Patents

Literature

39 results about "Polymer-bonded explosive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A polymer-bonded explosive, also called PBX or plastic-bonded explosive, is an explosive material in which explosive powder is bound together in a matrix using small quantities (typically 5–10% by weight) of a synthetic polymer. PBXs are normally used for explosive materials that are not easily melted into a casting, or are otherwise difficult to form. PBX was first developed in 1952 in Los Alamos National Laboratory, as RDX embedded in polystyrene with dioctyl phthalate plasticizer. HMX compositions with teflon-based binders were developed in 1960s and 1970s for gun shells and for Apollo Lunar Surface Experiments Package (ALSEP) seismic experiments, although the latter experiments are usually cited as using hexanitrostilbene (HNS).

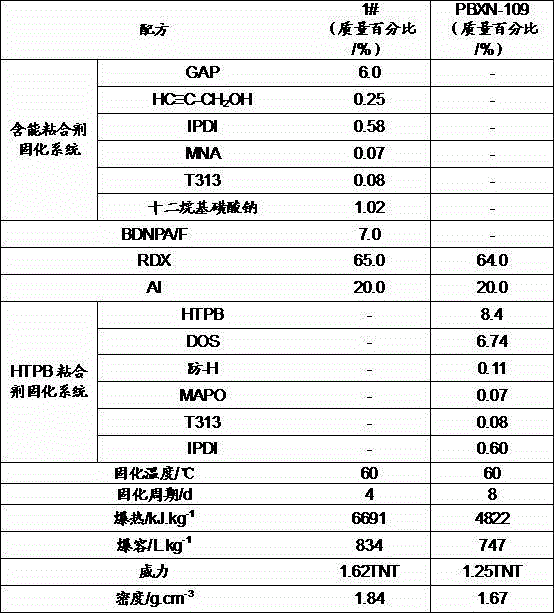

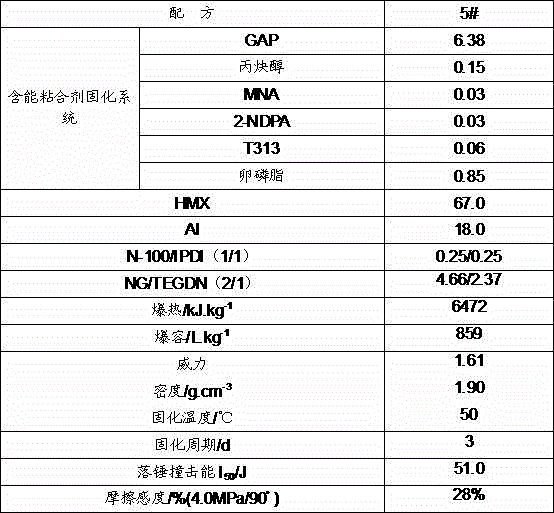

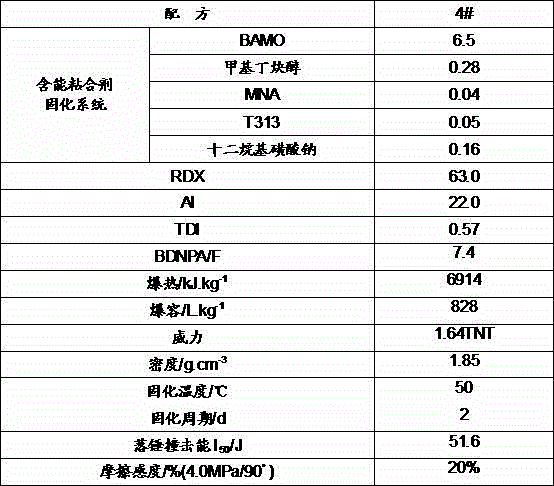

Poured-type azido high-polymer bonded explosive and preparation method of same

A poured-type azido high-polymer bonded explosive and a preparation method of same. For solving a problem of low energy of an HTPB-based PBX explosive, an azido polyether energetic binder is added to a formula system of the PBX explosive, and by means of addition of an alkynol compound as a curing additive agent, a curing reaction time of the azido polyether binder system is greatly reduced. By means of addition of a high-energy-density main explosive and a metal fuel component, the obtained poured-type azido PBX explosive has high explosion heat and explosion volume, is higher than 1.80 g / cm<3> in density and is more than 1.60 TNT in power. Meanwhile, the poured-type azido PBX explosive has a low sensitivity level, is higher than 49 J in drop hammer impact energy I50 and is not more than 40% in friction sensitivity.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

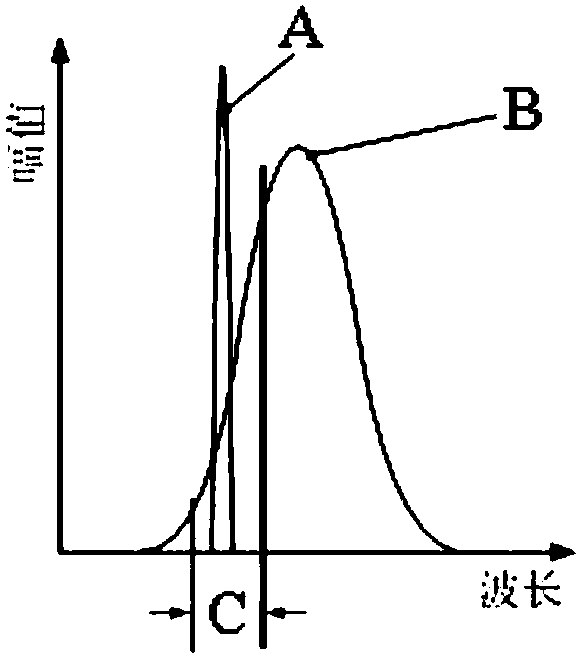

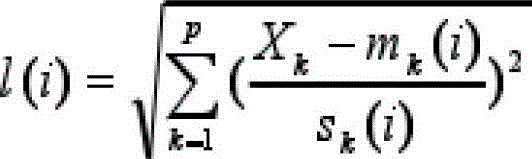

Method for determination of PCTFE content in PBX explosive by near infrared spectrum

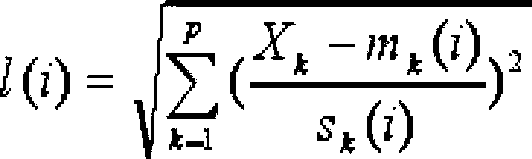

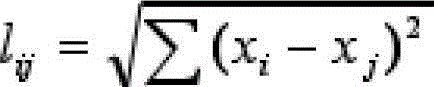

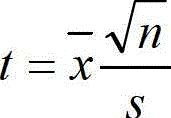

ActiveCN103018195AImprove robustnessImprove accuracyColor/spectral properties measurementsPolymer-bonded explosiveRoot mean square

The invention discloses a method for determination of the polychlorotrifluoroethylene (PCTFE) content in a polymer-bonded explosive (PBX) by near infrared spectroscopy. The method includes the steps of: preparing and collecting 260 PBX samples, taking 180 samples of them as a calibration set for establishing a calibration model, taking the remaining 80 samples as a validation set for model validation, and acquiring the near infrared spectrum data of all the samples; using a standard method to determine the PCTFE content in the samples; subjecting the spectrum data of the validation set samples in the wave bands of 6102.0cm<-1>-5697.0cm<-1> and 4680.2cm<-1>-4242.9cm<-1> to a first order derivative treatment, correlating the treated spectrum data with the PCTFE content by a partial least squares method, and establishing the calibration model by cross validation; employing the calibration model to predetermine the PCTFE content of the validation set samples, and selecting an optimal model according to a minimum root mean squared error of prediction (RMSEP) of the validation set; and acquiring the near infrared spectrum data of the samples to be determined, and making use of the optimal model to obtain the PCTFE content directly. Being suitable for determination of the PCTFE content in a PBX explosive, the method has the characteristics of convenient operation, and rapid and accurate analysis.

Owner:XIAN MODERN CHEM RES INST

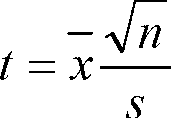

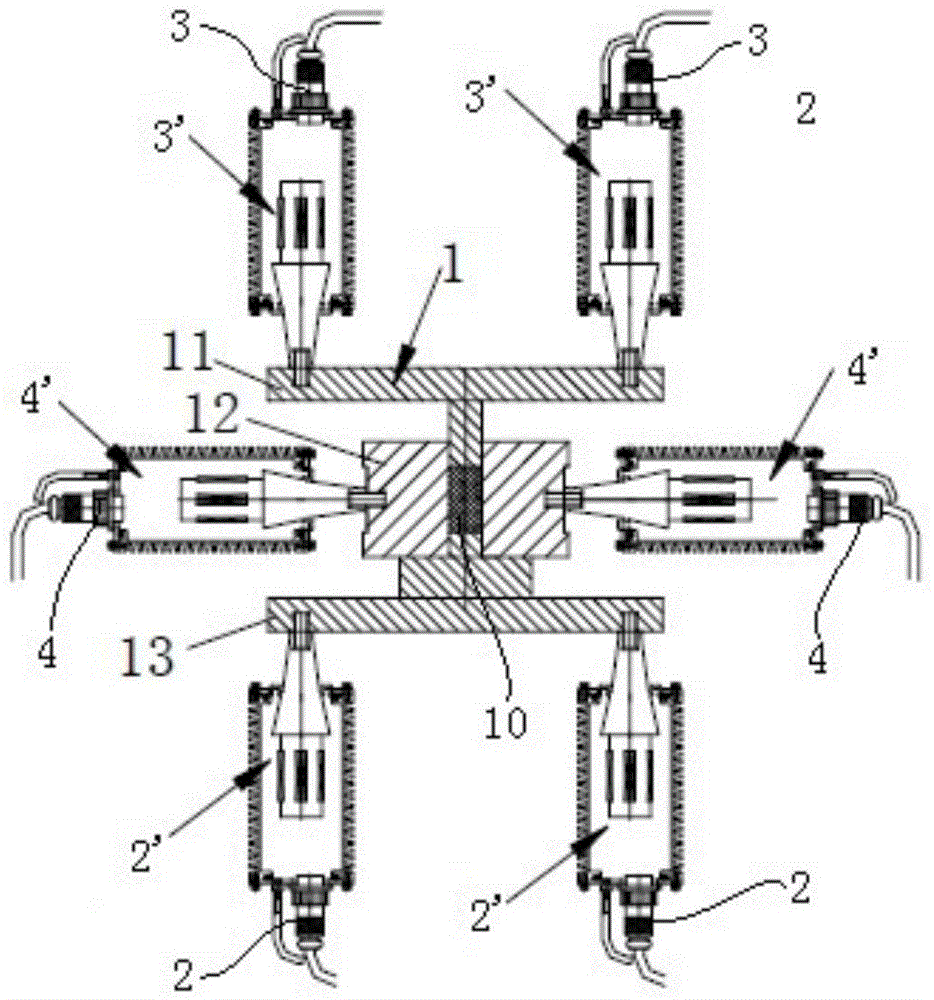

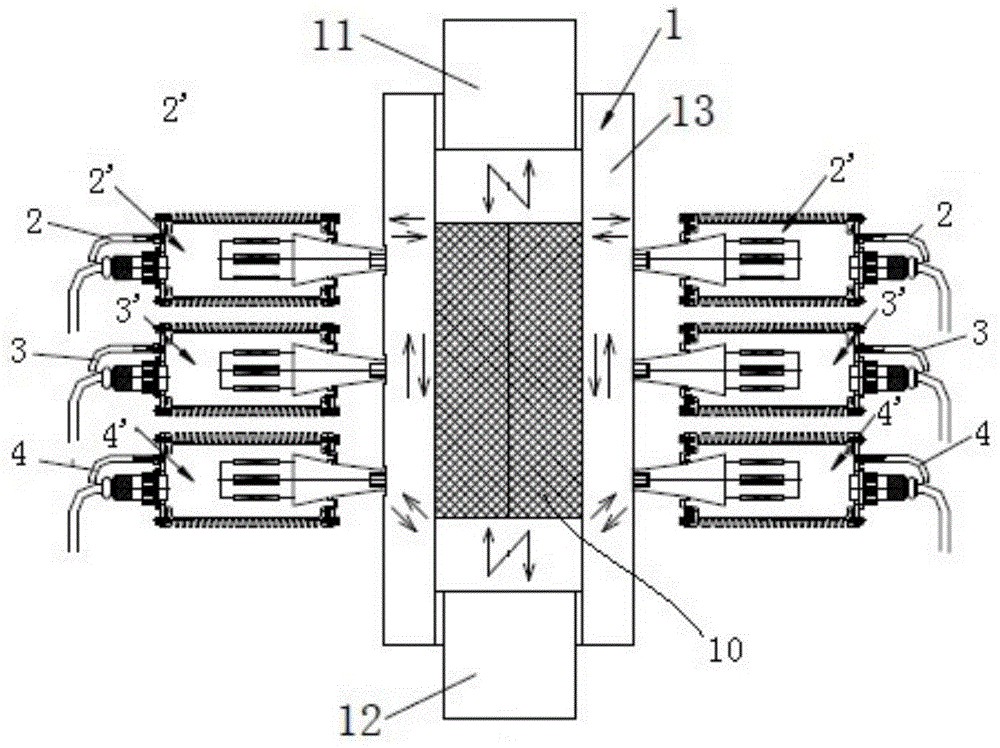

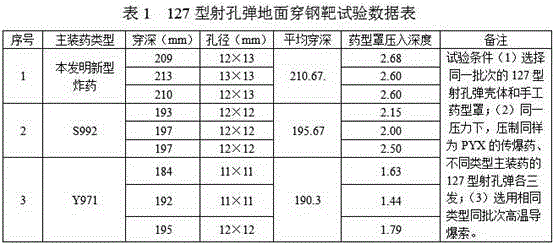

High-viscosity PBX (Polymer Bonded Explosive) injection-compression molding method and device

ActiveCN103936533AImprove filling qualitySolve the problem of poor rheology in high viscosity PBX processExplosive working-up apparatusCompression moldingEngineering

The invention discloses a high-viscosity PBX (Polymer Bonded Explosive) injection-compression molding method and device. The device is provided with an explosive charging barrel and an installing barrel, wherein an extrusion piston is arranged in the installing barrel and is connected to an air cylinder, the air cylinder can be used for controlling the extrusion piston to move up and down and stop, so that explosive slurry in the explosive charging barrel is pressed and injected into a mold to realize the explosive charging; the air cylinder is provided with two speed control valves so as to control the speed of the extrusion piston, and the device is aslo provided with a silencer, circulating water, a sealing ring and the like, so that the injection-compression molding device is further improved. The injection-compression molding device is used in the injection-compression molding method, so that the high-viscosity PBX charging is safely and efficiently realized. The injection-compression molding method and device can be used for solving the problem of poor rheological property of the high-viscosity PBX technology, can effectively ensure the controllability of internal quality of products when the explosive is charged in a complex structure in a large quantity, so as to obtain the explosive pouring parts with high filling quality; moreover, the charging process is rapid, safe, low in working noise, and simple and convenient to operate.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

