Composite filter material for cooperatively removing nitrogen oxides and dioxins, and preparation method thereof

A technology of nitrogen oxides and filter materials, applied in the field of functional composite filter materials, can solve the problems of large area occupied by factory flue gas treatment equipment and high treatment costs, and achieve the effect of improving wear resistance and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

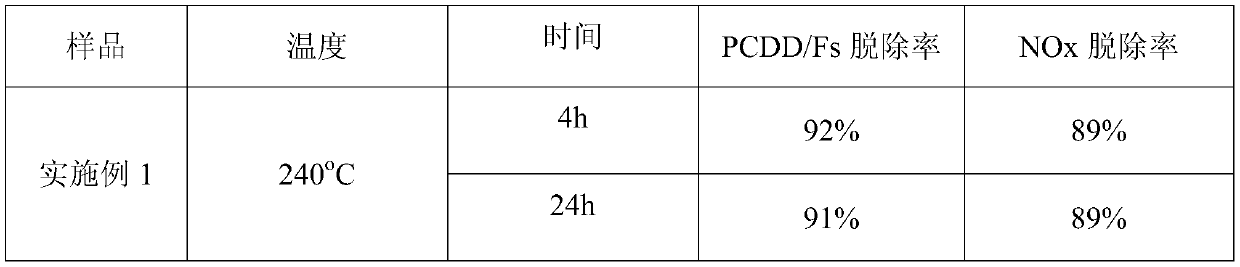

Embodiment 1

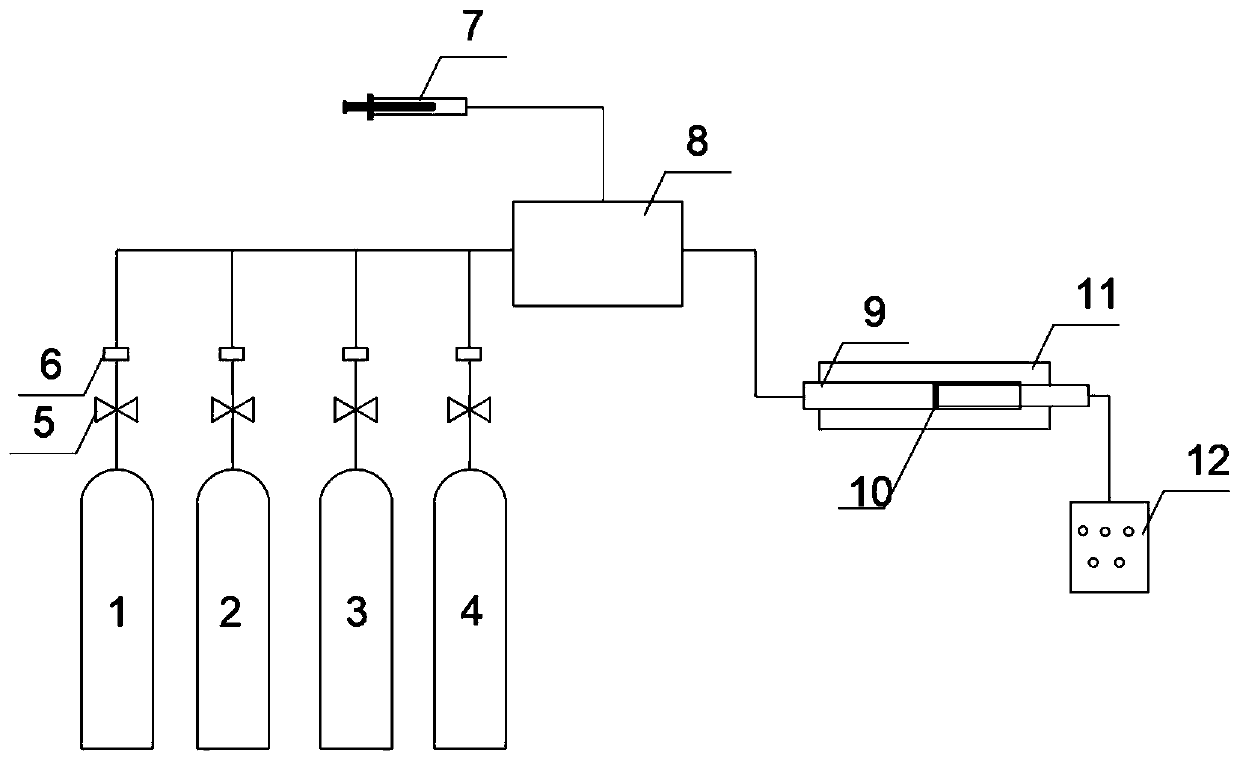

[0039] a. Weigh 1g (1wt%) bis(diisooctylpyrophosphoryl) methyl glycolate titanate, 15g (15wt%) polyethylene glycol 400 and dissolve in 84g (84wt%) distilled water, add 4g capsules TiO with a diameter of 150-250μm 2 , CeO 2 and V 2 o 5 The mixture, wherein, the molar ratio of V and Ce is 1:1, TiO 2 The mass is V 2 o 5 -CeO 2 / TiO 2 90% of the total mass of the catalyst. After mixing, oscillate ultrasonically for 3 hours, and stir with a magnetic stirrer for 12 hours, so that the catalyst particles are uniformly dispersed in the emulsion, and emulsion a is obtained.

