High polymer bonded explosive with self-repair function and preparation method thereof

A technology for bonding explosives and high polymers, which is applied in the directions of explosives, nitrification explosives, offensive equipment, etc., can solve the problems of no self-healing polyurethane bonded explosives preparation method, etc., and achieves prolonging the life of explosive components, simple preparation process and conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

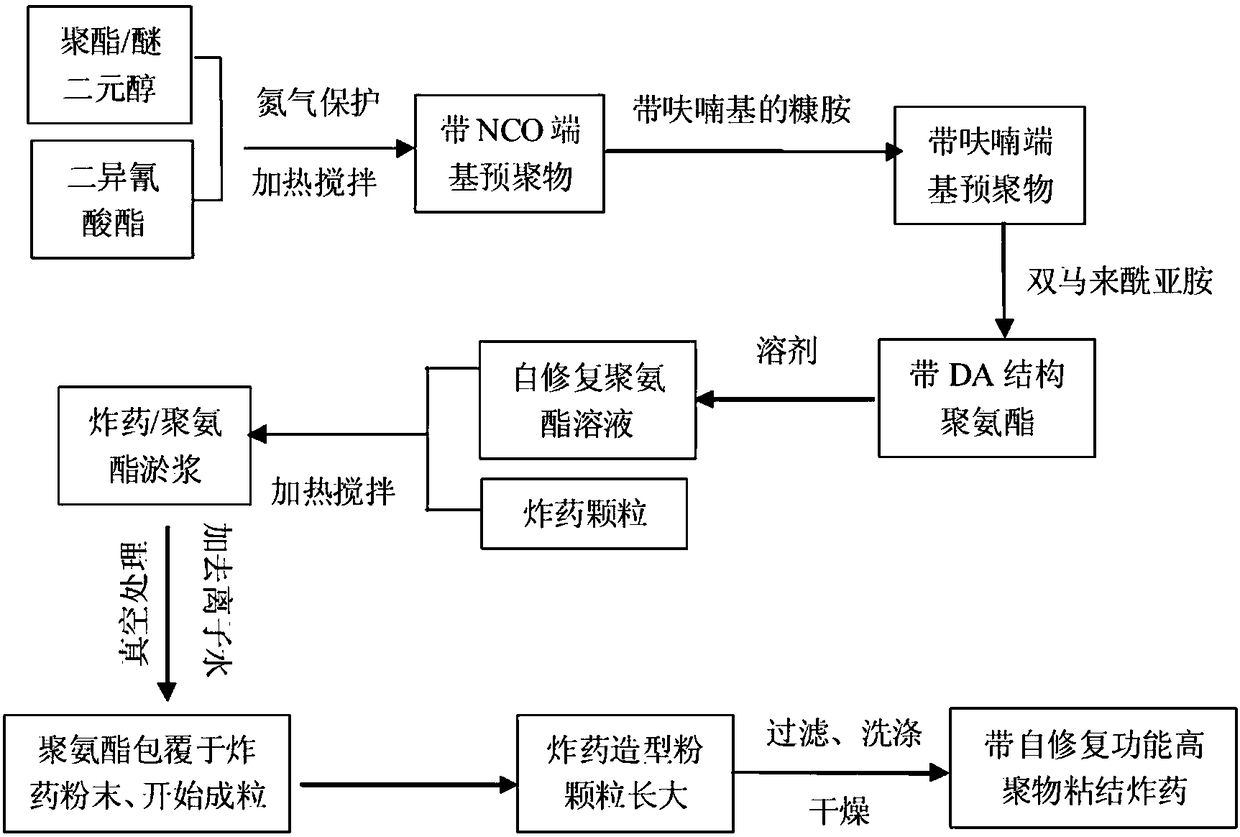

Method used

Image

Examples

Embodiment 1

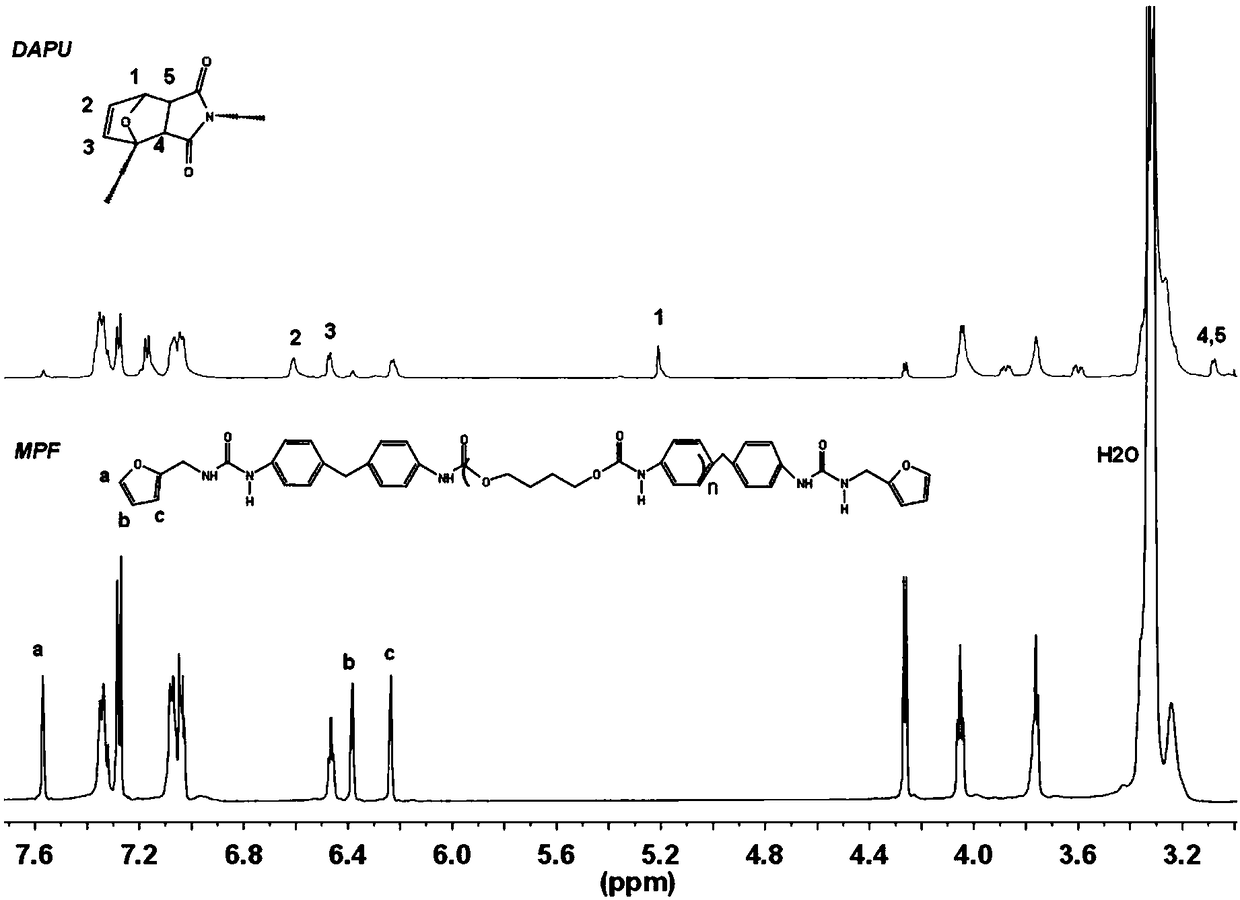

[0028]Under the conditions of nitrogen protection and mechanical stirring, polytetrahydrofuran diol-1000 (30.00g, 0.03mol) after dehydration, 4,4'-diphenylmethane diisocyanate (15.02g, 0.06mol) and 40mL N, Mix N-dimethylformamide thoroughly; raise the temperature to 80°C, and react at constant temperature for 3 hours; then cool to 0°C with an ice-water bath to obtain a prepolymer solution with isocyanate at both ends. Add furfurylamine (5.83g, 0.06mol) slowly to the prepolymer solution dropwise within 20min, raise the temperature to 80°C, and react for 4h to obtain polyurethane (MPF) with furan groups at both ends. Dissolve 4,4'-methylenebis(N-phenylmaleimide) (10.75g, 0.03mol) in 20mL N,N-dimethylformamide, add it to the MPF solution, at 70°C The reaction was carried out for 3 hours to obtain a pre-finished product; the pre-finished product was poured into a polytetrafluoroethylene mold and baked in a blast oven at 60°C for 48 hours to obtain 60.50 g of thermoplastic polyuret...

Embodiment 2

