Patents

Literature

72 results about "Nitrogen tetroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective catalytic reduction of nitrogen oxides in the exhaust gas of diesel engines

InactiveUS20110142737A1High activityGood choiceNitrogen compoundsInternal combustion piston enginesCeriumDiesel engine

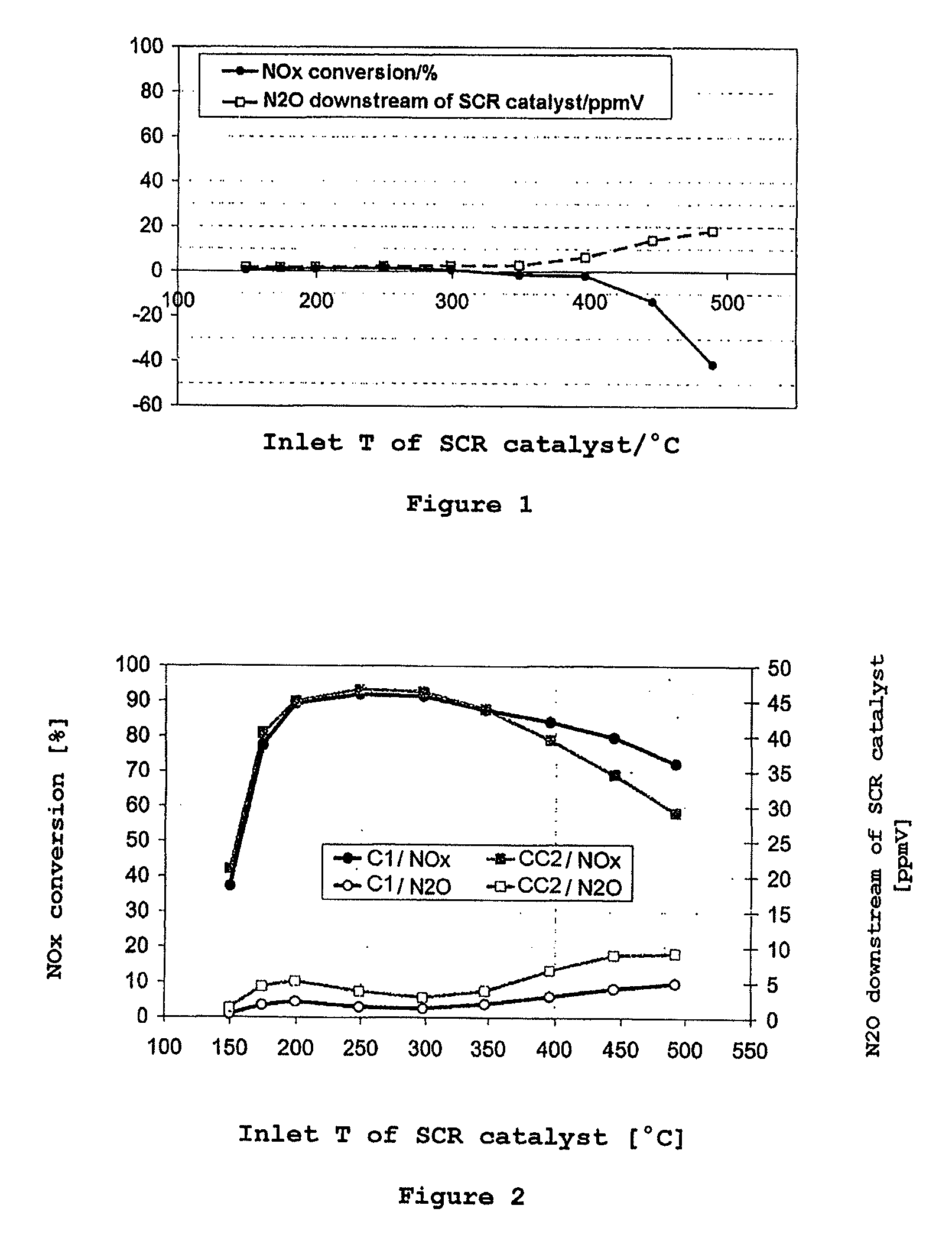

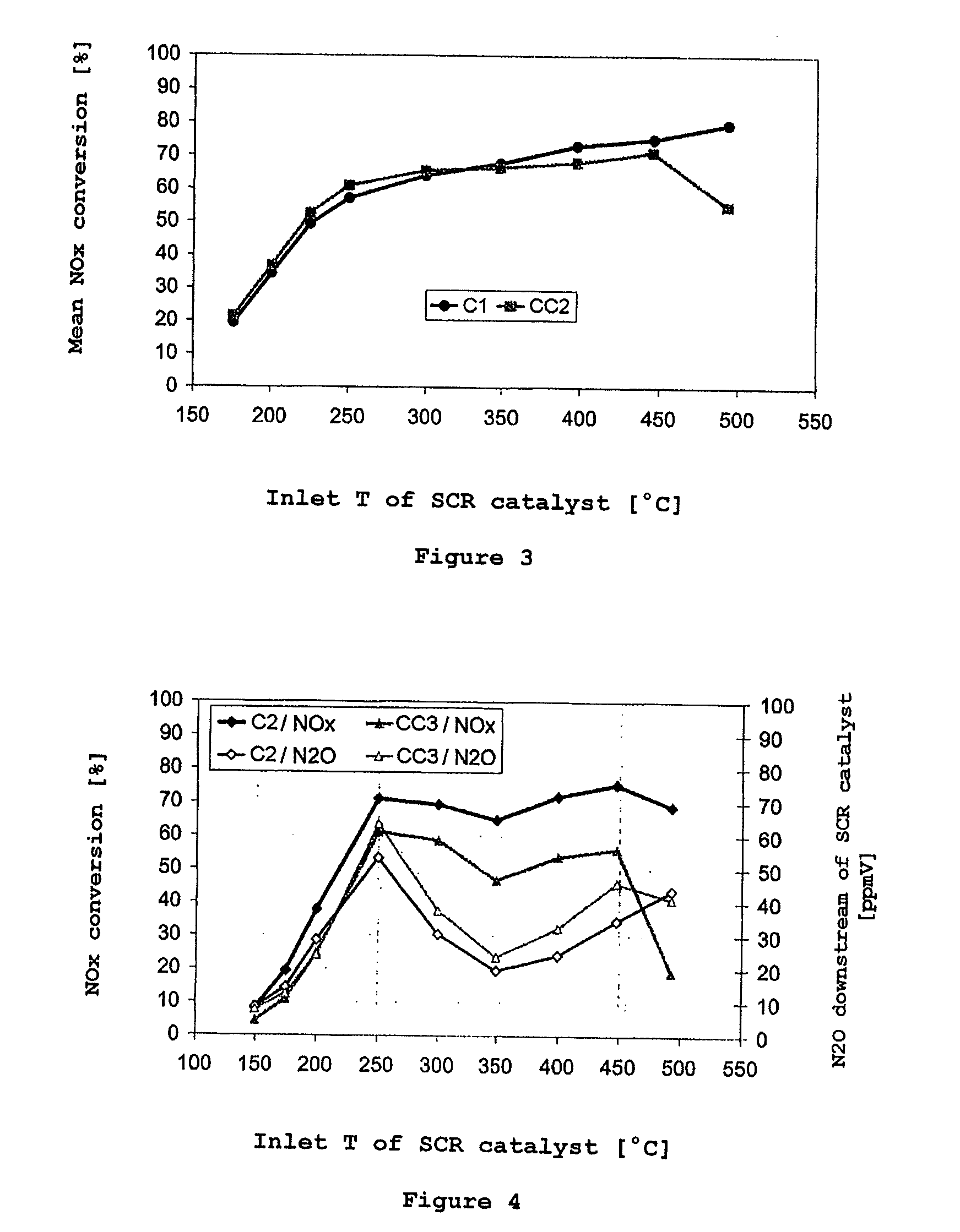

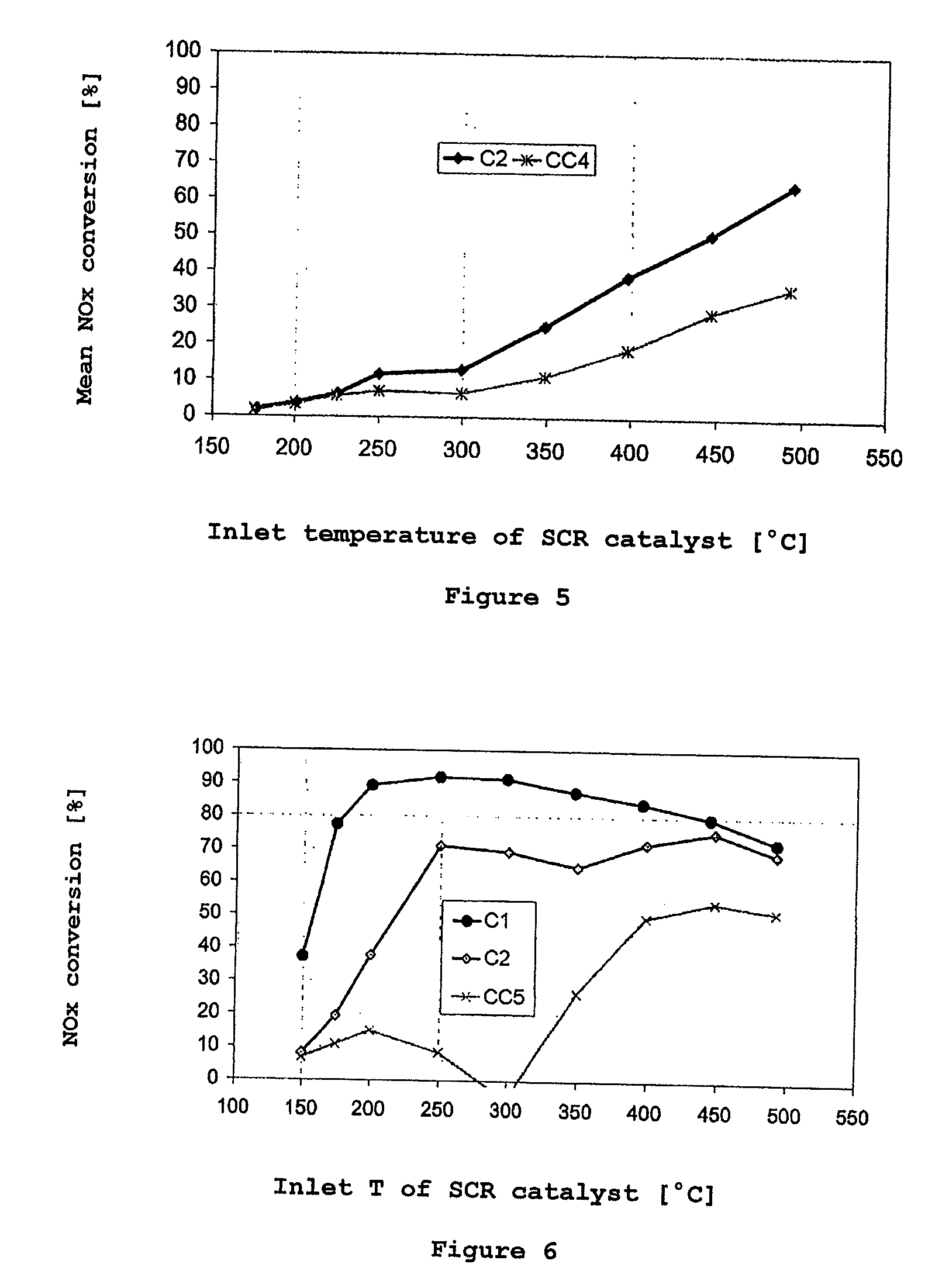

A catalyst and a process for selective catalytic reduction of nitrogen oxides in diesel engine exhaust gases with ammonia or a compound decomposable to ammonia are described. The exhaust gas to be cleaned is passed together with ammonia or a compound decomposable to ammonia over a catalyst which comprises a zeolite or a zeolite-like compound containing 1-10% by weight of copper, based on the total weight of the zeolite or of the zeolite-like compound, and a homogeneous cerium-zirconium mixed oxide and / or a cerium oxide. The zeolite used or the zeolite-like compound used is selected from the group consisting of chabazite, SAPO-34, ALPO-34 and zeolite-β.

Owner:UMICORE AG & CO KG

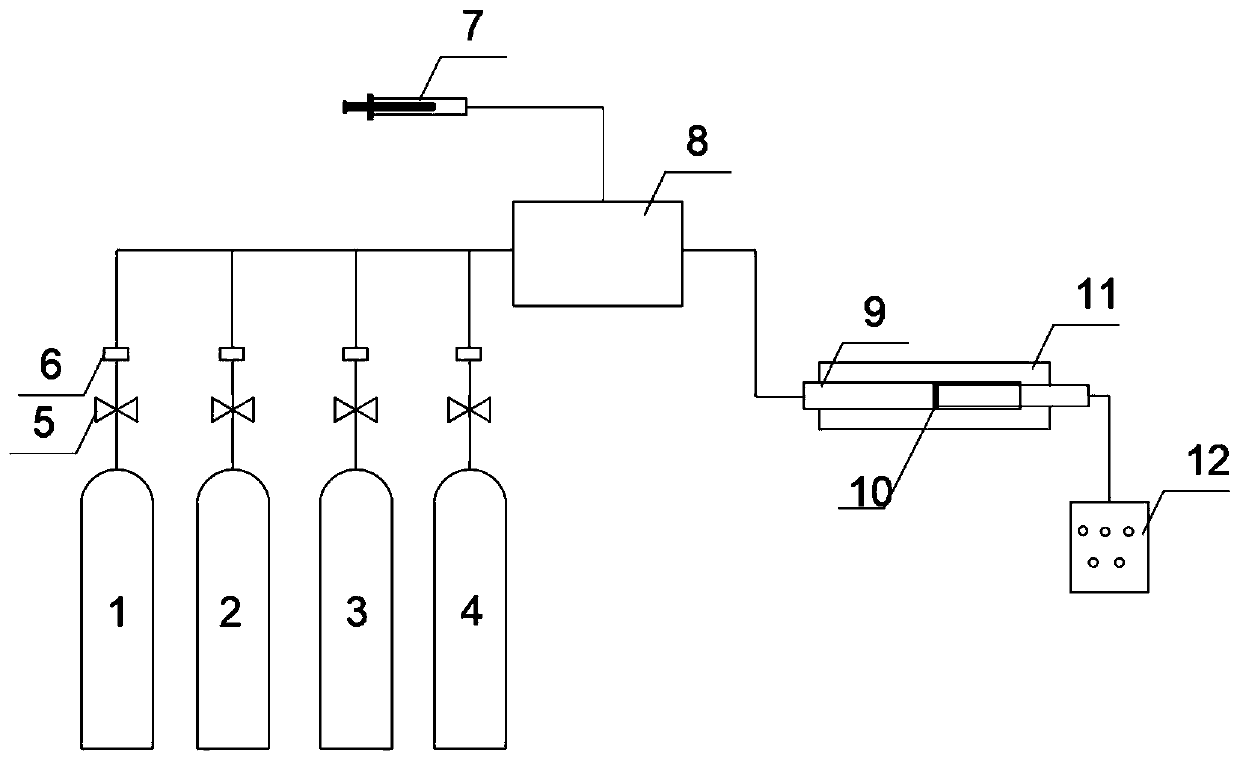

Composite filter material for cooperatively removing nitrogen oxides and dioxins, and preparation method thereof

InactiveCN110465288AReduce the impactImprove wear resistanceGas treatmentHeterogenous catalyst chemical elementsNitrogen tetroxideFlue gas

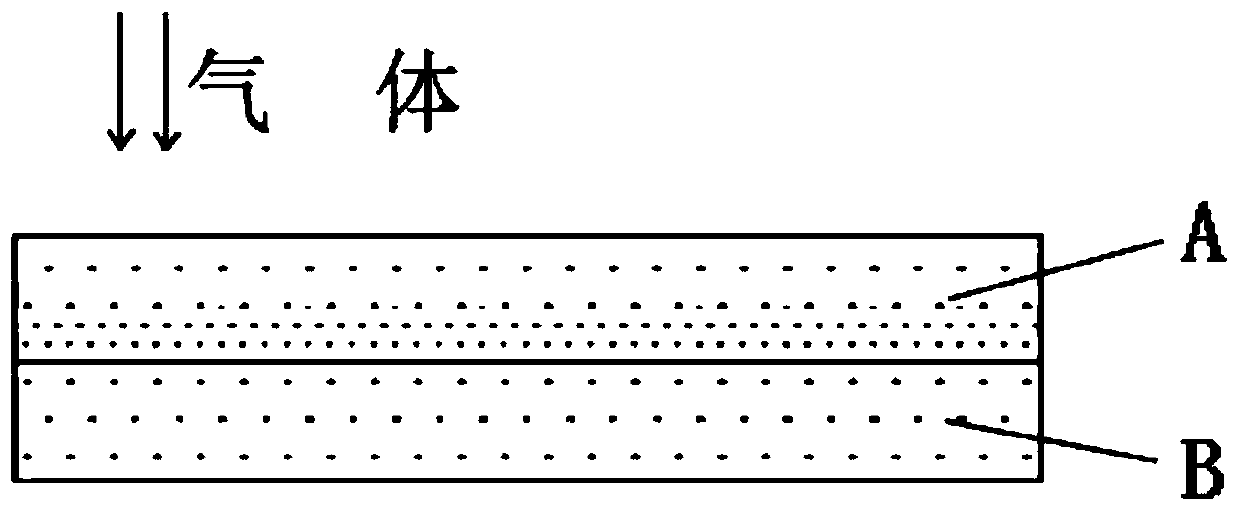

The invention provides a composite filter material for cooperatively removing nitrogen oxides and dioxins, and a preparation method thereof, and belongs to the field of composite filter materials. Thepurpose of the invention is to remove dusts in flue gas and simultaneously remove NOx and dioxins in the flue gas. The method concretely comprises the following steps: impregnating a template agent mixed with vanadium, cerium and titanium oxides at the gas outlet side of a filter material, carrying out suction filtration on the dust-facing side of the filter material to load a NOx catalyst, and performing drying to remove the template in order to obtain the composite filter material. The filter material prepared by the method effectively avoids NH3 from affecting the catalytic oxidation of dioxins, has a long service life, and has a good pollutant removal effect.

Owner:NANJING UNIV OF TECH +1

Method for inhibiting yellow smog during pickling of silicon materials

InactiveCN102020280ADoes not affect cleaning qualityImprove protectionSilicon compoundsElectrode potentialStandard electrode potential

The invention relates to the fields of photovoltaic or semiconductors, in particular to a method for inhibiting yellow smog during pickling of silicon materials. The main chemical components of the yellow smog are nitrogen oxides, such as nitric oxide, nitrogen monoxide, nitrogen dioxide and nitrogen tetroxide gas. The invention adopts the technical scheme that silicon material to be pickled is put in a mixed solution of mixed acid and strong oxidizer, wherein the mixed acid comprises hydrofluoric acid and nitric acid, or other inorganic acids or organic acids, and the strong oxidizer is a standard oxidant of which the electrode potential is higher than that of the nitric acid and can be hydrogen peroxide, potassium permanganate, manganese dioxide or ozone. By adopting the technical scheme, the quality for cleaning the silicon material cannot be influenced while the yellow smog is inhibited.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

