Low mechanical sensitiveness high-energy composite explosive and preparation method

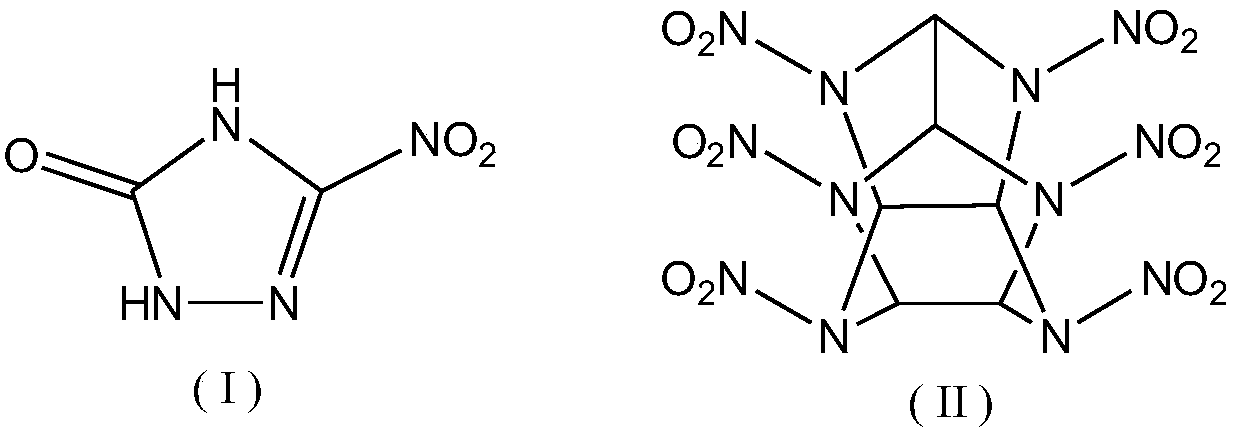

A technology of mechanical sensitivity and composite explosives, which is applied in the direction of explosives, non-explosive/non-thermal agent components, non-explosive desensitizers/passivators, etc., can solve the problem of reducing the detonation output energy of CL-20 explosives, and achieve a reduction The effect of mechanical sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Add 50g of water to the three-neck flask with stirring, then add 5g of NTO explosive solid, the stirring speed is 200r / min, raise the temperature to 80°C until the NTO is completely dissolved, and keep it warm for later use;

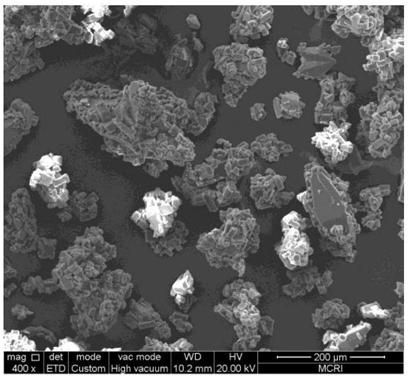

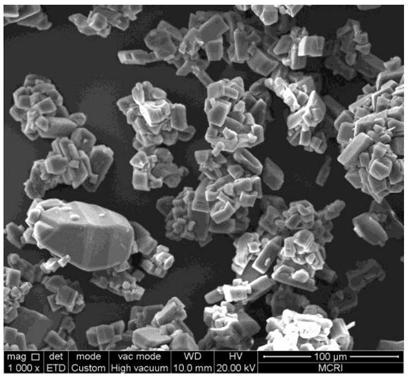

[0022] (2) Add 50g of water to the three-necked flask with stirring, control the temperature of the water at 0°C to 5°C, then add 5g of CL-20 explosive solids and 0.02g of polyvinyl alcohol, and the stirring speed is 300r / min to obtain The aqueous suspension of CL-20, and then the NTO aqueous solution obtained in step (1) is slowly added to the aqueous suspension of CL-20, filtered, washed and dried to obtain NTO / CL-20 composite explosive.

Embodiment 2

[0024] (1) Add 75g of water to the there-necked flask with stirring, then add 5g of NTO explosive solid, the stirring speed is 200r / min, heat up to 80°C until the NTO is completely dissolved, and keep warm for later use;

[0025] (2) Add 100g of water to the three-neck flask with stirring, control the temperature of the water at 0°C to 5°C, then add 10g of CL-20 explosive solid and 0.05g of polyvinyl alcohol, and stir at a speed of 300r / min to obtain CL -20 aqueous suspension, then the NTO aqueous solution obtained in step (1) is slowly added to the CL-20 aqueous suspension, filtered, washed and dried to obtain NTO / CL-20 composite explosive.

Embodiment 3

[0027] (1) Add 100g of water to the three-neck flask with stirring, then add 7.5g of NTO explosive solid, the stirring speed is 200r / min, raise the temperature to 80°C until the NTO is completely dissolved, and keep it warm for later use;

[0028] (2) Add 50g of water to the three-neck flask with stirring, control the temperature of the water at 0°C to 5°C, then add 5g of CL-20 explosive solids and 0.03g of polyvinyl alcohol, and the stirring speed is 200r / min to obtain The aqueous suspension of CL-20, and then the NTO aqueous solution obtained in step (1) is slowly added to the aqueous suspension of CL-20, filtered, washed and dried to obtain NTO / CL-20 composite explosive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com