Patents

Literature

79results about How to "Realize non-destructive measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

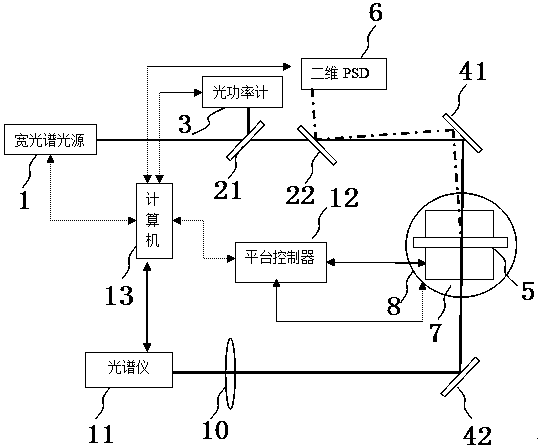

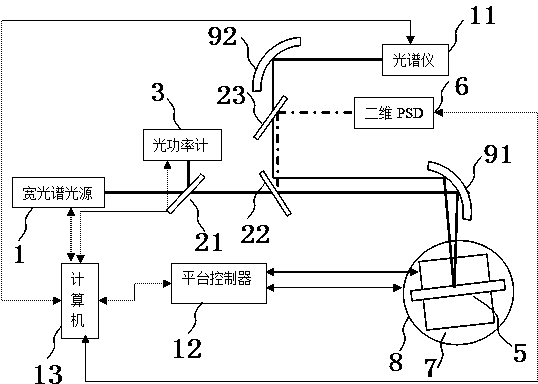

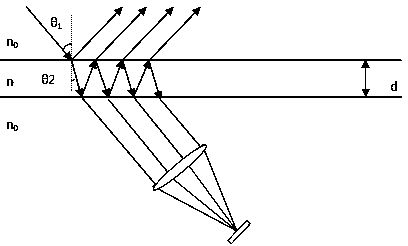

Precision measurement device and method for optical material refractive index

ActiveCN103954589AHigh measurement accuracyRealize non-destructive measurementPhase-affecting property measurementsUsing optical meansParallel plateWave band

The invention provides precision measurement device and method for an optical material refractive index. By adopting the device and the method, combination of a wide spectrum analysis method and a Fabry-Perot interference method can be achieved, accurate optical material thickness and refractive index are obtained by global residual analysis, and spectral analysis is carried out through a wide spectrum method Fabry-Perot interference system, so as to obtain a refractive index dispersion curve of the optical material under a continuous wave band. By adopting the device and the method, the measurement accuracy of the refractive index is improved, a stable interference cavity is formed by using parallel plate structures of most of optical materials, effects on the stability of an interference signal caused by air agitation are reduced, the optimal material is prevented from being processed into a special shape, and nondestructive measurement of the optical material is achieved.

