Patents

Literature

98results about "Nitroparaffin explosive compositions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for cladding energetic materials

InactiveCN104591932AImprove solubilityCoated evenlyNitroparaffin explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsNon solventAnti solvent

The invention relates to a method for cladding energetic materials and particularly relates to a method for coating energetic materials by taking liquid CO2 as an anti-solvent, a dispersion agent and a drying medium. The method provided by the invention is mainly used for solving the technical problems of the existing method for coating energetic material that the coating is not uniform, the operation is complicated, some special energetic materials cannot be coated by a wet process, the solvent cannot be mutually soluble with a non-solvent to limit the application of the water (or solution) suspension method and cause the environment pollution. The invention provides a method for coating energetic materials by taking liquid CO2 as an anti-solvent, a dispersion agent and a drying medium. The method provided by the invention has the advantages of uniform coating, simple operation, wide application range and no environmental pollution.

Owner:ZHONGBEI UNIV

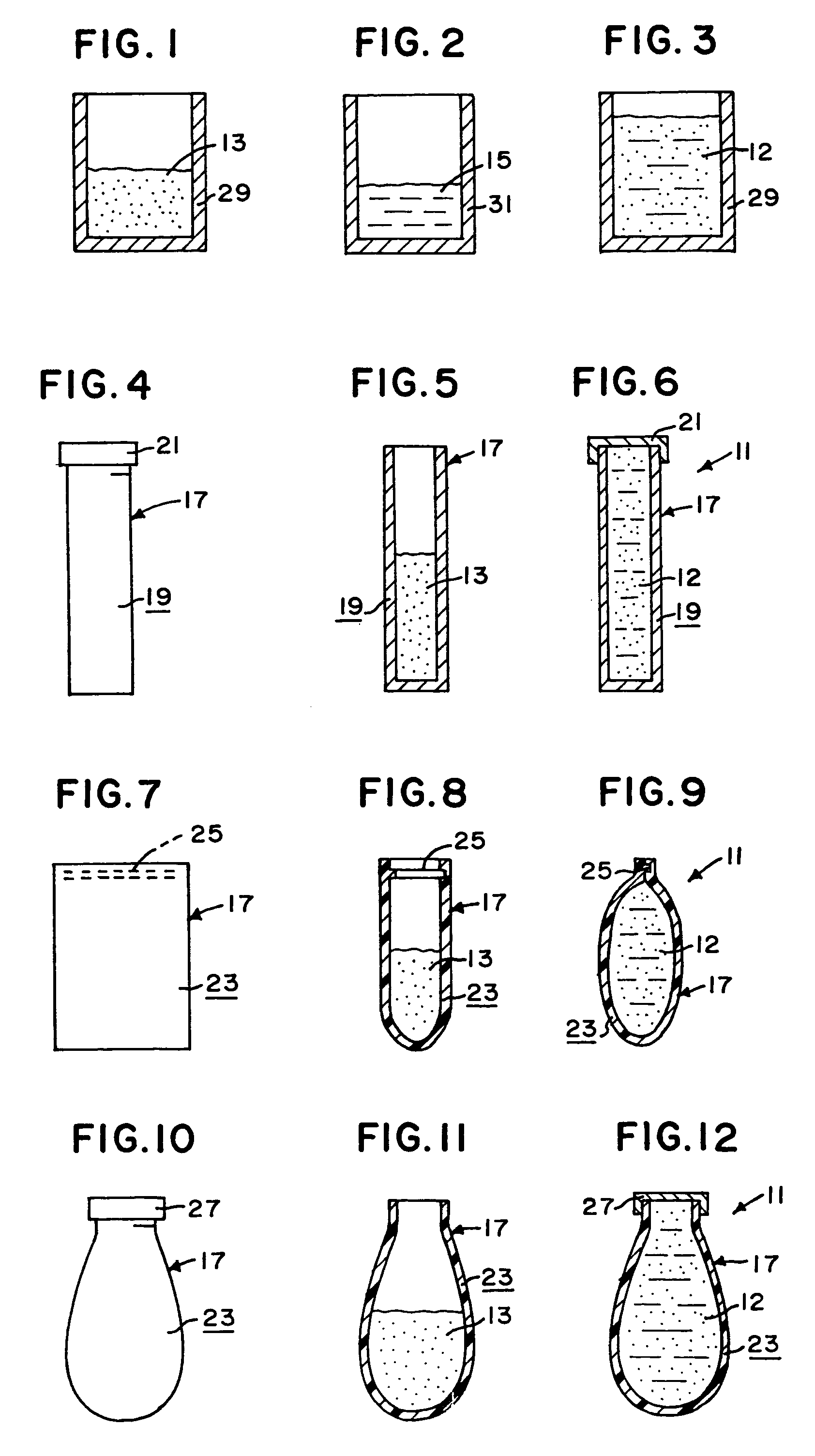

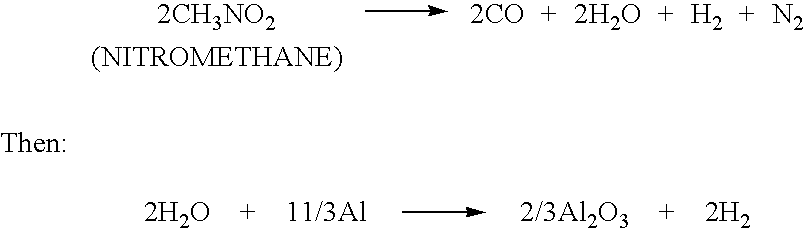

Multi-component liquid explosive composition and method

InactiveUS6960267B1Extended shelf lifeLoomsNitroparaffin explosive compositionsNitromethaneSquare meter

A multi-component liquid explosive composition and method of mixing thereof. The steps include (a) providing a powder consisting of aluminum preferably having an average particle size of 5 to 50 microns and a surface area of 0.5 to 2 square meters per cubic centimeter containing 0.1 to 5% stearic acid by weight; (b) providing a liquid consisting of nitromethane; and (c) mixing said aluminum powder with the nitromethane to form a liquid explosive formulation detonable at a wide range of temperatures and diameters with a standard commercial number 8 blasting cap.

Owner:NIXON III WILLIAM P

Preparation of explosive and explosion lamination method of texture interface

ActiveCN104227221AReduce critical diameterHigh densityNitroparaffin explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsDetonationEngineering

The invention discloses preparation of skin explosive and an explosion lamination method of a texture interface. A base plate with a certain texture structure is arranged on the surface; an outwards-protruding or flat covering plate is pressed into a concave part of the base plate under the action of the skin explosive or other explosion energy; a convex part of a base plate material is sunk into a concave part of the covering plate, so that the tight combination is realized. The skin explosive has the characteristics of stable detonation performance and good viscoelasticity, stability, storage performance and the like, and can be prepared into rolls in advance to be stored, so that explosive distribution time is shortened and the continuous production of compounding metal boards is convenient to realize; the skin explosive can be compounded with metal materials, namely plates, rods, pipes and the like. A texture interface composite plate is subjected to the explosion lamination by adopting a manner of combining physical extruding deformation with a metallurgical bonding phase, and the physical and chemical properties of sheet materials on the two sides of a combining interface are not changed; the explosive amount of a unit area is small and the energy utilization rate is high. The explosion lamination method of the texture interface can be applied to the production of metal plates and thin plates, which have greater physical property difference, such as melting points.

Owner:UNIV OF SCI & TECH OF CHINA

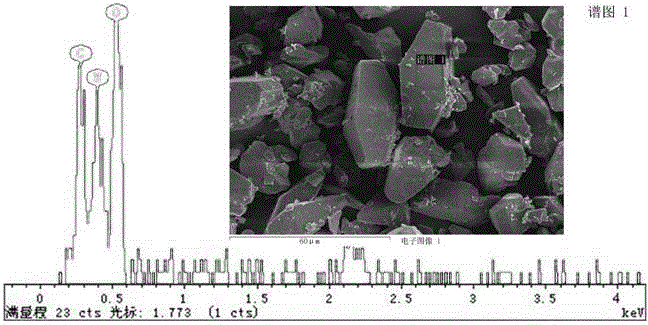

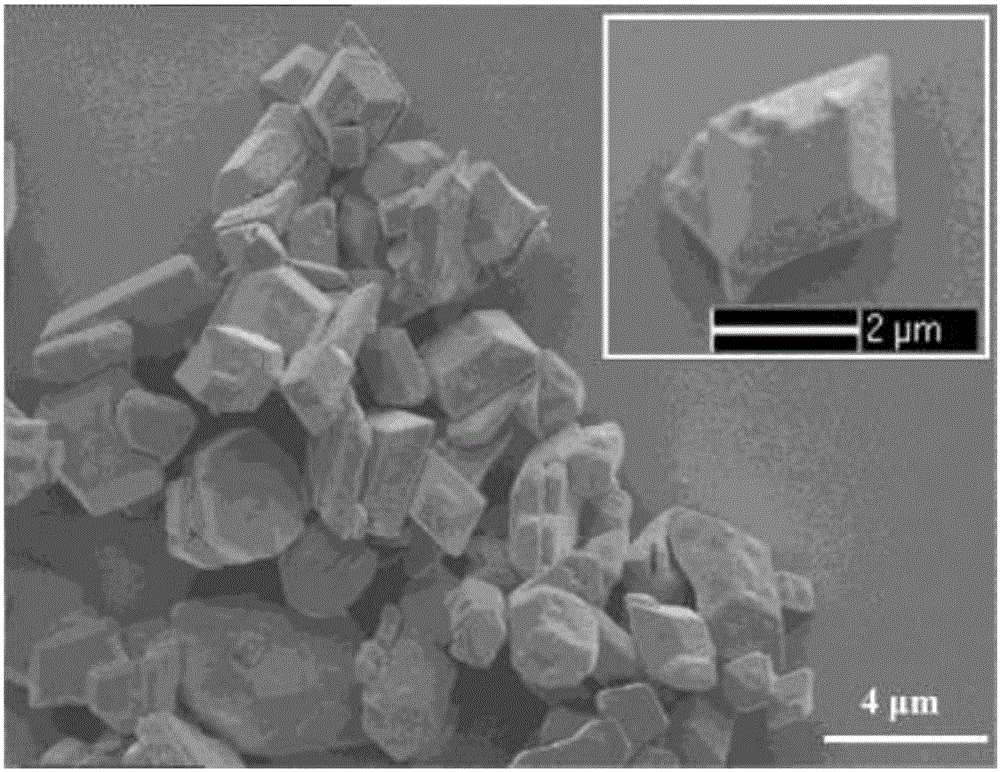

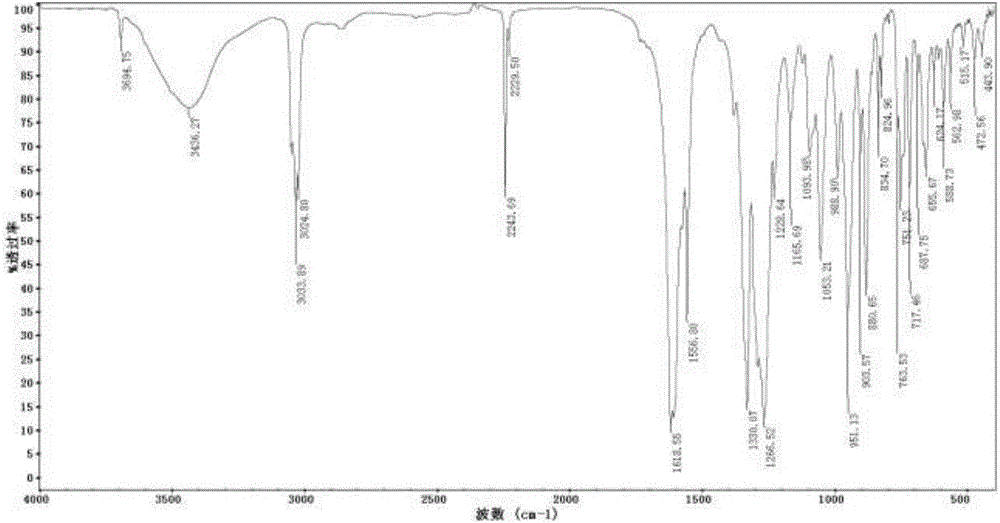

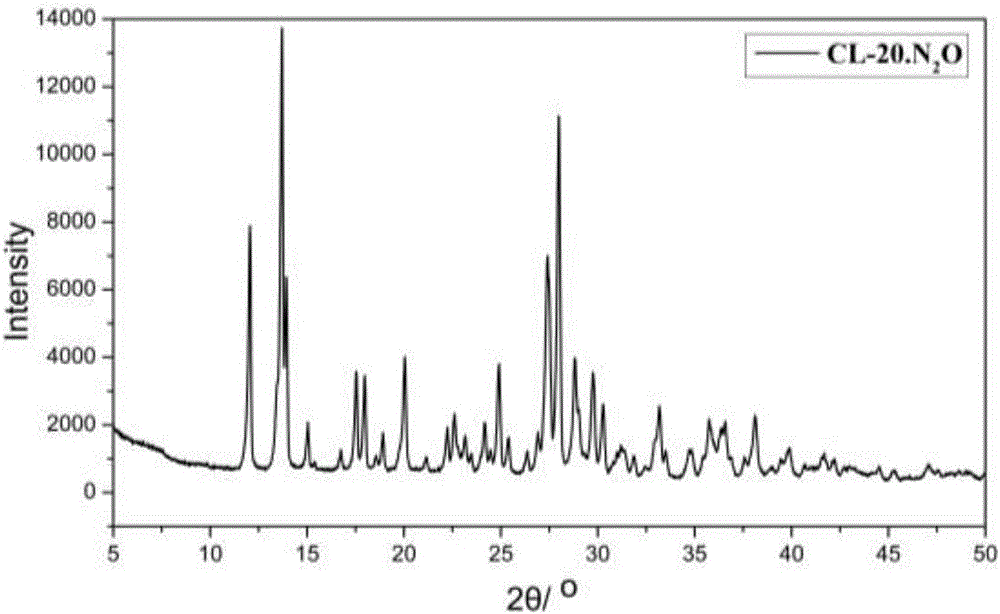

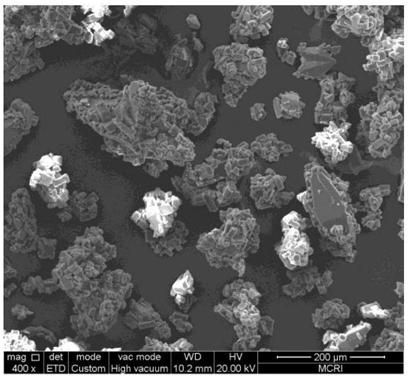

Host-guest explosive embedded with small molecule gas and preparation method thereof

ActiveCN106116993ASimple preparation processMild experimental conditionsNitroparaffin explosive compositionsHigh energyProduct gas

The present invention discloses a host-guest explosive embedded with small molecule gas, and a preparation method thereof, wherein N2O gas is continuously introduced into a CL-20 solution, and the CL-20 and the N2O are subjected to co-crystallizing by using a solution re-crystallization method so as to obtain the CL-20 and N2O co-crystallized host-guest explosive crystal. According to the present invention, the method is based on the host-guest chemical thought, and the gas-liquid co-crystallization method is used to co-crystallize the small molecule gas and the explosive in the solution so as to obtain the CL-20 host-guest explosive crystal embedded with the N2O gas; the method has characteristics of simple preparation process and mild experiment condition, wherein the small molecule gas can be embedded into the explosive crystal without the high pressure gas; and the new idea can be provided for the structural optimization and the performance control of the high energy explosives, and the basic support can further be provided for the design and the manufacture of the advanced weapon.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Coating method for in-situ generating energy-containing deterrent ANPZ on surface of 1,3,5-trinitro-1,3,5-triaza-cyclohexane (RDX)

The invention provides a coating method for in-situ generating energy-containing deterrent ANPZ on the surface of 3,5-trinitro-1,3,5-triaza-cyclohexane (RDX). The method comprises the following steps: dissolving dihydroxylpyrrolidine (DMDP) in methanol, and adding RDX and LBA306, and evenly mixing and stirring; slowly dropwise adding 25wt% ammonia, and generating the ANPZ on a RDX surface in situ; after cooling, filtering the reaction mixture; and drying in a safe water bath drying oven so as to obtain ANPZ-coated RDX explosive. The particle shape of the RDX coated by the method is relative regular, particles are evenly distributed, and no agglomeration phenomenon occurs; and by utilizing the method, the explosive energy of the RDX can be maintained, and the mechanical feeling degree of the RDX is reduced, thereby achieving the requirement on the RDX insensitivity and improving the safety in the process of explosive use.

Owner:ZHONGBEI UNIV

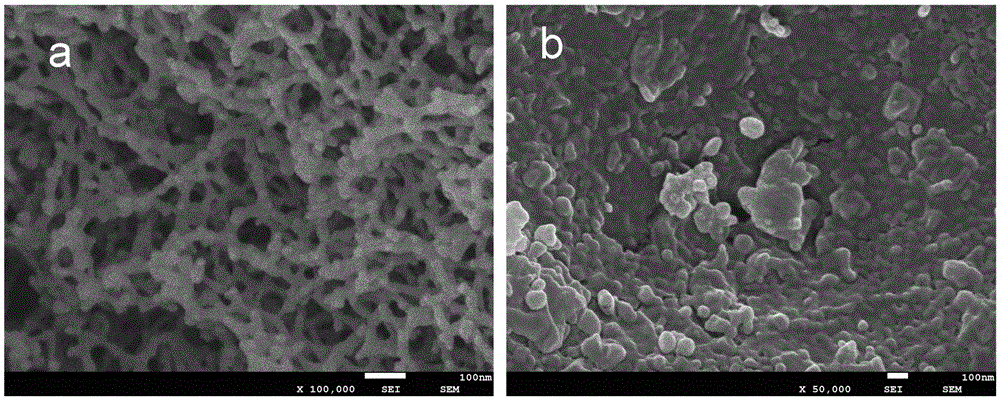

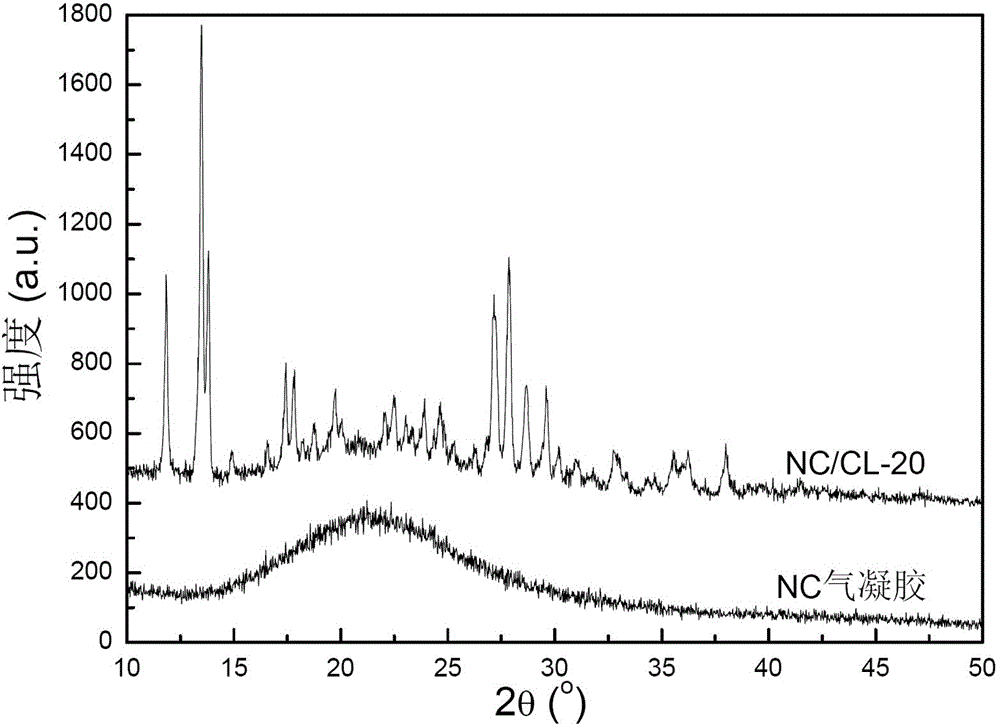

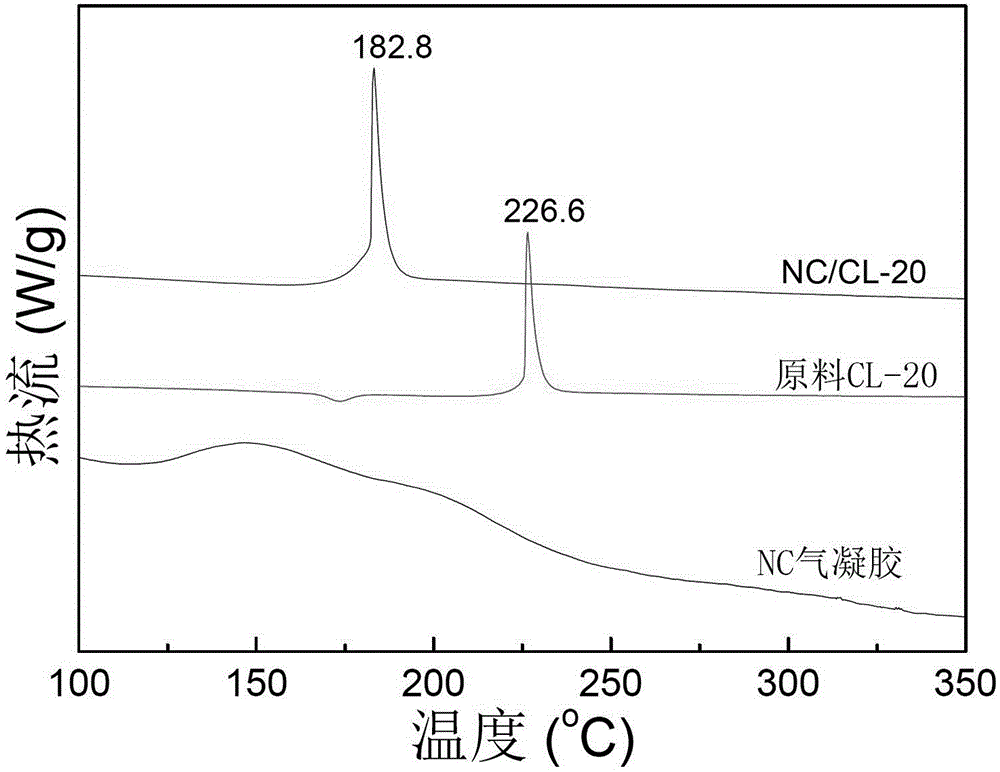

Nano-composite energetic material and preparation method thereof

InactiveCN105481617AHigh energyHigh activityExplosive working-up apparatusNitroparaffin explosive compositionsSupercritical dryingNano structuring

The invention discloses a nano-composite energetic material. The nano-composite energetic material is prepared through the steps that CL-20 and NC are taken as raw materials and then dissolved in weak-polar solvent according to the mass ratio (0.1-3):1 of the CL-20 to the NC to be prepared into a transparent solution, an isocyanate curing agent and a composite catalyst of T-12 and TEDA are added to form wet gel, the solvent is removed through supercritical drying after the wet gel is aged, and then the aerogel-state nano-composite energetic material is obtained. The prepared composite energetic material has the nano-structure, is higher in energy and activity and lower in sensitivity, has the good prospect on the aspects of improving the security feature and energy releasing efficiency of energetic components and the like and can be applied to the fields of high-energy density materials such as solid propellants, explosives and powders and pyrotechnic compositions.