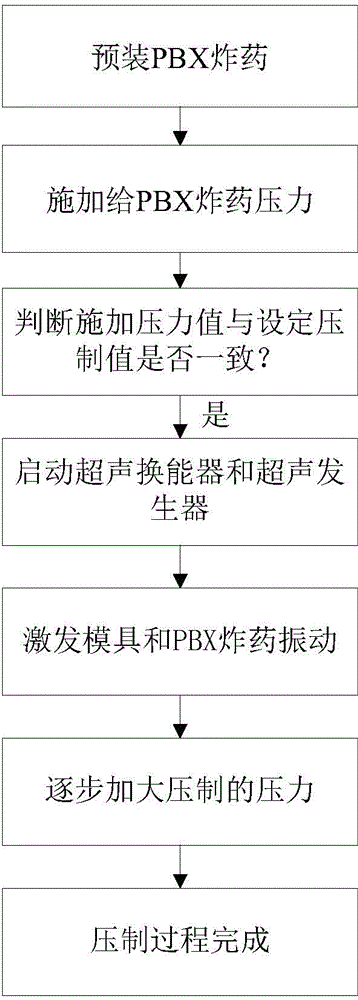

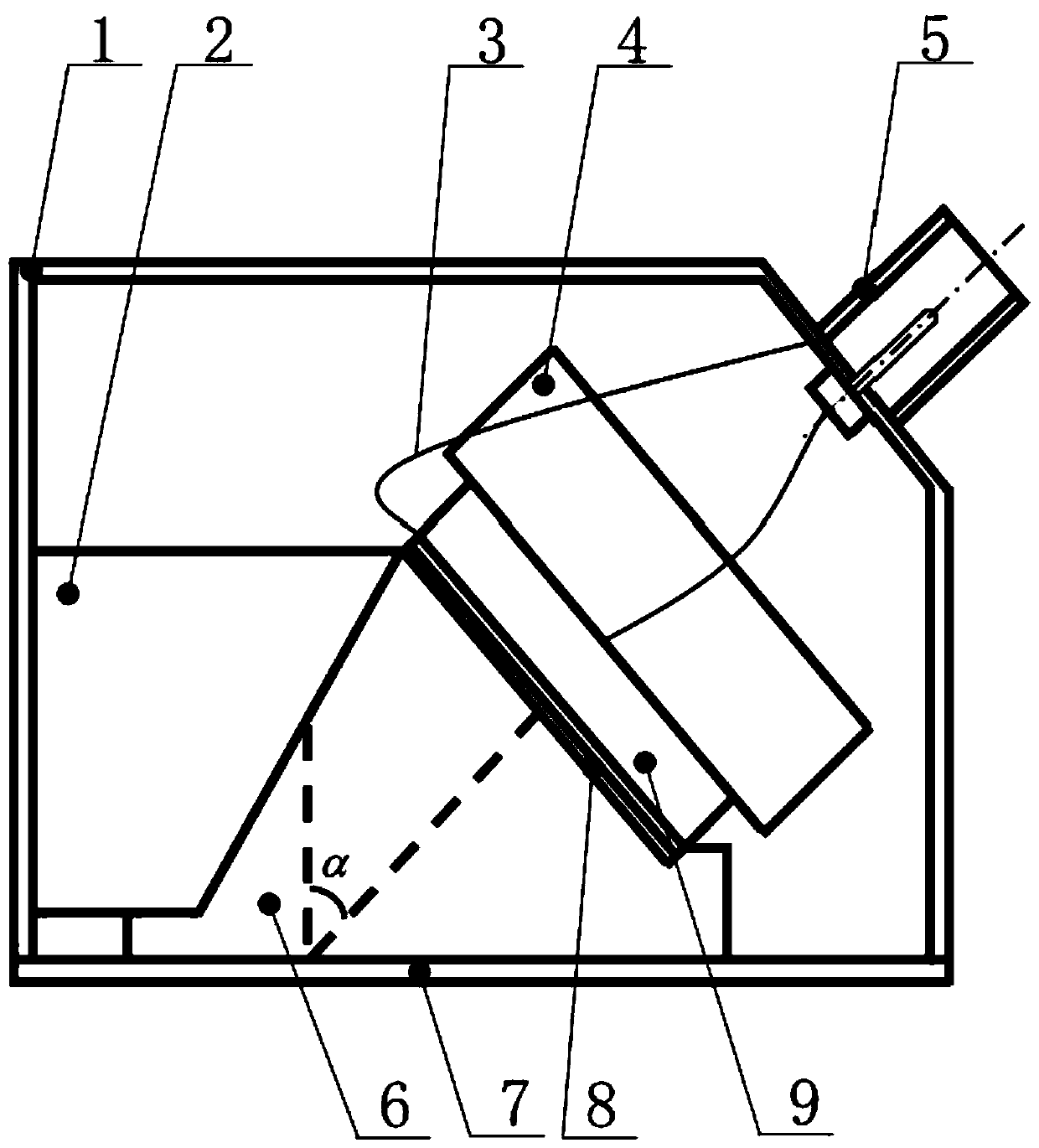

Production method for compression molding of PBX (Polymer Bonded Explosive)

InactiveCN104647793AHigh densityIncrease elasticityExplosive working-up apparatusShaping pressCompression moldingUltrasound - action

The invention relates to a production method for compression molding of PBX (Polymer Bonded Explosive) by using ultrasonic pressing. The production method comprises the following steps: a, feeding powder PBX (10) into a PBX forming device, starting a pressurizing device on the PBX forming device to enable the PBX (10) to be positioned in a pressed state; when a pressure value applied to the PBX (10) exceeds a set pressure value, starting ultrasonic transducers and ultrasonic generators; using ultrasonic waves generated by the ultrasonic transducers to act on a PBX powder body (10) to generate vibration; gradually increasing the pressure value applied to the PBX (10) until the PBX (10) is completely compressed. The production method disclosed by the invention has the technical effects that the density, the strength and the uniformity of the PBX obtained by compression molding are improved, the quality of a finished product of the PBX is effectively improved, and the energy effect of the PBX is improved.

Owner:SHANGHAI ACOUSTICS LAB CHINESE ACADEMY OF SCI

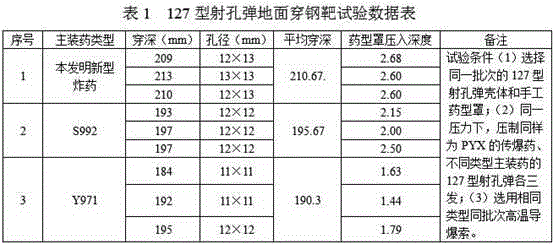

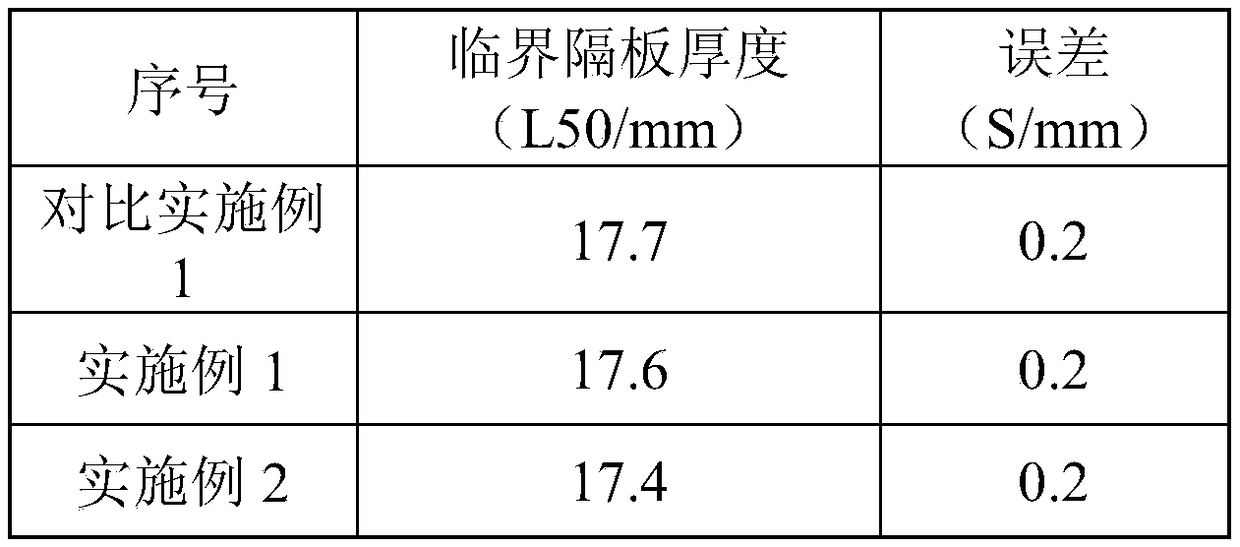

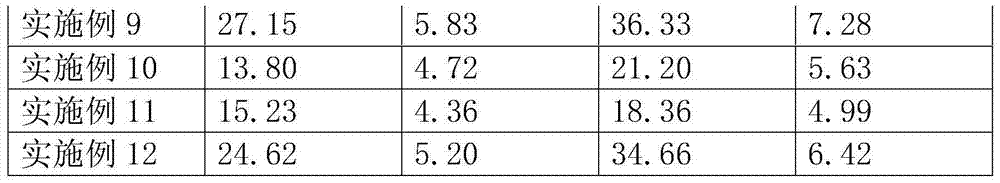

Polymer bonded explosive for ultra-high-temperature petroleum perforation bullet and preparation method for polymer bonded explosive

ActiveCN104447144AImprove heat resistanceMeet development and applicationNitrated aromatic explosive compositionsCombustionDetonation

The invention relates to the field of explosives, and particularly discloses a polymer bonded explosive for an ultra-high-temperature petroleum perforation bullet and a preparation method for the polymer bonded explosive. The explosive consists of hexanitrostilbene, a vinyl acetate-methyl acrylate-butyl acrylate terpolymer and graphite. The explosive has the characteristics of high heat-resistant elemental hexanitrostilbene content, easiness in detonation, high explosive pressing performance, higher pressing density and energy and high inter-component compatibility. The explosive consists of 96.8 to 98.2 mass percent of hexanitrostilbene, 1.5 to 2.5 mass percent of the vinyl acetate-methyl acrylate-butyl acrylate terpolymer and 0.3 to 0.7 mass percent of graphite. According to the explosive and the preparation method, combustion and explosion of the ultra-high-temperature petroleum perforation bullet under the conditions of 220 DEG C and 100 h or 250 DEG C and 4 h are avoided, and the explosive and the preparation method can be used for the exploitation of a deep well oilfield and an offshore oil-gas field.

Owner:SHANXI BEIHUA GUANLYU CHEM IND

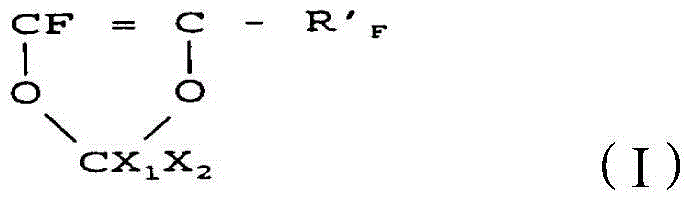

Perfluor dioxole-modified fluorine-containing polymer

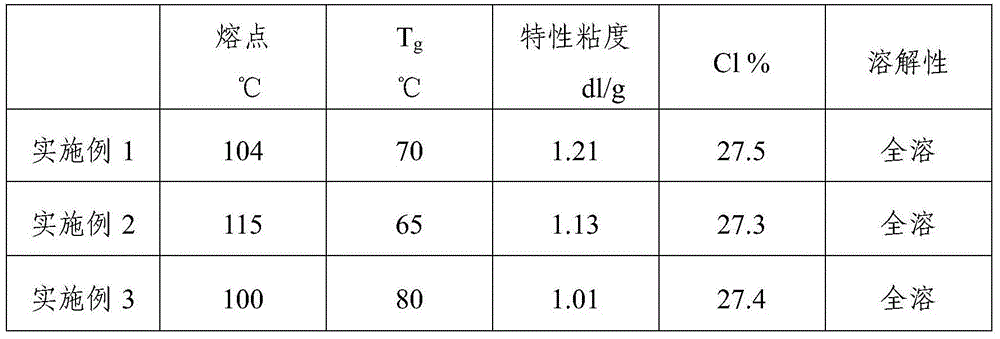

InactiveCN104448097ASolve problems such as low glass transition temperatureAchieve bondingNon-explosive/non-thermic compositionsPolymer scienceSolvent

The invention belongs to the field of organic chemistry and relates to a perfluor dioxole-modified fluorine-containing polymer. A general formula of the perfluor dioxole is as shown in the specification, wherein R and F represent RF or ORF; RF is C1-C5 linear or branched perfluoroalkyl; X1 and X2 are independently used as F or CF3; and a fluorine-containing olefin monomer accounts for 80-99.1% of mass of a copolymerized monomer. According to the polymer disclosed by the invention, the glass-transition temperature is greater than 65 DEG C; the particle size is smaller than 120mum; the intrinsic viscosity is greater than 1.0dl / g; the polymer can be completely dissolved into common esters and other strong polar solvents; the problems that the glass-transition temperature of F23 fluorine polymers at present is relatively low and the like are solved; and the polymer can be widely applied to the military industry, and can be used as a binder for a polymer-bonded explosive and a binder for current collector metal for cells.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

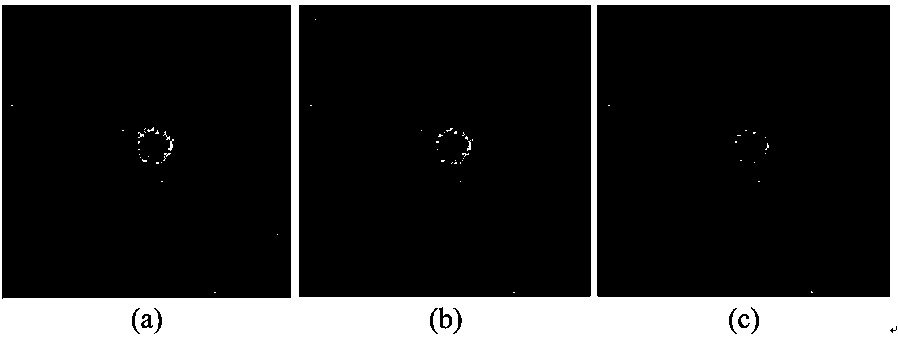

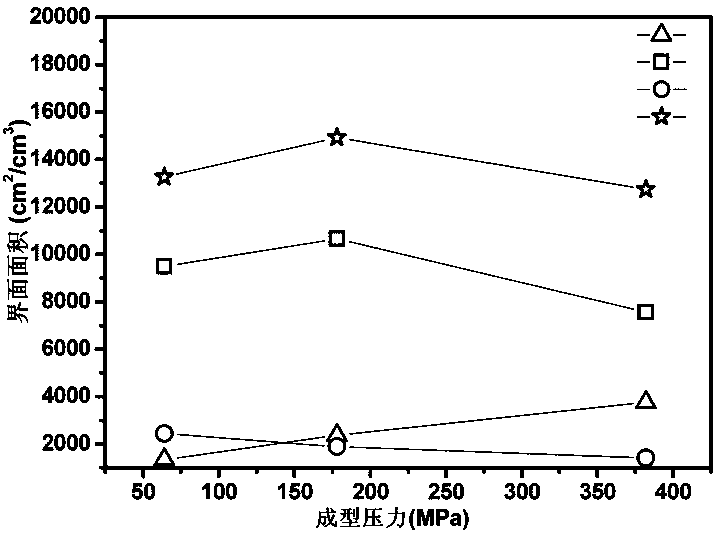

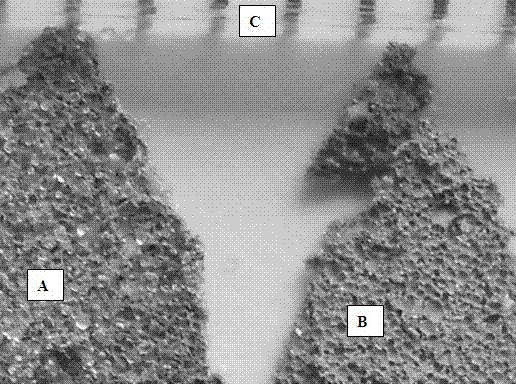

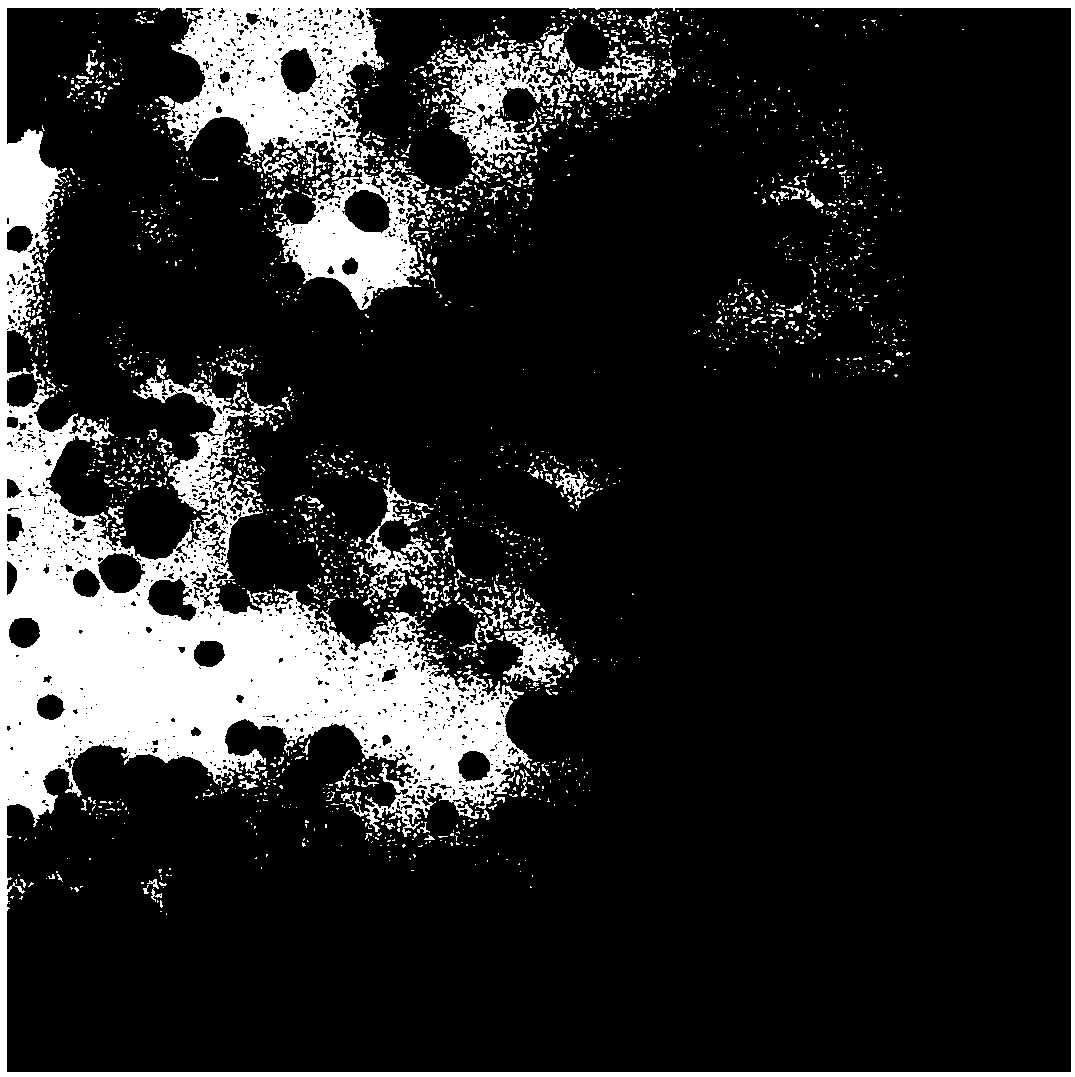

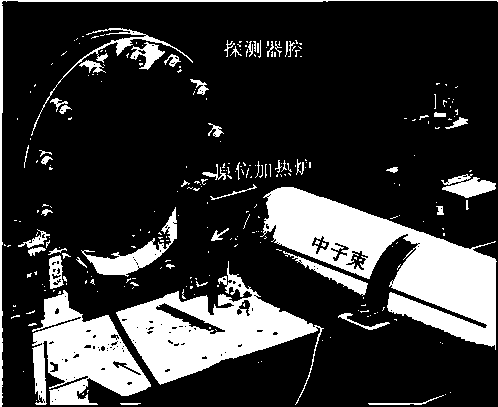

Method for characterizing multi-phase interface of polymer bonded explosive

InactiveCN108318511ARealize non-destructive measurementMaterial analysis using wave/particle radiationAdhesiveStructure function