Owner:HEFEI ZHICHANG PHOTOELECTRIC TECH

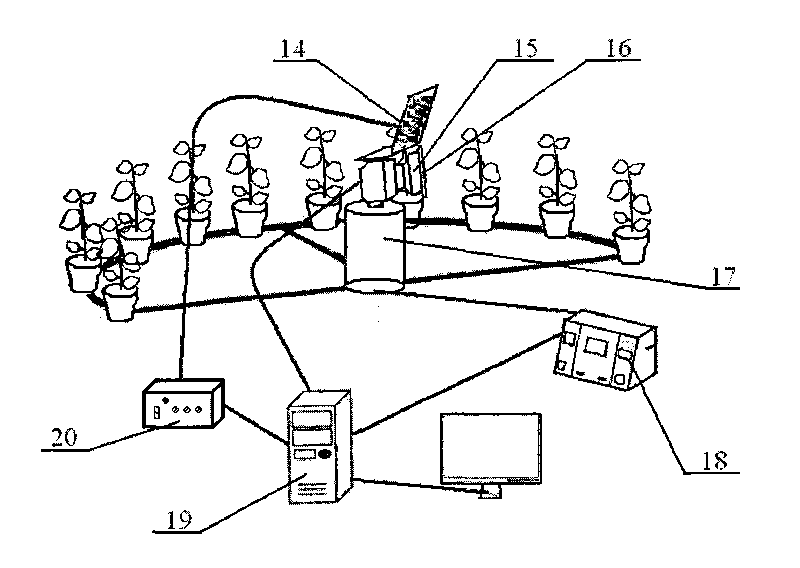

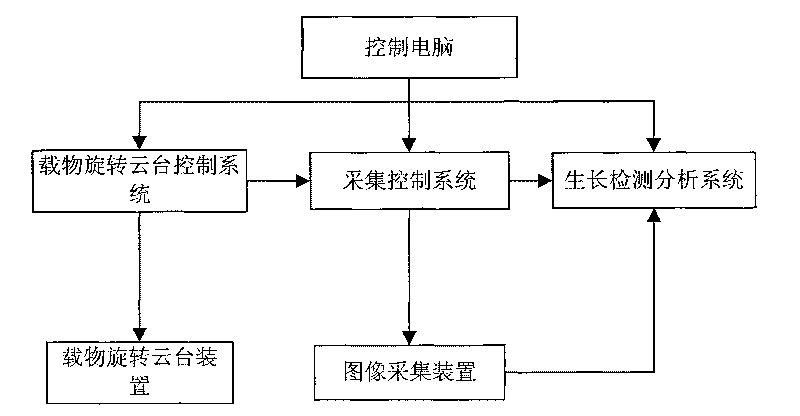

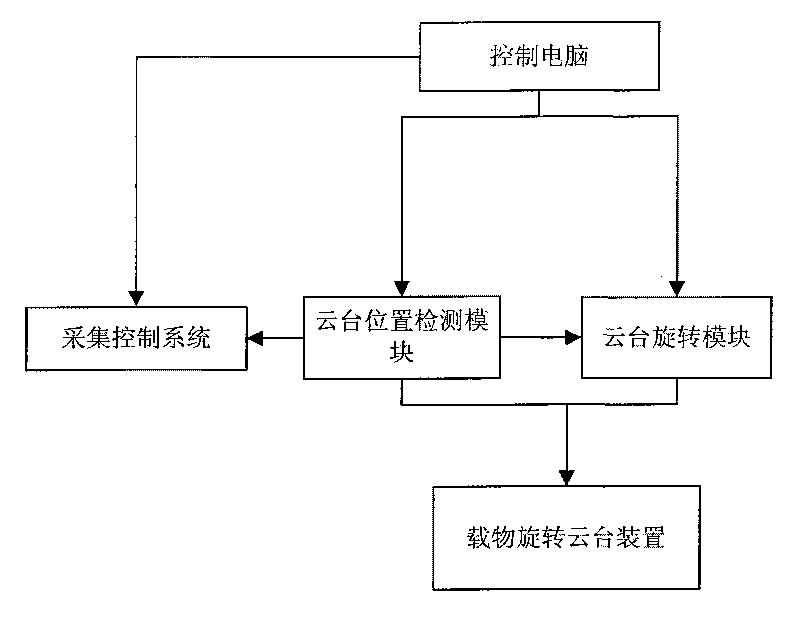

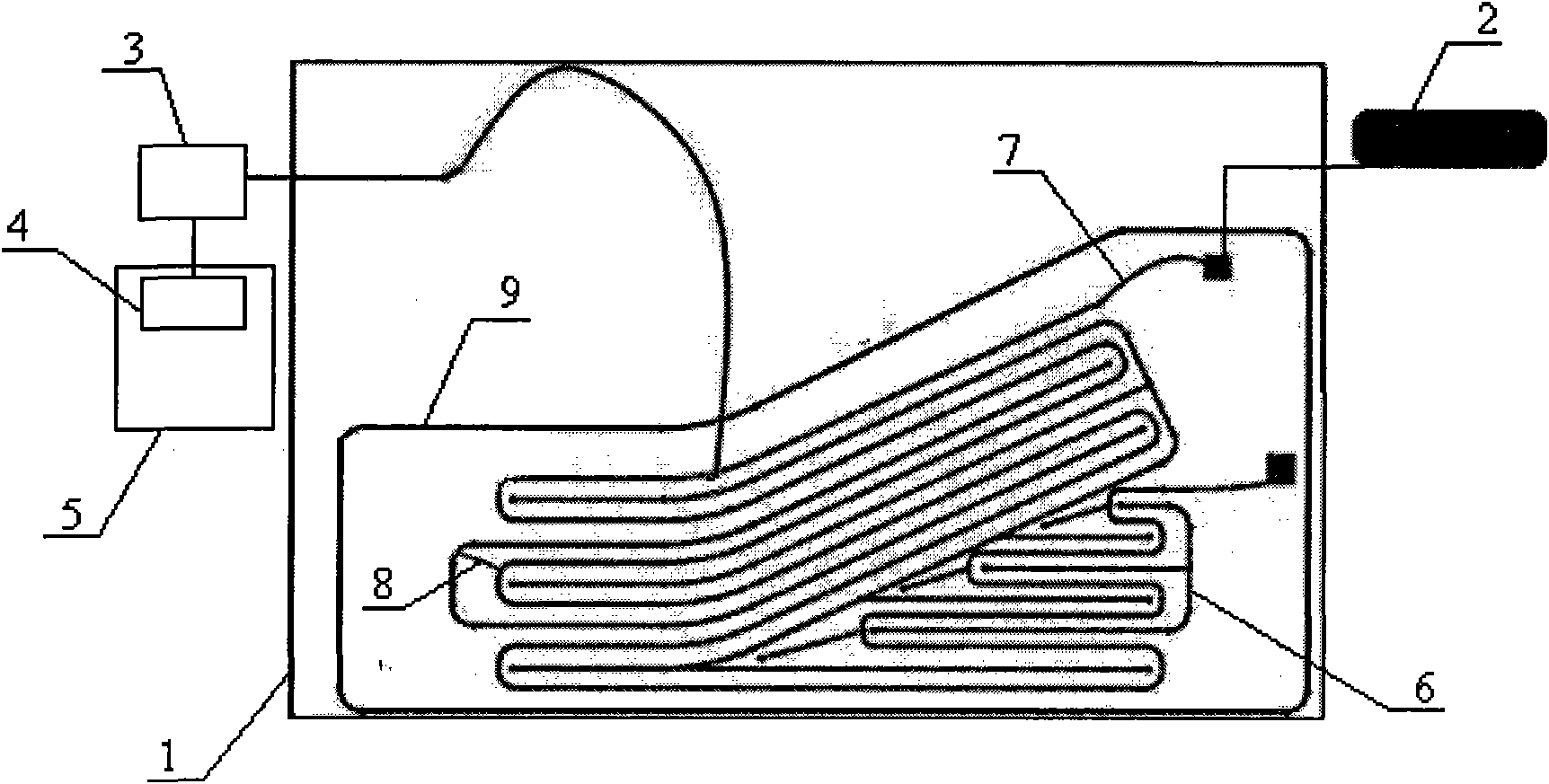

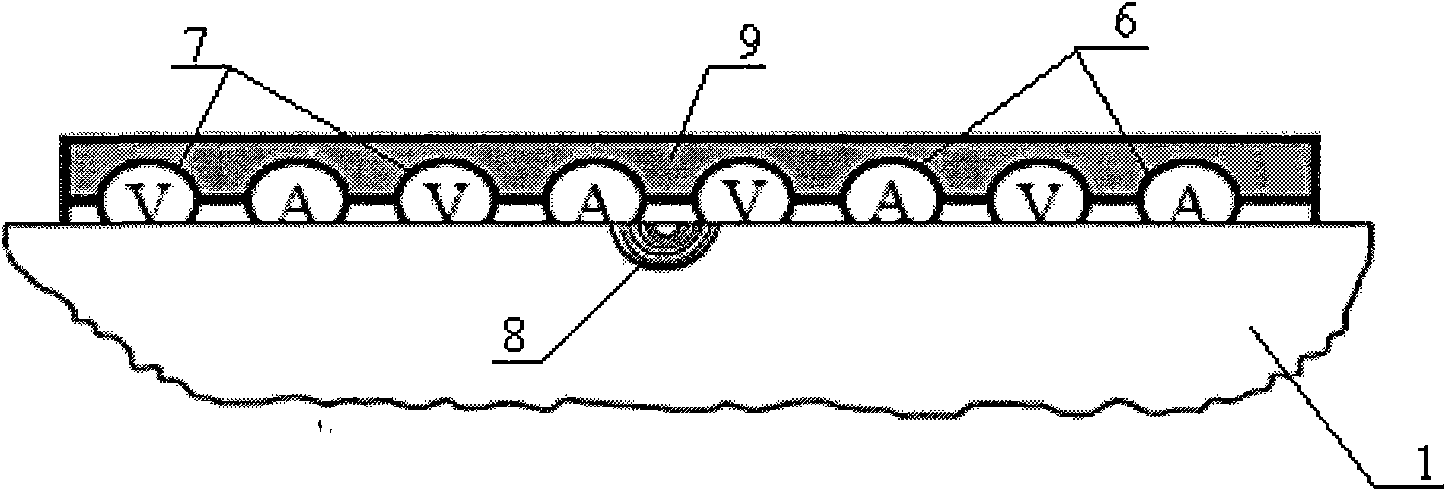

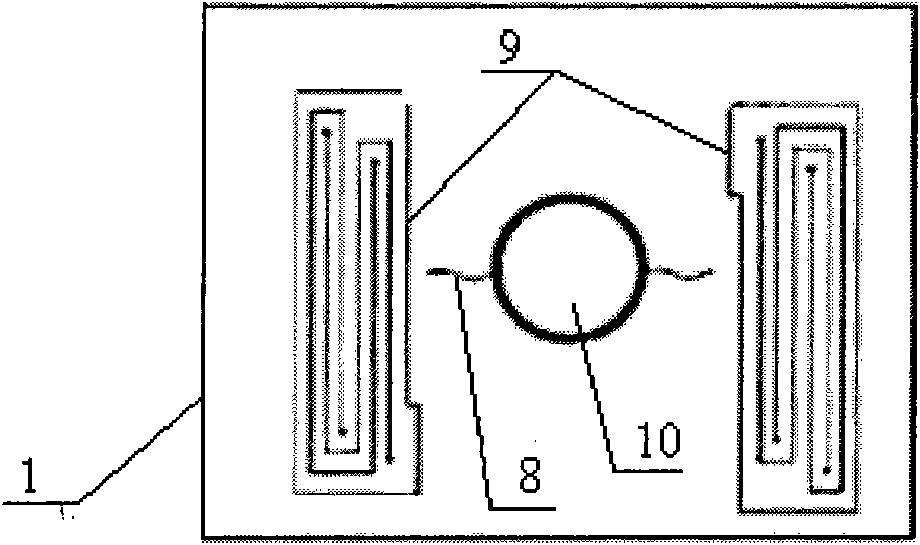

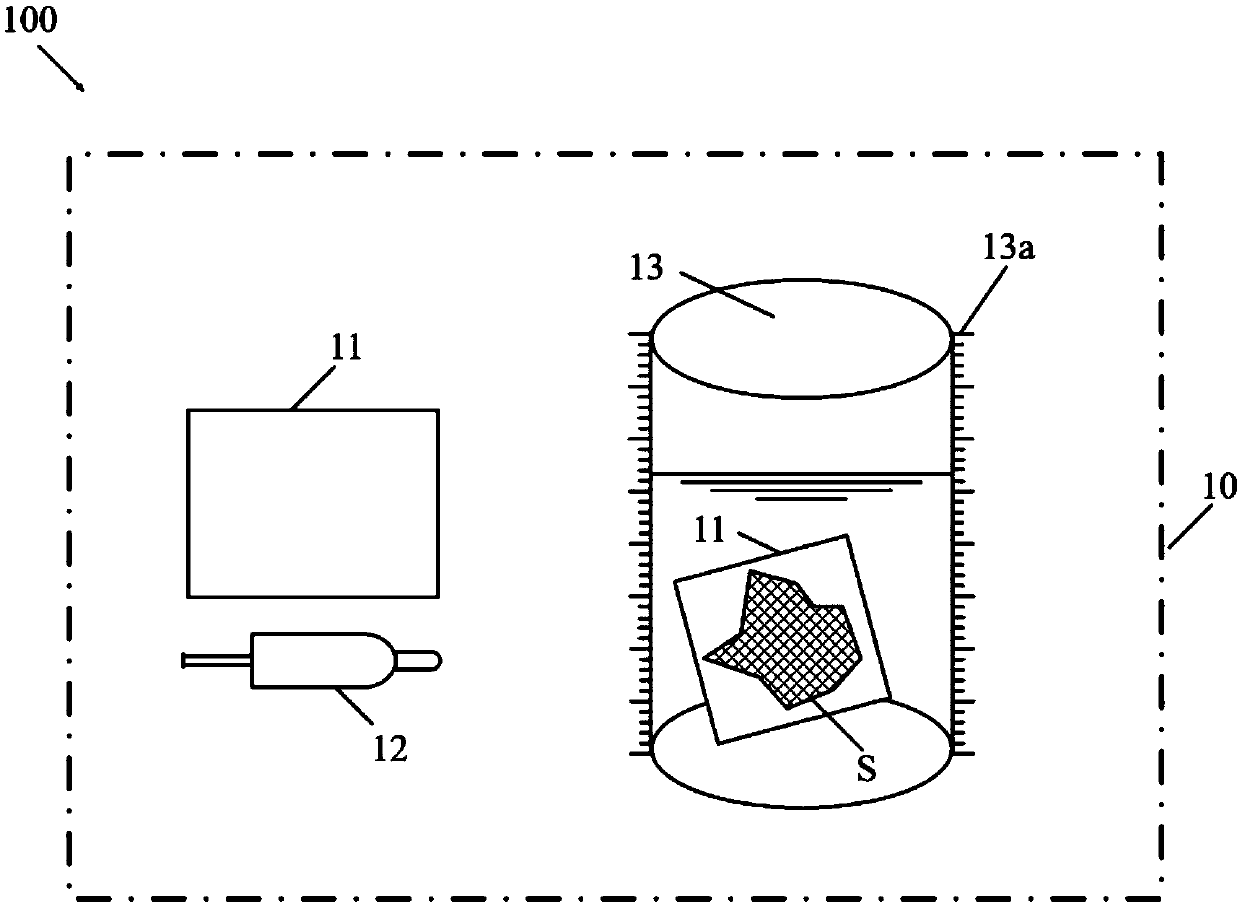

Non-contact type nondestructive detecting device for plant growth and detecting method thereof

InactiveCN101718522AHigh precisionHigh measurement accuracyUsing optical meansGrowth plantControl system

The invention provides a non-contact type nondestructive detecting device for plant growth, comprising a control computer, a material carrying and rotating holder device and an image acquisition system, wherein the control computer is internally provided with a material carrying and rotating holder control system, an acquisition control system and a growth detection and analysis system which are sequentially connected; the material carrying and rotating holder device is connected with the material carrying and rotating holder control system; and the acquisition control system and the growth detection and analysis system are respectively connected with the image acquisition device. The invention also provides a detecting method of the non-contact type nondestructive detecting device for plant growth. The invention can continuously detect a plurality of plants within a long time with a certain interval, automatically acquire images and analyze growth feature parameters of the plants at the same time of acquiring the images. The invention has the advantages of high image acquisition precision, accurate detection, and the like.

