Industrial flue gas synchronous desulfurization and denitration method

An industrial flue gas, desulfurization and denitrification technology, applied in the field of flue gas desulfurization and denitrification, can solve the problems of high cost and secondary pollution, and achieve the effect of low processing cost, secondary pollution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

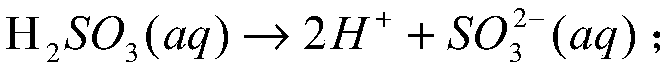

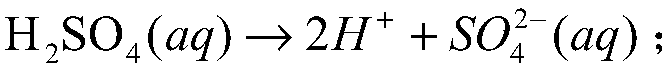

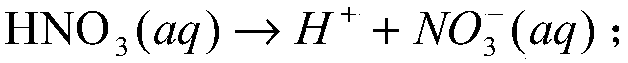

Method used

Image

Examples

Embodiment 1

[0040] A method for synchronous desulfurization and denitrification of industrial flue gas. Specifically, the content of sulfur dioxide in the flue gas components produced by a certain factory is 1000-3000 mg / m 3 , the nitrogen oxide content is 300~1000mg / m 3 . The simultaneous desulfurization and denitrification method comprises the following steps:

[0041] (1). Weigh 100g of anion ion exchange fiber, humidify the anion ion exchange fiber to a moisture content of 50%, and fill it into an ion exchange column;

[0042] (2). The above-mentioned industrial flue gas is cooled to 60°C, and the relative humidity of the industrial flue gas is 75% through the dust removal treatment and humidification treatment in the pretreatment chamber;

[0043] (3). Pressurize through the booster pump, inject the industrial flue gas treated in step (2) into the gas mixing chamber at a flow rate of 54L / h, pass into ozone for reaction, and control the molar ratio of ozone to nitric oxide to be 1.3...

Embodiment 2

[0049] A method for synchronous desulfurization and denitrification of industrial flue gas. Specifically, the content of sulfur dioxide in the flue gas components produced by a certain factory is 1000-3000 mg / m 3 , the nitrogen oxide content is 300~1000mg / m 3 . The simultaneous desulfurization and denitrification method comprises the following steps:

[0050] (1). Weigh 1.5kg of anion ion exchange fiber, humidify the anion ion exchange fiber to a moisture content of 50%, and fill it into an ion exchange column;

[0051] (2). The above-mentioned industrial flue gas is cooled to 60°C, and the relative humidity of the industrial flue gas is 75% through the dust removal treatment and humidification treatment in the pretreatment chamber;

[0052] (3). Pressurized by a booster pump, the industrial flue gas treated in step (2) is 3.2m 3 The flow rate of / h is injected into the gas mixing chamber, and ozone is introduced to react, and the molar ratio of ozone to nitric oxide is con...

Embodiment 3

[0058] A method for synchronous desulfurization and denitrification of industrial flue gas. Specifically, the content of sulfur dioxide in the flue gas components produced by a certain factory is 1000-3000 mg / m 3 , the nitrogen oxide content is 300~1000mg / m 3 . The simultaneous desulfurization and denitrification method comprises the following steps:

[0059] (1). Weigh 100g of anion ion exchange fibers, and pack the anion ion exchange fibers into an ion exchange column;

[0060] (2). The above-mentioned industrial flue gas is cooled to 60°C, and the relative humidity of the industrial flue gas is 75% through the dust removal treatment and humidification treatment in the pretreatment chamber;

[0061] (3). Pressurize through the booster pump, inject the industrial flue gas treated in step (2) into the gas mixing chamber at a flow rate of 54L / h, pass into ozone for reaction, and control the molar ratio of ozone to nitric oxide to be 1.35 ;

[0062] (4). Pass the industrial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com