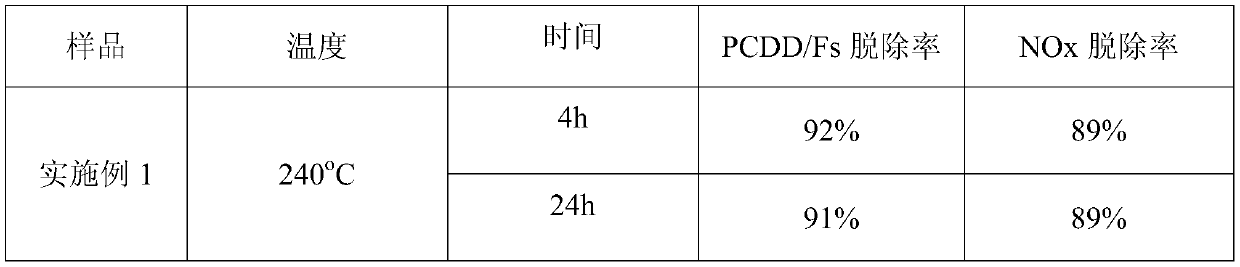

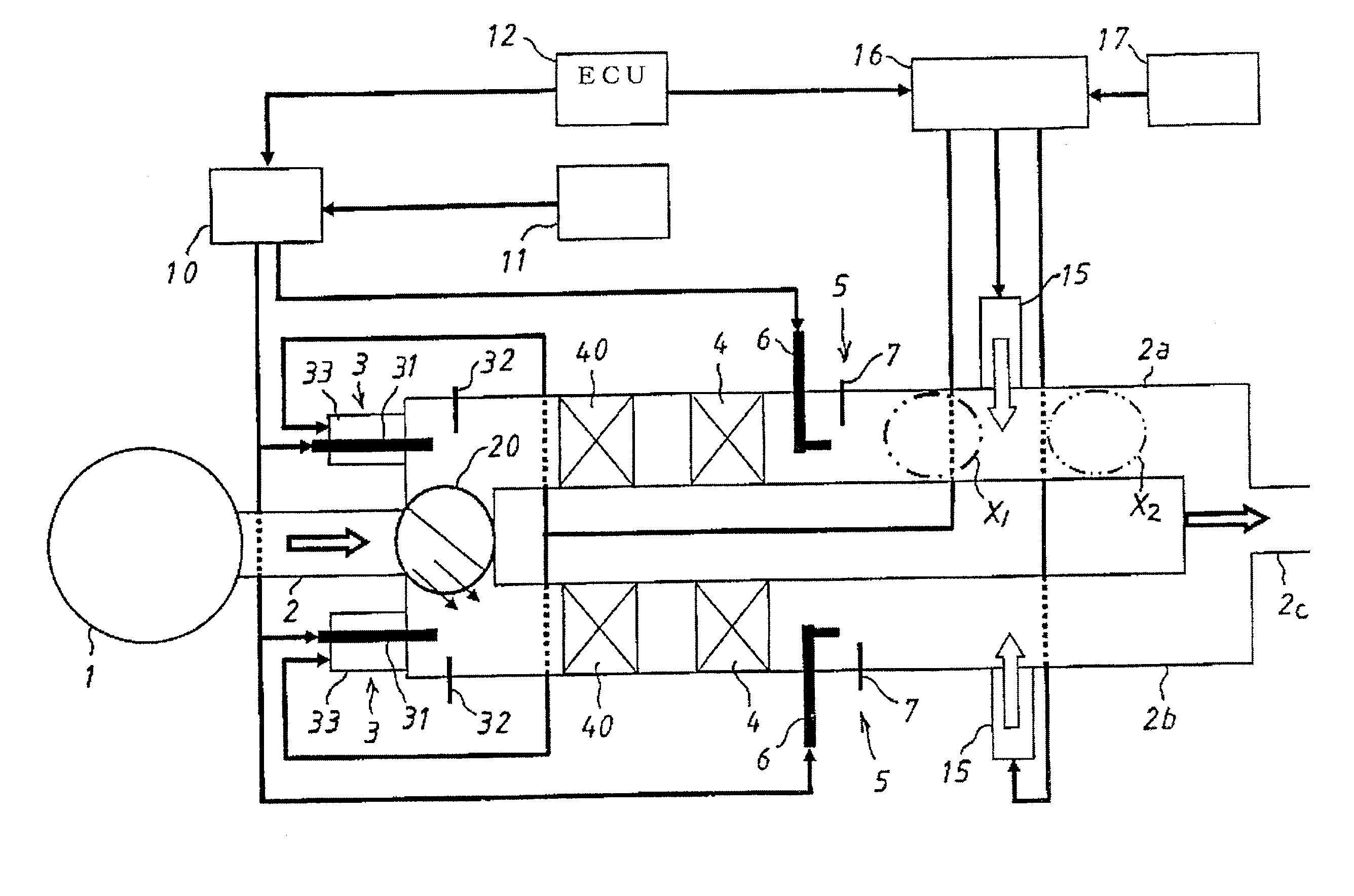

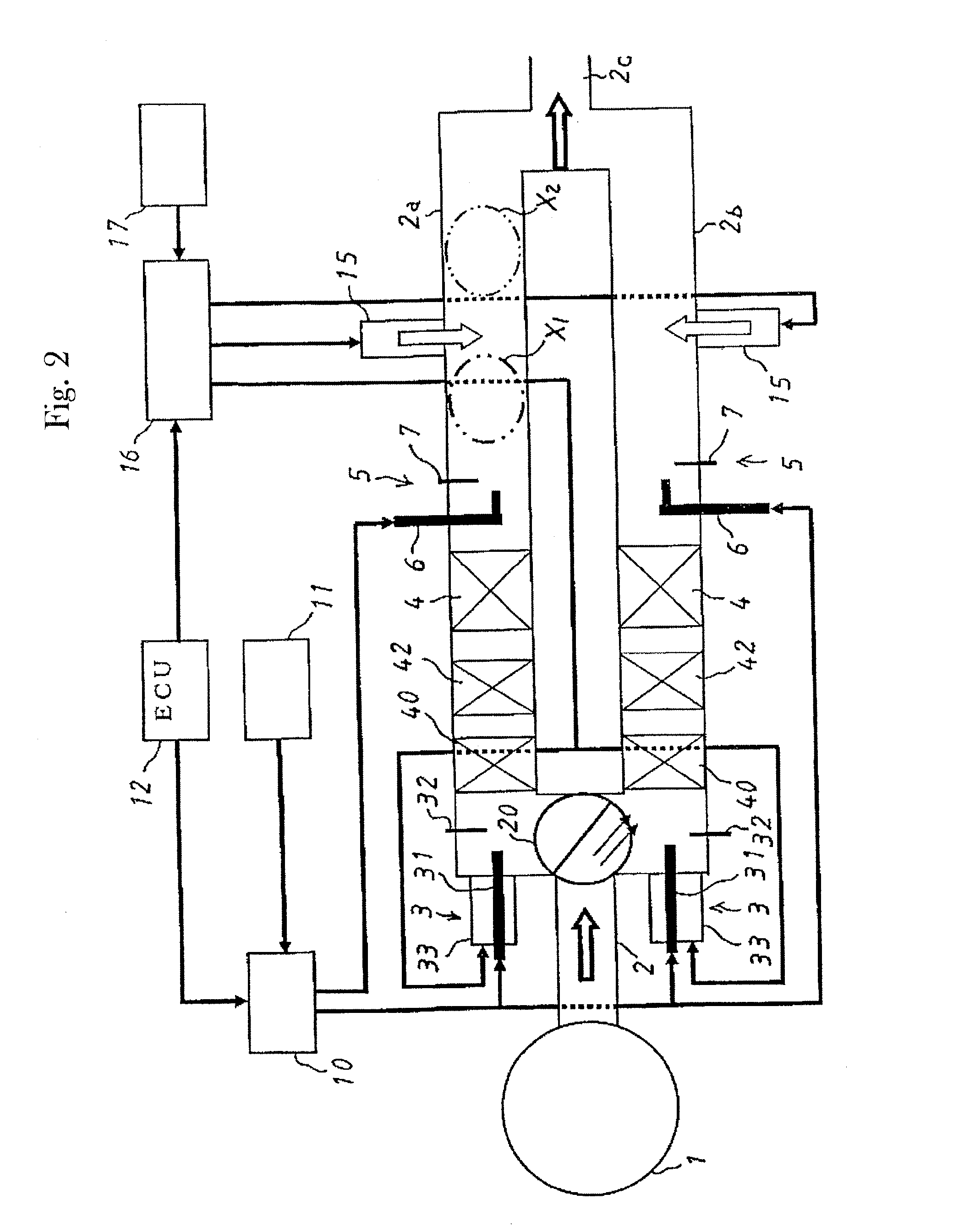

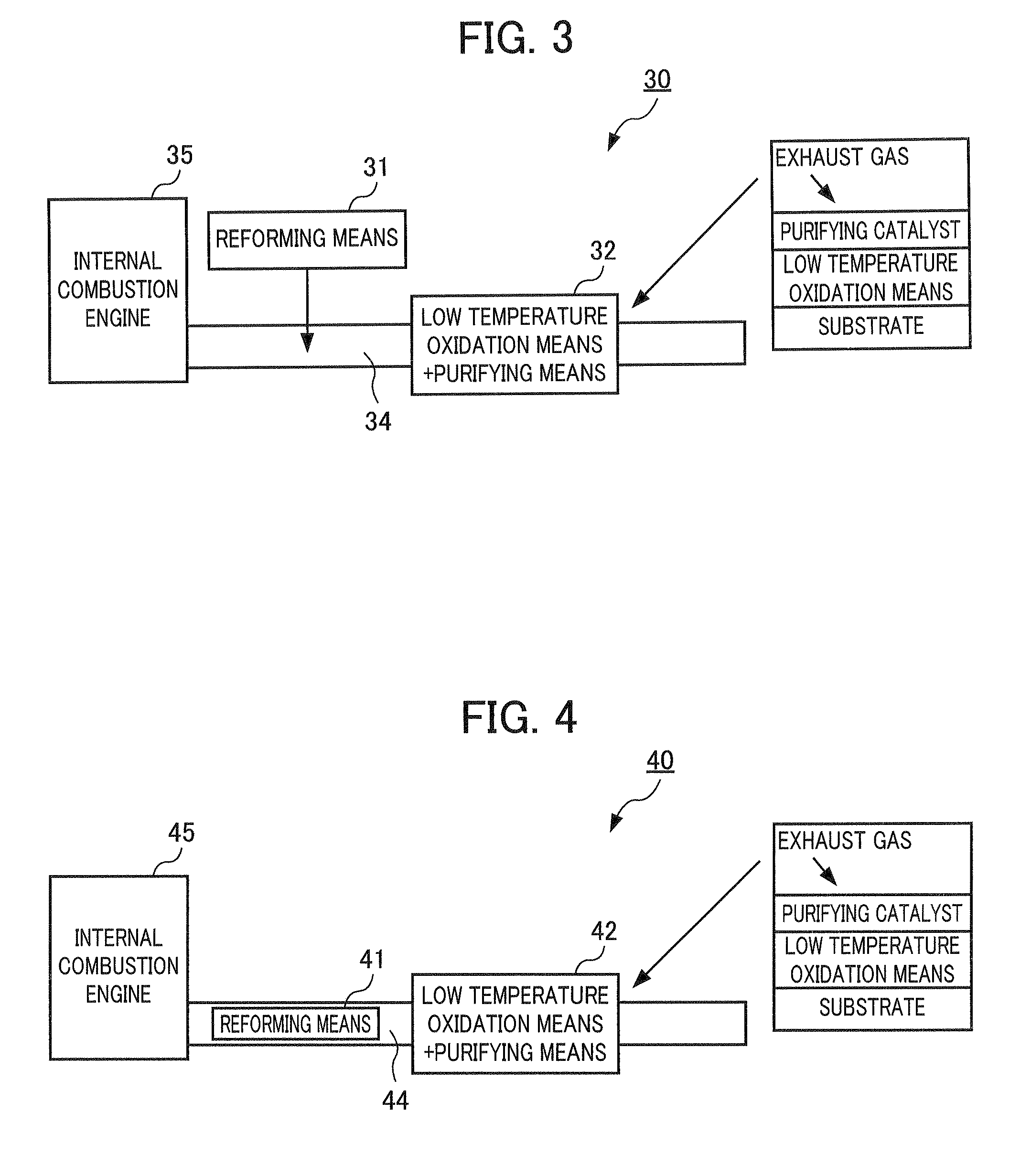

Exhaust Gas Purifier

InactiveUS20110138788A1Good NOx absorbing powerLow costInternal combustion piston enginesExhaust apparatusPhosphateSorbent

It is intend to provide at low cost an exhaust gas purifier capable of in an internal combustion engine or other combustion instrument mainly driven under excess air conditions, efficiently removing nitrogen oxides from exhaust gas. A nitrogen oxide adsorbent (4) is disposed in an exhaust passage, which the nitrogen oxide adsorbent (4) is composed of a lithium composite oxide of the general formula LiAxOy or LiAxPO4, containing as constituent elements lithium (Li) and at least one element (A) selected from the group consisting of manganese (Mn), nickel (Ni), cobalt (Co), vanadium (V), chromium (Cr), iron (Fe), titanium (Ti), scandium (Sc), and yttrium (Y). For example, the nitrogen oxide adsorbent (4) is composed of a lithium composite oxide, such as lithium manganate (LiMnO3), the lithium titanate (Li2TiO3) or lithium manganate phosphate (LiMnPO4).

Owner:YANMAR CO LTD

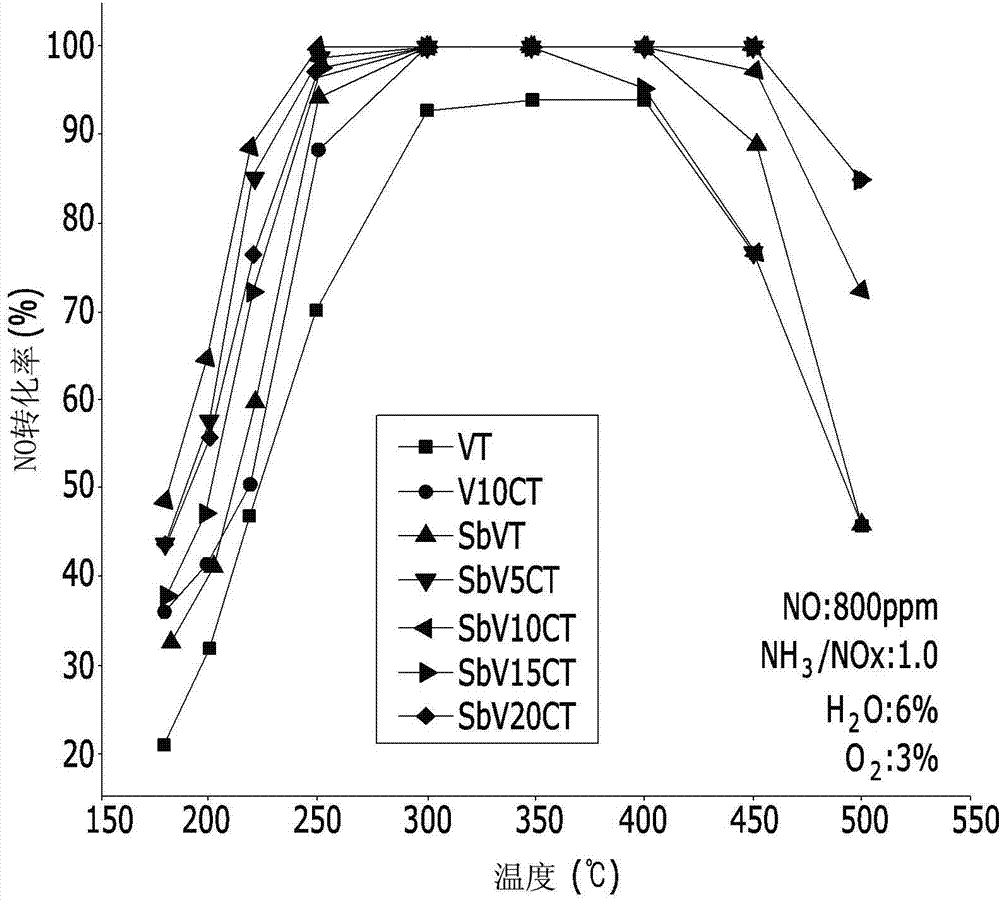

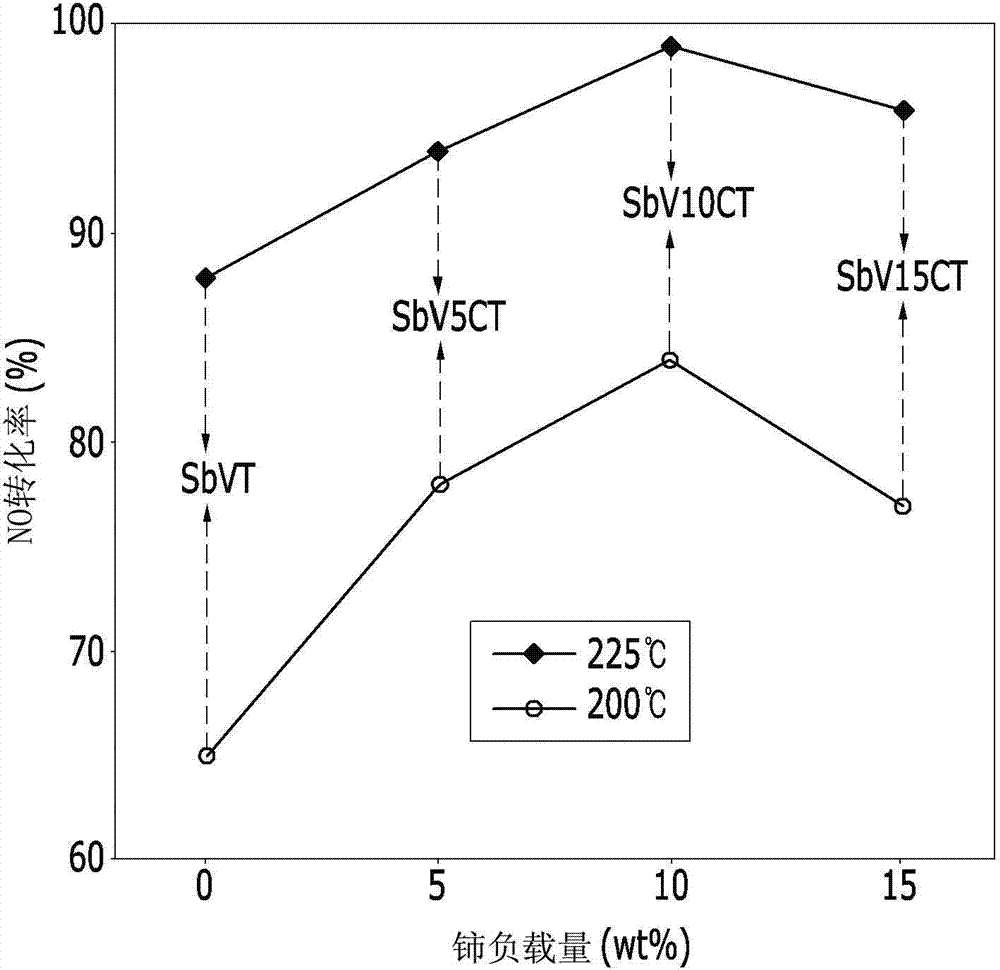

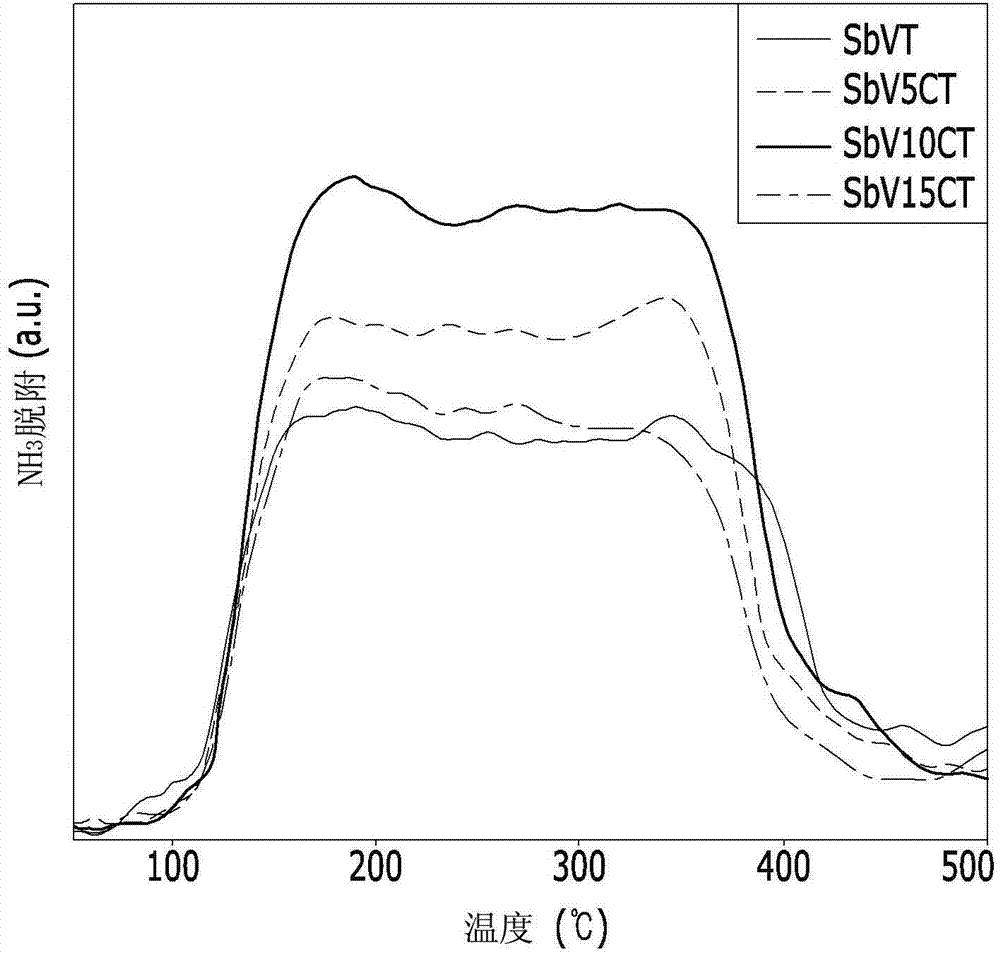

Catalyst for decomposing nitrogen oxide and preparation method thereof

ActiveCN103706351AImprove denitrification efficiencyImprove anti-sulfur poisoning propertiesGas treatmentDispersed particle separationNitrogen tetroxideSulfur

Provided is a catalyst including: a support including titanium oxide; an active catalyst component including vanadium oxide; and a co-catalyst including antimony and cerium, in which the catalyst is included in a deNox reduction reaction that decomposes nitrogen oxide. The catalyst may improve sulfur poisoning tolerance characteristics while improving the deNox efficiency at a temperature in a wide range from low temperature to high temperature.

Owner:KOREA INST OF SCI & TECH

Suede structure of crystalline silicon solar cells and manufacture method thereof

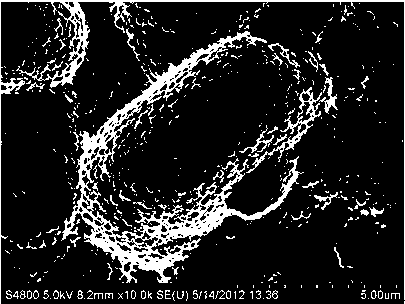

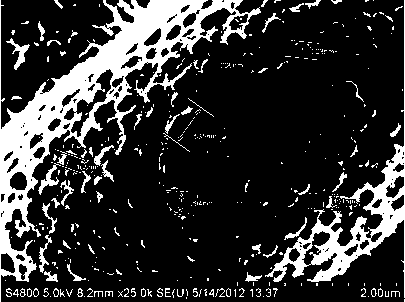

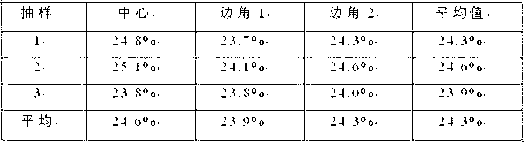

ActiveCN103000763AAbsorb moreImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationMicron scaleHydrogen fluoride

The invention discloses a manufacture method of a suede structure of crystalline silicon solar cells. The manufacture method comprises the following steps of (1) corroding a silicon wafer to be processed through acid liquor or alkali liquor and forming a micron-scale suede structure on the surface of the silicon wafer; and (2) conducting gaseous corrosion on the silicon wafer obtained in the step (1), further forming a nano-scale suede structure on the micron-scale suede structure. Gass for gaseous corrosion comprises nitric oxide gas, steam and hydrogen fluoride, and the nitric oxide gas is one or a plurality of nitric oxide, nitrogen dioxide and nitrogen tetroxide. The nano-scale suede structure is further formed on the micron-scale suede structure through the gaseous corrosion on the basis of the existing micron-scale suede structure, and surface reflectivity is further reduced.