Owner:SOUTH CHINA AGRI UNIV

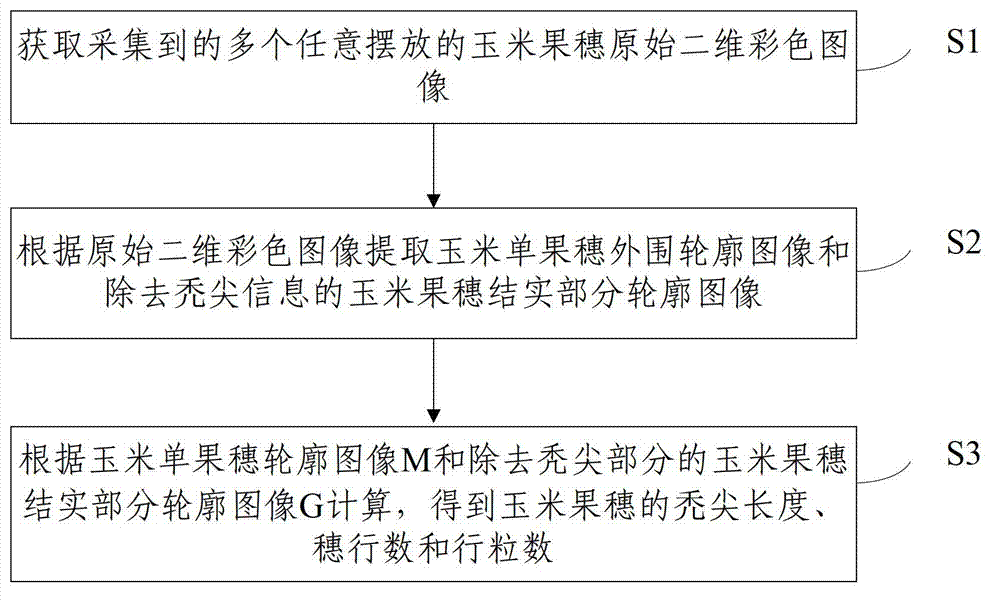

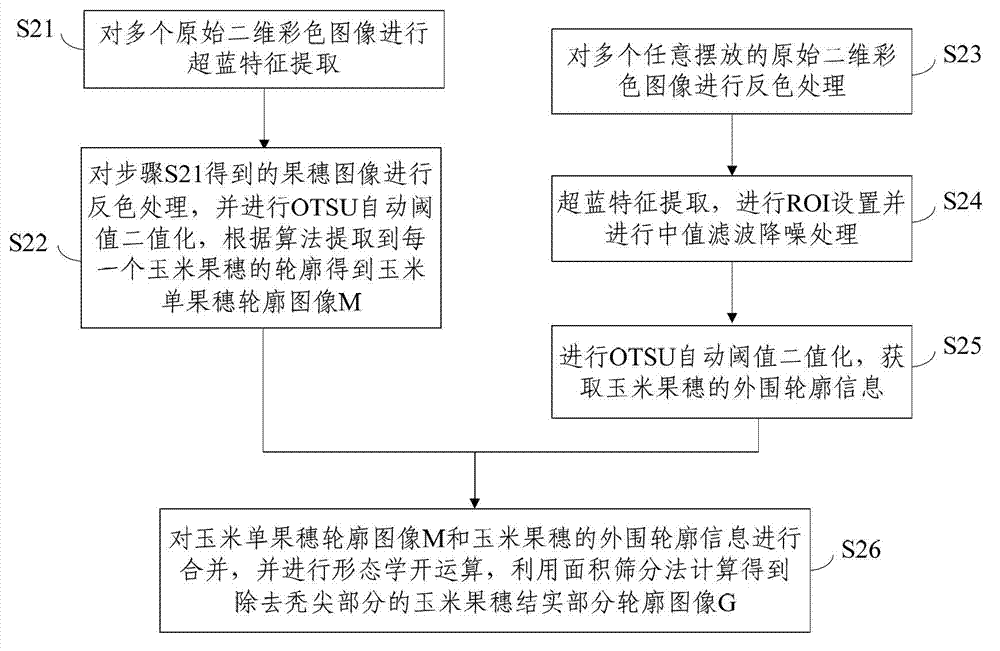

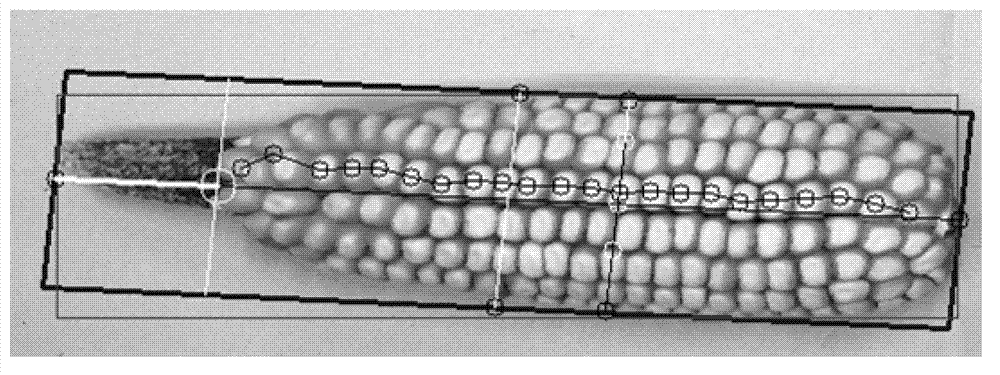

Computer vision technique-based corn ear species test method, system and device

ActiveCN103190224AAvoid 3D information collectionEnhanced grayscale differenceSeed and root treatmentCharacter and pattern recognitionColor imageFructification

The invention discloses a computer vision technique-based corn ear species test method, system and device. The method comprises the following steps of: collecting a plurality of corn ear original two dimension color images which are arranged arbitrarily; extracting the outline image of single ear of the corn and removing the outline image of the fructification part of the corn ear, the top of which is fruitless; and calculating and obtaining the fruitless length of the corn ear, the ear-to-row quantity and the grain quantity of each row according to the outline image of single ear of the corn and the outline image of the fructification part of the corn ear. Through enhancing the gray difference between the fruitless top of the corn ear and the grains, a partitioning algorithm is suitable for separation and extraction of a plurality of colors (purple and white) of fruitless top of the corn ear; based on the method of restoring the three-dimensional image information through a two dimensional ear image, the number of rows of the ear is calculated. The method can be used for rapidly and accurately measuring the phenotypic characters such as the fruitless length of the corn ear, the ear-to-row quantity and the grain quantity of each row and the like, and can greatly improve the breeding efficiency of new corn species.

Owner:CHINA AGRI UNIV

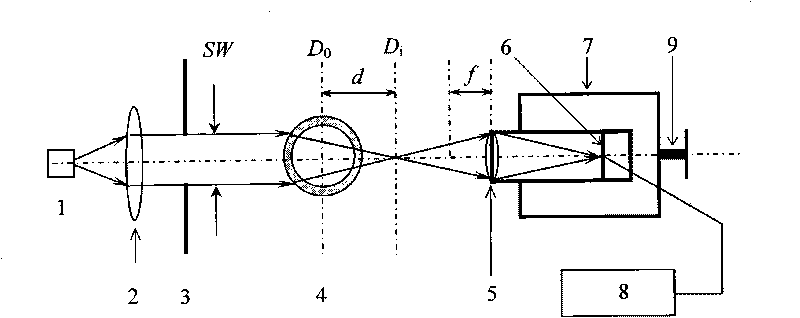

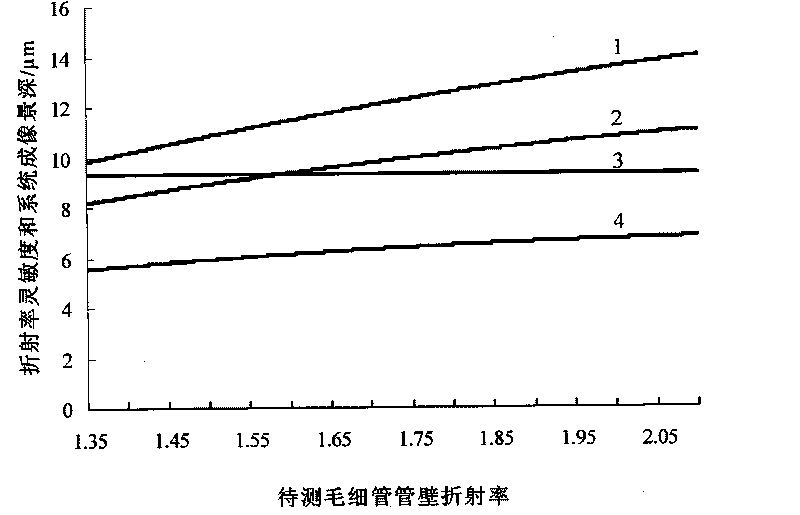

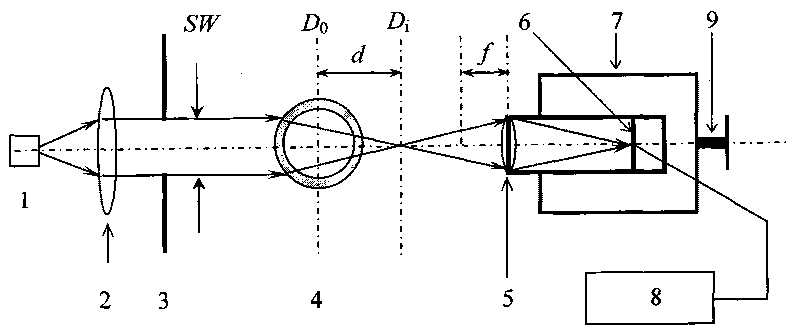

Method for nondestructive measurement of refractive index of transparent capillary wall and device thereof

InactiveCN101701912ARealize non-destructive measurementEliminate measurement errorsPhase-affecting property measurementsLight sourceAccuracy and precision

The invention relates to a method for the nondestructive measurement of the refractive index of a transparent capillary wall and a device thereof, belonging to a method for measuring the refractive index of solid by taking visible light as a light source. By utilizing the principle that parallel light has different convergence focus positions after passing through capillaries filled with liquid with different standards, the invention can be used for judging the image formed after the image formation of the convergence focus position by a CCD, calculating the outline position and focal distance of the capillary and further figuring out the refractive index of the capillary wall. The invention has the accuracy in the measurement of the refractive index of the capillary of being superior to 0.005, and has the characteristics of simple equipment, convenient operation and image observation, clear identification and high automation degree; furthermore, the invention realizes the accurate measurement for the refractive index of the capillary wall under the nondestructive condition, thus meeting the requirement for the accuracy of the refractive index of the capillary wall in the common experiment process.

