Nitrogen tetroxide leakage collection device and method

A dinitrogen tetroxide and collection equipment technology, applied in the field of dinitrogen tetroxide leakage collection, can solve the problems of poor environmental protection, limited availability of dinitrogen tetroxide, low safety performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

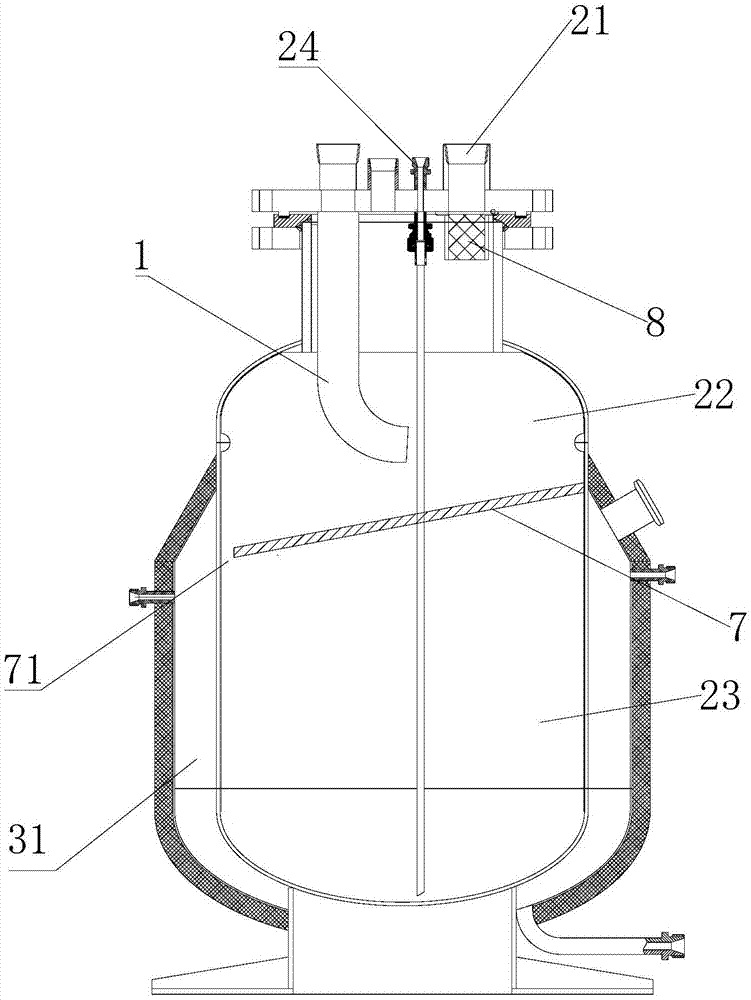

[0036] like figure 2 As shown, the chamber inner wall of the collection container 2 is equipped with a partition plate 7, and the partition plate 7 divides the collection container 2 into an upper gas-liquid separation area 22 and a lower liquid collection area 23, and the separation plate 7 is provided with at least A through hole 71 communicating the gas-liquid separation zone 22 with the lower liquid collection zone 23 . The gas-liquid mixture stays on the partition plate 7 for a period of time to fully condense, so as to prevent the mixed liquid from entering the lower part of the collection container 2 without sufficient gas-liquid separation. In order to facilitate the flow of liquid into the liquid collection area, the partition plate 7 has a downwardly inclined angle of 10°-30°, and a through hole 71 is provided at the lowest point.

[0037] like image 3 As shown, as a further preferred mode of the embodiment of the present invention, the absorption device 6 is at ...