The invention discloses a method for characterizing a multi-phase interface of polymer bonded explosive. The method comprises the following steps: preparing a series of PBX samples composed of explosive crystals and additives, performing a small angle neutron scattering experiment on the prepared samples, performing absolute strength correction on small angle neutron scattering experimental data,fitting the experimental data based on a Porod theorem, and solving linear system of equations, thereby obtaining interfacial areas between the explosive crystals and adhesives, between the adhesivesand holes and between the explosive crystals and the holes. The method is capable of directly providing numerical values of the interfacial areas among the explosive crystals, the adhesives and the holes in the PBX explosive, and is an effective method for characterizing a complex multi-phase interface inside a multi-component PBX material. The method provides the numerical values of various areas, and is an important foundation of deeply understanding a structure-function relationship of the PBX explosive, optimizing the preparation process and realizing performance improvement study.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

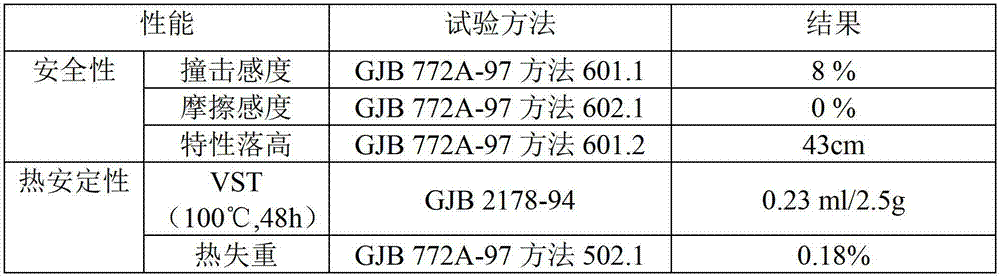

Polymer bonded explosive for missile of common jet hole

InactiveCN103204752AImprove heat resistanceLower surface energyNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsNon-explosive/non-thermic compositionsHeat resistanceGraphite

The invention discloses a polymer bonded explosive for a missile of a common jet hole. The polymer bonded explosive is prepared from the following components by weight percent: 95-98.5% of cyclonite, 1.2-4.0% of ethylene-ethylene vinyl-acetate copolymer and 0.3-1.0% of graphite. The ethylene-ethylene vinyl-acetate copolymer is adopted as a binder; the heat resistance of the ethylene-ethylene vinyl-acetate copolymer is more excellent than that of the cyclonite; the surface is lower than the cyclonite; the ethylene-ethylene vinyl-acetate copolymer has a certain sensitivity reduction effect, ensures good interface interaction and strong binding power of the binder and the cyclonite, enhances the grain strength, and can reduce the dosage of the binder, so as to meet the requirements of powder charge of the common jet hole. The prepared polymer bonded explosive is high in energy (the detonation velocity achieves 8526m / s), low in mechanical sensitivity, and good in heat resistance (non-burning and non-bursting at 150 DEG C for 24 hours), and can meet the requirements of the common jet hole.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Pretreatment method of polymer bonded explosive sample

InactiveCN102359899ASpeed up entryImprove extraction efficiencyPreparing sample for investigationExplosive AgentsPretreatment method

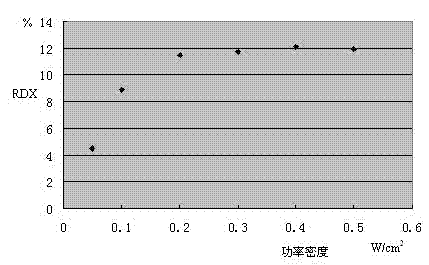

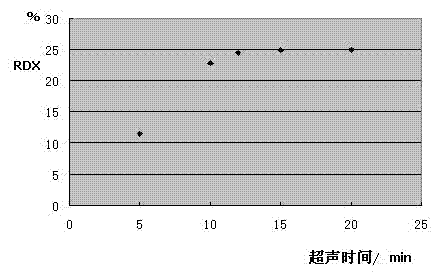

The invention discloses a pretreatment method of a polymer bonded explosive sample. The method comprises the steps of: processing a polymer bonded explosive into a sample block with an appropriate size, conducting ultrasonic extraction in an ultrasonic instrument with acetone for 15min-20min, and adjusting the power density to a range not less than 0.2W / cm<2> and not higher than 0.5W / cm<2>, thus obtaining a sample solution, i.e. able to carry out the next step of ingredient content analysis of the polymer bonded explosive with a routine method. The method of the invention effectively solves the problems of time-consuming pretreatment of explosive samples and poor repeatability of extraction results, and provides reliable data for design and application of explosive formulas.

Owner:XIAN MODERN CHEM RES INST

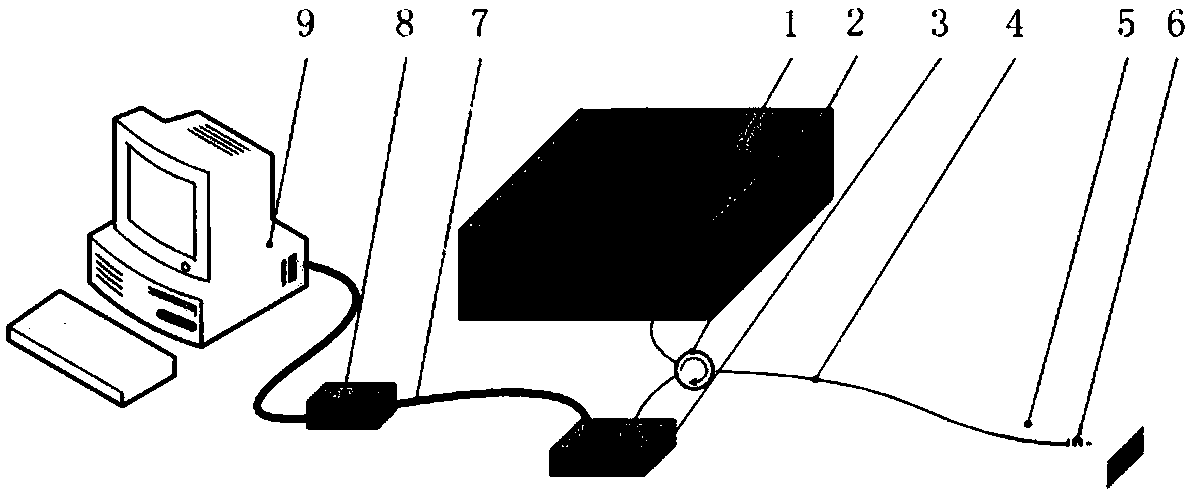

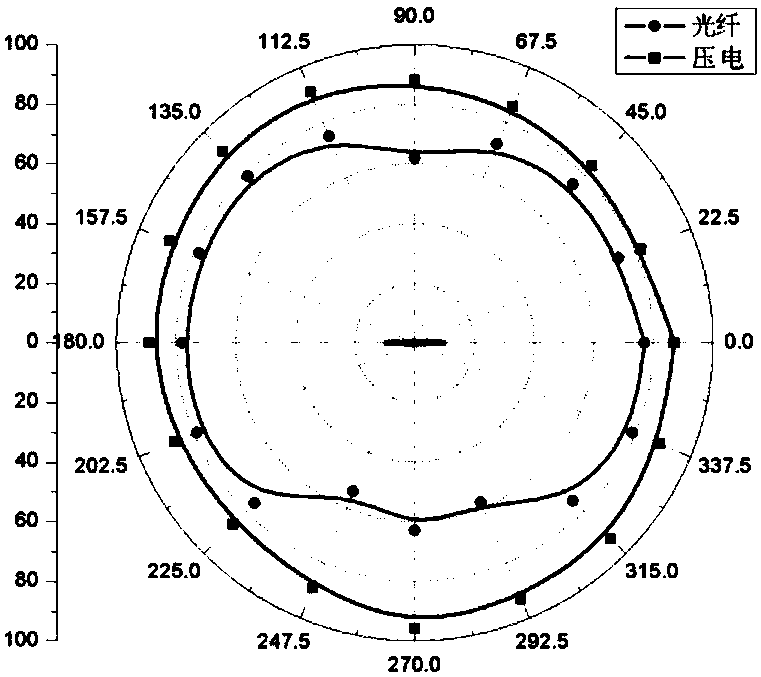

Optical fiber acoustic emission system for monitoring damage and destruction process of explosive and monitoring method thereof

PendingCN108195943AImprove coupling efficiencyReduce reflectivityMaterial analysis using acoustic emission techniquesGratingPhotodetector

The invention discloses an optical fiber acoustic emission system for monitoring a damage and destruction process of an explosive and a monitoring method thereof. A fiber Bragg grating is adopted as an acoustic emission sensor to replace traditional piezoelectric resonant acoustic emission sensors, and a tunable narrowband laser and a photodetector are used as a photoelectric conversion device. The optical fiber acoustic emission system is used for monitoring fracture and destruction of the polymer bonded explosive in the optical fiber acoustic emission monitoring method. Monitoring and analysis are carried out by taking a three-point bending fracture and destruction test of an explosive specimen as an example. The optical fiber acoustic emission system has a microsecond response speed andcan accurately monitor the time history of internal energy release amount in the explosive damage and destruction process and provide a data support for mastering a damage and destruction law of theexplosive.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

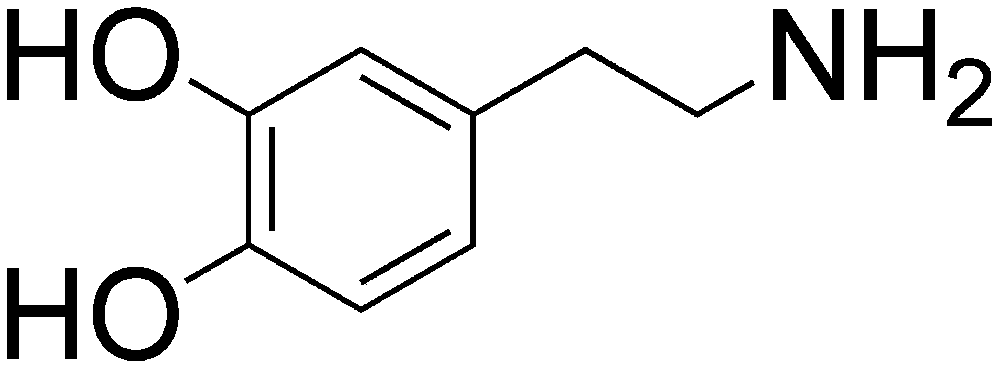

Bionic vertex face heat conduction enhancement filler, preparation method and application in PBX (polymer bonded explosive)

InactiveCN107805179AHigh thermal conductivityEnhanced interactionNon-explosive fillers/gelling/thickening agentsNitrated aromatic explosive compositionsEnvironmental resistanceHigh volume manufacturing

The invention discloses a bionic vertex face heat conduction enhancement filler which is prepared from the following raw materials based on the total weight which is 100 percent: 60 to 85 percent of asheet-like heat conduction filler, 8 to 19 percent of bionic polydopamine and 5 to 25 percent of high-heat-conduction metal nano particles. The invention further provides a preparation method of thebionic vertex face heat conduction enhancement filler. The invention further discloses application of the bionic vertex face heat conduction enhancement filler in a PBX (polymer bonded explosive). Thebionic vertex face heat conduction enhancement filler can fulfill the aim of further enhancing the heat conduction performance of the filler, and is high in heat conduction performance. When the PBXis filled with the high-heat-conduction enhancement filler, the heat conduction performance of the PBX can be substantially improved at a low content, and thermal stress inside a PBX component in faceof a complicated environment is effectively reduced; the method is simple, efficient, green and environmentally friendly. The bionic vertex face heat conduction enhancement filler is suitable for large batch production, and has an important application prospect.

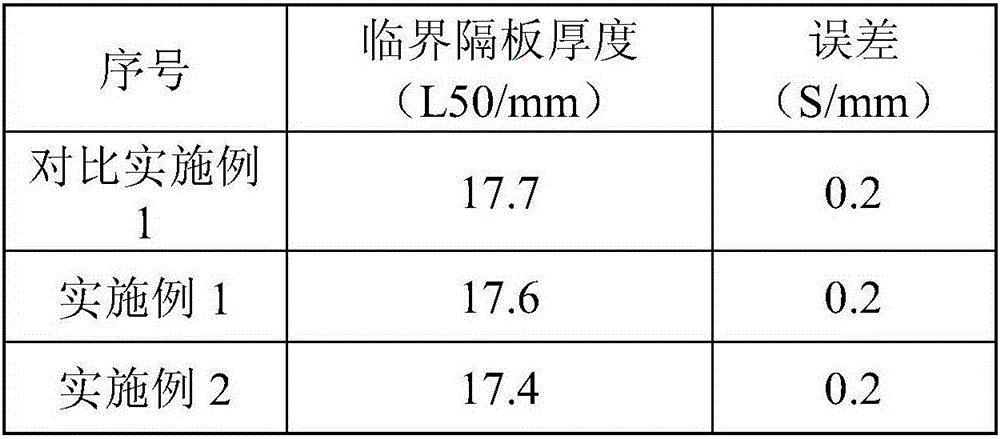

High mechanical property low impedance polymer bonded explosive and preparation method thereof

ActiveCN110304978ALower impedanceImprove mechanical propertiesNon-explosive fillers/gelling/thickening agentsExplosive working-up apparatusPolymer scienceHigh energy

The invention relates to a high mechanical property low impedance polymer bonded explosive and a preparation method thereof, and belongs to the technical field of composite energetic materials. The high mechanical property low impedance polymer bonded explosive is prepared from the components of polymer binder polyuria, an energetic material and an explosive performance modifier in a certain proportion. According to the high mechanical property low impedance polymer bonded explosive, a novel binder two-component slow reaction polyuria is introduced, high explosive and the like are effectivelyrecombined, the mechanical property of the energetic compound is obviously improved, and meanwhile the problems of low adhesive force and high acoustic impedance of the high energy composite explosiveare solved. According to the high mechanical property low impedance polymer bonded explosive, the bonding strength between the explosive components, and between the explosive and surrounding containing materials is improved, and important application value is achieved for improvement of the mechanical properties of the energy containing compound and the comprehensive performance of charging. In addition, the high mechanical property low impedance polymer bonded explosive is prepared at normal temperature, waste water, waste liquid or waste gas is not generated, and the advantages of safety, environmental protection, and simple technology are achieved.

