Positive grid lead-calcium alloy for lead-acid storage battery

A technology of lead-acid battery and lead-calcium alloy, which is applied in the direction of electrode carrier/collector, etc., can solve the problems of lead-acid battery early capacity decay, positive electrode grid alloy urgently needed to be improved, and poor deep discharge cycle performance, etc. Cycle performance, improvement of deep discharge performance, effect of refining alloy grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

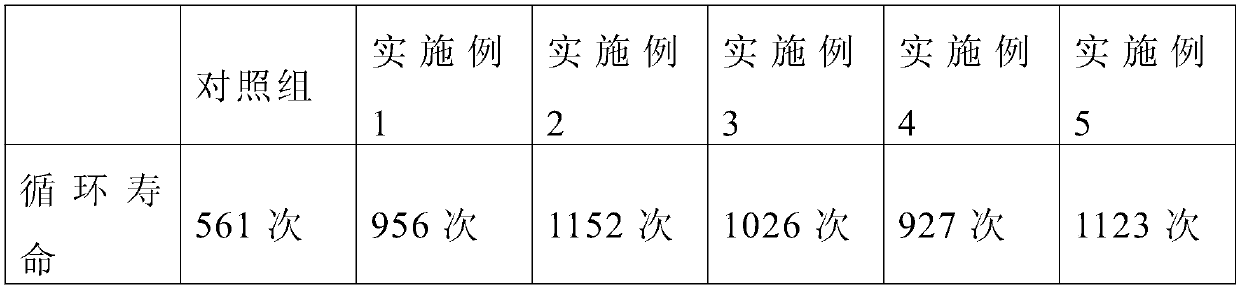

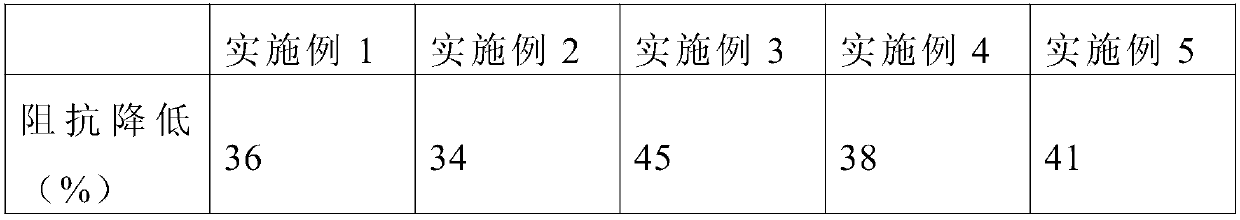

Examples

Embodiment 1

[0019] A lead-acid battery positive grid lead-calcium alloy, comprising the following components in weight percentages:

[0020] Calcium 0.08%, tin 0.1%, bismuth 0.0.09%, ytterbium 0.07%, gadolinium 0.02%, and the balance is lead.

[0021] According to the proportioning of the above-mentioned grid alloy, the preparation method is as follows:

[0022] Step 1. Divide the lead into two parts, one part of lead is melted at 450-470°C, and the other part is used; after the lead is melted, a part of tin is added, after it is completely melted, the temperature is raised to 1200-1400°C, calcium is added, After it is completely melted, stir evenly, and when it is lowered to 500-550°C, take it out of the furnace to obtain a lead-tin-calcium alloy;

[0023] Step 2. Melt another part of tin in a high-temperature furnace at 450°C. After it is completely melted, add bismuth. After it is completely melted, stir evenly; raise the temperature to 900-1000°C, add rare earth elements ytterbium an...

Embodiment 2

[0027] A lead-acid battery positive grid lead-calcium alloy, comprising the following components in weight percentages:

[0028] Calcium 0.05%, tin 1.5%, bismuth 0.06%, gadolinium 0.6%, lanthanum 0.03%, and the balance is lead.

[0029] According to the proportioning of the above-mentioned grid alloy, the preparation method is as follows:

[0030] Step 1. Divide the lead into two parts, one part of lead is melted at 450-470°C, and the other part is used; after the lead is melted, a part of tin is added, after it is completely melted, the temperature is raised to 1200-1400°C, calcium is added, After it is completely melted, stir evenly, and when it is lowered to 500-550°C, take it out of the furnace to obtain a lead-tin-calcium alloy;

[0031] Step 2. Melt another part of tin in a high-temperature furnace at 450°C. After it is completely melted, add bismuth. After it is completely melted, stir evenly; raise the temperature to 900-1000°C, add rare earth elements gadolinium and ...

Embodiment 3

[0035] A lead-acid battery positive grid lead-calcium alloy, comprising the following components in weight percentages:

[0036] Calcium 0.07%, tin 1.2%, bismuth 0.08%, ytterbium 0.08%, lanthanum 0.05%, and the balance is lead.

[0037] According to the proportioning of the above-mentioned grid alloy, the preparation method is as follows:

[0038] Step 1. Divide the lead into two parts, one part of lead is melted at 450-470°C, and the other part is used; after the lead is melted, a part of tin is added, after it is completely melted, the temperature is raised to 1200-1400°C, calcium is added, After it is completely melted, stir evenly, and when it is lowered to 500-550°C, take it out of the furnace to obtain a lead-tin-calcium alloy;

[0039] Step 2. Melt another part of tin in a high-temperature furnace at 450°C. After it is completely melted, add bismuth. After it is completely melted, stir evenly; raise the temperature to 900-1000°C, add rare earth elements ytterbium and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com