Owner:YANCHENG CANADIAN SOLAR INC

Exhaust gas purifier

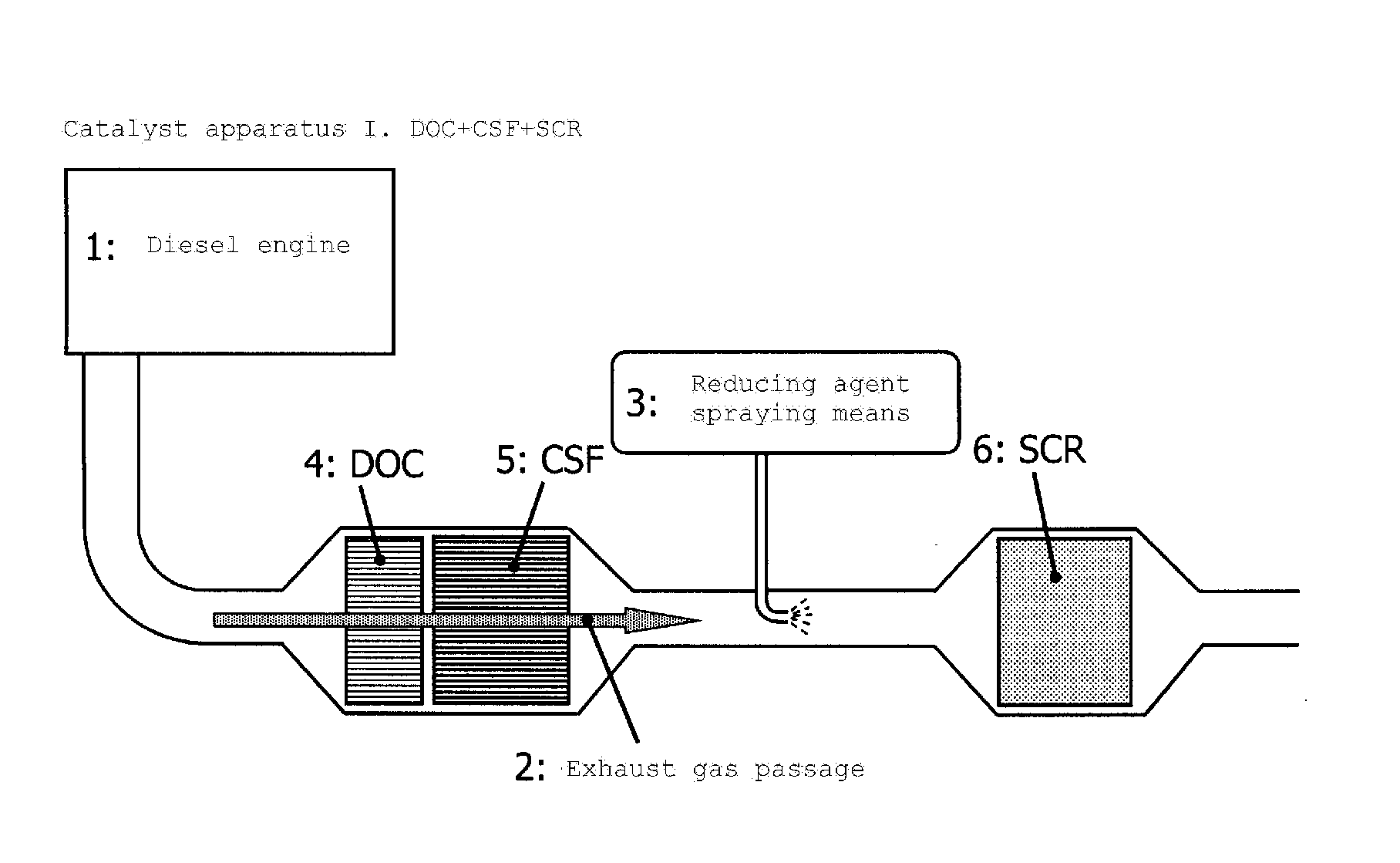

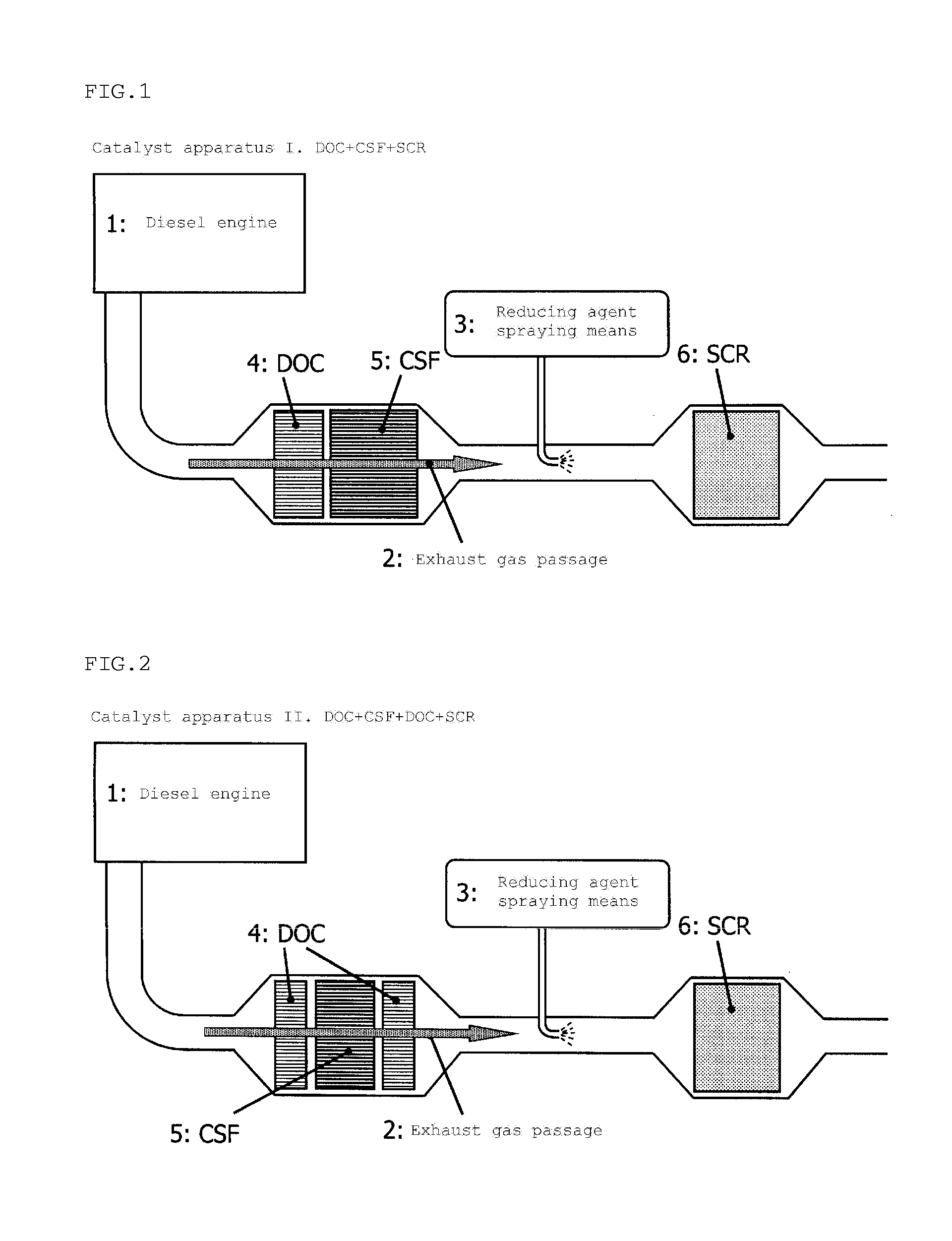

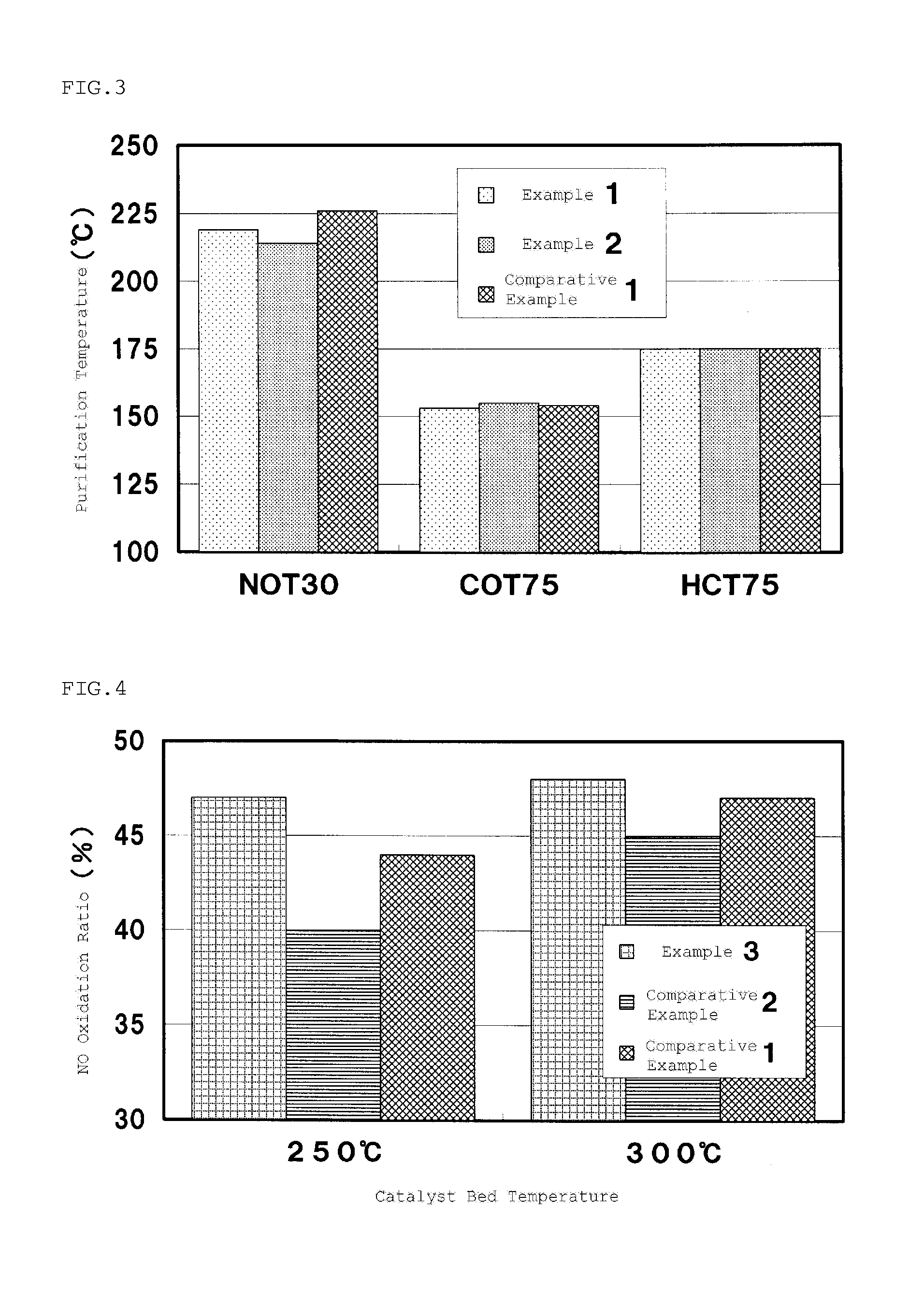

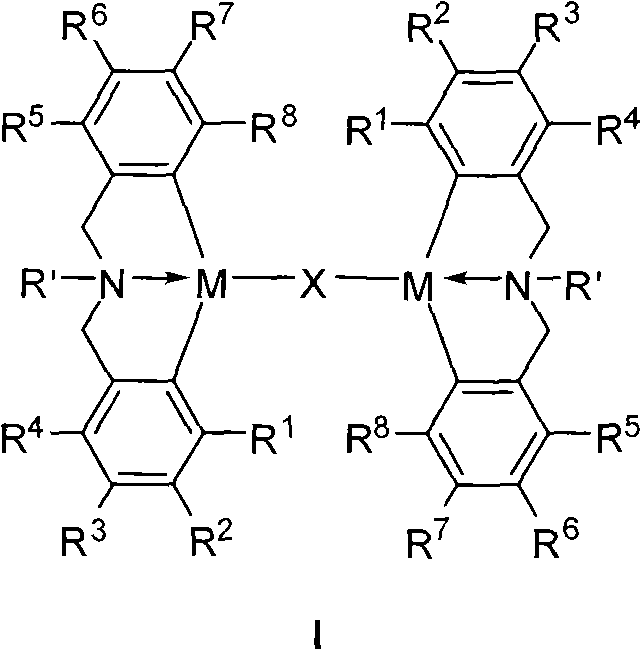

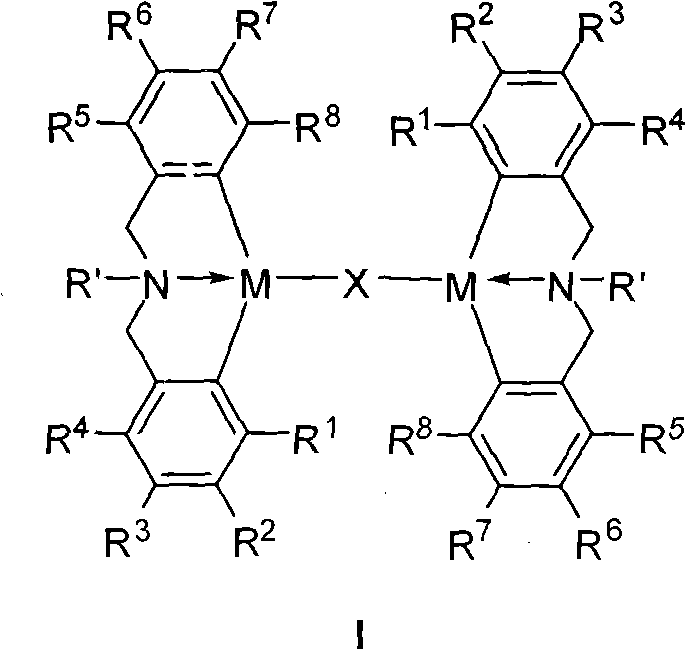

ActiveUS20150078966A1Superior in oxidation activityImprove performanceCombination devicesGas treatmentParticulatesComponents of crude oil

An exhaust gas purification catalyst apparatus, which is superior in oxidation performance of, in particular, nitrogen monoxide, among hydrocarbons, carbon monoxide, nitrogen oxides and particulate components such as soot, included in exhaust gas from a lean burn engine, and combustion performance of light oil. The exhaust gas purification apparatus arranged with an oxidation catalyst (DOC) comprising a noble metal component for oxidizing carbon monoxide, hydrocarbons, in particular, nitrogen monoxide among nitrogen oxides, and for combusting light oil, a catalyzed soot filter (CSF) including a noble metal component for collecting a particulate component such as soot and removing by combustion (oxidation). The oxidation catalyst (DOC) has a catalyst layer where platinum (Pt), palladium (Pd) and barium oxide (BaO) are supported on alumina (Al2O3) having a pore size of 12 to 120 nm, and ratio of platinum and palladium is 1:1 to 11:2 in weight equivalent.

Owner:N E CHEMCAT

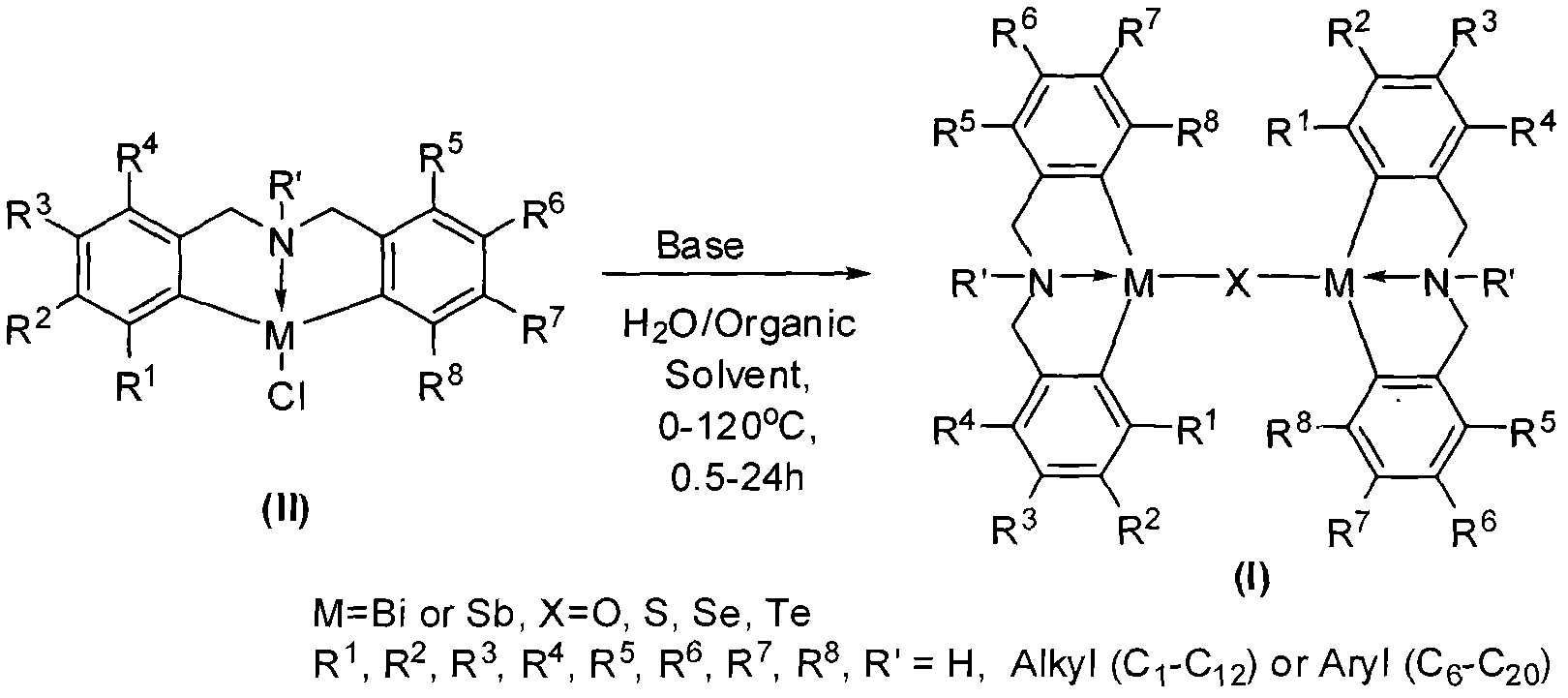

Chemical method for trapping, fixing and purifying carbon dioxide, sulfur dioxide, sulfur trioxide and nitrogen oxides

InactiveCN102091503APromote absorptionFast absorptionCarbon compoundsDispersed particle separationTrappingSolvent

The invention provides a chemical method for trapping, chemically fixing and purifying greenhouse gases such as carbon dioxide, sulfur dioxide, sulfur trioxide, nitrogen oxides and the like, which is characterized by adopting an organic metal compound and a solvent as trapping and chemical fixing agents, wherein the organic metal compound is a coordination compound of nitrogenous organic bismuth and organic antimony; and the solvent is an organic solvent. By means of the method, the trapping and chemical fixing of all the greenhouse gases can be realized to form corresponding metal salts; and at different temperatures, selective gradient analysis can be realized so that the trapping and purification of single gas is further realized. The trapping and fixing agents have high fixing capacity, high analytic speed, low regeneration energy consumption and low price, are easy and simple to prepare, have high stability and can be used repeatedly. The chemical method can be widely used for carrying out trapping and chemical fixing on the greenhouse gases in flue gas, synthesis ammonia, natural gas, kiln gas and the like and can realize enrichment purification of the single gas in one step.

Owner:HUNAN UNIV

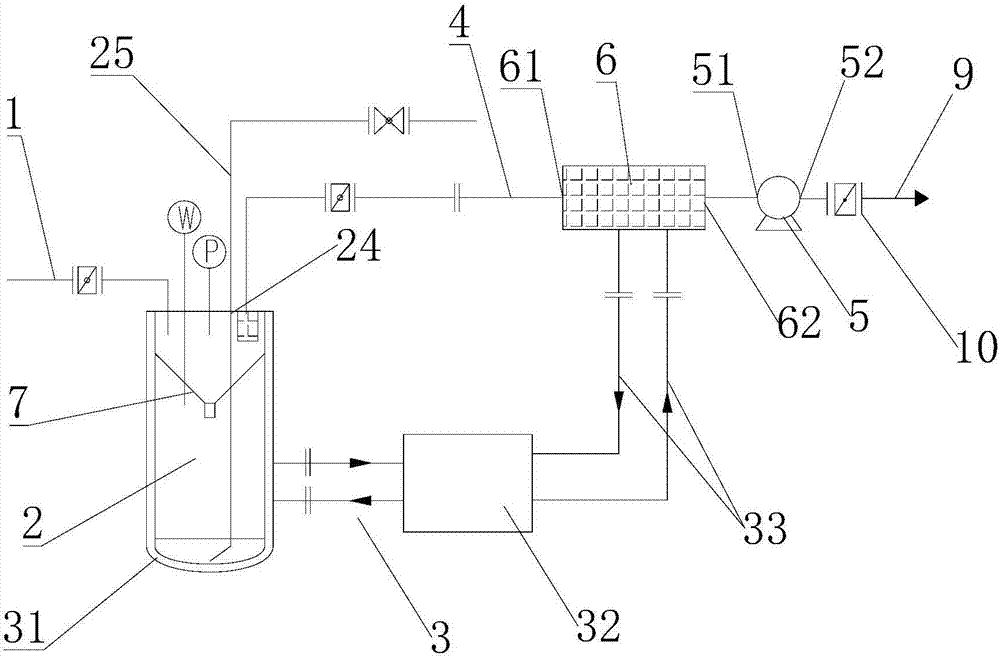

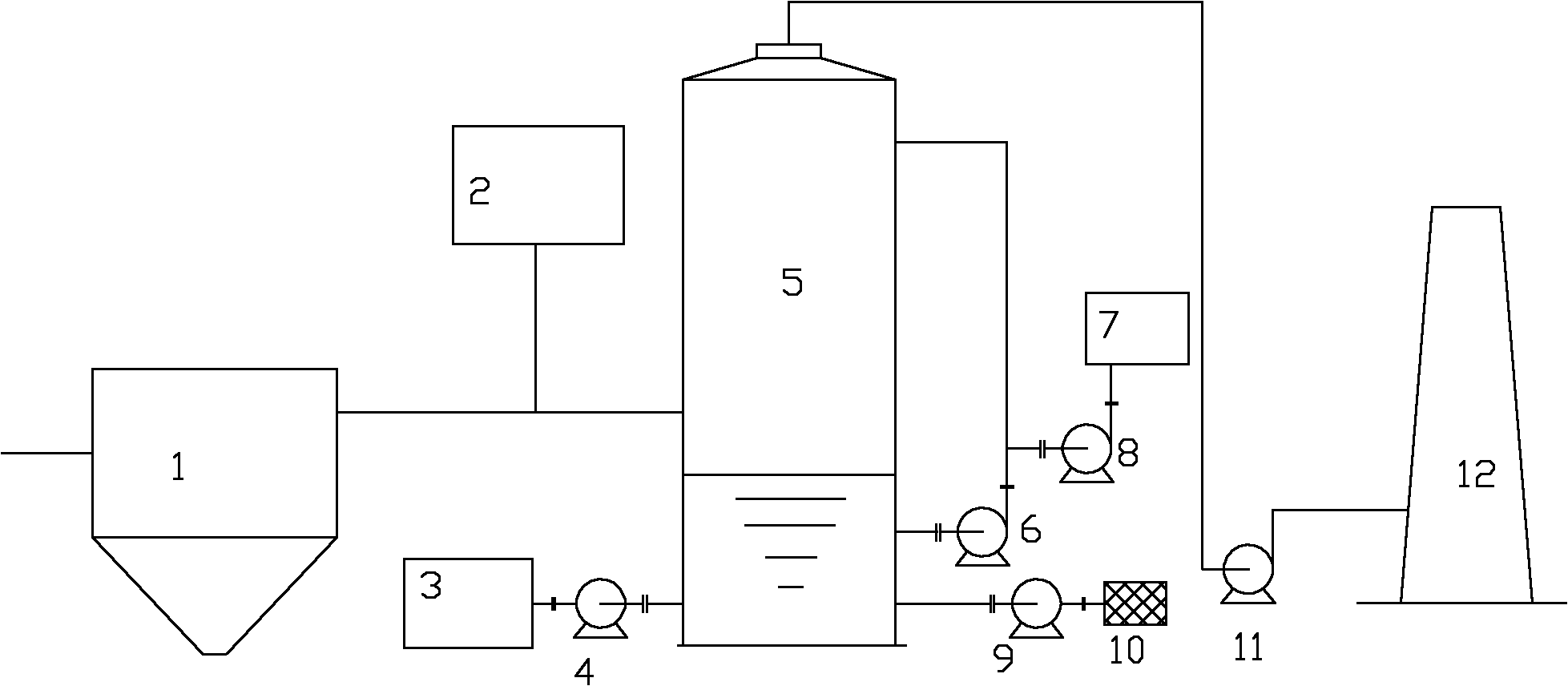

Nitrogen tetroxide leakage collection device and method

InactiveCN107998806ARemove completelyImprove collection efficiencyNitrous oxide captureGas treatmentNitrogen tetroxideHazardous substance

The invention discloses a nitrogen tetroxide leakage collection device and method. The nitrogen tetroxide leakage collection device comprises a collection pipe, a collection container connected to thecollection pipe, an exhaust gas treatment module, a high negative pressure suction device and an electronic control module. The collection container and the exhaust gas treatment module are providedwith cooling systems. The upper part of the collection container is provided with a gas outlet. The gas outlet is connected to the negative pressure suction device through a gas suction pipe. The gassuction pipe between the collection container and the negative pressure suction device is provided with an absorption device for removing exhaust gas. Through being driven by the negative pressure suction device, the leaked nitrogen tetroxide liquid / gas and nitrogen dioxide are sucked into the inner collection container through the collection pipe, the gas-liquid mixture is subjected to gas-liquidseparation and cooling liquidation, the nitrogen tetroxide liquid is collected, and the tail gas is subjected to adsorption filtration so that toxic and hazardous substances in the tail gas are removed and thus collection efficiency is high and the environmental protection and conservation of resources are realized.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