Owner:ZHONGBEI UNIV

Method for detecting thermal stability of polymer-bonded explosive

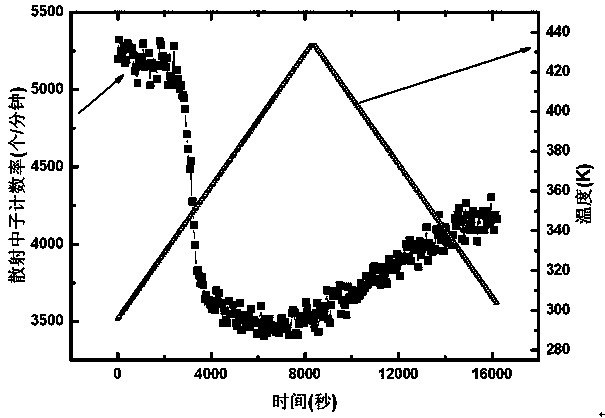

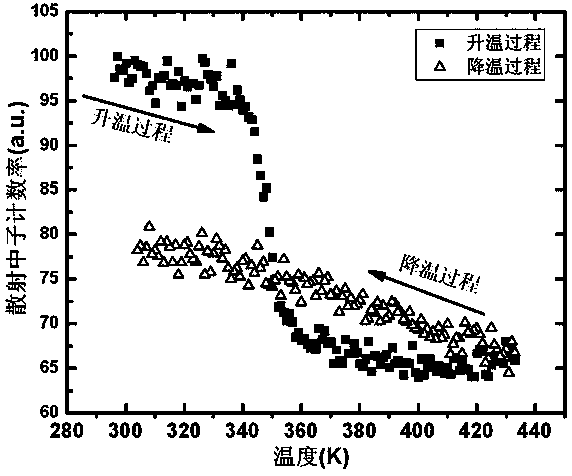

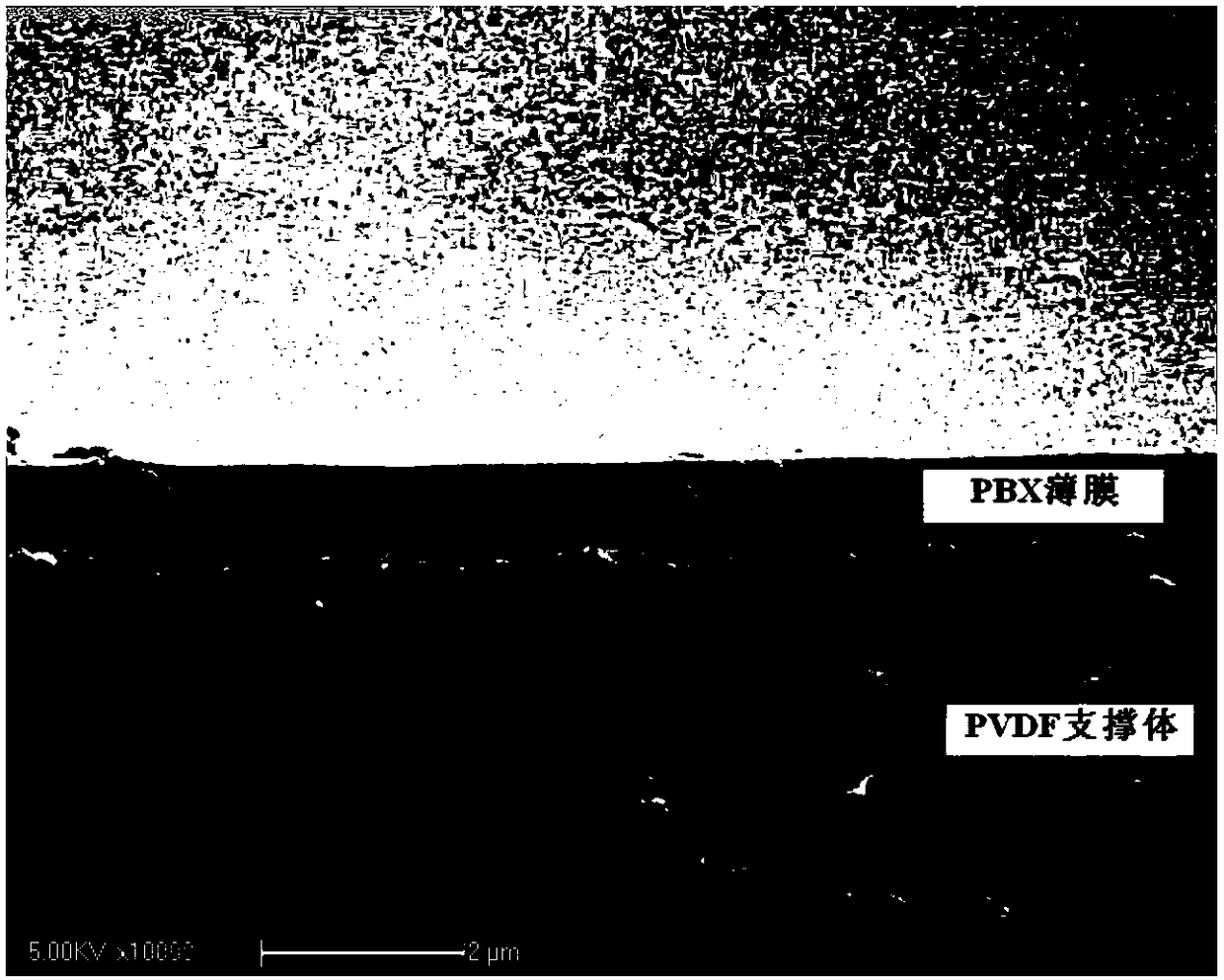

ActiveCN108414552AEasy to makeNo signal distortionMaterial analysis using wave/particle radiationPreparing sample for investigationMicro structureThermodynamics

The invention discloses a method for detecting the thermal stability of polymer-bonded explosive. The method is characterized in that the thermal stability of micro-structures of the polymer-bonded explosive can be detected. The method includes steps of preparing platy PBX (polymer-bonded explosive) samples from the formed PBX; carrying out in-situ variable-temperature neutron or X-photon small-angle scattering experiments in appropriate q ranges to acquire temperature-dependent variation curves of scattered neutron or X-photon counting rates; analyzing temperature-dependent relative and absolute variation of the scattered neutron or X-photon counting rates to judge the thermal stability characteristics of the micro-structures of the PBX. The method has the advantages that the influence offew relative integral micro-structures in the PBX on the thermal stability can be detected by the aid of the method, and the method is an effective method for detecting the thermal stability of micro-structures of complicated multi-component PBX materials; temperature-dependent variation, which is given by the aid of the method, of the scattered neutron or X-photon counting rates is an importantfoundation for intensive research on 'structure-function' relationships between the thermal stability and different types of macroscopic performance of the microscopic structures of the PBX.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

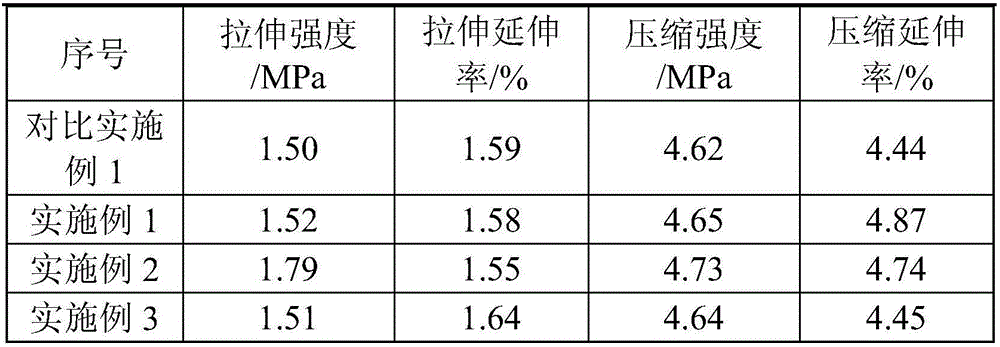

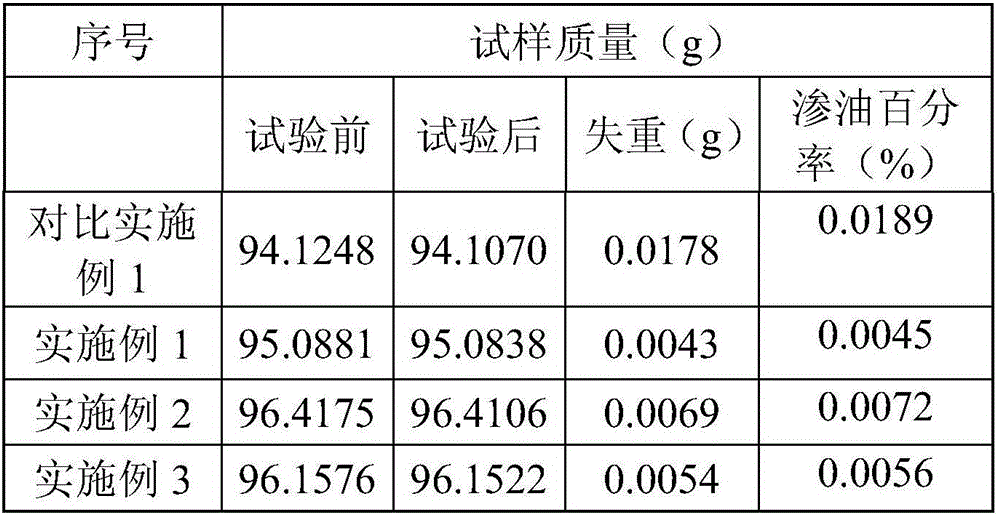

Oil penetration-preventing polymer-bonded explosive containing paraffin microcapsules and preparation method of explosive

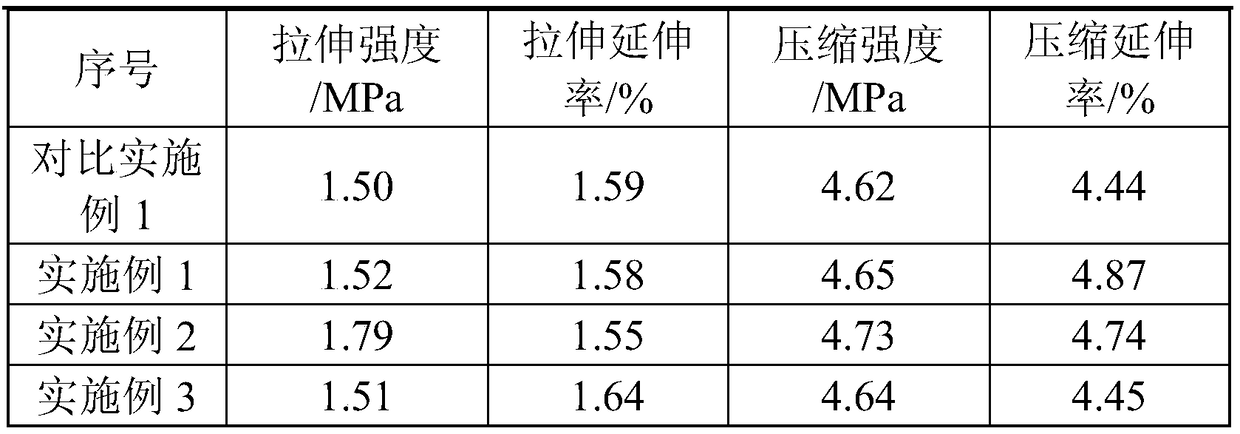

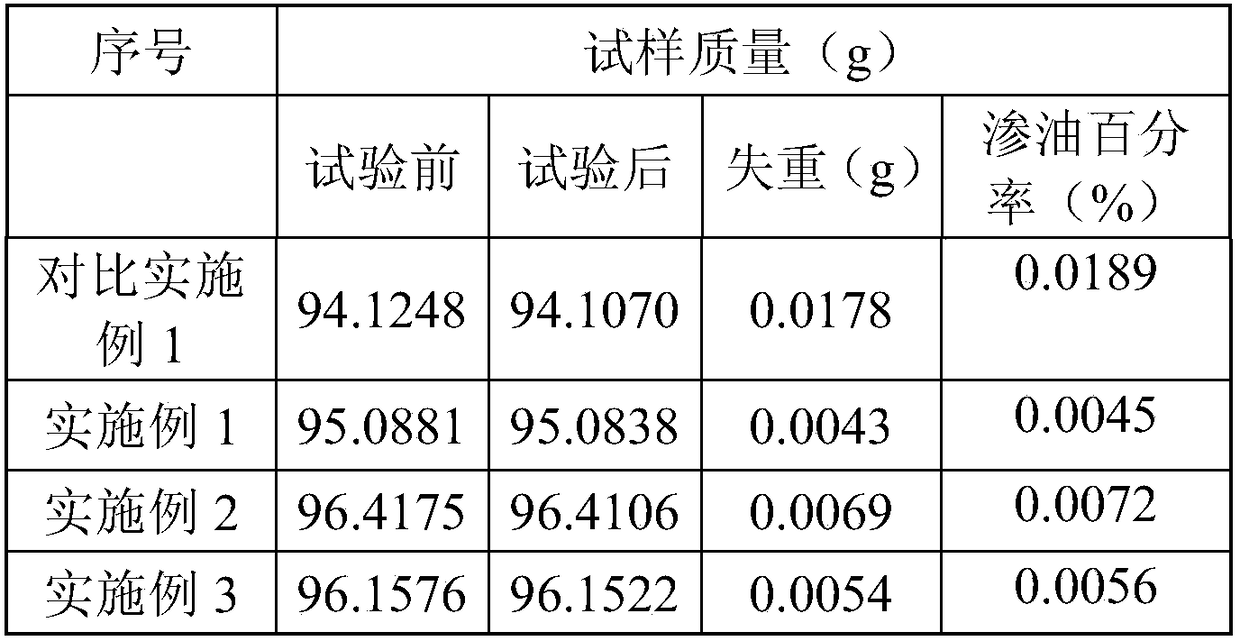

ActiveCN106365931APrevent seepageImprove mechanical propertiesNon-explosive desensitisers/phlegmatisersAmmonium perchlorate explosive compositionsShock waveParaffin wax

The invention discloses an oil penetration-preventing polymer-bonded explosive containing paraffin microcapsules and a preparation method of the explosive. The explosive is prepared from, by mass, 30-90 parts of an explosive, 0-45 parts of metal, 0-35 parts of ammonium perchlorate, 8-20 parts of a bonding agent, 0-5 parts of paraffin, 0.1-5 parts of the paraffin microcapsules and 0-1 part of a curing agent. The method comprises the following steps that batching is conducted; the materials are put in a kneader to be mixed; the mixed materials are poured into a mold, and the mold is put in an oven for curing the materials. According to the oil penetration-preventing PBX explosive containing the paraffin microcapsules, the oil penetration performance is reduced by 60%-70%, the mechanical properties such as the tensile and compressive strength, the strain rate and the elasticity modulus are all improved, and the shock wave sensitivity is reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

