Oxidizer compound for rocket propulsion

a rocket propulsion and oxidizer compound technology, applied in the direction of engine starters, turbine/propulsion engine ignition, explosions, etc., can solve the problems of high toxic and/or detonation, high toxicity, and associated consequences, and achieve the effect of promoting spontaneous ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

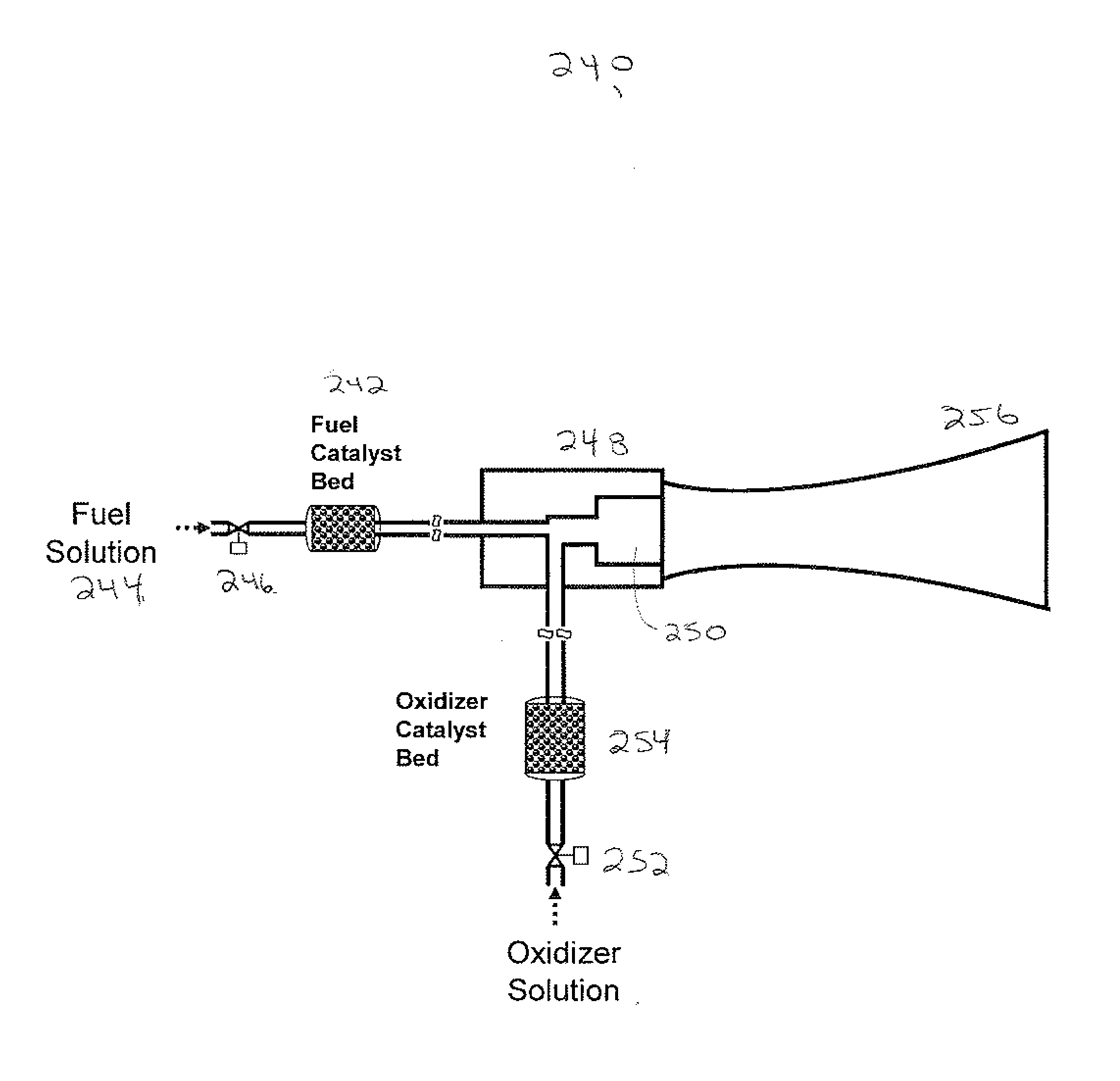

[0027]The novel oxidizer solution of the present invention can be used in a variety of rocket propulsion systems to include, for example, those used in launch vehicle propulsion systems, multi-mode spacecraft propulsion systems, upper stage spacecraft propulsion systems, and missile propulsion systems. Furthermore, the oxidizer solution of the present invention can be matched with a variety of propellant fuels in these propulsion systems. Accordingly, it is to be understood that the type of propulsion system and / or propellant fuel used therein are not limitations of the present invention.

