Device and method for combined removal of sulphur dioxide (SO2), nitrogen oxide (NOX) and mercury from fume

A technology for sulfur dioxide and nitrogen oxides, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve problems such as high operating costs, flue gas denitrification, and incomplete recycling of by-products, and achieve mature production processes , low investment and operating costs, and increased removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

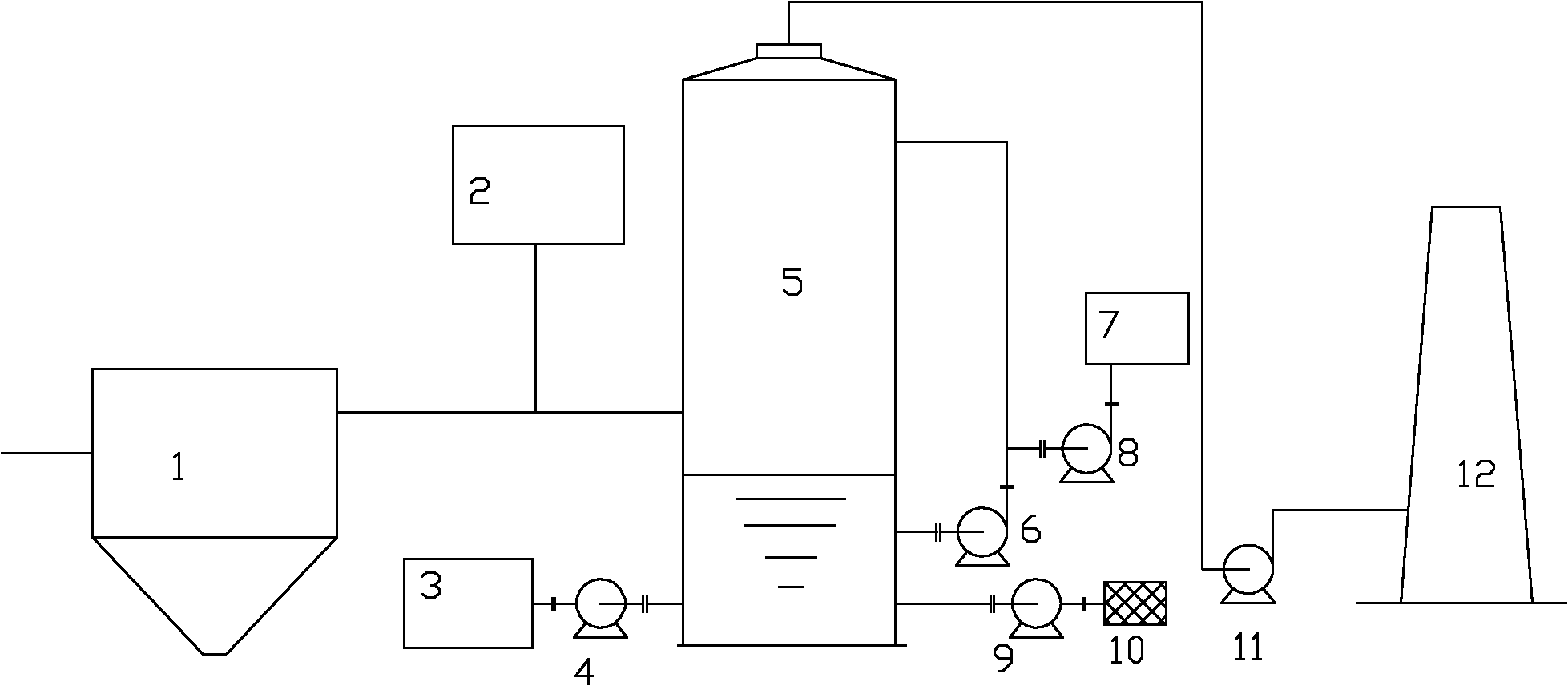

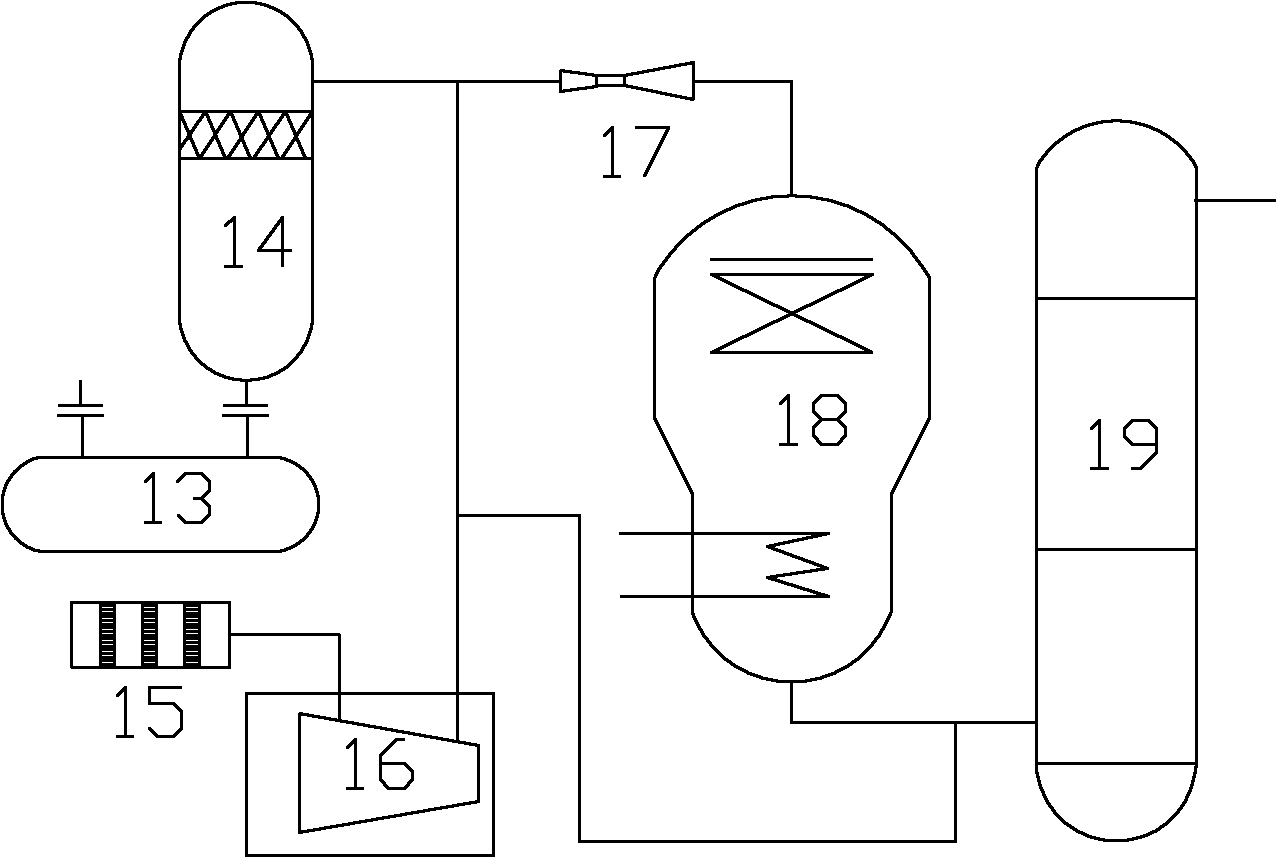

[0030] Such as figure 1 As shown, the device for the joint removal of sulfur dioxide, nitrogen oxides and mercury in the flue gas of the present invention includes a dust collector 1, a wet desulfurization tower 5 and an ammonium sulfate ammonium nitrate recovery system 3, and the connection between the dust collector 1 and the wet desulfurization tower 5 set with NO 2 Generating device 2, the air outlet of dust collector 1 is connected with the inlet of wet desulfurization tower 5 through a flue, NO 2The gas outlet of the generating device 2 is connected to the flue; the wet desulfurization tower 5 is provided with a demister, an absorbent spray device and a slurry tank in sequence from top to bottom, and the wet desulfurization tower 5 is equipped with a circulation pump 6 , the two ends of the circulation pump 6 are respectively connected with the absorbent spraying device and the slurry pool through the slurry circulation pipeline, one end of the absorbent replenishment p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com