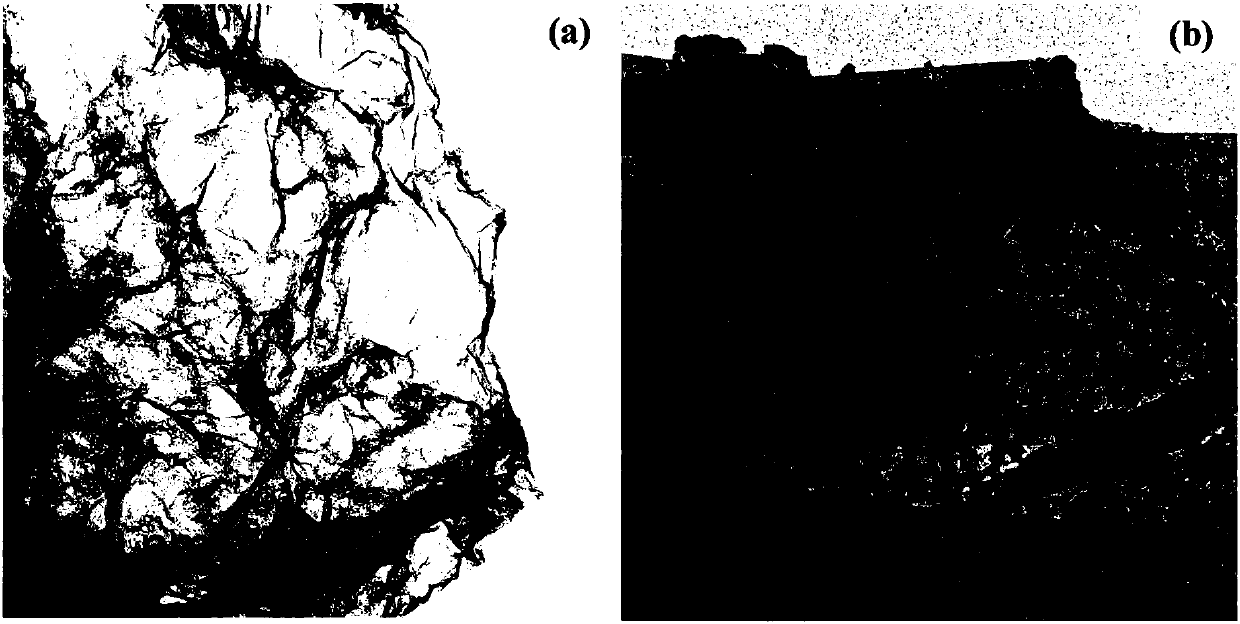

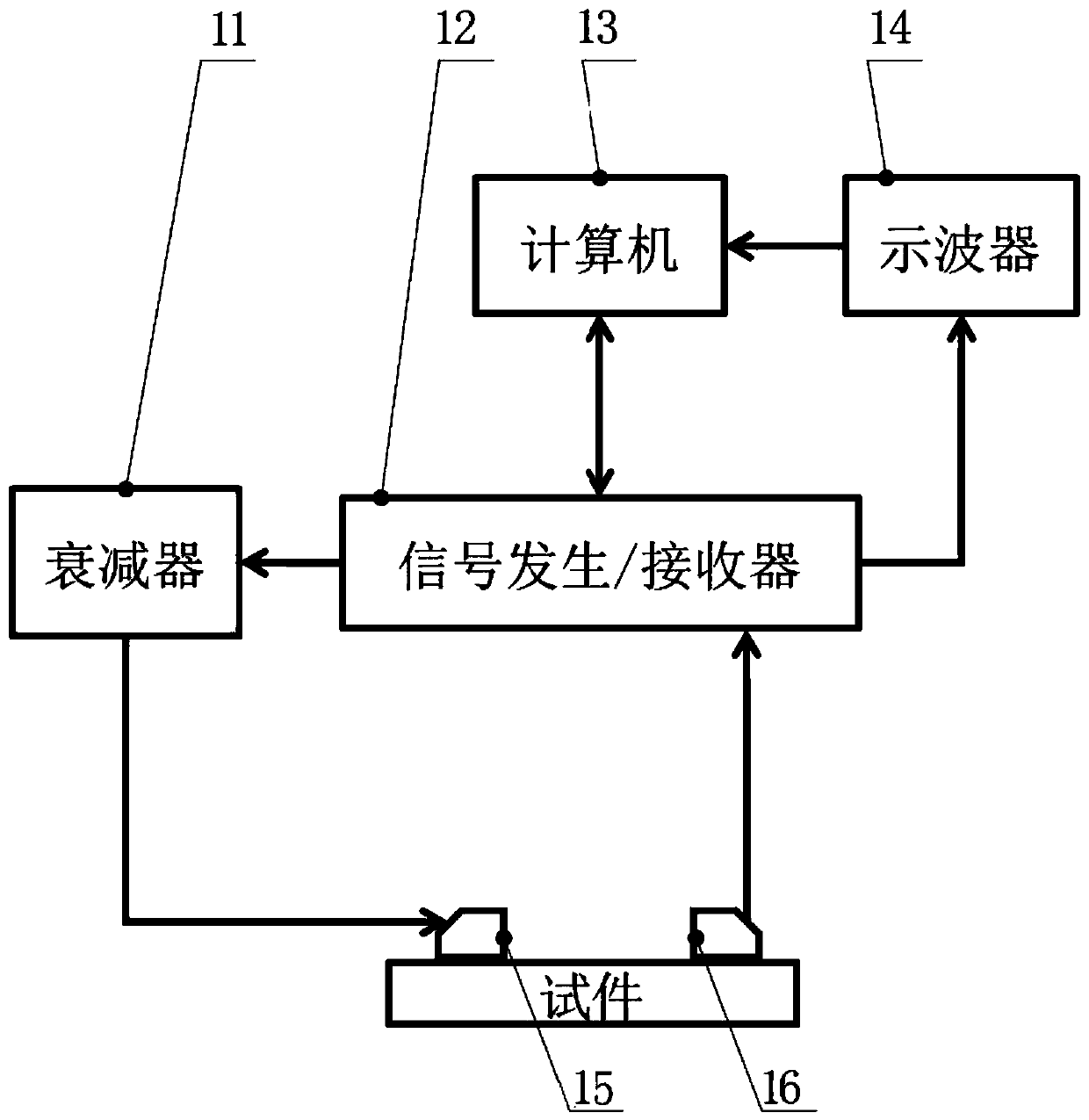

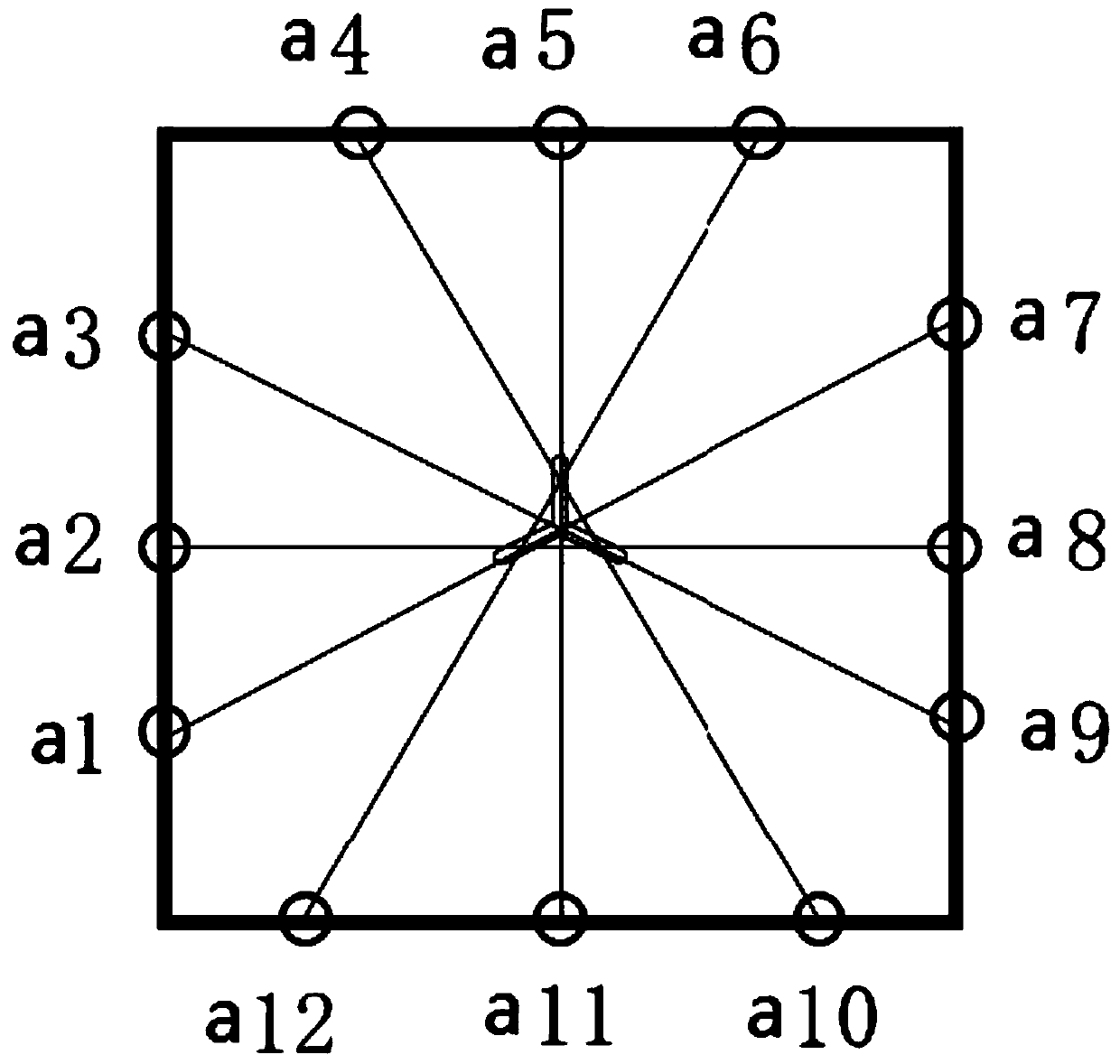

Ultrasonic imaging method for polymer bonded explosive surface crack detection and device

InactiveCN109781865AEffective imagingReflect sizeAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSensor arrayNon destructive

The invention discloses an ultrasonic imaging method for polymer bonded explosive surface crack detection and device. A transducer for detecting a surface crack of a detected material is used as a sensor, array sensors are arranged on non-destructive and destructive detection pieces respectively, ultrasonic waves of a certain frequency are excited, reference signals in a non-destructive case and destructive signals in a destructive case when passing through each path are collected, the SDC value and the spatial distribution function of each path are calculated by using the reference signals and the destructive signals, and according to the SDC value and the spatial distribution function of each path, the image of a destructive detection piece detection area is reconstructed. An improved correlation analysis-based probability destruction reconstruction algorithm is adopted, the sensor array mode is optimized for cracks with complex structures and shapes, and through collection and processing of time domain signals, non-destructive evaluation on the crack with a complex shape on the surface of the polymer bonded explosive can be effectively realized.

Owner:XIAMEN UNIV

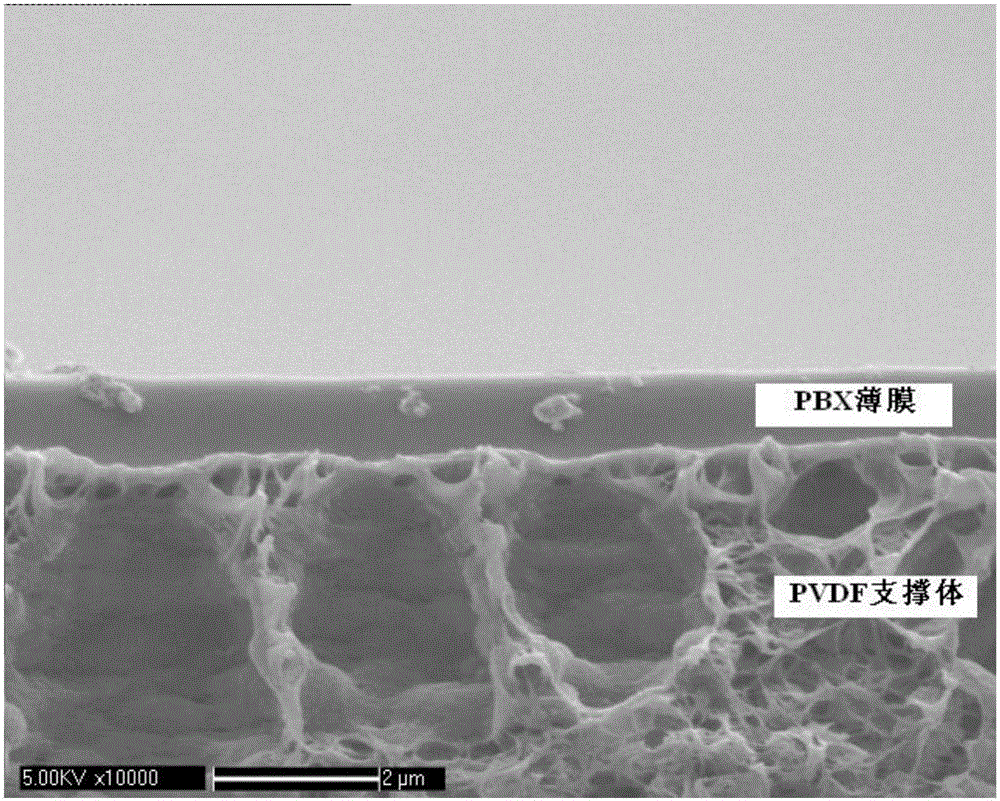

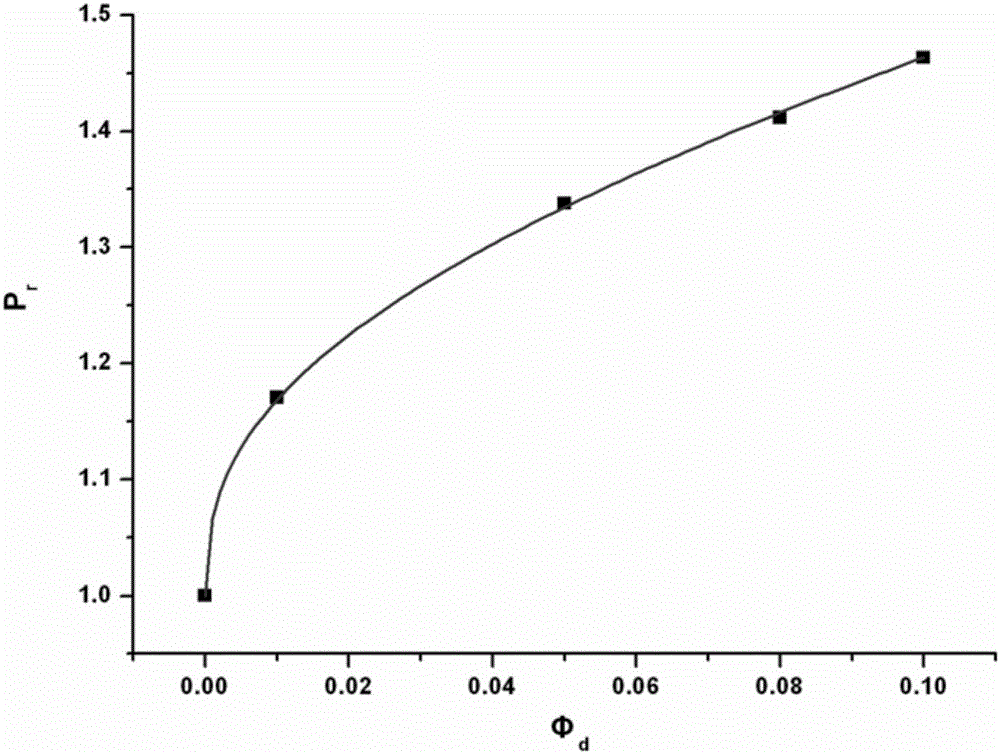

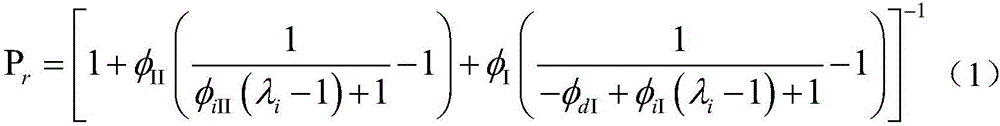

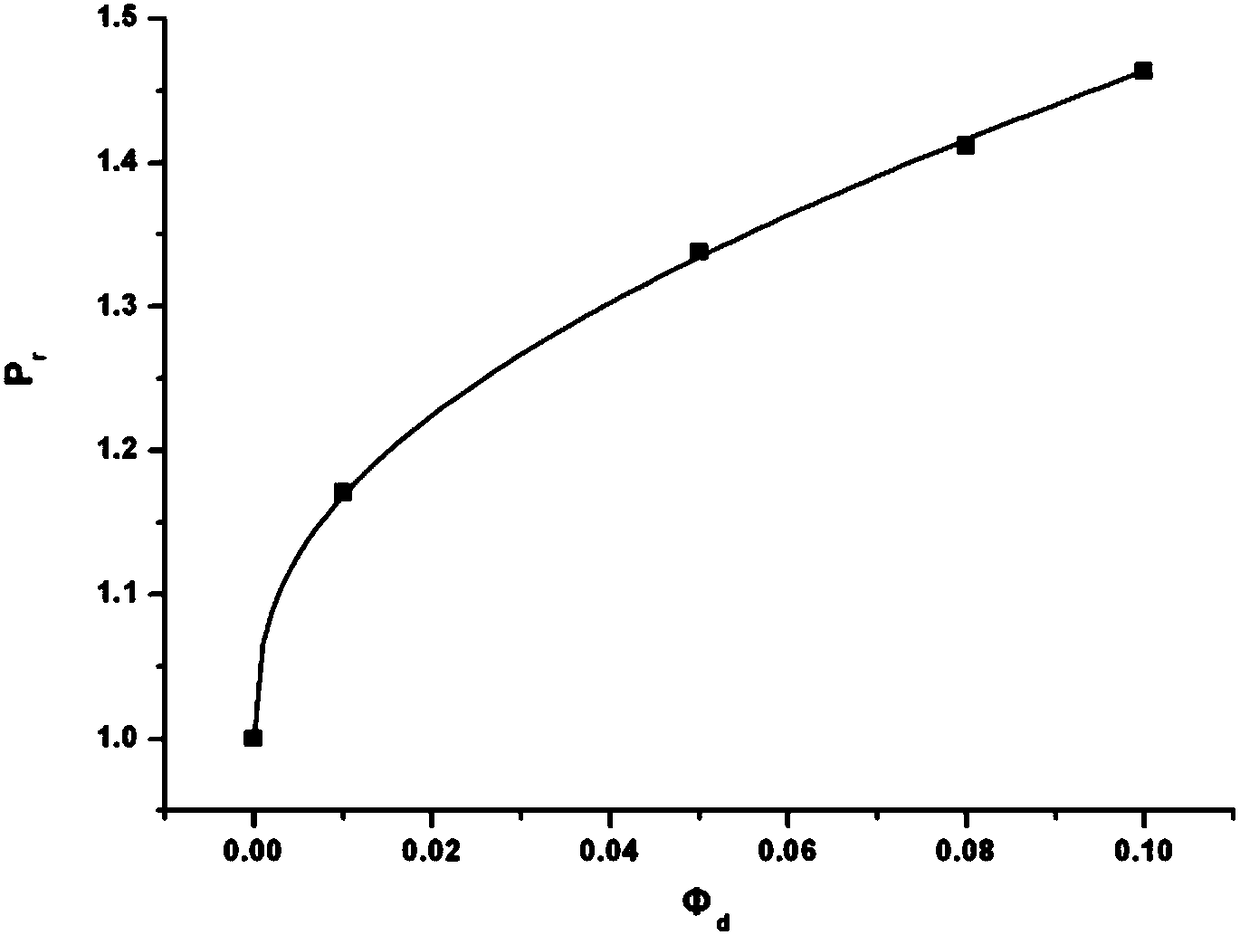

Method for characterizing interface structures in plastic bonded explosive on basis of gas permeation processes

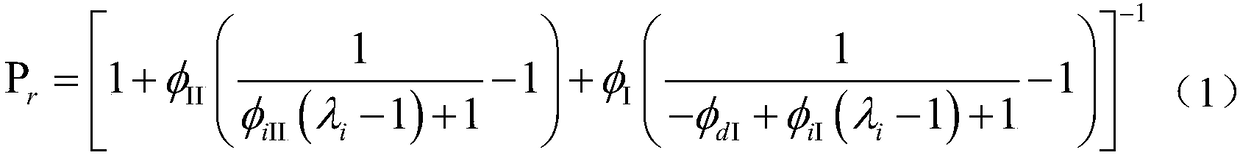

ActiveCN106248553ACharacterization techniques are simple and easy to implementPermeability/surface area analysisEngineeringEvolution rule

The invention discloses a method for characterizing interface structures in plastic bonded explosive on the basis of gas permeation processes. The method includes steps of A, testing gas permeability coefficients of bonders and gas permeability coefficients of at least one piece of PBX (polymer bonded explosive) with explosive contents unequal to zero by the aid of gas molecules under certain pressure and temperature conditions; B, fitting the gas permeability coefficients of the bonders and the gas permeability coefficients of the PBX by the aid of improved HIM (hierarchical hashing index models) and acquiring the thicknesses of interface cavities in the PBX by means of computing. The gas molecules are used as probes. The gas permeability coefficients of the bonders and the gas permeability coefficients of the PBX are obtained at the step A by means of testing. The method has the advantages that technologies for characterizing the interface structures in the PBX are simple and feasible, the interface structures in the PBX can be quantitatively characterized in nanometer scales, important effects can be realized for research on evolution rules of the interface structures in the PBX under temperature and stress loading conditions, and an effective way can be provided for investigating influence rules of different bonding agents on the interface structures in the PBX.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