Owner:ZHONGBEI UNIV

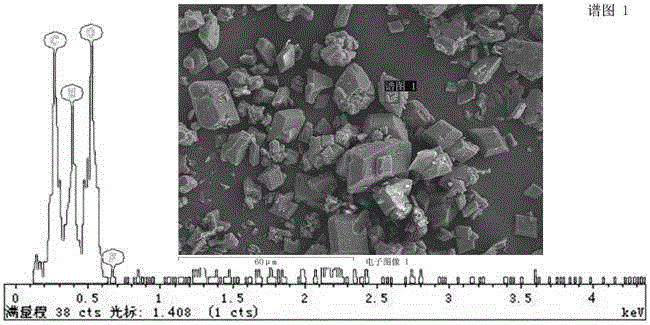

Fine-particle high-energy low-sensitivity explosive compound and preparation method thereof

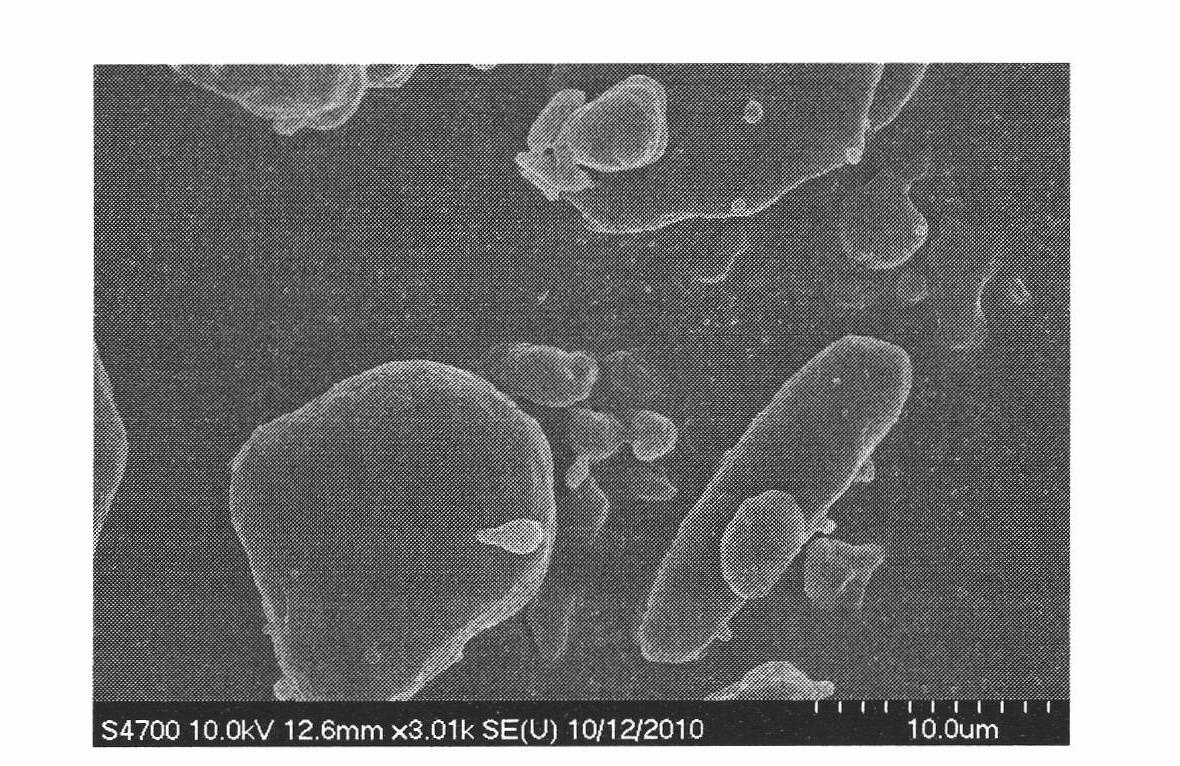

ActiveCN104193564ALow mechanical sensitivitySuitable for mass productionNitroparaffin explosive compositionsFriction sensitivityOrganic solvent

The invention relates to a fine-particle high-energy low-sensitivity explosive compound and a preparation method thereof. The method comprises the following steps: mixing an explosive with a macromolecular bonder according to a weight part ratio of 100 to (2-5), and stirring at 40-60 DEG C for dissolving in an organic solvent to obtain an explosive compound solution with 5%-30% by weight of explosives; putting the explosive compound solution into an ejection tank, pumping air into the ejection tank to increase the pressure in the ejection tank to be 0.3-0.7MPa, ejecting the explosive compound solution into an explosive antisolvent with the temperature of -10 DEG C to 10 DEG C, performing centrifugal separation on a solid product, washing, and drying to obtain the explosive compound. According to the explosive compound, explosive particles are micron-sized, the CL-20 surface is densely wrapped with the macromolecular bonder in the form of an interwoven mesh shape, the impact sensitivity of the wrapped CL-20 is reduced to be 24%-40% from 100%, and the friction sensitivity is reduced to be 66%-92% from 100%.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

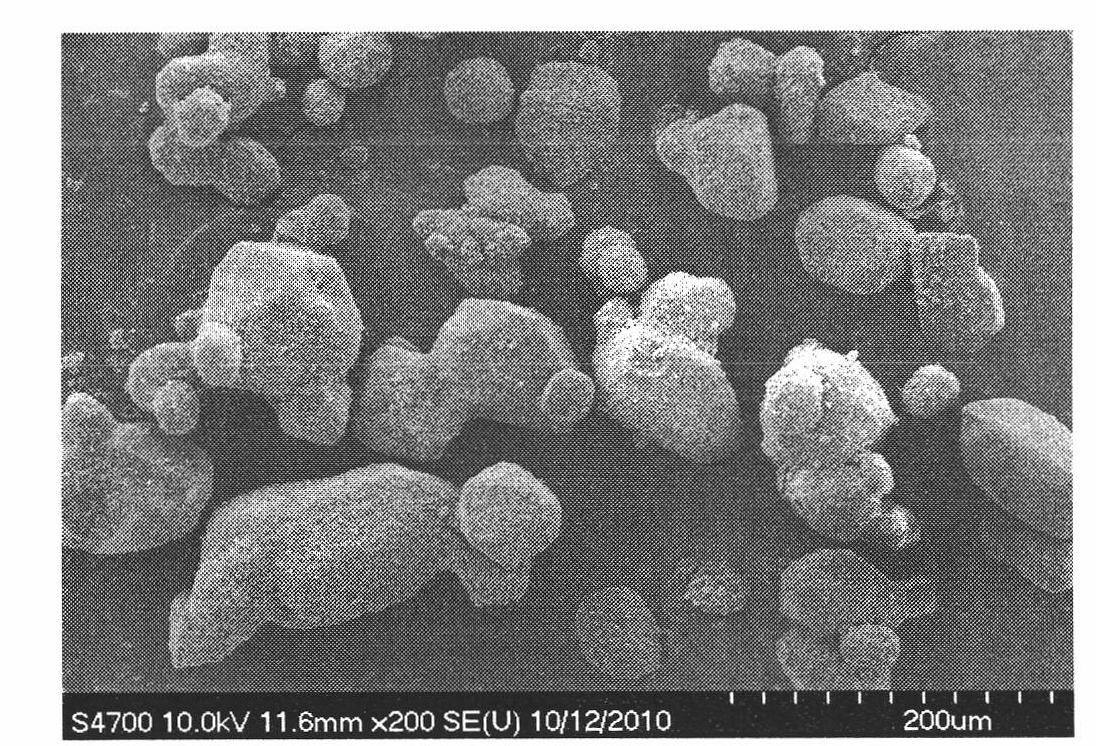

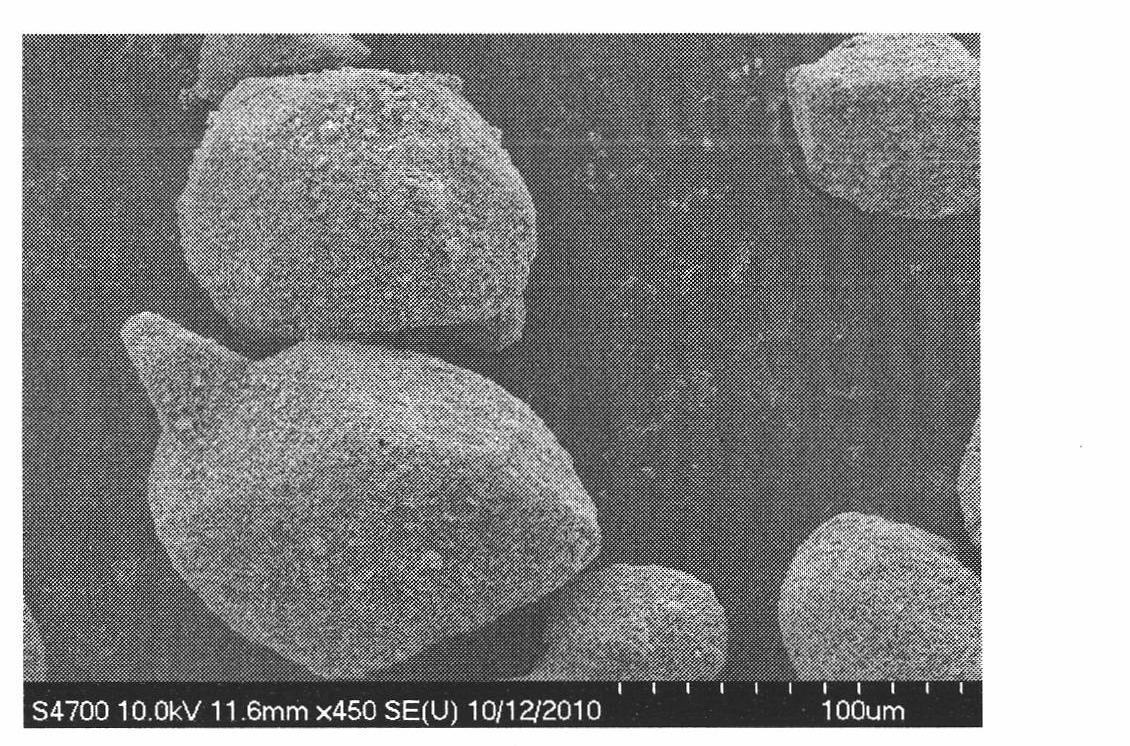

Method for preparing spherical organic micro-molecular monomer or compound through emulsion technology

ActiveCN106748584AImprove stabilityImprove bioavailabilityOrganic chemistry methodsExplosive working-up apparatusNonlinear optical crystalSolubility

The invention discloses a method for preparing a spherical organic micro-molecular monomer or compound through an emulsion technology. The method comprises the following steps: adding one or more organic micro-molecules to a solvent-nonsolvent, stirring the one or more organic micro-molecules and the solvent-nonsolvent, adding a surfactant, carrying out ultrasonic or mechanical emulsion after the above obtained emulsion is uniformly dispersed, precipitating crystals through adopting a crystal precipitation technology to obtain a solid and liquid mixture, filtering the mixture, washing the obtained solid, and drying the washed solid to obtain monomer or compound spherical crystals. Compounding, super refinement and spheroidization of the organic micro-molecules are combined in the invention, so the sensitivity of an energetic material is greatly reduced, the fluidity and the loading density of the energetic material are improved, and the viscosity of the crystals in the 3D printing or PBX explosive slurry of the energetic material is reduced; the change of the melting point and the solubility of a medicine improves the stability and the bioavailability of the medicine and facilitates pressing into tablets; and the crystals allow the researching and application fields of conductive organic crystals, nonlinear optical crystals, dyes, photograph raw material pigments and agrochemicals to be expanded.