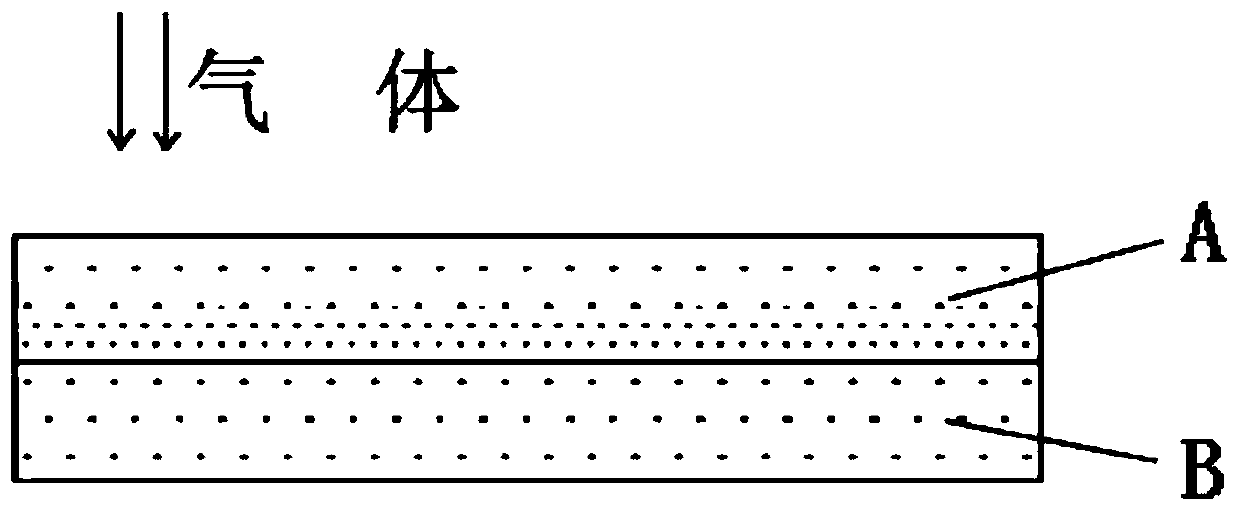

[0040]b. Pour the emulsion a into the container, the liquid level is 1mm, cut the filter material into a disc shape of 5cm, and dip it in the emulsion with the dust-facing side up, the liquid level is exactly half of the thickness of the filter material, dipping for 3 Take it out before the upper surface of the filter material becomes wet, dry it at 105°C for 4 hours, weigh it, and the mass of the filter m...

Embodiment 2

[0052] a. Weigh 0.2g (0.2wt%) bis(diisooctylpyrophosphoryl) methyl glycolate titanate, 10g (10wt%) polyethylene glycol 200 and dissolve in 89.8g (89.8wt%) distilled water , add 2g of TiO with a particle size of 150-250m 2 , CeO 2 and V 2 o 5 The mixture, wherein, the molar ratio of V and Ce is 1:1, TiO 2 The mass is 90% of the total mass of the catalyst system. After mixing, ultrasonically shake for 2 hours, and stir with a magnetic stirrer for 11 hours, so that the catalyst particles are uniformly dispersed in the emulsion.

[0053] b. Pour the emulsion into the container, the liquid level is 1mm, cut the filter material into a disc shape of 5cm, and immerse it in the emulsion with the dust side up, the liquid level is exactly half of the thickness of the filter material, and soak for 3 minutes , before the upper surface of the filter material is wet, take it out, dry it at 105°C for 4 hours, weigh it, and the mass of the filter material increases by 0.6108g. Immerse th...

Embodiment 3

[0060] a. Weigh 0.2g (0.2wt%) bis(diisooctylpyrophosphoryl) methyl glycolate titanate, 8g (10wt%) polyethylene glycol 600 and dissolve in 91.8g (91.8wt%) distilled water , add 2g of TiO with a particle size of 150-250μm 2 , CeO 2 and V 2 o 5 The mixture, wherein, the molar ratio of V and Ce is 1:1, TiO 2 The mass is 90% of the total mass of the catalyst system. After mixing, ultrasonically vibrate for 2 hours, and stir with a magnetic stirrer for 10 hours, so that the catalyst particles are uniformly dispersed in the emulsion.

[0061] b. Pour the emulsion into the container, the liquid level is 1mm, cut the filter material into a disc shape of 5cm, and immerse it in the emulsion with the dust side up, the liquid level is exactly half of the thickness of the filter material, and soak for 3 minutes , take it out before the upper surface of the filter material gets wet, dry it at 105°C for 4 hours, weigh it, the mass of the filter material increases by 1.4340g, and the calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com