Nano epsilon crystal form hexanitrohexaazaisowurtzitane (CL-20) explosive and massive preparation method thereof

A technology of heteroisopentazine explosive and hexanitrohexanitrogen, which is applied in nitroalkane composition, organic chemistry method, organic chemistry and other directions, can solve the problems of unsuitable industrial amplification of supercritical fluid method and introduction of mechanical impurities, etc. To achieve the effect of simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

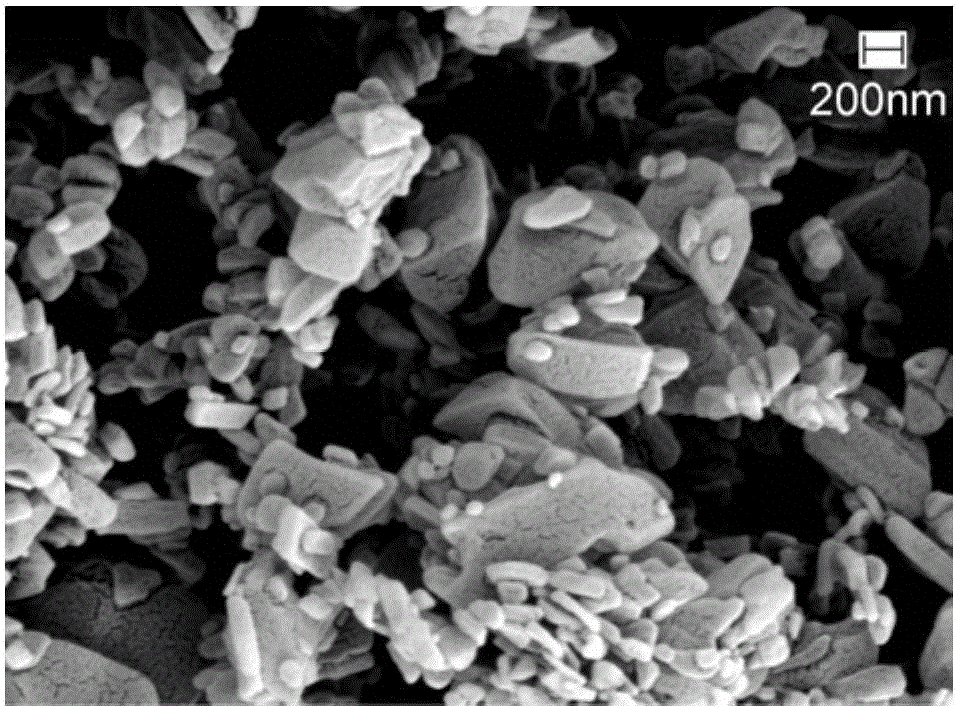

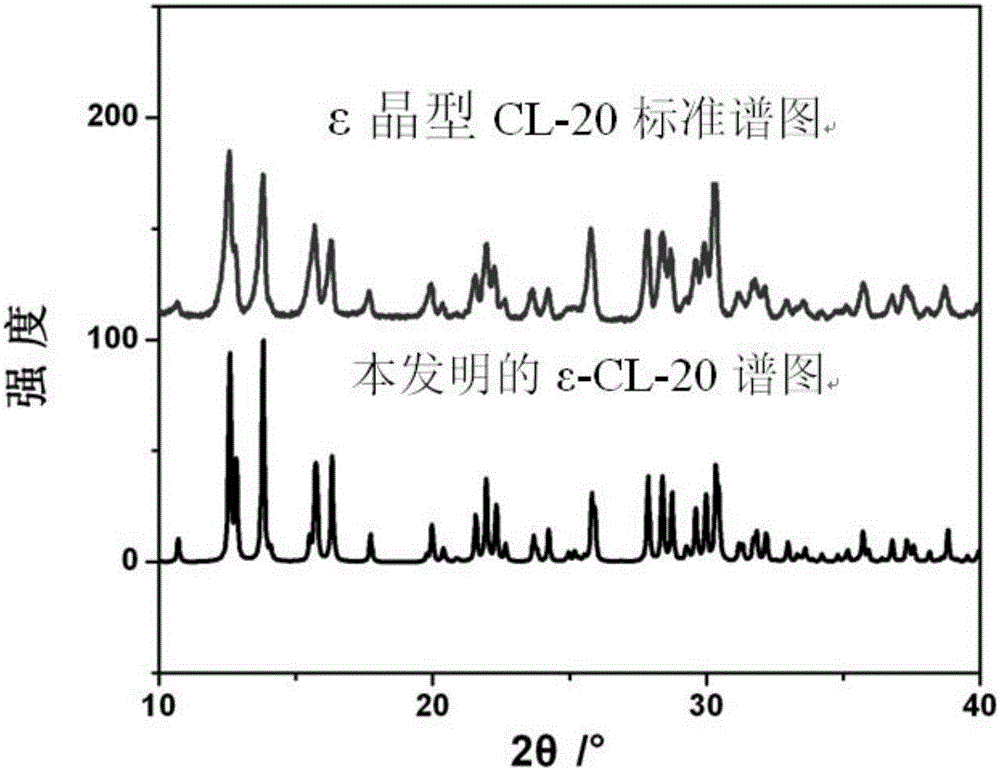

[0033] Add 2000mL toluene to the beaker, put it in the refrigerator to pre-freeze to -30°C; measure 100mL DMF, add 60g CL-20 to it, stir to dissolve it, and heat it to 65°C to prepare the explosive solution; put the beaker in a low temperature Turn on the ultrasound in the ultrasonic tank, use a stirrer to vigorously stir the toluene in the beaker, spray the heated explosive solution into the toluene, and the system temperature after the spraying is -16°C; the obtained material is washed with -20°C toluene several times, filtered , and dried at room temperature to obtain 52g of ε crystal form CL-20 explosive with an average particle diameter of 320nm.

Embodiment 2

[0035] Add 3000mL of n-heptane into the beaker, put it in the refrigerator to pre-freeze to -25°C; measure 250mL of ethyl acetate, add 100g of CL-20 into it, stir to dissolve it, and heat it to 50°C to prepare the explosive solution; Put the beaker into a low-temperature ultrasonic pool and turn on the ultrasound, use a stirrer to stir the n-heptane in the beaker vigorously, spray the heated explosive solution into the n-heptane, and the temperature of the system after the injection is -10°C; the obtained materials are used- Washed several times with n-heptane at 15°C, filtered, and freeze-dried at -40°C to obtain 88 g of ε crystal form CL-20 explosive with an average particle size of 380 nm.

Embodiment 3

[0037] Add 1000mL dichloroethane into the beaker, put it in the refrigerator to pre-freeze to -20°C; measure 100mL acetone, add 40g CL-20 into it, stir to dissolve, and heat to 45°C to prepare the explosive solution; put the beaker Put it into a low-temperature ultrasonic pool and turn on the ultrasound, use a stirrer to stir the dichloroethane in the beaker vigorously, spray the heated explosive solution into the dichloroethane, and the system temperature after the spray is -8°C; the obtained material is Wash with dichloroethane at -10°C several times, filter, and vacuum-dry at 60°C to obtain 34 g of ε crystal form CL-20 explosive with an average particle size of 350 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com