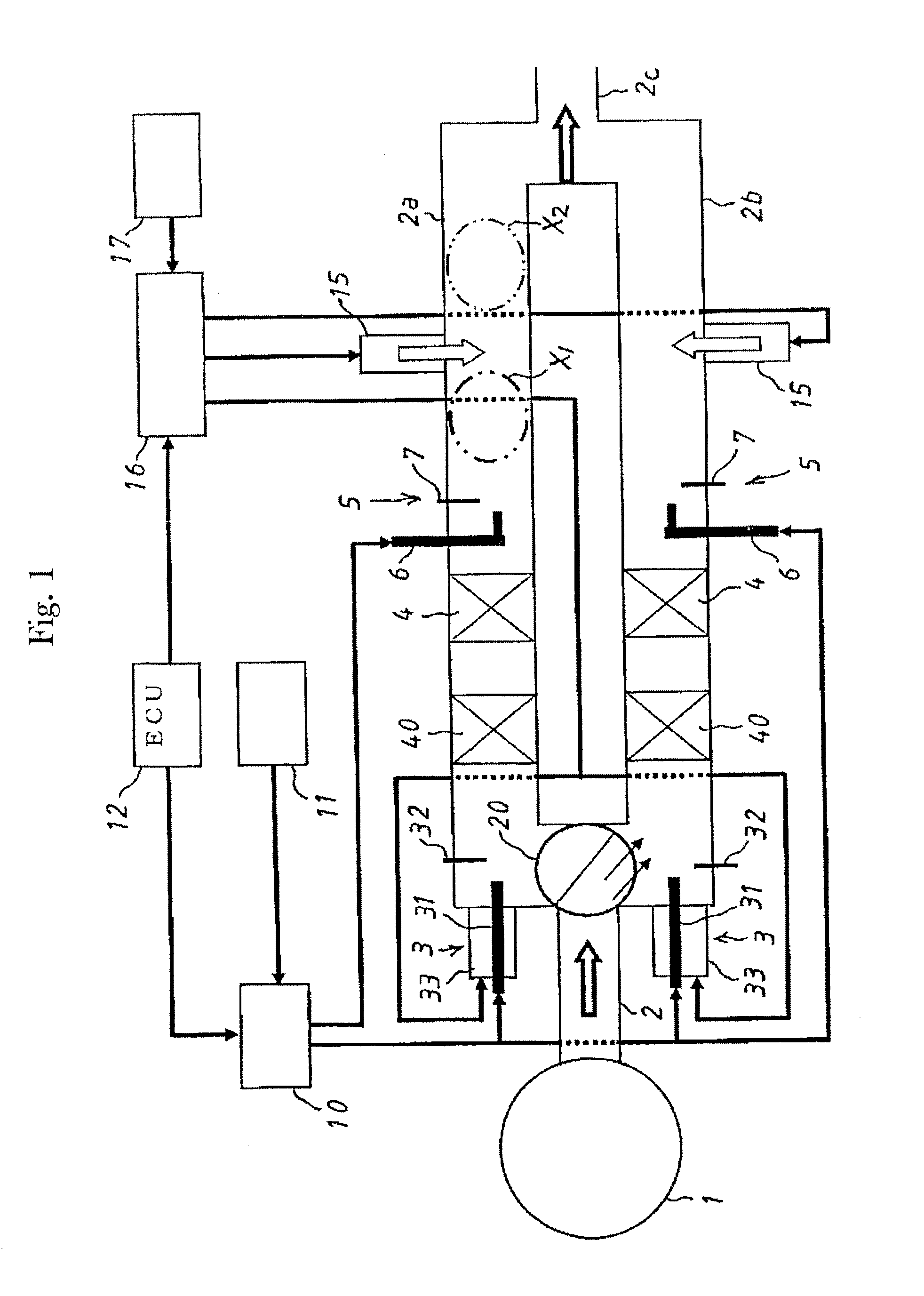

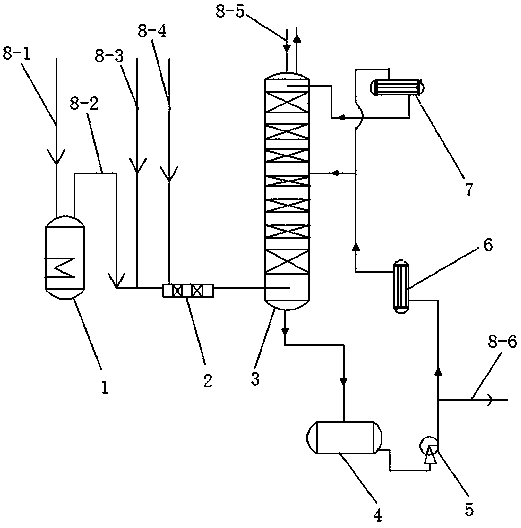

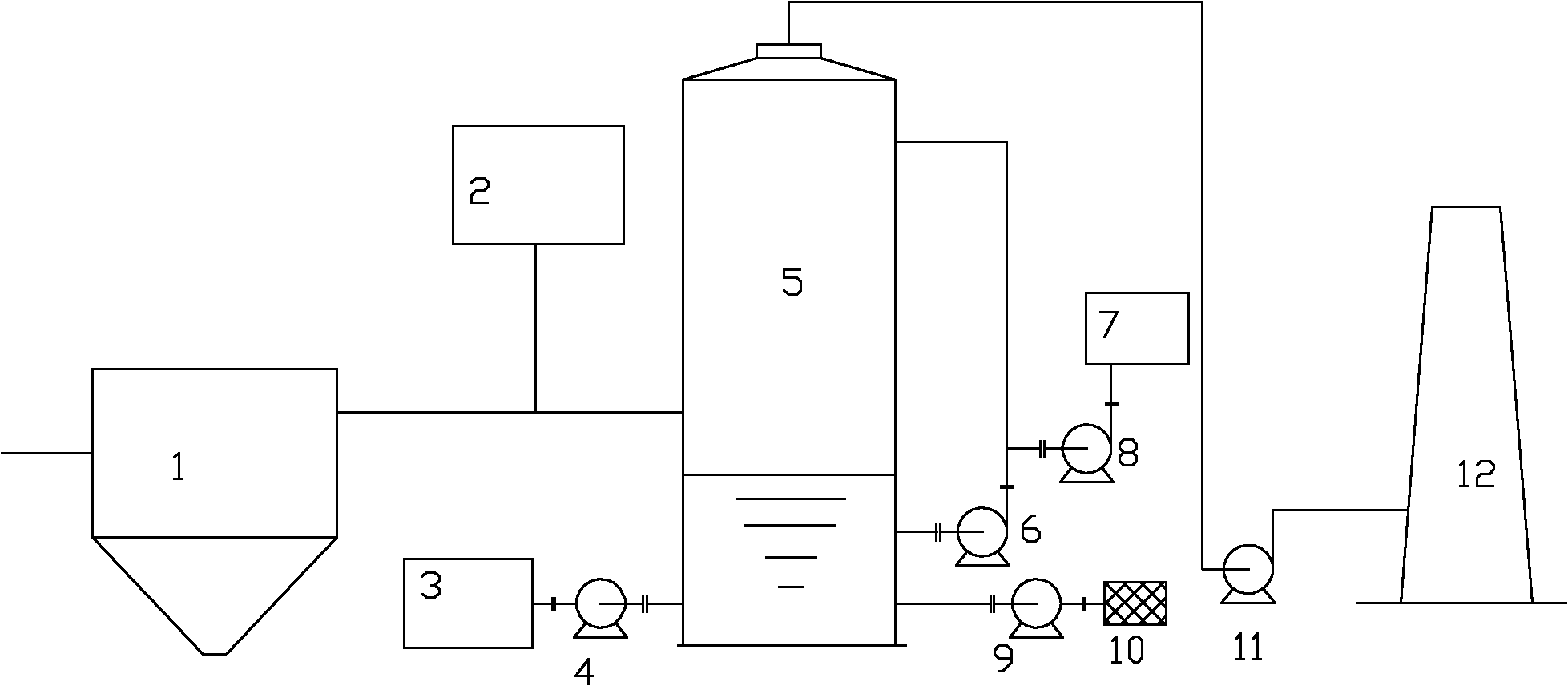

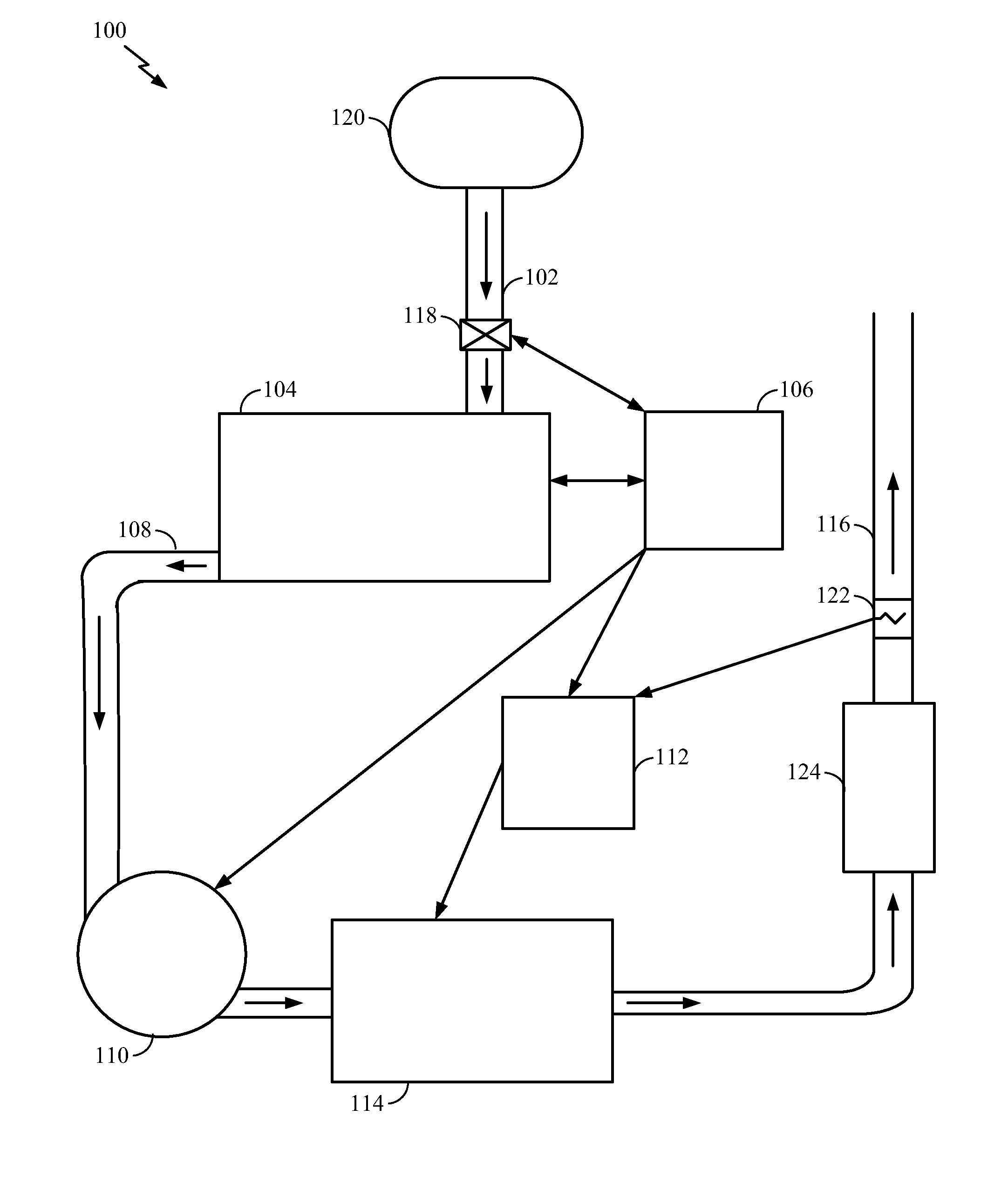

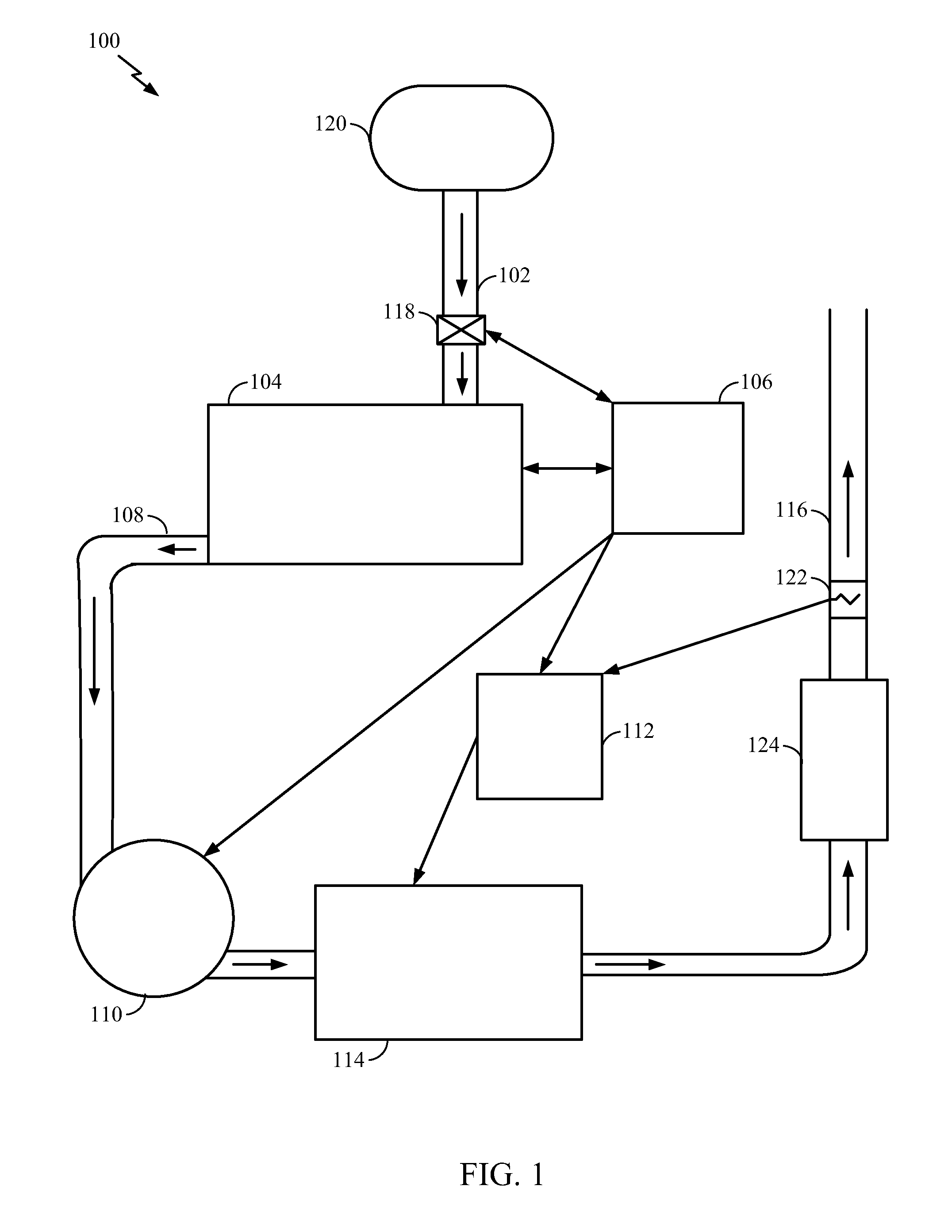

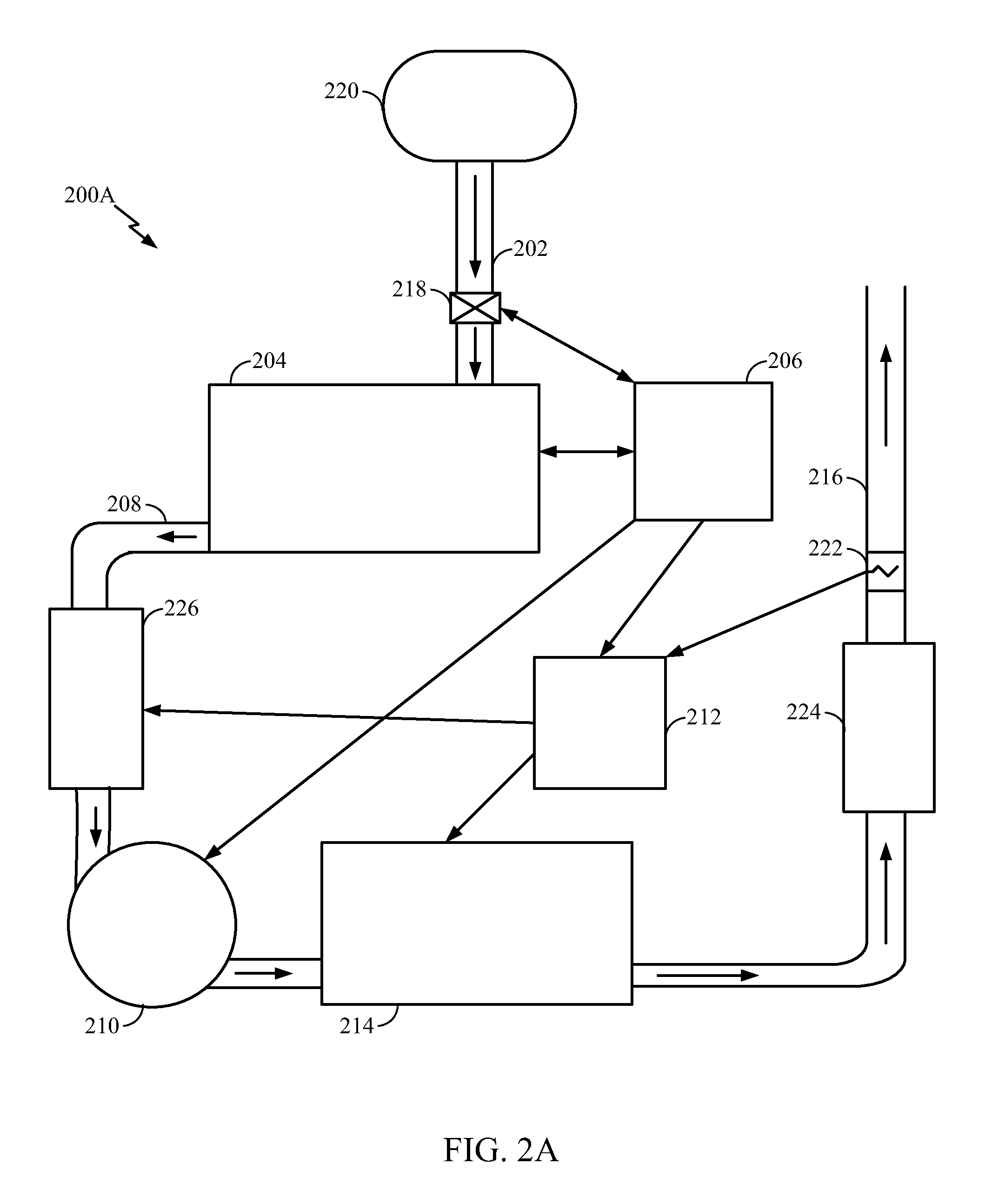

Nitrogen tetroxide tail gas recycling system

ActiveCN103691287AReduce pollutionIncrease profitDispersed particle separationNitric acidNitrogen tetroxideEmission standard

The invention provides a nitrogen tetroxide tail gas recycling system which comprises a receiver for receiving and conveying nitrogen tetroxide, wherein an exhaust end at the top end of the receiver is connected with a gas inlet end of a blender through an exhaust pipe, an air pipe and a nitrogen tetroxide tail gas pipe used for conveying the tail gas in nitrogen tetroxide production equipment are respectively connected on the blender, a gas outlet end of the blender is connected with a gas inlet end at the bottom of an absorption tower, a spraying water pipe is connected at the top end of the absorption tower, and a liquid outlet end at the bottom end of the absorption tower is connected with an acid storage tank. The nitrogen tetroxide tail gas recycling system fully uses a N2O4 production device and the N2O4 tail gas not completely utilized during loading and unloading and transferring, water and air are added to react sufficiently to produce dilute nitric acids the concentration of which is smaller than 68% and which meet different concentration requirements, in addition, the content of NO2 in the air is lower than 200PPM and reaches the emission standard, the purposes of saving energies and protecting environments are fulfilled, and the production cost is saved.

Owner:ANHUI HUAIHUA

Mixed metal oxide catalyst for decomposition of nitrogen oxides

InactiveUS9352303B2Efficient decompositionLow production costNitrous oxide captureGas treatmentNitrogen tetroxideDecomposition

The present invention relates to a mixed metal oxide catalyst in which a hydrotalcite precursor containing an alkali metal is impregnated or intercalated with a nonprecious metal, a method of manufacturing the same, and a method of decomposing nitrogen oxide using the mixed metal oxide catalyst. The mixed metal oxide catalyst has excellent catalytic activity because it can decompose NOx, N2O or a mixture thereof even at low temperature, and is economical because it does not use a precious metal.

Owner:SANGMYUNG UNIV IND ACAD COOP FOUND

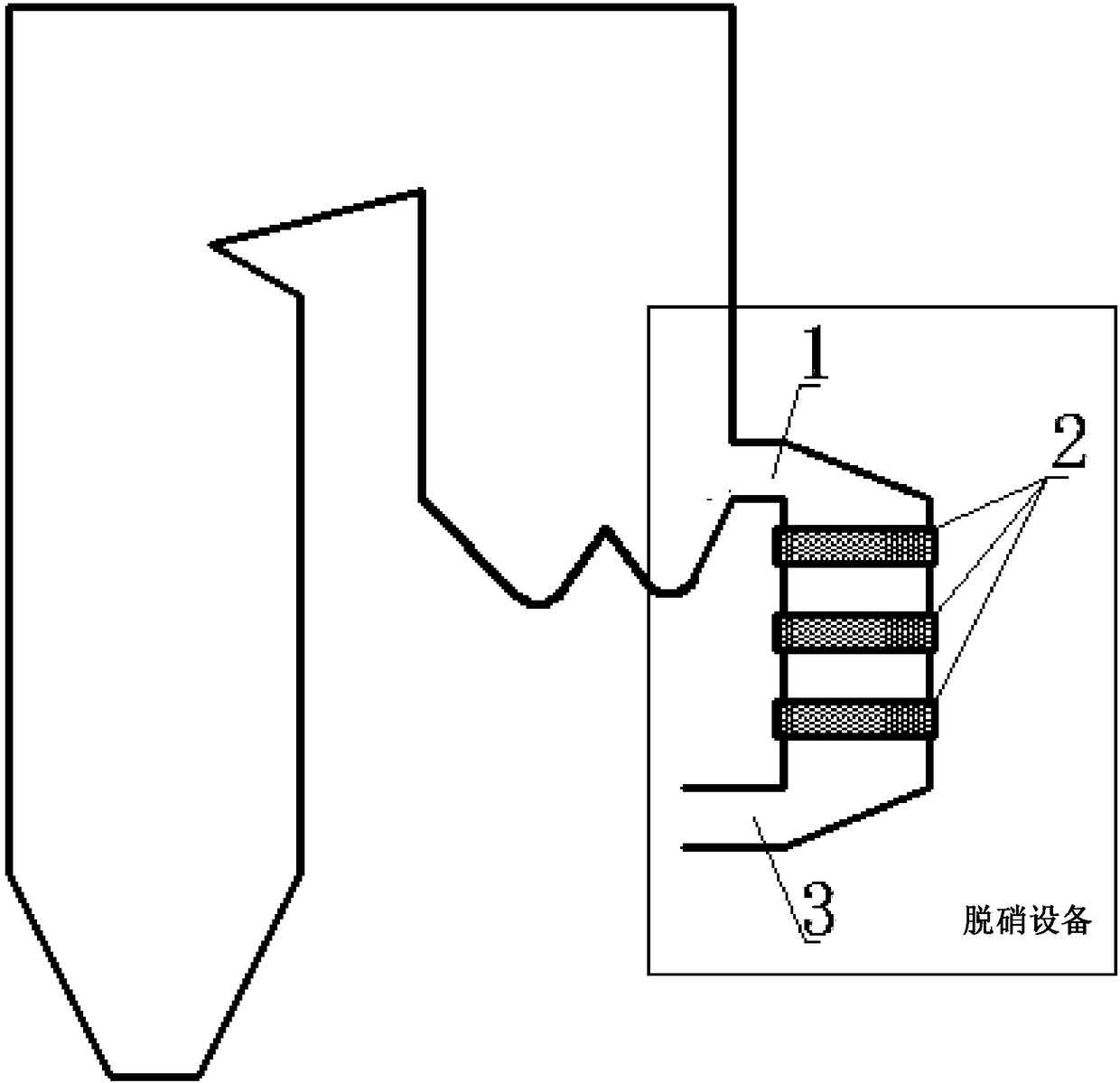

Selective catalytic reduction denitration method for flue gas

InactiveCN109248562AEmission reductionEmission controlGas treatmentDispersed particle separationNitrogen gasPollution

The invention provides a selective catalytic reduction denitration method for flue gas, wherein the method comprises the following technological steps: feeding flue gas to be treated into a selectivecatalytic denitration device; taking carbon monoxide in the flue gas as a reductant, and under the action of a catalyst, carrying out redox reaction with nitrogen oxides in the flue gas; reducing thenitrogen oxides in the flue gas into nitrogen gas, and oxidizing carbon monoxide into carbon dioxide, and outputting carbon dioxide from an outlet of the denitration device. According to the selectivecatalytic reduction denitration method of the flue gas, carbon monoxide contained in the flue gas itself is used as the reductant, and undergoes reaction with the nitrogen oxides in the flue gas under the action of the catalyst, and the emission of carbon monoxide is significantly reduced while the nitrogen oxides are reduced. Not only does the problem of ammonia escape not exist, but also the problems of secondary pollution and downstream corrosion caused by ammonia escape can be solved.

Owner:TSINGHUA UNIV

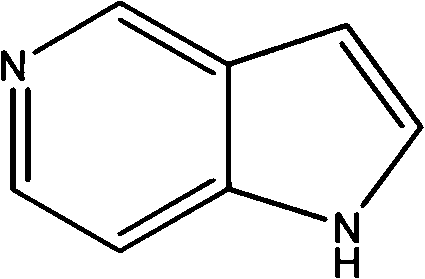

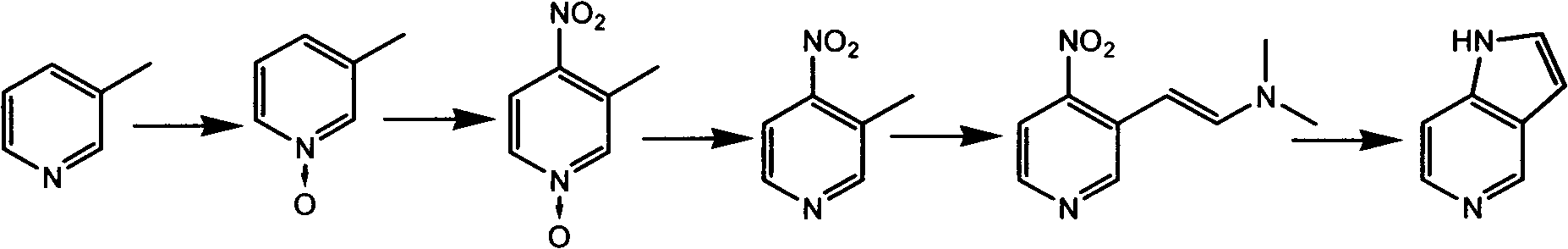

5-azaindole preparation method

InactiveCN103421004ARaw materials are cheap and easy to getReduce manufacturing costOrganic chemistryNitrationMethyl group

The present invention discloses a 5-azaindole preparation method, wherein 3-methylpyridine is adopted as a raw material, and the 5-azaindole preparation method comprises the following five steps that: (1) 3-methylpyridine is subjected to an oxidation reaction under an oxidant effect to obtain a 3-methylpyridine nitrogen oxide, (2) the 3-methylpyridine nitrogen oxide is subjected to a nitration reaction under a mixed acid effect to obtain a 3-methyl-4-nitropyridine nitrogen oxide, (3) the 3-methyl-4-nitropyridine nitrogen oxide and phosphorus trichloride are subjected to a reaction in a solvent to obtain 3-methyl-4-nitropyridine, (4) the 3-methyl-4-nitropyridine and N,N-dimethyl formamide dialkyl acetal are subjected to a reaction in a solvent N,N-dimethyl formamide under a heating condition to obtain 3-dialkylamine vinyl-4-nitropyridine, and (5) the 3-dialkylamine vinyl-4-nitropyridine is subjected to a reduction reaction under a metal catalyst effect while ring closure is performed to obtain the final product 5-azaindole.

Owner:ASCEPION PHARMA

Device and method for combined removal of sulphur dioxide (SO2), nitrogen oxide (NOX) and mercury from fume

InactiveCN102188889AIncrease added valueAccelerate the process of industrializationDispersed particle separationAir quality improvementAmmonium nitrateAmmonium sulfate

The invention discloses a device and a method for combined removal of sulphur dioxide (SO2), nitrogen oxide (NOX) and mercury from fume. In the device, a nitrogen dioxide (NO2) generation device is added between a dust remover and a wet desulphurization tower in a wet desulphurization system. The method comprises the following steps of: adding 9 percent of NO2 gas into the fume which is subjected to dust removal by the dust remover by using the NO2 generation device; adjusting the content of NO2 in the fume to 50 percent of the total amount of the NOX; controlling the pH value of a circulating solution in an absorption tower to 5.5 to 6.3; absorbing and oxidizing the SO2 and the NOX in the fume by a reaction tower to obtain a mixed solution of ammonium sulphate and ammonium nitrate; carrying out operation on the mixed solution in an ammonium sulphate and ammonium nitrate recovery system to generate a fertilizer which can be used for agricultural production, wherein desulphurization efficiency is over 95 percent and denitration efficiency is over 80 percent; and after adding the NO2 into the fume, oxidizing a certain amount of mercury oxide (Hg<O>) as Hg<2+>, absorbing the Hg<2+> by a water solution of the system, and removing from the fume, wherein the removal efficiency of the Hg<O> can be increased by over 50 percent.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Industrial flue gas synchronous desulfurization and denitration method

ActiveCN109126417AReduce processing costsSimple processGas treatmentDispersed particle separationFiberNitrogen tetroxide

The invention relates to the technical field of flue gas desulfurization and denitration, and in particular, provides a method for synchronously desulfurizing and denitrifying industrial flue gas, which comprises the following steps at least: S01. mixing the industrial flue gas which has been cooled, dedusted and humidified with ozone to convert the nitric oxide in the industrial flue gas into high-valence nitrogen oxides; S02. carrying out humidifying treatment of the anion ion exchange fiber in an ion exchange tower, then introducing the industrial flue gas treated in the step S01, of which,the sulfur dioxide and the high-valence nitrogen oxides exchange ions with the anion ion exchange fiber, and are adsorbed by the anion ion exchange fiber so as to obtain a gas reaching the dischargestandard. In the method, sulfur dioxide and nitrogen oxide can be removed synchronously, the removal rate of sulfur dioxide and nitrogen oxide reaches higher than 99.0%, and in the finally dischargedflue gas, the content of the sulfur dioxide and the nitrogen oxide are far lower than the national discharge standard, the method is suitable for the treatment of industrial flue gas.