Embodiment 2

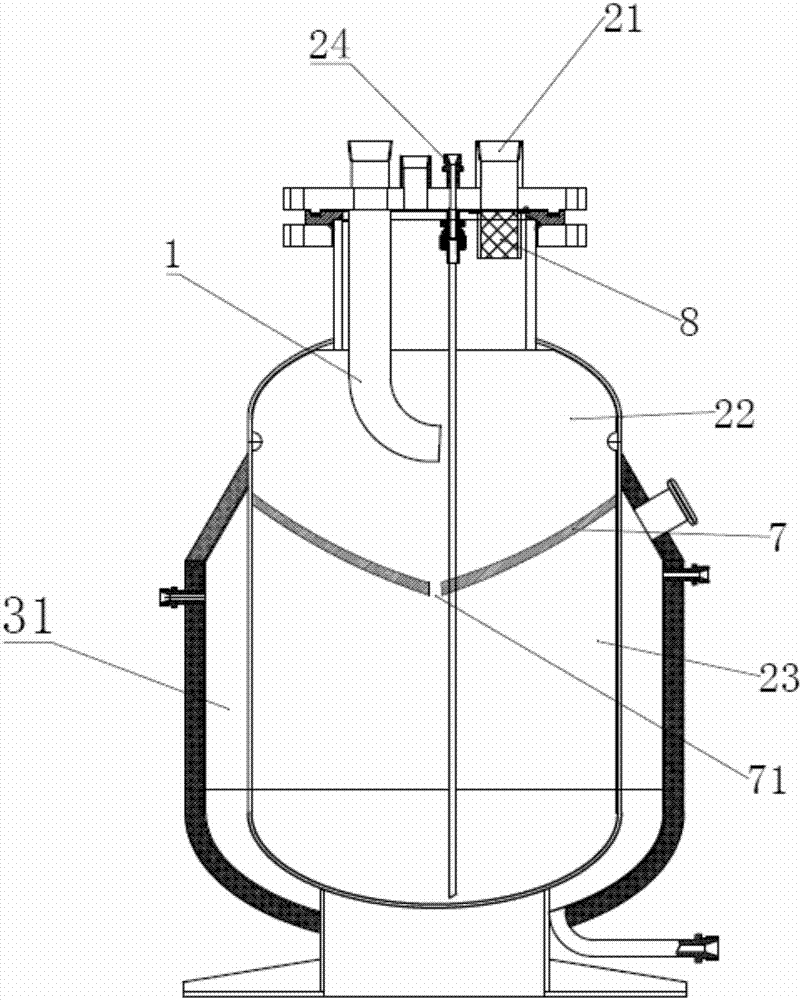

[0044] like image 3 As shown, the difference between this embodiment and the above-mentioned embodiment lies in the design of the partition plate 7, the chamber inner wall of the collection container 2 is equipped with a partition plate 7, and the partition plate 7 separates the collection container 2 into the upper gas-liquid separation. Between the zone 22 and the lower liquid collection zone 23 , the partition plate 7 is funnel-shaped with its apex downward, and the partition plate 7 is provided with at least one through hole 71 communicating the gas-liquid separation zone 22 and the lower liquid collection zone 23 . Preferably, the through hole 71 is arranged at the lowest level of the partition plate 7 . When the leakage liquid enters the collection container 2 through the collection pipe 1, it flows to the partition plate 7 under the action of gravity. Since the partition plate 7 is shaped like a funnel with the apex downward, when the mixed liquid enters the collection...

Embodiment 3

[0047] The only difference between this embodiment and the above embodiment is that the vortex air pump is replaced by a vacuum pump, and the vacuum pump is used to suck dinitrogen tetroxide waste liquid and waste gas.

[0048] Describe below in conjunction with the specific work process of the present invention:

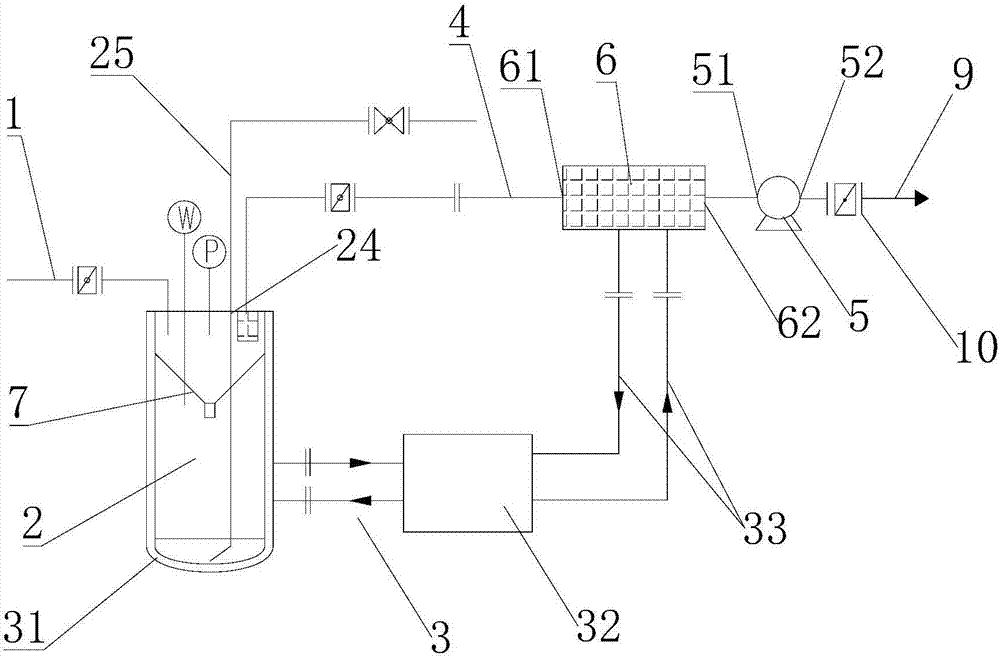

[0049] like figure 1 As shown, when it is necessary to collect the leakage liquid, open the control switch of the equipment and the valves of each pipeline, and use the negative pressure absorption device 5 as the driving force to suck the leakage liquid / gas into the collection container 2 through the collection pipeline 1 for gas-liquid separation In the zone 22, the gas-liquid mixture is condensed by the cooling system 3 to reduce the evaporation of the liquid, and since the collecting container 2 is provided with a partition plate 7, the partition plate 7 is shaped like a funnel with the apex downward. When the direction enters the collection container 2, the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com