Oxidizer Compound for Rocket Propulsion

a rocket propulsion and compound technology, applied in the field of rocket propulsion systems, can solve the problems of difficult to meet the objectives, difficult to improve the technology, and the system utilizing current propellants is still daunting, and achieves the effects of reducing toxicity in the stored state, easy storage at ambient conditions, and good performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

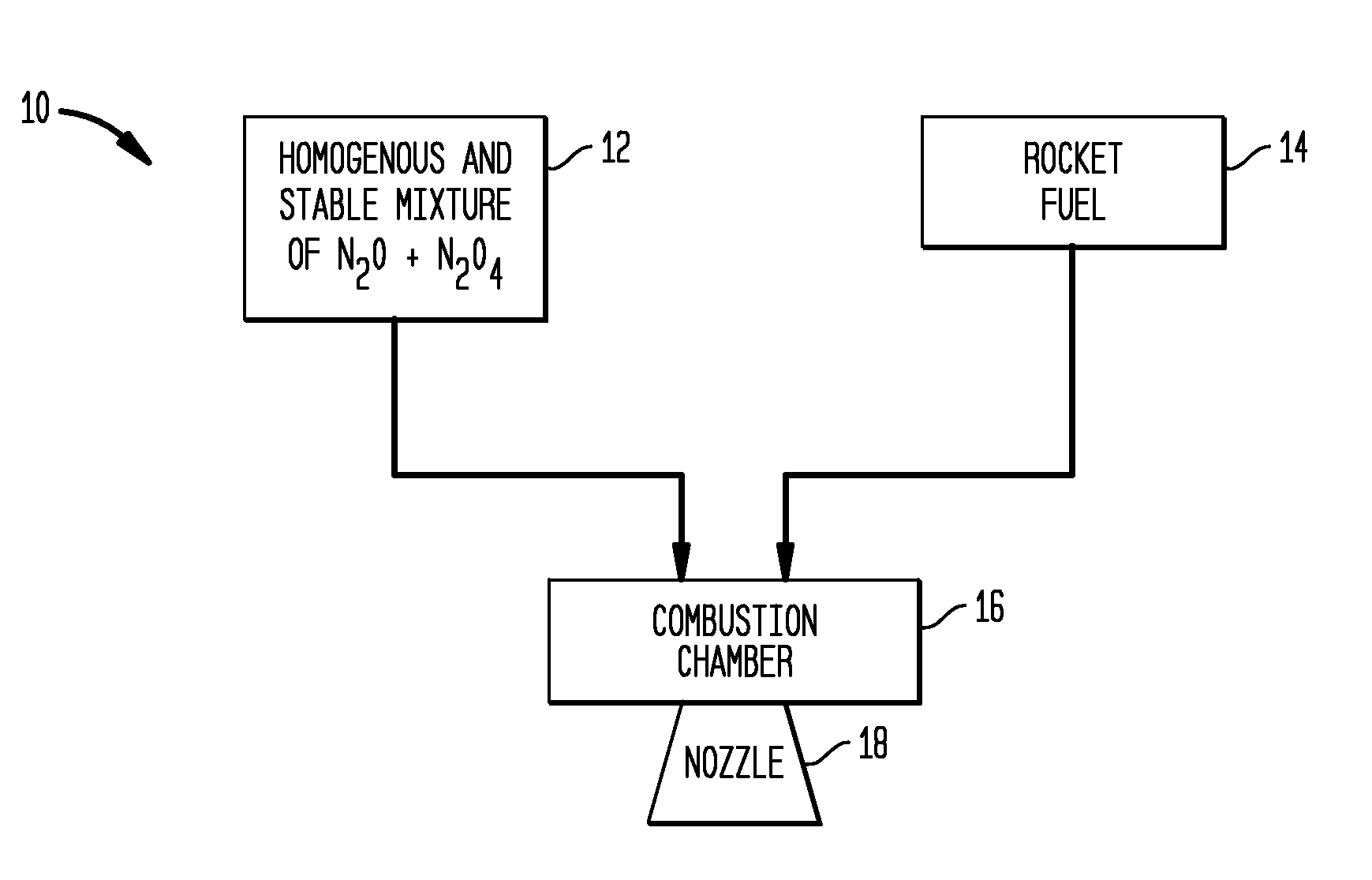

[0018]The novel oxidizer compound of the present invention can be used in a variety of rocket propulsion systems to include, for example, those used in launch vehicle propulsion systems, multi-mode spacecraft propulsion systems, upper stage spacecraft propulsion systems, and missile propulsion systems. Furthermore, the oxidizer compound of the present invention can be matched with a variety of propellant fuels in these propulsion systems. Accordingly, it is to be understood that the type of propulsion system and / or propellant fuel used therein are not limitations of the present invention.