Owner:SHENZHEN QIANHAI ZHONGSHENG ENVIRONMENTAL PROTECTION TECH

Application of N2O4 as catalyst in dimethyl sulfoxide production

InactiveCN1887422AAvoiding Oxidation Reaction Explosion AccidentsOrganic chemistryPhysical/chemical process catalystsNitrogen tetroxideNitrogen dioxide

The present invention discloses the application of N2O4 as catalyst in producing dimethyl sulfoxide. Liquid N2O4 is pressurized into a gasifier at the pressure of 0.2-0.25 MPa and gasified at 45-65 deg.c to produce NO2 gas, and the produced NO2 gas is made to enter buffering tank at 0.15-0.2 MPa and further flow from the buffering tank to oxidizing reactor at controlled flow rate for serving as catalyst in producing dimethyl sulfoxide. The present invention has the advantages of no waste produced, stable reaction and no explosion accident.

Owner:HUBEI XINGFA CHEM GRP CO LTD

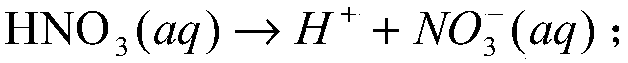

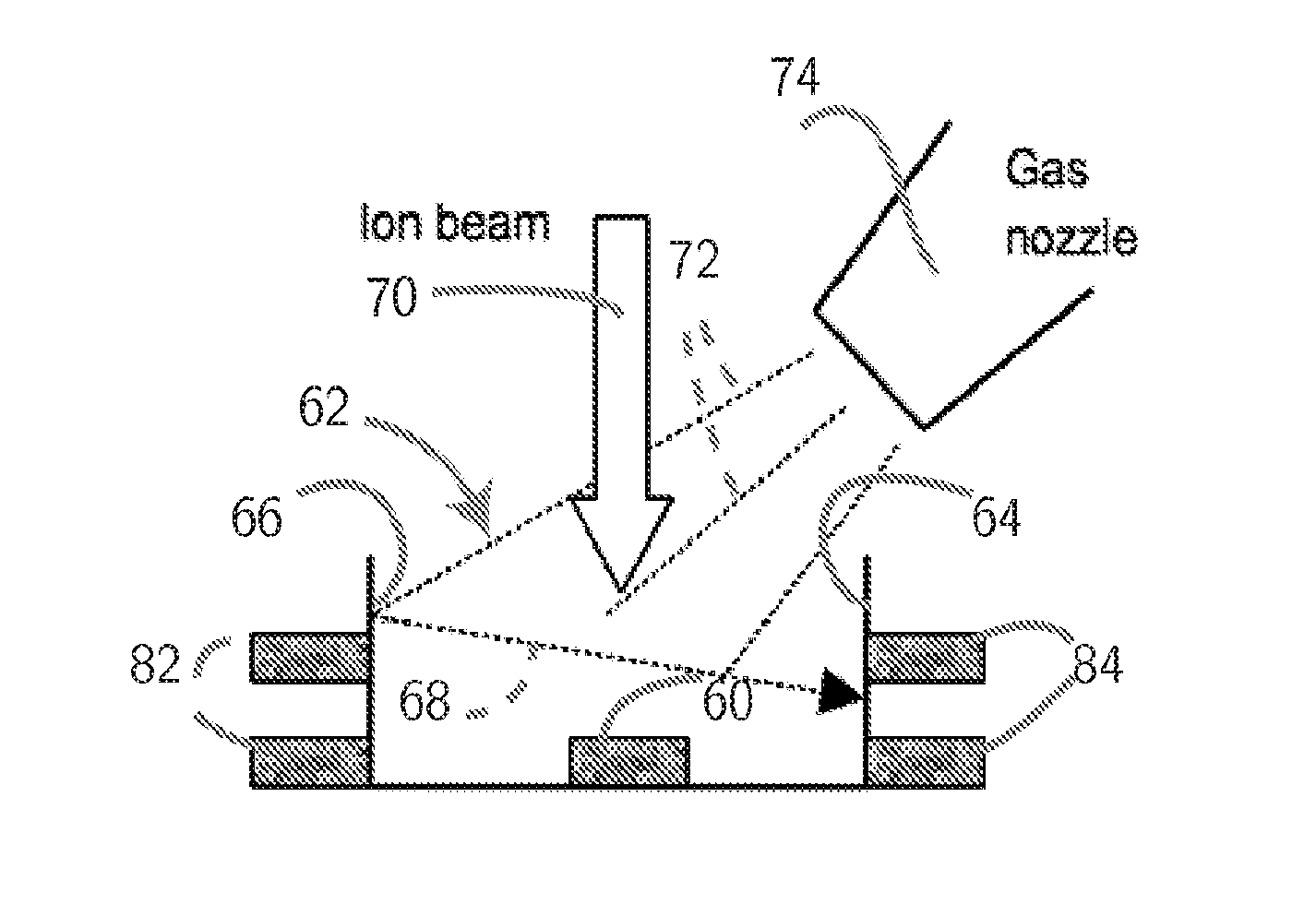

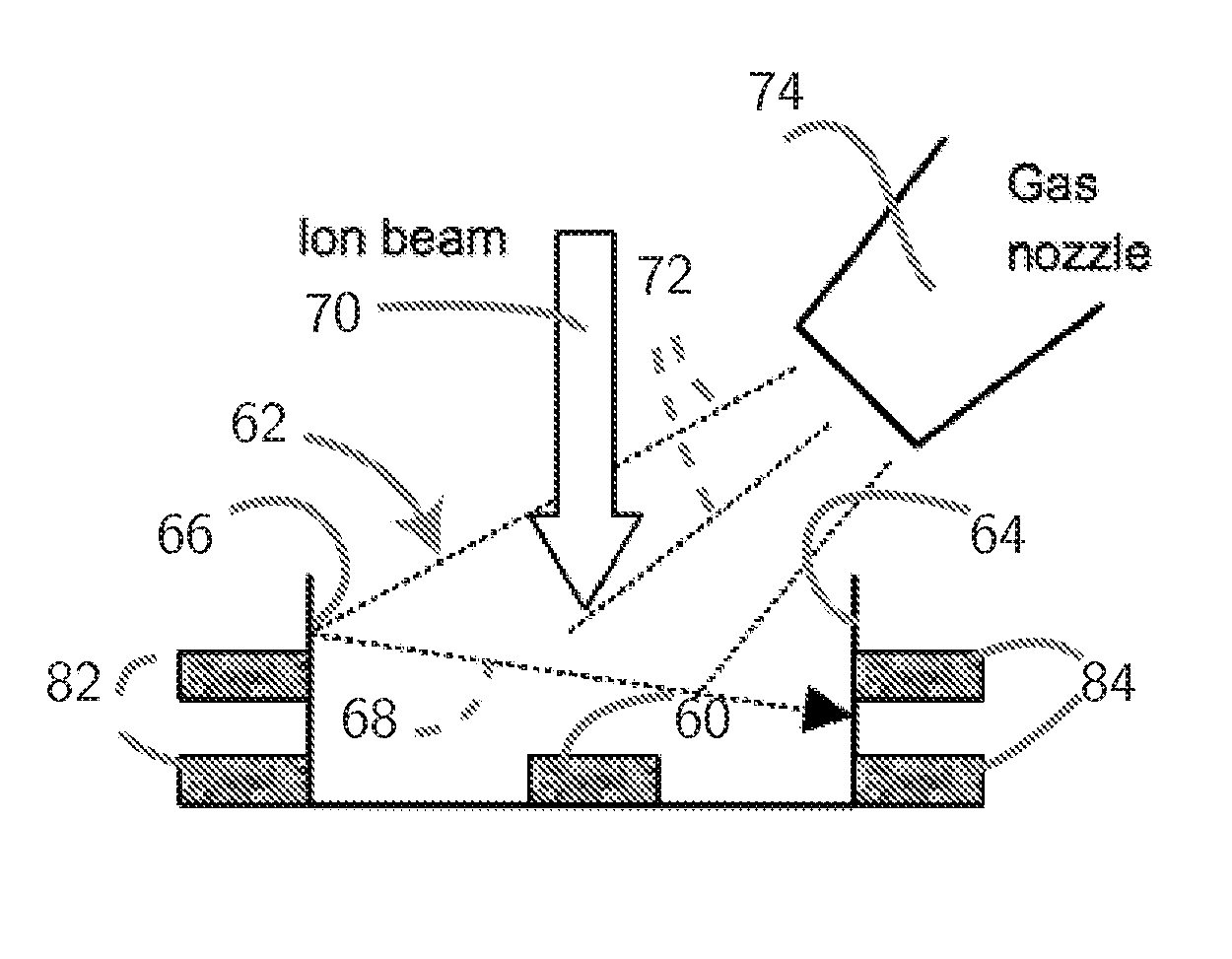

FIB Process for Selective and Clean Etching of Copper

InactiveUS20120211356A1Reduce volatilityHigh stickinessVacuum evaporation coatingSputtering coatingDielectricEtching

Etch assisting agents for focused ion beam (FIB) etching of copper for circuit editing of integrated circuits both prevent loss of adjacent dielectric due to sputtering by the ion beam, and render sputtered re-deposited copper on adjacent surfaces non-conductive to avoid electrical short circuits. The agents are characterized by having an N—N (N being Nitrogen) bonding in their molecules and boiling points between about 70° C. and about 220° C., and include hydrazine and water solutions, hydrazine derivatives, NitrosAmine derivatives saturated with two hydrocarbon groups selected from Methyl, Ethyl, Propyl and Butyl, NitrosAmine related compounds, and Nitrogen Tetroxide. Preferred agents are Hydrazine monohydrate (HMH), HydroxyEthylHydrazine (HEH), CEH, BocMH, BocMEH, NDMA, NDEA, NMEA, NMPA, NEPA, NDPA, NMBA, NEBA, NPYR, NPIP, NMOR and Carmustine, alone or in combination with Nitrogen Tetroxide. The agents are effective for etching copper in high aspect ratio (deep) holes.

Owner:TIZA LAB

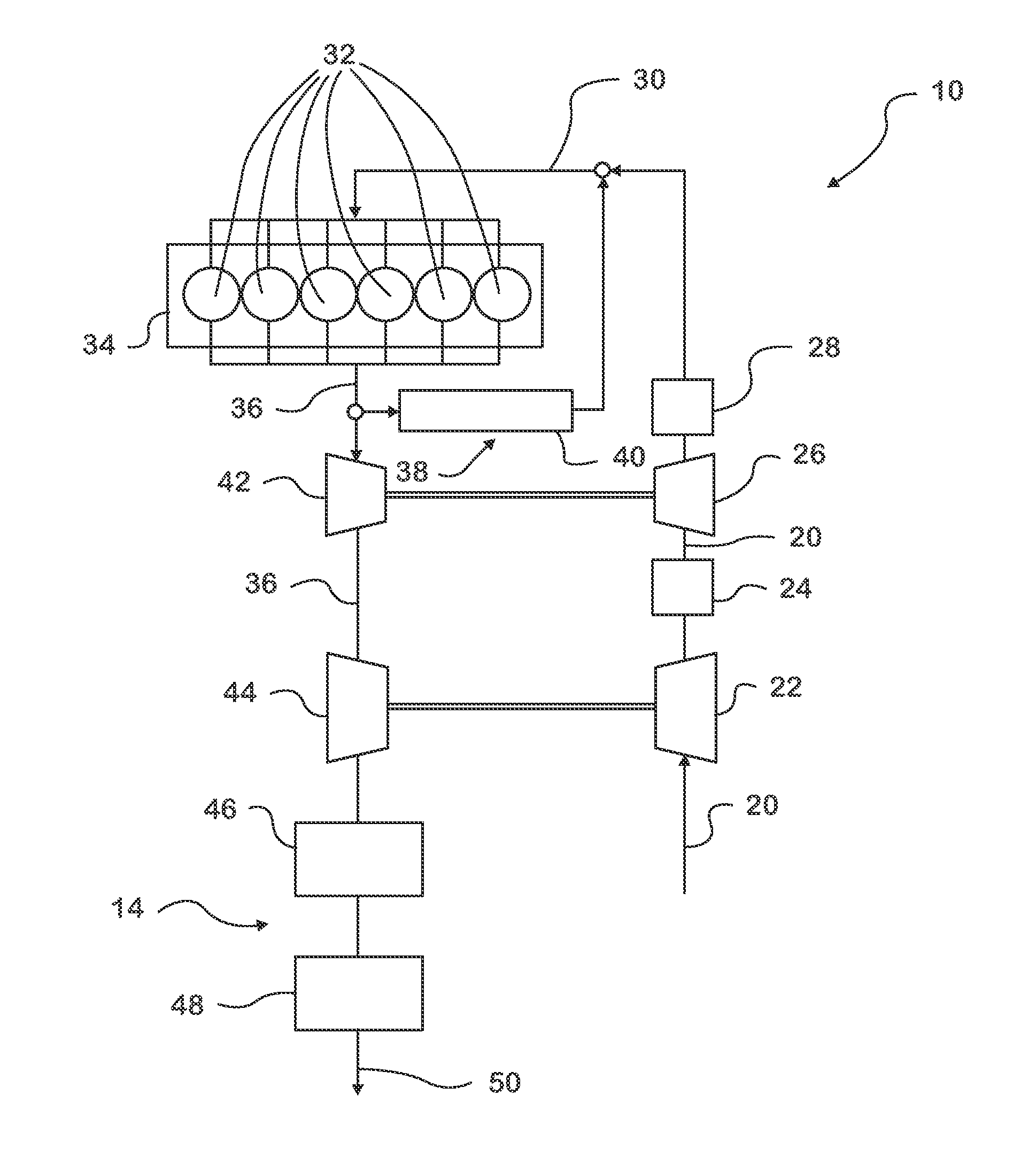

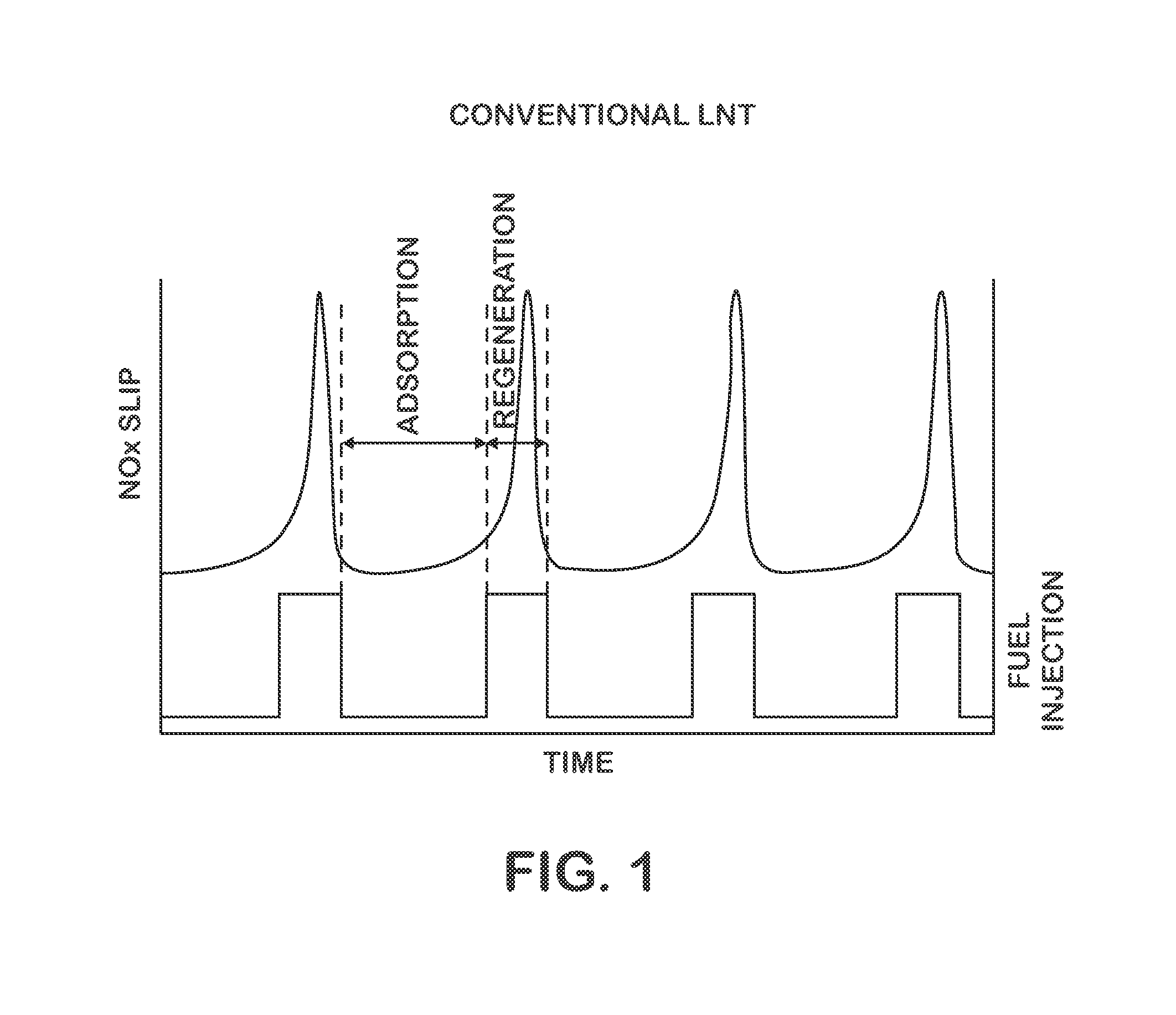

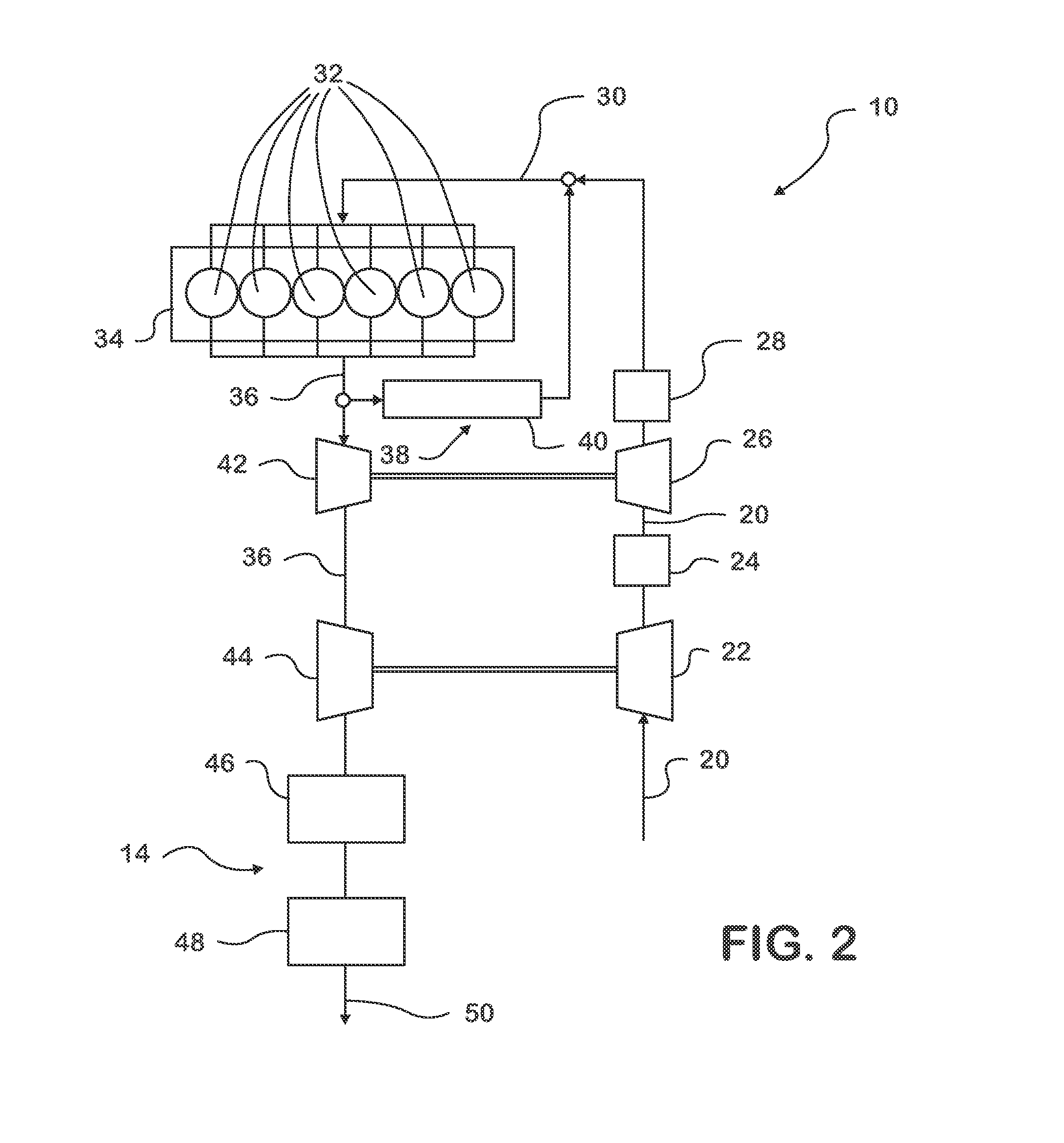

Diesel Engine Nox Reduction

InactiveUS20150113961A1Internal combustion piston enginesNon-fuel substance addition to fuelNitrogen tetroxideNitrate

An engine system for treating nitrogen oxides present in an exhaust gas generated by the combustion of fuel. The engine system includes one or more long breathing lean nitrogen oxide traps that is / are configured to store at least a portion of the nitrogen oxide in the exhaust gas when the lean nitrogen oxide trap operates in an absorption mode. The lean nitrogen oxide trap is also configured for the conversion of the nitrates stored by the lean nitrogen oxide trap during a regeneration event. The engine-out nitrogen oxide levels may be reduced to extend the duration of the absorption process, thereby reducing both the frequency of regeneration events and the associated fuel penalty. The system may include primary and secondary exhaust gas recirculation systems, with exhaust gas from the secondary system being returned to the engine cylinder to reduce the level of nitrogen oxides in that exhaust gas.

Owner:INT ENGINE INTPROP CO LLC

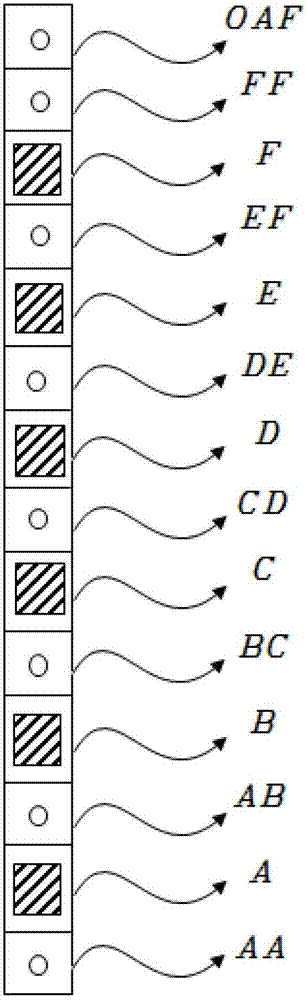

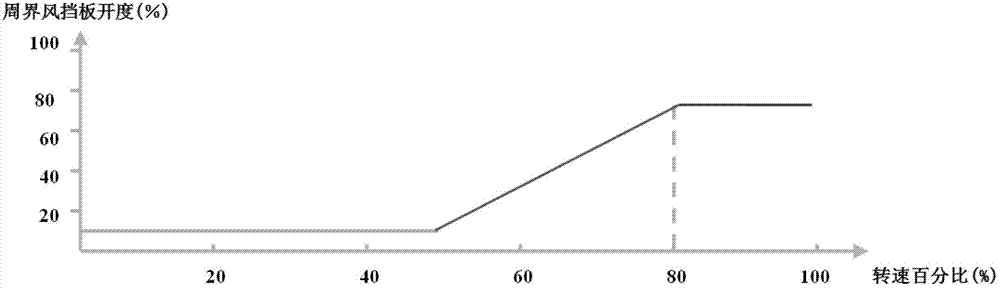

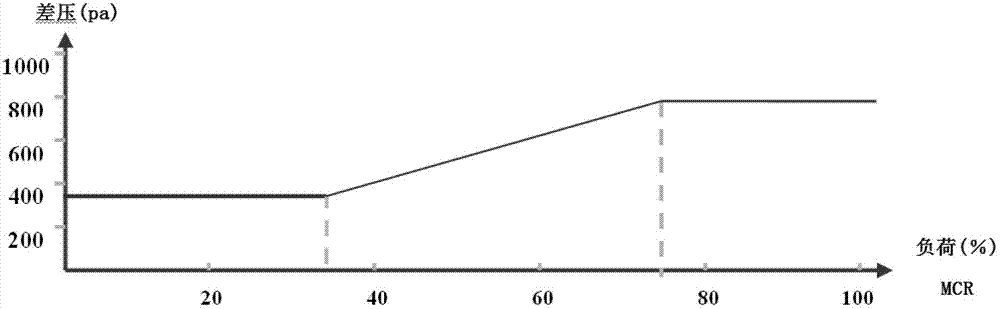

Boiler optimization method for reducing nitrogen oxide discharge

InactiveCN102734833AReduce generationGuaranteed wall-mounted air volumeAir supply regulationNitrogen oxidesNitrogen tetroxide

The invention discloses a boiler optimization method for reducing nitrogen oxide discharge. A boiler is a 600MW machine set boiler, and a hearth of the boiler is sequentially divided into an AA layer, an A layer, an AB layer, a B layer, a BC layer, a C layer, a CD layer, a D layer, a DE layer, an E layer, an EF layer, an E layer, an FF layer and an OFA layer from bottom to top. The method comprises the following steps that the opening degree of a secondary air baffle plate of the AA layer of the boiler is set to -40 percent bias switching automation, the opening degree of a secondary air baffle plate of the AB layer of the boiler is set to -10 percent bias switching automation, the opening degree of a secondary air baffle plate of the BC layer of the boiler is set to -23-30 percent bias switching automation, the opening degree of secondary air baffle plates of the CD layer and the DE layer of the boiler is set to unbiassed switching automation, the opening degree of secondary air baffle plates of the EF layer, the FF layer and the OFA layer of the boiler is set to +15 percent bias switching automation, the opening degree of a secondary air baffle plate of the boiler is set to +15 percent bias switching automation, and the opening degree of a circumferential air baffle plate of the boiler is set to 70 percent when the rotation speed of a coal feeding machine of the boiler is higher than 80 percent of the rated rotating speed. The method realizes the low NOx (nitrogen oxide) discharge.