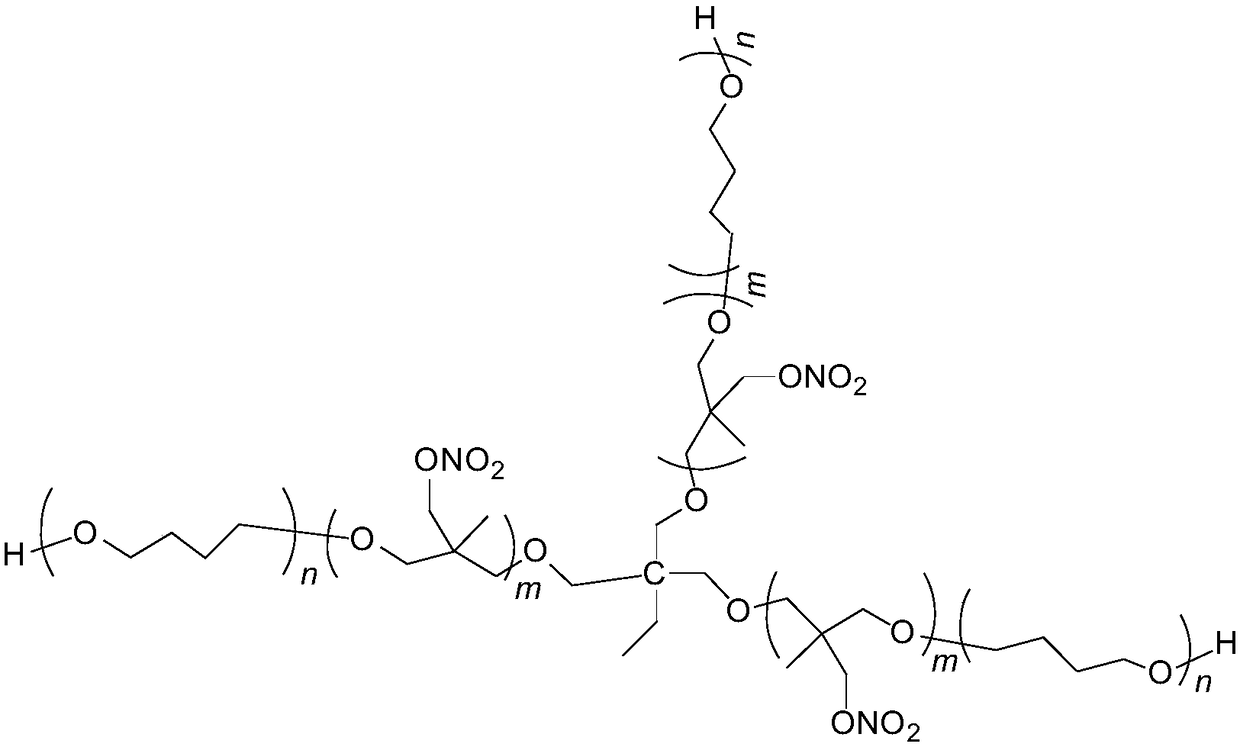

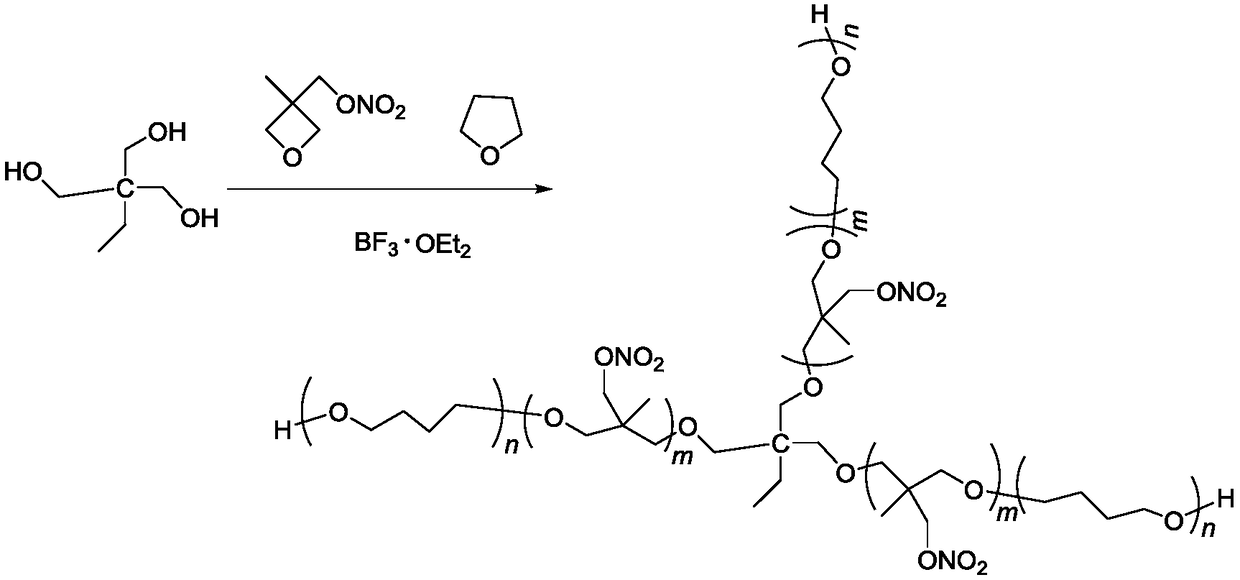

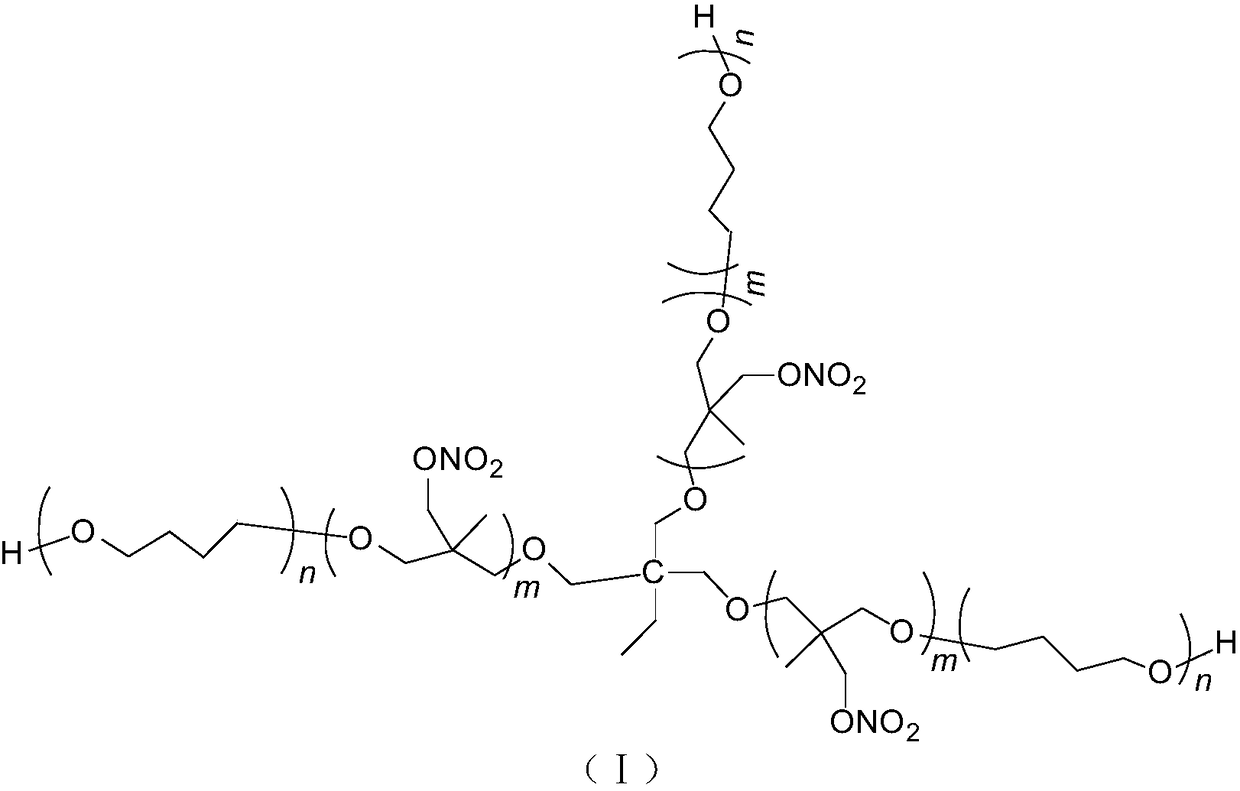

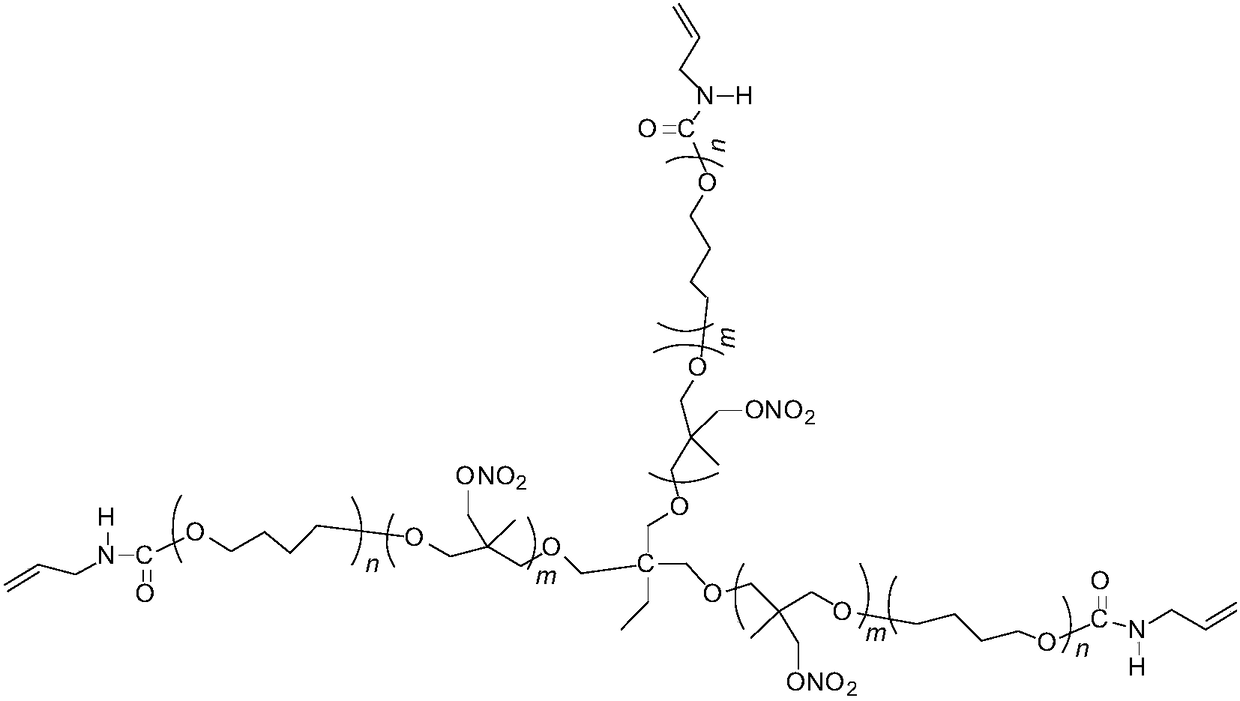

Tri-functionality NIMMO-THF (3-nitatomcthyl-3-methyl oxetane-tetrahydrofuran) copolymer ether energetic binder and synthetic method thereof

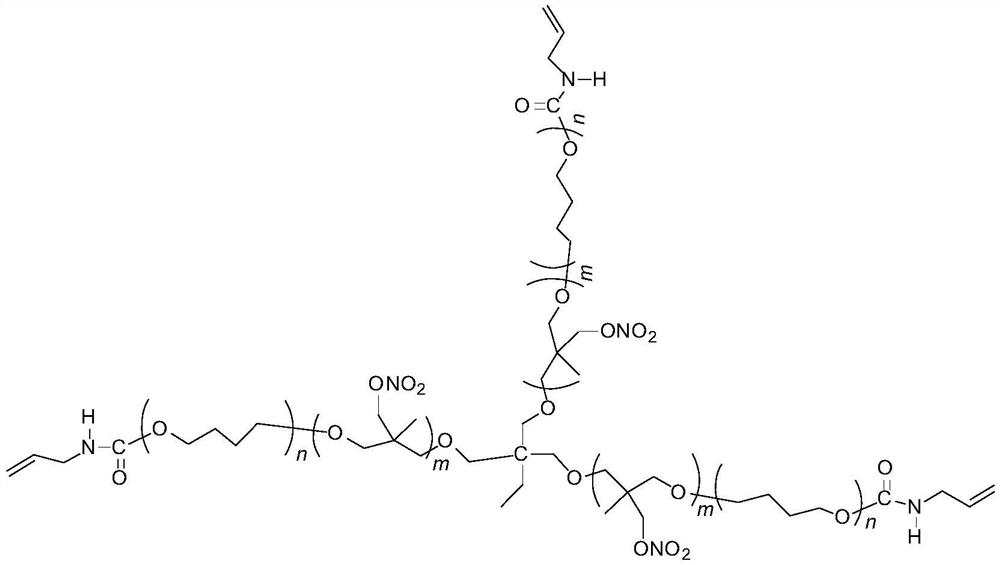

The invention discloses a tri-functionality NIMMO-THF (3-nitatomcthyl-3-methyl oxetane-tetrahydrofuran) copolymer ether energetic binder and a synthetic method thereof. The structural formula of the tri-functionality NIMMO-THF (3-nitatomcthyl-3-methyl oxetane-tetrahydrofuran) copolymer ether energetic binder is as shown in figure (I) in the specification. The synthetic method comprises the following steps that trimethylolpropane (TMP) serves as an initiator, 3-nitatomcthyl-3-methyl oxetane (NIMMO) and tetrahydrofuran (THF) serves as a monomer, and cationic ring opening polymerization reactionis carried out so as to obtain the tri-functionality NIMMO-THF (3-nitatomcthyl-3-methyl oxetane-tetrahydrofuran) copolymer ether energetic binder. The binder can be directly cured by adopting dual-functionality isocyanate, and a cross-linking agent does not need to be added. The binder is mainly used for a composite solid propellant and a polymer-bonded explosive. The structural formula of the tri-functionality NIMMO-THF (3-nitatomcthyl-3-methyl oxetane-tetrahydrofuran) copolymer ether energetic binder is as shown in figure (I) in the specification, wherein m is equal to 5-20, n is equal to 5-20 and is an integer.

