Extracting method for high-content sweet inulin A3

An extraction method and technology of stevioside, applied in sugar derivatives, food science, food preparation, etc., can solve the problems of insufficient purity, unreported extraction methods, and no technical reports, etc., and achieve obvious refining effect and ethanol concentration Choose effects that are reasonable and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

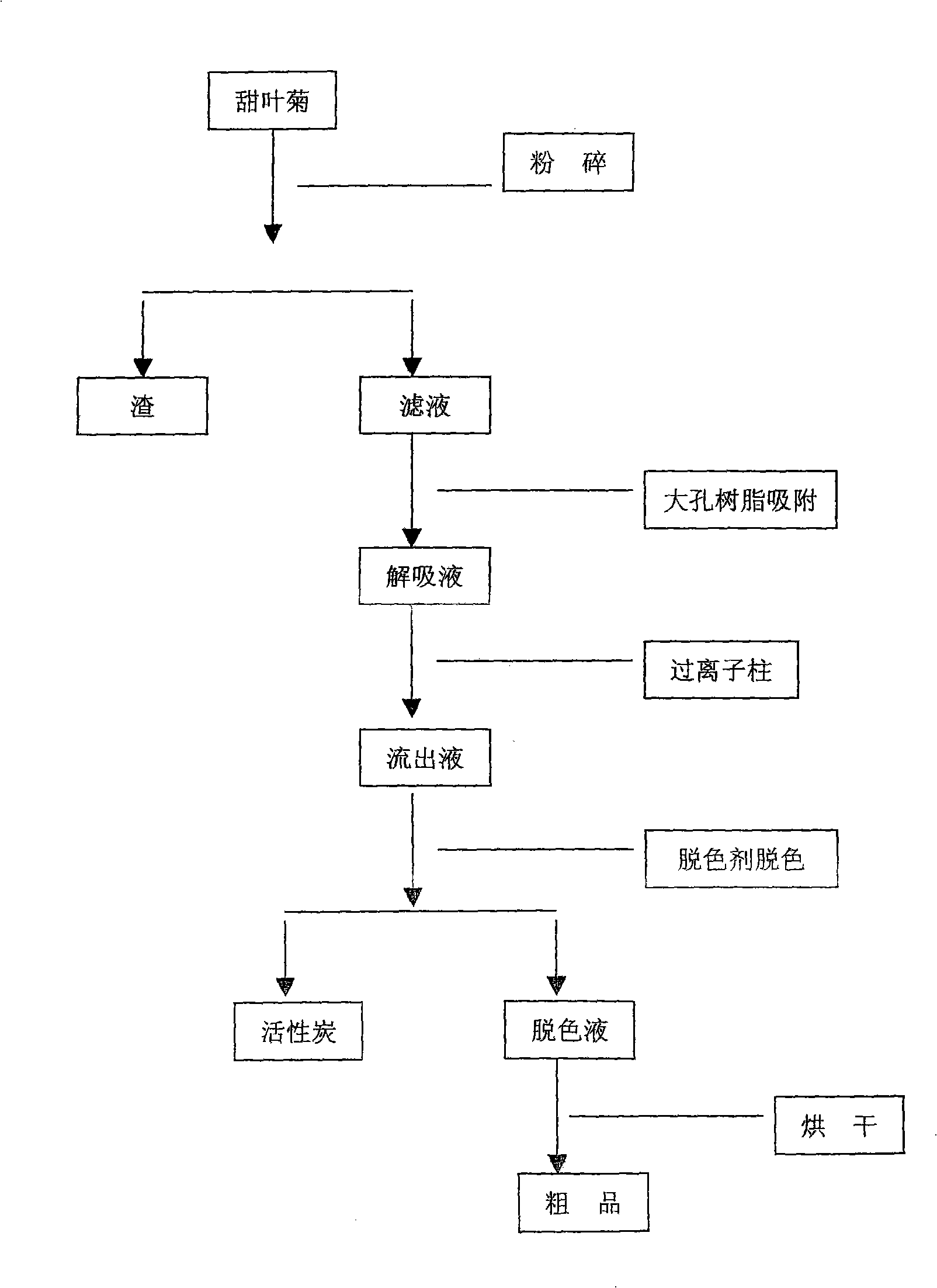

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] Implementation example 1:

[0029] A kind of high content stevioside A 3 The extraction method of glucoside, its steps are as follows:

[0030] 1) Water extraction step: extract 200g of crushed Stevia rebaudiana with 2000ml of drinking water at a water temperature of 80±5°C for 2-3 times, 1 hour each time, and filter.