[0031] Under nitrogen protection and mechanical stirring conditions, polytetrahydrofuran diol-1000 (30.00g, 0.03mol), hexamethylene diisocyanate (10.09g, 0.06mol) and 20mL N,N-dimethyl The formamide was thoroughly mixed; the temperature was raised to 80°C, and the temperature was reacted for 3 hours; then cooled to 0°C with an ice-water bath to obtain a prepolymer solution with isocyanate at both ends. Add furfurylamine (5.83g, 0.06mol) slowly to the prepolymer solution dropwise within 20min, raise the temperature to 80°C, and react for 4h to obtain polyurethane (MPF) with furan groups at both ends. Dissolve 4,4'-methylenebis(N-phenylmaleimide) (10.75g, 0.03mol) in 20mL N,N-dimethylformamide, add it to the MPF solution, at 70°C The reaction was carried out for 3 hours to obtain a pre-finished product; the pre-finished product was poured into a polytetrafluoroethylene mold and baked in a blast oven at 60°C for 48 hours to obtain 56.00 g of thermoplastic polyurethane (DAPU) with...

Embodiment 3

[0034] Under nitrogen protection and mechanical stirring conditions, polypropylene glycol-1000 (20.00g, 0.02mol), 4,4'-diphenylmethane diisocyanate (5.01g, 0.02mol) and 15mL N,N- Dimethylformamide was thoroughly mixed; the temperature was raised to 80°C, and the temperature was reacted for 3 hours; then cooled to 0°C with an ice-water bath to obtain a prepolymer solution with isocyanates at both ends. Add furfurylamine (3.89 g, 0.04 mol) slowly to the prepolymer solution dropwise within 20 min, raise the temperature to 80° C., and react for 4 h to obtain polyurethane (MPF) with furan groups at both ends. 4,4'-methylenebis(N-phenylmaleimide) (7.17g, 0.02mol) was dissolved in 20mL N,N-dimethylformamide, added to the MPF solution, at 70°C React for 3 hours to obtain a pre-finished product; pour the pre-finished product into a polytetrafluoroethylene mold and bake in a blast oven at 60°C for 48 hours to obtain 36.00 g of thermoplastic polyurethane (DAPU) with DA bonds.

[0035] D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com