Silicon carbide aerogel material and preparation method thereof

A technology of airgel and silicon carbide, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of poor crystallinity, complex preparation process, and single phase of silicon carbide airgel, and achieve good chemical stability Sexuality, simplification of the preparation process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

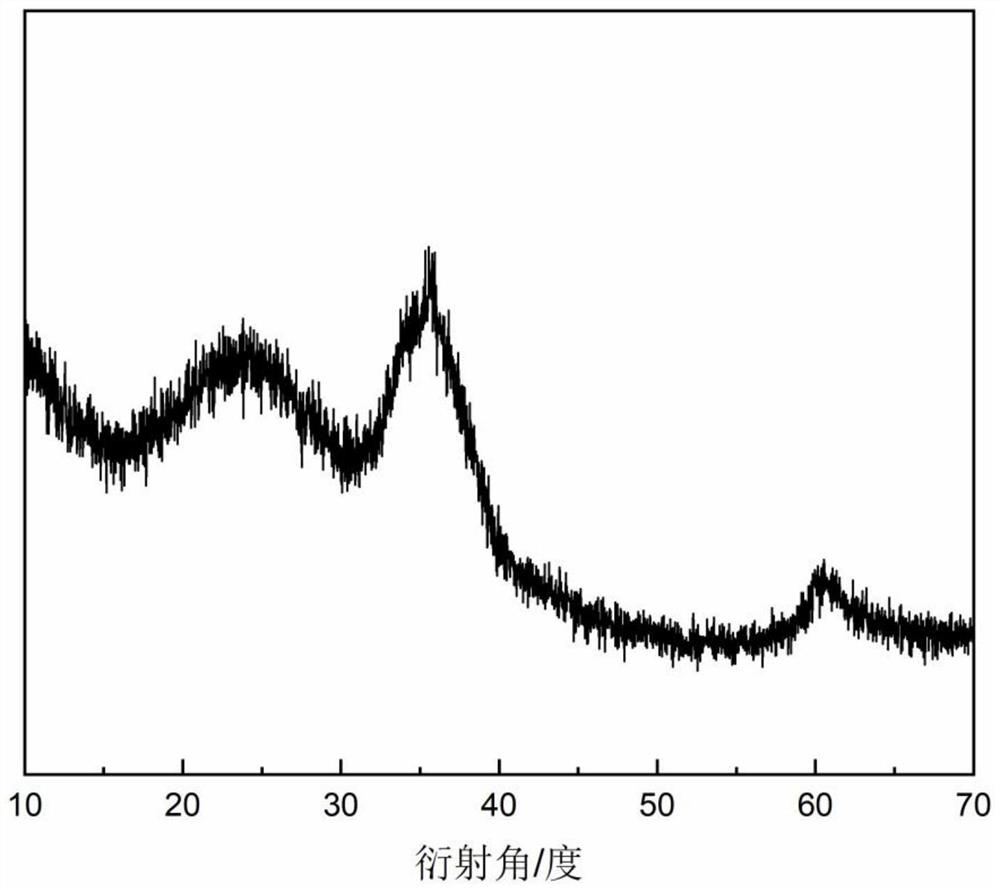

[0027] Terephthalaldehyde (4mol), 3-aminopropyltriethoxysilane (1mol), tetraethoxysilane (0.5mol), methyltrimethoxysilane (0.5mol), ethanol (50ml), de Ionized water (10ml) and acetic acid (1ml) were mixed evenly, and then the mixed solution was placed in a constant temperature oven at 50°C for 48h to fully gel. The wet gel obtained above was placed in a constant temperature environment of 60° C., and replaced with ethanol 6 times, 12 hours each time. Then the wet gel was placed in a vacuum drying oven, dried at 40° C. for 12 hours, and then dried at 80° C. for 12 hours to obtain polysiloxane airgel. The above polysiloxane airgel was heated up to 1400° C. at a heating rate of 1° C. / min under an argon atmosphere, kept for 5 hours, and then naturally cooled to obtain a silicon carbide ceramic airgel. The airgel surface is a gray-green thin layer, and the interior is a black block, which is composed of silicon carbide crystals and silicon oxygen carbon amorphous ( figure 1 ), th...

