Exhaust Gas Purifier

a gas purifier and exhaust gas technology, applied in the field of exhaust gas purifiers, can solve the problems of high possibility, large apparatus itself, and increased maintenance costs of reducing agents such as ammonia and urea, and achieve the effects of low cost, good nox absorption power, and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

of the Invention

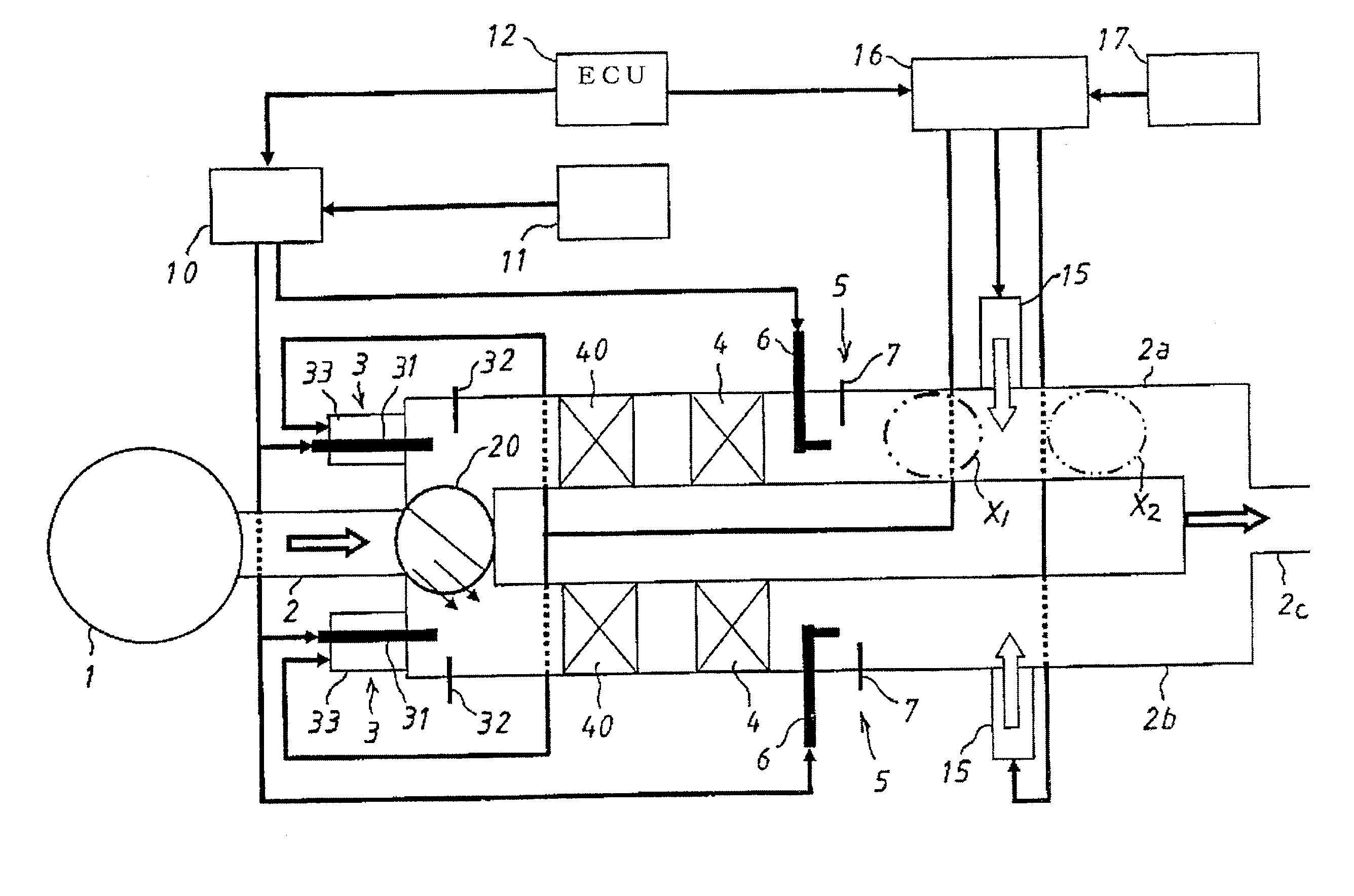

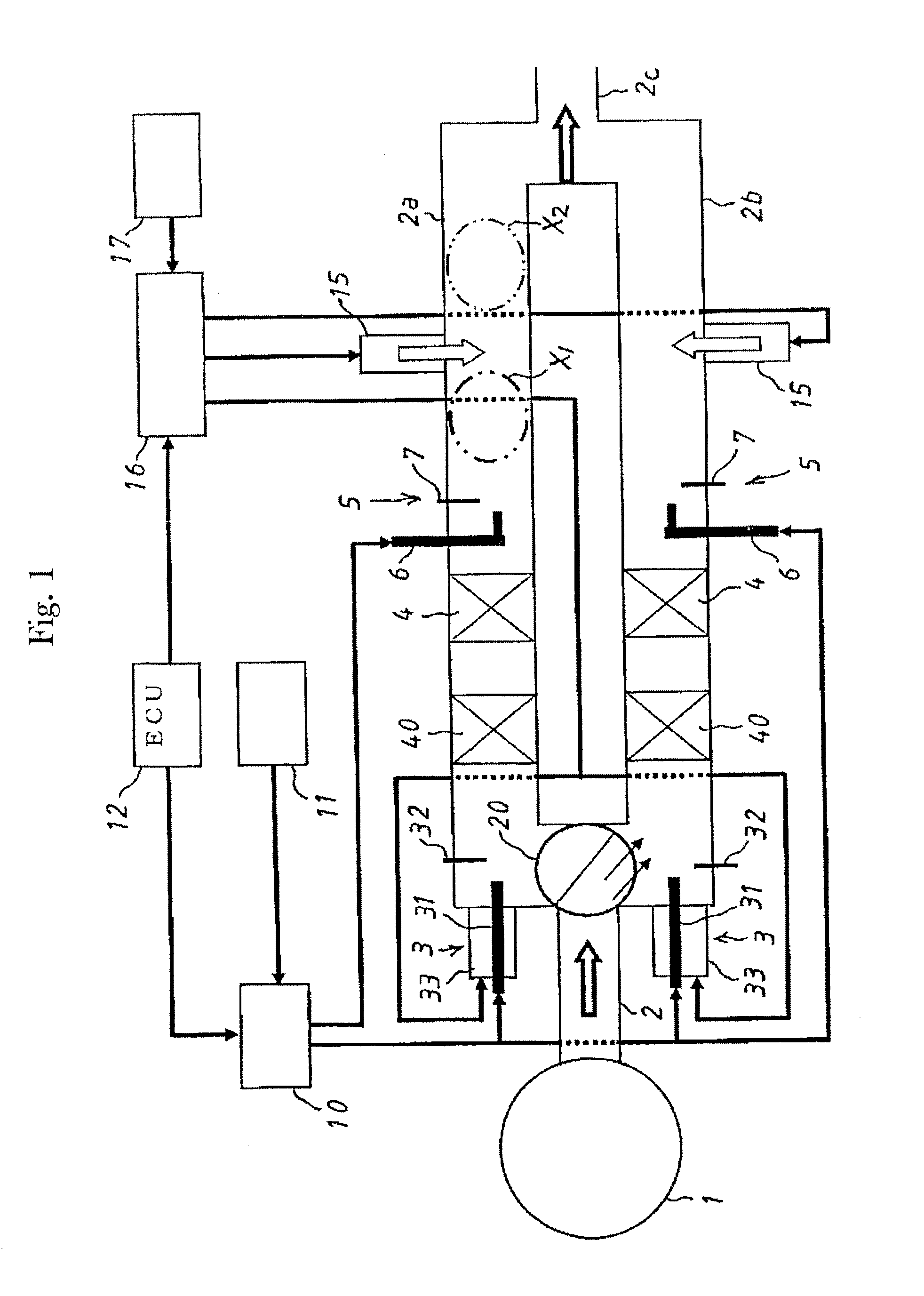

[0101]FIG. 1 shows a first embodiment of an exhaust gas purifier according to the invention. An exhaust passage 2 of an internal combustion engine 1 or a combustion instrument is branched into first and second branch exhaust passages 2a and 2b, a switching valve 20 is provided in a branch portion on an upstream side of the exhaust gas, and the branch exhaust passages 2a and 2b are merged at an end portion on a downstream side of the exhaust gas and connected to a downstream-side exhaust passage2c. The exhaust gas from the internal combustion engine 1 is selectively discharged to one of the branch exhaust passages 2a and 2b by switching the switching valve 20, and the regenerating operation can be performed in the other branch exhaust passage. Examples of the internal combustion engine 1 include a diesel engine, a gas engine, a gasoline engine, and a gas turbine engine, and an industrial boiler can be cited as an example of the combustion instrument. The internal comb...

second embodiment

Working of Second Embodiment

[0128]The working of the second embodiment is basically similar to that of the first embodiment of FIG. 1 except for the working of the SOx adsorbent 42, so that only the working of the SOx adsorbent 42 will be described.

[0129]During the normal operation of the internal combustion engine 1, the SOx in the exhaust gas is adsorbed to the SOx adsorbent 42. Therefore, the SOx does not flow into the NOx adsorbent 4, and the NOx adsorbent 4 can be prevented from being poisoned by the sulfur. Particularly, in the case where the lithium oxide except for the noble metal-added lithium titanate (Pt—Li2TiO3) is used as the NOx adsorbent 4, the SOx adsorbent 42 is disposed on the upstream side of the NOx adsorbent 4 because of a low SOx-resistant property, which allows the poisoning of the NOx adsorbent 4 to be prevented.

