Boiler optimization method for reducing nitrogen oxide discharge

An optimization method and nitrogen oxide technology, applied in the field of boilers, can solve problems such as aggravating boiler coking and high temperature sulfur corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

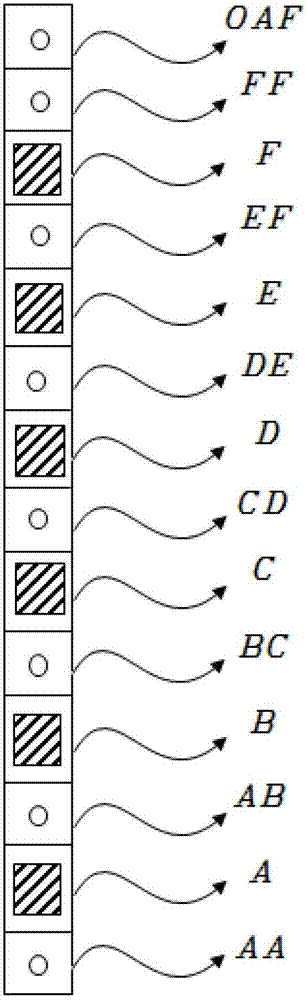

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

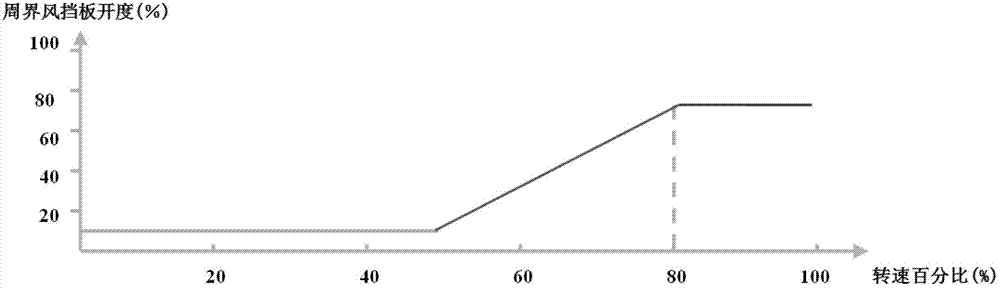

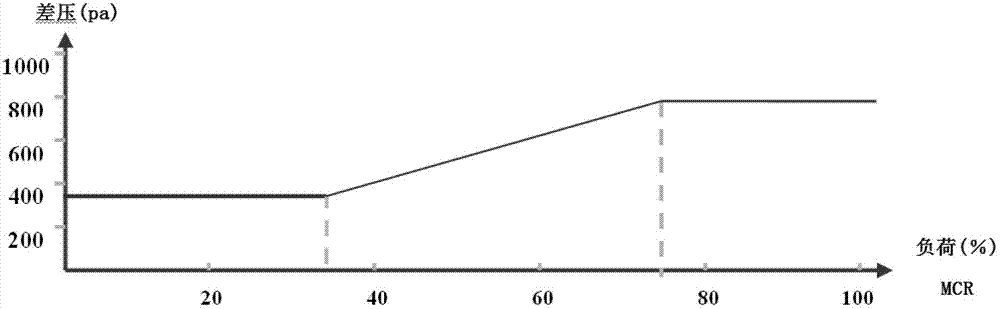

[0018] As mentioned in the previous article, during the normal operation of the boiler, the reduction of NO x Emissions mainly depend on the physical nitrogen content, and the main measure to reduce physical nitrogen is to reduce the oxygen content in the furnace. In the absence of experimental data, excessively reducing the oxygen content in the furnace will inevitably cause CO, H 2 A large amount of S gas is produced, which will inevitably aggravate the high-temperature corrosion of the heating surface for power plants burning high-sulfur coal, so the reduction of NO should be done without equipment modification. x In fact, there is a certain risk. In order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com