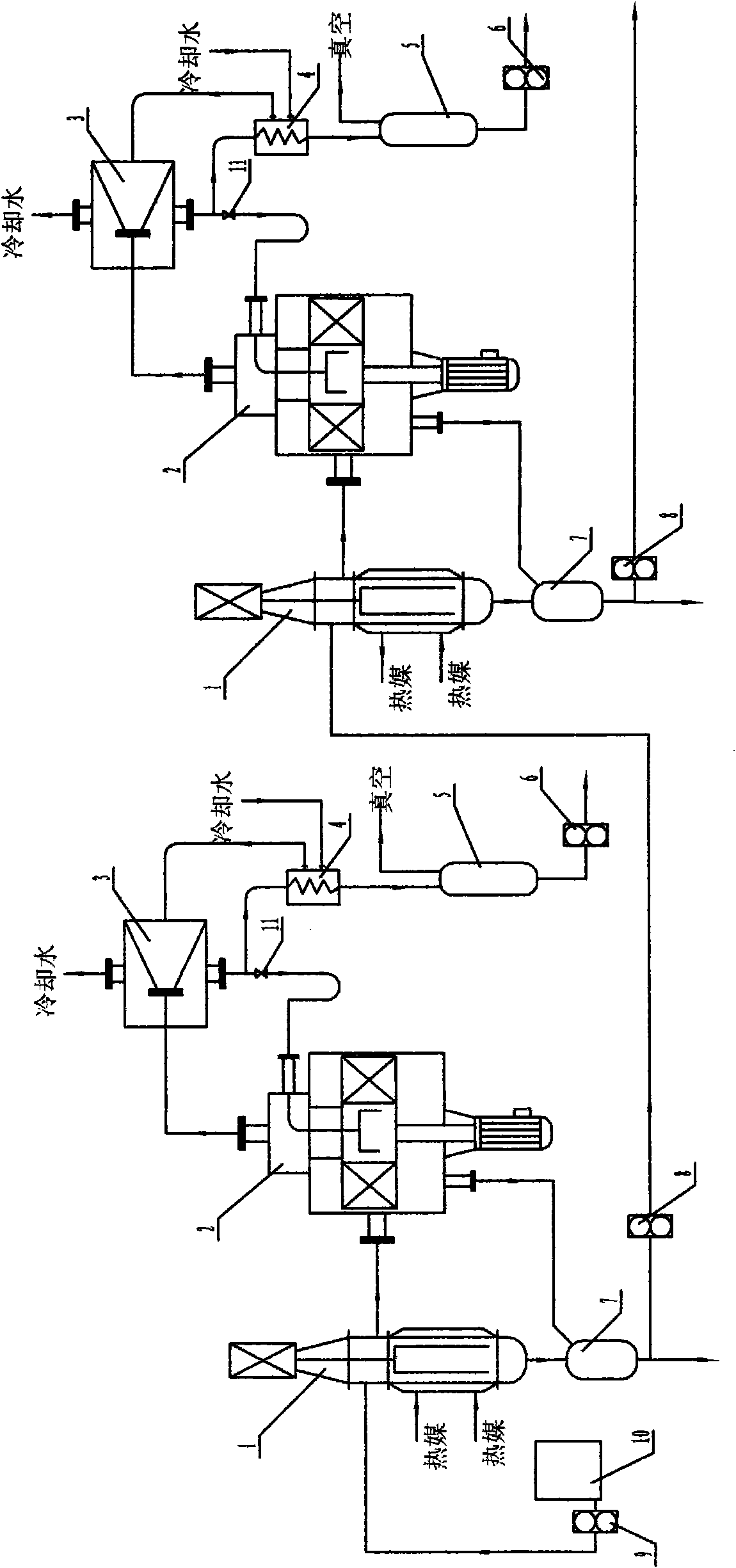

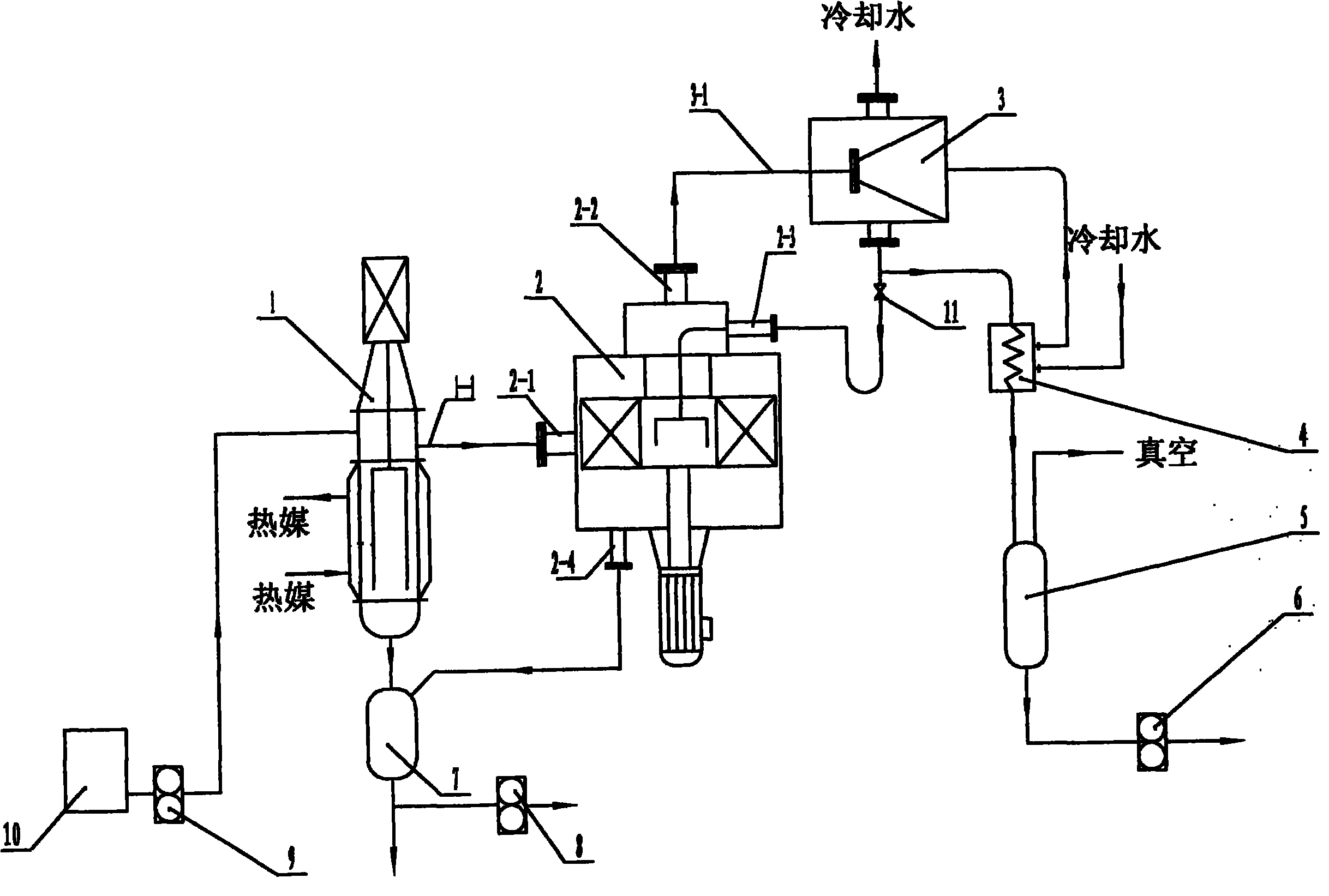

Method for separating and recovering product oil from waste lubricating oil and device thereof

ActiveCN101831348AImprove heating efficiencyShort heating timeLubricant compositionEvaporationEngineering

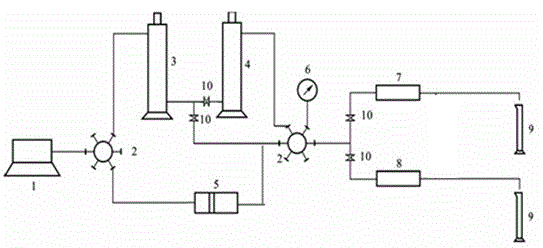

The invention relates to a method for separating and recovering product oil from waste lubricating oil and a device thereof, which relates to chemical production methods and devices. The method adopts the process that after preliminary treatment of dewatering, degassing and mechanical purity removal, multi-time intermittent rectification or multistage continuous rectification is carried out on the waste lubricating oil by thin-film evaporation and hypergravity revolving field. The device is a 1-4 time intermittent rectifying device or a 1-4 stage multistage continuous rectifying device comprising a raw material tank, a material pump and one to four thin-film evaporators, hypergravity revolving beds, condensers, coolers, finished product tanks, discharging pumps, heavy constituent receiving tanks, material pumps and reflux regulating valves. The method has high rectification speed, good product quality and high recovery rate, and meets the requirements of environmental protection; compared with short path distillation technology, the invention has smaller device volume and higher rectification efficiency and can further refine materials; the device for treating the materials with the same scale has lower requirements for field, less investment and relatively lower vacuum degree requirement.

Owner:HANDWAY TECH FOSHAN

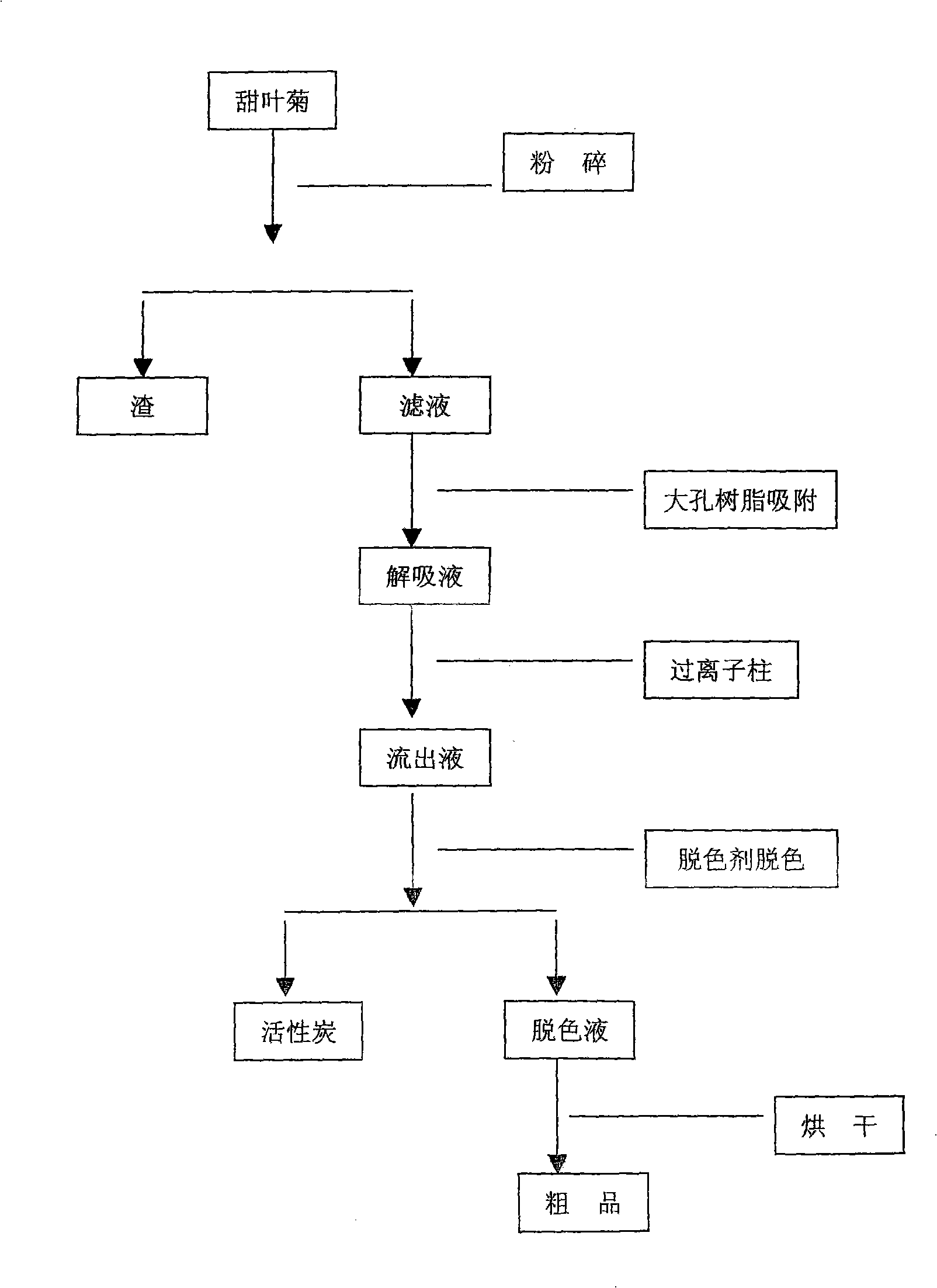

Extracting method for high-content sweet inulin A3

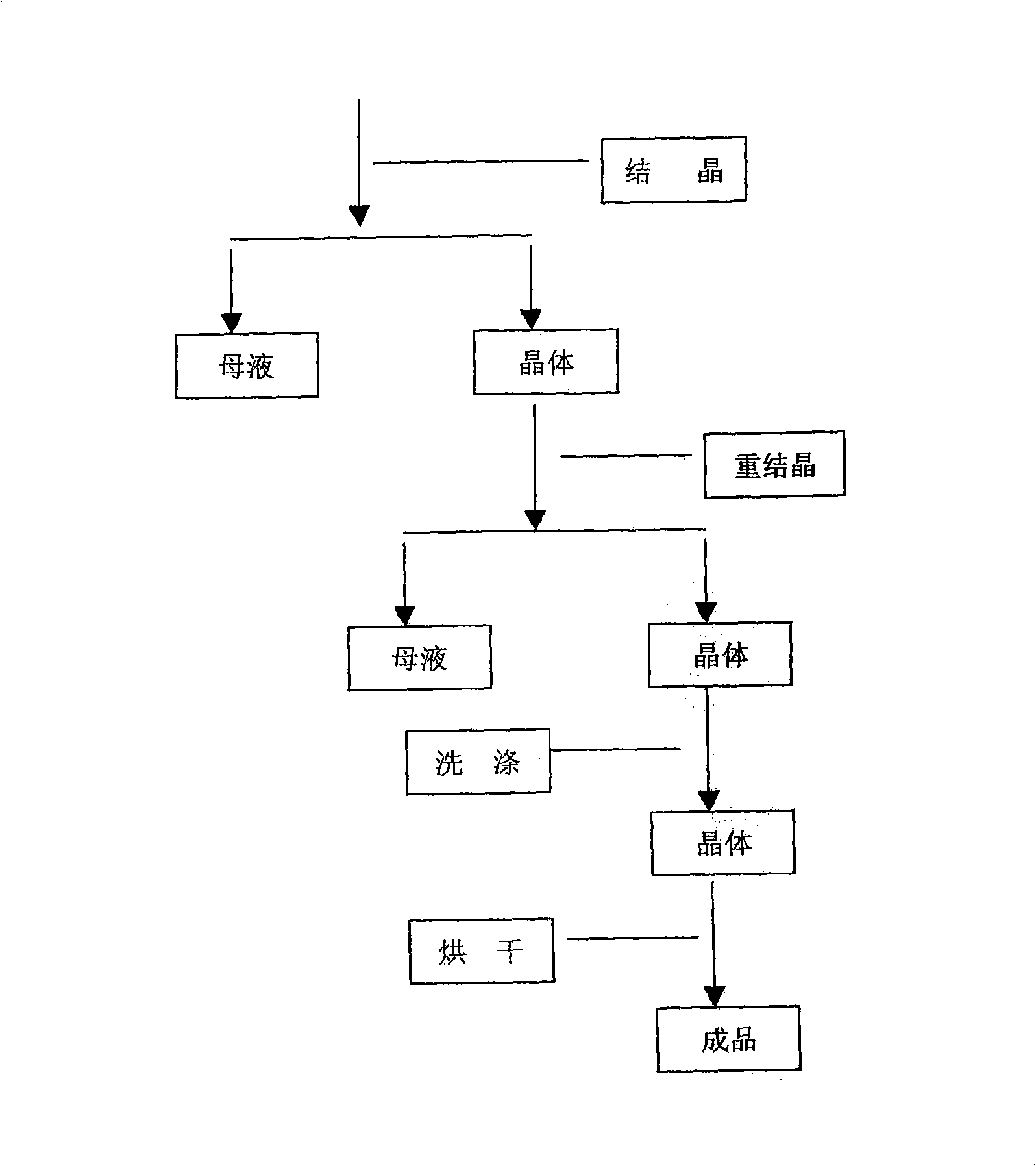

The utility model relates to a method for extracting high-content stevioside A3 glycoside, which includes six steps: (1) water extraction: the ground stevia rebaudiana is extracted with water and filtered; (2) resin separation: Filtrate passes through a macroporous resin column and is eluted by alcoholic solvent, stripping liquid passes through a duolite column, and effluent liquid is collected; (3) decolorization: decolourant is added into the effluent liquid, which is then filtered and dried to produce a crude product: (4) crystallization: the crude product is resolved into alcoholic solvent, kept static and filtered to obtain crystals; (5) recrystallization: alcoholic solvent is used again for multiple recrystallizations; (6) washing: the crude product is washed by anhydrous alcoholic solvent and dried to obtain the finished product. The purity of the produced high-content stevioside A3 glycoside is high, so the high-content stevioside A3 glycoside can better improve the taste, the quality and the grade of food, and the method is reasonable and can be easily implemented.

