Suede structure of crystalline silicon solar cells and manufacture method thereof

A technology for solar cells and crystalline silicon, applied in the field of solar energy, can solve the problems of expensive equipment, low surface reflectivity, low battery efficiency, etc., and achieve the effects of simple and easy preparation method, reducing surface reflectivity, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

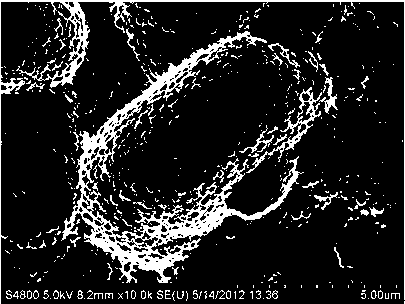

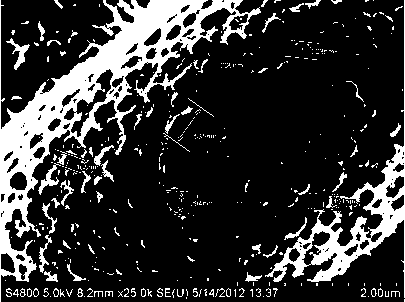

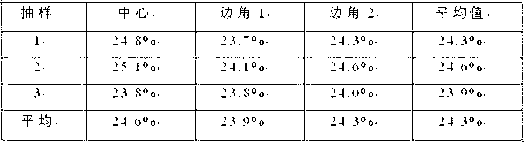

[0030] see Figure 1~2 Shown, a kind of preparation method of the textured structure of crystalline silicon solar cell comprises the steps:

[0031] (1) Corroding the conventional polycrystalline P156 silicon wafer with the same crystal orientation by acid solution to form a micron-scale suede structure on the surface of the silicon wafer; the concentration ratio of the acid solution is HF:HNO 3 =1: HNO of 5.7 3 -HF system, the depth of corrosion is 7~8 microns, and then after a series of cleaning and drying;

[0032] (2) Perform gas etching on the silicon wafer obtained in step (1): place the dried polysilicon wafer horizontally above the etching gas, and under the action of draft (pressure -50~-500 Pa), the gas will mix with silicon The silicon wafer is fully contacted to achieve single-sided vapor phase etching of the silicon wafer. After 1-2 minutes of etching, the surface of the silicon wafer turns black;

[0033] The corrosive gas used is produced in this way: the vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com