[0031] 2) Resin separation step: put on the column, pass the filtrate through a HPD-600 type macroporous resin column, elute with 85% (mass) methanol, pass the desorption solution through an anion exchange resin column, and get the effluent part to obtain 2500ml.

[0032] 3) Decolorization step: add 25g of activated carbon, decolorize at a temperature of 80±5°C for 30 minutes, filter, and dry to obtain 5.5g of crude product.

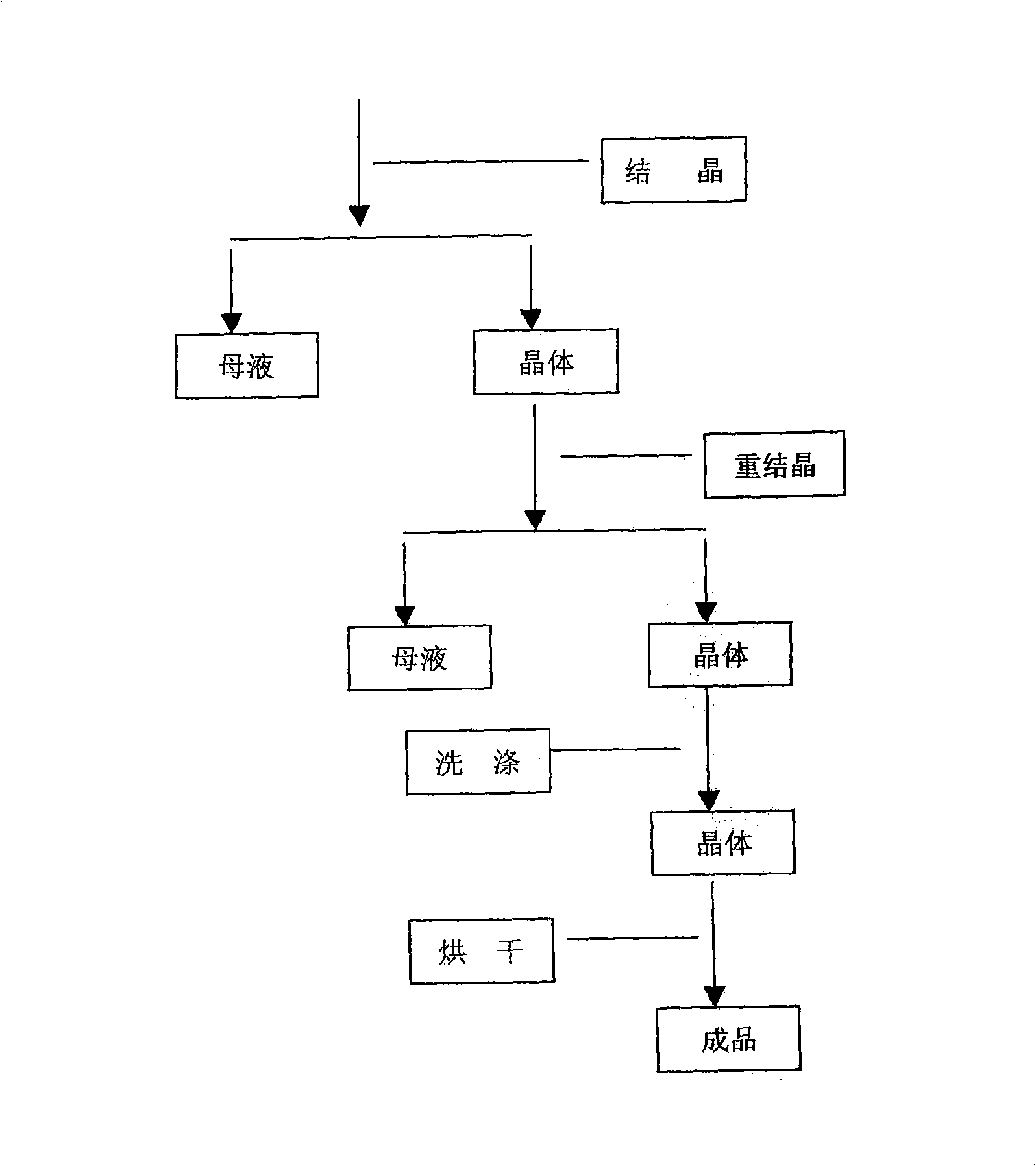

[0033] 4) Crystallization step: 5.5 g of the crude product was dissolved with 22 ml of 70% m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com