Owner:NINGBO GREEN HEALTH PHARMACEUTICAL CO LTD

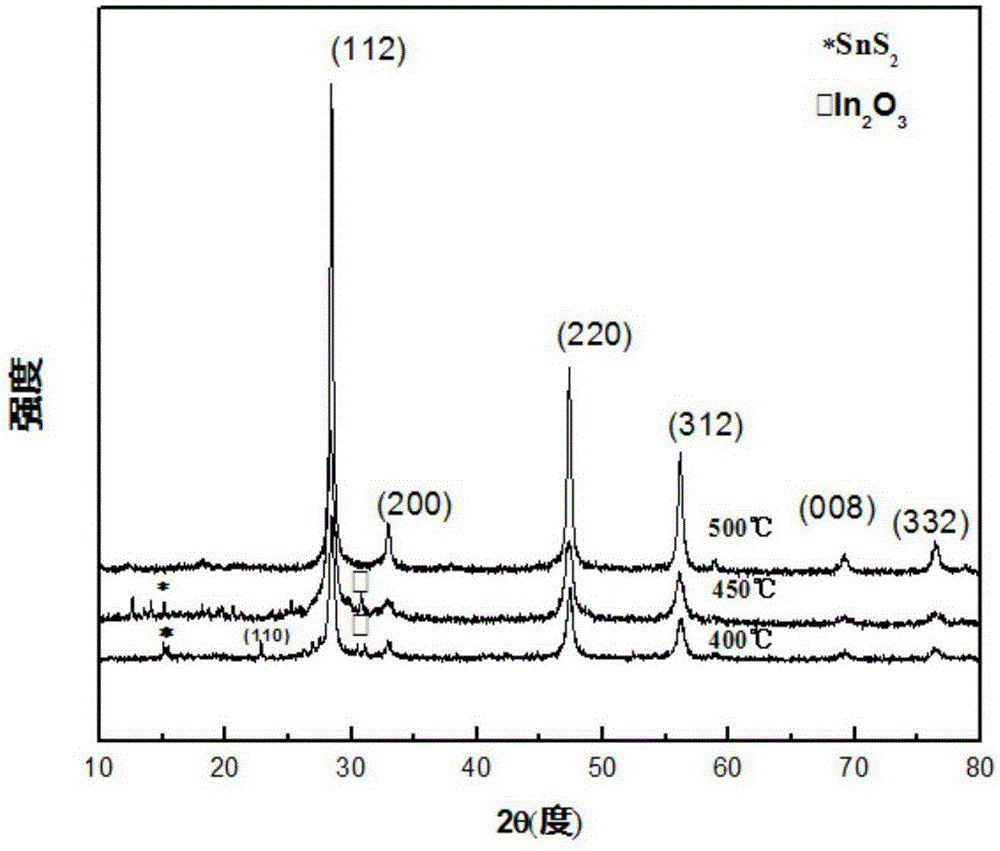

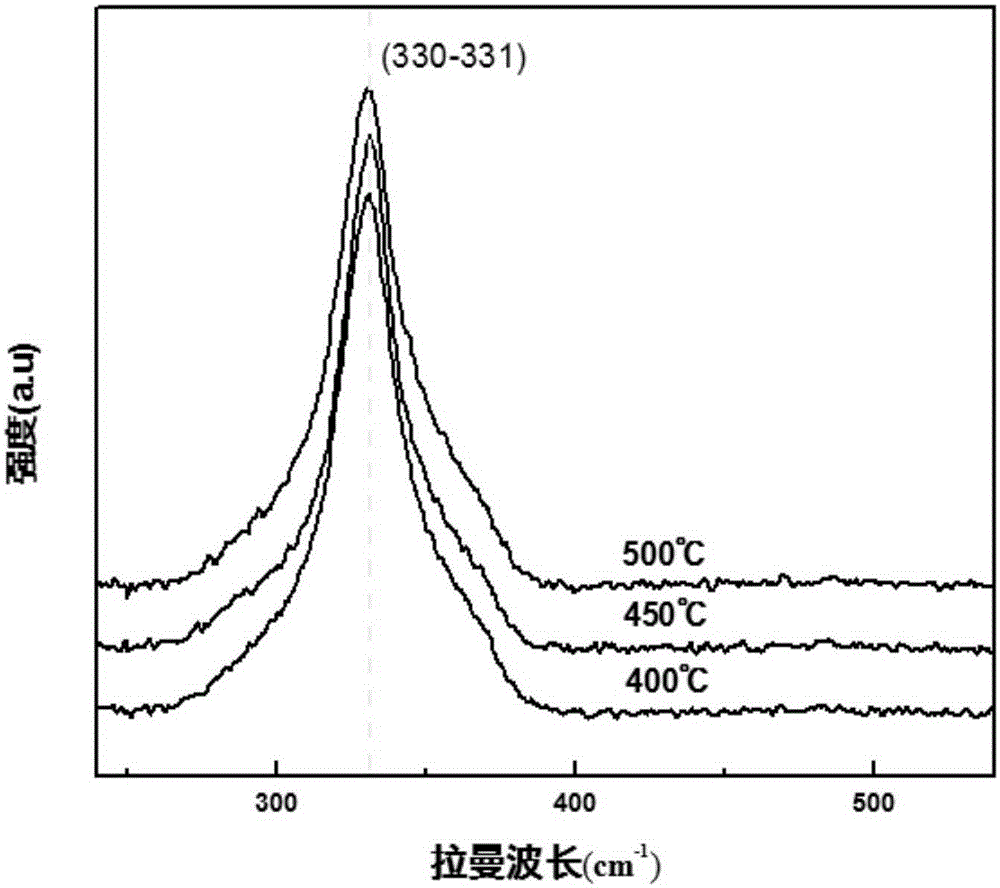

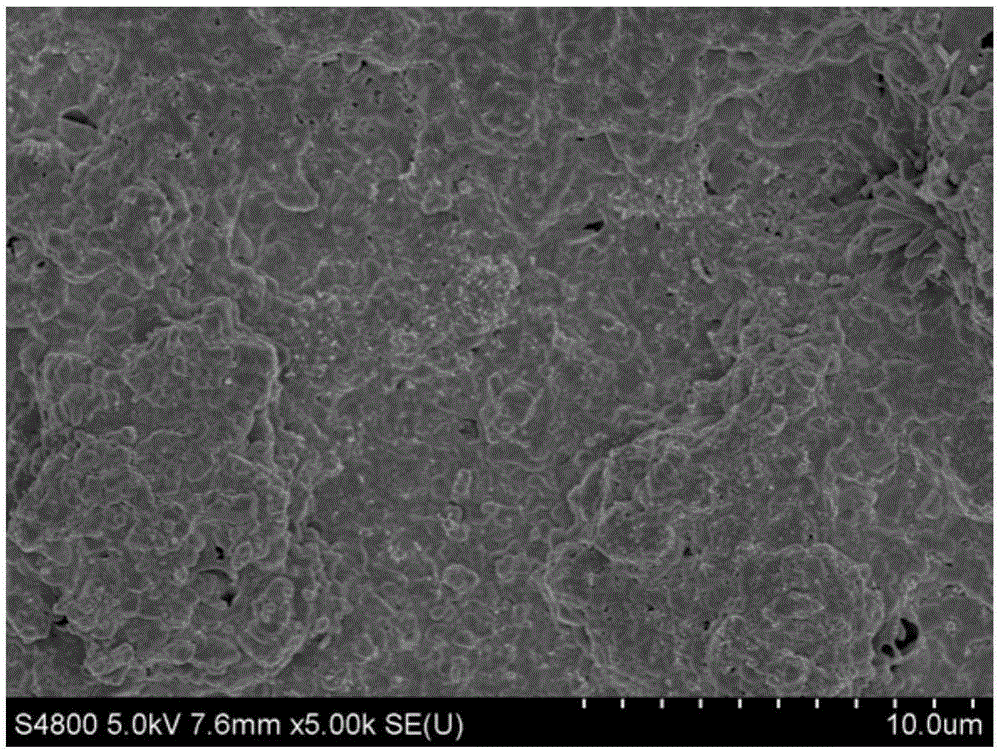

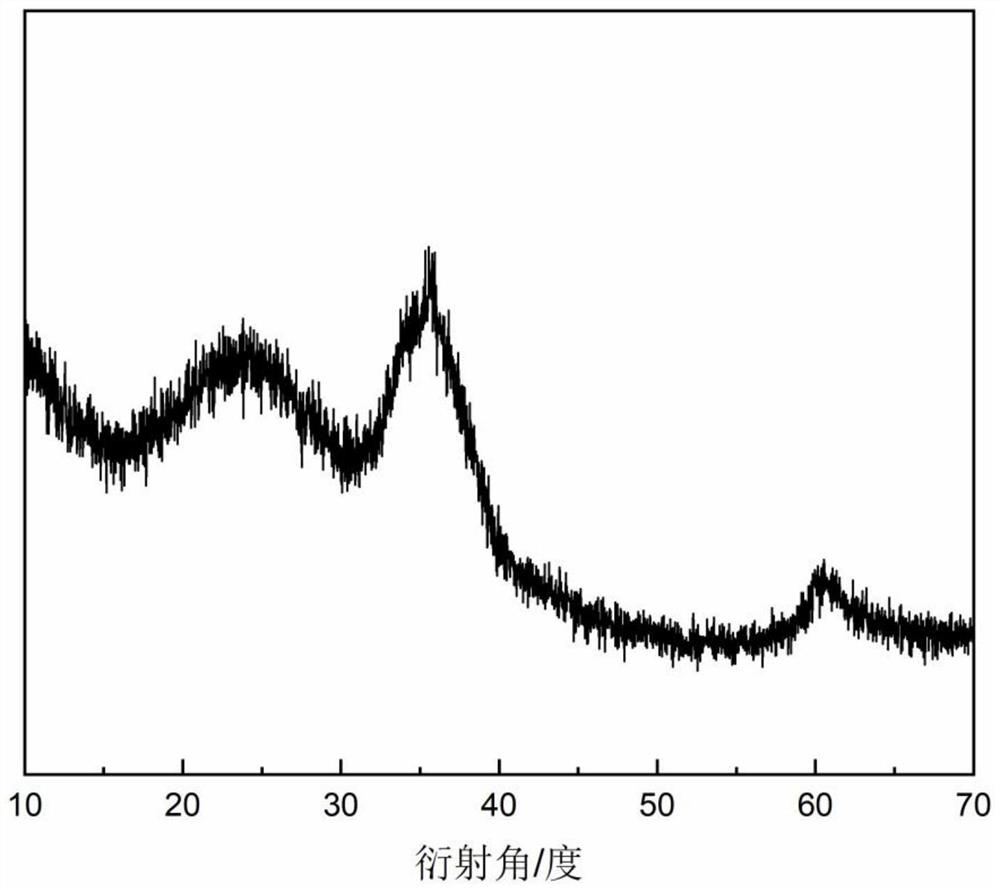

Method for preparing copper-zinc-tin-sulfur film

The invention discloses a method for preparing a copper-zinc-tin-sulfur film, and the method comprises the following steps: (1) washing a substrate: sequentially carrying out the ultrasonic washing of the substrate through liquid soap, acetone, ethanol and deionized water, enabling the substrate to be immersed into prepared alkaline washing liquid for some time, and drying the substrate for use; (2) preparing solution: sequentially enabling a compound containing copper, zinc, tin and sulfur to be dissolved in an alcohols solvent, and preparing a solution with certain concentration; (3) carrying out coating, wherein the manufacturing processes of spin coating, dipping, lifting or reel-to-reel can be employed; (4) carrying out preprocessing: enabling a coated wet film to be heated on an electric heating plate for several minutes under constant temperature, wherein step (3) and step (4) can be carried out for a plurality of times in a circulating manner in order to achieve an ideal film thickness; (5) carrying out annealing: carrying out annealing in an inert atmosphere under high temperature, and obtaining the copper-zinc-tin-sulfur film. The method is simple, is low in cost, is controllable in the whole process, causes no pollution, and is suitable for scale production.

Owner:YANGZHOU UNIV

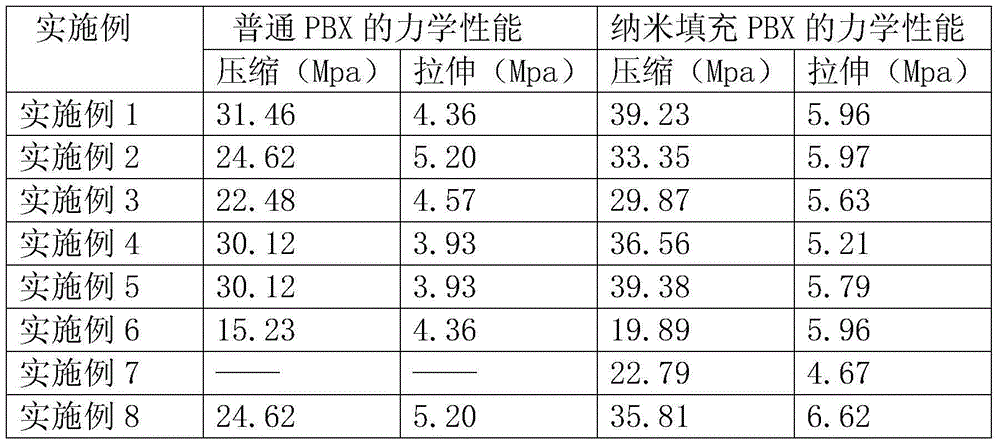

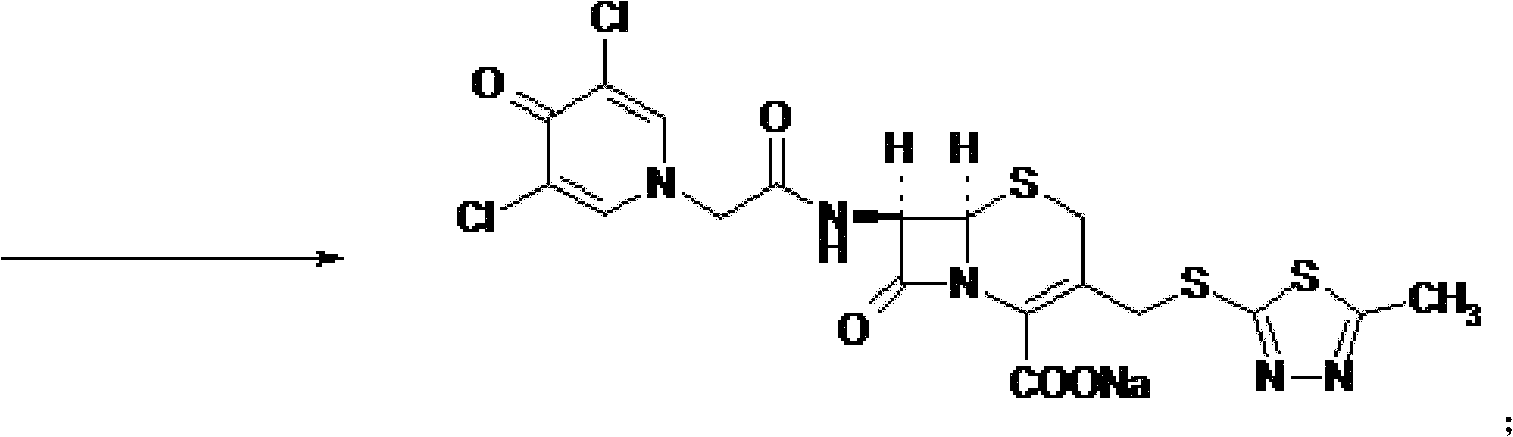

High polymer bonded explosive enhancing mechanical properties with nanoparticles and preparation method of high polymer bonded explosive

ActiveCN104649850AImprove mechanical propertiesIncrease energy densityNitrated aromatic explosive compositionsNitroparaffin explosive compositionsPolymer scienceHigh energy

The invention discloses a high polymer bonded explosive enhancing mechanical properties with nanoparticle and a preparation method of the high polymer bonded explosive. The high polymer bonded explosive contains 2-75% by mass of nano explosive particles with the particle size of 50-600nm. The preparation method comprises the following steps: mixing an explosive with an average particle size with the nano explosive particles in water in a proportion; then slowly adding a bonding agent solution to ensure that the explosive particles are gradually compounded into microparticles along with the volatilization of a solvent under the action of the bonding agent; and pressing an explosive product after washing and drying. According to the preparation method disclosed by the invention, the nano explosive particles are adopted to replace average granular explosive in the high polymer bonded explosive, and the PBX formula components and contents thereof are not needed to be changed, so that the mechanical properties of the high polymer bonded explosive can be significantly improved, a large amount of multi-component bonding agent systems which are used for improving the mechanical properties can be effectively avoided, the high-energy density of the high polymer bonded explosive is ensured, and meanwhile, the high polymer bonded explosive is relatively single in component, simple in preparation method and low in cost.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