Owner:XIAN MODERN CHEM RES INST

Method for determination of PCTFE content in PBX explosive by near infrared spectrum

ActiveCN103018195BImprove robustnessImprove accuracyMaterial analysis by optical meansPolymer-bonded explosiveRoot mean square

Owner:XIAN MODERN CHEM RES INST

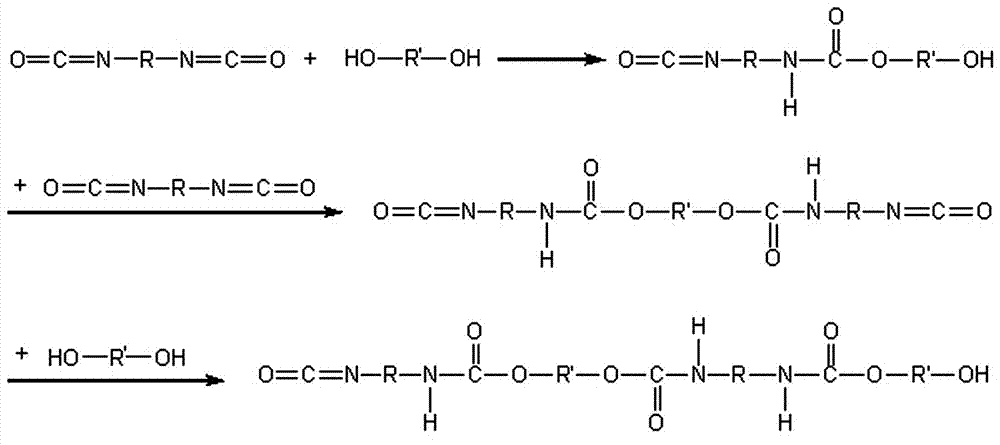

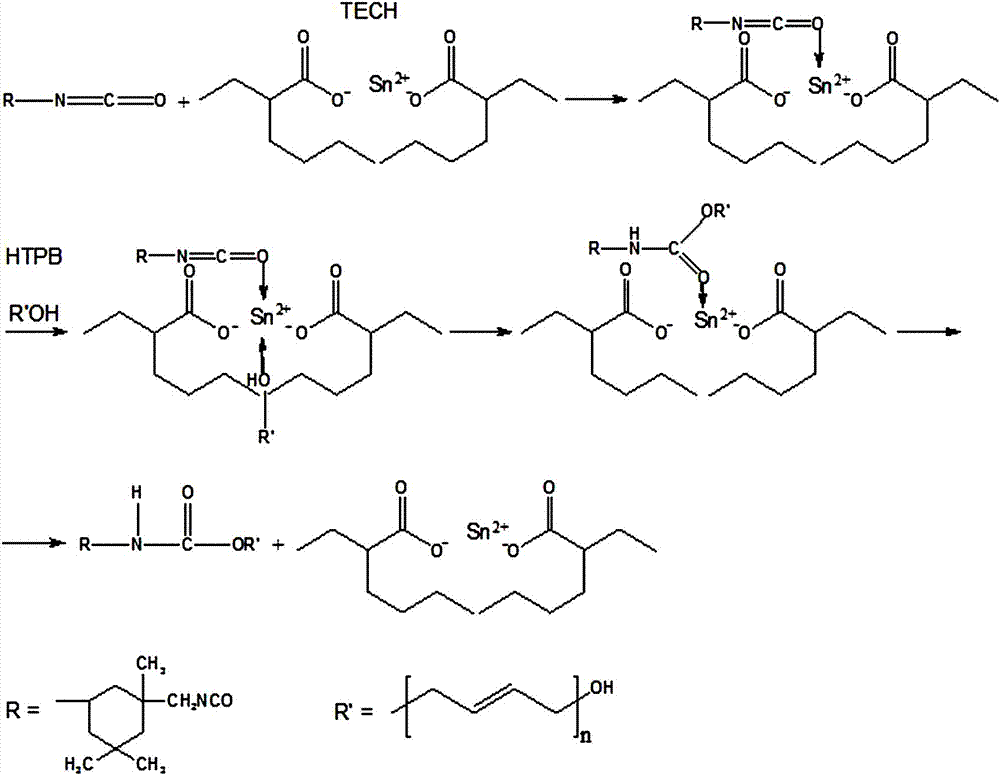

Room temperature curing polyurethane bonding agent system for PBX (polymer bonded explosive) casting explosives

ActiveCN106866930AImprove machinabilityViscosity growth is slowExplosivesSolid componentPolymer-bonded explosive

The invention belongs to the technical field of casting explosives and solid propellants. In order to overcome the problems of the existing HTPB (hydroxyl-terminated polybutadiene) type PBX ((polymer bonded explosive)) casting explosive, including high curing forming temperature, long room temperature curing time, easy sedimentation of solid ingredients and the like, the invention provides a room temperature curing polyurethane bonding agent system for PBX casting explosives. The room temperature curing polyurethane bonding agent system for the PBX casting explosives is prepared from polyalcohol, plasticizing agents, polyisocyanates and curing catalysts according to a certain proportion. Good processing performance is realized; the viscosity is low in an early curing period; the viscosity increase is slow; bubbles can be favorably removed in a construction process; the system is suitable for charging process construction processes of PBX casting explosives in different dimensions; the system viscosity increase is obviously accelerated in a later curing period; the solid phase sedimentation problem of the PBX casting explosives in a curing and forming process can be inhibited to a certain degree; on the basis of meeting each construction index, the temperature requirements in the curing process are obviously reduced; the curing and forming under room temperature conditions can be achieved; the effects in aspects of improving the safety in the PBX casting explosive production process, the casting explosive column quality and the energy saving effect are obvious.

Owner:ZHONGBEI UNIV

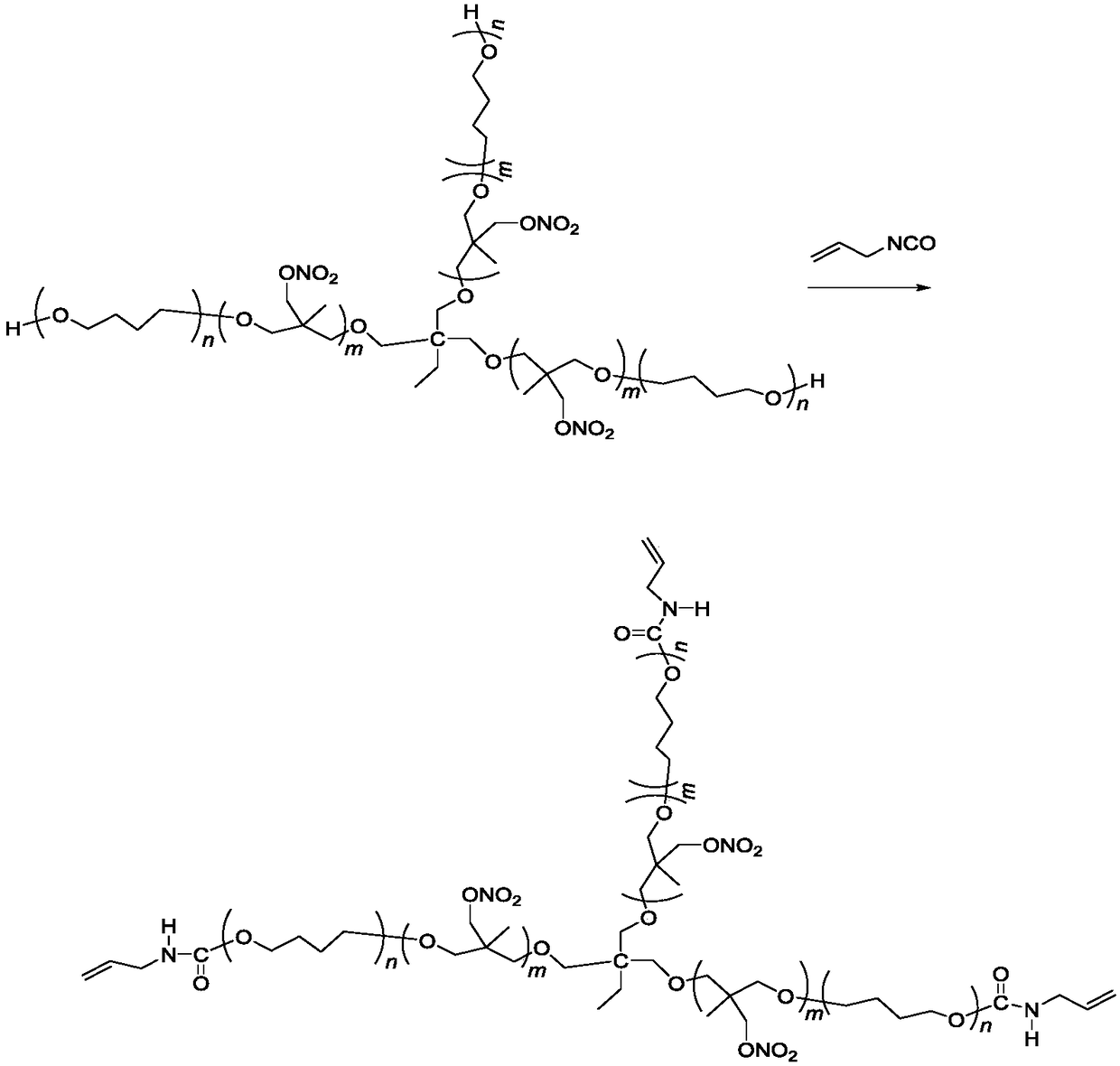

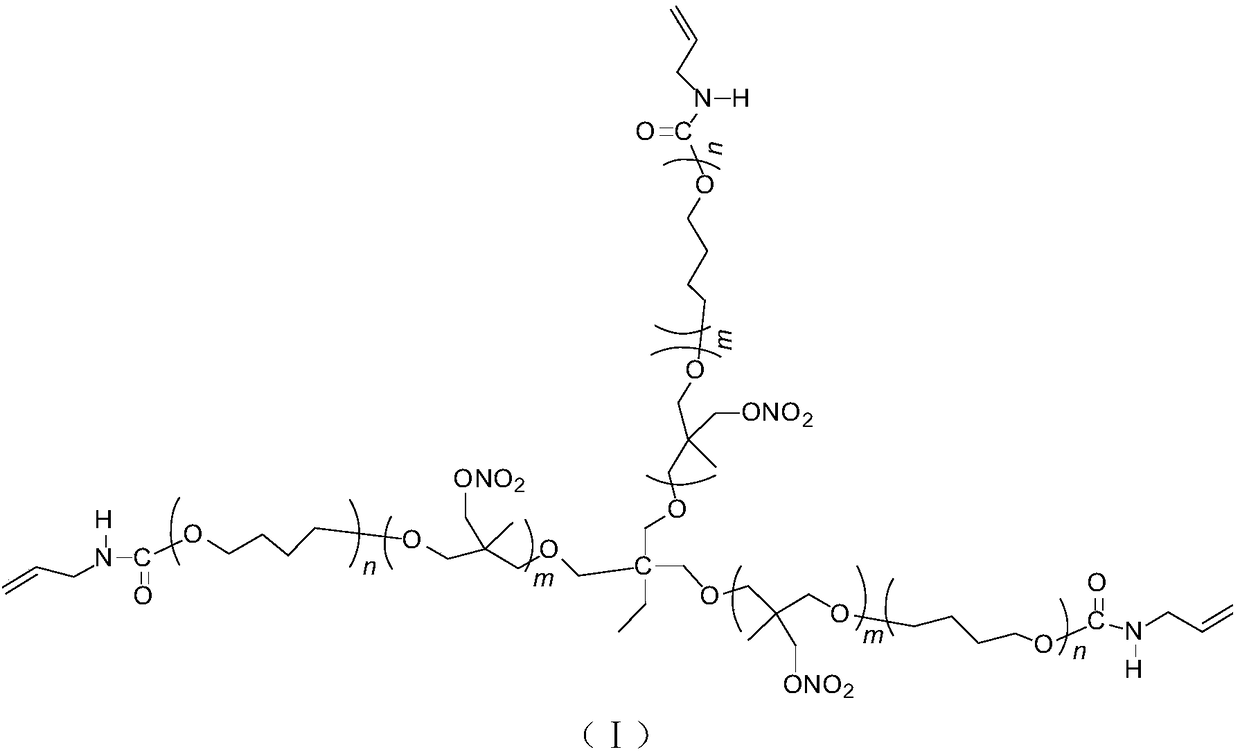

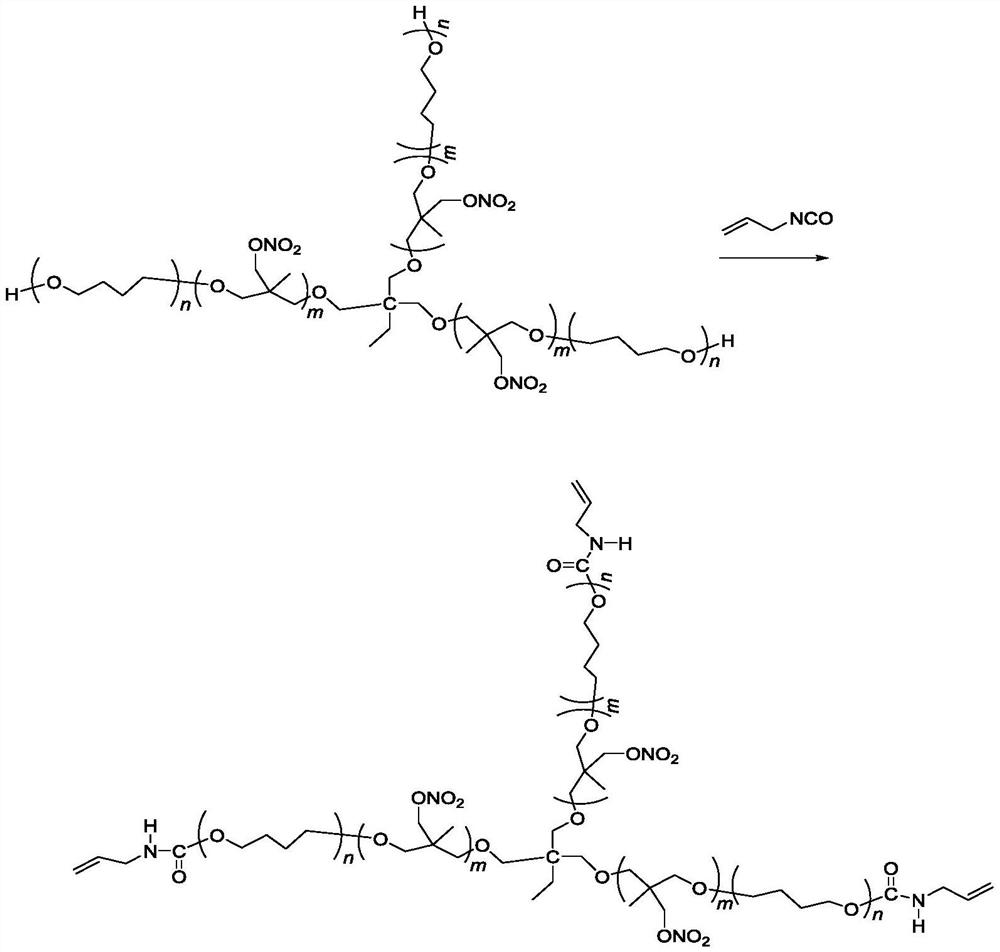

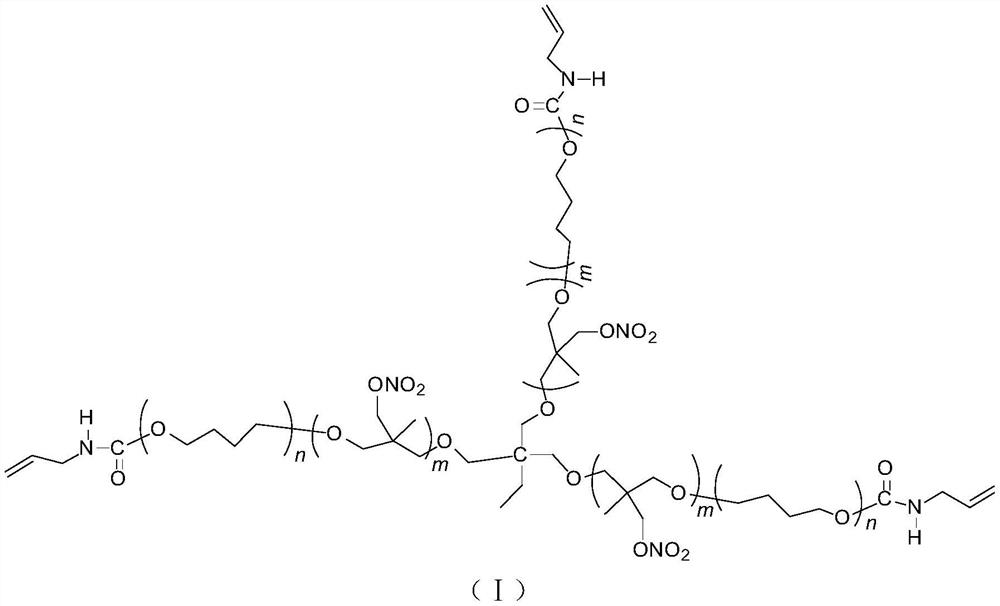

Trifunctional end-alkenyl copolyether energetic binder and synthesis method thereof

The invention discloses a trifunctional end-alkenyl copolyether energetic binder and a synthesis method thereof. A structural formula of the trifunctional end-alkenyl copolyether energetic binder is shown as Figure (I), and a synthesis process thereof comprises the following steps: using trifunctional NIMMO-THF copolyether as a raw material, adding allyl isocyanate, and carrying out addition reaction to obtain the trifunctional end-alkenyl copolyether energetic binder. The synthesis method facilitates large-scale preparation, and double bonds endow the binder with the capability of curing at room temperature. The trifunctional end-alkenyl copolyether energetic binder and the synthesis method thereof disclosed by the invention are mainly used for composite solid propellants and polymer bonded explosives, (formula shown in the specification), where m=5-20, n=5-20, and m and n are integers.

