Production method for compression molding of PBX (Polymer Bonded Explosive)

A technology of compression molding and production method, which is applied in the production field of PBX explosive compression molding, can solve the problems of uneven distribution and low density, and achieve the effects of increasing energy effect, increasing density and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

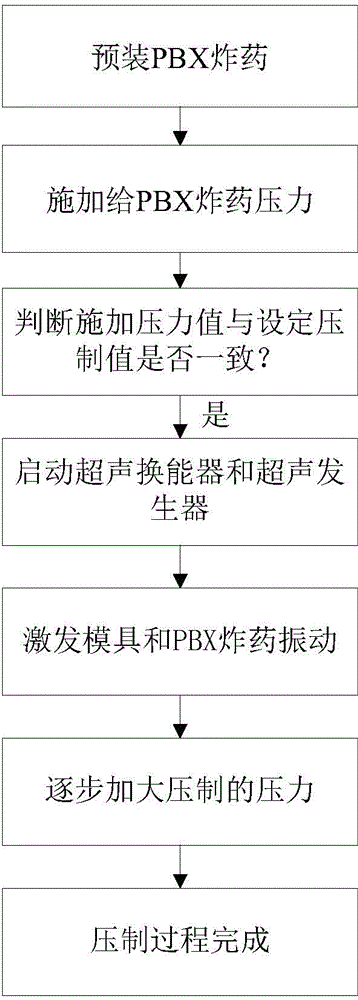

Method used

Image

Examples

Embodiment 1

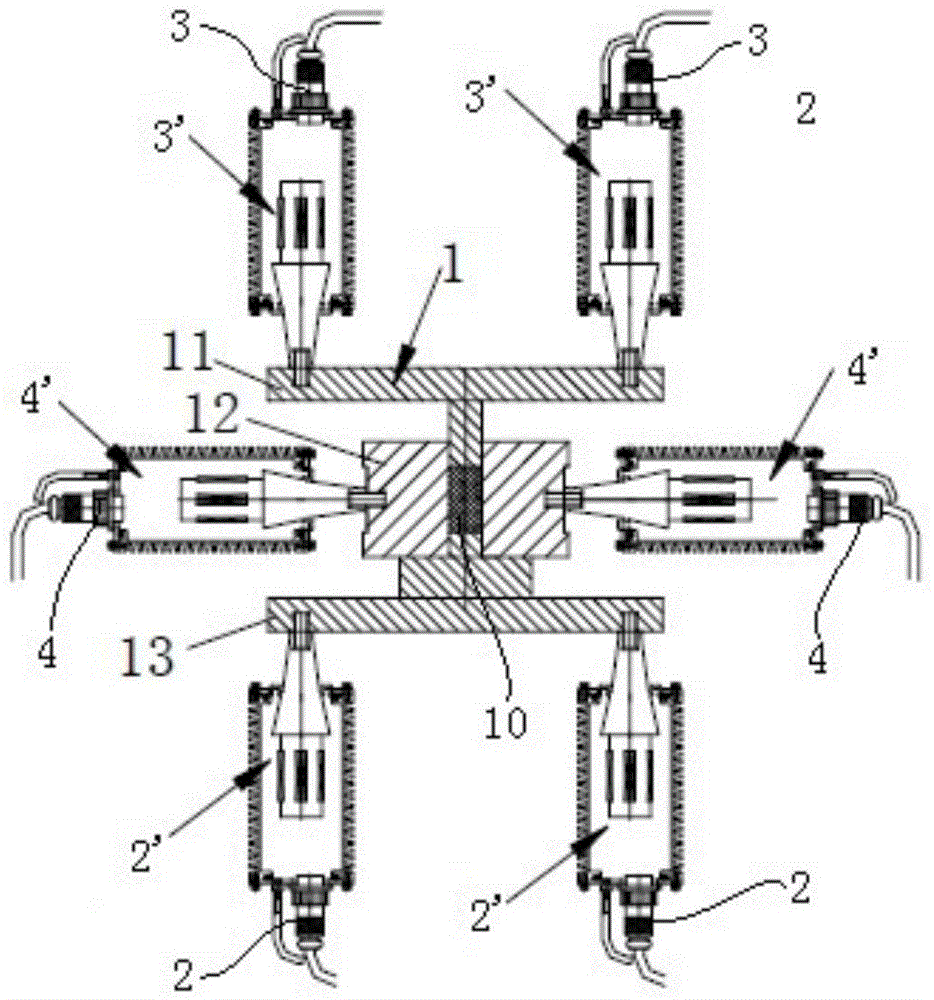

[0032] refer to figure 2 As shown, the PBX explosive molding device includes a mold 1, a pressurizing device, an ultrasonic transducer, an ultrasonic generator, and a controller, wherein the mold 1 includes an upper mold 11, a lower mold 12, and a female mold 13, and the transducer includes a first Ultrasonic transducer 2, the second ultrasonic transducer 3, the third ultrasonic transducer 4, the ultrasonic generator includes the first ultrasonic generator 2', the second ultrasonic generator 3', the third ultrasonic generator 4', The ultrasonic generators (2, 3, 4) are arranged in the ultrasonic transducers (2', 3', 4') and have a one-to-one correspondence with the ultrasonic transducers, wherein the first ultrasonic transducer 2 and the first ultrasonic generator 2' are arranged on the lower mold 12, the second ultrasonic transducer 3 and the second ultrasonic generator 3' are arranged on the upper mold 11, the third ultrasonic transducer 4 and the third ultrasonic generator...