Owner:CHINA SHENHUA ENERGY CO LTD +2

FIB Process for Selective and Clean Etching of Copper

InactiveUS20110048931A1Prevent electrical short circuitingReduce volatilityVacuum evaporation coatingSputtering coatingDielectricEtching

Etch assisting agents for focused ion beam (FIB) etching of copper for circuit editing of integrated circuits both prevent loss of adjacent dielectric due to sputtering by the ion beam, and render sputtered re-deposited copper on adjacent surfaces non-conductive to avoid electrical short circuits. The agents comprise hydrazine and hydrazine derivatives having an N—N(N being Nitrogen) bonding in their molecules and boiling points between about 70° and 220° C., and NitrosAmine derivatives saturated with two hydrocarbon groups selected from Methyl, Ethyl, Propyl and Butyl. Preferred agents are Hydrazine monohydrate (HMH), HydroxyEthylHydrazine (HEH), NDMA, NMEA, NDEA, NMPA, NEPA, NDPA, NMBA or NEBA, alone or in combination with Nitrogen Tetroxide. The agents are effective for etching copper in high aspect ratio (deep) holes.

Owner:TIZA LAB

Exhaust gas cleaner

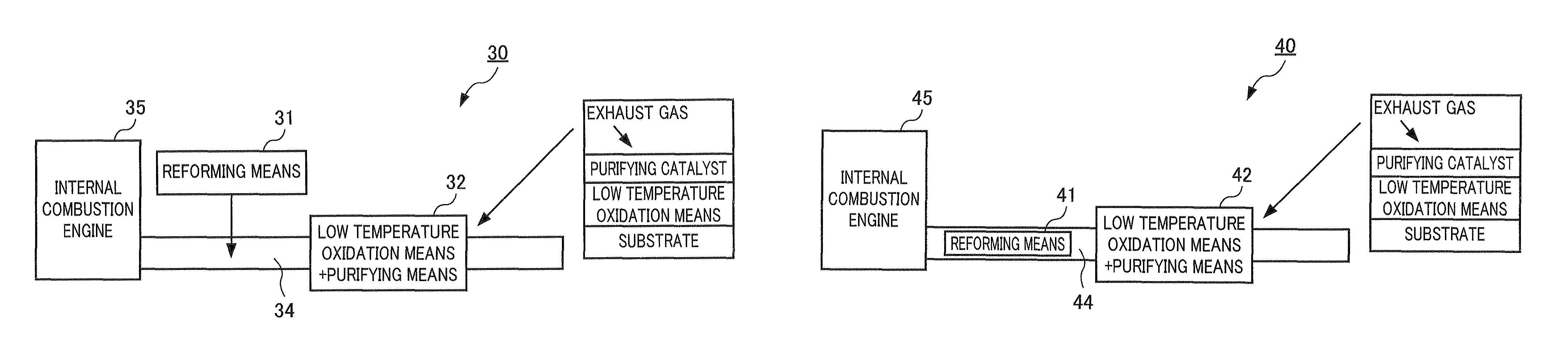

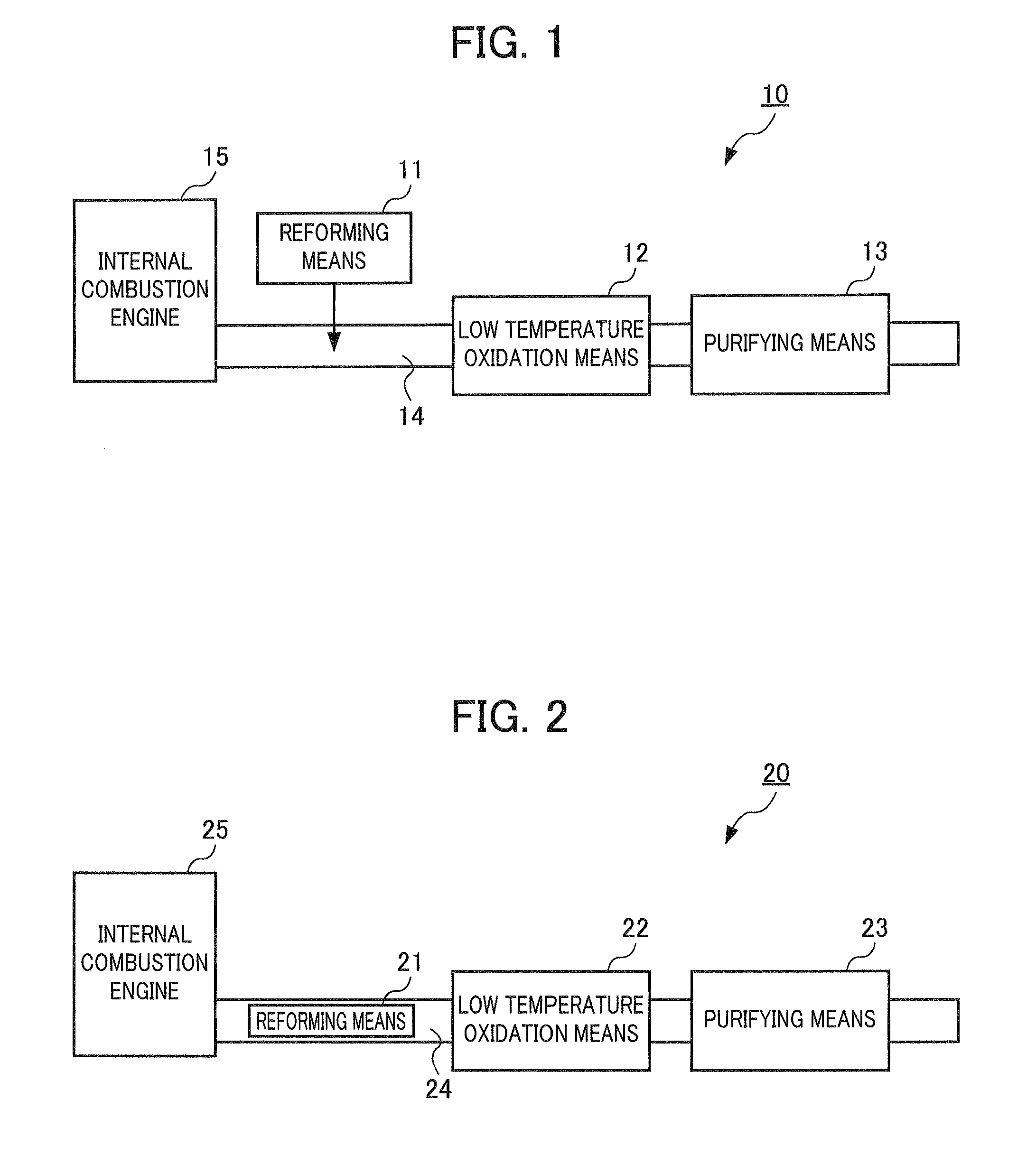

InactiveUS8151742B2Efficient purificationIncrease temperatureExhaust apparatusCombustion enginesNitrogen tetroxideHydrogen

Owner:HONDA MOTOR CO LTD

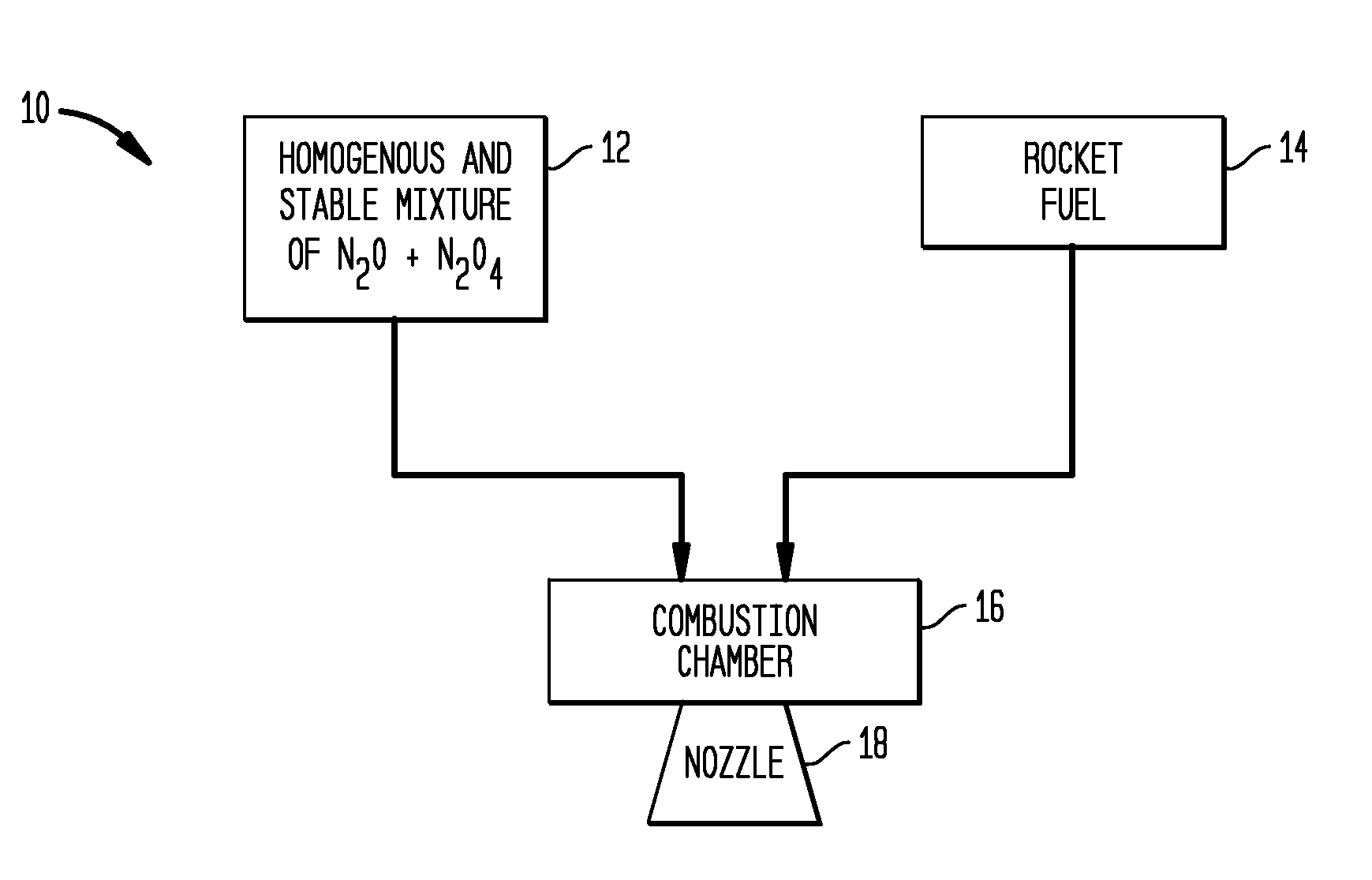

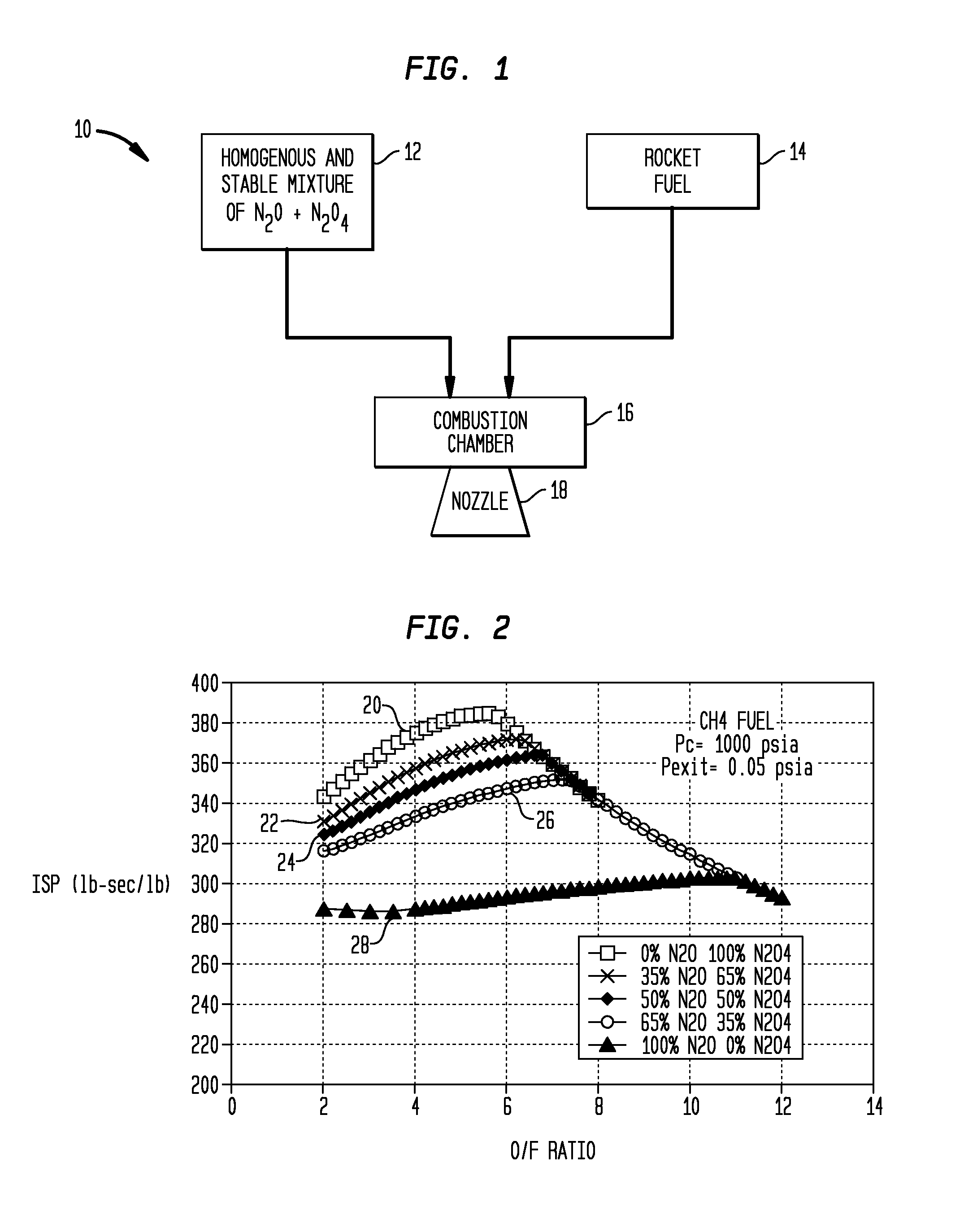

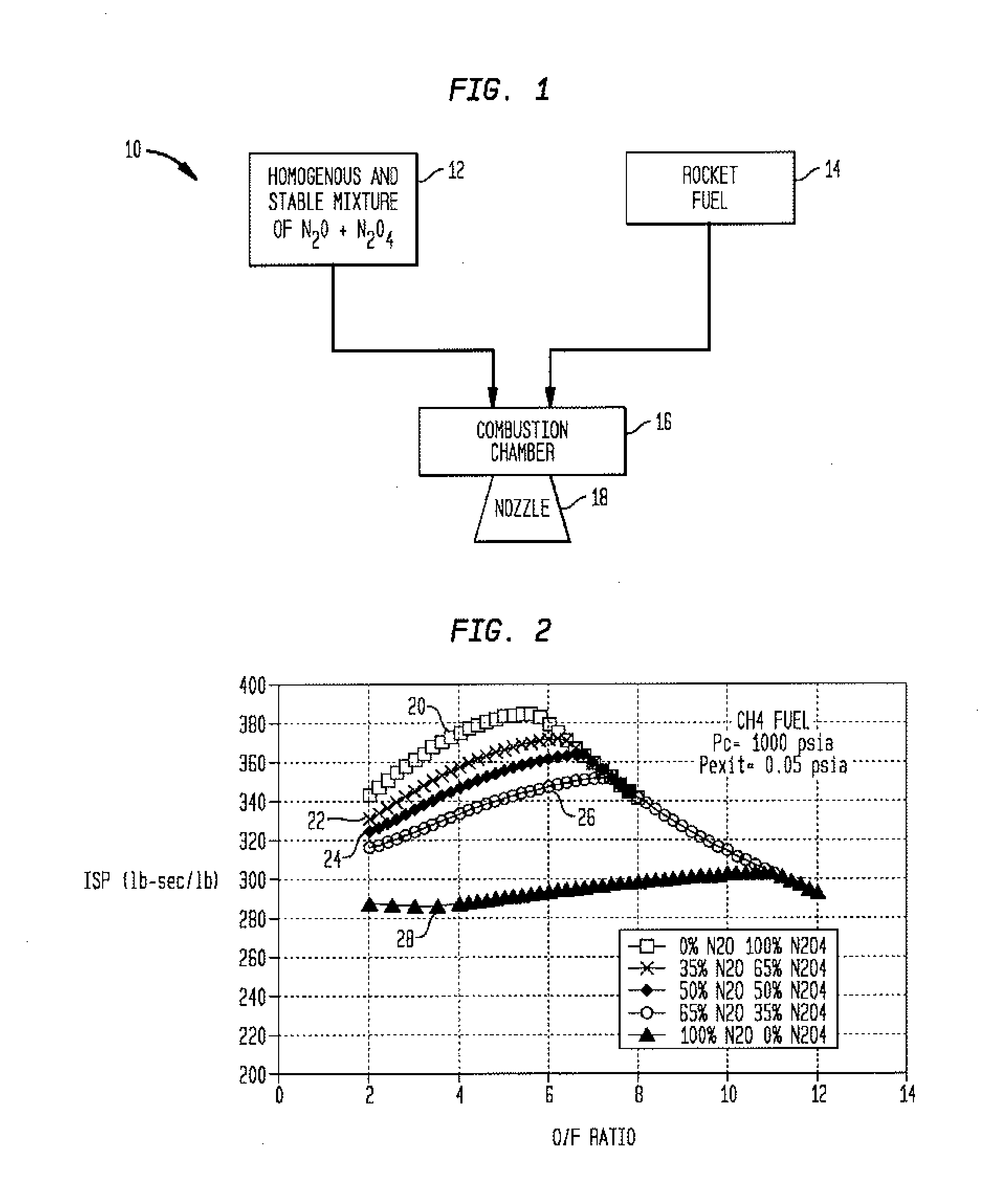

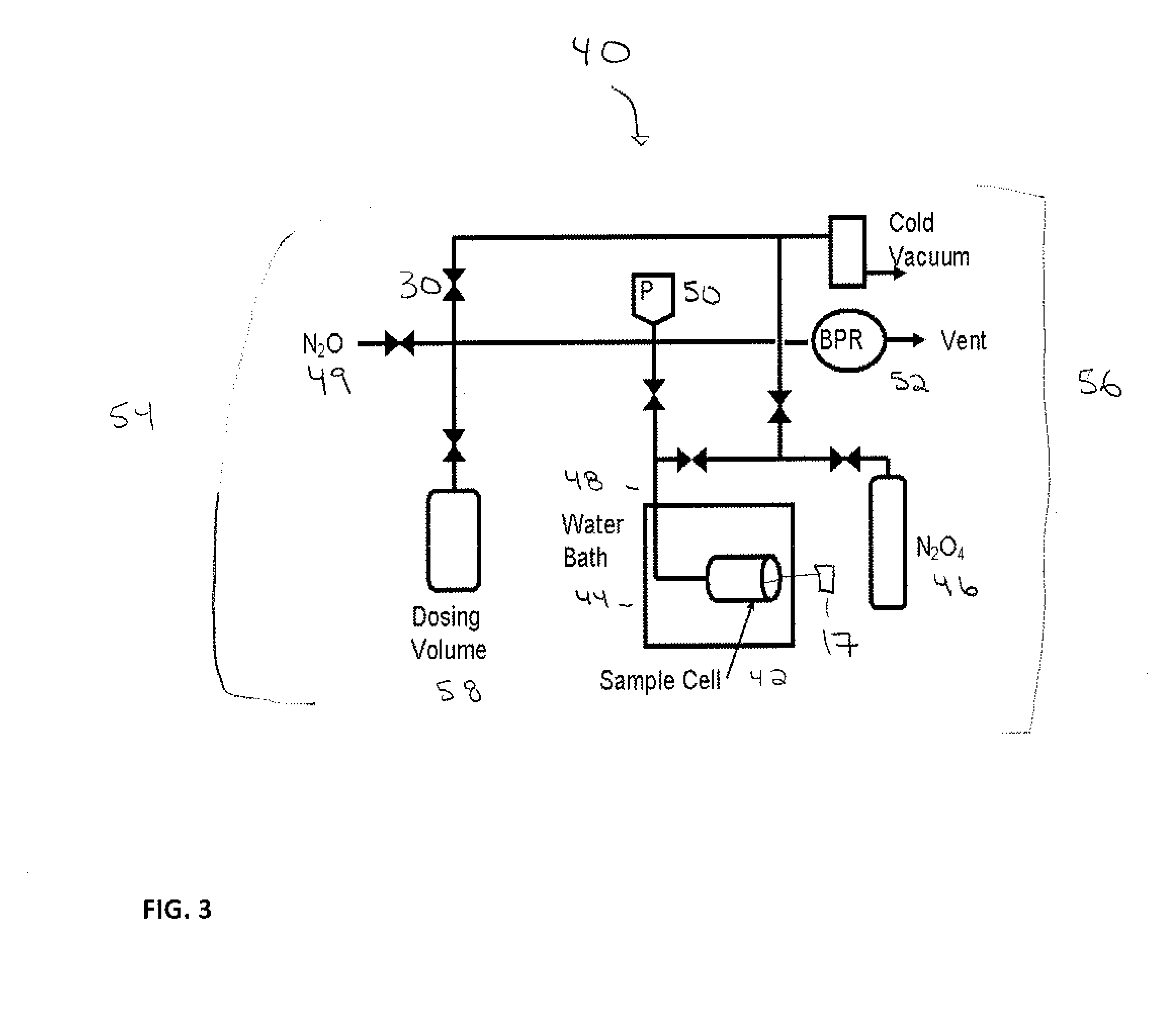

Oxidizer Compound for Rocket Propulsion

InactiveUS20120144799A1Low toxicityEasy to storeTurbine/propulsion fuel supply systemsExplosivesNitrogen tetroxideRoom temperature

A rocket propulsion oxidizer compound that is a mixture that is a homogenous and stable liquid at room temperature that includes nitrous oxide and nitrogen tetroxide.