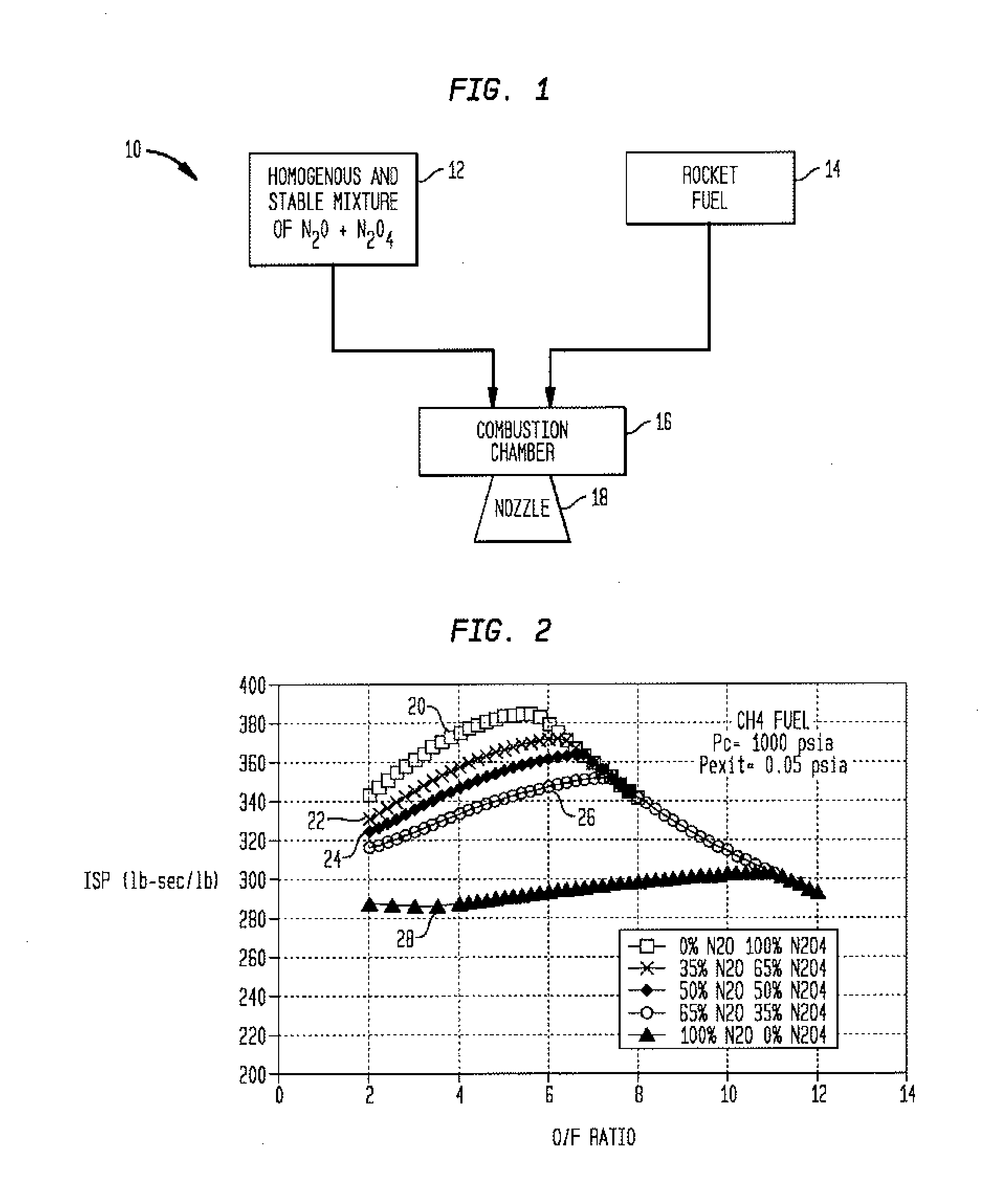

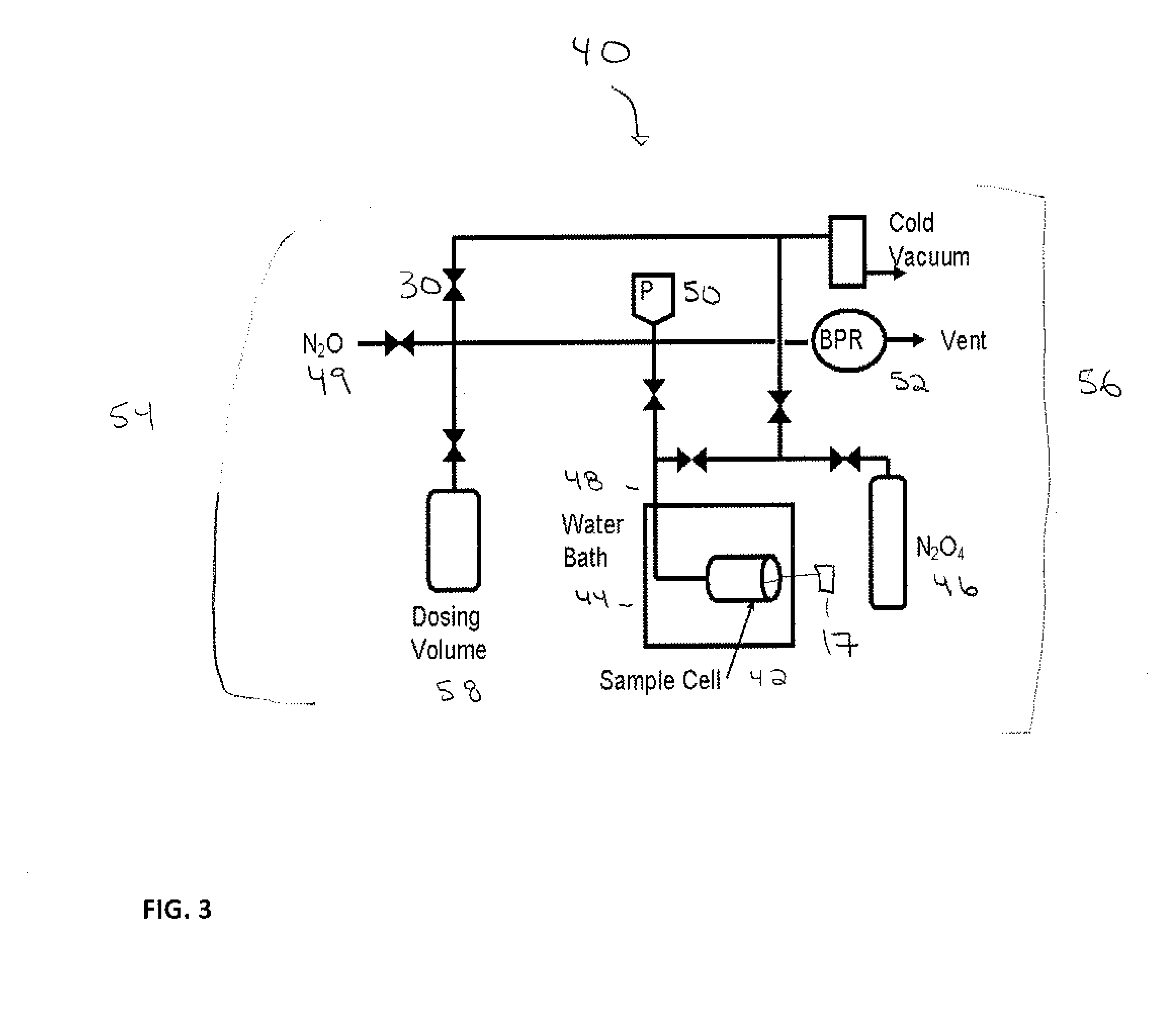

[0028]In general, the oxidizer solution of the present invention is a solution of nitrous oxide dissolved into nitrogen tetroxide that is homogenous and a stable liquid (i.e., will not boil off as long as it is contained in a pressure vessel) at room temperature. As used herein, the term “room temperature” is defined as temperatures that are generally close to approximately 20° C. or 72° F. as would...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com