Embodiment 2

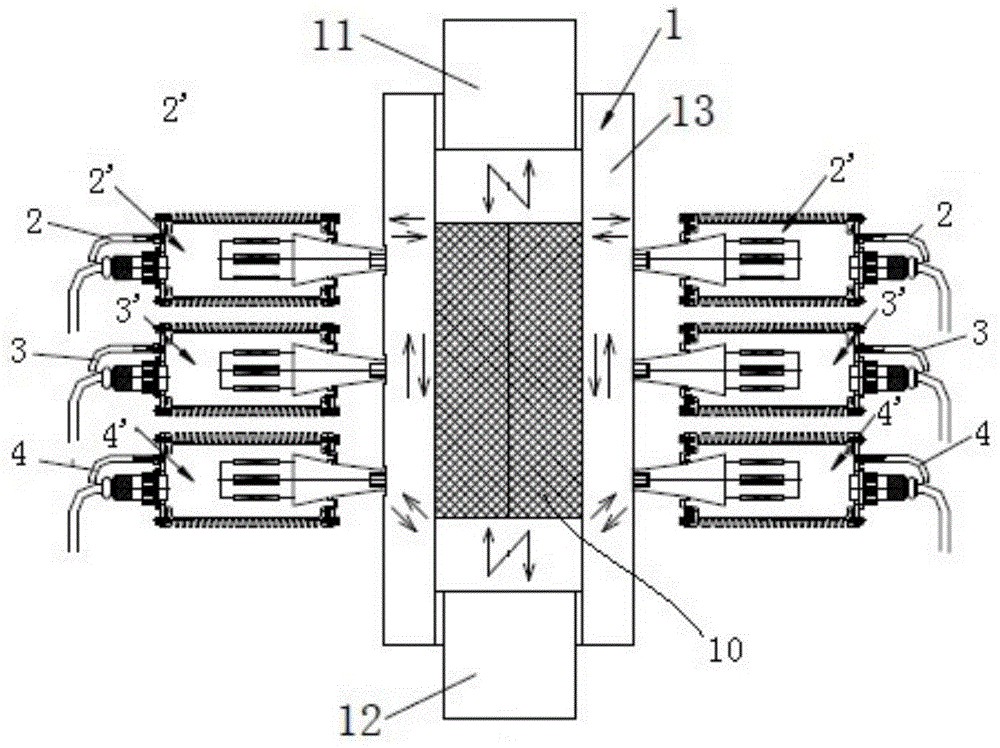

[0035] refer to image 3 As shown, the PBX explosive forming device includes a mold 1, a pressurizing device, an ultrasonic transducer, an ultrasonic generator, and a controller, wherein the mold 1 includes an upper mold 11, a lower mold 12, and a female mold 13, and the transducer includes a first Ultrasonic transducer 2, the second ultrasonic transducer 3, the third ultrasonic transducer 4, the ultrasonic generator includes the first ultrasonic generator 2', the second ultrasonic generator 3', the third ultrasonic generator 4', The ultrasonic generator is arranged in the ultrasonic transducer and has a one-to-one correspondence with the ultrasonic transducer, wherein the first ultrasonic transducer 2 and the first ultrasonic generator 2', the second ultrasonic transducer 3 The second ultrasonic generator 3 ′, the third ultrasonic transducer 4 and the third ultrasonic generator 4 ′ are symmetrically arranged on both sides of the female mold 13 . The corresponding ultrasonic ...

Embodiment 3

[0037] refer to Figure 4 As shown, the PBX explosive forming device includes a mold 1, a pressurizing device, an ultrasonic transducer, an ultrasonic generator, and a controller, wherein the cross section of the mold 1 is circular, and the transducer includes a first ultrasonic transducer 2 and a second ultrasonic transducer. Ultrasonic transducer 3, the third ultrasonic transducer 4, the fourth ultrasonic transducer 5, the ultrasonic generator includes the first ultrasonic generator 2', the second ultrasonic generator 3', the third ultrasonic generator 4', 4th Ultrasonic Generator 5'

[0038] The ultrasonic generators (2', 3', 4', 5') are arranged in the ultrasonic transducers (2, 3, 4, 5) and connected with the ultrasonic transducers (2, 3, 4, 5) It is a one-to-one correspondence, wherein, the first ultrasonic transducer 2 and the first ultrasonic generator 2', the second ultrasonic transducer 3 and the second ultrasonic generator 3', the third ultrasonic transducer 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com