Owner:SOUTHWEAT UNIV OF SCI & TECH

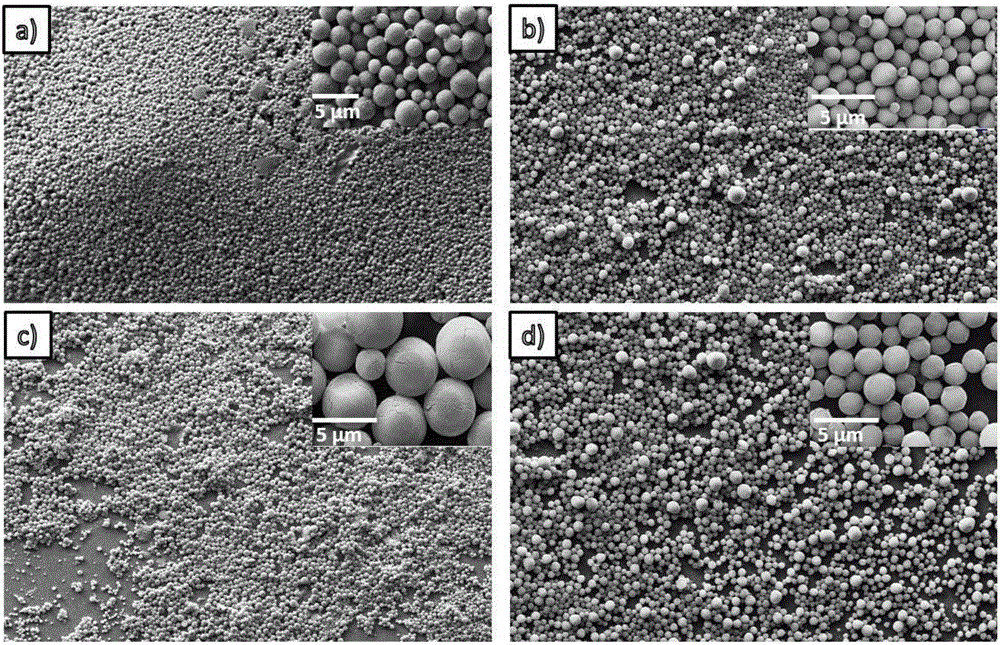

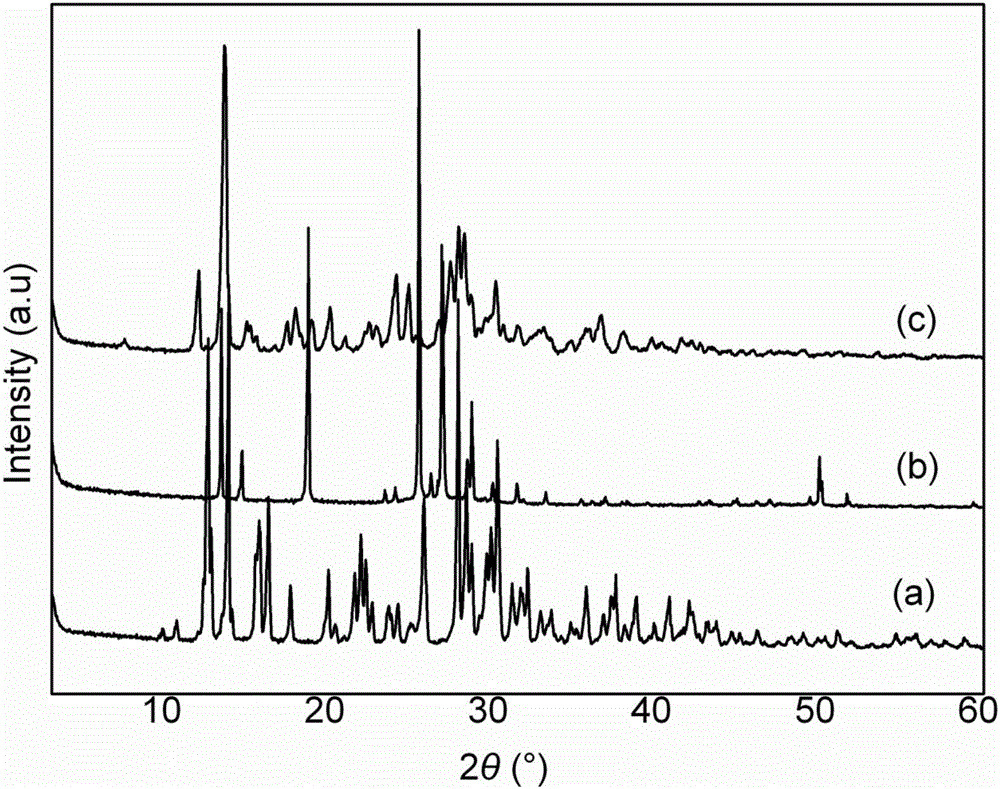

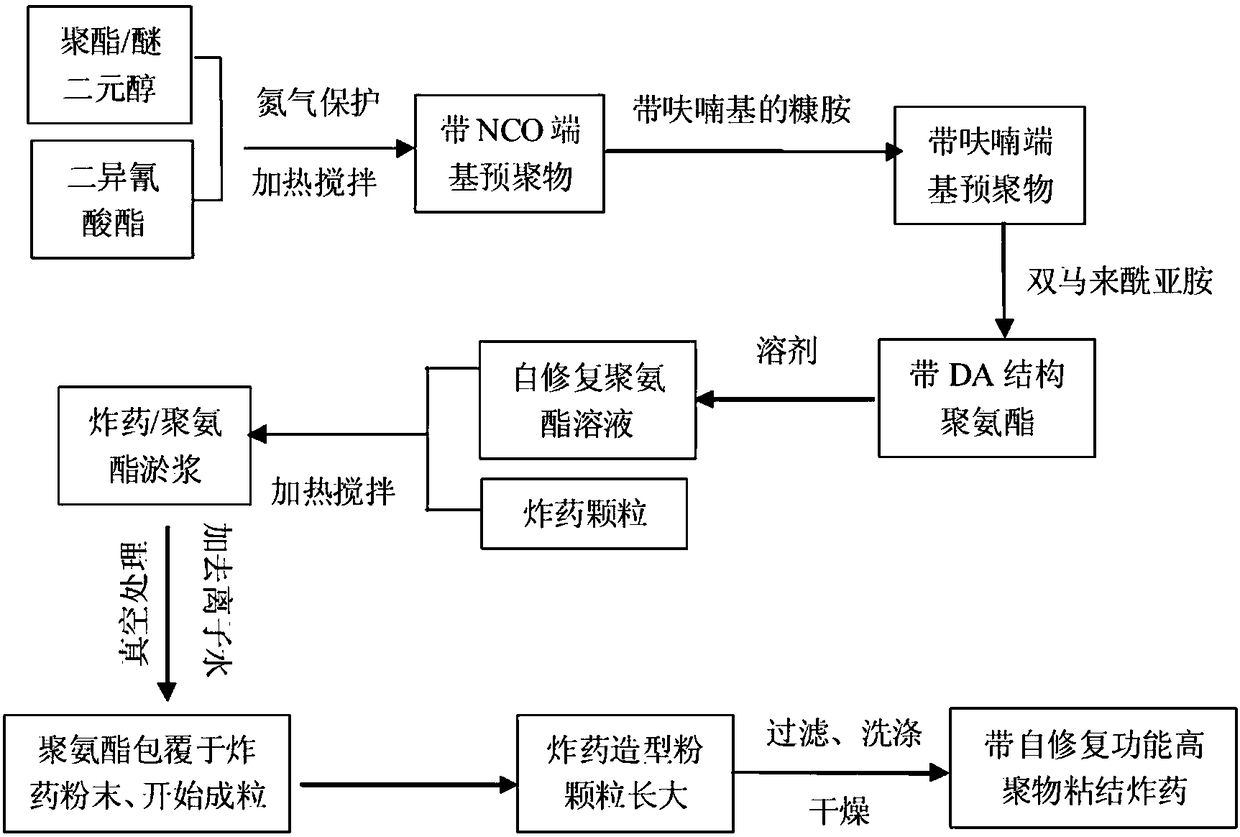

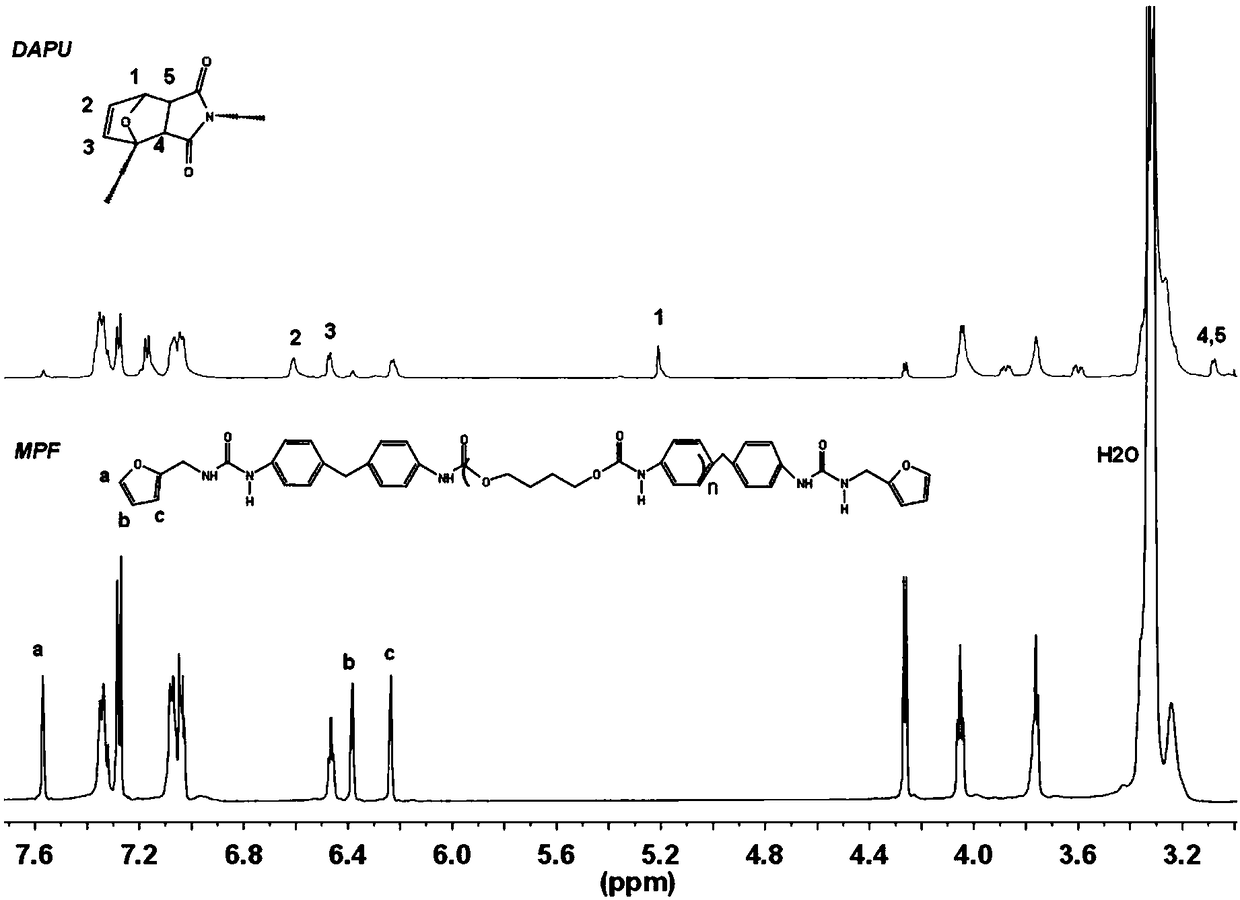

High polymer bonded explosive with self-repair function and preparation method thereof

ActiveCN108329184AReturn to normal structureRecovery strengthNitroparaffin explosive compositionsPolymer scienceEnd-group

The invention provides a preparation method of a high polymer bonded explosive with a self-repair function, wherein the preparation method includes the following steps: step 1, firstly, carrying out areaction of excess diisocyanate with polyether / ester diol to produce a prepolymer with -NCO groups at both ends; step two, then, carrying out a reaction of furfuryl amine with a furan group with theprepolymer, to generate polyurethane with a furan end group; step three, carrying out a reaction of bismaleimide with the polyurethane, to generate a thermoplastic polyurethane with a DA bond; and step four, preparing a dilute solution from the thermoplastic polyurethane, and adding an explosive with metered proportioning; and heating to make the solvent gradually evaporated, then adding a properamount of deionized water, wrapping the surface of the explosive after the polyurethane is precipitated, filtering and drying, and thus obtaining the high polymer bonded explosive with the self-repairfunction. The invention also provides the high polymer bonded explosive with the self-repair function. The preparation method has the advantages of simple preparation process, mild conditions and high universality.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

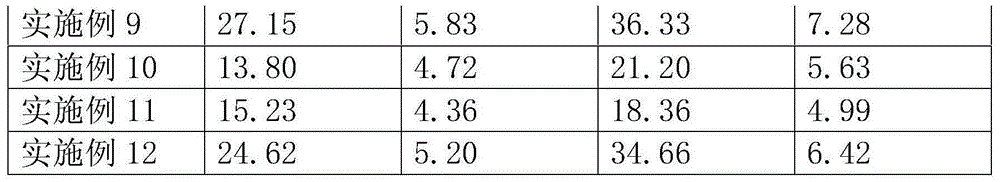

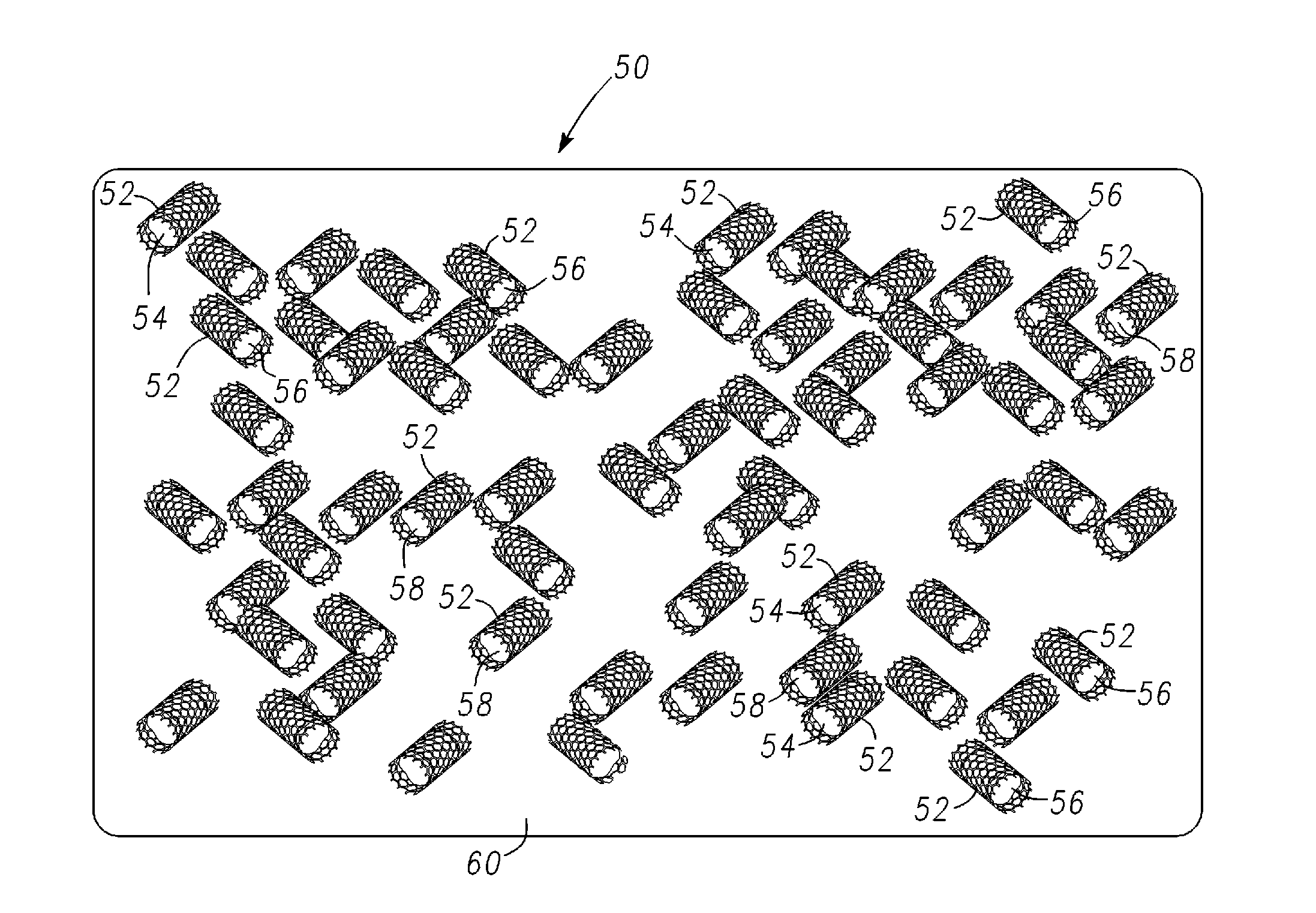

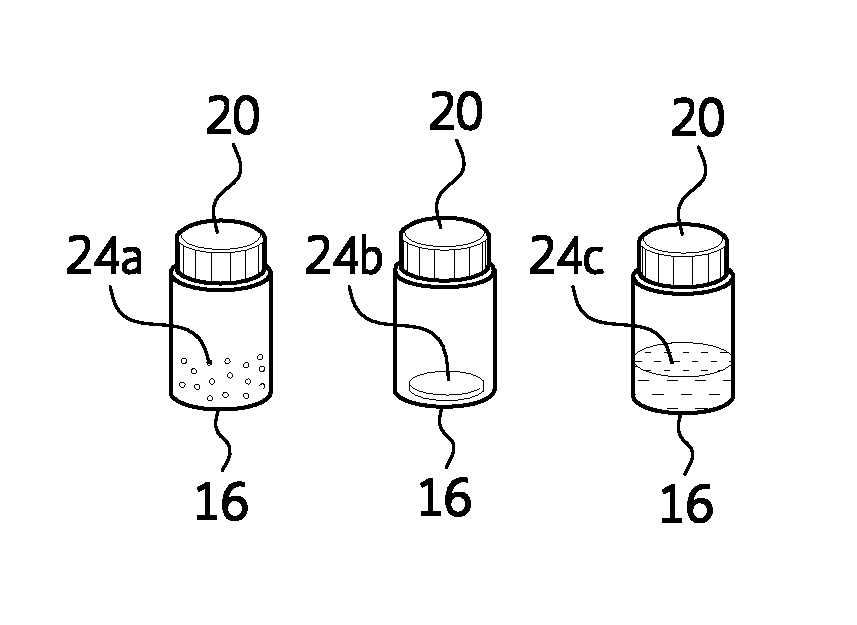

High polymer bonded explosive enhancing mechanical properties with nanoparticles and preparation method of high polymer bonded explosive

ActiveCN104649850AImprove mechanical propertiesIncrease energy densityNitrated aromatic explosive compositionsNitroparaffin explosive compositionsPolymer scienceHigh energy

The invention discloses a high polymer bonded explosive enhancing mechanical properties with nanoparticle and a preparation method of the high polymer bonded explosive. The high polymer bonded explosive contains 2-75% by mass of nano explosive particles with the particle size of 50-600nm. The preparation method comprises the following steps: mixing an explosive with an average particle size with the nano explosive particles in water in a proportion; then slowly adding a bonding agent solution to ensure that the explosive particles are gradually compounded into microparticles along with the volatilization of a solvent under the action of the bonding agent; and pressing an explosive product after washing and drying. According to the preparation method disclosed by the invention, the nano explosive particles are adopted to replace average granular explosive in the high polymer bonded explosive, and the PBX formula components and contents thereof are not needed to be changed, so that the mechanical properties of the high polymer bonded explosive can be significantly improved, a large amount of multi-component bonding agent systems which are used for improving the mechanical properties can be effectively avoided, the high-energy density of the high polymer bonded explosive is ensured, and meanwhile, the high polymer bonded explosive is relatively single in component, simple in preparation method and low in cost.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

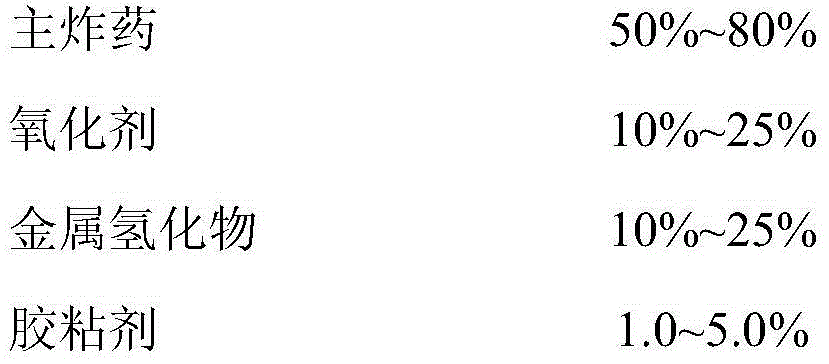

Preparation method of high-heat explosive containing cerium hydride

ActiveCN103980073ASimple production processSimple preparationNitroparaffin explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsAdhesiveCerium

According to the invention, metal hydride and an oxidizing agent are mixed, and under the action of an adhesive, the mixture is granulated to prepare a high-heat mixed explosive. The explosive contains the following components, by mass, 50-80% of cyclonite (RDX) and octogen (HMX) or hexanitrohexaazaisowurtzitane (CL-20), 10-25% of an oxidizing agent, 10-25% of metal hydride and 1.0-5% of a binder. According to the invention, metal hydride is added into the explosive for the first time so as to obtain the high-heat high-power explosive with the value of explosion heat being 14000-22000kJ / kg. The explosive has excellent sensitivity, and storage life of the explosive reaches 30 years. The explosive is suitable for charge by using press-fitting technology.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

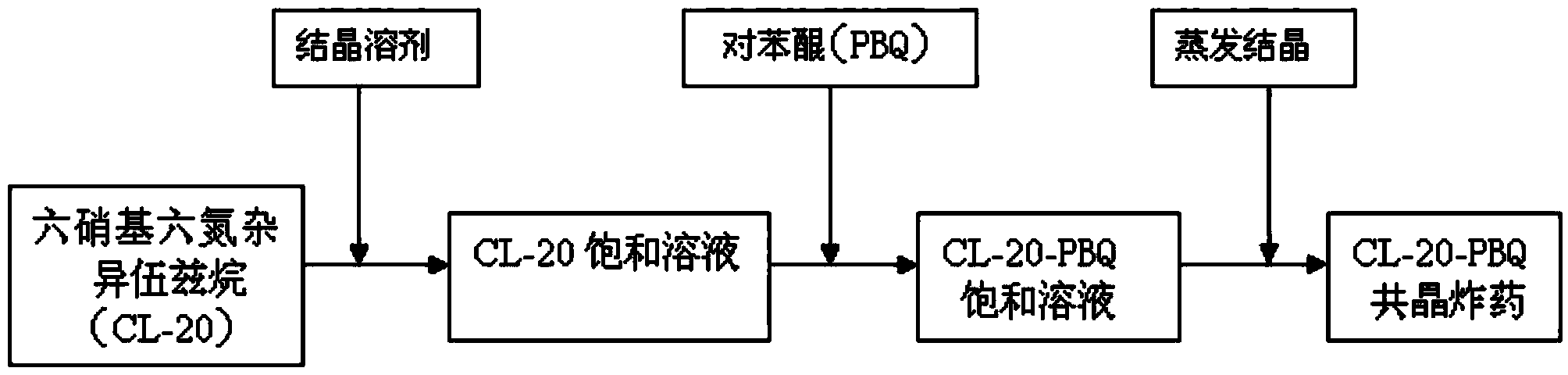

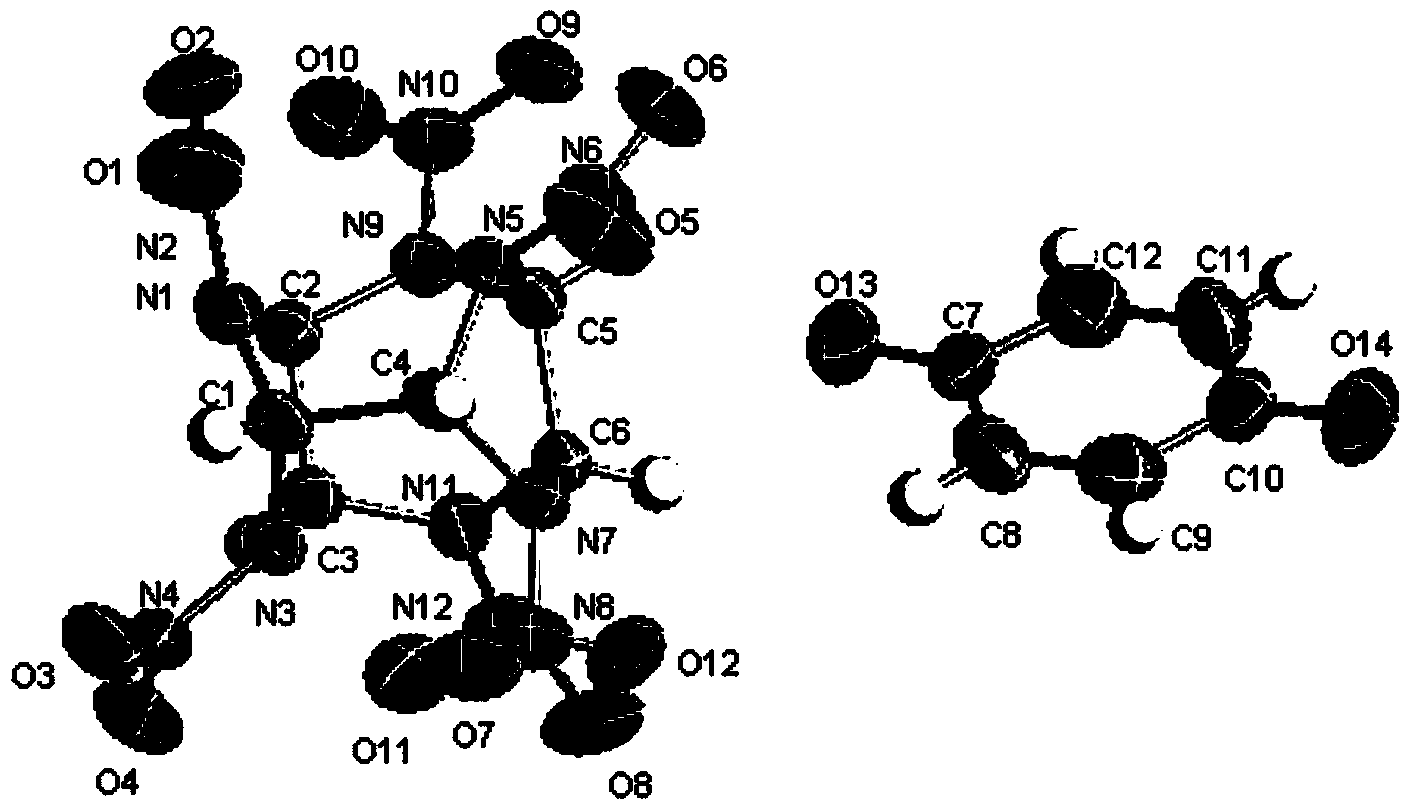

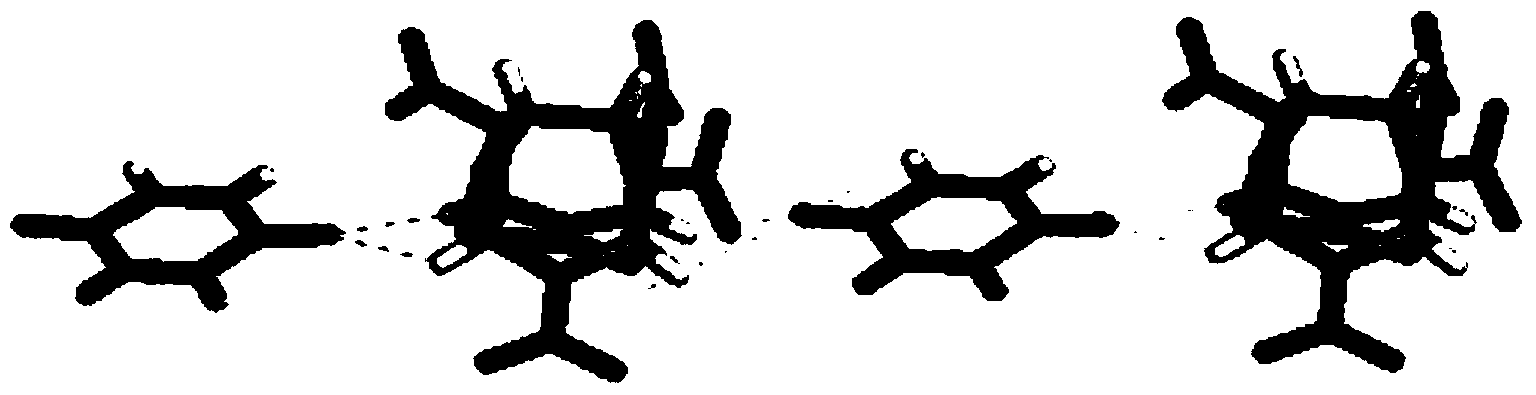

Preparation method of hexanitrohexaazaisowurtzitane/p-benzoquinone cocrystal explosive