Owner:YUNNAN UNIV

Apparatus for measuring stem intensity of crops in colony plantation

ActiveCN103217336APortableAccurate measurementMaterial strength using tensile/compressive forcesCoverage TypeComputer module

The invention relates to an apparatus for measuring stem intensity of crops in colony plantation, which comprises a touch rod contacted to the colony crop, more than two sensors, a hollow tube and a processing system; the touch rod is uniformly provided with the sensors, and the sensor is fixed on the hollow tube; the processing system comprises an acquisition module, a correction processing module, a displaying module and a power supply, and the processing system is fixed on one end of the hollow tube. The apparatus for measuring stem intensity of crops in colony plantation base on mechanics provided by the invention has the advantages of accurate and reliable measurement result, thereby realizing all coverage type measurement of the plantation district, and especially adapting to crop stem intensity measurement of the breeding district.

Owner:BEIJING RES CENT FOR INFORMATION TECH & AGRI

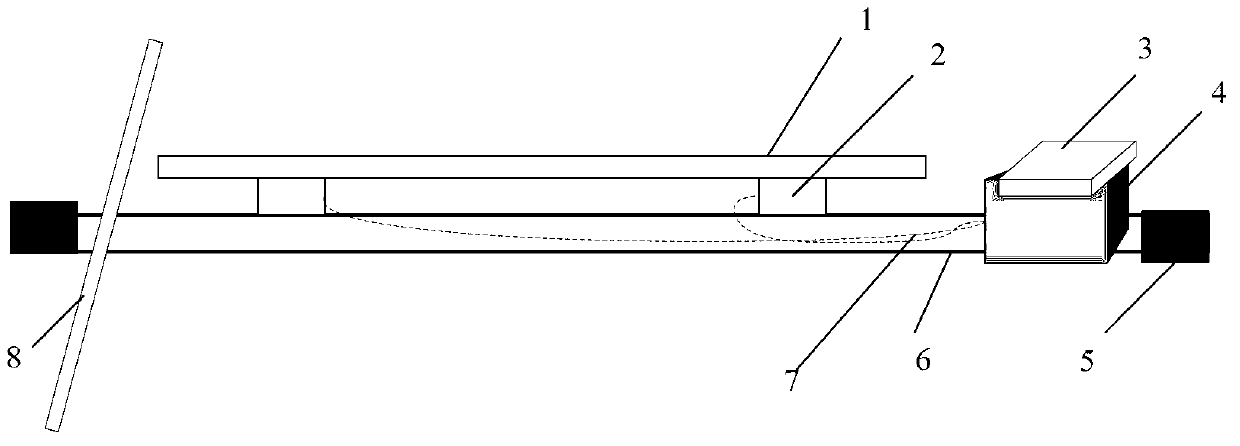

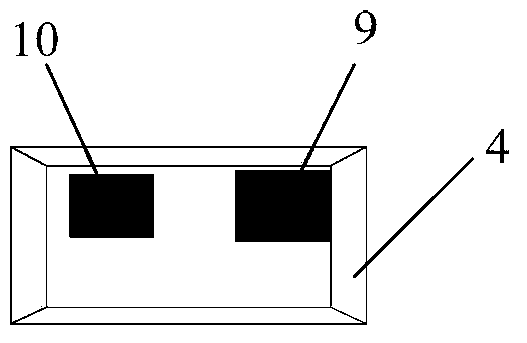

Concrete absolute stress measurement device and method

ActiveCN104864990AAccurate measurementComplete measurementForce measurementStress measurementStressed state

The invention provides a concrete absolute stress measurement device and method. The concrete absolute stress measurement device comprises a first stainless steel tube and a second stainless steel tube, wherein an end opening A and an end opening B of the first stainless steel tube are both openings, the second stainless steel tube is vertically arranged on the side surface, close to the end opening B, of the first stainless steel tube, an end opening C of the second stainless steel tube is an opening and communicated with the first stainless steel tube, and an end opening D of the second stainless steel tube is sealed; a first ultrasonic receiving probe is arranged in the first stainless steel tube and close to the end opening A, and an ultrasonic transmitting probe is arranged above the end opening C; a second ultrasonic receiving probe is arranged in the second stainless steel tube and close to the end opening D. Through the method, the internal real stress state of a concrete structure can be accurately and integrally measured, the measurement operation is simple and quickly, and nondestructive measurement can be realized. The concrete absolute stress measurement device is simple in structure, low in manufacturing cost, high in practicability and simple and convenient to use.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