Embodiment 2

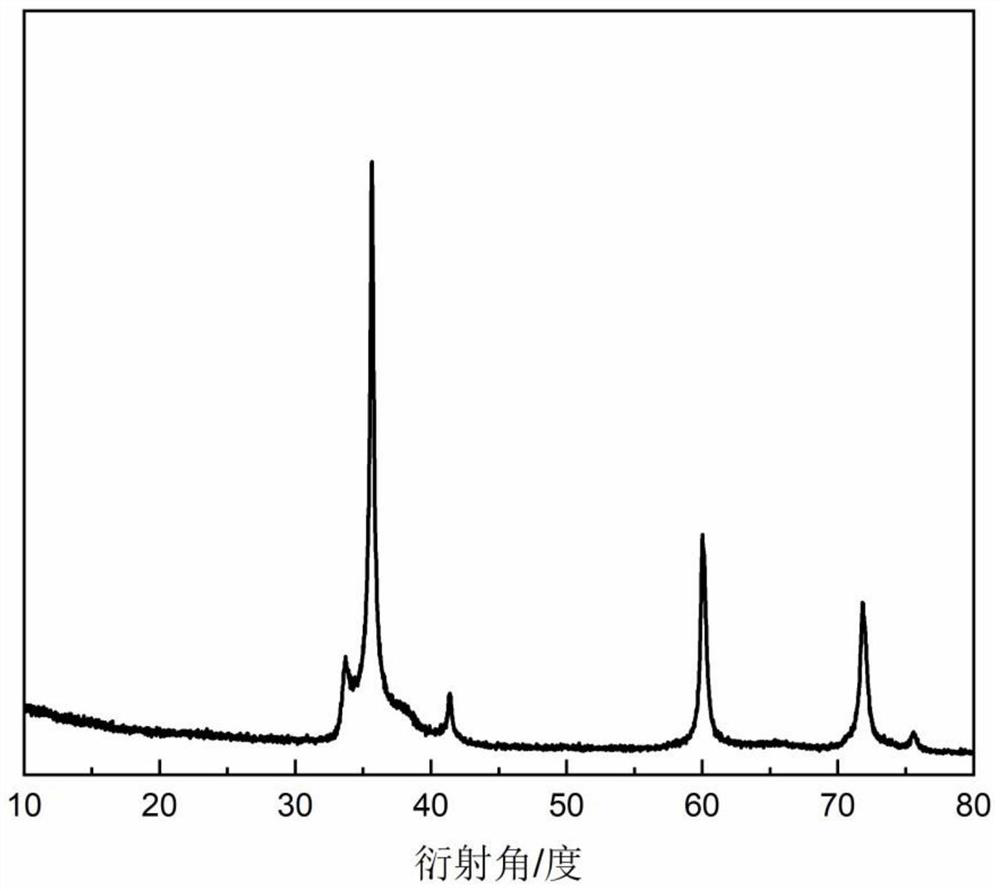

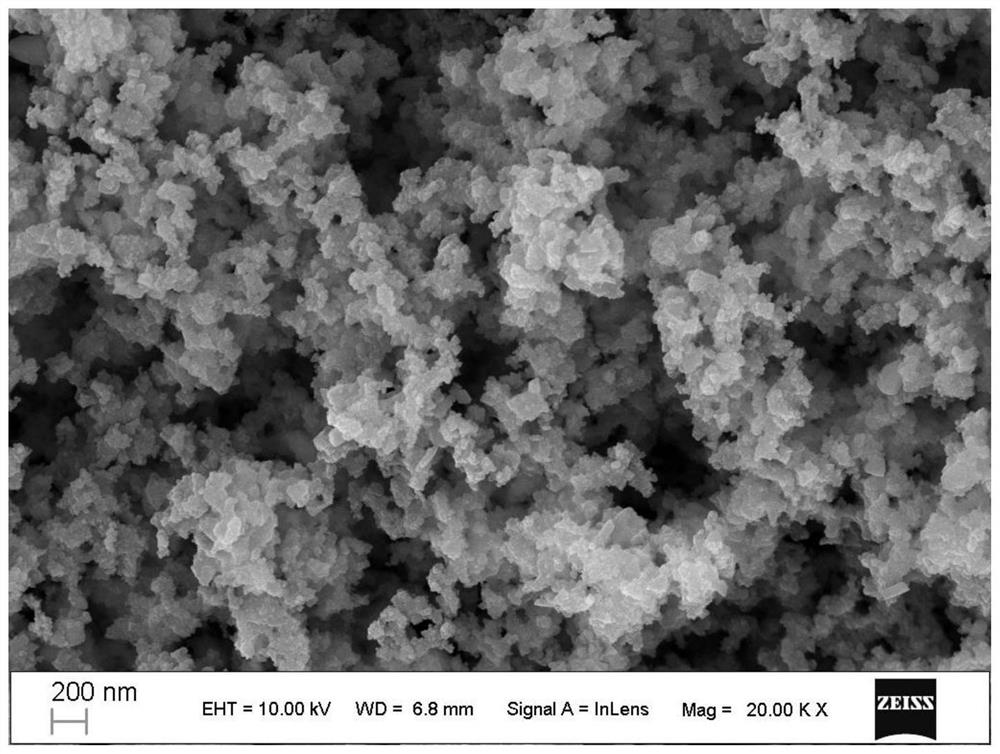

[0029] Terephthalaldehyde (4mol), 3-aminopropyltriethoxysilane (4mol), tetramethoxysilane (2mol), tetramethyldisiloxane (2mol), ethanol (10ml), deionized Water (5ml) and acetic acid (0.5ml) were mixed evenly, and then the mixed solution was placed in a constant temperature oven at 70°C for 36h to fully gel. The wet gel obtained above was placed in a constant temperature environment of 70° C., and replaced with n-hexane 4 times, 6 hours each time. Then the wet gel was placed in a vacuum drying oven and dried at 100° C. for 6 hours to obtain polysiloxane airgel. The above polysiloxane airgel was heated up to 1500°C at a heating rate of 3°C / min in an argon atmosphere, kept for 5 hours and then cooled naturally to obtain a silicon carbide ceramic airgel. The airgel is a gray-green block, and its composition is composed of silicon carbide crystals ( figure 2 ), the interior presents a three-dimensional porous network structure ( image 3 ), the density is 0.090g / cm 3 , thermal...

Embodiment 3

[0031] Terephthalaldehyde (4mol), 3-aminopropyldiethoxymethylsilane (2mol), phenyltrimethoxysilane (2mol), ethanol (10ml), deionized water (5ml) and acetic acid (1ml ) were mixed evenly, and then the mixed solution was placed in a constant temperature oven at 80° C. for 12 hours to make it fully gel. The wet gel obtained above was placed in a constant temperature environment of 40° C., and replaced with isopropanol 6 times, each time for 12 hours. Then the wet gel was placed in a vacuum drying oven, dried at 60° C. for 6 hours, and then dried at 90° C. for 8 hours to obtain polysiloxane airgel. The above polysiloxane airgel was heated up to 1600°C at a heating rate of 5°C / min under an argon atmosphere, kept for 2 hours and then cooled naturally to obtain a silicon carbide ceramic airgel. The airgel is a gray-green block, and its composition is composed of silicon carbide crystals ( Figure 4 ), the density is 0.085g / cm 3 , thermal conductivity 0.04W / (m·K), temperature resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com