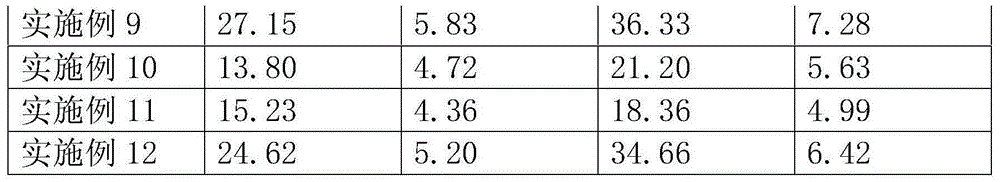

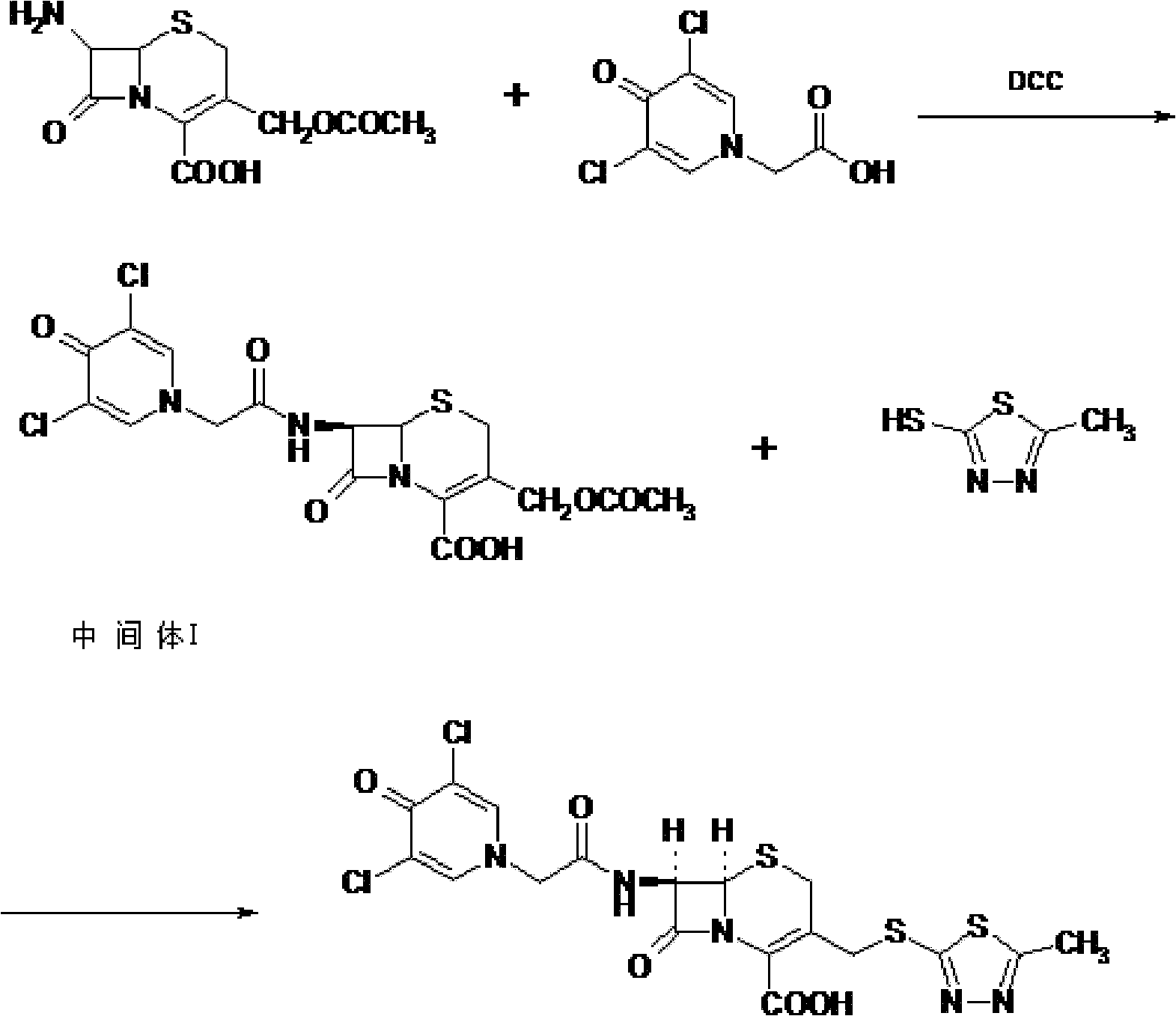

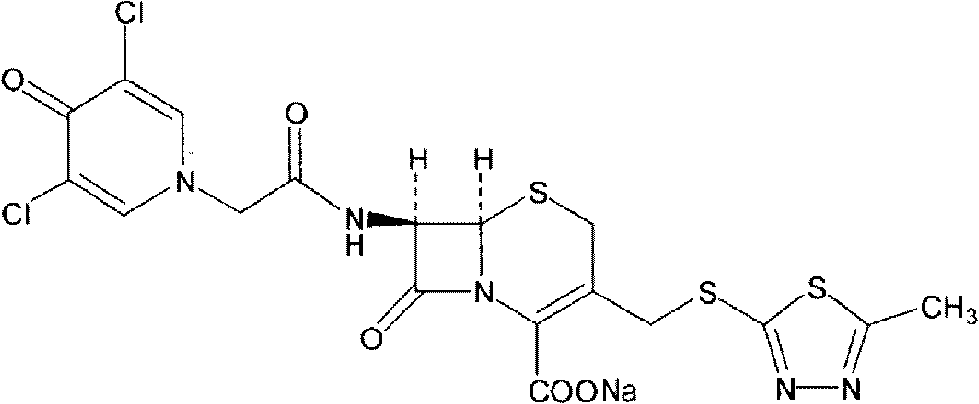

Cefazedone sodium medicament powder injection and method for synthesizing raw medicine of Cefazedone sodium

ActiveCN101584671BSingle componentImprove solubilityAntibacterial agentsOrganic active ingredientsSodium bicarbonateNitrogen gas

The present invention provides a cefazedone sodium medicament powder injection composed of 100% of cefazedone sodium. The cefazedone sodium is prepared by a method as follows: (1) 7-ACA and 3, 5-dichloro pyridine acetic acid react with each other with the action of an anhydrating agent, a mixture after the reaction is post-processed to obtain an intermediate product I; (2) the intermediate productI and 2-mercapto-5-methyl-1, 3, 4-thiadiazoles react with each other with the protection of nitrogen at a temperature of 50 to 90 DEG C, a mixture after the reaction is purified to obtain a water solution which is added with an inorganic acid to regulate pH value to be equal to 1 to 3, a precipitation is extracted from the water solution and is post-processed to obtain cefazedone; (3) the cefazedone and sodium hydrogen carbonate react with each other in water to obtain a cefazedone sodium solid body after an aftertreatment. The powder injection has single component and perfect dissolution performance, the raw medicine has a short synthetic route, the aftertreatment of the intermediate product or final product are all simple, and the yield and purity of the whole reaction process are all high.

Owner:SHANDONG LUOXIN PHARMA GRP CO LTD

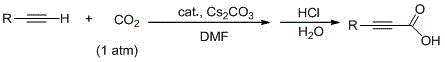

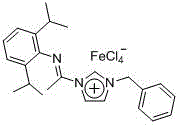

Method for preparing propiolic acid compounds

ActiveCN105585473AClear structureSimple structureCarboxylic acid nitrile preparationOrganic compound preparationPhenyl-acetyleneAlkyne

The invention discloses a method for preparing propiolic acid compounds. An ionic type iron (III) complex containing monoimide functionalized imidazolium cations is taken as the single-component catalyst, carbon dioxide is taken as the carboxylation reagent, and various propiolic acid compounds are prepared through carboxylation reaction of terminal alkyne under normal pressure. The terminal alkyne substrate relates to phenylacetylene, substituted phenylacetylene, heterocyclic aryne, aromatic diyne or aliphatic series terminal alkyne. The method for preparing the propiolic acid compounds through carboxylation reaction of terminal alkyne and carbon dioxide under the catalysis of the iron-based catalyst is provided for the first time. Compared with the prior art, the method has the advantages that the catalyst is more environmentally friendly, synthesis is easier, reaction conditions are mild, and catalytic activity and functional group tolerance are unchanged or improved.

Owner:东营悦来湖园区运营管理有限公司

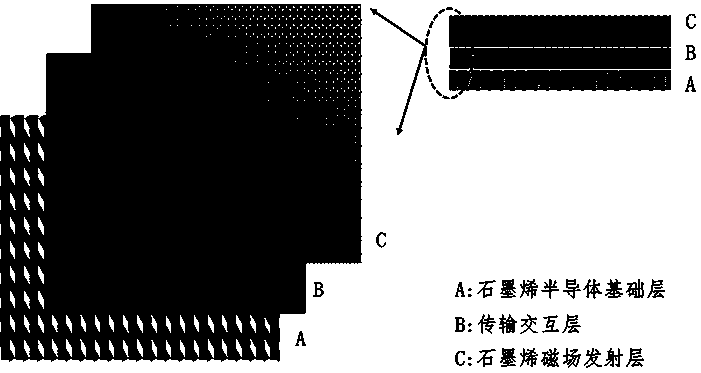

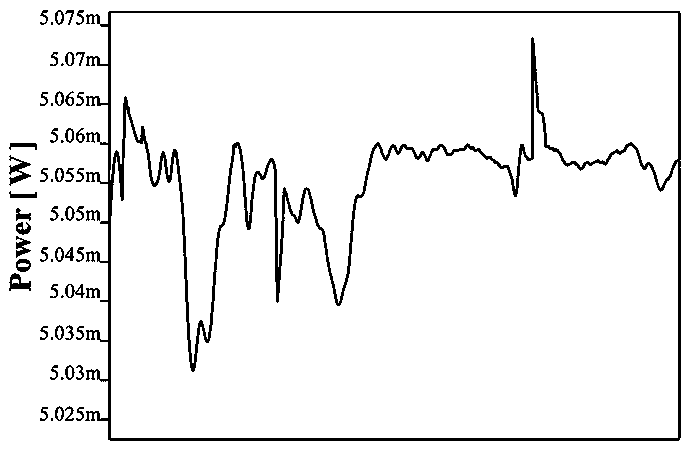

Terahertz wave radiation source based on graphene material

The invention discloses a terahertz wave radiation source based on a graphene material, relates to a terahertz emission source, and belongs to the technical field of terahertz waves. The basic main body material is graphene and a modified graphene material thereof. The main structure mainly comprises three parts, namely, a semiconductor base layer constructed by graphene and the modified graphenematerial thereof, a transition transmission interaction layer formed by a transition metal compound, and a graphene magnetic field emission layer formed by graphene and a composite material thereof. The invention provides a real terahertz wave source, the output frequency completely covers the terahertz wave range of 0.1-10THz, and terahertz waves with the average power of milliwatts can be emitted even under the 24V direct-current voltage. The radiation source is simple in structure, light, high in thin film degree, wide in working range, high in conversion efficiency far superior to that ofthe existing terahertz wave radiation source and completely suitable for large-scale production and application, and has far-reaching influence on expanding the cognitive dimension and depth in the fields of spectroscopy, material science, biology, medical imaging, environmental science, information science, astrophysics, plasma physics and the like.

Owner:滨州市腾源电子科技有限公司

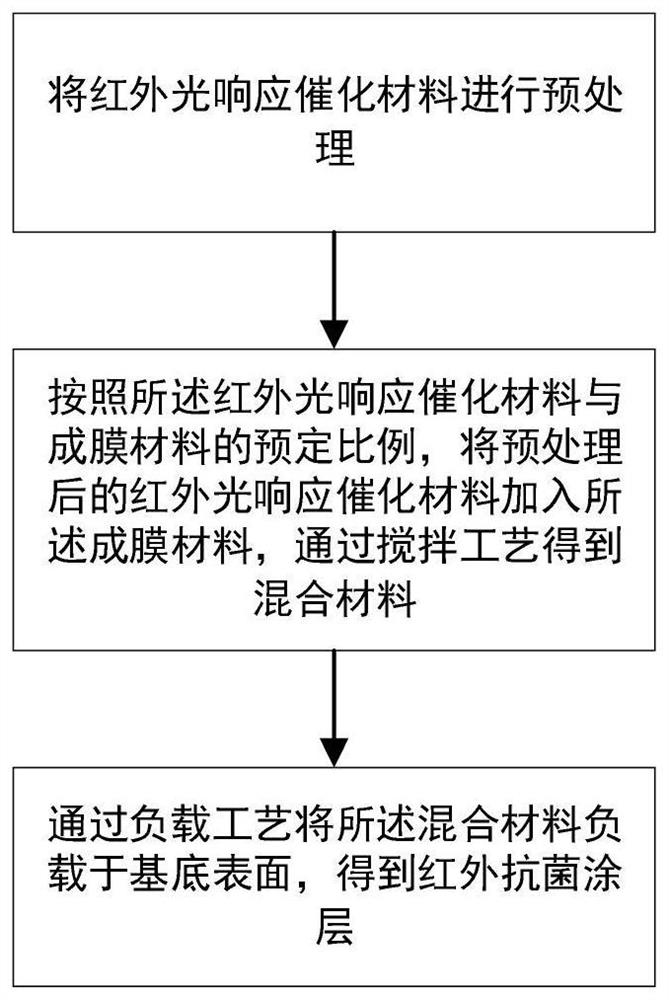

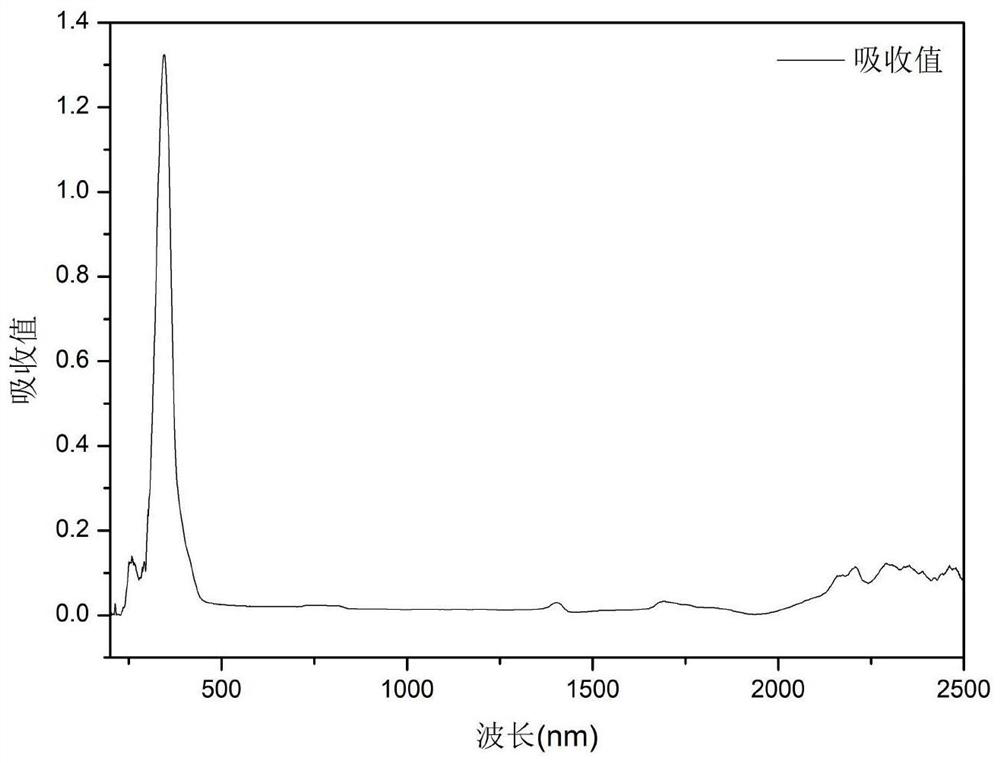

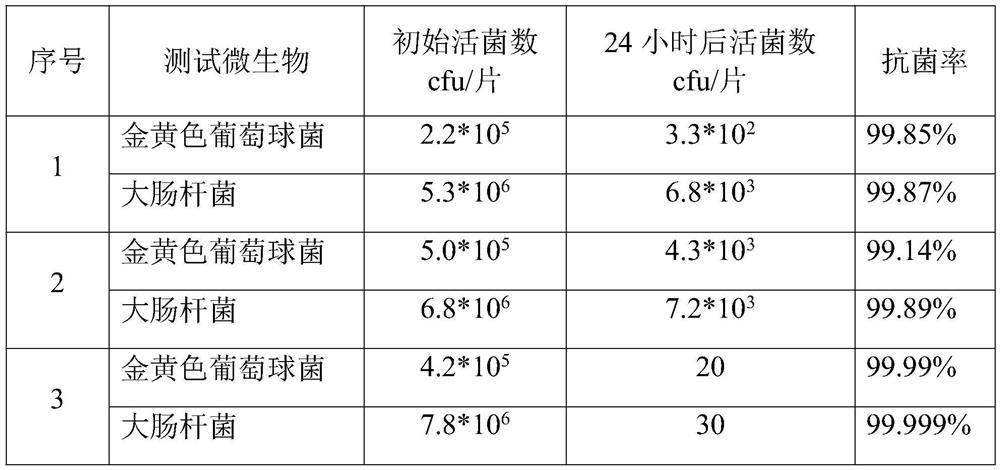

Infrared antibacterial coating and preparation method

PendingCN112452683AImprove antibacterial propertiesIncreased photoresponsive areaAntifouling/underwater paintsPaints with biocidesMixed materialsAnti bacterial

The invention relates to the technical field of antibiosis, and discloses a preparation method of an infrared antibacterial coating. The preparation method comprises the following steps that an infrared photoresponsive catalytic material is pretreated; the pretreated infrared photoresponsive catalytic material is added into a film-forming material according to a preset ratio of the infrared photoresponsive catalytic material to the film-forming material, and a mixed material is obtained through a stirring process; and the mixed material is loaded on the surface of a substrate through a loadingprocess to obtain the infrared antibacterial coating. The infrared antibacterial coating obtained by the preparation method has good antibacterial performance, the photoresponse area of the materialis expanded, illumination can be more fully utilized, and the antibacterial performance is improved; and the process is simple and suitable for large-scale industrial production.