[0130]During the regenerating operation, the high-temperature air is also supplied to the SOx adsorbent 42 from the adsorbed substance desorbing mean...

third embodiment

of the Invention

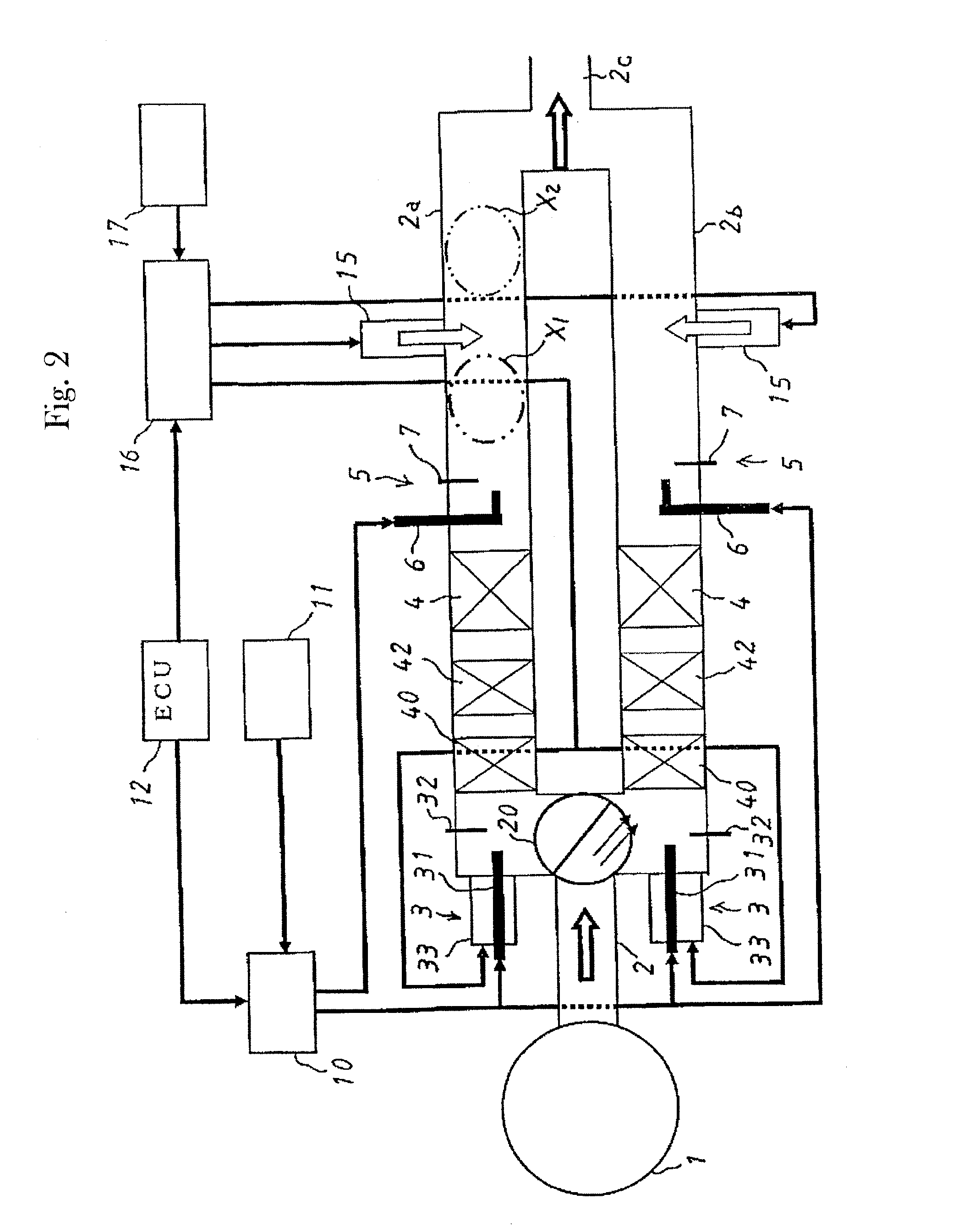

[0133]Metal oxide which does not contain the noble metal is used as the NOx adsorbent 4 of the exhaust gas purifier shown in FIG. 2. Particularly, the metal oxide can efficiently adsorb the NOx in the excessive air atmosphere, and the metal oxide desorbs the adsorbed NOx when the metal oxide is heated to a predetermined temperature or when the exhaust gas is converted into the reducing atmosphere. For example, the NOx adsorbent 4 is made of the transition metal oxide containing the manganese oxide and zirconium oxide, and the compounding ratio of the manganese oxide and zirconium oxide becomes 1:1 in terms of metal ratio.

[0134]In the third embodiment, the SOx adsorbent 42 is made of the copper oxide and zirconium oxide, and the metal ratio of the copper and zirconium becomes 1:1.

Working of the Embodiment

[0135]In FIG. 2, in the case where the internal combustion engine 1 is operated, the switching valve 20 switches the connection of the exhaust passage 2 to utilize on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com