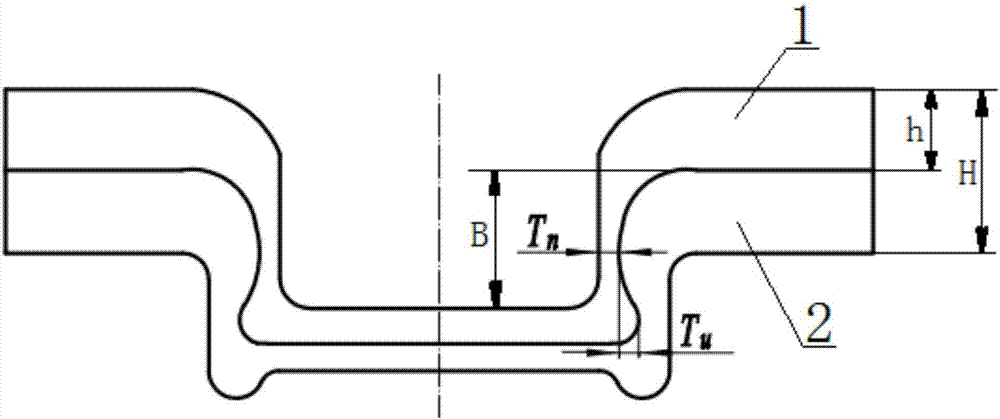

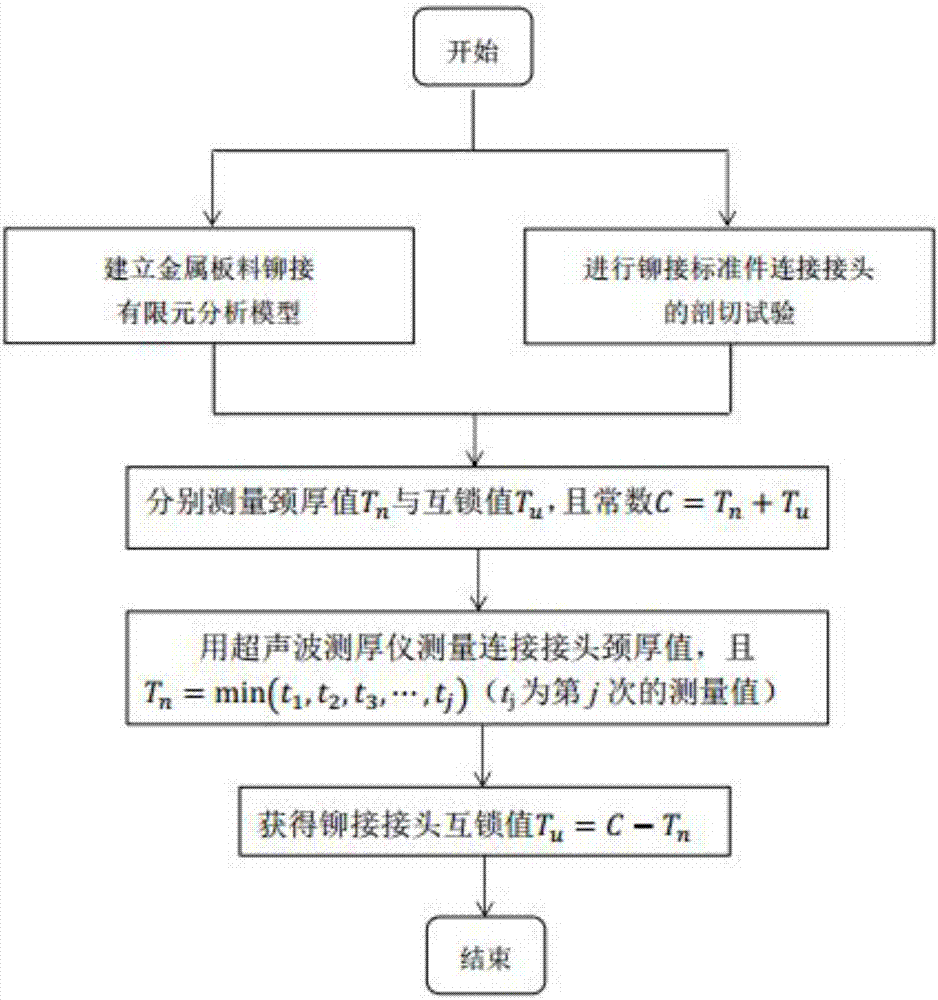

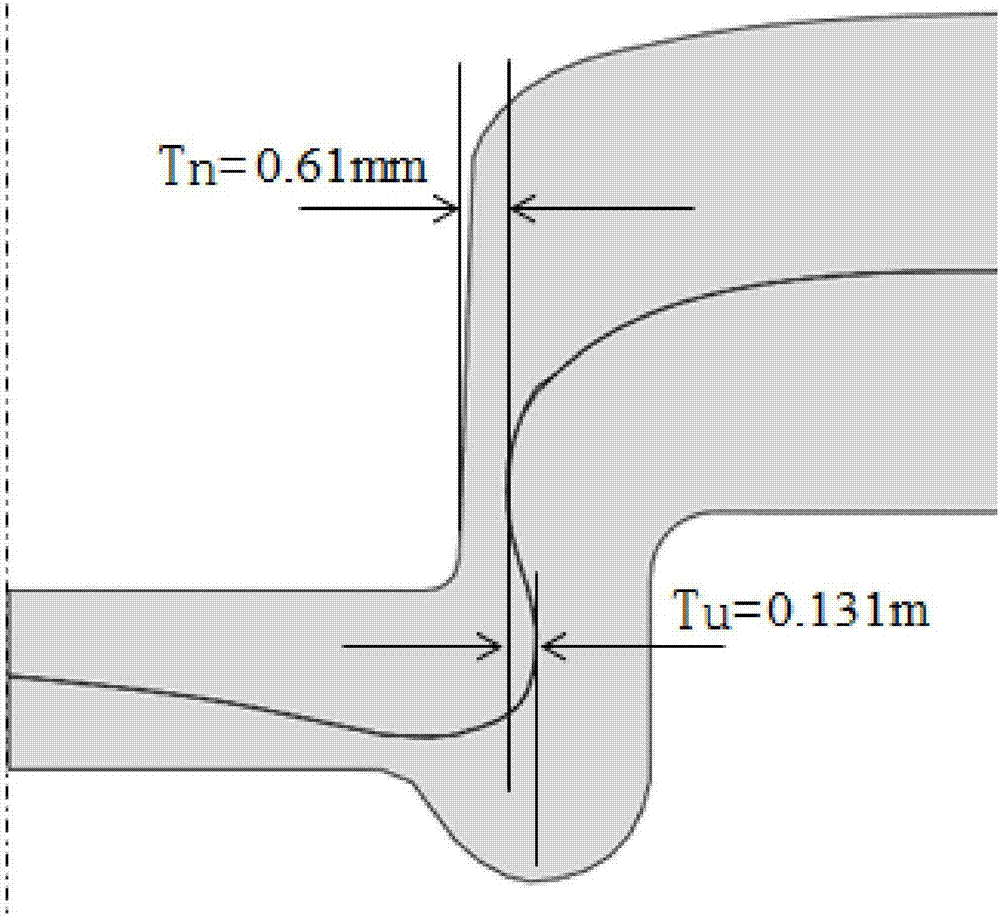

Riveting joint geometric parameter detection method

ActiveCN106931918AImprove measurement efficiencyQuick checkUsing subsonic/sonic/ultrasonic vibration meansUsing optical meansObservational errorMeasuring instrument

The invention relates to a riveting joint geometric parameter detection method. The method comprises the following steps that: a riveting analysis model is built in finite element analysis software, and a plurality of groups of mechanical clinching connection processes are simulated through the analysis model, the corresponding riveting constants C of two kinds of corresponding riveting material plates of a riveting joint are obtained, and it is proved that that the riveting constant C can be expressed through an equality that C=Tn+Tu, wherein Tn is a neck thickness value, and Tu is an interlocking value; a thickness measuring instrument is utilized to determine a measurement area B along the inner side of the riveting joint; the thickness measuring instrument is utilized to measure the neck thickness value Tn of the riveting joint in the measurement area B along the inner side of the riveting joint; and the interlocking value Tu which can be expressed through the equality Tu=C-Tn is obtained through the riveting constant C and the neck thickness value. With the riveting joint geometric parameter detection method adopted, fast and accurate detection of the geometrical parameters of the mechanical clinching riveting joint can be realized, nondestructive measurement can be realized, the measurement efficiency of the riveting joint is improved, and measurement errors are reduced.