[0019]In general, the oxidizer compound of the present invention is a mixture of nitrous oxide and nitrogen tetroxide that is homogenous and a stable liquid (i.e., will not boil off) at room temperature. As used herein, the term “room temperature” is defined as temperatures that are generally close to approximately 20° C. or 72° F. as would be well understood in the art.

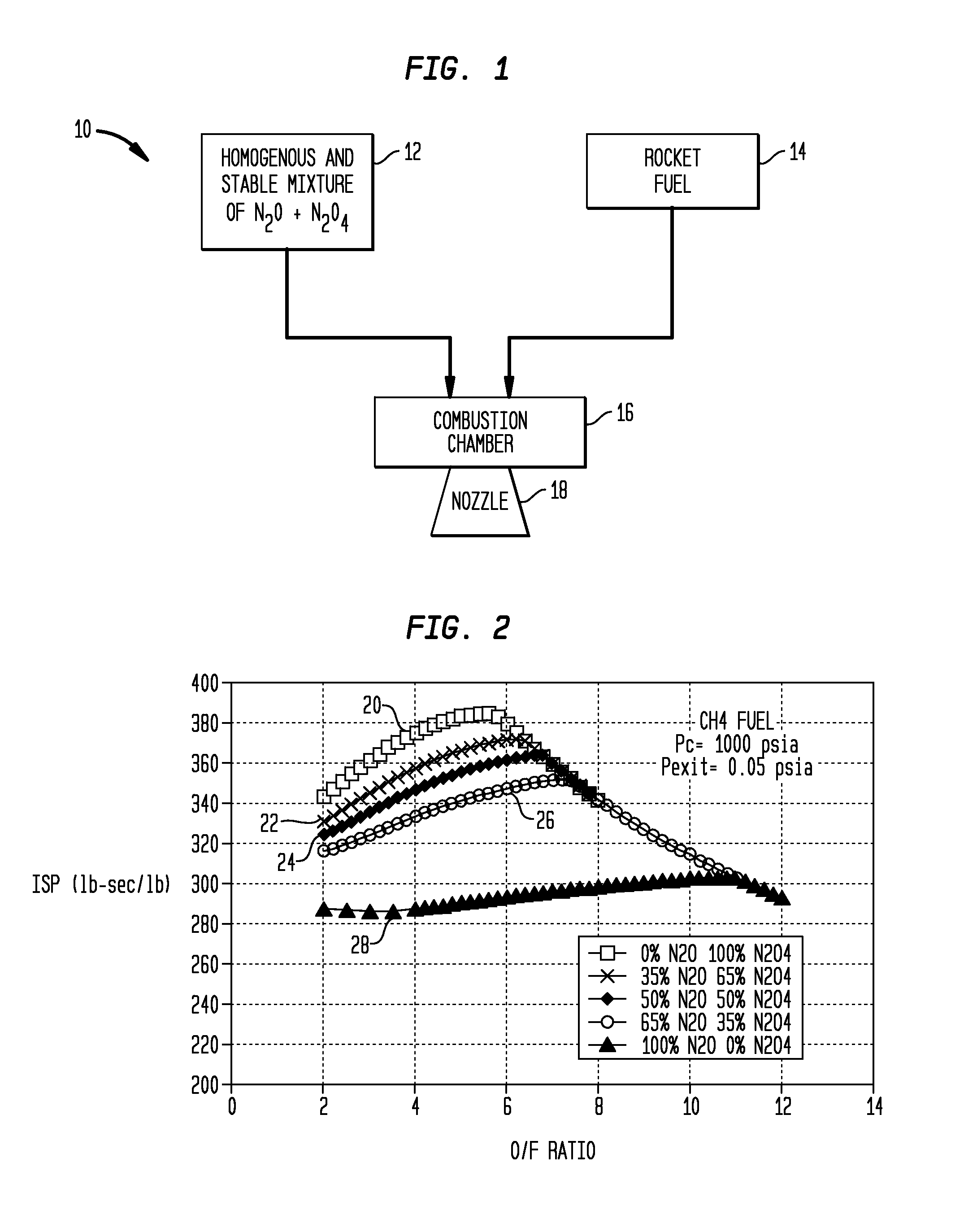

[0020]The new oxidizer compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com