ActiveCN103435427ARegulation of Thermal Decomposition BehaviorImprove securityExplosive working-up apparatusNitroparaffin explosive compositionsDecompositionHigh energy

The invention discloses a preparation method of a hexanitrohexaazaisowurtzitane / p-benzoquinone cocrystal explosive. Firstly a saturated solution of hexanitrohexaazaisowurtzitane and a saturated solution of p-benzoquinone are prepared using a crystallization solvent, and then the solvent is allowed to evaporate through a constant-temperature incubator, followed by crystallization to prepare a hexanitrohexaazaisowurtzitane / p-benzoquinone cocrystal explosive. The invention has the benefits as follows: the crystal density of the hexanitrohexaazaisowurtzitane / p-benzoquinone cocrystal explosive is up to 1.737 g / cm3, the melting point of the cocrystal explosive is 132 DEG C and is greatly increased by 17 DEG C as compared with relatively-pure component PBQ, and the cocrystal decomposition temperature is lower than that of both CL-20 and BQ and 207 DEG C lower than that of PBQ. Therefore, by virtue of cocrystallization, the thermal decomposition behavior of the explosive can be obviously controlled, the high efficiency and desensitivity of cocrystallization of the explosive are achieved, the safety of the explosive is improved, and the explosive has a good application prospect in high-energy low-sensitivity ammunition.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

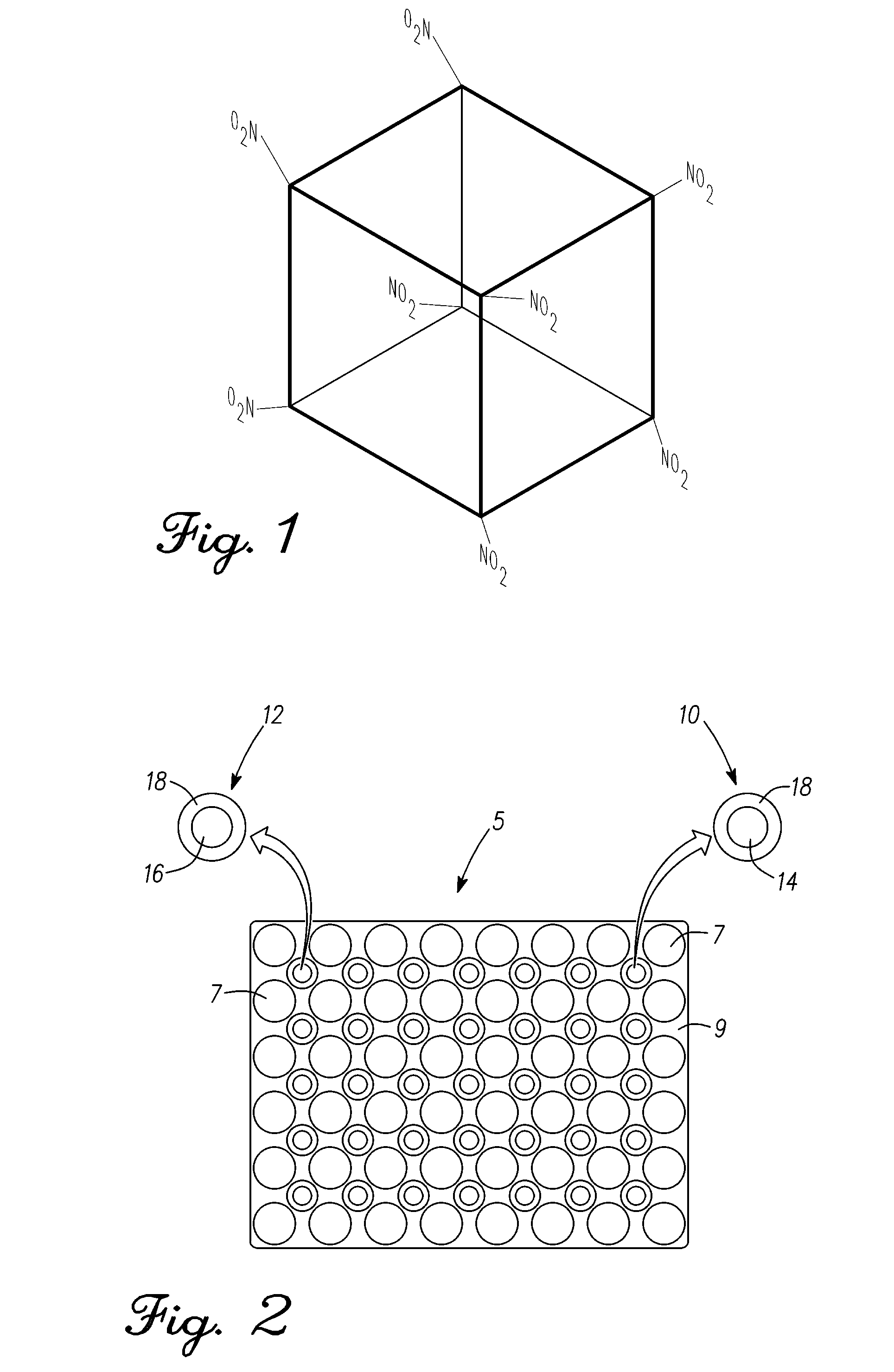

Explosive compositions and methods for fabricating explosive compositions

PBX compositions and methods for fabricating PBX compositions are provided. In an exemplary embodiment, a PBX composition comprises a binder matrix comprising a thermoset resin and an oxidizer comprising octanitrocubane (ONC), the oxidizer homogeneously dispersed within the binder matrix. In another embodiment, a method for fabricating a PBX composition comprises providing an oxidizer comprising octanitrocubane (ONC) and blending the oxidizer with a prepolymer that, upon cure, forms a thermoset resin.

Owner:RAYTHEON CO

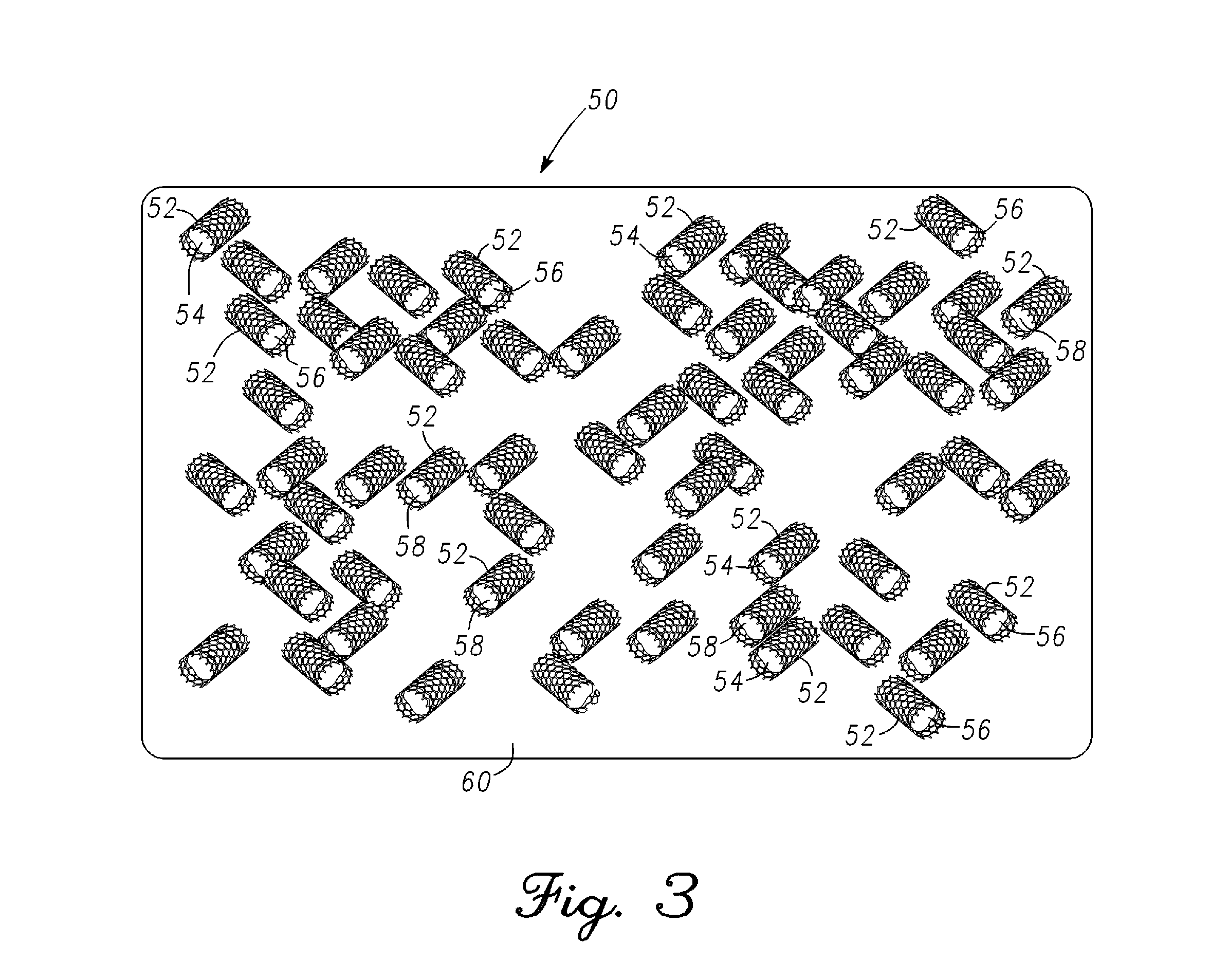

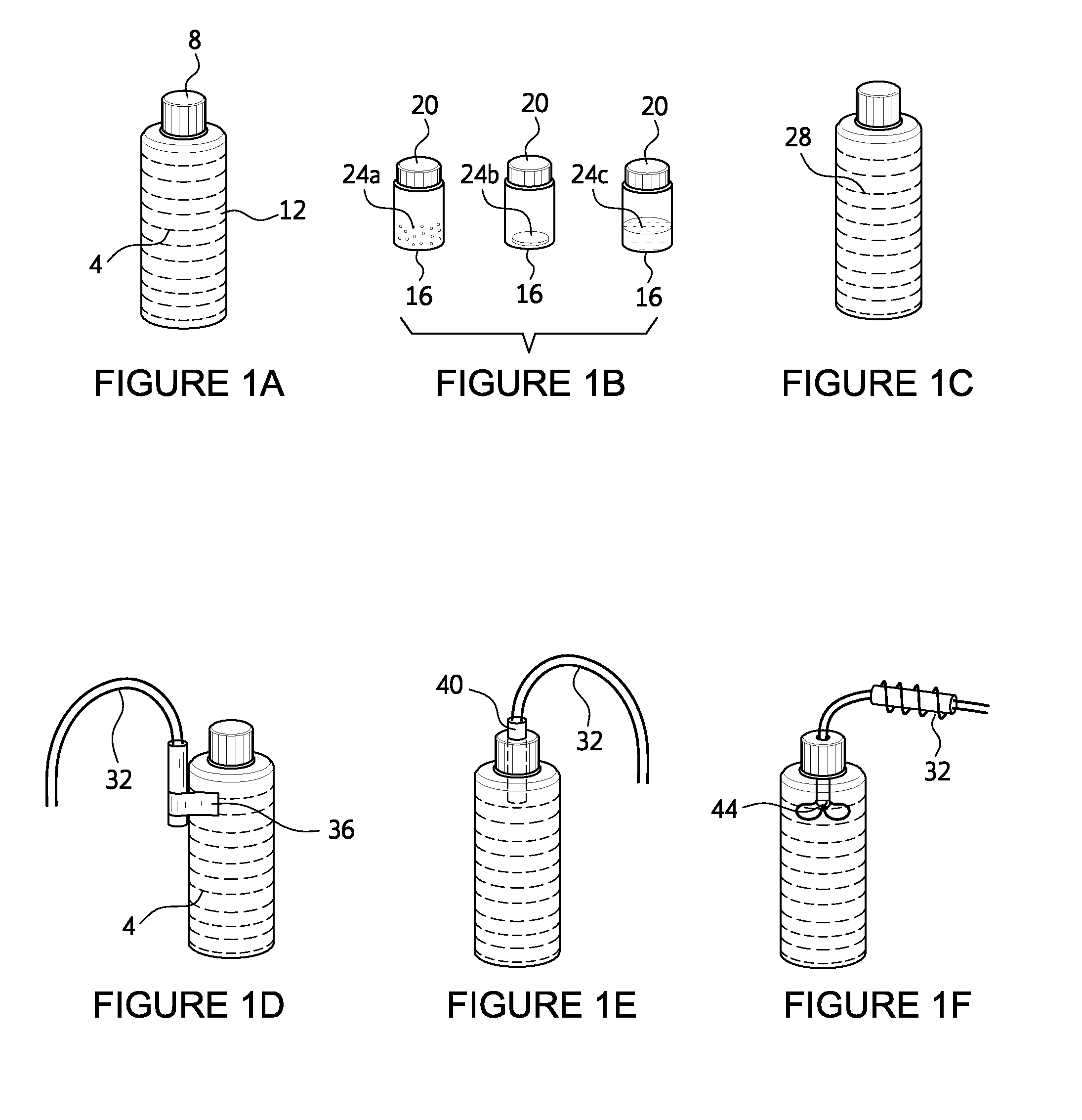

Simple low-cost hand-held landmine neutralization device

InactiveUS9175933B2Easy to practiceExtended shelf lifeDefence devicesAmmunition projectilesDetonationHexamethylenetetramine