Owner:CHENGDU QINHUAN TECH CO LTD

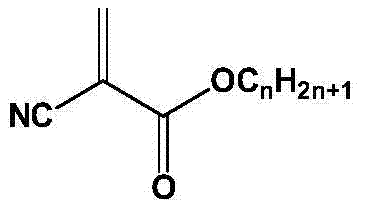

Adhesive and preparation method thereof

InactiveCN104710953ASimple processLow viscosityNitrile polymer adhesivesViscosityCyanoacrylate adhesive

The present invention relates to the field of medical materials. Particularly, the present invention relates to an adhesive of α-cyanoacrylate and a preparation method therefor. An adhesive with desired viscosity is obtained by radiation crosslinking of the above adhesive. The method of the invention has a simple process and a short production cycle. The α-cyanoacrylate adhesive according to the invention does contain a thickening agent, and has good product homogeneity, a higher safety and a long shelf-life.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

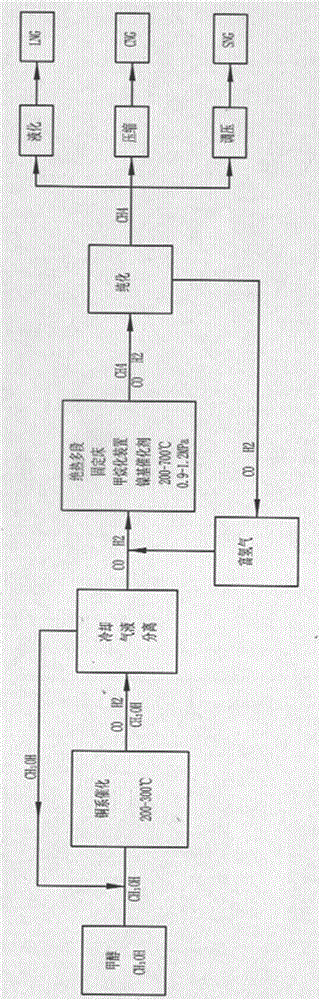

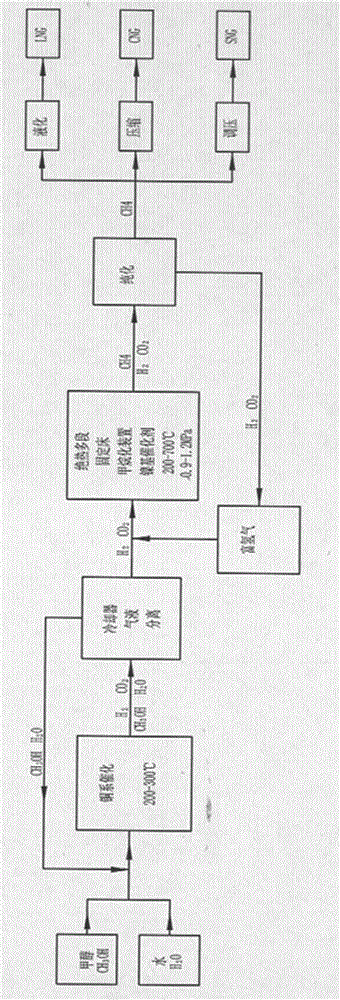

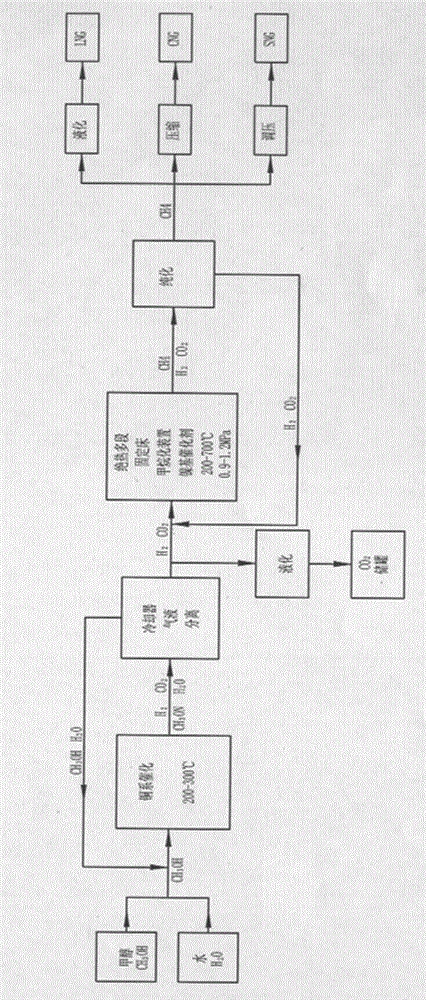

Method for production of synthetic natural gas by utilization of methanol

InactiveCN105820850ARealize comprehensive utilizationReasonable workmanshipHydrocarbon from carbon oxidesGaseous fuelsPtru catalystMethanation

A method for production of synthetic natural gas by the utilization of methanol comprises the following steps: methanol and pure water are vaporized, or in a converter and by the use of a copper-based catalyst, methanol is cracked into hydrogen and carbon dioxide or a gas mixture I of hydrogen and carbon monoxide; the gas mixture I and purified and desulphurized hydrogen rich gas are blended to obtain a gas mixture II according to theoretical hydrogen consumption of CO and CO2 in the formula of 3H2+CO--CH4+H2O and 4H2+CO2--CH4+2H2O; the gas mixture II is sent into a thermal-insulation multistage fixed bed and undergoes a methanation reaction under the action of a nickel-based catalyst to synthesize methane; and methane is purified by the utilization of pressure swing adsorption or membrane separation. The invention has the following advantages: the technology is simple; product composition is single; for enterprises of releasing coke oven gas and methanol, comprehensive utilization of hydrogen-rich gas is realized; the method is environmentally friendly; low-priced unsalable methanol is converted into high-priced best-selling natural gas; cost is low; and the method has remarkable economic benefit and social benefit.

Owner:王连成

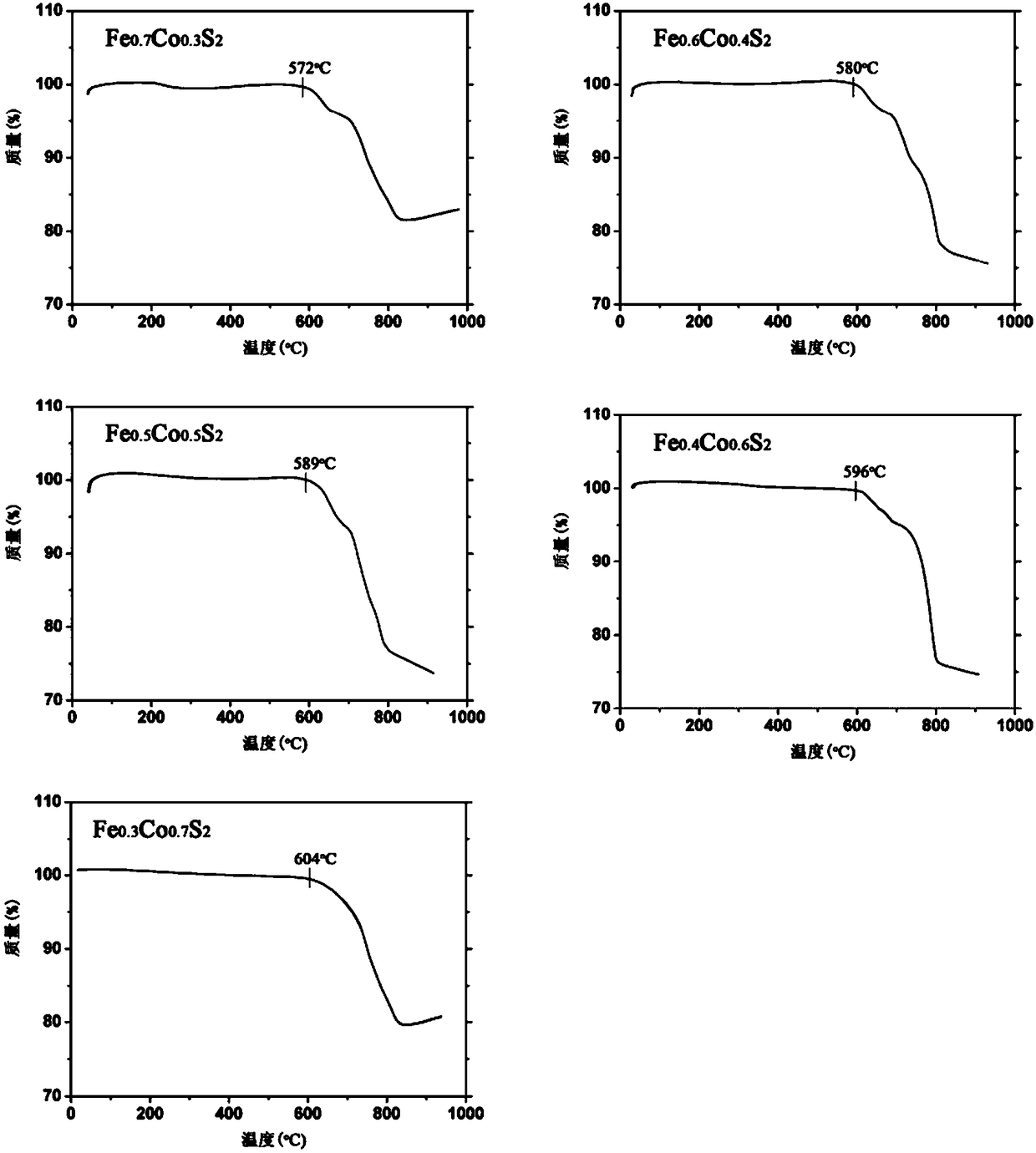

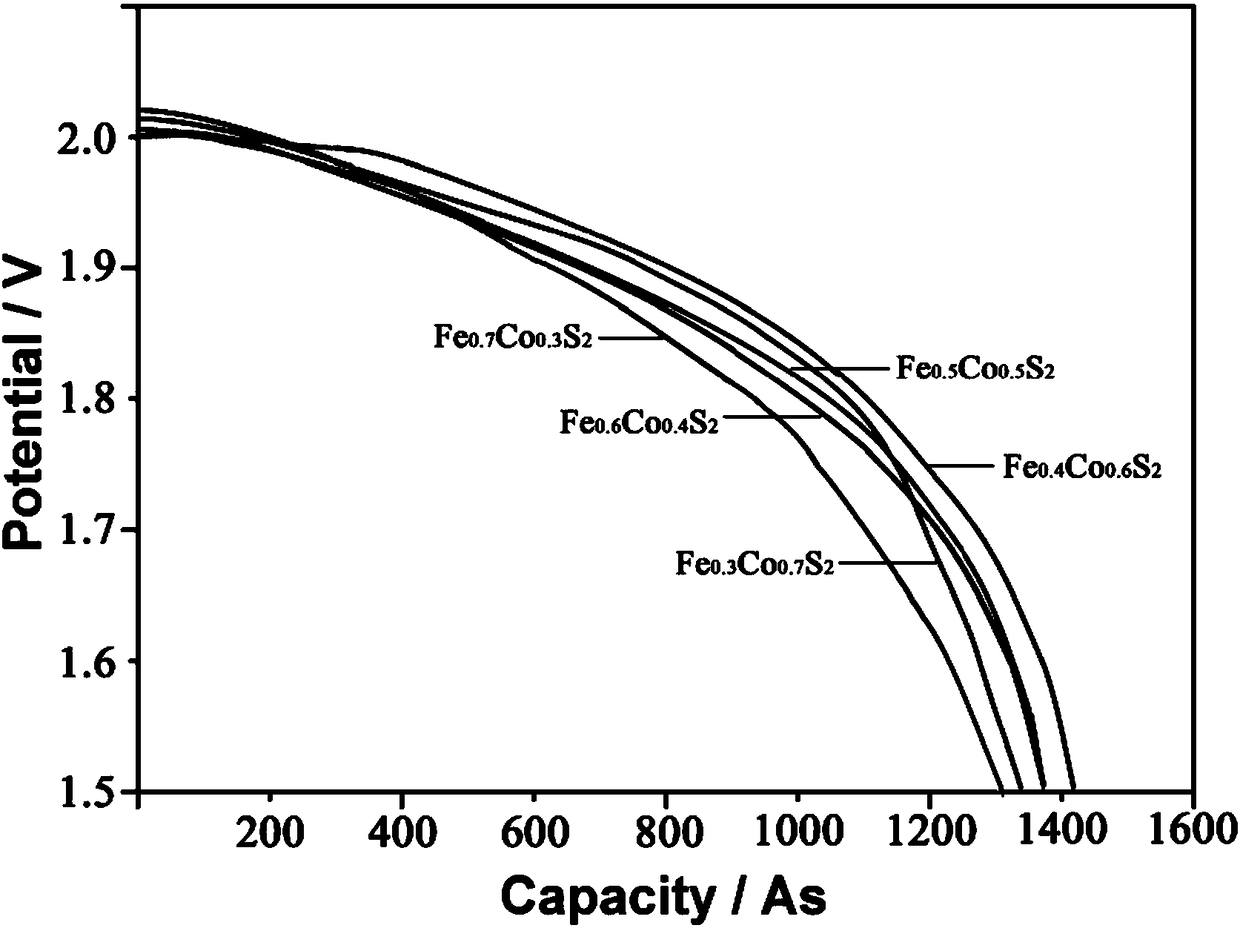

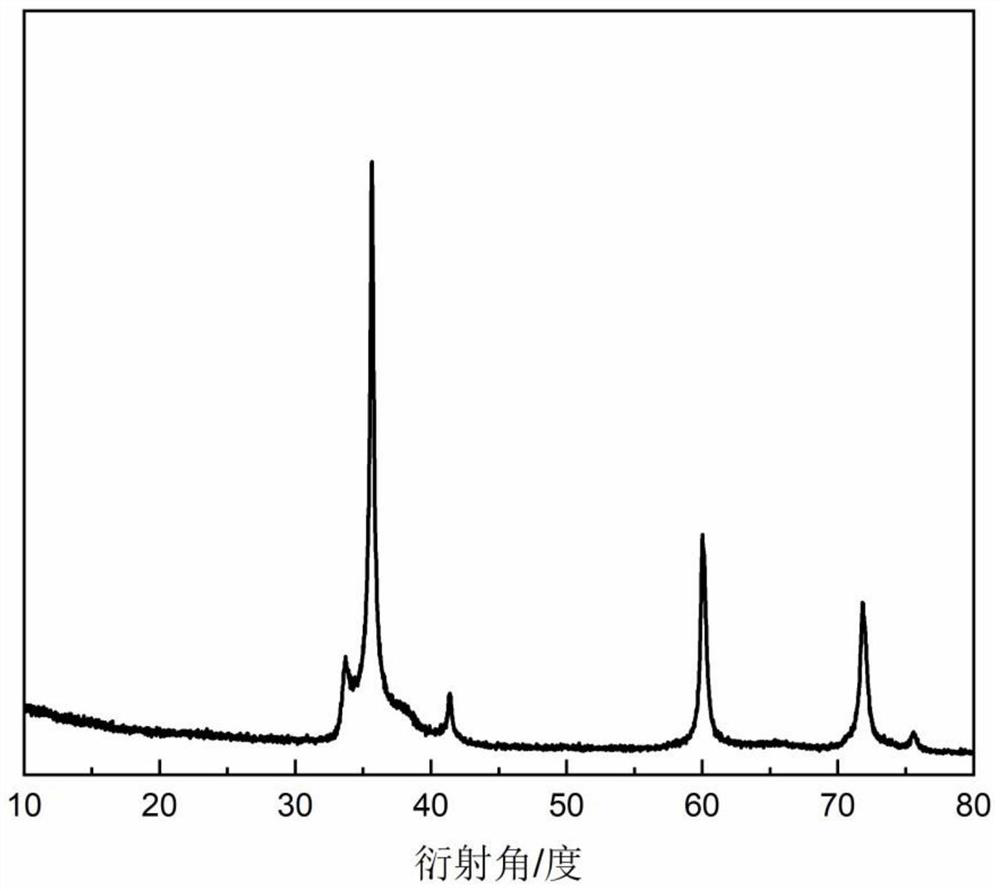

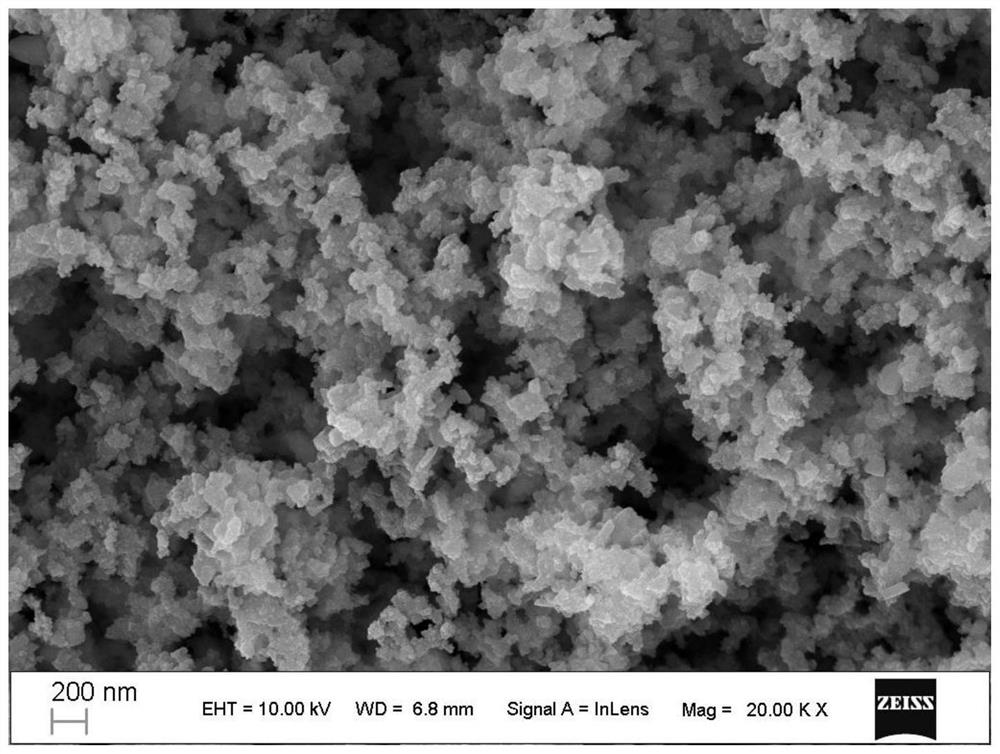

Solid solution type FexCo1-xS2 positive electrode material for thermal batteries, and preparation method of solid solution type FexCo1-xS2 positive electrode material

ActiveCN108539195APrecise control of active ingredient ratiosSingle componentDeferred-action cellsPositive electrodesVulcanizationInternal resistance

The invention aims at providing a solid solution type FexCo1-xS2 positive electrode material for thermal batteries, and a preparation method of the solid solution type FexCo1-xS2 positive electrode material. The component contents of a Fe-Co alloy skeleton is precisely controlled by a Raney method, and a FexCo1-xS2 solid solution is synthesized by means of a high temperature solid phase vulcanization method. The preparation method provided by the invention can realize the precise regulation and control of the atomic ratio in a target product simply by changing a feeding proportion, and provides the performance-oriented positive electrode material in a customized way aiming at the electrical performance requirements of the thermal batteries. The solid solution type FexCo1-xS2 positive electrode material obtained by using the preparation method provided by the invention has the characteristics of being controllable in active component content, high in electrode potential, stable in voltage platform, small in polarization internal resistance and high in thermal stability; thermal decomposition temperature of the positive electrode material is not lower than 570 DEG C, and the actual discharge specific capacity is not lower than 1300 As / g.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

