Catalyst for decomposing nitrogen oxide and preparation method thereof

一种催化剂、共催化剂的技术,应用在催化剂活化/制备、物理/化学过程催化剂、分离方法等方向,能够解决废气经济损失、加强空间限制等问题,达到提高脱硝效率、提高抗硫中毒特性、脱硝效率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be described more fully with reference to the accompanying drawings, in which exemplary embodiments of the invention are shown. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit or scope of the present invention. The drawings and descriptions should be regarded as illustrative in nature and not restrictive. Like reference numerals refer to like elements throughout the specification. Also, detailed descriptions of known techniques will be omitted.

[0022] Then, a catalyst for decomposing nitrogen oxides and a preparation method thereof according to an embodiment will be described in detail.

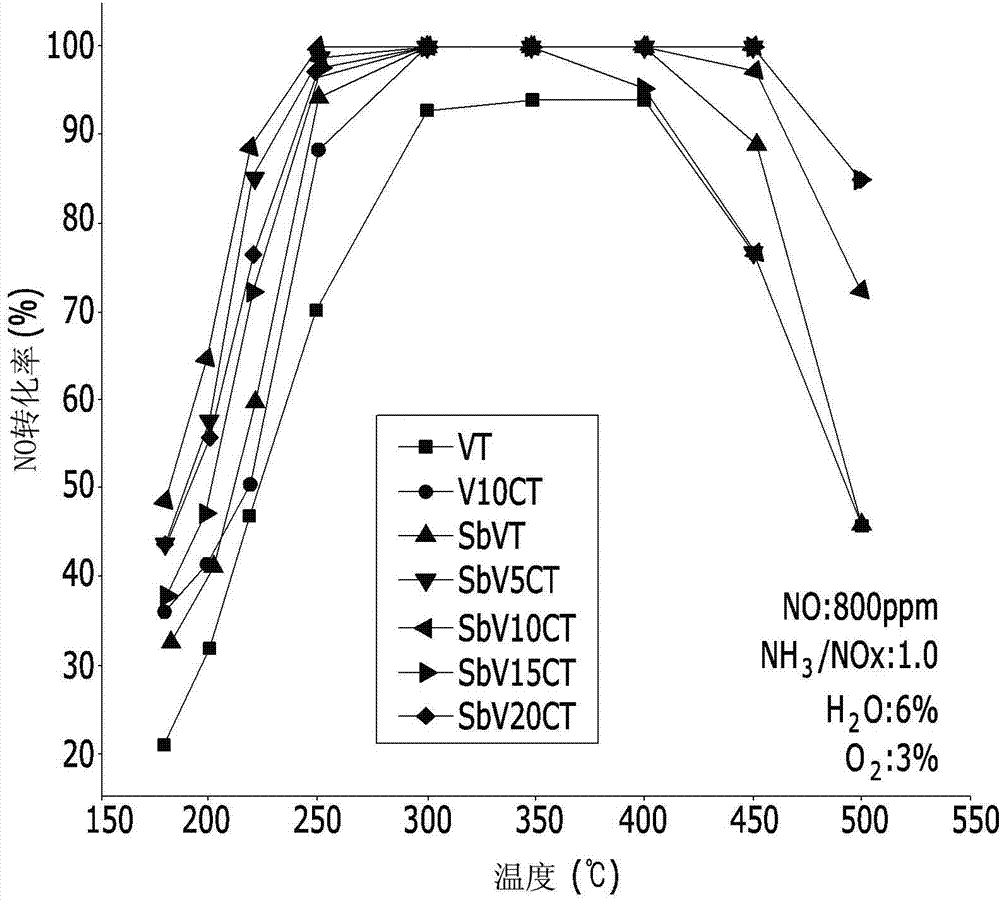

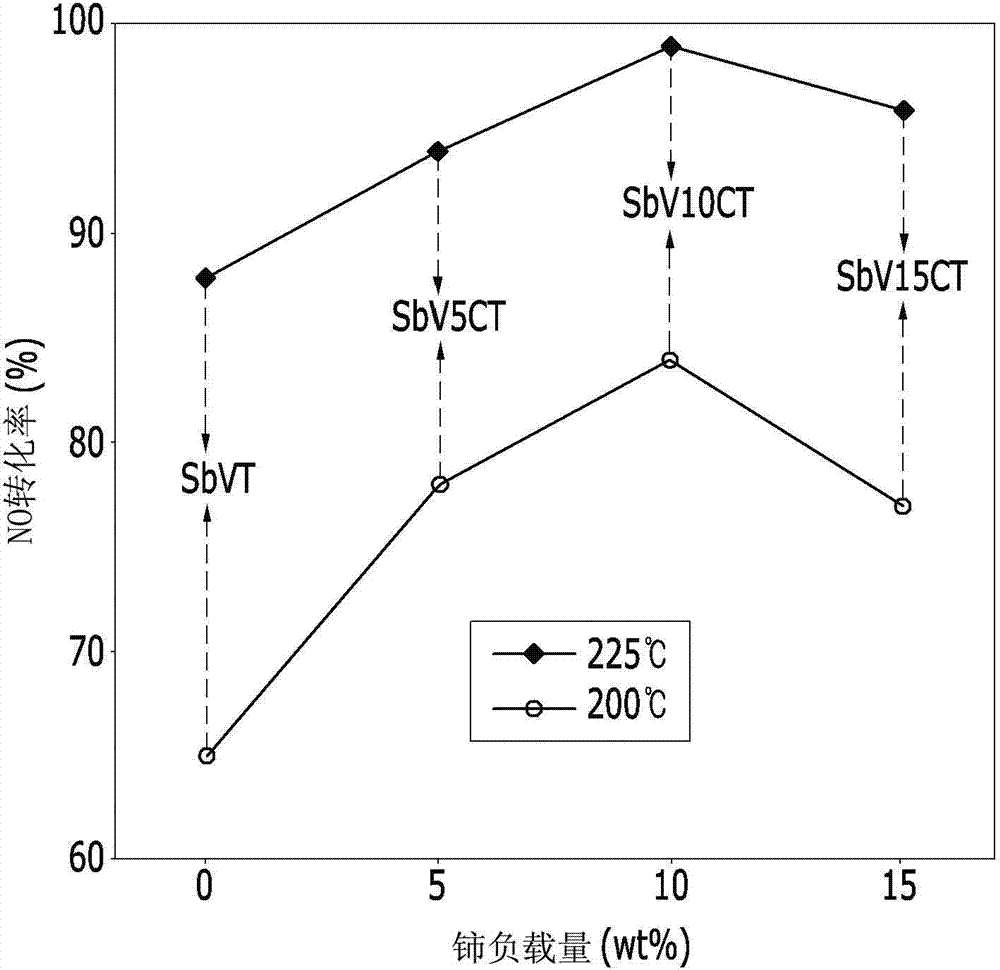

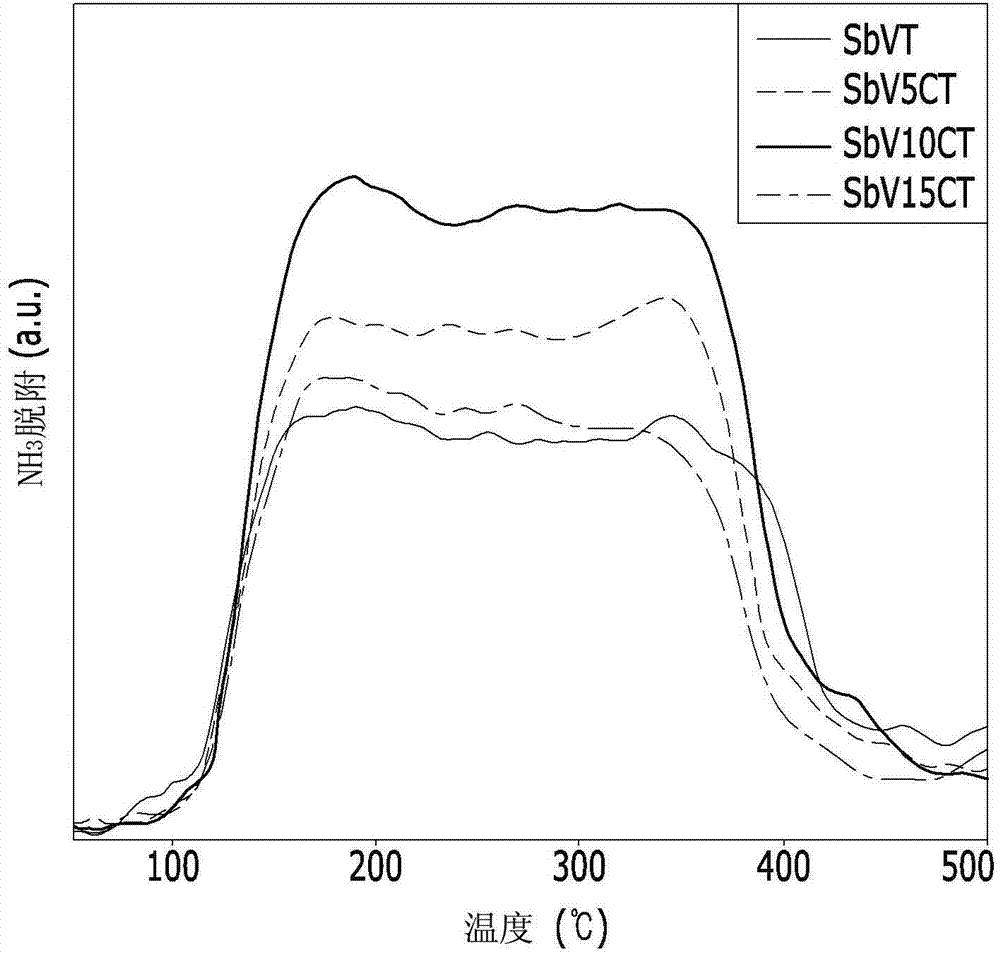

[0023] Exemplary embodiments relate to a catalyst for selectively removing nitrogen oxides in exhaust gas by a reduction method, denitrification characteristics at low and high temperatures may be improved, and sulfur poisoning resistance cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com