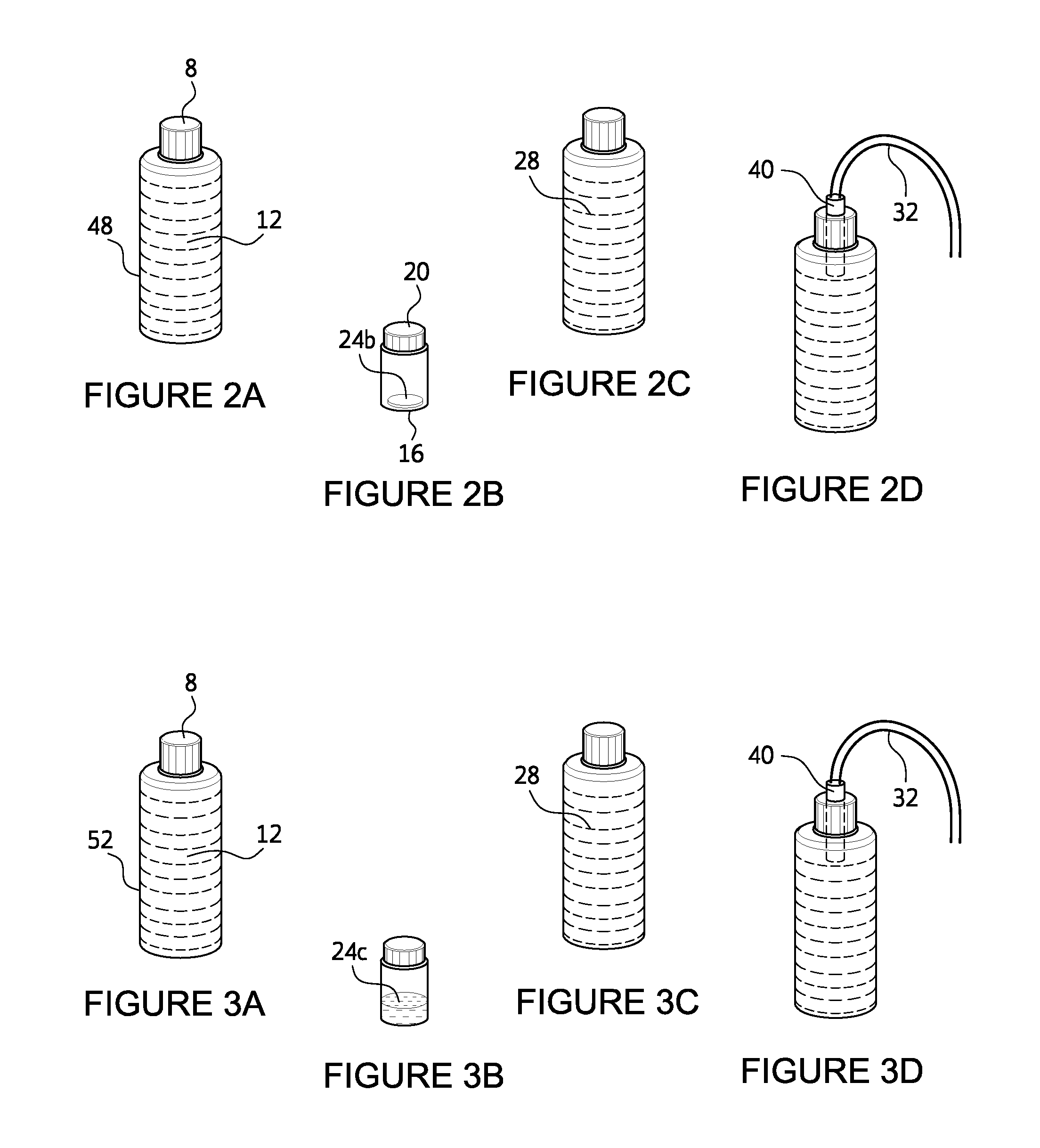

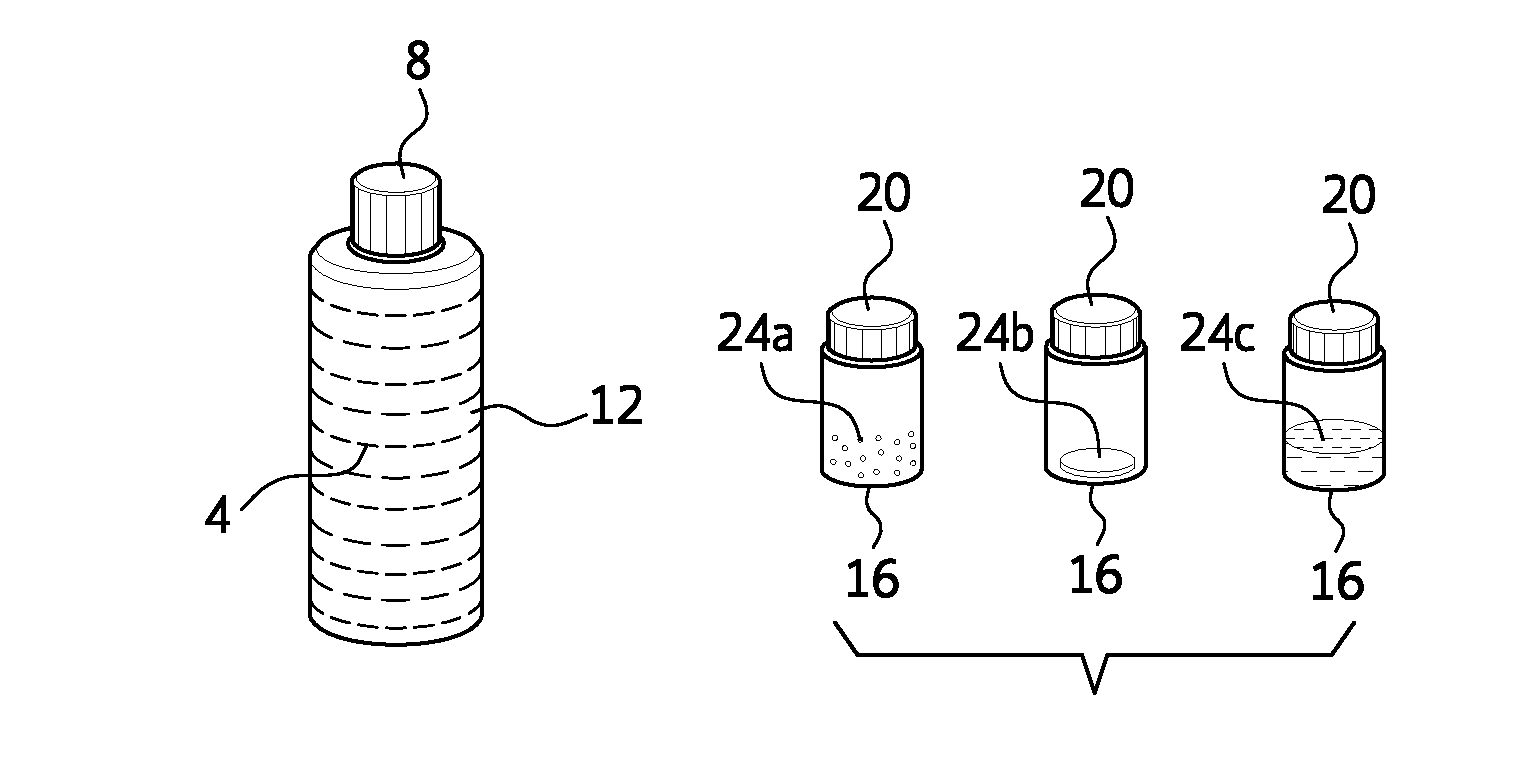

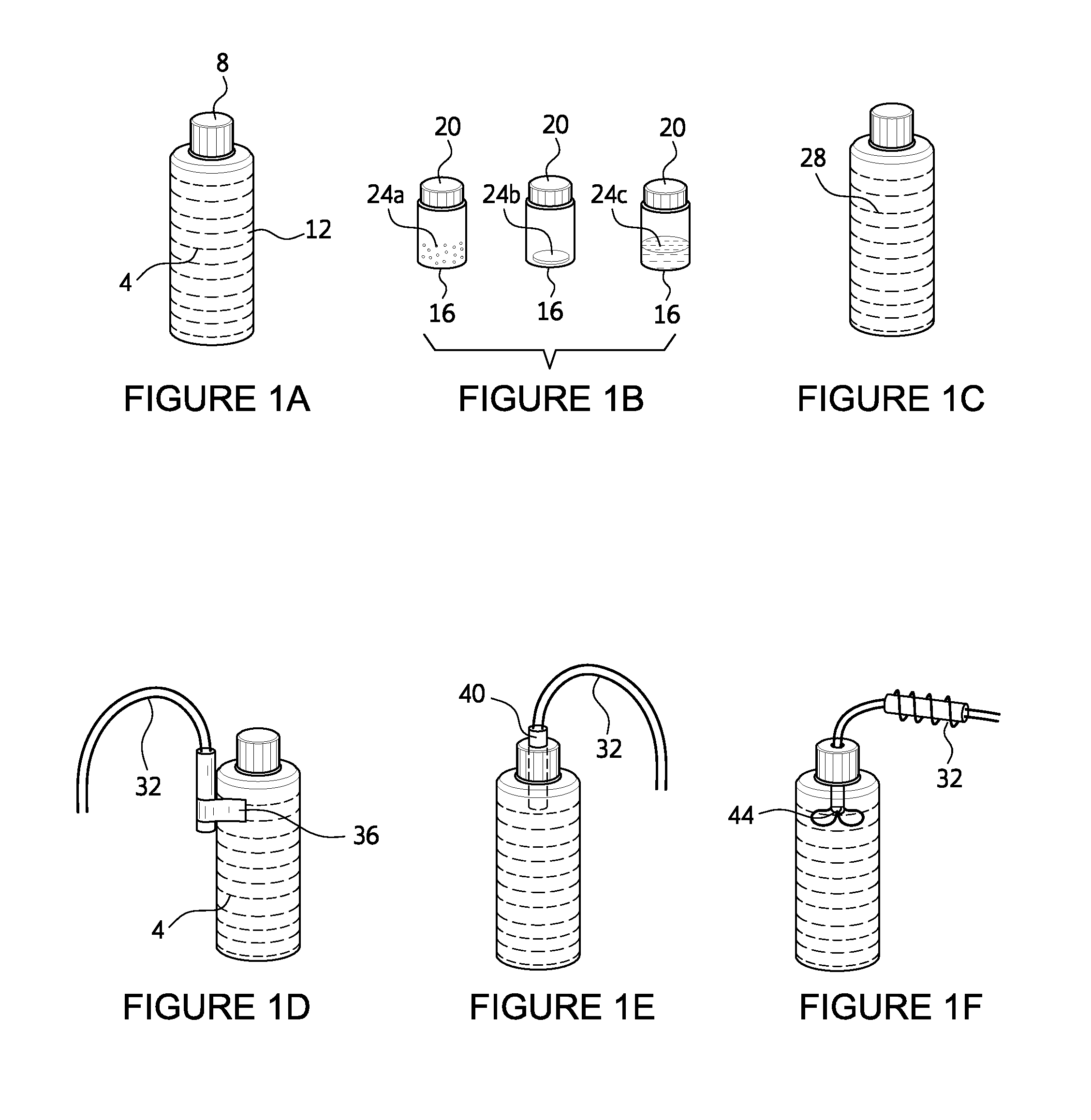

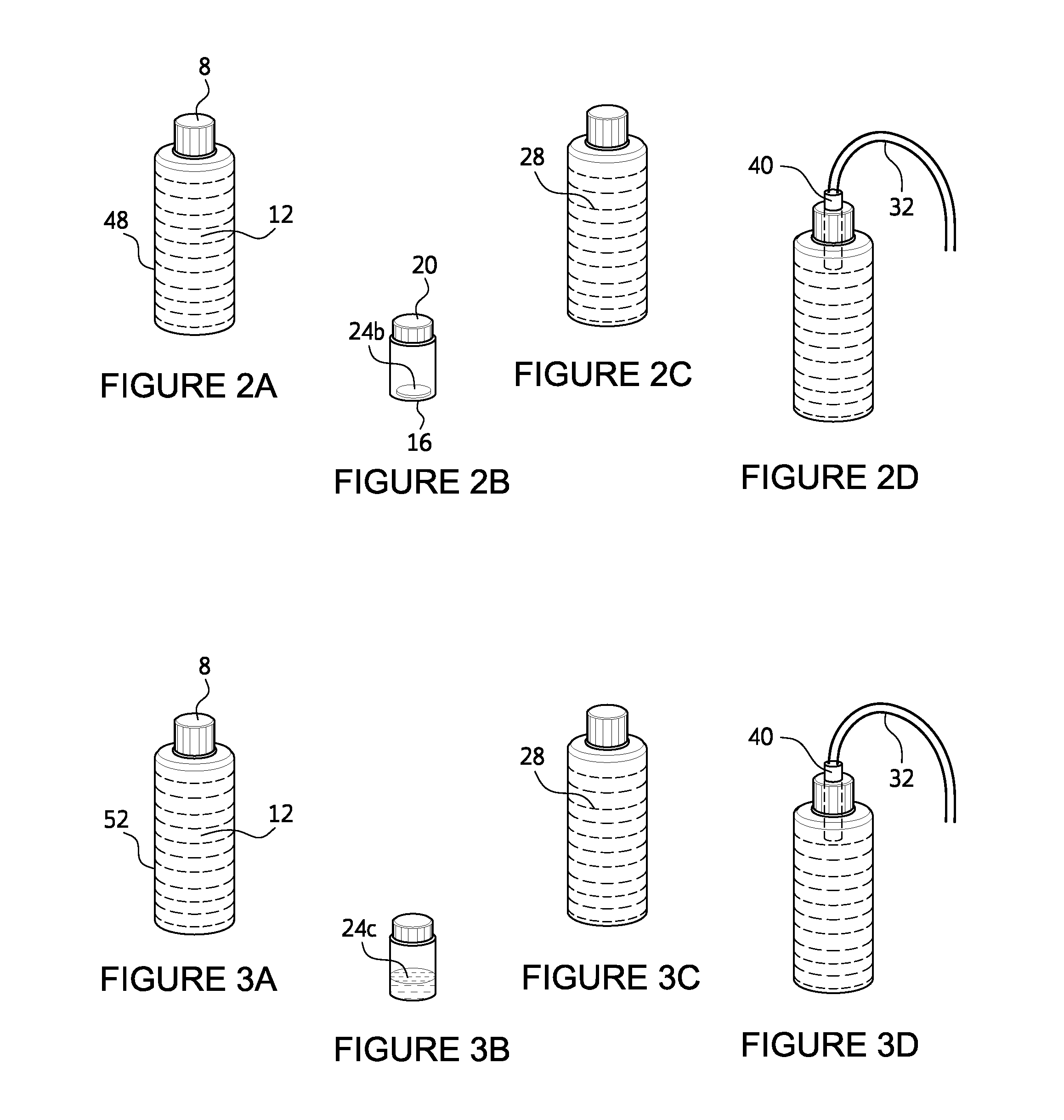

A low-cost, reliable and easy to use kit for neutralizing surface exposed landmine and unexploded ordnance for humanitarian demining is provided. The kit contains a liquid fuel and a solid / soluble fuel. Both fuels are premeasured in separate, sealed containers. The addition of a small quantity of solid / soluble fuel into the liquid creates an explosive. The resulting mixture is capable of detonating with a standard No. 8 blasting cap. The solid / soluble fuel can be in the form of a powder, tablet, or its saturated solution in water. The solid / soluble fuel is hexamethylenetetramine. The liquid fuel, nitromethane, is provided in premeasured quantities. User is provided instructions for choosing the appropriate quantity of liquid fuel, the corresponding solid / soluble fuel required, the method of mixing, placement and detonation of the kits. Also disclosed is a simple wooden stand to hold the bottle of explosive in place. A special fuel, liquid 2-ethylhexylnitrate, is provided to desensitize the mixed and sensitized explosive.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Simple low-cost hand-held landmine neutralization device

InactiveUS20150241179A1Easy to practiceExtended shelf lifeAmmunition projectilesDefence devicesDetonationHexamethylenetetramine

A low-cost, reliable and easy to use kit for neutralizing surface exposed landmine and unexploded ordnance for humanitarian demining is provided. The kit contains a liquid fuel and a solid / soluble fuel. Both fuels are premeasured in separate, sealed containers. The addition of a small quantity of solid / soluble fuel into the liquid creates an explosive. The resulting mixture is capable of detonating with a standard No. 8 blasting cap. The solid / soluble fuel can be in the form of a powder, tablet, or its saturated solution in water. The solid / soluble fuel is hexamethylenetetramine. The liquid fuel, nitromethane, is provided in premeasured quantities. User is provided instructions for choosing the appropriate quantity of liquid fuel, the corresponding solid / soluble fuel required, the method of mixing, placement and detonation of the kits. Also disclosed is a simple wooden stand to hold the bottle of explosive in place. A special fuel, liquid 2-ethylhexylnitrate, is provided to desensitize the mixed and sensitized explosive.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Non-toxic and non-corrosive ignition mixture

InactiveUS6964287B1High sensitivityEasy feedingLoomsNitroparaffin explosive compositionsNitrocellulosePolyvinyl alcohol

A non-toxic and non-corrosive ignition mixture is created by combining the energy system and the pyrotechnic system. The energy system comprises a high explosive from the groups of nitroesters and nitramines and a senzibiliser of the type of tetrazene or derivatives of tetrazoles for its activation. The pyrotechnic system comprises an oxidizing agent from the group of oxides and peroxides of metals, from the group of salts of inorganic oxygen-containing acids, and a fuel which is amorphous boron. The mixture is supplemented with a friction agent which is preferably ground glass. Nitrocellulose, polyvinyl alcohol and acacia gum are used as bonding agents. Mixtures are utilizable in the field of ammunition production for the production of primers, especially for central ignition cartridges.

Owner:SELLIER & BELLOT

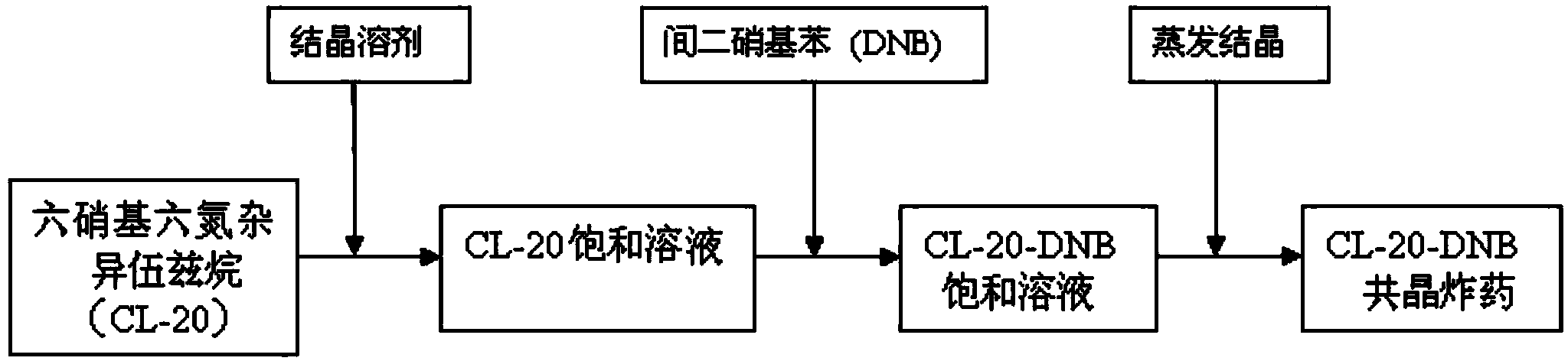

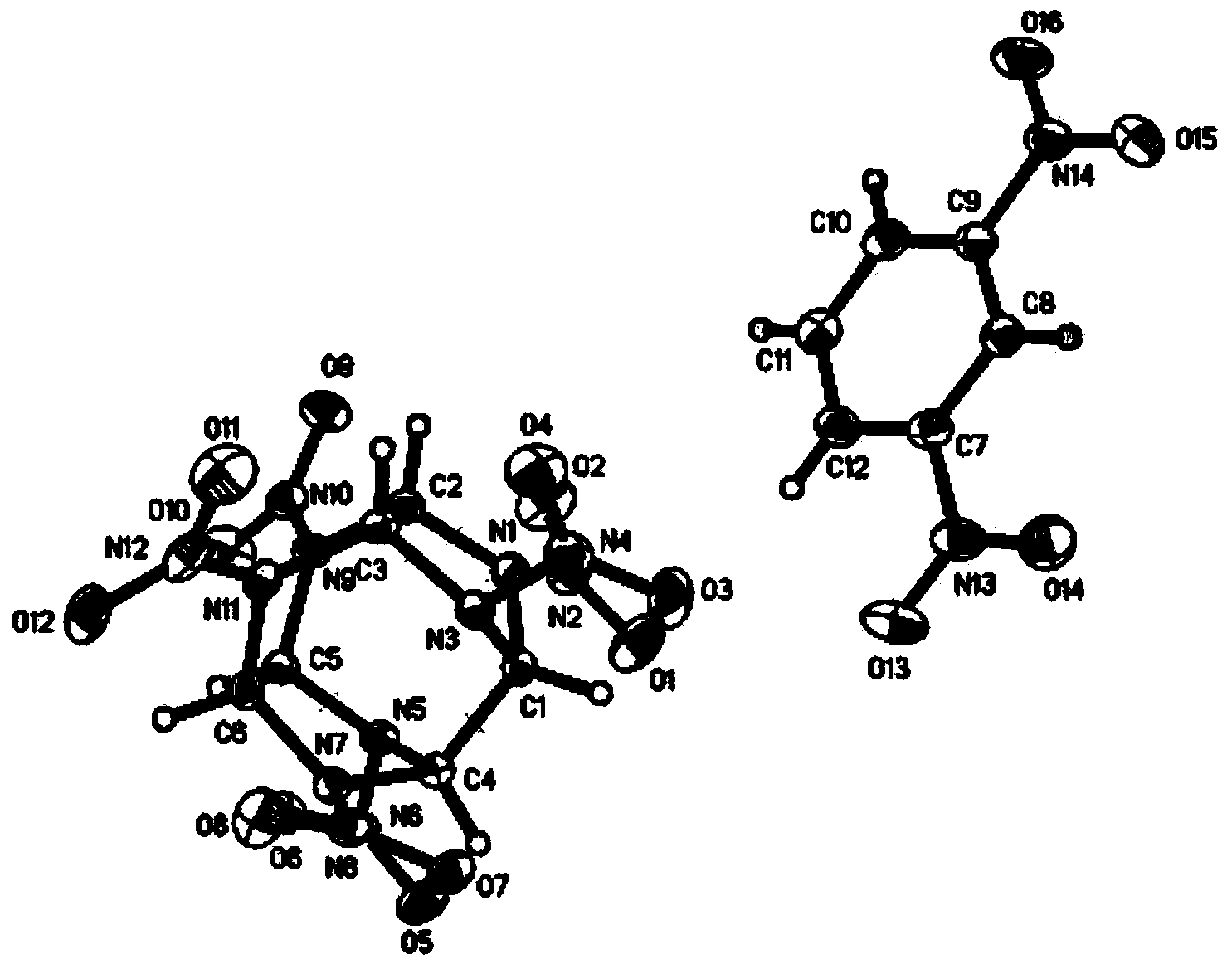

Preparation method for hexanitrohexaazaisowurtzitane and m-dinitrobenzene co-crystallized explosive

ActiveCN103396274AHigh detonation velocityIncrease burst pressureNitroparaffin explosive compositionsSolvent evaporationSolvent

The present invention discloses a preparation method for a hexanitrohexaazaisowurtzitane and m-dinitrobenzene co-crystallized explosive, wherein a crystallization solvent is adopted to prepare a hexanitrohexaazaisowurtzitane and m-dinitrobenzene saturated solution, and a constant temperature incubator is adopted to perform solvent evaporation and crystallization to obtain the hexanitrohexaazaisowurtzitane and m-dinitrobenzene co-crystallized explosive. According to the present invention, crystal density of the hexanitrohexaazaisowurtzitane and m-dinitrobenzene (CL-20-DNB) co-crystallized explosive is significantly increased by 19.6% compared with crystal density of DNB, detonation velocity and detonation pressure of the CL-20-DNB co-crystallized explosive are respectively increased by 46.2% and 147.5% compared to detonation velocity and detonation pressure of DNB, and the CL-20-DNB co-crystallized explosive has characteristics of a good detonation performance and high safety performance, and can be used for preparing low sensitivity ammunition.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