Owner:WUHAN UNIV OF TECH

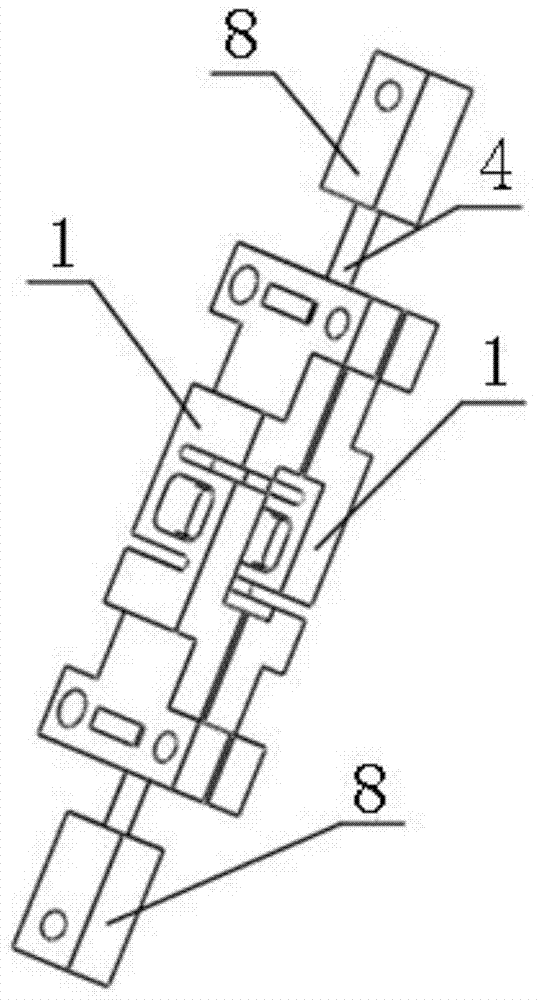

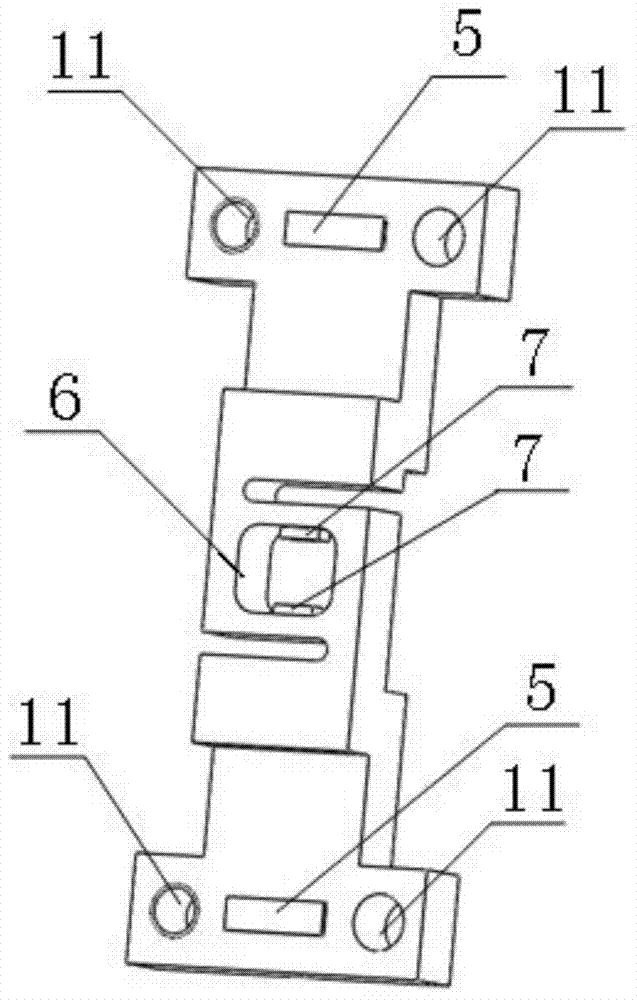

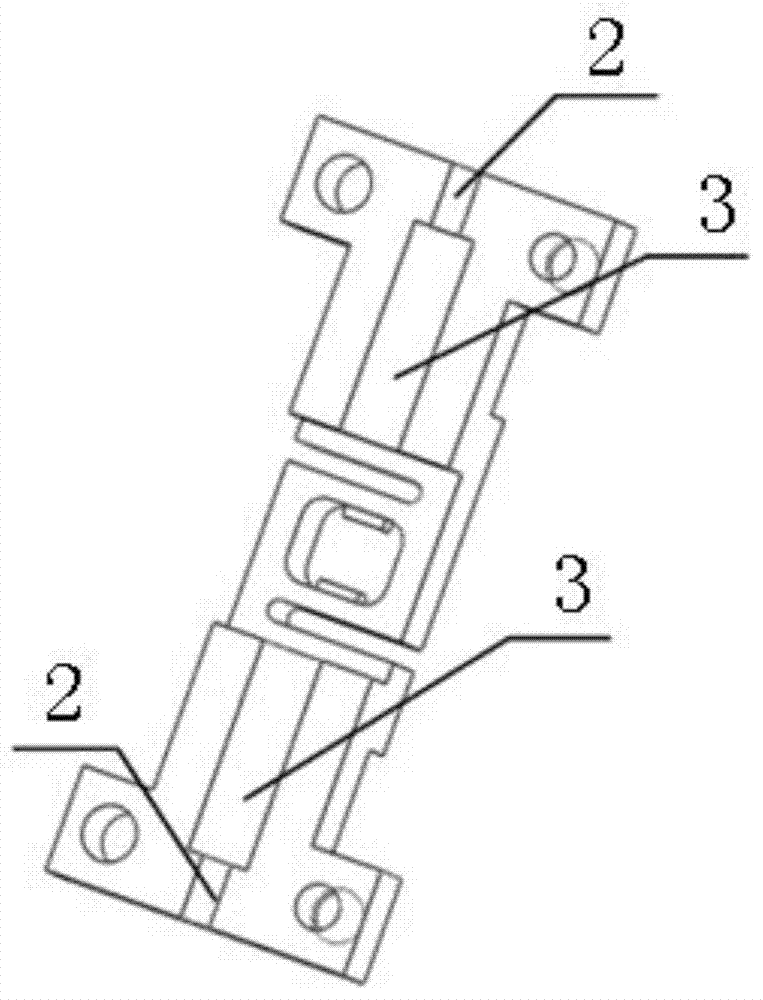

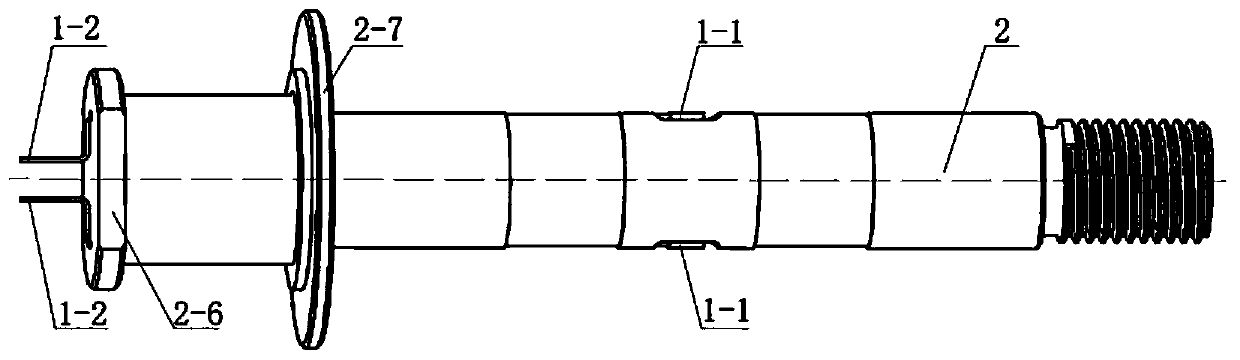

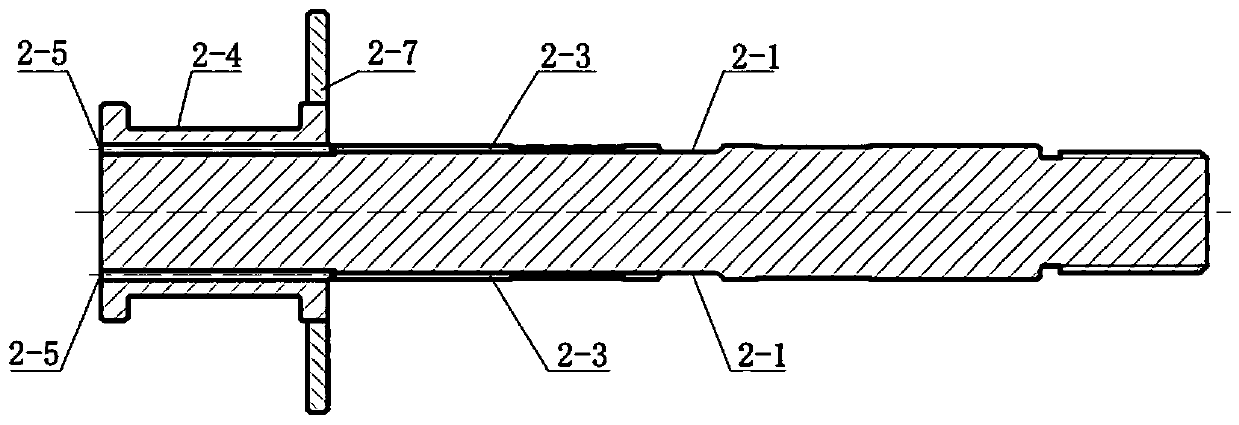

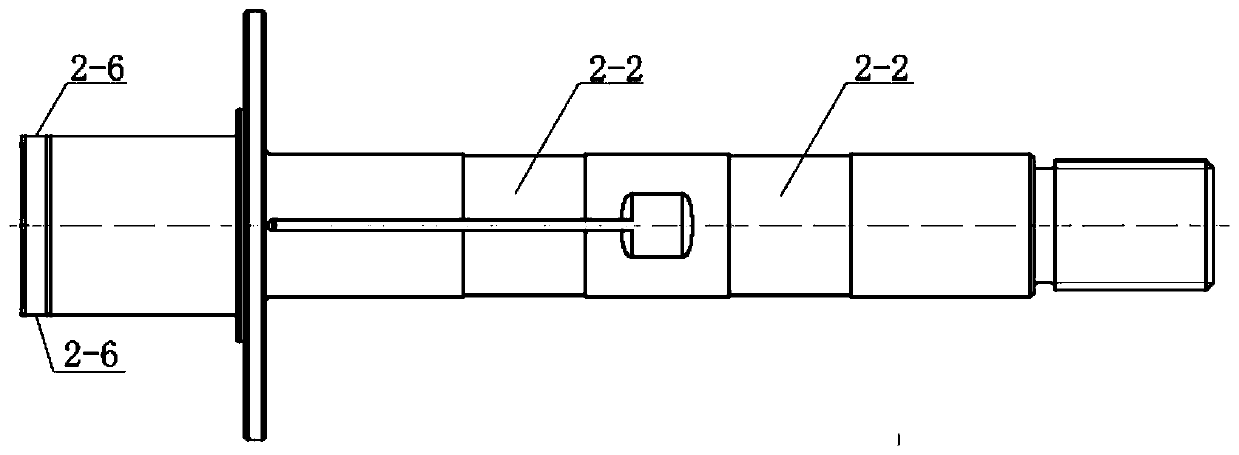

Slender rod bi-directional internal force measuring sensor and calibration method

ActiveCN103884458AGood repeatabilityNo loss of measurement accuracyForce measurementForce/torque/work measurement apparatus calibration/testingVoltageEngineering

The invention discloses a slender rod bi-directional internal force measuring sensor which comprises two identical clamping plates which are arranged symmetrically. The two clamping plates are fixed together in a back to back mode, the distance between the two clamping plates is adjustable, and a clearance is reserved between the two clamping plates. Clamping grooves and grooves are formed in the back face of each clamping plate, the clamping grooves and the grooves are formed in the same straight line, the clamping grooves are matched with slender rods, and the slender rods are clamped