System and process for condensing and recovering nitrogen tetroxide waste gas resource

A technology of dinitrogen tetroxide and condensation recovery, applied in inorganic chemistry, vapor condensation, nitrogen compounds, etc., can solve problems such as the loss of meaning of condensation recovery, and achieve the effect of improving operating efficiency and improving recovery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

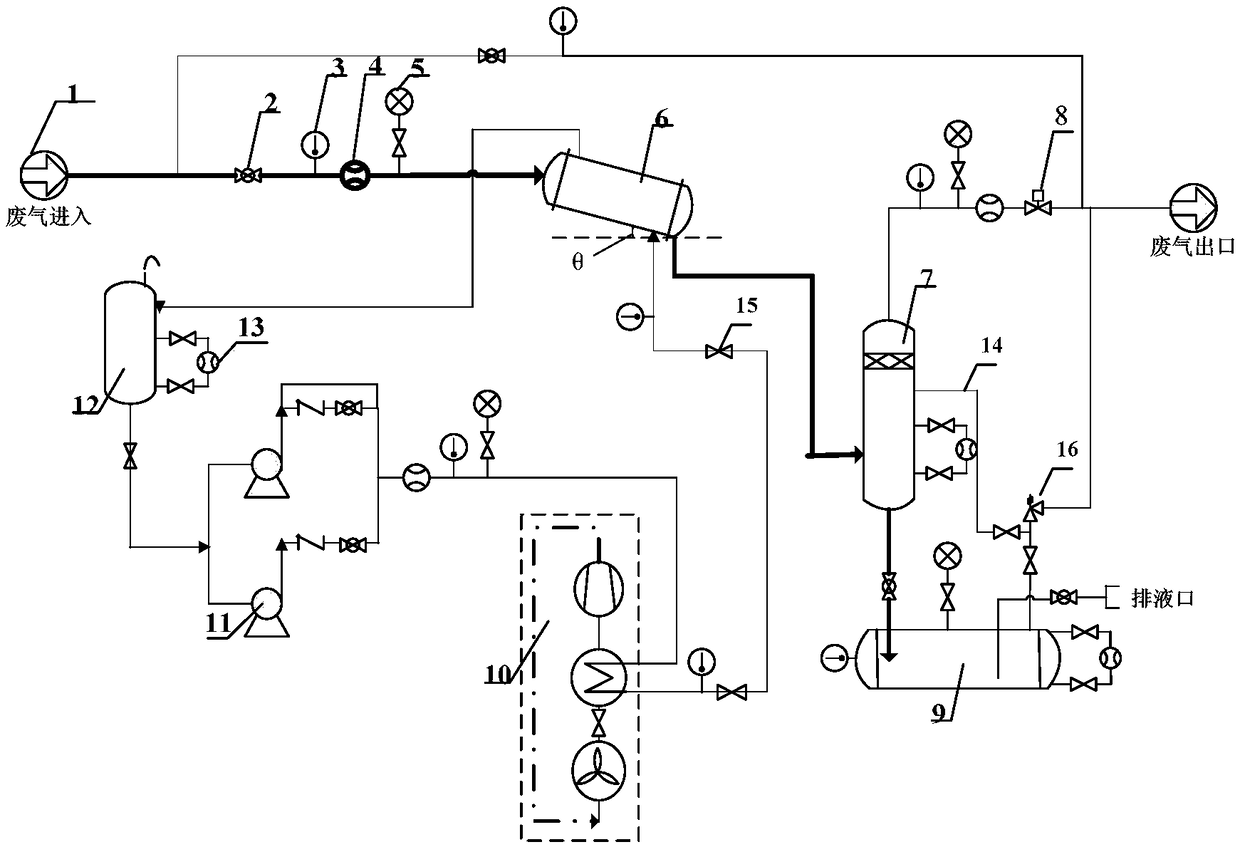

[0042] see figure 1 , a system for double-cycle condensation recovery of dinitrogen tetroxide waste gas resources, including a condensation heat exchanger 6, a gas-liquid separator 7, an electric control valve 8, a condensate collection tank 9, a low-temperature chiller 10, a circulation pump 11, a Glycol solution buffer and expansion tank 12;

[0043] The exhaust gas pipeline containing dinitrogen tetroxide vapor enters the condensation heat exchanger 6, and the gas-liquid mixture outlet pipeline of the condensation heat exchanger 6 is connected to the gas-liquid separator 7, and the bottom of the gas-liquid separator 7 is The liquid pipeline is connected with the liquid phase space of the condensate collection tank 9 (the position where the liquid pipeline extends into the bottom of the tank is about 10 cm), and the middle part is connected with the gas phase space of the condensate collection tank 9 through the gas communication pipe 14. The top of the gas-liquid separator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com