Preparation method of MTNP/TNAZ eutectic mixture

A low eutectic and solution technology, which is applied to attack equipment, explosives processing equipment, nitroalkane compositions, etc. The effect of mechanical sensitivity, improved safety, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of embodiment 1-5 of the present invention is identical, is the preparation method of a kind of MTNP / TNAZ eutectic, and described method comprises the steps:

[0030] Step 1, preparing a solution: adding 1-methyl-3,4,5-trinitropyrazole and 1,3,3-trinitroazetidine into an organic solvent to prepare a solution;

[0031] Step 2, Precipitate the drug: Use a syringe to slowly add the prepared solution into the anti-solvent, and precipitate.

Embodiment 1

[0033] This example involves a preparation of eutectics with a molar ratio of MTNP / TNAZ of 1:3. Step1: Configuration solution

[0034] At room temperature, 1-methyl-3,4,5-trinitropyrazole and 1,3,3-trinitroazetidine were added to 2 mL of acetone as an organic solvent to form a solution. in:

[0035] The total mass of MTNP and TNAZ is 2 g, and the molar ratio of MTNP / TNAZ is 1:3.

[0036] Step2: Precipitation of drugs

[0037] Add the prepared solution into the anti-solvent, and the dropping speed should be slow.

[0038] First, put the prepared solution into the syringe, and use the syringe to slowly drop the solution into 200mL of anti-solvent water. During this process, keep stirring and control the speed at 350-400r / min, and then wait for the drug to precipitate.

[0039] Suction filtration and freeze-drying of the obtained medicine can complete the preparation of the eutectic product.

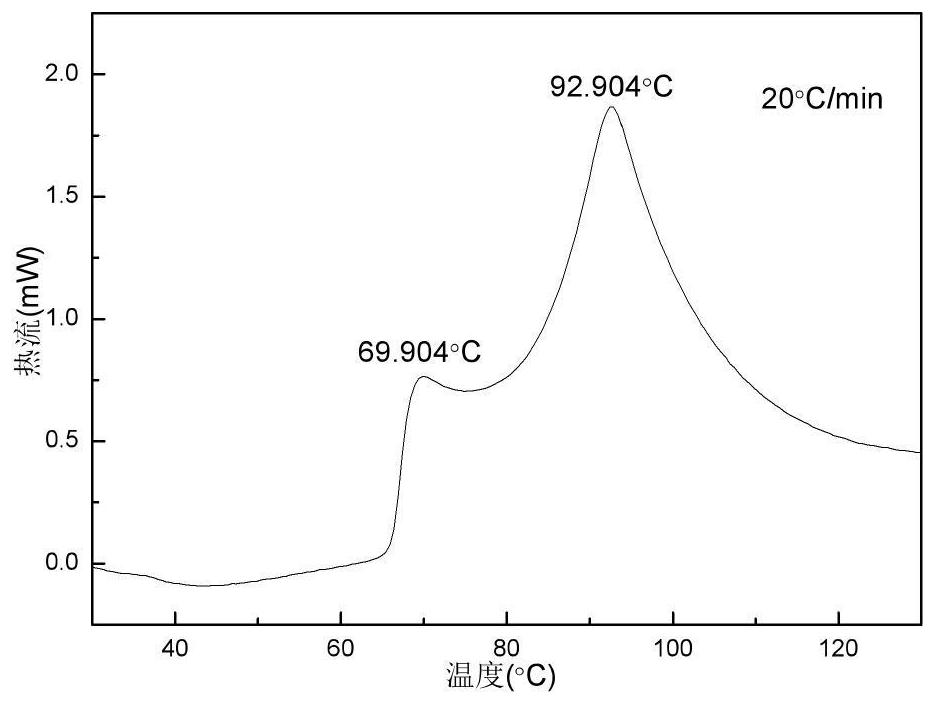

[0040] The DSC spectrum of the eutectic with a molar ratio of 1:3 of MTNP / TNAZ obta...

Embodiment 2

[0042] This example involves the preparation of eutectics with a molar ratio of MTNP / TNAZ of 1:2

[0043] Step1: Configure the solution

[0044] At room temperature, 1-methyl-3,4,5-trinitropyrazole and 1,3,3-trinitroazetidine were added to 4 mL of organic solvent acetone to form a solution. in:

[0045] The total mass of MTNP and TNAZ is 2 g, and the molar ratio of MTNP / TNAZ is 1:2.

[0046] Step2: Precipitation of drugs

[0047] Add the prepared solution into the anti-solvent water, and the dropping speed should be slow.

[0048] First, put the prepared solution into the syringe, and slowly drop the solution into 250mL of anti-solvent water using the syringe. During this process, keep stirring and control the speed at 350-400r / min, and then wait for the drug to precipitate.

[0049] Suction filtration and freeze-drying of the obtained medicine can complete the preparation of the eutectic product.

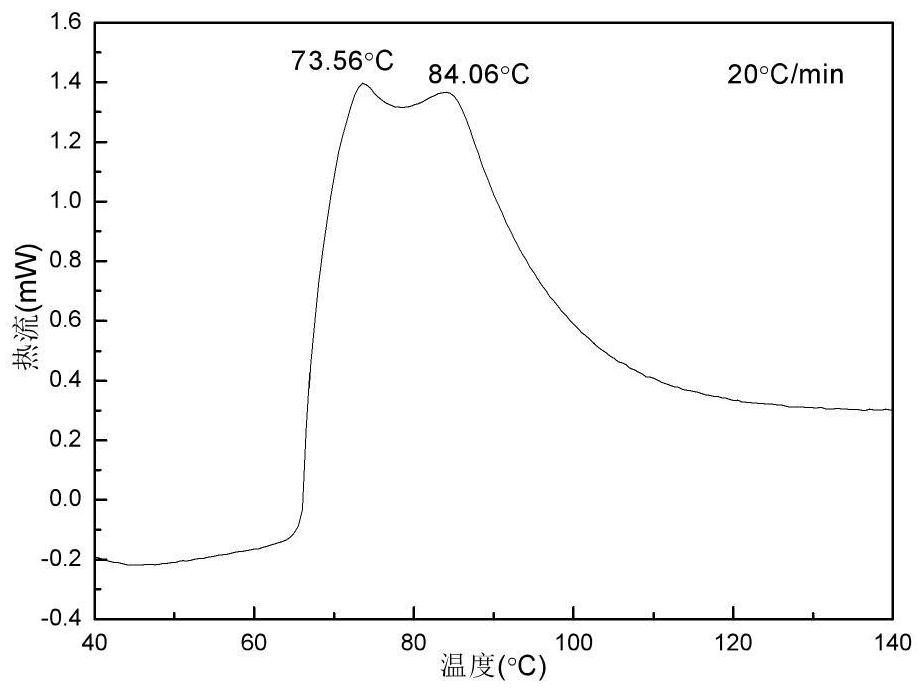

[0050] The DSC spectrum of the eutectic with a molar ratio of 1:2 of MTNP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com