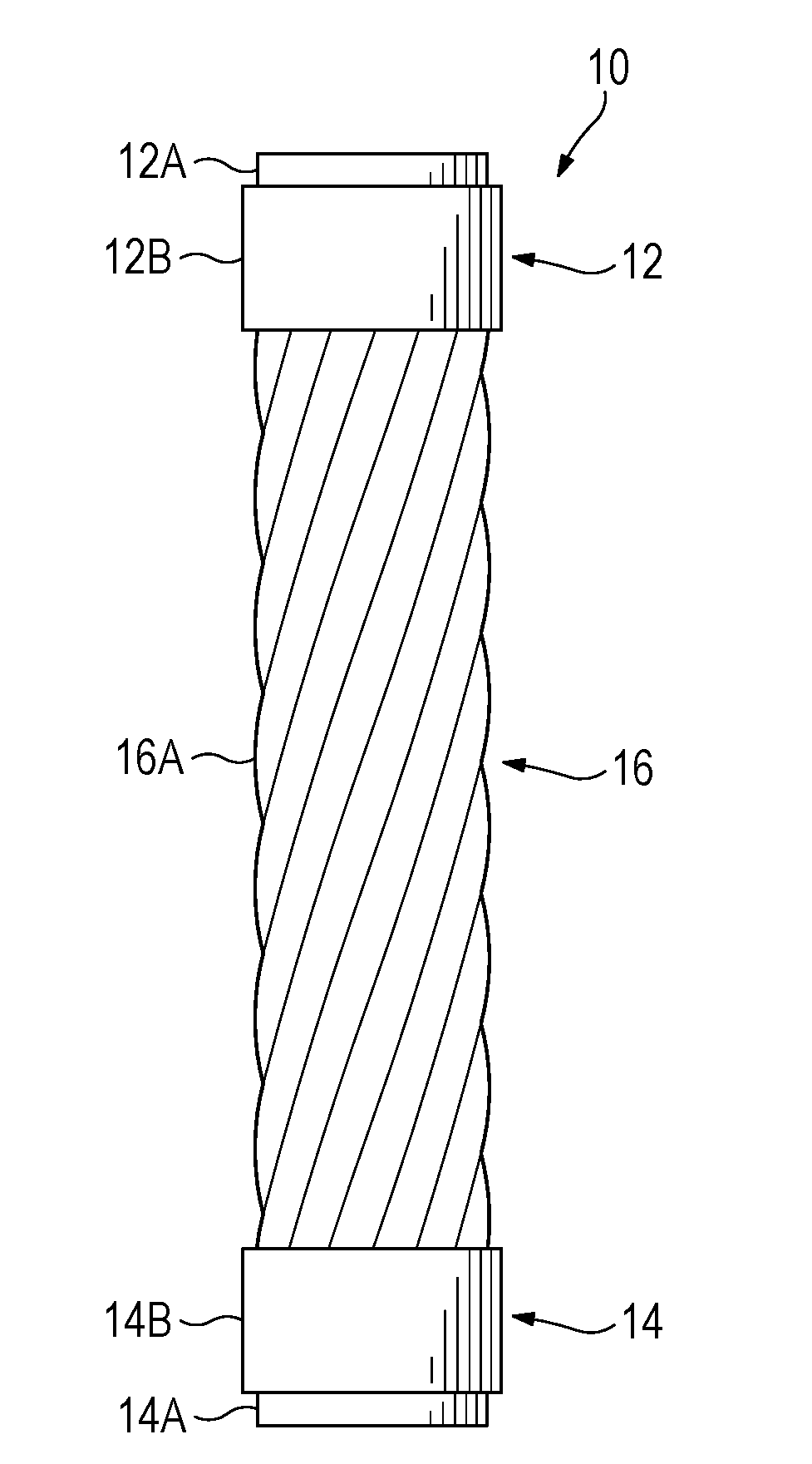

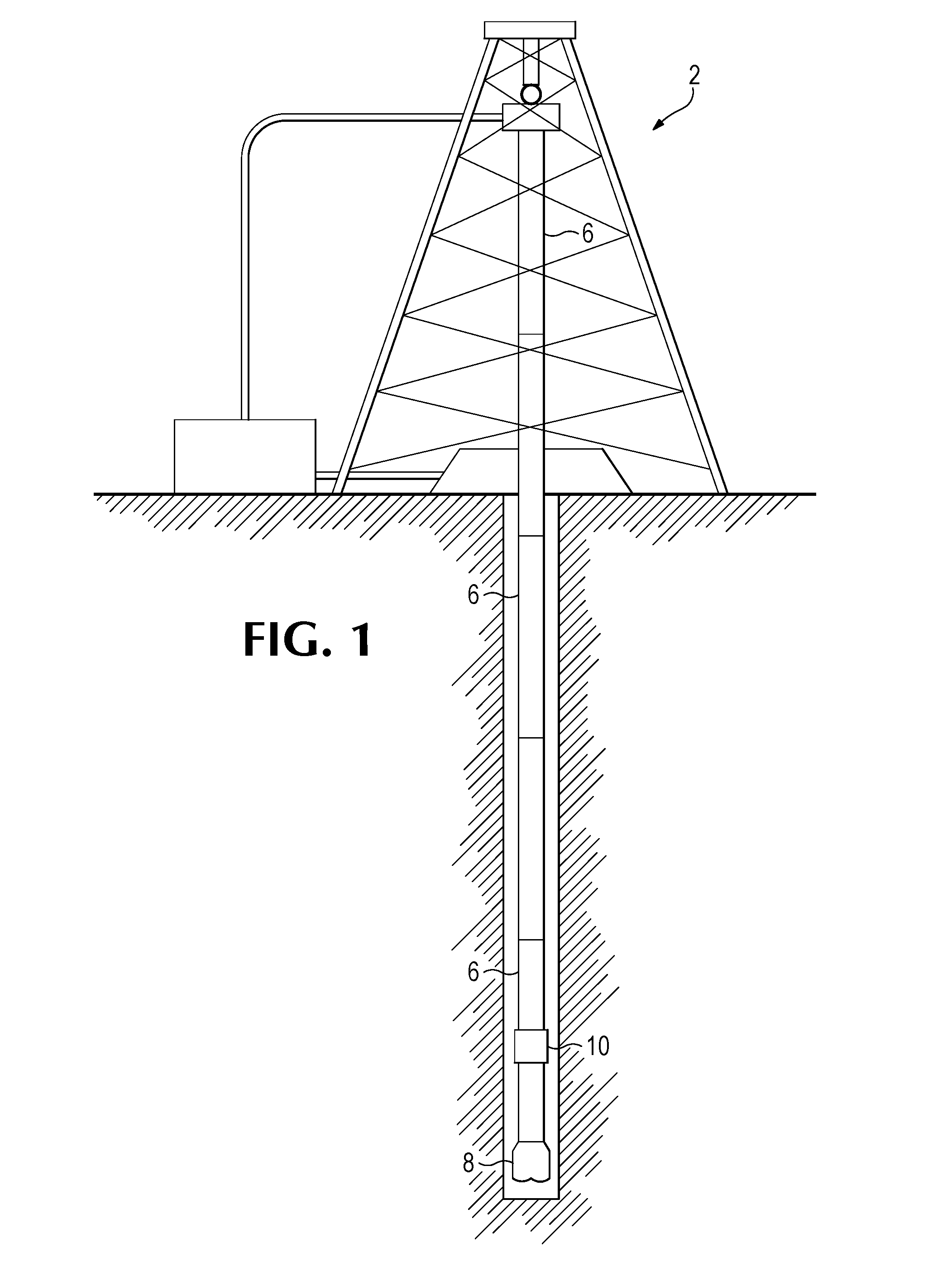

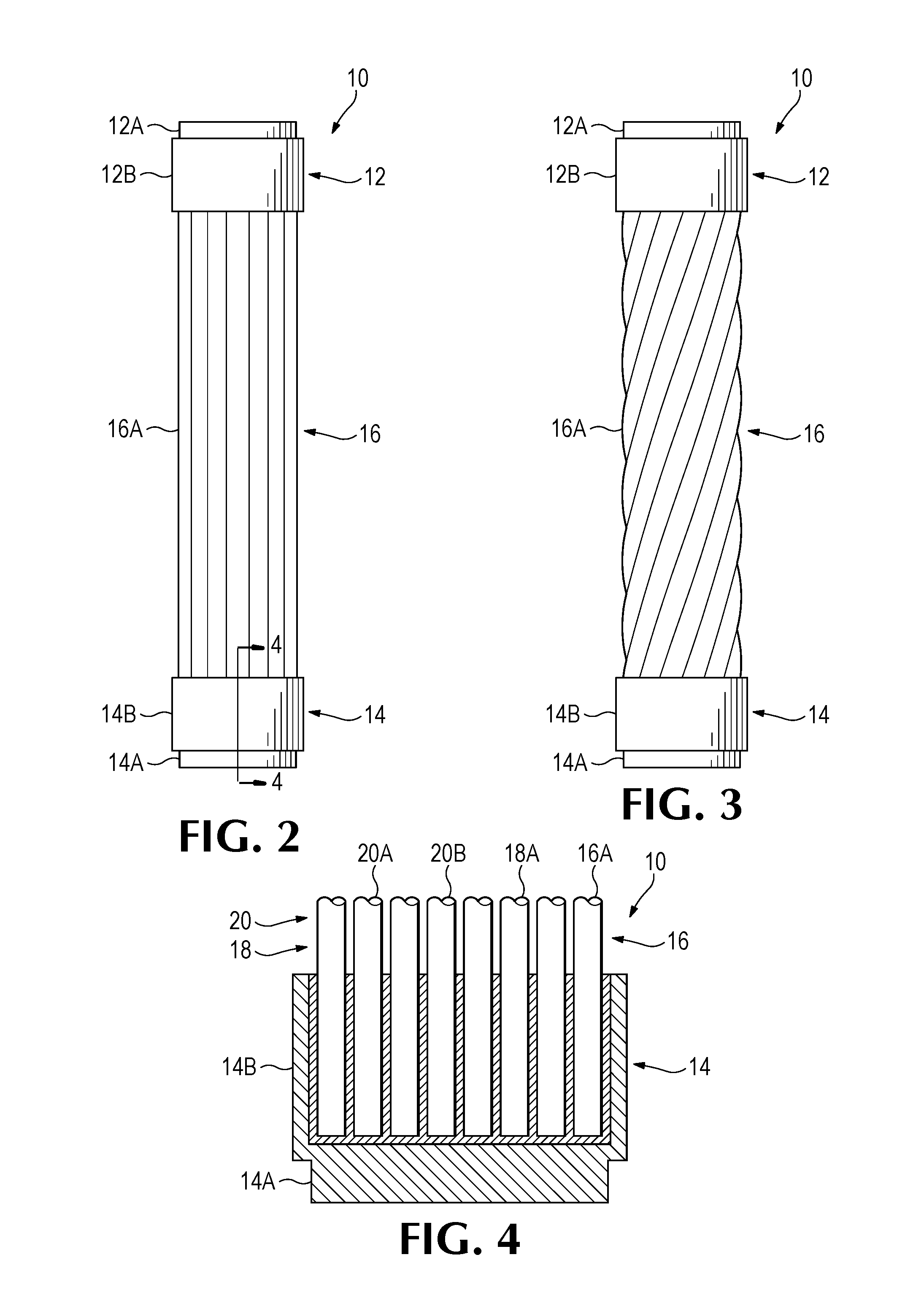

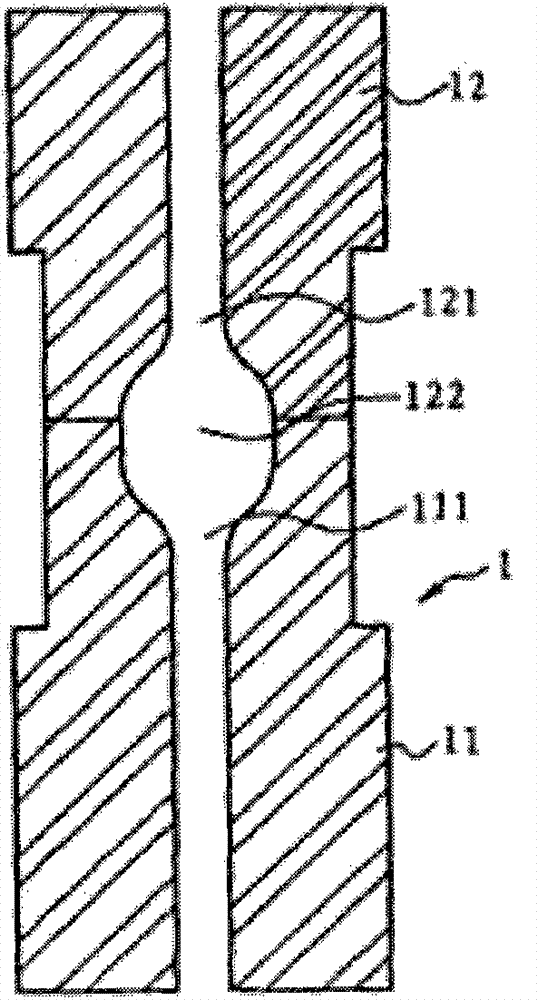

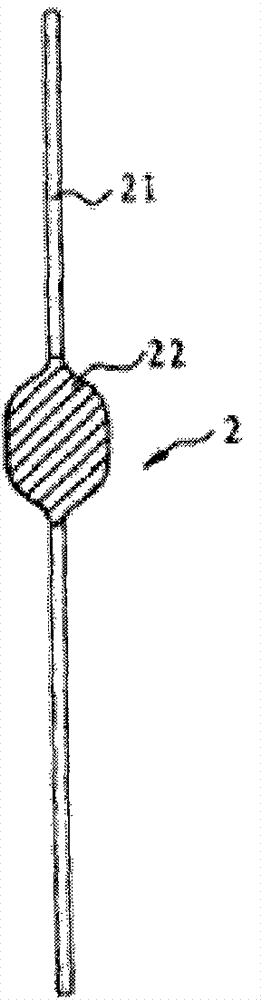

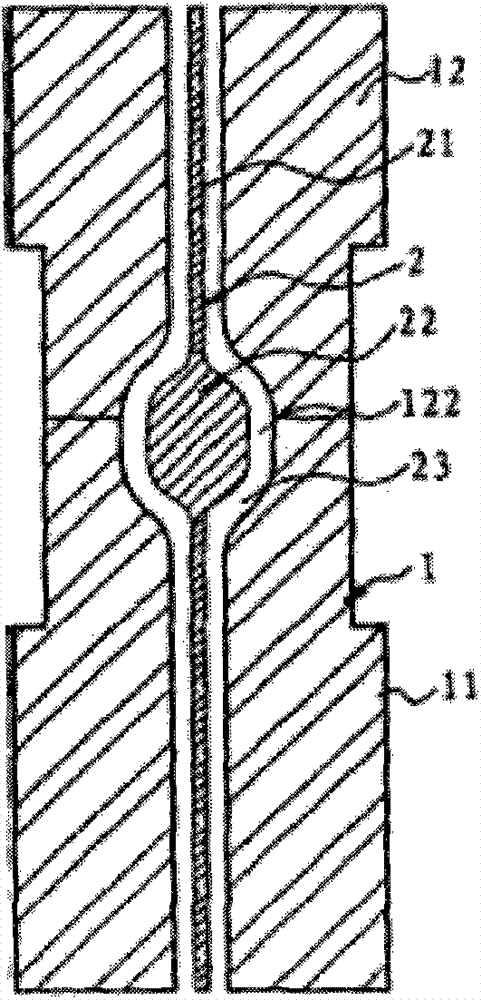

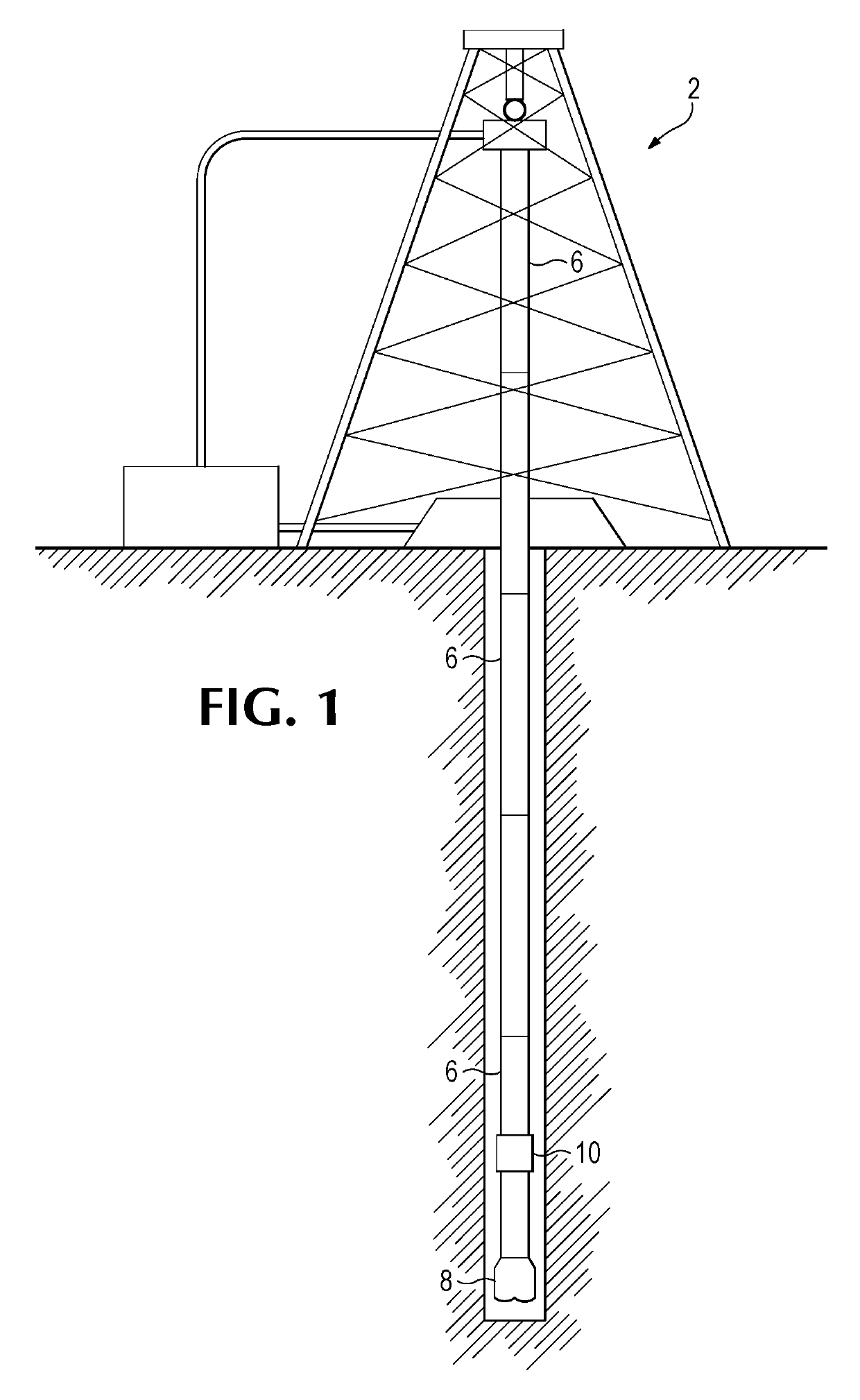

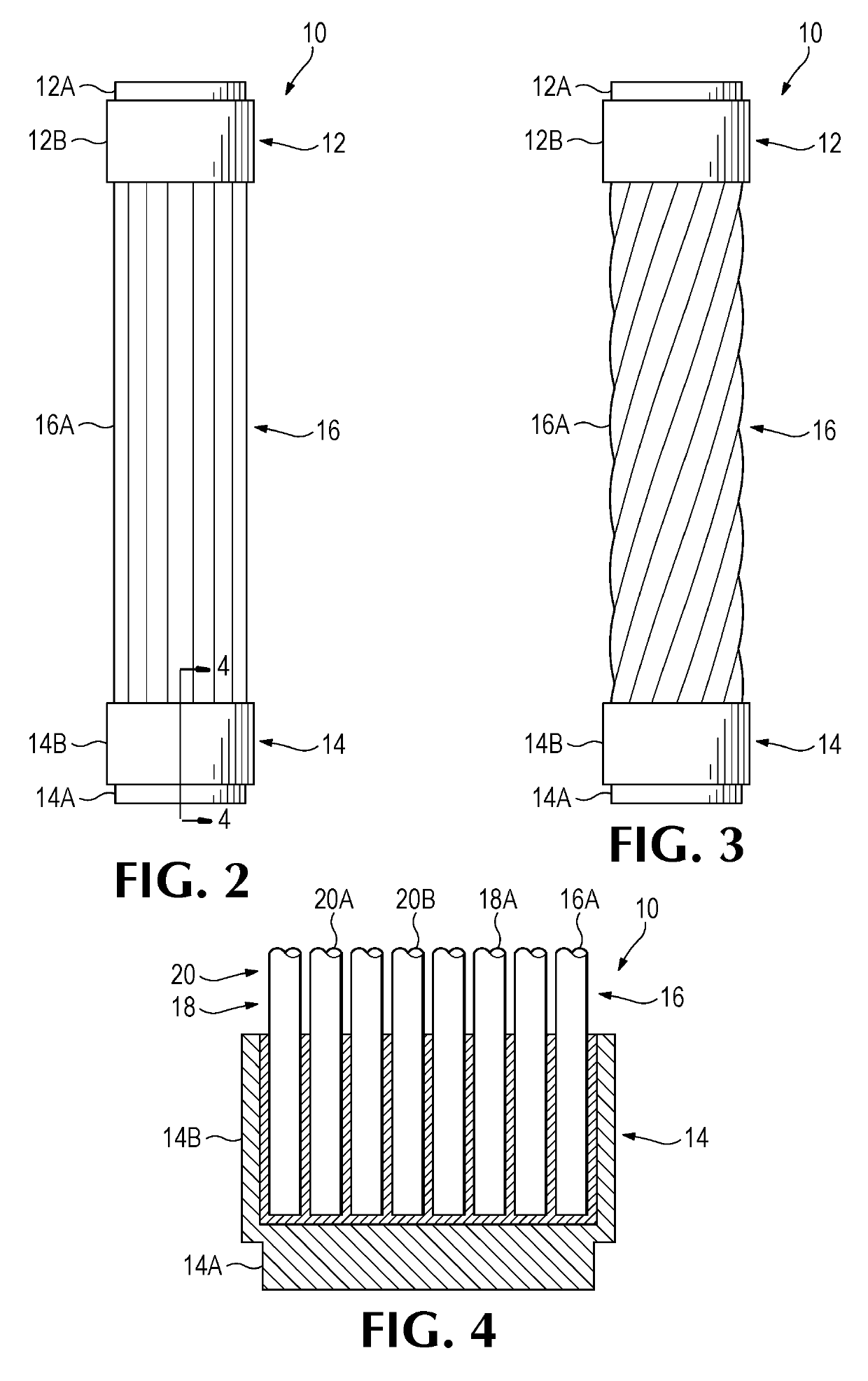

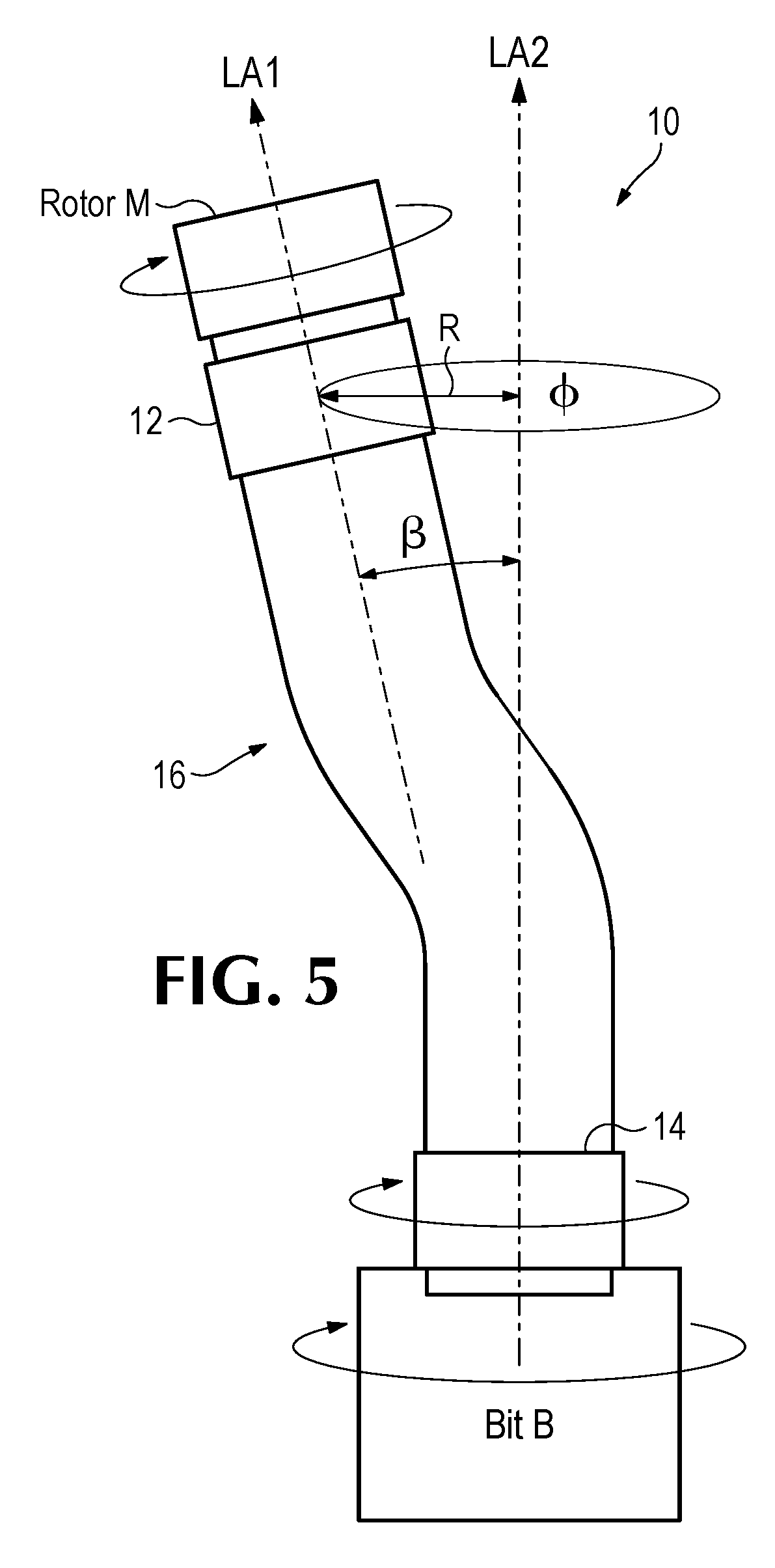

Universal joint

ActiveUS20170002871A1Reduce manufacturing costControl erosionYielding couplingDrilling rodsUniversal jointAxial force

A universal joint assembled to a drill string transfers torque and axial force between two components where the shafts of the components are not completely aligned. The universal joint includes end members connected to opposite ends of a cable for connecting to components of the drill string. As the joint rotates the cable flexes to accommodate misalignment between the connected drill string components.

Owner:ULTERRA DRILLING TECH LP

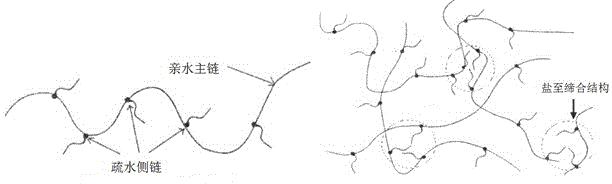

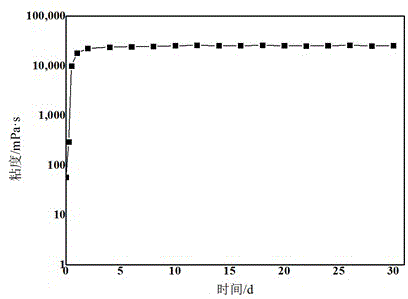

Method for improving crude oil recovery ratio by utilizing salt sensitive self-thickening polymer

ActiveCN104314533AWeaken the effect of viscosityLow viscosity propertiesFluid removalDrilling compositionSaline waterVacuum pumping

The invention relates to a method for improving the crude oil recovery ratio by utilizing a salt sensitive self-thickening polymer. The method comprises the following steps: firstly vacuum-pumping high and low sand filling tube cores respectively and saturating formation simulated water; respectively displacing the high and low sand filling tube cores at an injection sped of 1 mL / min by using simulated salt water and determining the pore volume and the permeability; saturating dehydrated and degassed ground crude oil at an injection speed of 1 mL / min; sealing the sand filling tube cores after the crude oil is saturated and then placing for 48 hours at a constant temperature; displacing the high and low sand filling tube cores which are connected in parallel at an injection speed of 1 mL / min and calculating the water drive recovery ratio; injecting a certain volume of salt sensitive self-thickening polymer solution at an injection sped of 1 mL / min and then injecting the stimulated salt water to carry out over displacement; sealing the high and low sand filling tube cores which are connected in parallel and placing for 120 hours at a constant temperature till the crude oil is thickened. The method has the benefits that the operation is simple and convenient, the injection property is good, the formation application scope is wide, and the water injection profile of a water injection formation can be effectively improved, and the crude oil recovery ratio is improved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

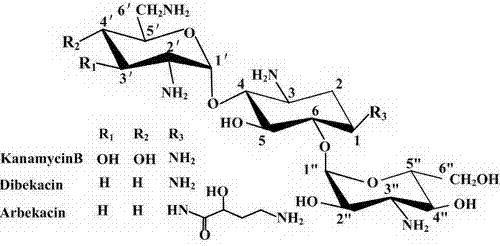

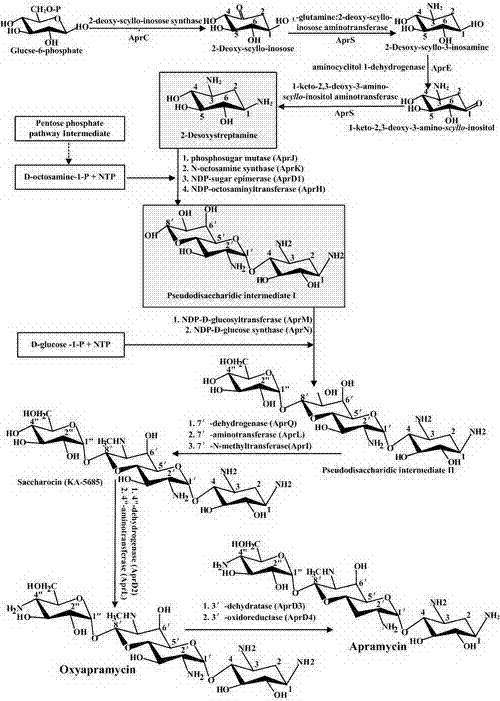

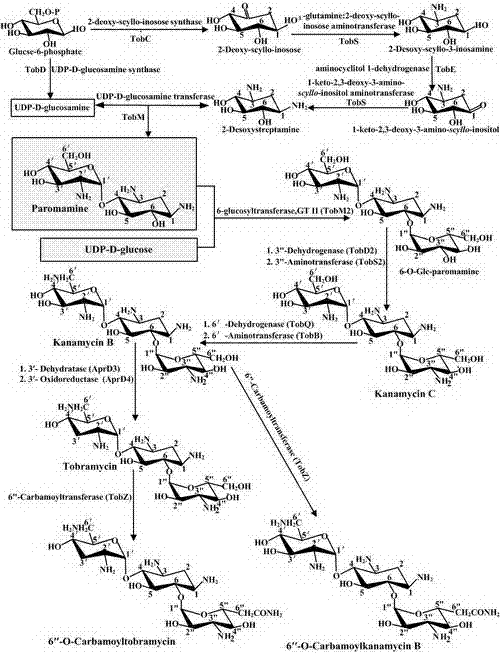

Kanamycin B yielding engineering strain and construction and application thereof

ActiveCN103614330AEliminate formationIncrease productionBacteriaMicroorganism based processesBiotechnologyEngineered genetic

The invention discloses a kanamycin B high-yielding engineering strain and construction and application thereof. According to the construction, apramycin biosynthesis genes aprD3-D4 in Streptomyces tenebrarius are firstly subjected to intraframe knockout, and then, carbamoyl transferase genes tobZ are further subjected to knockout, so as to obtain a large number of accumulated kanamycin B yielding strains Streptomyces tenebrarius 314([delta]aprD3-D4+[delta]tobZ). The strain disclosed by the invention is high in yield, good in quality, single in ingredient and stable in heredity and can be applied to the large-scale production of kanamycin B, the long-standing predicament that a small amount of kanamycin B is required to be separated from residual liquid generated during kanamycin A production is solved, the unique advantage of producing kanamycin B through direct fermentation is realized, the clean production aims of low cost, low energy consumption and no secondary pollution are achieved, a bran-new kanamycin B preparation method is created, and the problem that raw materials for synthesis of Arbekacin and Dibekacin are scarce is solved, so that the strain has a good application prospect.