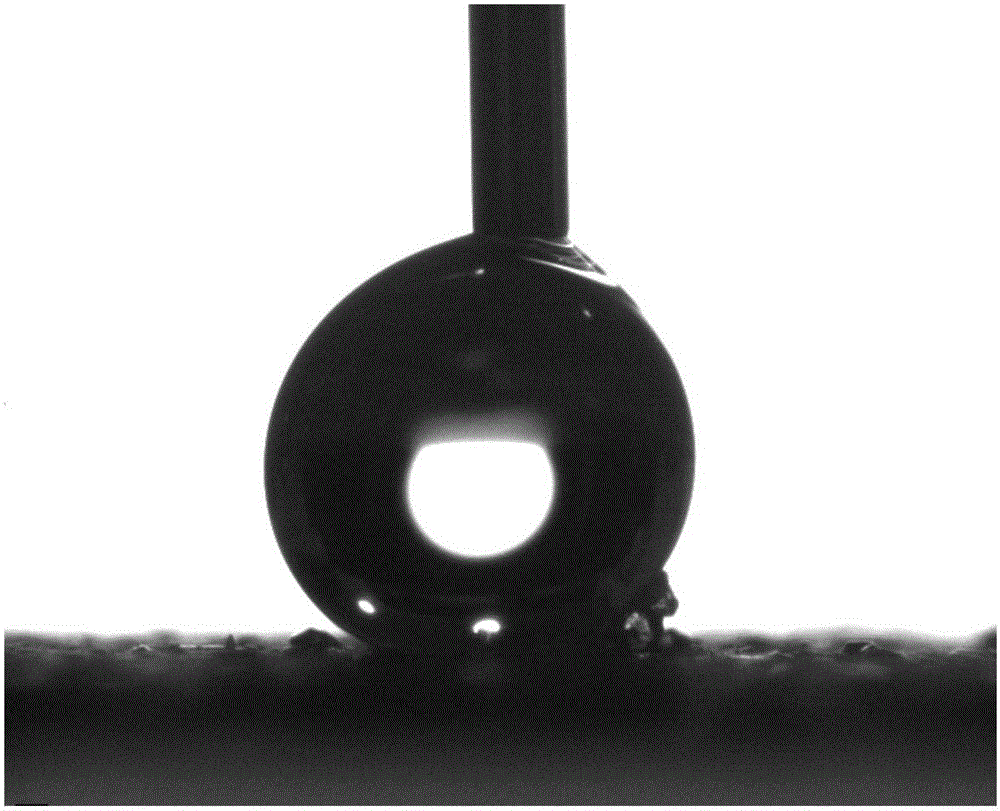

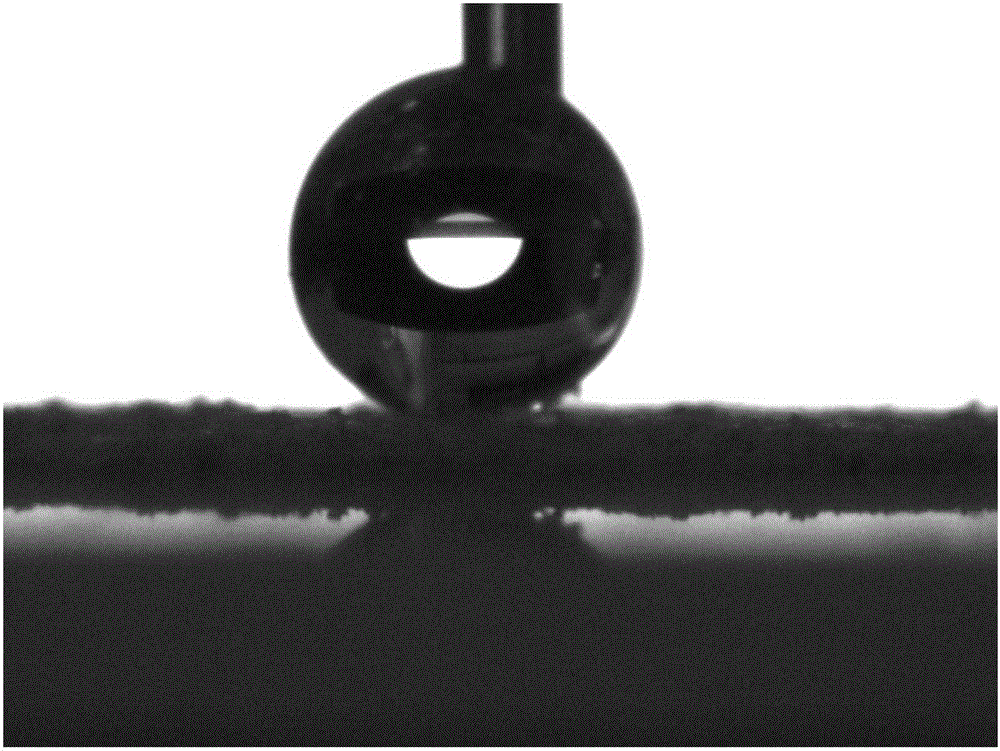

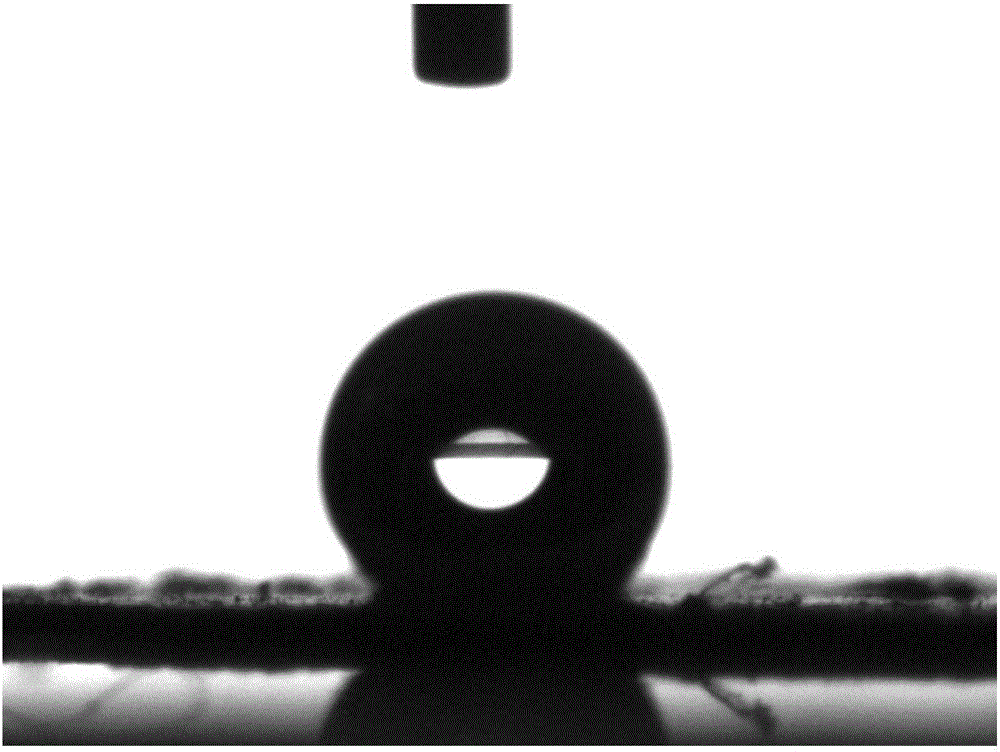

Preparation method of energetic material with controllable interface infiltration performance

ActiveCN106518582AReduce manufacturing costGood full wetting coating effectNitrated aromatic explosive compositionsNitroparaffin explosive compositionsTATBWater insoluble

The invention discloses a preparation method of an energetic material with controllable interface infiltration performance. The preparation method includes the steps that firstly, an energetic material with hydrophilicity is prepared; secondly, an energetic material wrapping specific nanometer particles is prepared; thirdly, washing and drying are conducted; fourthly, soaking with an alkyl siloxane solution is conducted; and fifthly, washing and drying are conducted, so that the energetic material with the controllable interface infiltration performance is obtained. The preparation method has the beneficial effects that expensive equipment and severe experiment conditions do not need to be used, and the production cost is reduced; the characteristics of convenience and rapidness are achieved, and good infiltration performance controllability is achieved; the energetic material which is prepared through the preparation method and has the controllable surface and interface infiltration performance is used for the field of PBX, the infiltration performance can be changed at any time according to changes of a bonding system, and a good solid-liquid complete infiltrating and wrapping effect is achieved; and water-insoluble energetic materials such as HMX, RDX and TATB can be used as modification matrixes, and the wide application range is achieved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Explosive composition for fireworks and method for manufacturing the same

InactiveUS6982014B1Laborious processNitrocellulose explosive compositionsNitroparaffin explosive compositionsNitro compoundNitrocellulose

A method for preparing a pyrotechnic composition which comprises preparing a composition in a gel form using nitrocellulose and a nitro compound other than nitrocellulose, adding an oxidizing agent, a combustible material and a color rendering agent to the composition, followed by mixing, forming the resultant mixture into a desired shape, and then drying; and a pyrotechnic composition obtainable by using the method. This method can be used for simplifying a production process while maintaining the effect of a star and a lance used in a pyrotechnic composition, particularly in a firework composition.

Owner:NIPPON KAYAKU CO LTD

Low mechanical sensitiveness high-energy composite explosive and preparation method

InactiveCN109053341ALow mechanical sensitivityReduced friction sensitivityNon-explosive desensitisers/phlegmatisersNitroparaffin explosive compositionsChemistryHigh energy

The invention discloses a low mechanical sensitiveness high-energy composite explosive which consists of NTO (Nitrogen Tetroxide) and CL-20, wherein the mass ratio of CL-20 to NTO is 1:(0.5-1.5). Thepreparation method comprises the following steps: putting an NTO explosive solid into water, stirring, and increasing the temperature till NTO is completely dissolved so as to obtain an NTO solution;putting the CL-20 explosive solid and a surfactant into water, controlling the temperature to be less than 20 DEG C, stirring so as to obtain a CL-20 water suspension, slowly putting the NTO solutioninto the water suspension of CL-20, filtering, washing, and drying, thereby obtaining the NTO / CL-20 composite explosive. The composite explosive disclosed by the invention has the advantages of beinghigh in density, high in explosion speed, low in mechanical sensitiveness, and the like, the mechanical sensitiveness of CL-20 is effectively degraded, and the security of CL-20 is improved.

Owner:XIAN MODERN CHEM RES INST

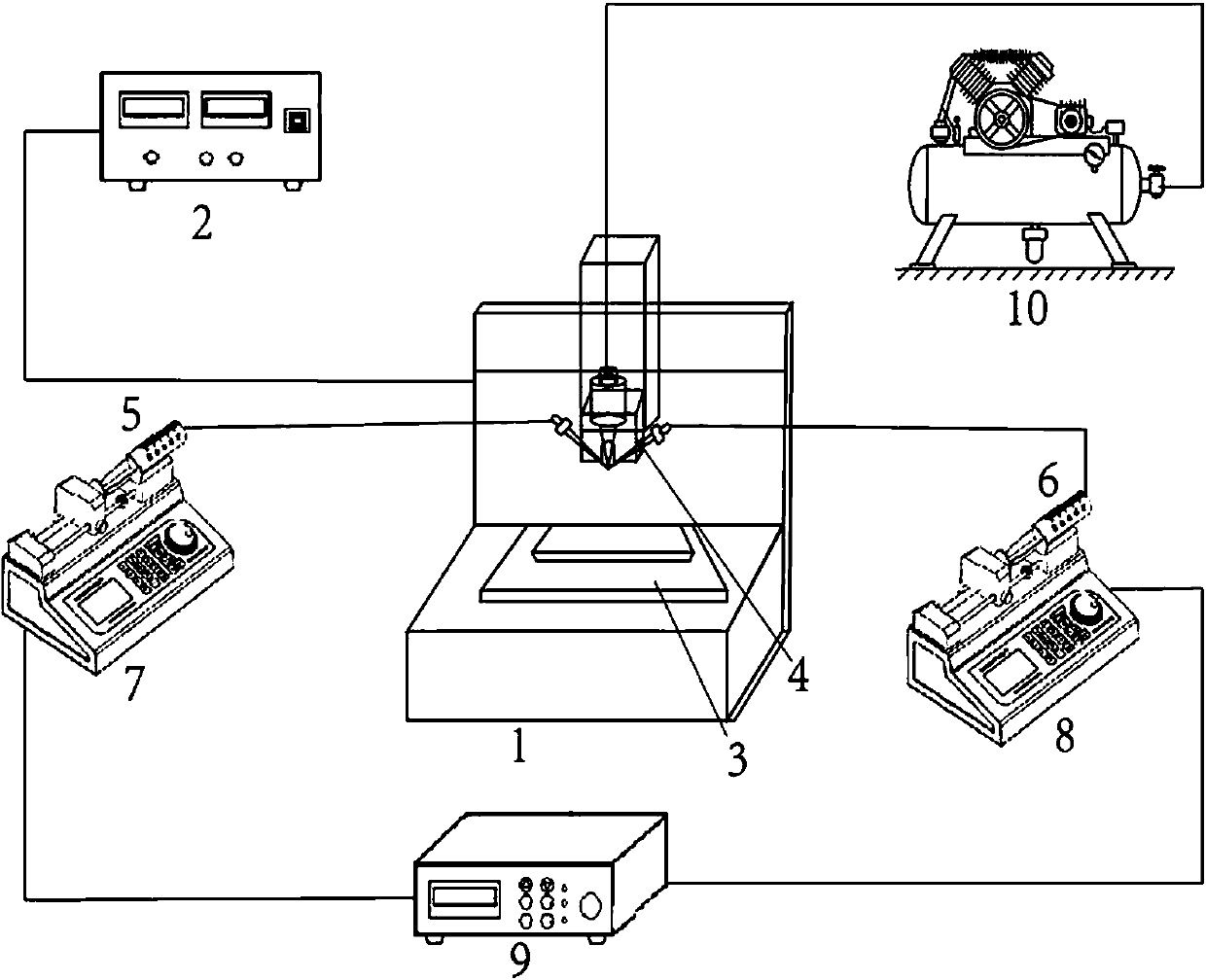

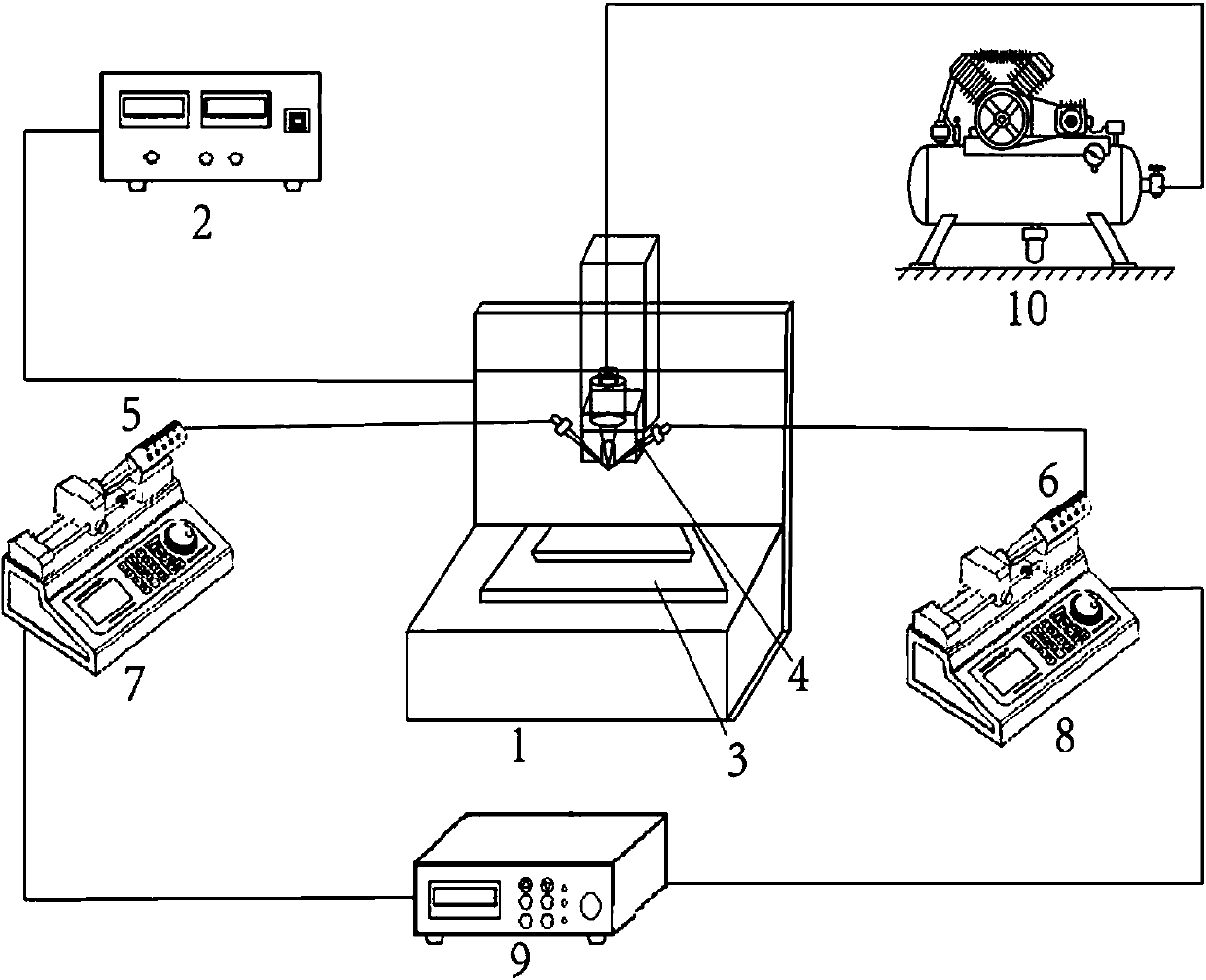

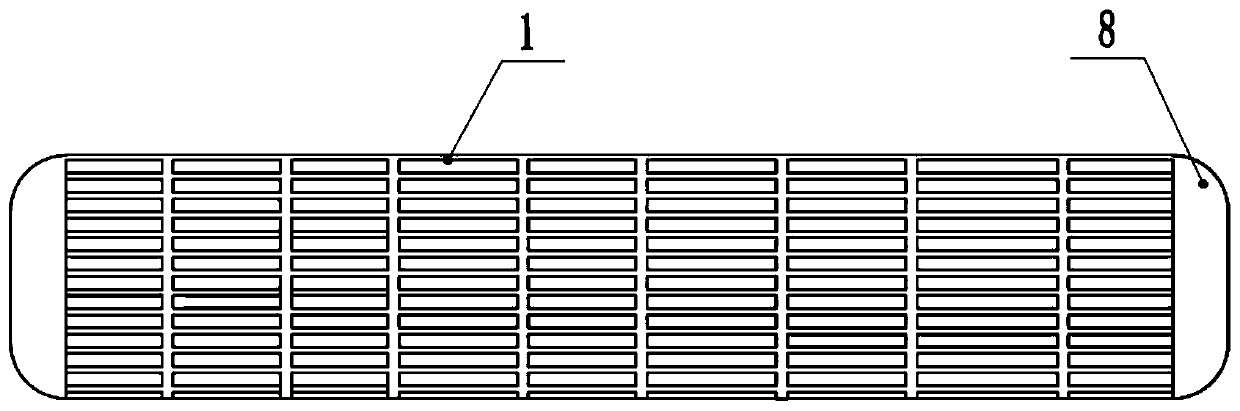

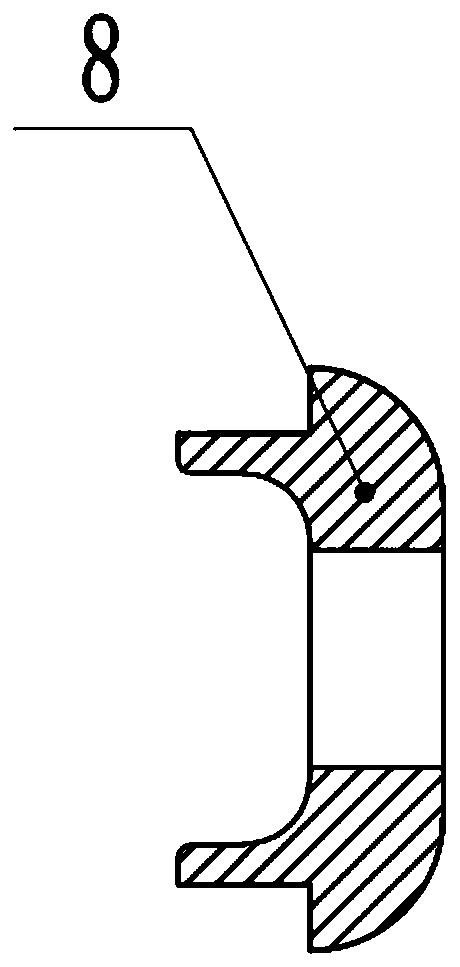

CL-20-based energetic film spraying material and micro-spraying direct-writing forming method

ActiveCN111170814AEffective controlFeed rate controllableExplosive working-up apparatusNitroparaffin explosive compositionsCrystallographyOrganic solvent

The invention discloses a CL-20-based energetic thin film spraying material and a micro-spraying direct-writing forming method thereof. The formula of the spraying material comprises the following components in parts by weight: 5-20 parts of CL-20; 0.5 to 2 parts of a binding agent; 20-48 parts of an organic solvent I; 20-48 parts of an organic solvent II; 0 to 5 parts of CL-20 seed crystal; and 0-2 parts of an auxiliary agent; wherein the forming process parameters are as follows: the spraying material feeding speed is 0.1-1ml / min, the micro-spraying direct-writing speed is 1-100mm / s, the distance between a spray head and a substrate is 20-50mm, the substrate temperature is 20-70 DEG C, and the air inlet pressure is 0.01-0.10 MPa. The formula of the spraying material contains a small amount of superfine epsilon-type CL-20 seed crystals, so that an epsilon-type CL-20-based energetic film is easy to obtain; the spraying material feeding speed is adjustable at 0.1-10 ml / min, the formingspeed is higher than that of an ink-jet printing process, and efficient and rapid preparation of the energetic film can be achieved.

