Method and device for disinfecting and sterilizing plastic packaging containers

A plastic packaging, disinfection and sterilization technology, applied in disinfection, water supply devices, sanitary equipment for toilets, etc., can solve the problems of low sterilization effect, residual water stains, etc., achieve good sterilization and disinfection effect, avoid aging, prolong life and effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

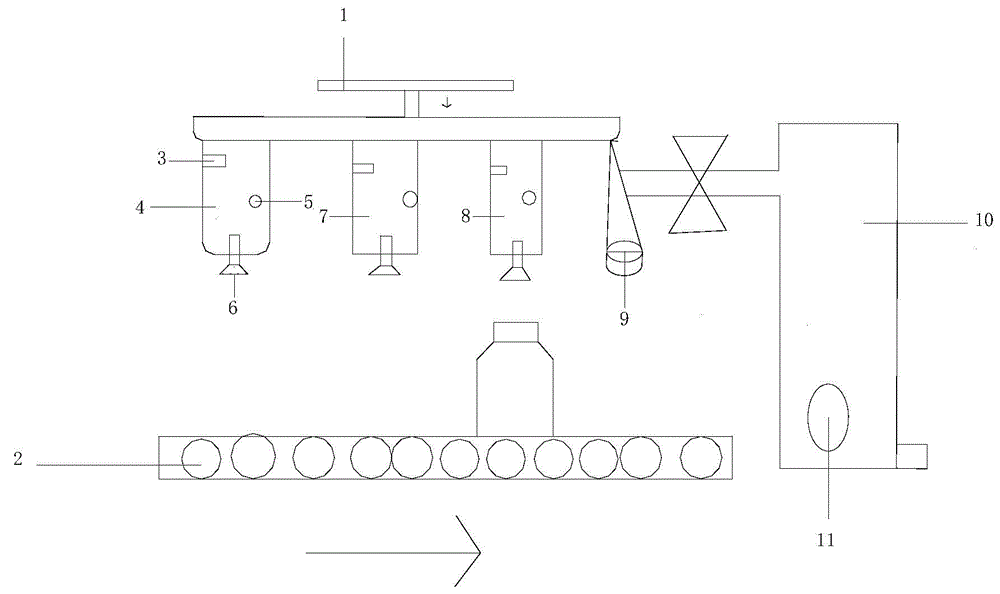

example 1

[0019] Will contain a concentration of 5mg / m 3 The ethyl acetate enters the organic substance filling chamber through the inlet, turns on the flow rate switch, sprays a small amount of spray to the plastic container through the nozzle, sprays for 2 minutes, and the pulley will drive the plastic packaging container to slide to the right, so that it is placed in the nitrogen oxide filling chamber Next, spray nitrogen oxides through the nozzle to make it enter the plastic packaging container. After spraying for 4 minutes, it will slide to the disinfectant filling chamber for 3 minutes of disinfection spraying. After the three spraying processes are completed, the plastic packaging container will rest on the pulley. Set it aside for 2 minutes to allow it to fully react. After the reaction, use a blower to blow dry. At the same time, the residual nitrogen oxide gas in the plastic packaging container is sucked into the recovery device to reduce nitrogen substances and generate nitrog...

example 2

[0021] Will contain a concentration of 5mg / m 3 The ethyl acetate enters the organic substance filling chamber through the inlet, turns on the flow rate switch, sprays a small amount of spray to the plastic container through the nozzle, sprays for 2 minutes, and the pulley will drive the plastic packaging container to slide to the right, so that it is placed in the nitrogen oxide filling chamber Next, spray nitrogen oxides through the nozzle to make it enter the plastic packaging container. After spraying for 4 minutes, it will slide to the disinfectant filling chamber for 3 minutes of disinfection spraying. After the three spraying processes are completed, the plastic packaging container will rest on the pulley. Set it aside for 2 minutes to allow it to fully react. After the reaction, use a blower to blow dry. At the same time, the residual nitrogen oxide gas in the plastic packaging container is sucked into the recovery device to reduce nitrogen substances and generate nitrog...

example 3

[0023] Will contain a concentration of 6mg / m 3 The ethyl acetate enters the organic substance filling chamber through the inlet, turns on the flow rate switch, and sprays a small amount of spray to the plastic container through the nozzle. After spraying for 3 minutes, the pulley will drive the plastic packaging container to slide to the right, so that it is placed in the nitrogen oxide filling chamber. Next, spray nitrogen oxides through the nozzle to make it enter the plastic packaging container. After spraying for 4 minutes, it will slide to the disinfectant filling chamber for 3 minutes of disinfection spraying. After the three spraying processes are completed, the plastic packaging container will rest on the pulley. Set it aside for 3 minutes to allow it to fully react. After the reaction, use a blower to blow dry. At the same time, the residual nitrogen oxide gas in the plastic packaging container is sucked into the recovery device to reduce nitrogen substances and genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com