Owner:XIAN MODERN CHEM RES INST

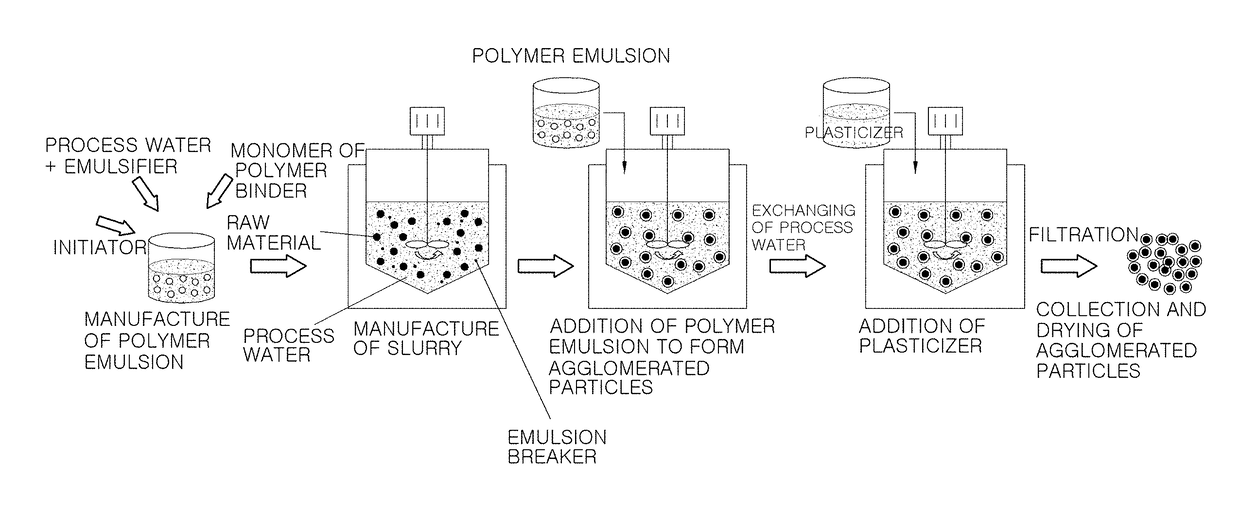

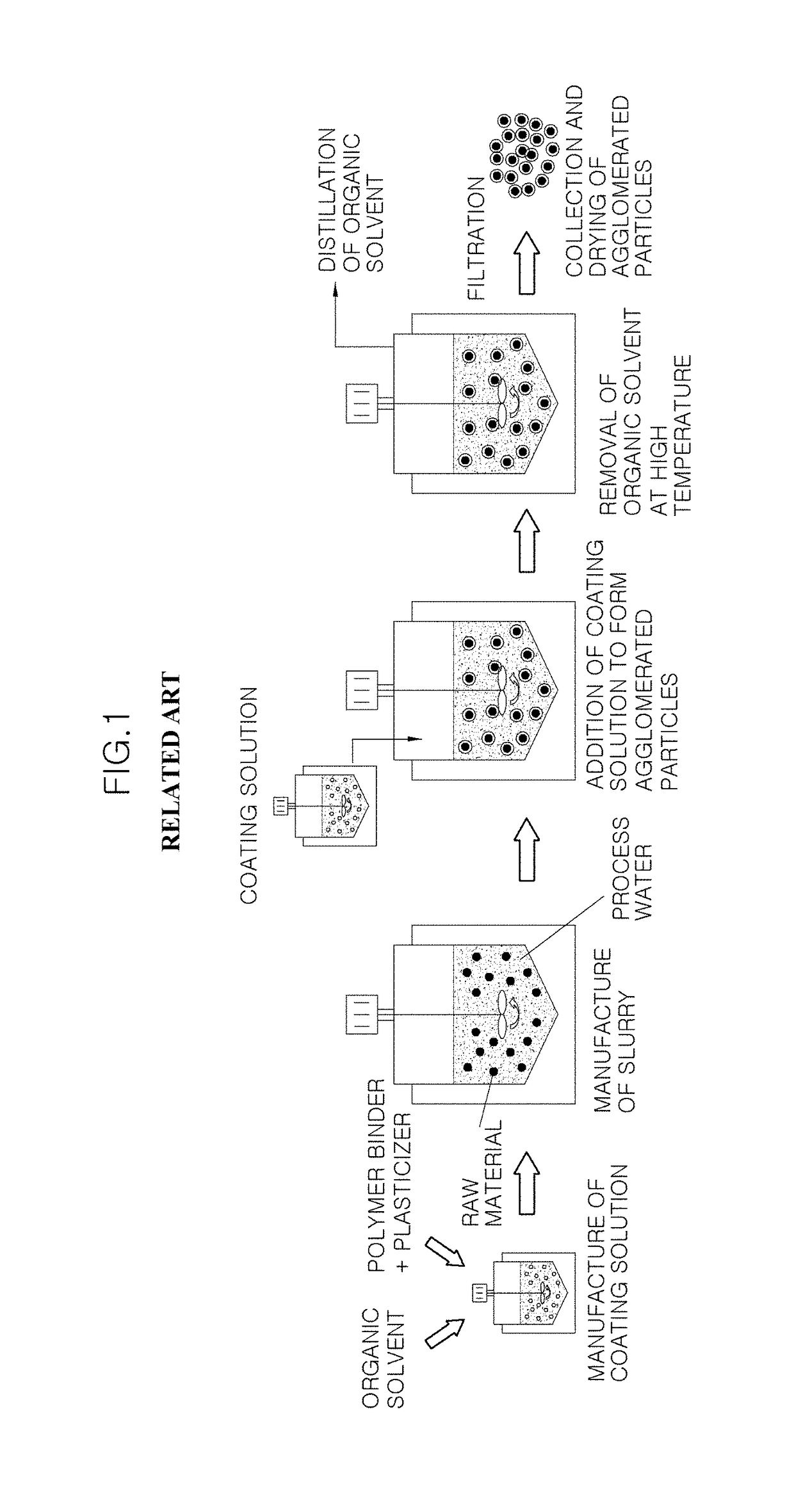

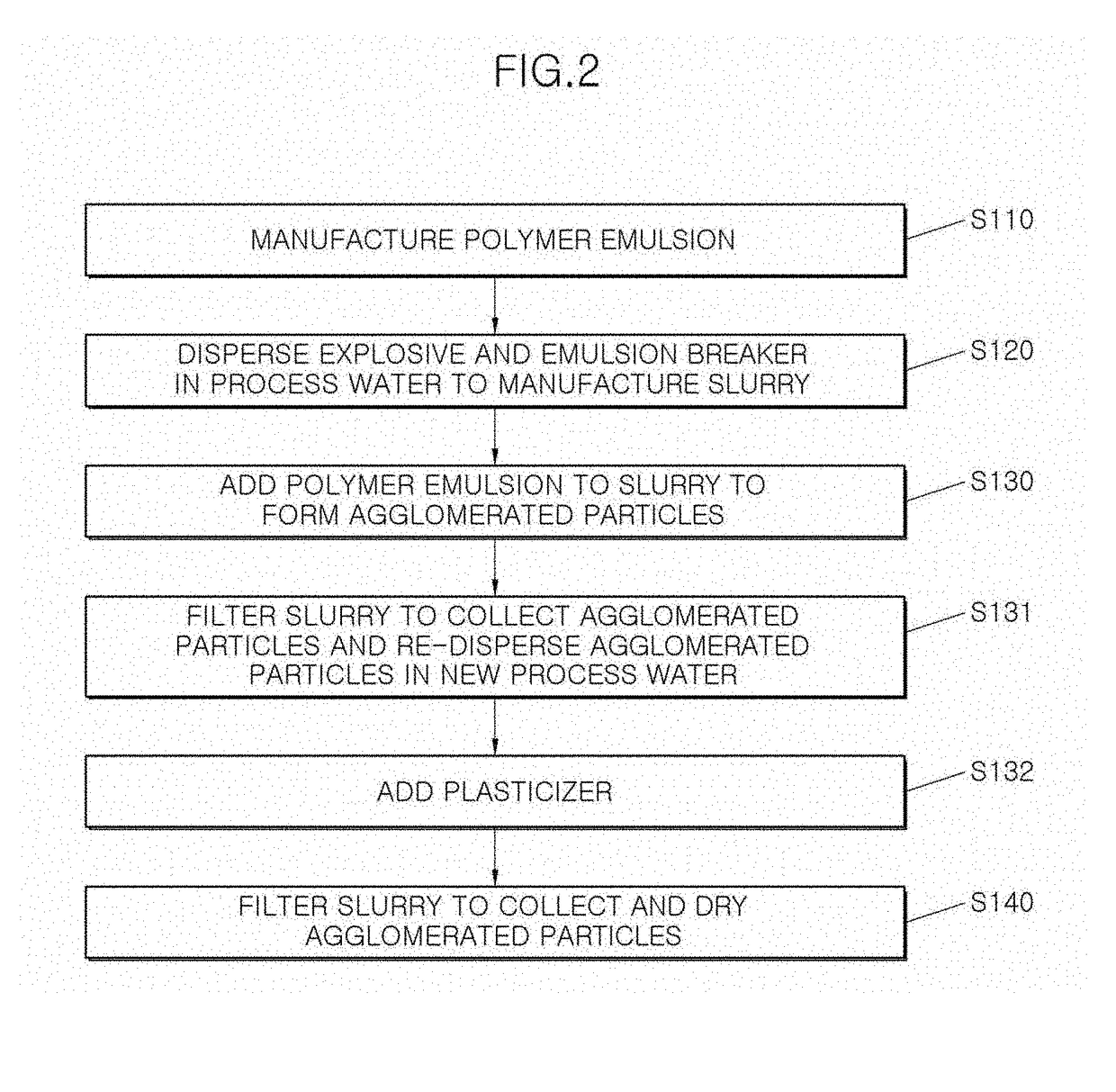

Method of manufacturing press polymer-bonded explosive using polymer emulsion and press polymer-bonded explosive manufactured using the same

InactiveUS20180297909A1Low costMaximize processing efficiencyNon-explosive desensitisers/phlegmatisersExplosive working-up apparatusPolymer scienceEmulsion

A method of manufacturing a press polymer-bonded explosive, in which a polymer emulsion is used to maximize the efficiency of a process, and a press polymer-bonded explosive manufactured using the same. The method includes a polymer-emulsion-manufacturing step of mixing a monomer of a polymer binder and an emulsifier with a process water and then adding an initiator to thus manufacture a polymer emulsion using a polymerization reaction, a slurry-manufacturing step of mixing a raw material including an explosive and an emulsion breaker with fresh process water to thus manufacture a slurry, an agglomerated-particle-forming step of adding the manufactured polymer emulsion to the manufactured slurry to thus form agglomerated particles in which a surface of the raw material is coated with the polymer binder, and an agglomerated-particle-obtaining step of collecting the agglomerated particles using filtration and drying the collected agglomerated particles.

Owner:AGENCY FOR DEFENSE DEV

Characterization of Interface Structure in Plastic Bonded Explosives Based on Gas Permeation Method

ActiveCN106248553BCharacterization techniques are simple and easy to implementPermeability/surface area analysisEngineeringEvolution rule

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Paraffin microcapsule anti-seepage oil polymer bonded explosive and preparation method thereof

InactiveCN106365931BReduced oil leakage performanceHigh tensile strengthNon-explosive desensitisers/phlegmatisersAmmonium perchlorate explosive compositionsShock waveParaffin wax

The invention discloses an oil penetration-preventing polymer-bonded explosive containing paraffin microcapsules and a preparation method of the explosive. The explosive is prepared from, by mass, 30-90 parts of an explosive, 0-45 parts of metal, 0-35 parts of ammonium perchlorate, 8-20 parts of a bonding agent, 0-5 parts of paraffin, 0.1-5 parts of the paraffin microcapsules and 0-1 part of a curing agent. The method comprises the following steps that batching is conducted; the materials are put in a kneader to be mixed; the mixed materials are poured into a mold, and the mold is put in an oven for curing the materials. According to the oil penetration-preventing PBX explosive containing the paraffin microcapsules, the oil penetration performance is reduced by 60%-70%, the mechanical properties such as the tensile and compressive strength, the strain rate and the elasticity modulus are all improved, and the shock wave sensitivity is reduced.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

A high-energy insensitive pressure-packed polymer bonded explosive

ActiveCN107879867BHigh energyImprove securityNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsFriction sensitivityExplosive Agents

The invention relates to a high energy insensitive press-fitting high polymer bonded explosive which is prepared from the following components in percentages by weight: 45-75% of main body explosive,5-20% of auxiliary explosive, 15-30% of metal fuel, 1-5% of an adhesive and 1-3% of an insensitive agent, wherein the main body explosive is TKX-50. In order to solve the existing problem that press-fitting PBX is not compatible in power properties and low vulnerability, a high energy insensitive explosive system is introduced. By adding the high energy insensitive main body explosive, the PBX formula has good power properties and low vulnerability. The detonation velocity of the explosive formula is greater than 7500m / s, the explosion heat is greater than 7500J / g, the power is greater than 1.85TNT (2,4,6-trinitrotoluene), and meanwhile, the friction sensitivity of the explosive formula is smaller than 20%, the impact sense is 0, and the explosive can pass examinations of low vulnerabilitytest items such as quick cook-off, slow cook-off and bullet impact.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

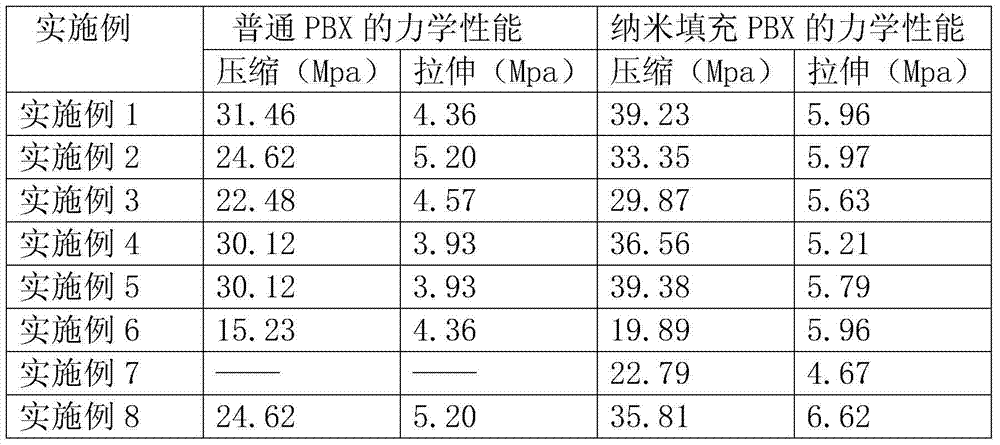

High polymer bonded explosive with nanoparticle enhanced mechanical properties and preparation method thereof

ActiveCN104649850BImprove mechanical propertiesIncrease energy densityNitrated aromatic explosive compositionsNitroparaffin explosive compositionsPolymer sciencePolymer adhesive

The invention discloses a high polymer bonded explosive whose mechanical properties are enhanced by nanoparticles and a preparation method thereof. The high polymer bonded explosive whose mechanical properties are enhanced by nanoparticles contains a mass fraction of The nano-explosive particle is 50-600nm. The preparation method is to mix the ordinary-sized explosive and the nano-explosive particle in water in proportion, and then slowly add the binder solution, and the explosive particle is gradually compounded under the action of the binder as the solvent volatilizes. Granular, washed and dried explosive products are then pressed. The invention adopts the nano-explosive particles to replace the ordinary granular explosive in the high polymer bonded explosive, without changing the composition and content of the PBX formula, and can significantly enhance the mechanical properties of the high polymer bonded explosive. It can effectively avoid the use of a large number of multi-component binder systems in order to improve the mechanical properties, ensure the high energy density of the high polymer bonded explosive, and at the same time make the high polymer bonded explosive have a single component, the preparation method is simple, and the cost is low.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Polymer bonded explosive for ultra-high temperature petroleum perforating bullet and preparation method thereof

ActiveCN104447144BImprove heat resistanceMeet development and applicationNitrated aromatic explosive compositionsHexanitrostilbeneDetonation

Owner:SHANXI BEIHUA GUANLYU CHEM IND

High-viscosity pbx explosive injection molding method and device

ActiveCN103936533BImprove filling qualitySolve the problem of poor rheology in high viscosity PBX processExplosive working-up apparatusCompression moldingEngineering

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

A kind of trifunctional end alkenyl copolyether energetic adhesive and its synthesis method

The invention discloses a trifunctional end-alkenyl copolyether energetic binder and a synthesis method thereof. A structural formula of the trifunctional end-alkenyl copolyether energetic binder is shown as Figure (I), and a synthesis process thereof comprises the following steps: using trifunctional NIMMO-THF copolyether as a raw material, adding allyl isocyanate, and carrying out addition reaction to obtain the trifunctional end-alkenyl copolyether energetic binder. The synthesis method facilitates large-scale preparation, and double bonds endow the binder with the capability of curing at room temperature. The trifunctional end-alkenyl copolyether energetic binder and the synthesis method thereof disclosed by the invention are mainly used for composite solid propellants and polymer bonded explosives, (formula shown in the specification), where m=5-20, n=5-20, and m and n are integers.

Owner:XIAN MODERN CHEM RES INST

High mechanical property low impedance polymer bonded explosive and preparation method thereof

ActiveCN110304978BLower impedanceImprove mechanical propertiesNon-explosive fillers/gelling/thickening agentsExplosive working-up apparatusExplosive AgentsPolymer-bonded explosive

The invention relates to a high-mechanical performance low-resistance high-polymer bonded explosive and a preparation method thereof, belonging to the technical field of composite energetic materials. The explosive of the present invention is prepared from a certain ratio of polymer bonding material polyurea, energetic material and explosive performance improving agent. The explosive of the present invention introduces a new type of binder, two-component slow-response polyurea, to effectively compound high-energy explosives, thereby significantly improving the mechanical properties of the energetic compound, and at the same time solving the problem of low adhesion of the existing high-energy composite explosives. High acoustic impedance problem. The high-polymer bonded explosive with high mechanical properties of the present invention improves the bonding strength between the explosive components and between the explosive and the surrounding materials, and plays an important role in improving the mechanical properties of the energetic compound and the improvement of the comprehensive performance of the charge. Value. In addition, the explosive of the present invention is prepared at normal temperature without generating waste water, waste liquid and waste gas, and has the advantages of safety and environmental protection, simple process and the like.

Owner:ZHONGBEI UNIV

Low-cost high-safety polymer-bonded explosive (PBX) and preparation method thereof

InactiveCN110343026AImprove securityImprove mechanical propertiesExplosive working-up apparatusHigh energyUltimate tensile strength

The invention discloses a low-cost high-safety polymer-bonded explosive (PBX), and relates to the technical field of energetic materials. The PBX comprises the following raw materials in parts by weight: 40 parts of a main explosive, 6-10 parts of an insensitive explosive, 46.5-50.5 parts of high-energy metal, 2.5 parts of a binder, 0.5 part of a first insensitive agent and 0.5 part of a second insensitive agent. The high-safety PBX based on DNAN has good safety performance and mechanical strength, and meanwhile the sensitivity to initiation is low.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com