Owner:福州市鼓楼区荣德生物科技有限公司

Method for planting lawn through mushroom compost containing cottonseed hulls

InactiveCN105103935AWide variety of sourcesSingle componentHops/wine cultivationTurf growingRoot systemLawn

The invention relates to the technical field of agriculture, in particular to a method for planting a lawn through mushroom compost containing cottonseed hulls. The method comprises specific steps as follows: the mushroom compost containing the cottonseed hulls is taken as a culture medium, grass seeds are sown on the culture medium, and the lawn is obtained. The material of the culture medium used for the method is widely sourced and simple in composition, and the mushroom compost containing the cottonseed hulls has good water holding capacity and can provide sufficient nutrition for growth of the grass seeds; the method is simple in operation, convenient to use, feasible and easy to master, soil can be saved, and environmental pollution cannot be caused; the lawn planted with the method has the characteristics of light weight, cleanness, excellent appearance quality, good root activity and the like, and the lawn can be laid on a hardened road surface and can last for 15-20 days.

Owner:BEIJING UNIV OF AGRI

Kanamycin extracting process

ActiveCN102127127AHigh puritySingle componentSugar derivativesSugar derivatives preparationKanamycinEthanol

The invention relates to a kanamycin extracting process, which comprises: introducing waste water from recovery of ethanol from kanamycin crystallization mother liquor into a resin column at a speed of 7 million of kanamycin units per liter of resin per hour for dynamic absorption; collecting components; analyzing; collecting different kinds of analytical liquid in different time periods to separate different components in the waste water; and concentrating and crystallizing different kinds of analytical liquid to obtain the finished products of the different components.

Owner:山东齐发药业有限公司

Poly-lactide, poly-glycolide and preparation for copolymer of the same

The invention discloses a preparation method for poly-lactide acid, polyglycolide and copolymer of the poly-lactide acid and the polyglycolide, which adopts the steps that arbitrary one of lactide or glycolide or the mixture thereof is considered as a monomer, suspending agent and catalyzer are added into the monomer, then the agitation is performed, and the granular product is polymerized. The suspending agent is alkane with the boiling point of higher than 90 DEG C, and the polymerizing temperature is higher than the melting point of the monomer but less than the boiling point of the suspending agent. The preparation method of the invention can be applied in the industrialized large-scale production, effectively solving the problems existing in the prior art that the heat emission of the materials is difficult during the preparation process, and the dissolution is time-consuming, the cost of melting granulating or crushing granulating is high, and the investment of the equipment is large during the late processing process. The product polymerized by utilizing the method has the advantages that the molecular weight is high, the purity is high, the product directly presents a granular shape, the re-granulation operation is not required, the process is simple, and both the equipment investment and the labor cost are very low.