Owner:ZHONGBEI UNIV

Wax composite insensitive agent with adjustable friction coefficient and preparation method thereof

PendingCN108456124ALow mechanical sensitivityImprove securityNon-explosive desensitisers/phlegmatisersNitroparaffin explosive compositionsWaxEnergetics

The invention belongs to the field of energetics, and particularly provides a wax composite insensitive agent with an adjustable friction coefficient and a preparation method thereof. The wax composite insensitive agent comprises wax materials and functional agents; the functional agents are selected from at least one of graphene, graphene oxide, nitrified graphene, fluoridized graphene, molybdenum disulfide, tungsten disulfide, graphene and carbon nanotube. The adjustable range of the friction coefficient of the wax composite insensitive agent is 0.03-0.25, the content of the composite insensitive agent only covers 1.5%-3% of the mass of energetic compounds such as RDX, HMX, CL-20, AP and the like, mechanical sensitivity of the energetic compounds can be significantly reduced, the safetyperformance of the energetic compounds can be greatly improved to further improve the content application safety performance of the energetic compounds in the energetic materials such as composite explosive, propellent and the like, and the preparation method is simple in process, economic and effective.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

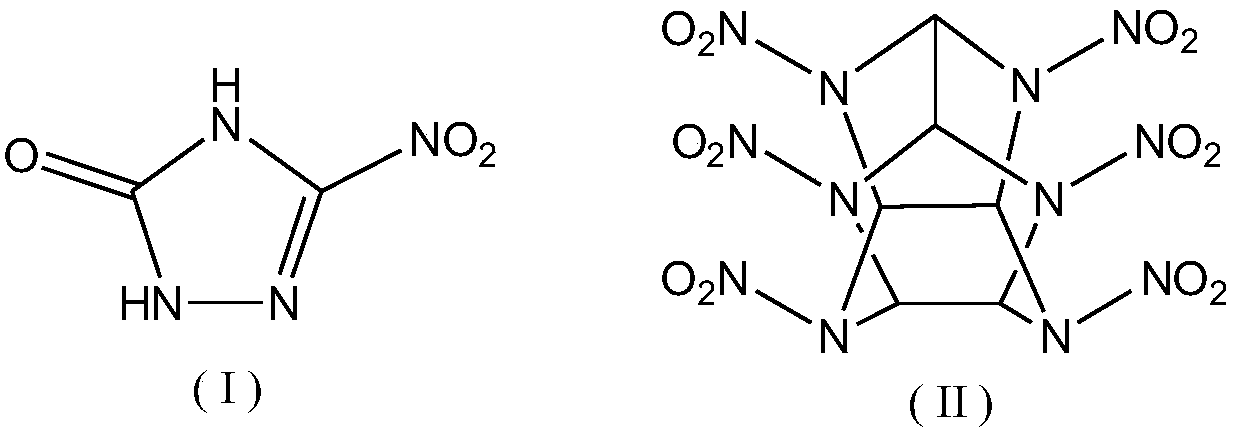

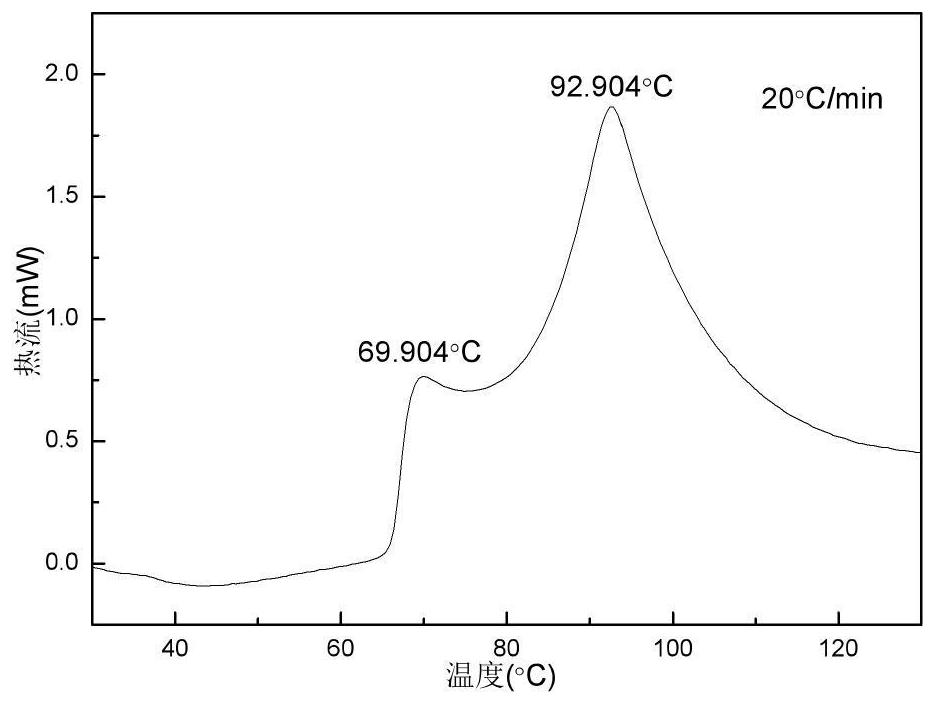

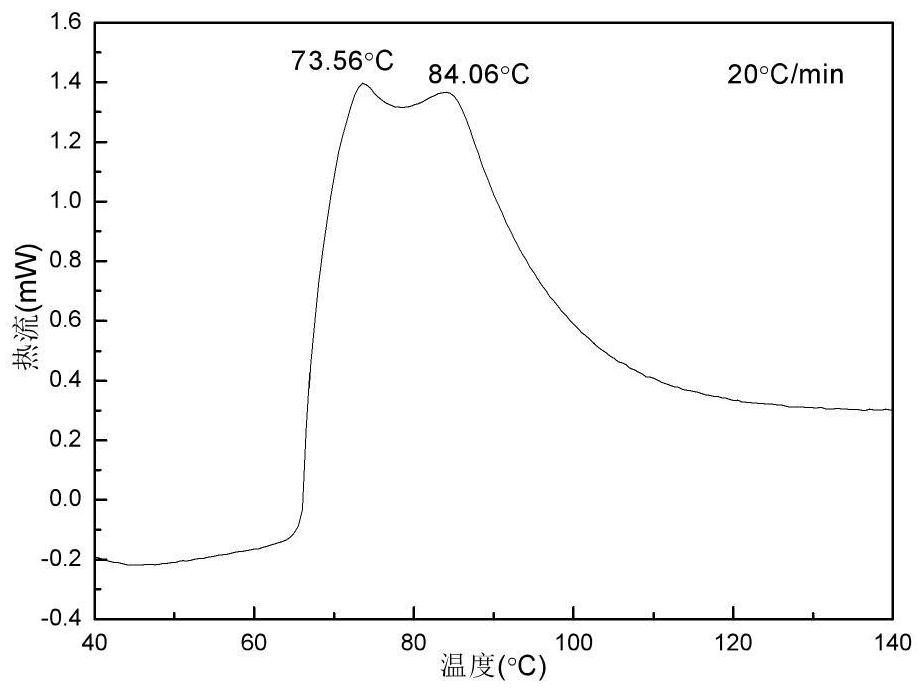

Preparation method of MTNP/TNAZ eutectic mixture

ActiveCN111875456AImprove securityEnsure safetyNitroparaffin explosive compositionsExplosive ingredient compoundingOrganic solventMetallurgy

The invention discloses a preparation method of an MTNP / TNAZ eutectic mixture. The preparation method comprises the following steps: (1) adding MTNP and TNAZ into an organic solvent to prepare a solution, wherein the molar ratio of MTNP to TNAZ is 1-3 : 1-3; (2) controlling the flow rate by using an injector, slowly dropwise adding the prepared solution into an anti-solvent, and continuously performing stirring in the process. According to the invention, a solvent anti-solvent method is adopted, experimental operation can be conducted at the room temperature, the link that a water area or an oil bath is used for heating and temperature rising in the melting process of a traditional melting method is effectively avoided, and the safety and convenience of an experiment are greatly improved;in addition, the eutectic prepared by using the solvent anti-solvent method is higher in quality, more uniform in mixing and very stable in performance, and the defect that different batches of eutectic prepared by using a traditional melting method are different in performance is completely avoided, so the proportion of the obtained lowest eutectic is more accurate.

Owner:ZHONGBEI UNIV

Fiber-reinforced rubber explosive and preparation method thereof

ActiveCN106748591AOvercoming Process ComplexityOvercoming dangerNitroparaffin explosive compositionsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsPolymer scienceReinforced rubber

The invention relates to the field of explosive processing, and in particular relates to a fiber-reinforced rubber explosive and a preparation method thereof. The problems in the existing explosive processing technology that the mechanical properties are poor and the process is complicated and has dangerousness are solved. The fiber-reinforced rubber explosive is composed of the following raw materials in parts by mass: 5-20 parts of rubber, 55-90 parts of high explosives, 2-5 parts of chopped fibers and 3-10 parts of additives. The invention has the beneficial effects that the prepared explosive has excellent mechanical properties and adjustable detonation velocity and detonation output energy; and with the adoption of recyclable rubber powder and chopped fibers, recycling of wastes is realized; the fiber-reinforced rubber explosive has the advantages that the production process is simple, the components are uniformly mixed, and batch production can be realized; and the fiber-reinforced rubber explosive is used in the explosion working industry and can also be used in other special industries, particularly operations in low-temperature environments.

Owner:灵石县安盛工程爆破有限公司

High-thermal stability PBX explosive and preparation method thereof

InactiveCN109836300AGood thermal stabilityWith high explosive contentExplosive working-up apparatusNitroparaffin explosive compositionsAcetic acidHigh energy

The invention provides a high-thermal stability PBX explosive and a preparation method thereof. The explosive comprises, by mass, 84-88% of cyclotetramethylenetetranitramine, 8-12% of triaminotrinitrobenzene and 2-6% of a bonding system; and a binder in the bonding system is polyacrylate rubber HyTemp 4454, and a plasticizer in the bonding system is dioctyl sebacate or dioctyl phthalate. The preparation method comprises the following steps: dissolving the bonding system by analytically pure ethyl acetate through adopting a solvent volatilization process, carrying out vibrating dispersion on TATB in analytically pure petroleum ether, and pouring the obtained bonding system solution into an HMX explosive while stirring until the solvent is completely volatilized; and adding the obtained TATBsuspension, performing stirring for 1-2 h until the solvent volatilizes to form a paste, sieving the paste to form 0.5-1.0 mm particles, and drying the particles to obtain the PBX explosive. The PBXexplosive prepared in the invention has the advantages of high energy, low mechanical sensitivity and good thermal stability.

Owner:NANJING UNIV OF SCI & TECH

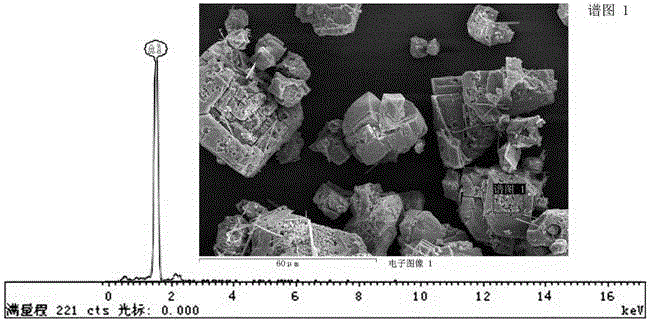

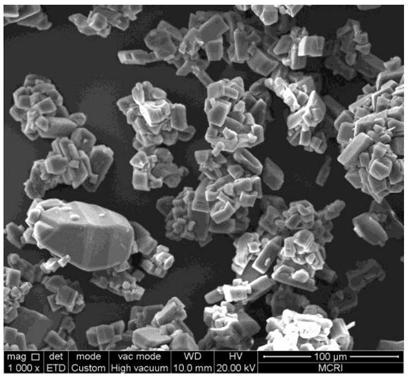

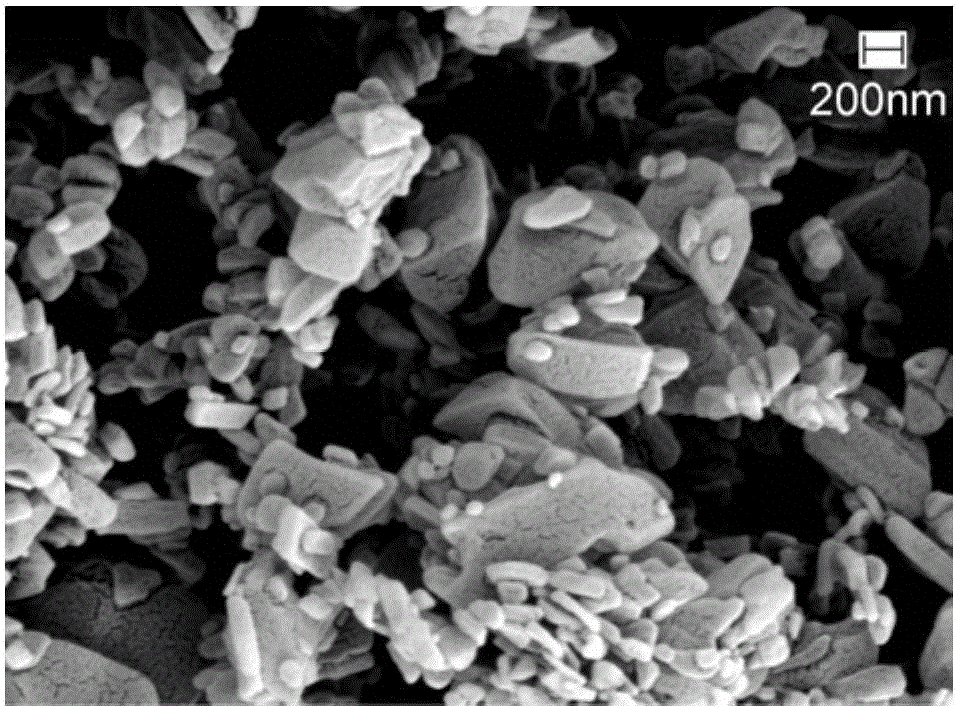

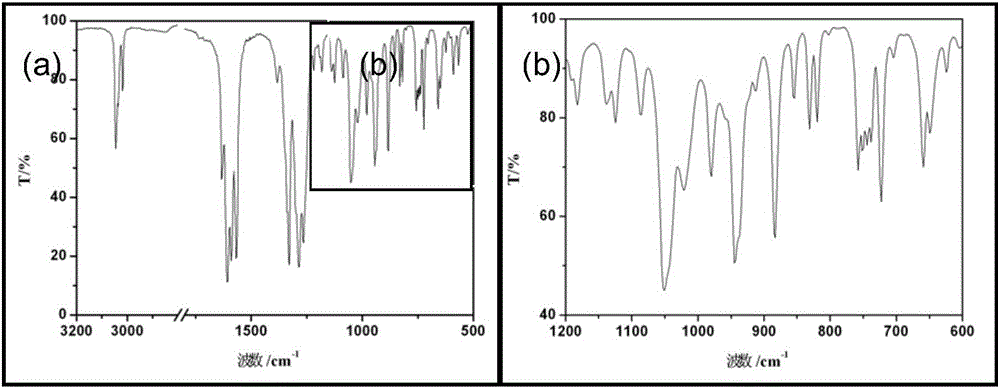

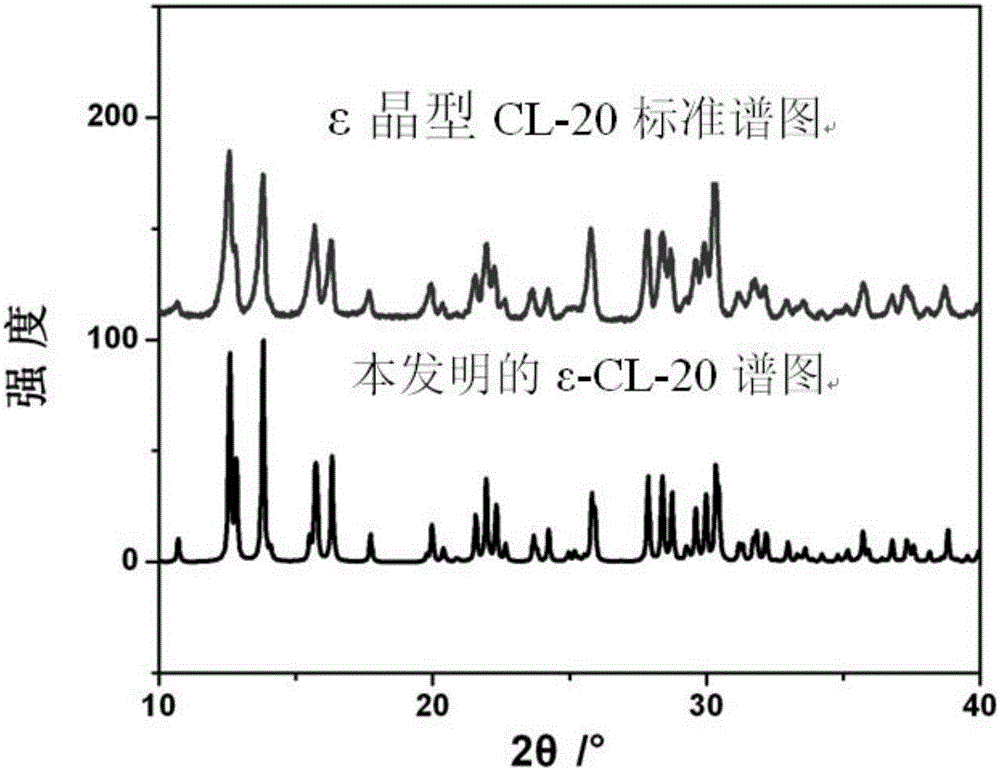

Nano epsilon crystal form hexanitrohexaazaisowurtzitane (CL-20) explosive and massive preparation method thereof

ActiveCN106518883ASimple processSimple and fast operationOrganic chemistry methodsNitroparaffin explosive compositionsNon solventGram

The invention discloses a nano epsilon crystal form hexanitrohexaazaisowurtzitane (CL-20) explosive and a massive preparation method thereof. The preparation method is characterized by comprising the following steps: dissolving CL-20 explosive into a solvent to prepare an explosive solution; pre-cooling a non-solvent; heating the explosive solution to a certain temperature, ejecting the explosive solution into the pre-cooled non-solvent under stirring and ultrasonic waves, and finally carrying out solid-liquid separation, washing, purification, and drying to obtain the nano epsilon crystal form hexanitrohexaazaisowurtzitane (CL-20) explosive. The problem solves the problem that in a conventional solvent-non-solvent rapid crystallization method, crystal transformation of CL-20 happens easily; the epsilon crystal form hexanitrohexaazaisowurtzitane (CL-20) explosive is obtained through direct crystallization; the technical process is simple, the operation is convenient, moreover, the epsilon crystal form hexanitrohexaazaisowurtzitane (CL-20) explosive can be produced in batches, and the yield of each batch can reach 100 grams. By optimizing the technological parameters, epsilon crystal form CL-20 powder with an average particle size less than 500 nm can be obtained.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