Owner:SACKHEIM ROBERT L

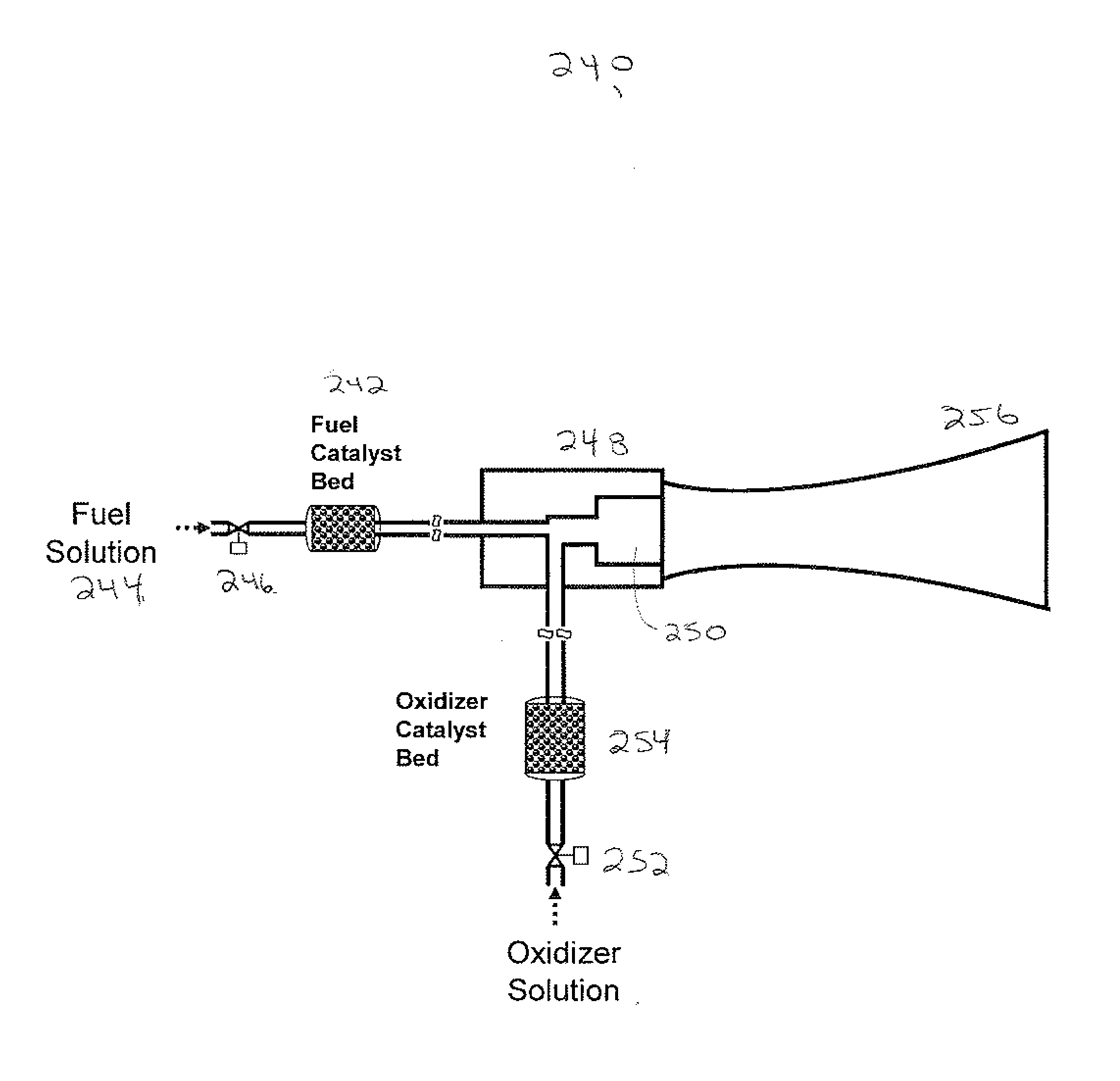

Oxidizer compound for rocket propulsion

InactiveUS20130205754A1Promotes spontaneous ignitionTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionNitrogen tetroxideCombustor

The present disclosure generally pertains to a rocket propulsion oxidizer compound that is a solution, is a homogenous and stable liquid at room temperature and includes nitrous oxide and nitrogen tetroxide. In addition, an apparatus is provided for burning a fuel and nitrous oxide / nitrogen tetroxide. The apparatus has a combustor, a catalyst, a nitrous oxide / nitrogen tetroxide supply passage for directing the nitrous oxide / nitrogen tetroxide to a contact position with the catalyst, and a fuel supply passage for supplying the fuel to the combustor. The catalyst acts to facilitate decomposition of the nitrous oxide / nitrogen tetroxide, while the combustor burns the fuel, the decomposed nitrous oxide / nitrogen tetroxide and / or nitrous oxide / nitrogen tetroxide decomposed in the reaction.

Owner:CFD RES CORP

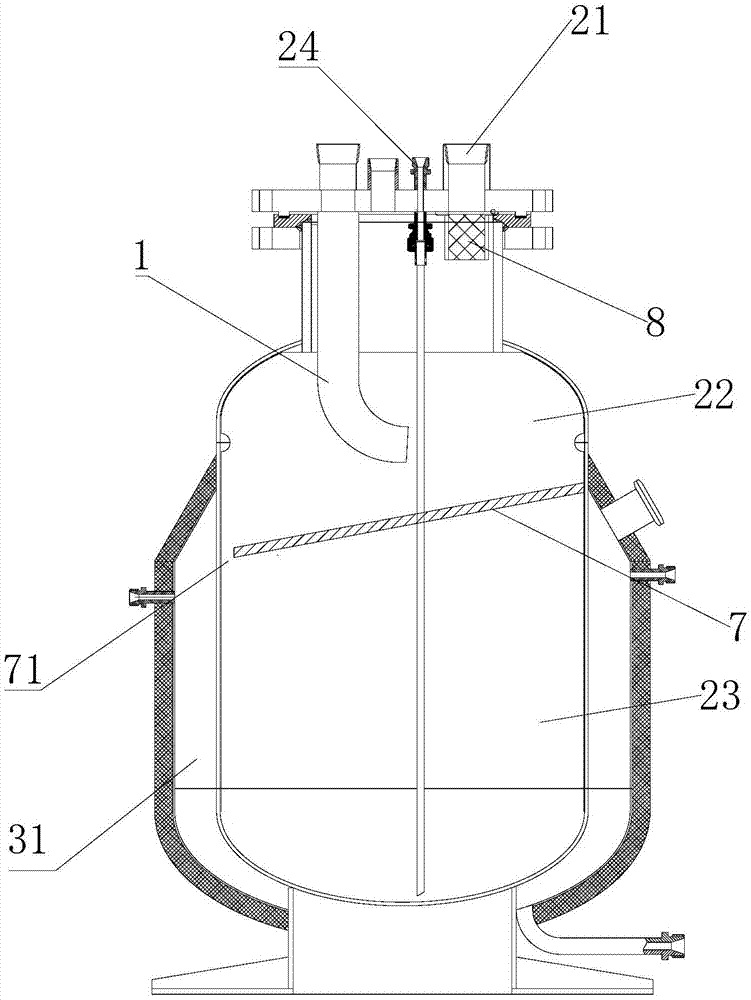

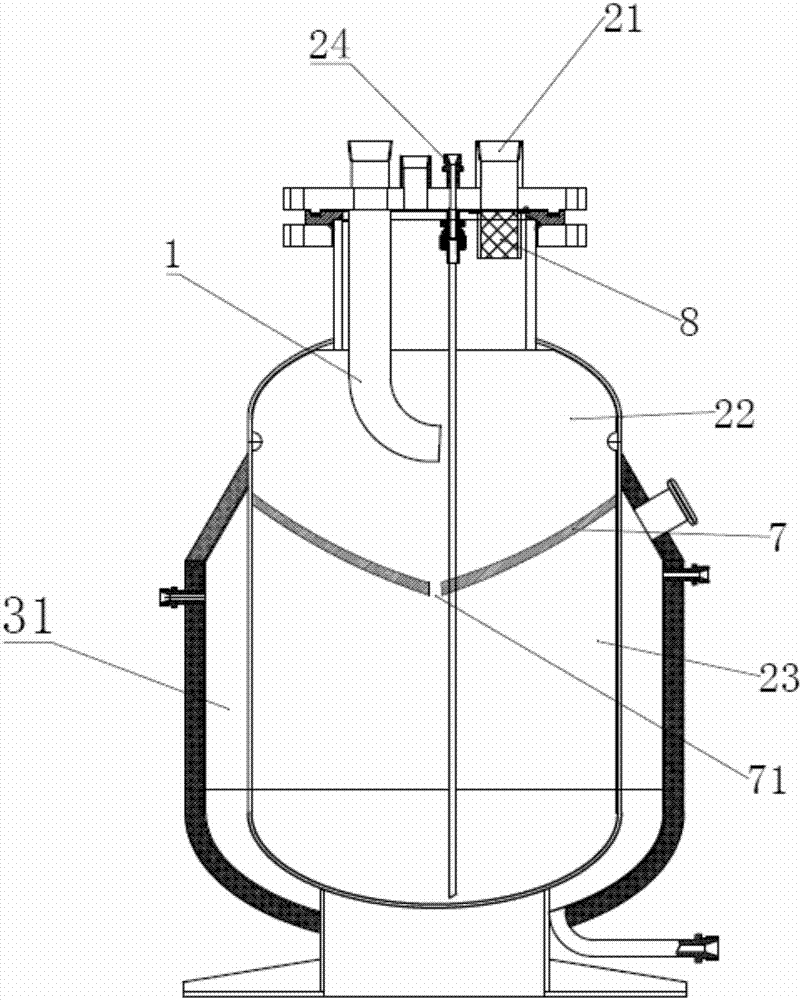

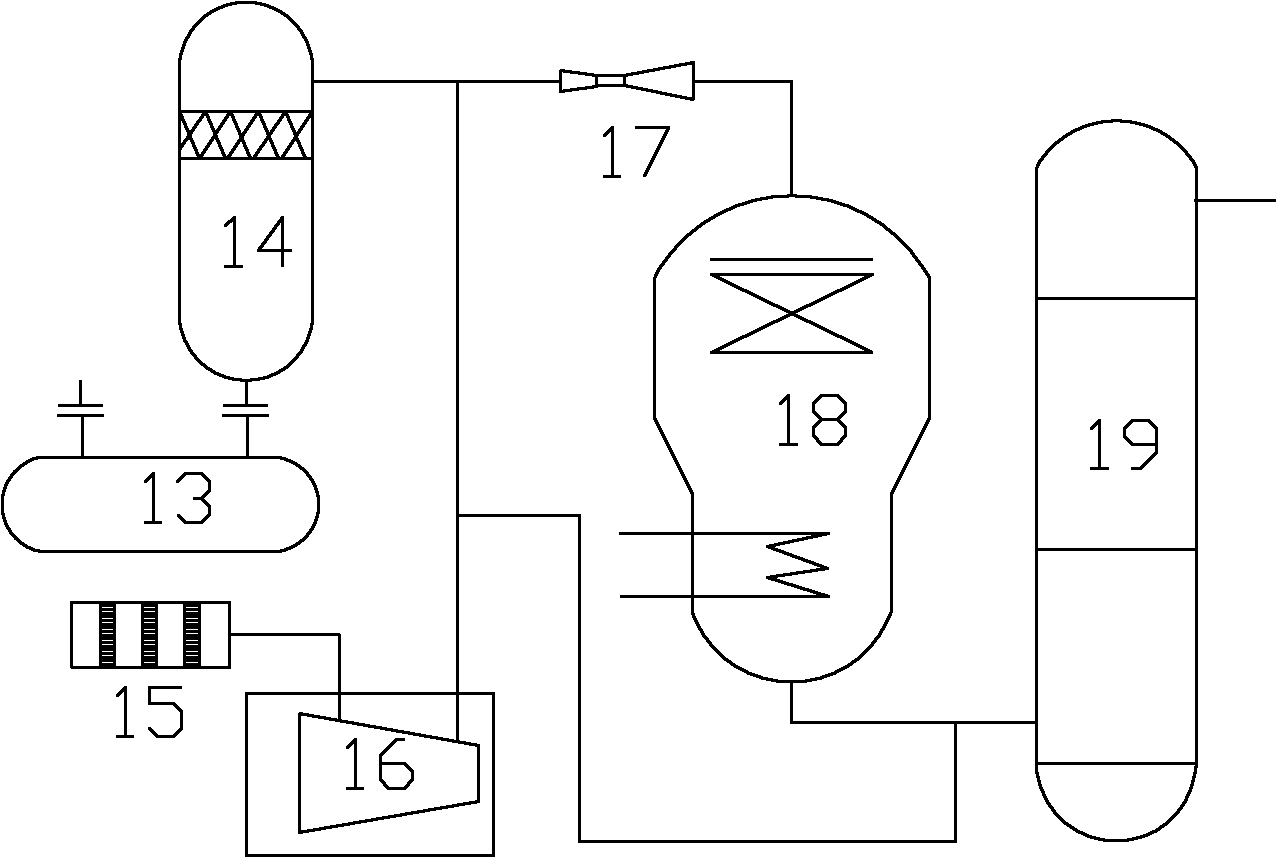

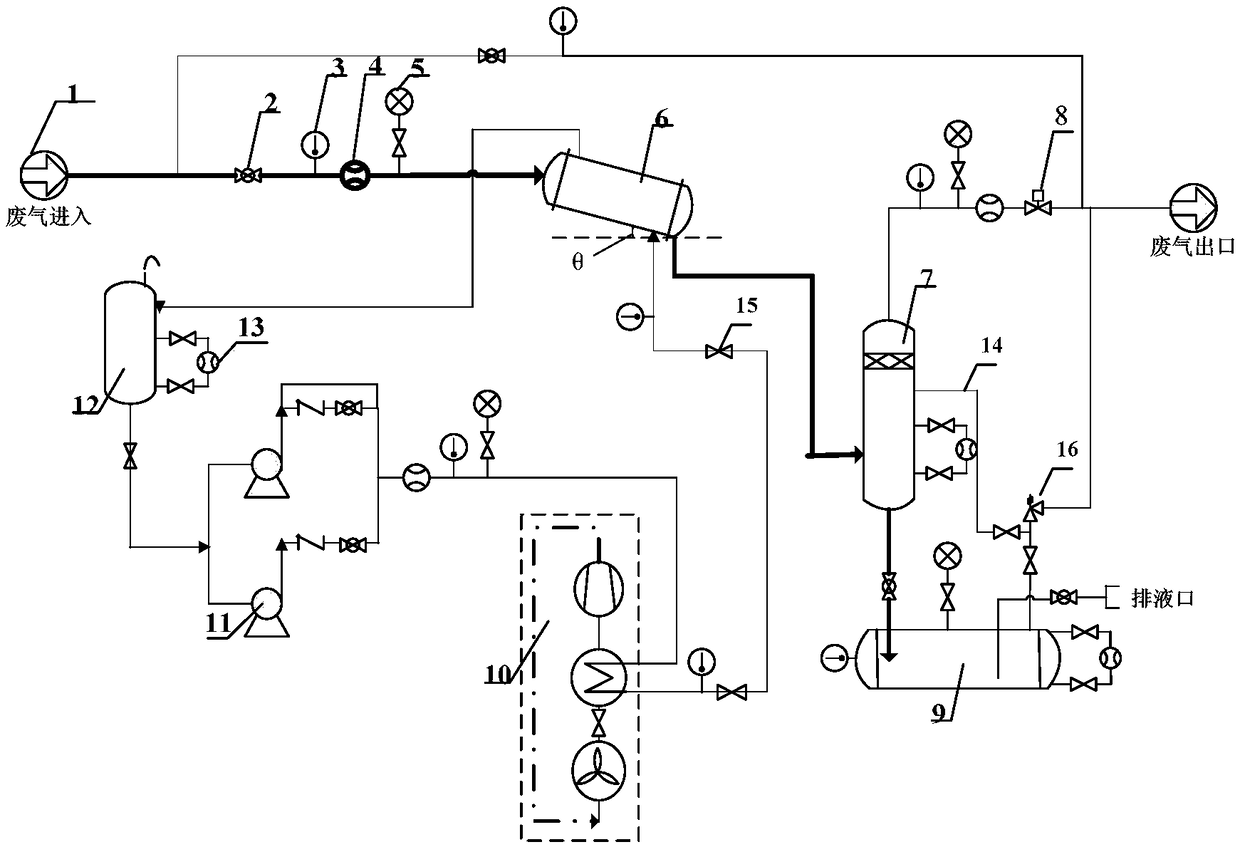

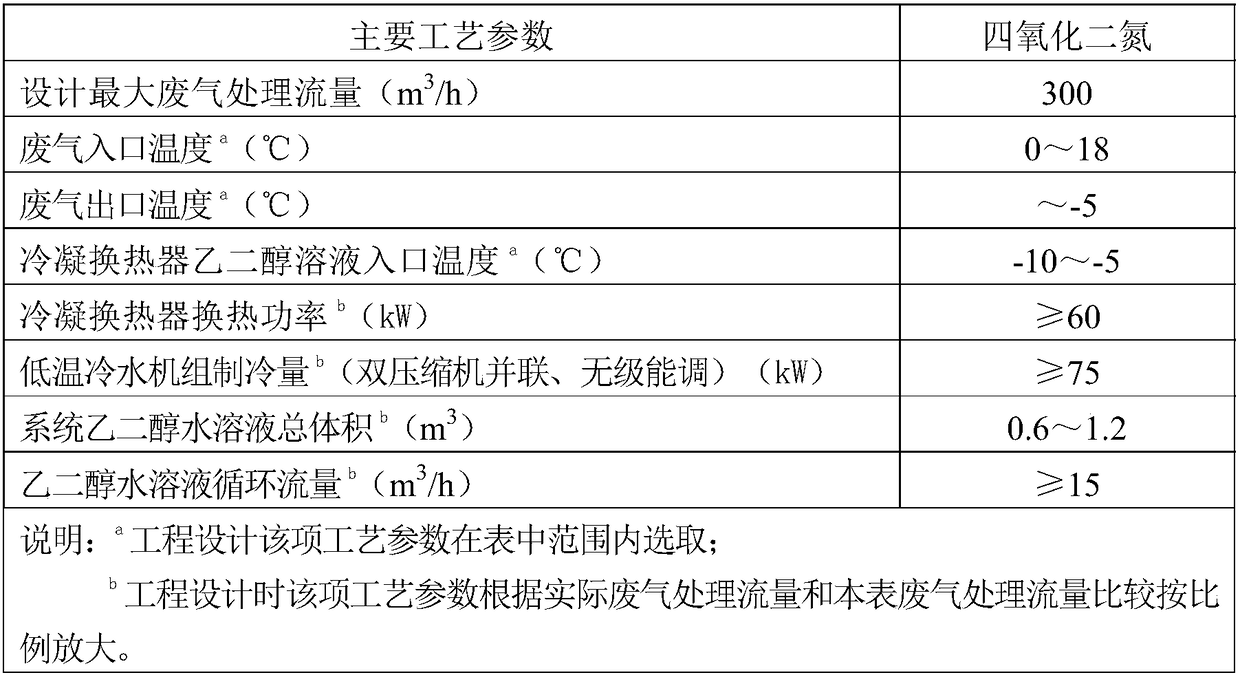

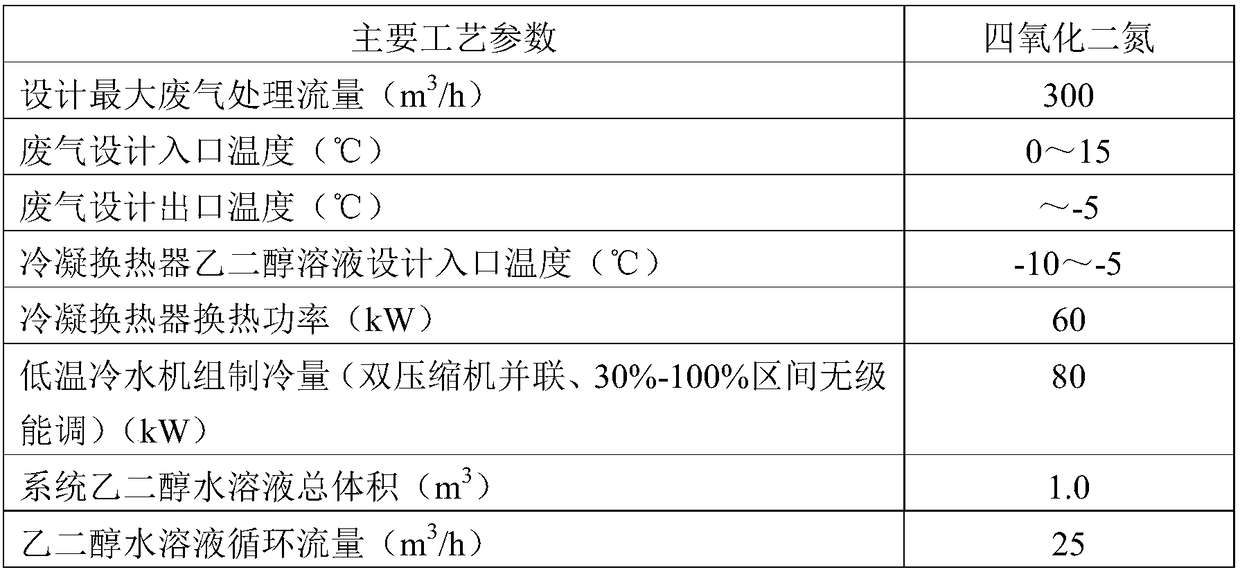

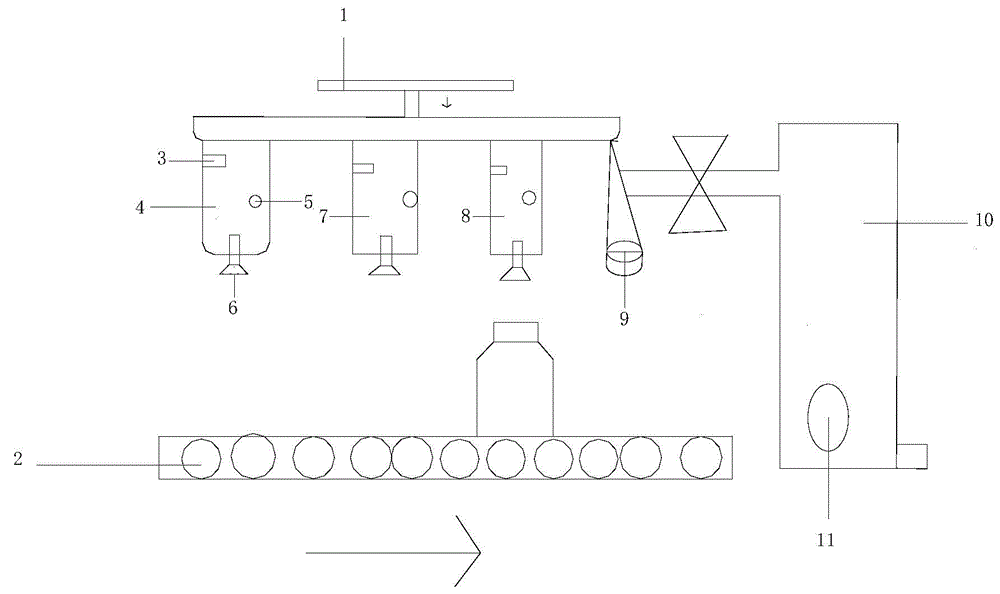

System and process for condensing and recovering nitrogen tetroxide waste gas resource

PendingCN108057257AReduce decompression expansionImprove recycling efficiencyNitrogen compoundsDispersed particle separationExpansion tankElectric control

The invention provides a system and a process for condensing and recovering a nitrogen tetroxide waste gas resource, which belong to the field of waste gas treatment. The system comprises a condensingheat exchanger, a gas-liquid separator, an electric control valve, a condensate collecting tank, a low-temperature water chilling unit, and an ethylene glycol water solution buffer and expansion tank. A pipeline of waste gas containing nitrogen tetroxide steam enters the condensing heat exchanger; a gas-liquid mixture outlet pipeline of the condensing heat exchanger is connected with the gas-liquid separator; the gas-liquid separator is connected with the condensate collecting tank through a gas communicating pipe. In the system, the low-temperature water chilling unit provides a cooling capacity for cooling the temperature of an ethylene glycol water solution to the operating temperature, the ethylene glycol water solution cools the waste gas containing the nitrogen tetroxide steam through heat exchange so as to achieve a supersaturated state, and nitrogen tetroxide is recovered through gas-liquid separation. In the process, the ethylene glycol water solution is not only an intermediate heat transfer working medium but also a cold storage working medium, so that the system is ensured to operate stably.

Owner:中国人民解放军63605部队 +1

Method and device for disinfecting and sterilizing plastic packaging containers

InactiveCN104906611ANo secondary pollutionWill not deformLavatory sanitoryChemicalsUltravioletEthyl acetate

The invention discloses a method and a device for disinfecting and sterilizing plastic packaging containers. According to the invention, the disinfecting and sterilizing purpose is achieved by performing photochemical reaction by virtue of sequentially adding 5-10mg / m<3> ethyl acetate, a nitrogen oxide composed of nitrous oxide, nitrogen tetroxide and nitrogen dioxide, 0.1-0.3% of ferrous and 35-45% of hydrogen peroxide to generate radical ions which have a strong oxidation property. The method and the device disclosed by the invention have the beneficial effects that the plastic packaging containers are disinfected and sterilized by generating the radical ions, without secondary pollution and plastic deformation, thus avoiding ageing due to the action of ultraviolet ray and prolonging the service life and time; the plastic packaging containers after being disinfected and sterilized by the radicals are free from water stain residue and good in effect.

Owner:CHANGZHOU UNIV

Method for preparing nitrocompounds from nitrogen suboxides

InactiveCN103396319AIncrease profitAtom economy is highNitro compound preparationNitro compoundHeteropoly acid

The invention discloses a method for preparing nitrocompounds from nitrogen suboxides. Under the acceleration of molecular oxygen, nitrogen suboxides, such as nitrogen monoxide, nitrogen dioxide, nitrous oxide, nitrogen trioxide, nitrogen tetroxide and the like, reacts with alicyclic compounds, aromatic compounds and heterocyclics under the actions of heteropoly acid salts (such as aluminosilicate, phosphate aluminosilicate, sodium phosphomolybdate and the like), transition metal oxides, triphenylphosphine metal organic complexes and transition metal ion clay catalysts to obtain the nitrocompounds. The method disclosed by the invention is used for substituting the traditional industrial preparation method for preparing nitrocompounds from nitrogen pentoxide, nitric acid, nitrate, nitrate ester and other high-valence nitrogen (V) compounds; and the invention enhances the atom utilization ratio of the industrial nitrocompound preparation reaction by nitrification, and has the characteristic of atom economy in industrial preparation of nitrocompounds.