Owner:胡权

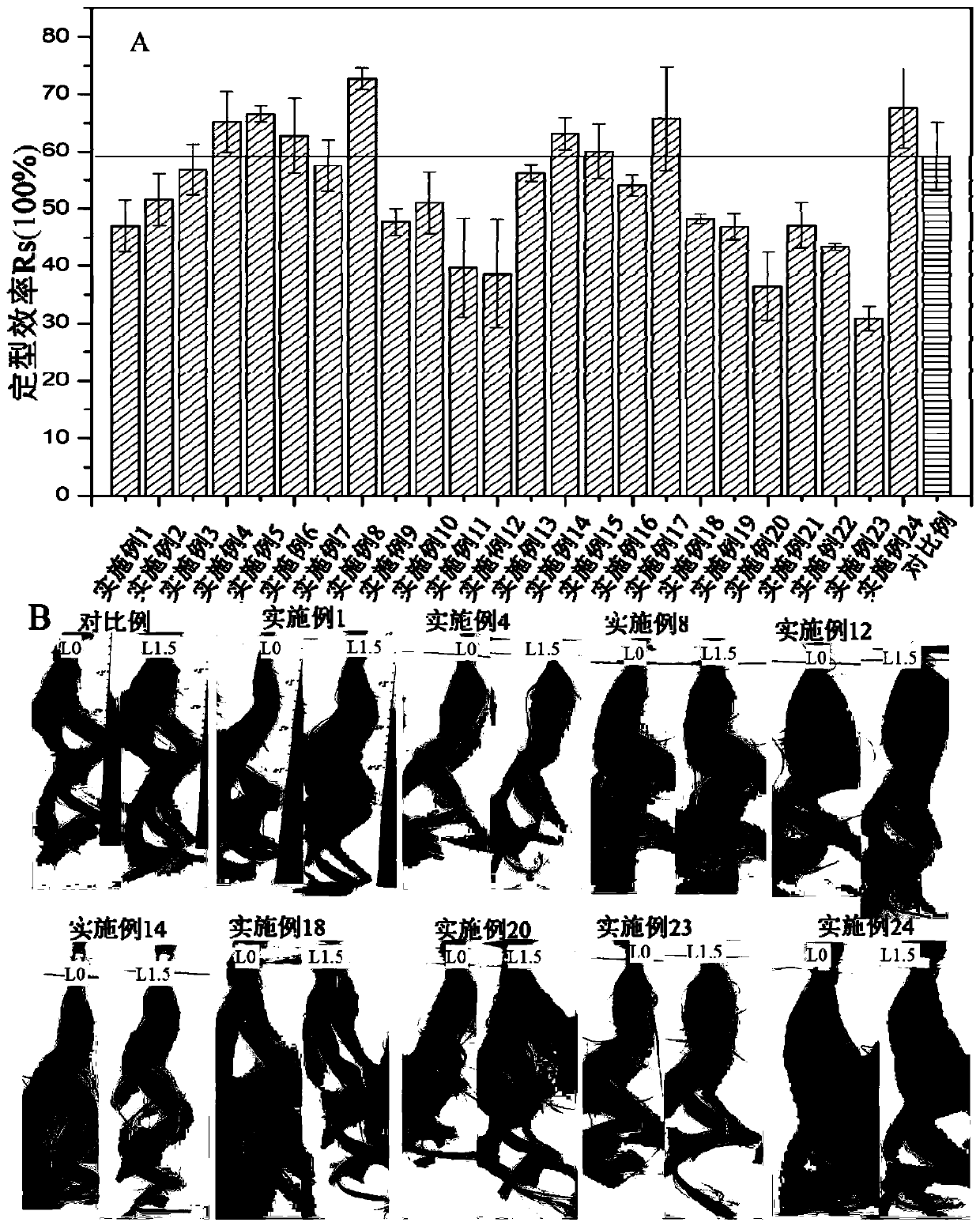

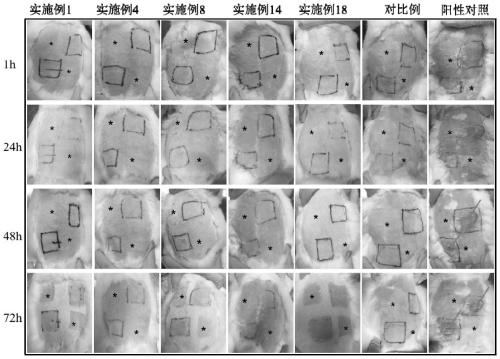

Application of plant oil-base waterborne polyurethane emulsion as styling product and hair styling product

ActiveCN109796569ASingle componentEasy to shapeCosmetic preparationsHair cosmeticsEmulsionNew materials

The invention discloses application of plant oil-base waterborne polyurethane emulsion as a styling product and a hair styling product. Plant oil-base polyalcohol, one or more of DMPA, DMBA and MDEA are chain extenders, and the plant oil-base waterborne polyurethane emulsion is prepared. A preparation technology for the emulsion is matured, simple in process and easy to control, and industrial production is convenient; the effect of styling is excellent, and a new material source is provided for the hair styling product.

Owner:SOUTH CHINA AGRI UNIV

Producing method for environmentally-friendly enzyme used for high-efficiency safe detergent

InactiveCN107828544AExtend the production cycleLow enzyme productionMicroorganismsMicroorganism based processesOrganic acidFruits vegetables

The invention provides a producing method for an environmentally-friendly enzyme used for a high-efficiency safe detergent. The method comprises the following processes: (1) preparing raw materials; (2) performing primary natural fermentation; (3) producing a yeast seed liquid; (4) performing secondary improvement fermentation; and (5) filtering the fermentation liquid subjected to secondary improvement fermentation through a plate-and-frame pressure filter, and discarding the filter cake to obtain a clear essence liquid of the environmentally-friendly enzyme. According to the method providedby the invention, non-fruit-vegetable protein raw materials soybean meal and camellia oleifera seed cakes are introduced into a culture medium, and the fermentation period is shortened to 30%-50% of an original fermentation period, the enzyme activity is improved by 2-6 times, and the organic acid level is improved by 1-3 times; the introduction of a biological surfactant greatly enhances and optimizes the washing efficacy; and the introduction of bioactive ingredients gives the product a better skin caring function. The method thoroughly eliminates the unpleasant sourness of a previous enzymeproduct, thereby improving the product quality; and the method greatly improves the economic additional value of agricultural waste resources.

Owner:HANGZHOU PENGLONG TECH

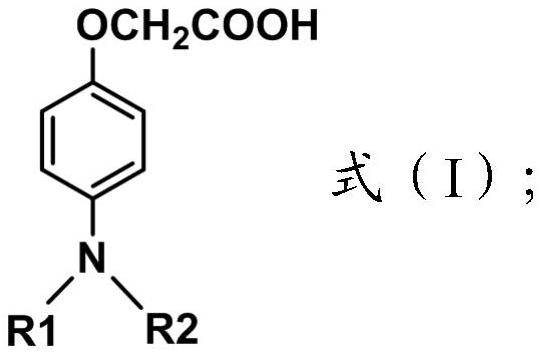

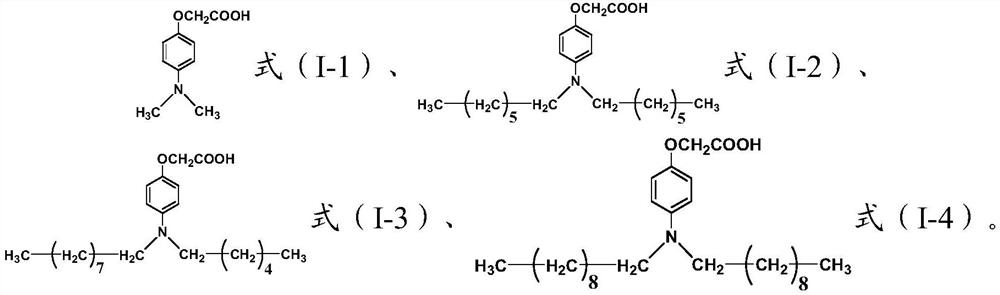

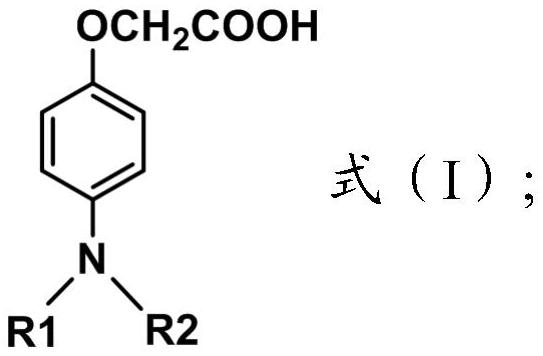

Dialkylaminophenoxy acetic acid extracting agent and preparation method and application thereof

ActiveCN112575188ASingle componentThe extraction process is stableProcess efficiency improvementPhenoxy acetic acidLanthanoid Series Elements

The invention belongs to the field of rare earth resource recovery, and particularly relates to a dialkylaminophenoxy acetic acid extracting agent and a preparation method and application thereof. Thedialkylaminophenoxy acetic acid extracting agent has a chemical structure shown in a formula (I); and R1 and R2 are independently selected from alkyl groups of C1-C10. The dialkylaminophenoxy aceticacid extracting agent can effectively separate yttrium from other lanthanide elements, and compared with industrially-applied naphthenic acid extracting agents, the extracting agent is single in component, free of emulsification and more stable in extraction process; and compared with other alkyl-substituted phenoxy carboxylic acid extracting agents, the extracting agent keeps a high separation coefficient of light rare earth elements and yttrium, meanwhile, the separation coefficient of heavy rare earth elements and yttrium is improved, the extraction stage number can be further reduced, theprocess can be shortened, the economic cost can be saved, and the production efficiency can be improved.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

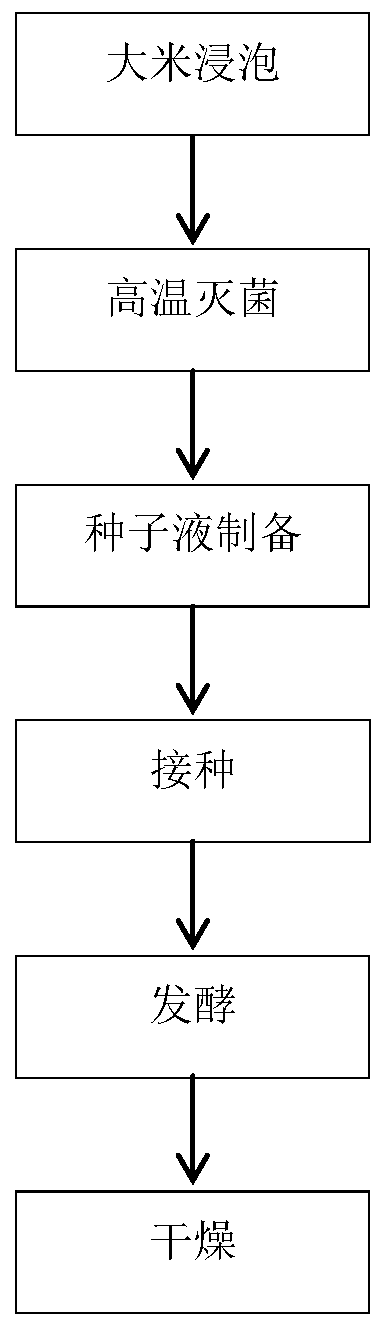

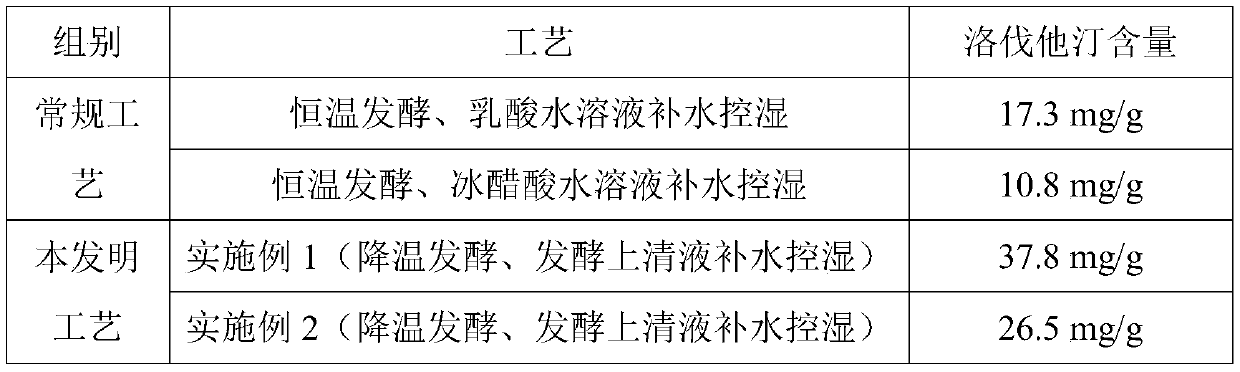

Preparation method of lovastatin-rich functional red yeast rice

PendingCN110623206ASingle componentEasy to operateMetabolism disorderPlant ingredientsRed yeast riceYeast

The invention discloses a preparation method of lovastatin-rich functional red yeast rice. The preparation method comprises the steps of rice soaking, high-temperature sterilization, seed solution preparation, inoculation, fermentation and drying. The preparation method is characterized in that in the fermentation step, the fermentation culture time is controlled at 18-24 d, cooling fermentation is adopted, the culture temperature is controlled at 30-35 DEG C on the 0-5th d during fermentation culture, and the culture temperature is controlled at 22-27 DEG C from the 6th d of fermentation culture to the end of fermentation; during fermentation culture, first yeast turning is performed on the 3d d of fermentation culture, and water replenishment and humidity control are performed by fermentation supernatant; second yeast turning is performed on the 5th d of fermentation culture, and water replenishment and humidity control are performed by fermentation supernatant; yeast turning is performed once every day from 5th d to 16th d of fermentation culture, and water replenishment and humidity control are performed; water replenishment and humidity control are performed by fermentation supernatant on the 12th d and 16th d, and water replenishment and humidity control are performed by sterile water for the rest of time; and yeast turning is performed once every two days after the 16thd of fermentation culture until the end of fermentation. The preparation method can increase the content of lovastatin in functional red yeast rice and enhance the fermentation effect of the functional red yeast rice and product quality.

Owner:湖南微著生物科技有限公司

Silicon carbide aerogel material and preparation method thereof

The invention belongs to the field of ceramic aerogel, and discloses a silicon carbide aerogel material and a preparation method thereof.The preparation method comprises the following steps that 1, terephthalaldehyde, amino silane, organosiloxane, acetic acid, ethyl alcohol and deionized water are mixed to be uniform, and polysiloxane wet gel is obtained through organosilane hydrolysis copolycondensation reaction; (2) performing aging and vacuum drying on the polysiloxane wet gel obtained in the step (1) to obtain polysiloxane aerogel; and (3) heating the polysiloxane aerogel obtained in the step (2) to 1400-1600 DEG C in an argon atmosphere at a heating rate of 1-5 DEG C / min, and carrying out high-temperature heat treatment for 2-5 hours to obtain the blocky silicon carbide aerogel. According to the invention, sol-gel is combined with vacuum drying to prepare an organic bridged silsesquioxane aerogel precursor, and then the blocky silicon carbide aerogel with good crystallinity, single phase and complete structure is obtained through a one-step high-temperature carbon thermal reduction process.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Method for preparing high-toughness PET (Polyethylene Terephthalate)

ActiveCN105524433AImprove toughnessSingle componentPolyethylene terephthalatePolyethylene terephthalate glycol

The invention discloses a method for preparing high-toughness PET (Polyethylene Terephthalate). According to the method, a PET / BPS blend is prepared through adding a proper amount of branched polystyrene (BPS) into a PET base body and carrying out melt blending, wherein the use level of BPS is 0.5-2.0% the weight of PET. Compared with pure PET, the PET / BPS blend has the advantages that the impact strength is improved by 10-20%, the elongation at break reaches 50-400%, and the toughness is improved greatly. According to the method, the high-toughness PET with good processability is prepared through carrying out melt blending on branched BPS with high molecular weight and high degree of branching and PET, the preparation method is easy and feasible, the application of the PET in production is enlarged, and thus the commercial application value of the PET is more outstanding.

Owner:CHANGZHOU UNIV

Manufacturing method of ceramic tube

A manufacturing method of a ceramic tube comprises the following steps: a, an external mold and a wax-based internal mold are manufactured; b, the wax-based internal mold is positioned inside a holding cavity, and a gap between the wax-based internal mold and the holding cavity is left to form a cavity; c, a powder is poured into the cavity, and the powder is hardened to form a tube blank; d, the external mold is removed from the tube blank; e, the wax-based internal mold is removed from the inside of the tube blank; and f, the tube blank is sintered to form a ceramic tube. During the Step c, the powder is hardened by a static pressure method, and static pressure is set as 100kPa-200kPa / cm<2>. The Step e contains the following steps: e1, high temperature radiation is applied on the position where the wax-based internal mold and the tube blank are contacted by the use of external equipment, the temperature of the position where the wax-based internal mold and the tube blank are contacted is raised to more than 500 DEG C within 3-5 s, and the state lasts for 2-6 s; and e2, double heating is carried out on the wax-based internal mold so as to make the wax-based internal mold flow out. According to the manufacturing method, the internal mold and the powder have a single material component; no chemical reaction happens during the manufacturing process; and demoulding time is fast and the tube will not be cracked.