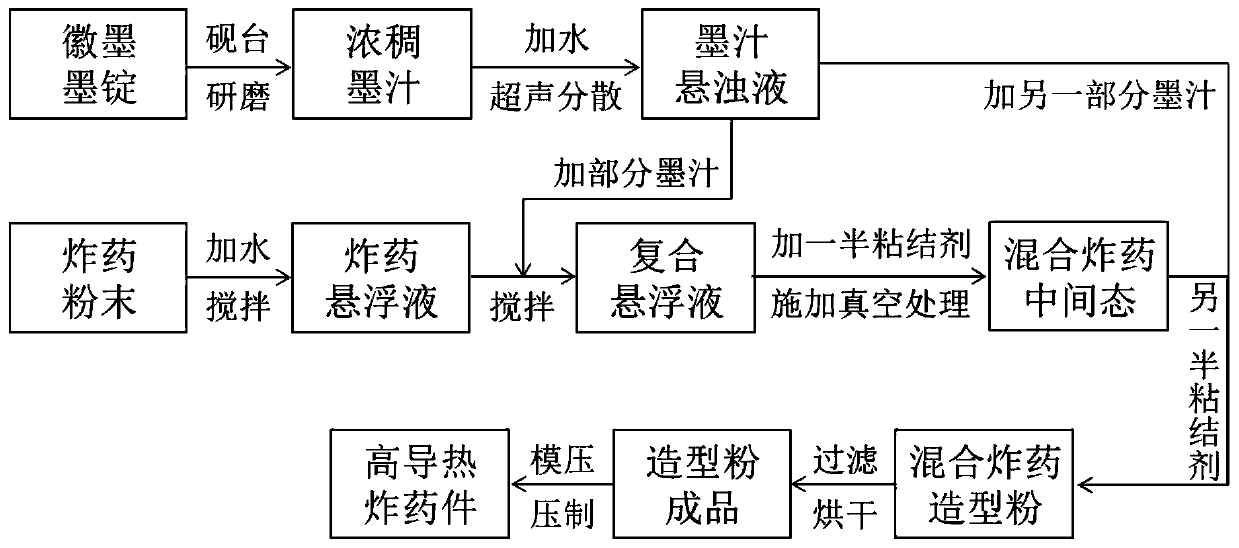

Method for improving heat conduction performance of mixed explosive

ActiveCN110183291AGood dispersionImprove thermal conductivityNon-explosive fillers/gelling/thickening agentsStarch/sugar nitrate explosive compositionsEngineeringCarbon nanomaterials

The invention discloses a method for improving heat conduction performance of a mixed explosive, and belongs to the technical field of energetic composite materials. The method comprises the followingsteps: step 1, adding water into an ink stick for grinding the ink stick in a inkstone, adding a proper amount of a surfactant, and carrying out ultrasonic dispersing to obtain an ink turbid liquid;and step 2, adding the ink turbid liquid into an explosive by two stages, dropwise adding a high polymer binder to prepare explosive molding powder by a water suspension granulation method, carrying out filtering, water washing and drying, and pressing the explosive molding powder into a reagent column to obtain the mixed explosive with heat conduction performance. According to the invention, a natural hybrid carbon nano material in the ink stick is used as heat conduction filler, and meanwhile, good adhesion capability of the natural hybrid carbon nano material is fully utilized, so that heatconduction performance of the mixed explosive is improved. The method disclosed by the invention has the advantages that the effect is remarkable, the preparation process is simple, amplification iseasy, universality is strong, and the method is suitable for all types of mixed explosives.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

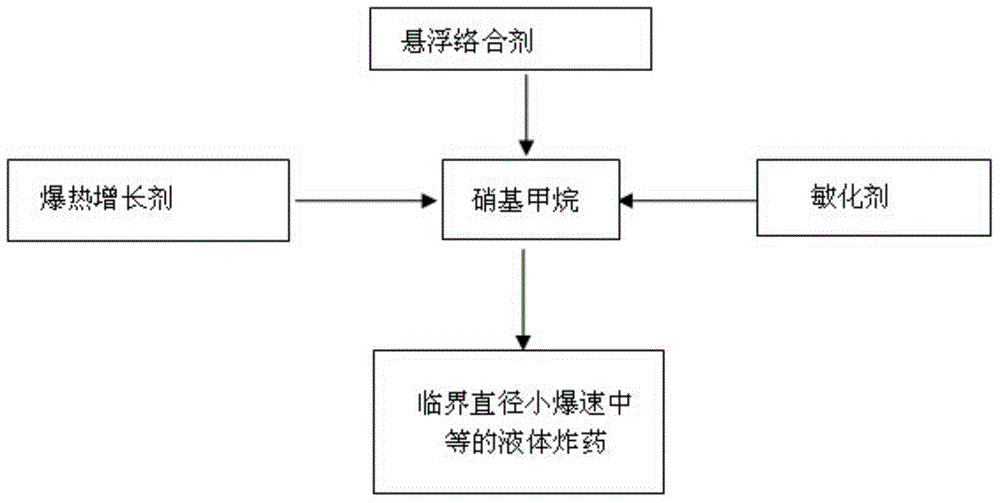

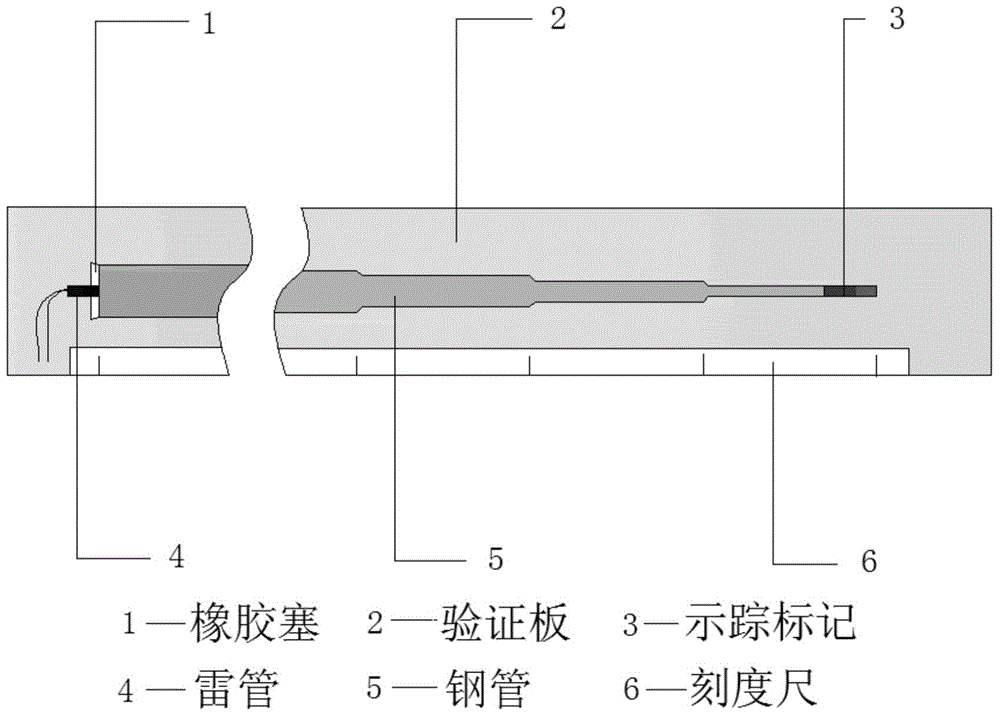

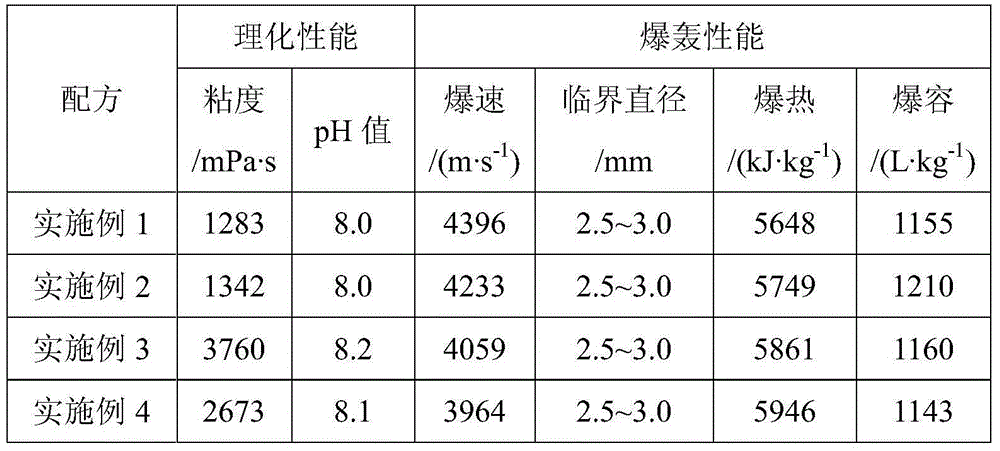

Liquid explosive with small critical diameter and medium detonation velocity and preparation technology thereof

InactiveCN105712808ALow detonation velocityReduce critical diameterNitroparaffin explosive compositionsNitromethaneBuffering agent

The invention discloses a liquid explosive with a small critical diameter and medium detonation velocity and a preparation technology thereof. The liquid explosive is composed of the following components in percentage by weight: 60 to 90% of nitromethane, 3 to 10% of sensitizing agent, 5 to 20% of performance buffering agent, and 2 to 10% of complexing agent. The liquid explosive has the following characteristics: (1) the mechanical sensitiveness is low, and the operation is safe; (2) the detonation is reliable, the critical diameter is small, and the energy is proper; (3) the fluidity is good, and thus the liquid explosive is suitable for long distance pumping; (4) the whole system is in a weak alkali state and is non-corrosive to metals; (5) the preparation method is simple, the price is low, and the liquid explosive can be mixed onsite before using. The liquid explosive is applied to oil and gas exploitation and is especially suitable for oil and gas exploitation in low permeable hard rock areas.

Owner:NANJING UNIV OF SCI & TECH +1

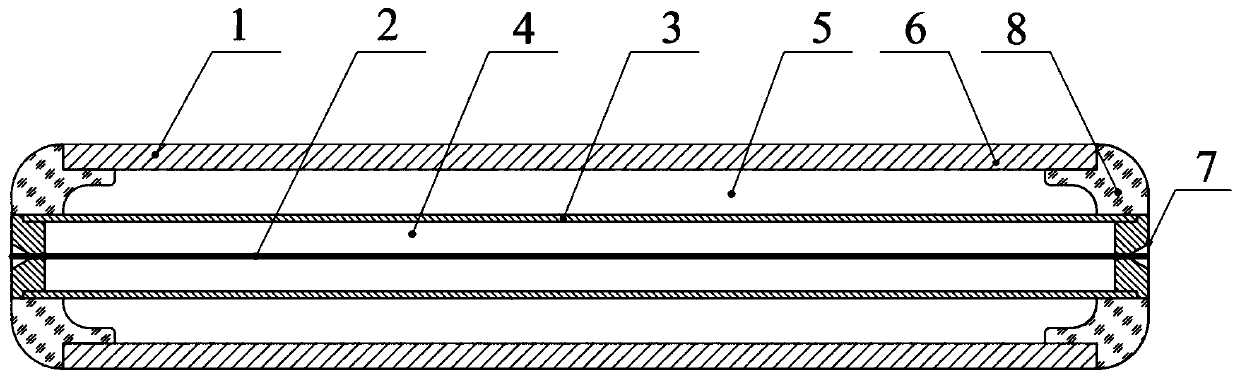

Composite liquid rock breaking rod used for generating controllable shock waves and manufacturing method of composite liquid rock breaking rod

ActiveCN111472773AImprove securityShock wave strengthDisloding machinesUnderground miningMineral SourcesMetal filament

The invention relates to a composite liquid rock breaking rod used for generating controllable shock waves and a manufacturing method of the composite liquid rock breaking rod, and aims to solve the problem that mining of mineral resources is restricted due to the defect that the electric energy storage density is low when the the mineral resources are mined through metal wire electric explosion.According to the composite liquid rock breaking rod used for generating the controllable shock waves, a shell and an inner pipe are both hollow straight pipes with two closed ends, the shell sleeves the inner pipe coaxially, the outer diameter of the shell is 35-40 mm, the length of the shell is 380-430 mm, a metal wire is arranged along the axis of the shell and the inner pipe, the two ends of the metal wire extend out of the shell and are fixedly installed, powdery energetic materials fill the interior of the inner pipe, and liquid energetic materials fill the space between the inner pipe and the shell. The manufacturing method of the composite liquid rock breaking rod used for generating the controllable shock waves comprises the steps of preparing all components, assembling the metal wire, an inner pipe end and the inner pipe, filling the inner pipe with the powdery energetic materials and packaging the powdery energetic materials through the inner pipe end, assembling the inner pipe, an end cover and a straight pipe, and filling the straight pipe with the liquid energetic materials and packaging the liquid energetic materials through the end cover.

Owner:西安闪光能源科技有限公司

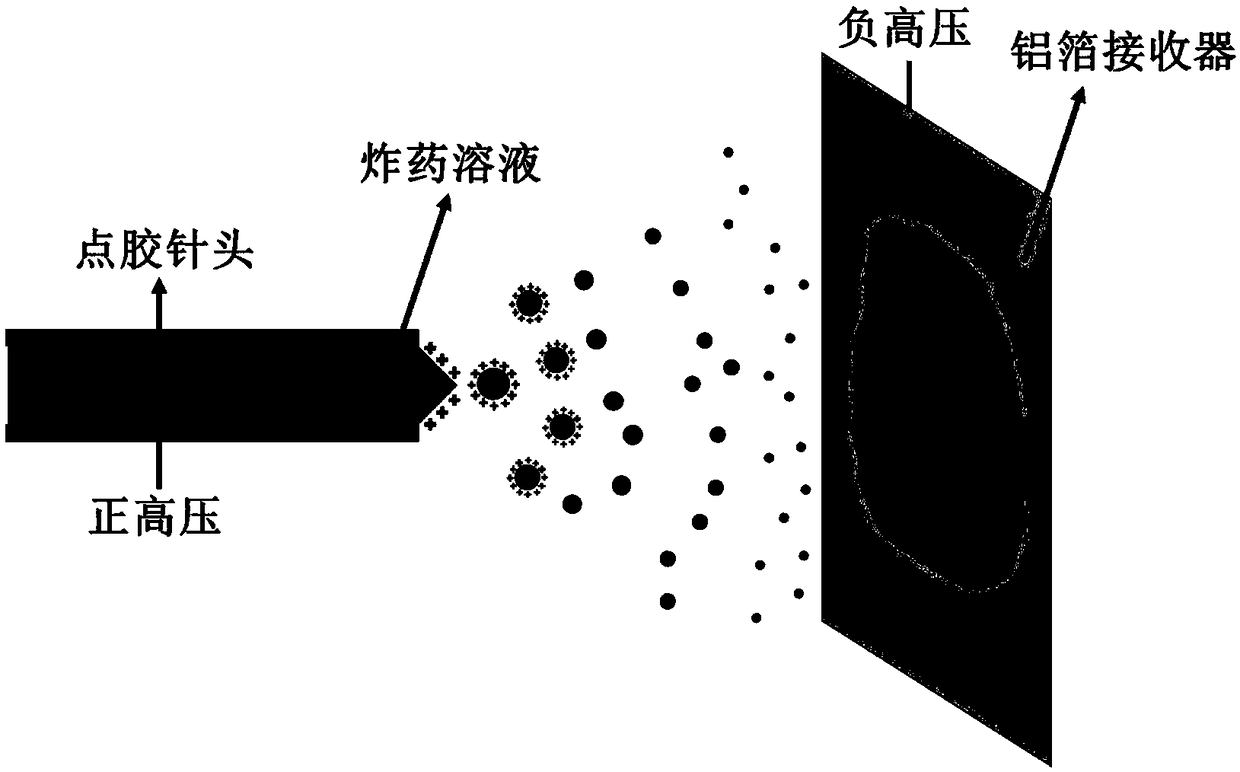

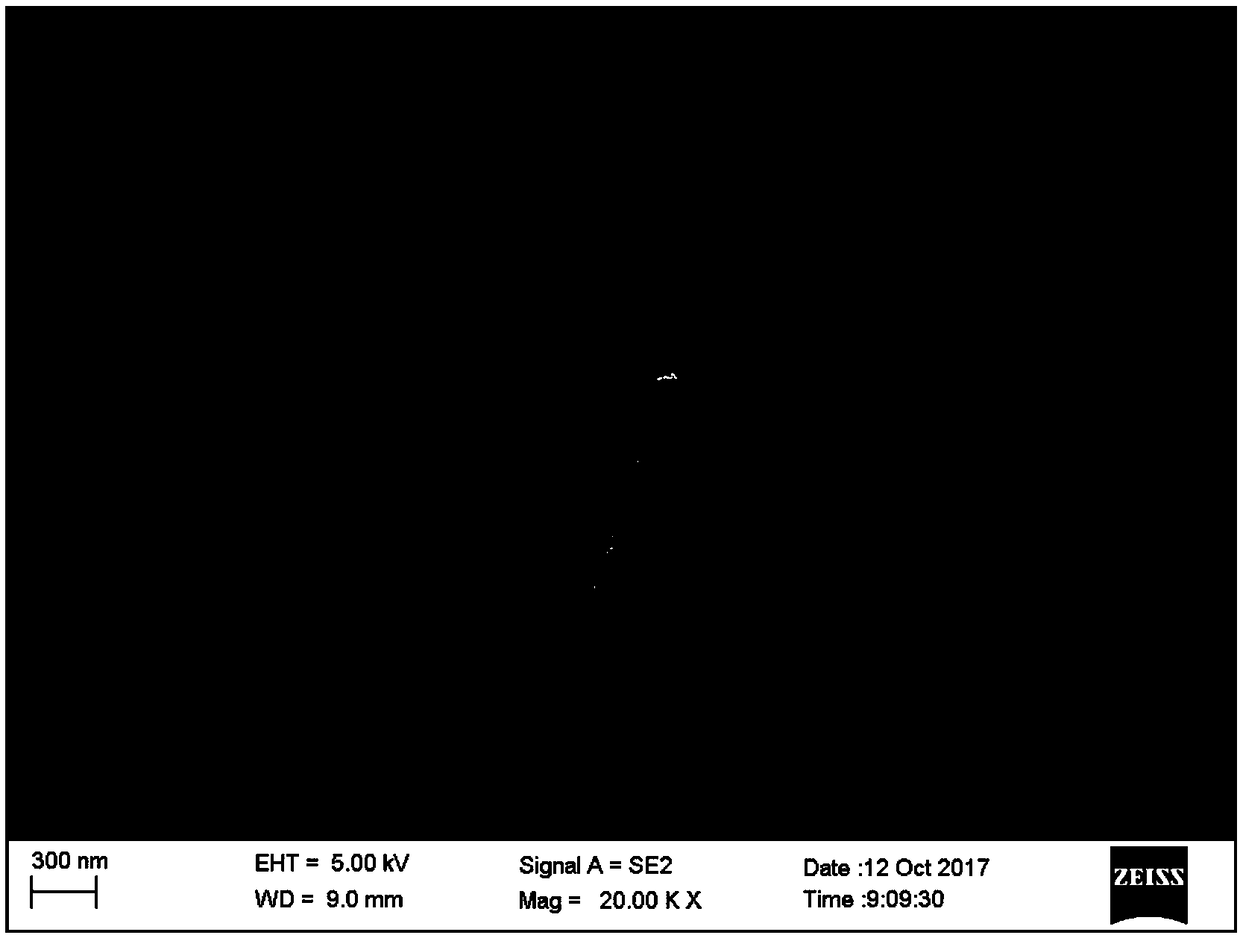

Nano eutectic explosive and preparation method thereof

InactiveCN108164378AImprove mechanical sensitivityNarrow particle size distributionExplosive working-up apparatusNitroparaffin explosive compositionsMagnetic tension forceOrganic solvent

The invention discloses a preparation method of a nano eutectic explosive. The preparation method comprises following steps: step one, weighing CL-20 and a TNB explosive according to a mole ratio of 1:1, adding the mixture into a good organic solvent, and stirring the solvent by a magnetic force at a room temperature so as to completely dissolve the explosives until the solution becomes transparent and clear; step two, sucking the explosive solution obtained in the step one by a syringe with a dispensing needle, placing the syringe on a micro boost pump, setting the parameters of the boost pump, and adjusting the distance between the needle and a collector; and step three, opening a high voltage power supply, adjusting the voltage, when a Taylor cone appears on the metal needle, maintaining the current experimental conditions, and after a period of spraying, collecting the CL-20 / TNB nano eutectic explosive on a collection plate. The novel CL-20 / TNB nano eutectic explosive has the advantages that the size distribution of the explosive particles is narrow, and the mechanical sensitiveness of CL-20 is improved effectively.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com