Owner:彭新华

Coal combustion improver and preparation method thereof

InactiveCN104673430AImprove combustion efficiencyEmission reductionSolid fuelsNitrogen oxidesCombustion

The invention discloses a coal combustion improver which comprises components in percentage by weight as follows: 15%-40% of nano active titanium dioxide, 10%-30% of a promoter, 2%-8% of a surfactant, 4%-10% of a smoke suppressor, 10%-30% of a sulfur-fixing agent and the balance of a solvent. The coal combustion improver can reduce coal consumption effectively and reduce emission of sulfur dioxide and nitrogen oxide, is stable in performance, high in coal saving rate, and simple and convenient to use.

Owner:郭跃辉

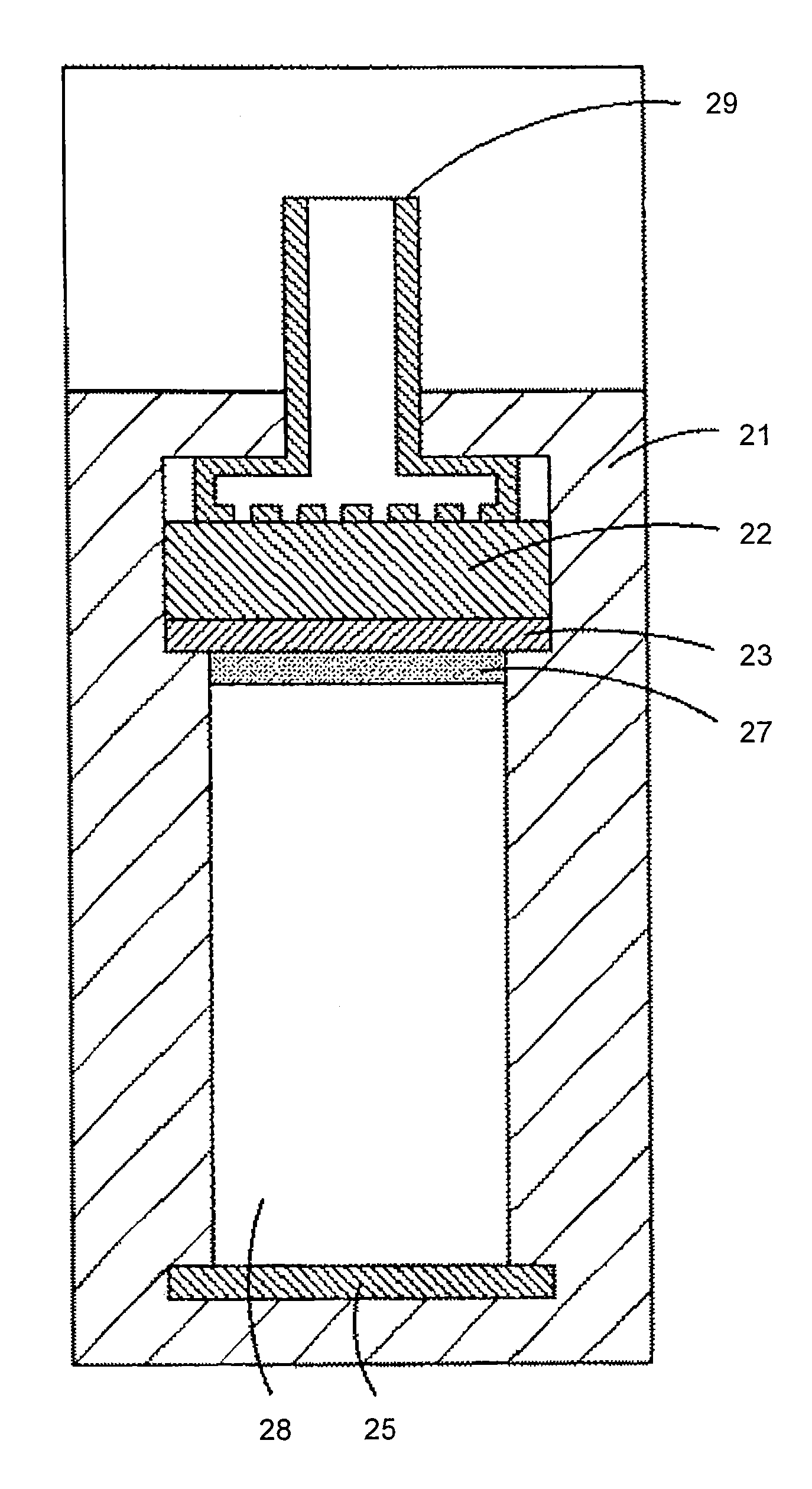

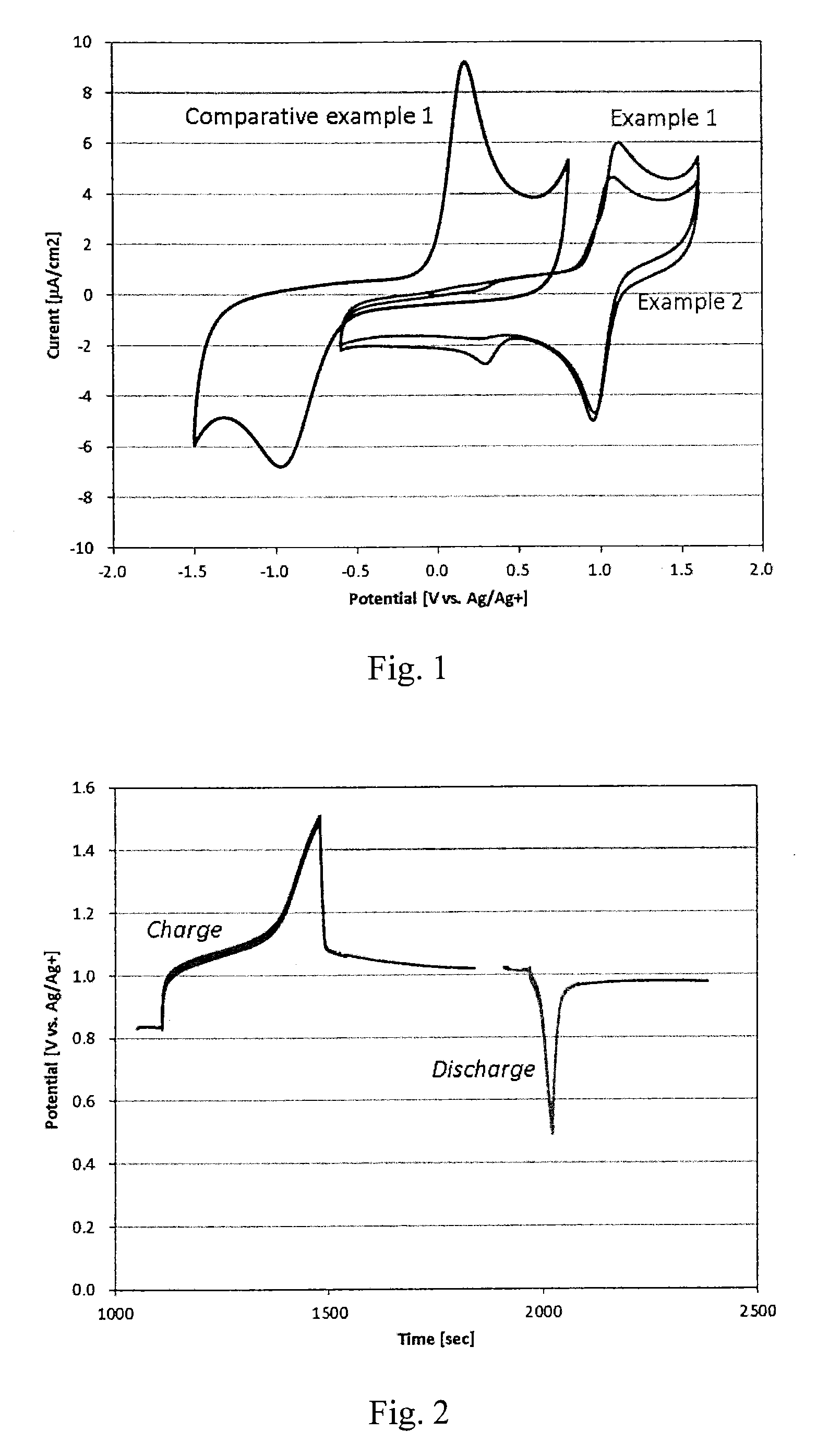

Rechargeable metal NxOy gas battery system

A metal-nitric oxide electrochemical cell which is fed a gas comprising nitric oxide (NO) and at least one gas selected from the group consisting of a nitrogen oxide of formula NxOy, oxygen, water vapor, a gaseous hydrocarbon, carbon monoxide and carbon dioxide is provided. Also provided is a rechargeable battery containing the metal-nitrogen oxides electrochemical cell. A vehicle system wherein exhaust gas from a combustion engine serves as a feed of active cathode material to a metal-nitrogen oxides battery is additionally provided.

Owner:TOYOTA JIDOSHA KK

Explosives vapor detector

ActiveUS10113983B1The process is fast and efficientMinimal intrusivenessWithdrawing sample devicesPreparing sample for investigationPlatinumNitrogen tetroxide

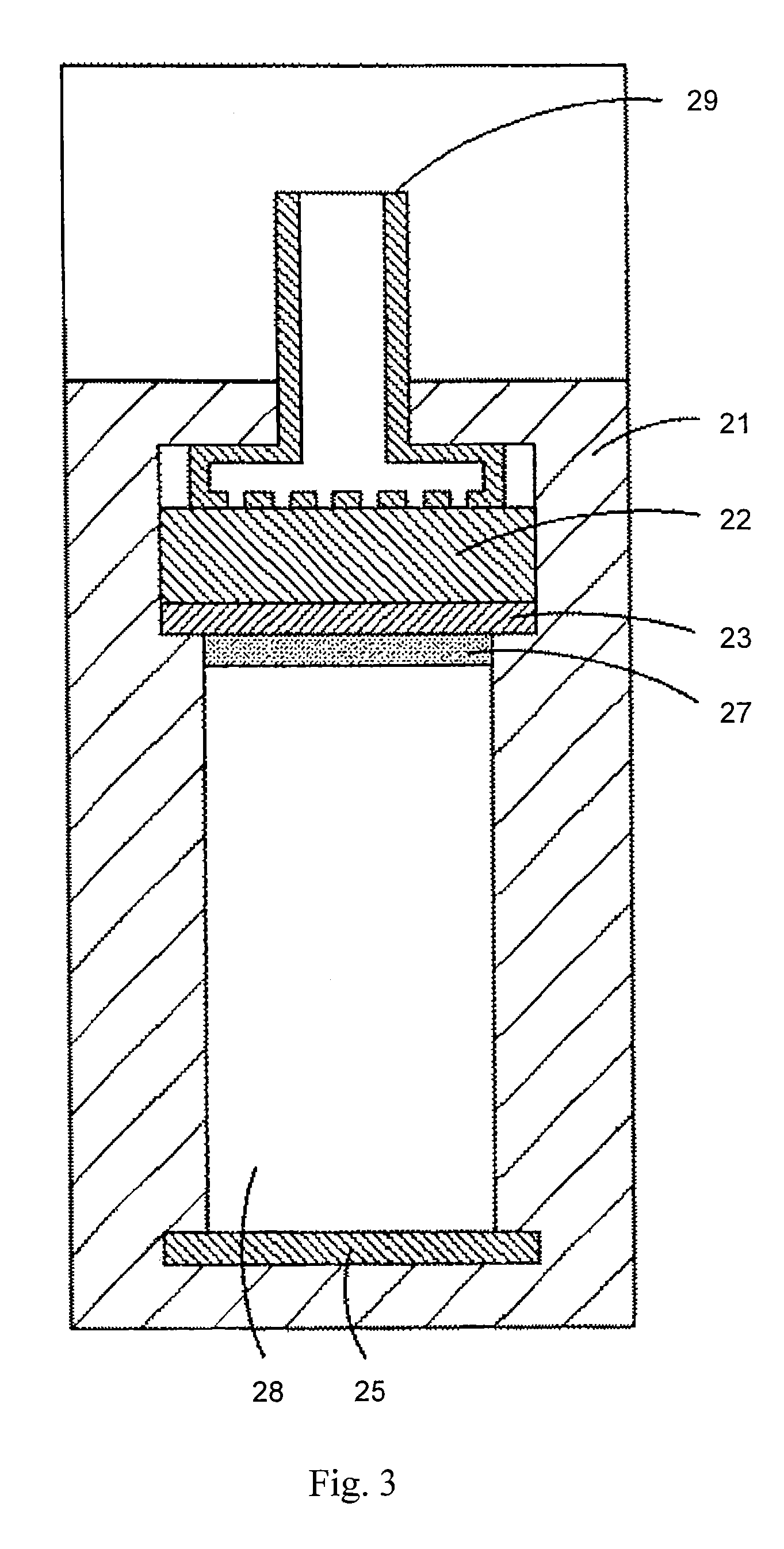

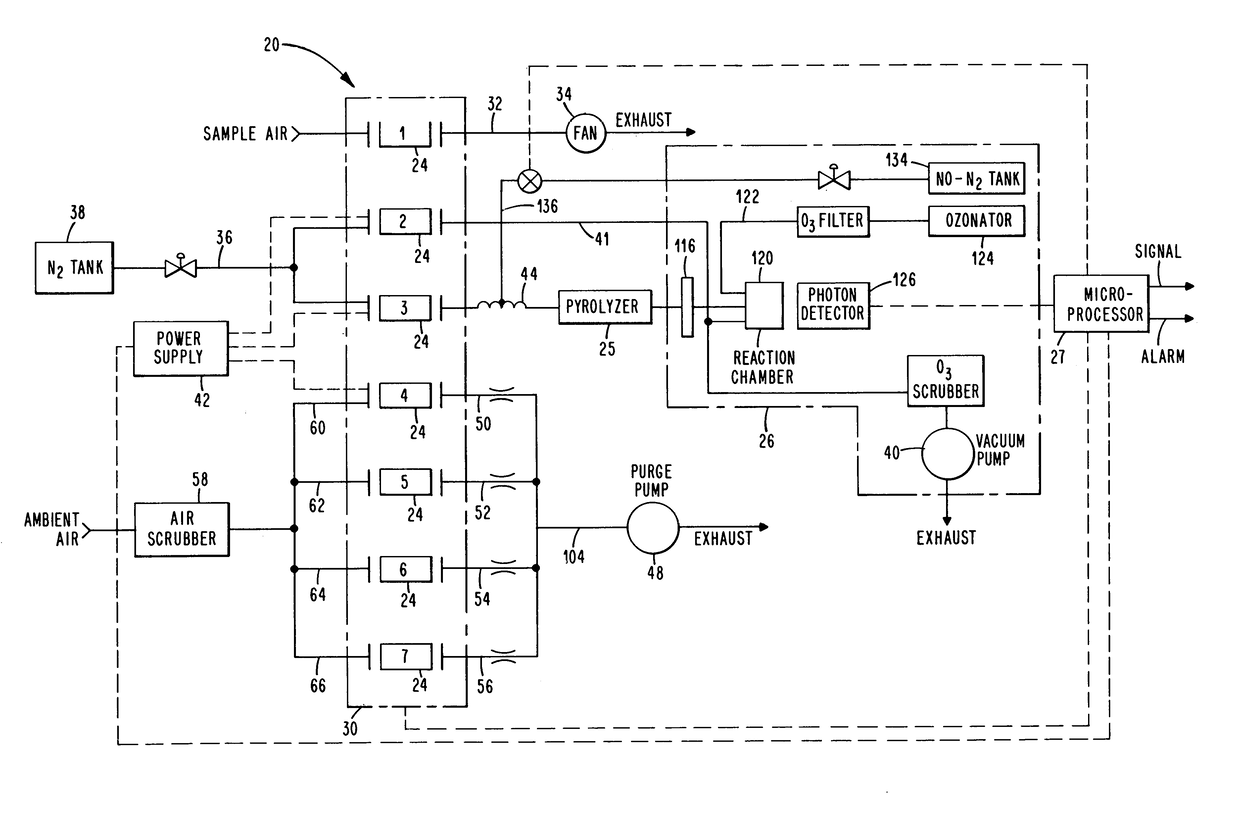

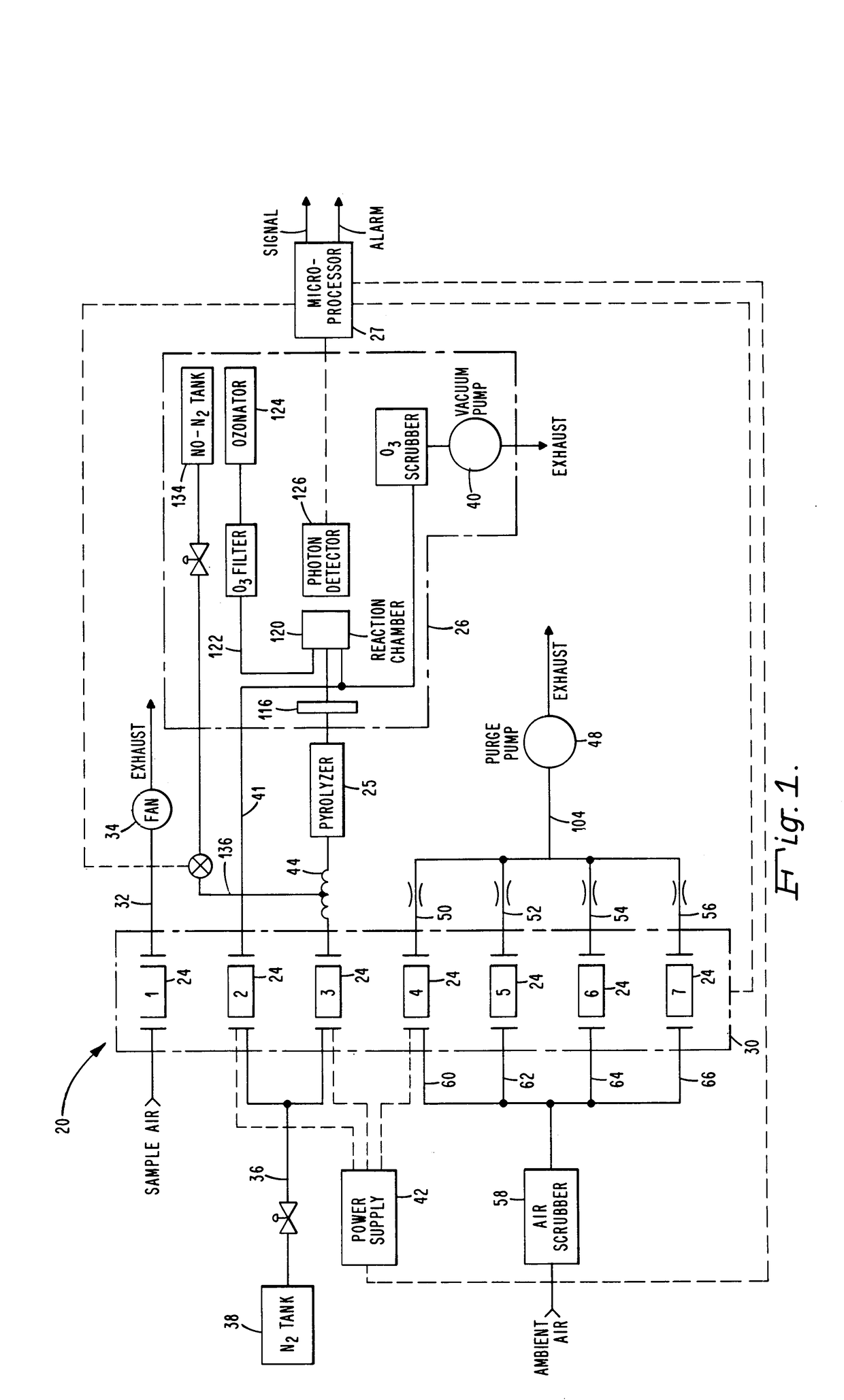

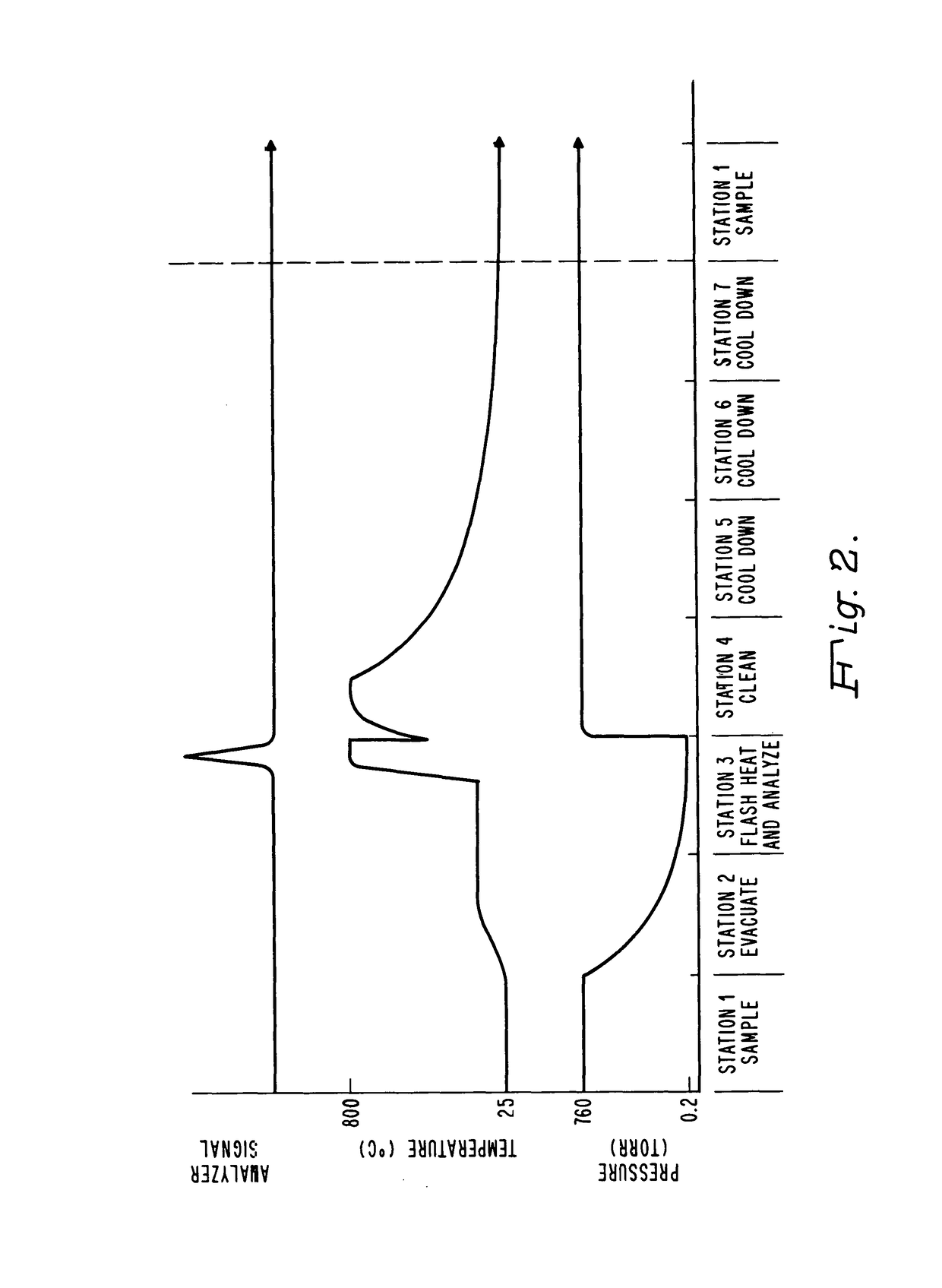

Disclosed are a highly selective, highly sensitive method and apparatus for detecting vapors from explosives at low concentrations such as 1 part in 1014. Airborne explosives vapors are selectively adsorbed on a spiral-wound platinum or platinum-coated ribbon of a preconcentrator cartridge while trapping of nitrogen oxides is avoided. The vapors are released and partially decomposed to liberate nitric oxide gas by flash-heating of the ribbon, these products may then be pyrolyzed if necessary to complete the liberation of nitric oxide gas, and then the liberated nitric oxide gas is detected, as by chemiluminescent detection. Also described are various systems incorporating the explosives vapor detector such as a walk-through portal, a vehicle sniffer, and a system incorporated into the air-handling apparatus of a building. A walk-through explosives detection system is disclosed having a carousel containing an array of preconcentrator cartridges for rapid acquisition and analysis of explosives vapor samples, and which is capable of screening up to ten persons per minute for possession of explosives.

Owner:THERMO FISHER SCIENTIFIC INC

Nitrogen oxide abatement in semiconductor fabrication

InactiveUS20160276179A1Dispersed particle separationSemiconductor/solid-state device manufacturingCombustionNitrogen tetroxide

Embodiments enclosed herein relate to methods and apparatus for reducing nitrogen oxides (NOx) produced during processing, such as during semiconductor fabrication processing. A processing system may include an abatement controller and an effluent abatement system, wherein the abatement controller controls the effluent abatement system to reduce NOx production, while ensuring abatement of the effluent gases from the processing system. The effluent abatement system may include a combustion-type effluent abatement system and / or a plasma-type effluent abatement system. The abatement controller may select operating modes of the effluent abatement systems to reduce NOx production.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com