Owner:王伟军

Dipeptide aerogel and preparation method and application thereof

ActiveCN109821484ASimple methodEase of industrial mass productionLiquid separationColloidal chemistry detailsPorosityDipeptide

The invention discloses dipeptide aerogel and a preparation method thereof. The specific surface area of the dipeptide aerogel is 20-60 m<2> / g, the density is 1.5-5 mg / cm<3>, and the porosity is 99.5-99.85%. The preparation method comprises the following steps that organic gel of dipeptide is converted into alcohol gel through solvent replacement, then the alcohol gel is replaced with hydrogel, and finally, the hydrogel is freeze-dried to obtain the dipeptide aerogel. The prepared aerogel is good in stability, large in specific surface area and low in density, has a good oil-water separation effect, and can serve as a novel, safe and efficient oil-water separation material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

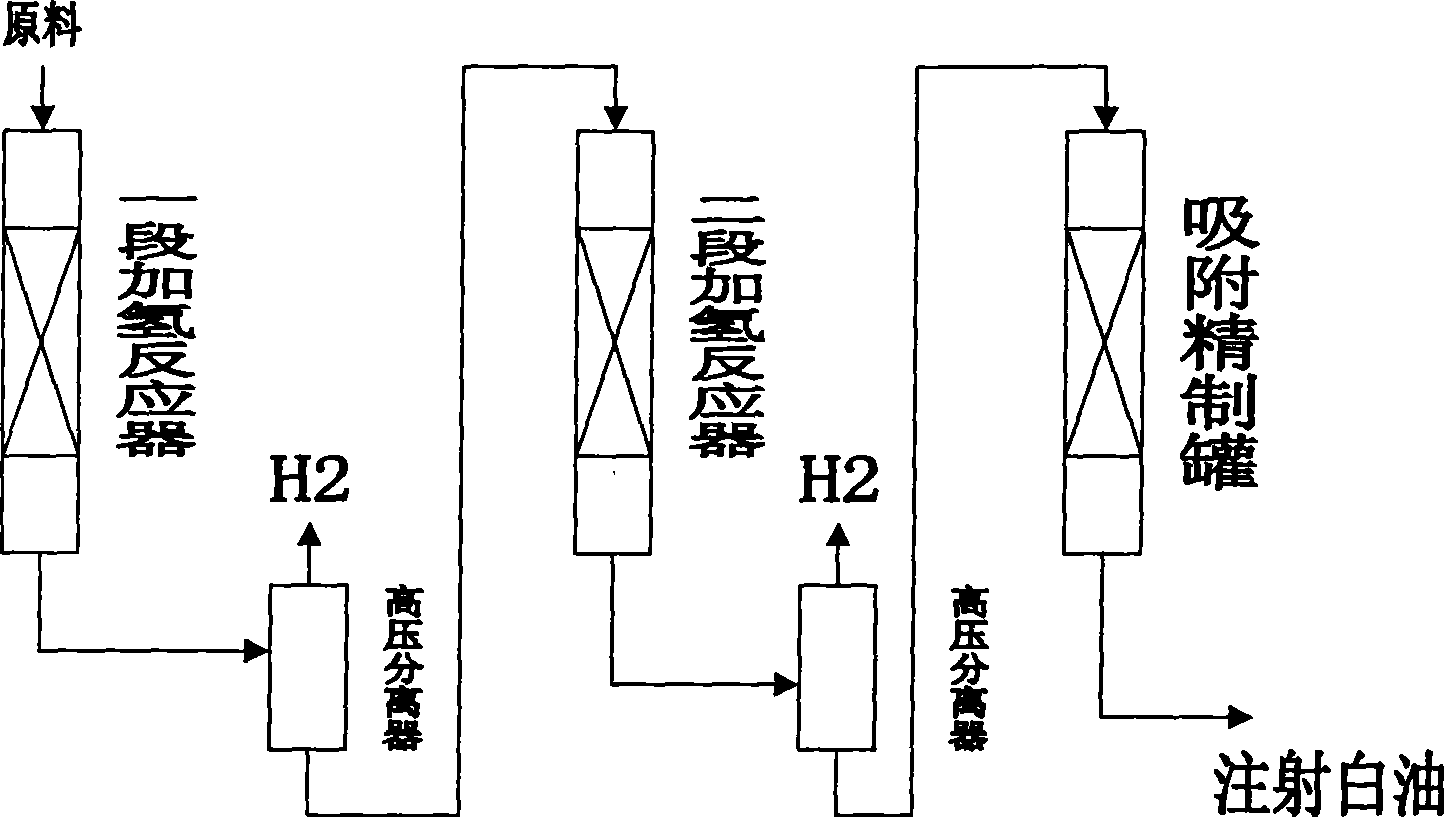

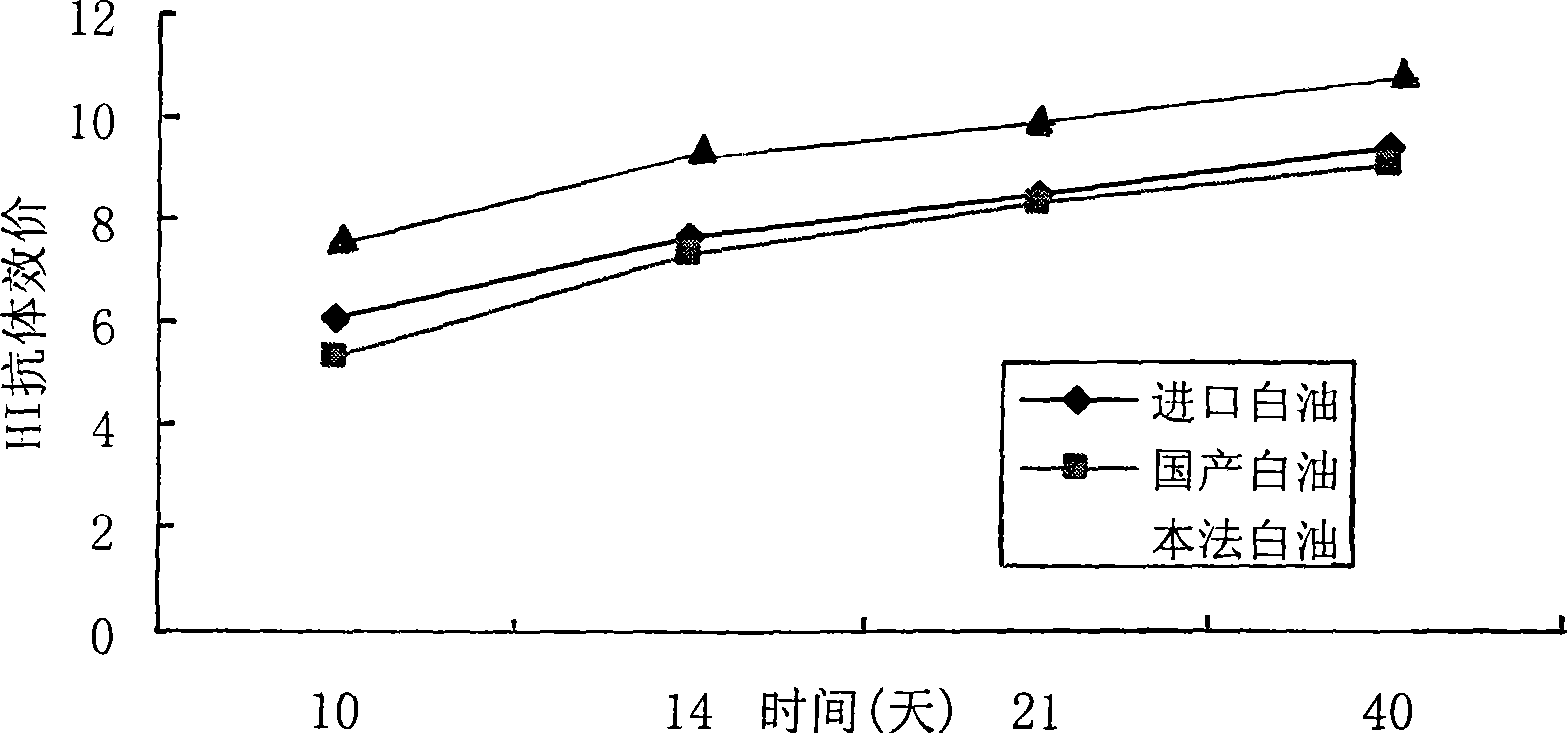

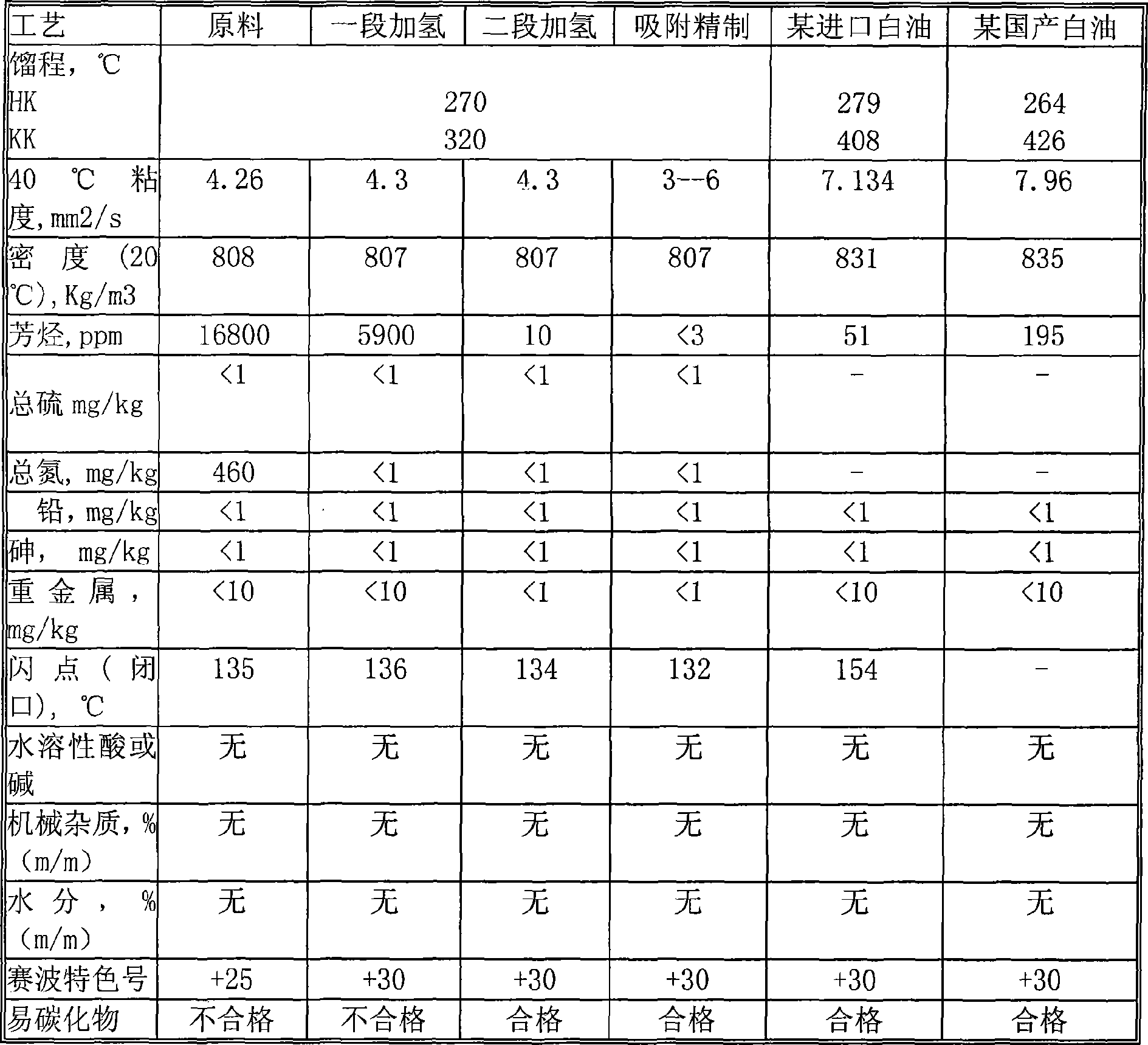

Preparation of low aromatic and low viscosity narrow fraction injection liquid paraffine

InactiveCN101475837ANarrow distillation rangeSingle componentTreatment with hydrotreatment processesPetroleum productHydrogenation reaction

The invention relates to a method for injection preparation of low-aromatic low-viscosity narrow fraction. The method has the advantages that the method comprises the steps of: 1) the preparation of a raw material, in which a related petroleum product is distilled to obtain fraction with a temperature of between 270 and 320 DEG C to serve as an injection white oil raw material; 2) the impurity removal of the raw material, in which hydrogen and the raw material are added into a hydrogenation reactor according to the volume ratio of 500: 1000 for a first-stage hydrogenation reaction to obtain impurity-removed white oil; 3) deep dearomatization, in which the hydrogen and the impurity-removed white oil are added into the hydrogenation reactor according to the volume ratio of 300: 500 for a second-stage hydrogenation reaction to obtain dearomatized white oil with the content of aromatic hydrocarbon less than 50ppm; and 4) adsorption refining, in which the dearomatized white oil is removed with foreign odor and mechanical impurities through an adsorptive reactor with 13X as an adsorbent under the condition that the pressure is normal pressure, the temperature is between 115 and 125 DEG C, and the volume space velocity is between 0.5 and 1.0h, and is refined to obtain injection white oil. The method has the advantages that the method adopts the narrow fraction, and has relatively single product components and good performance stability; and the content of the aromatic hydrocarbon of the injection white oil prepared by adopting two-step hydrogenation and adsorption refining is less than 50ppm, and is lower than those of import white oil and domestic white oil, so a product almost has no toxicity.

Owner:江苏联东化工有限公司

A kind of preparation method of high toughness PET

The invention discloses a method for preparing high-toughness PET (Polyethylene Terephthalate). According to the method, a PET / BPS blend is prepared through adding a proper amount of branched polystyrene (BPS) into a PET base body and carrying out melt blending, wherein the use level of BPS is 0.5-2.0% the weight of PET. Compared with pure PET, the PET / BPS blend has the advantages that the impact strength is improved by 10-20%, the elongation at break reaches 50-400%, and the toughness is improved greatly. According to the method, the high-toughness PET with good processability is prepared through carrying out melt blending on branched BPS with high molecular weight and high degree of branching and PET, the preparation method is easy and feasible, the application of the PET in production is enlarged, and thus the commercial application value of the PET is more outstanding.

Owner:CHANGZHOU UNIV

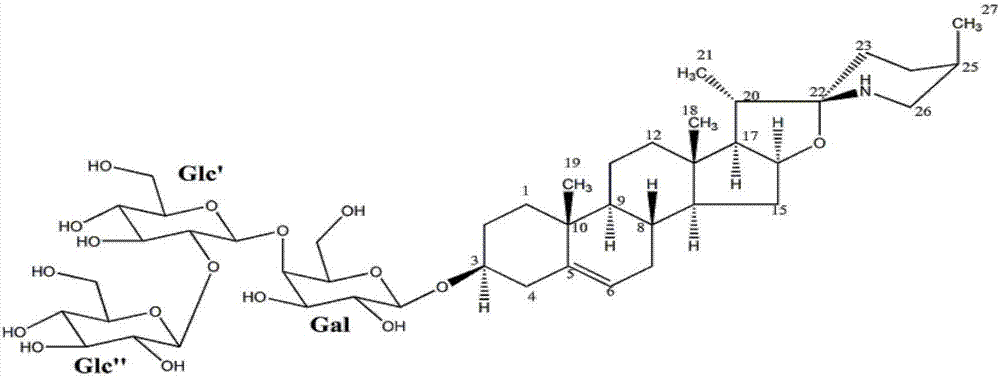

Spirosolane type glycoalkaloid as well as preparation method and application thereof

InactiveCN106928309ASingle componentExact functionOrganic active ingredientsSteroidsNon small cellGlycoalkaloid

The invention provides spirosolane type glycoalkaloid (3 beta, 22 alpha, 25R)-spirosolane-5-alkenyl-3-O-beta-D-glucopyranosyl-(1-2)-O-beta-D-glucopyranosyl-(1-4)-beta-D-galactopyranoside as well as a preparation method and application thereof. The spirosolane type glycoalkaloid has an inhibiting effect on human lung adenocarcinoma cells A549, human large cell lung carcinoma cells H460 and human lung squamous carcinoma cells SK-MES-1; the semi-inhibitory concentration of the cells A549 is 61.53 [mu]g / ml; the semi-inhibitory concentration of the cells A460 is 159.11 [mu]g / ml; the semi-inhibitory concentration of the cells SK-MES-1 is 81.64 [mu]g / ml. Visibly, the (3 beta, 22 alpha, 25R)-spirosolane-5-alkenyl-3-O-beta-D-glucopyranosyl-(1-2)-O-beta-D-glucopyranosyl-(1-4)-beta-D-galactopyranoside prepared by the preparation method provided by the invention and a preparation thereof can be used for treating non-small cell lung cancers.

Owner:XIYUAN HOSPITAL OF CHINA ACAD OF CHINESE MEDICAL SCI

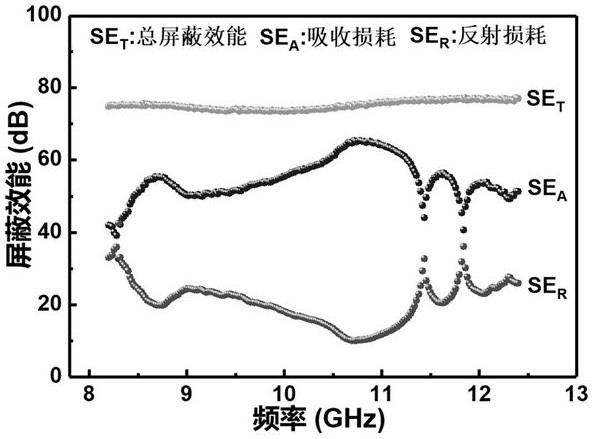

Flexible electromagnetic shielding film and preparation method thereof

PendingCN113858742AThe overall thickness is thinLow densityMagnetic/electric field screeningFilm/foil adhesivesFlocculationLight irradiation

The invention designs a flexible electromagnetic shielding film and a preparation method thereof. The preparation method of the flexible electromagnetic shielding film comprises the following steps: inducing self-crosslinking or flocculation of one or more metal nanowires of gold, silver, copper, nickel and zinc to prepare metal-based gel; S2, compressing the aerogel prepared in step S1 into a thin film, performing surface local enhancement through chemical vapor treatment or light irradiation, and then performing cutting, folding or shaping; and S3, attaching an aerogel thin film prepared in step S2 to a flexible substrate in a covering mode, so as to prepare the flexible electromagnetic shielding film. The prepared flexible stretchable electromagnetic shielding film is small in thickness, high in conductivity, good in flexibility, good in machinability and excellent in electromagnetic shielding performance, and can shield 99.9999999% of electromagnetic waves within the frequency of 2-18 GHz.

Owner:南京恒电先进微波技术研究院有限公司 +1

Universal joint

ActiveUS10316895B2Reduce manufacturing costControl erosionYielding couplingDrilling rodsUniversal jointAxial force

Owner:ULTERRA DRILLING TECH LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com