Shock-resisting flexible protection structure and manufacturing method

A flexible protection and manufacturing method technology, applied in textiles and papermaking, knitting, warp knitting and other directions, can solve the problems of limited protection ability and poor wearing comfort, and achieve high production efficiency, good compression resistance and resilience, and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation process of shear thickening liquid in step 2 comprises the following steps:

[0038] Step 201: gradually adding nano silicon dioxide particles into polyethylene glycol and stirring continuously;

[0039] Step 202: dispersing the mixed suspension obtained in step 201 by ultrasonic waves;

[0040] Step 203: Put the dispersed mixed solution obtained in step 202 into a vacuum drying oven to evacuate to remove air bubbles to obtain a shear thickening solution.

[0041] Step 3: Mix silicone rubber 1 with two different components in a ratio of 1:1. After removing air bubbles, dip-coat the surface of the warp-knitted spacer fabric in step 1, and then perform curing treatment to form an anti-leakage pocket spacer fabric;

[0042] Step 4: Pour the shear thickening liquid 3 in step 2 into the middle layer 23 of the bagged spacer fabric in step 3, and then use step 3 to mix the silicone rubber of two different components in a ratio of 1:1 Sealing is carried out t...

Embodiment 1

[0046] Fabrication of Shear Thickened Fluid Filled Polyester Warp Knit Spacer Fabric Impact Resistant Flexible Protective Structure:

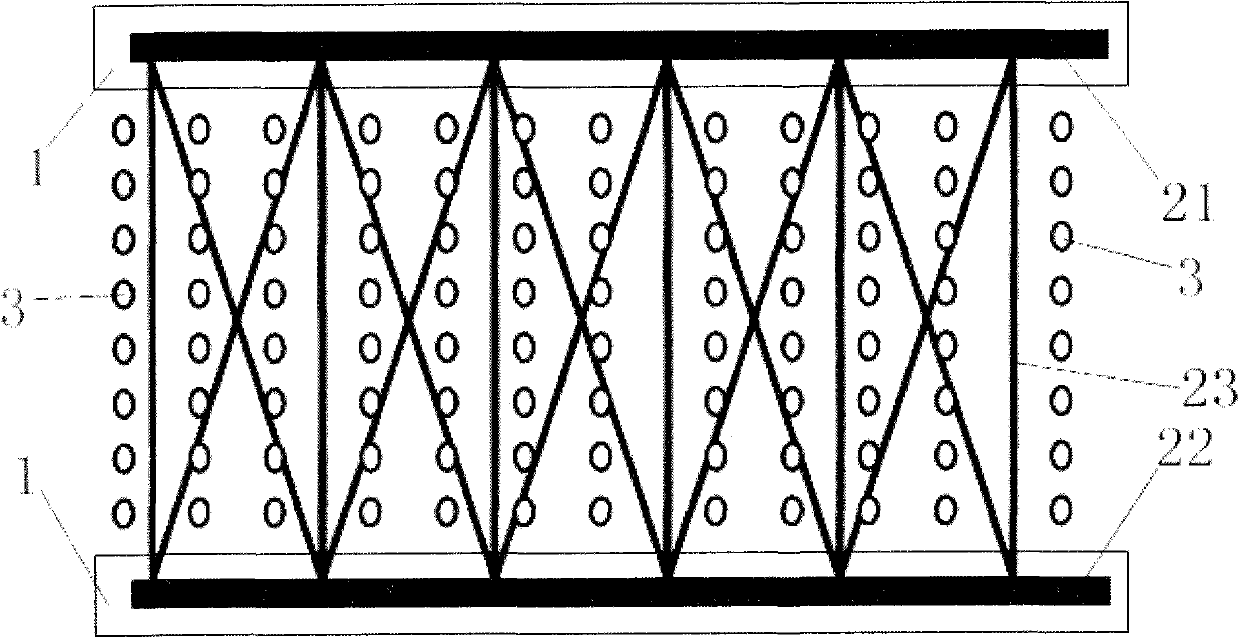

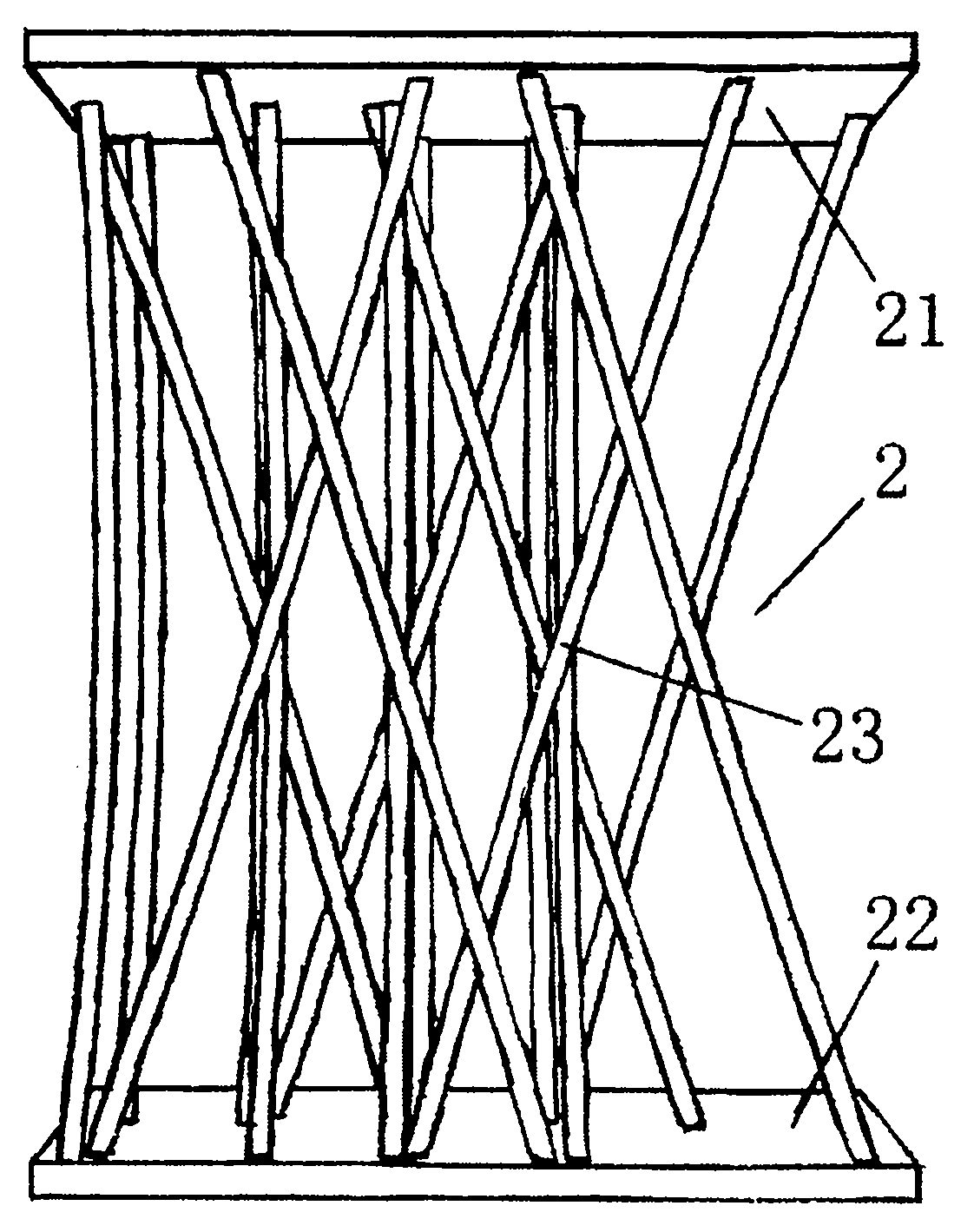

[0047] Step 1: Warp-knitted spacer fabric 2 with a three-dimensional structure is woven by Raschel double-needle bed warp knitting machine at one time. The upper layer 21 and the lower layer 22 are woven from 300D / 96F polyester multifilament through chain knitting. The middle layer 23 is woven from 0.2mm polyester monofilament;

[0048] Step 2: Prepare a shear thickening solution with 12nm nanometer silicon dioxide particles and polyethylene glycol PEG200, the mass fraction of silicon dioxide is 30%:

[0049]The preparation process of shear thickening liquid in step 2 comprises the following steps:

[0050] Step 201: gradually adding 12nm nano-silica particles into polyethylene glycol PEG200, and stirring continuously;

[0051] Step 202: dispersing the mixed suspension obtained in step 201 by ultrasonic waves;

[0052] Step 203: Put the disp...

Embodiment 2

[0056] Manufacture of shear thickening fluid filled high-strength polyethylene warp-knit spacer fabric impact-resistant flexible protective structure:

[0057] Step 1: The warp-knitted spacer fabric 2 with a three-dimensional structure is woven by a Raschel double-needle bed warp knitting machine at one time. The upper layer 21 and the lower layer 22 are woven from 300D / 96F high-strength polyethylene multifilament through a chain weave. The middle layer 23 is woven from 0.2mm polyester monofilament;

[0058] Step 2: Prepare a shear thickening solution with 12nm nanometer silicon dioxide particles and polyethylene glycol PEG400, the mass fraction of silicon dioxide is 25%:

[0059] The preparation process of shear thickening liquid in step 2 comprises the following steps:

[0060] Step 201: gradually adding 12nm nano-silica particles into polyethylene glycol PEG400 and stirring continuously;

[0061] Step 202: dispersing the mixed suspension obtained in step 201 by ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com