Selective catalytic reduction denitration method for flue gas

A catalytic denitrification and selective technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as high carbon monoxide concentration and pollution, and achieve the effects of controlling emissions, wide application range, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

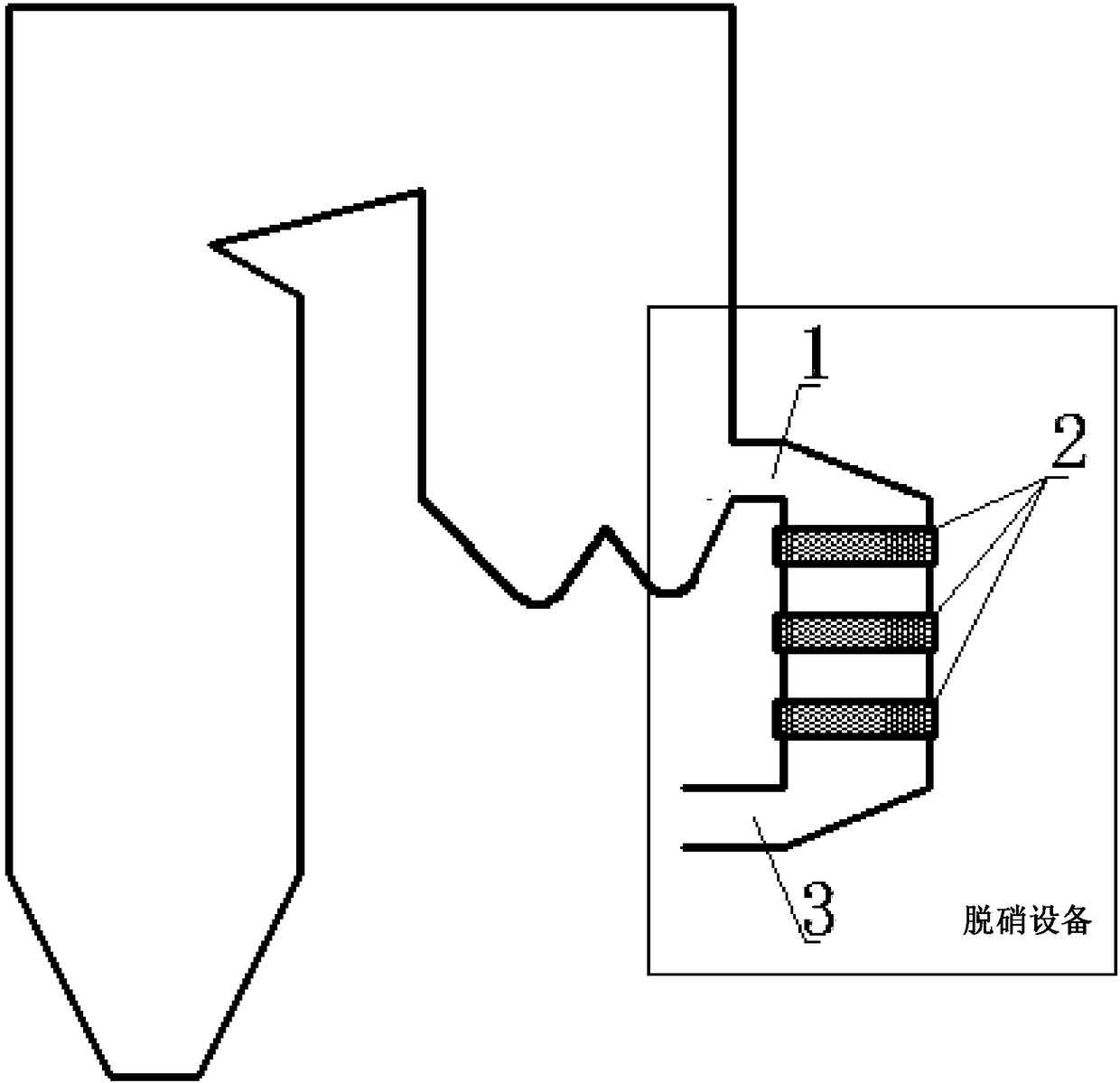

Embodiment 1

[0030] There are three layers of Al in the denitrification equipment 2 o 3 As the base carrier, mainly MnO, Fe 2 o 3 , CeO 2A honeycomb catalyst in which a mixture of metal oxides is an active ingredient. The flow velocity of the hot flue gas is 7m / s, the temperature of the flue gas at the reactor inlet is 385°C, and the temperature at the reactor outlet is 300°C. The carbon monoxide concentration in the initial flue gas is 544mg / Nm 3 , the concentration of nitrogen oxides is 105mg / Nm 3 . The concentration of carbon monoxide in the flue gas after catalytic treatment is 432mg / Nm 3 , the concentration of nitrogen oxides is 26mg / Nm 3 .

Embodiment 2

[0032] In the embodiment of the present invention, the catalyst in the denitrification equipment is the same as that in embodiment 1.

[0033] The flow rate of the hot flue gas is 3m / s, the temperature of the flue gas at the reactor inlet is 380°C, and the temperature at the reactor outlet is 260°C. The carbon monoxide concentration in the initial flue gas is 314mg / Nm 3 , the concentration of nitrogen oxides is 176mg / Nm 3 . The concentration of carbon monoxide in the flue gas after catalytic treatment is 103mg / Nm 3 , the concentration of nitrogen oxides is 41mg / Nm 3 .

Embodiment 3

[0035] In the embodiment of the present invention, the catalyst in the denitrification equipment is the same as that in embodiment 1.

[0036] The flow rate of the hot flue gas is 5m / s, the temperature of the flue gas at the reactor inlet is 388°C, and the temperature at the reactor outlet is 297°C. The carbon monoxide concentration in the initial flue gas is 446mg / Nm 3 , the concentration of nitrogen oxides is 131mg / Nm 3 . The concentration of carbon monoxide in the flue gas after catalytic treatment is 265mg / Nm 3 , the concentration of nitrogen oxides is 40mg / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com