in the clamping grooves and penetrate through the grooves without making contact with the grooves. The front face of each clamping plate is provided with pressure measuring units, and the position of each pressure measuring unit is opposite to the corresponding clamping grooves. Tension and pressure measuring holes are further formed in the positions, opposite to the grooves, of each clamping plate, and tension and pressure measuring devices are arranged on the inner walls of the tension and pressure measuring holes. Under the condition that the clamping force of the slender rods is not changed, the pressure and the tension borne by the slender rods in the axial direction are measured in multiple angles, and the pressure and the tension are finally expressed into a relational expression between force and voltages, and when the slender rod bi-directional internal force measuring sensor is put into actual use, the size of the internal force of the slender rods to be measured can be reflected simply by reading corresponding voltages.

Owner:SOUTHEAST UNIV

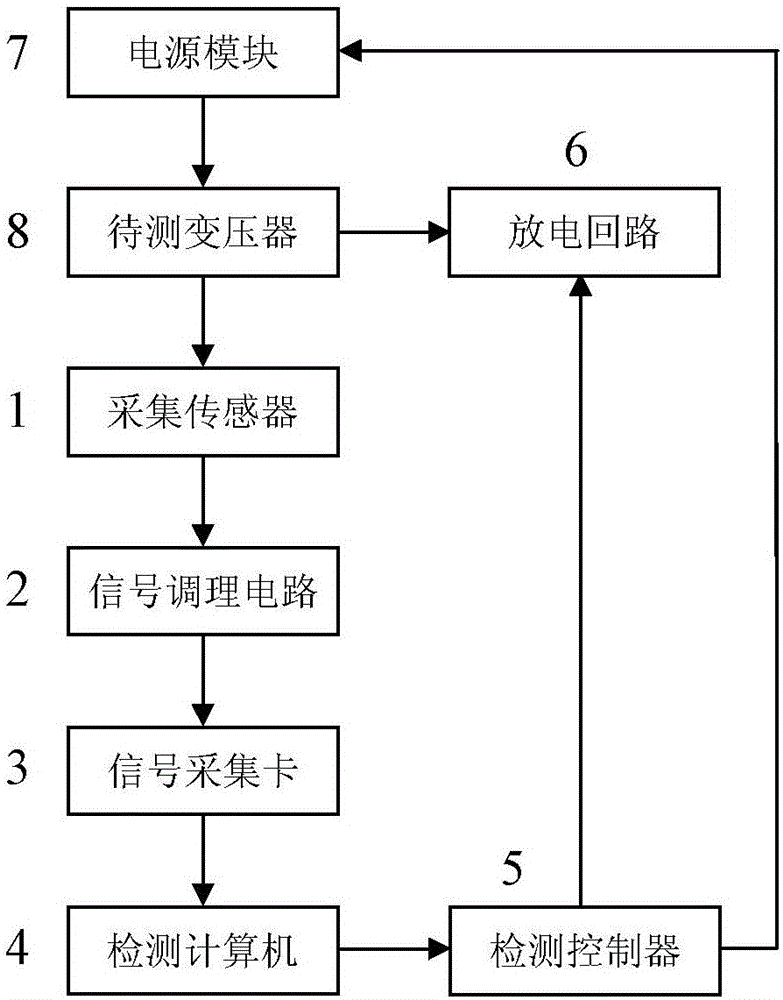

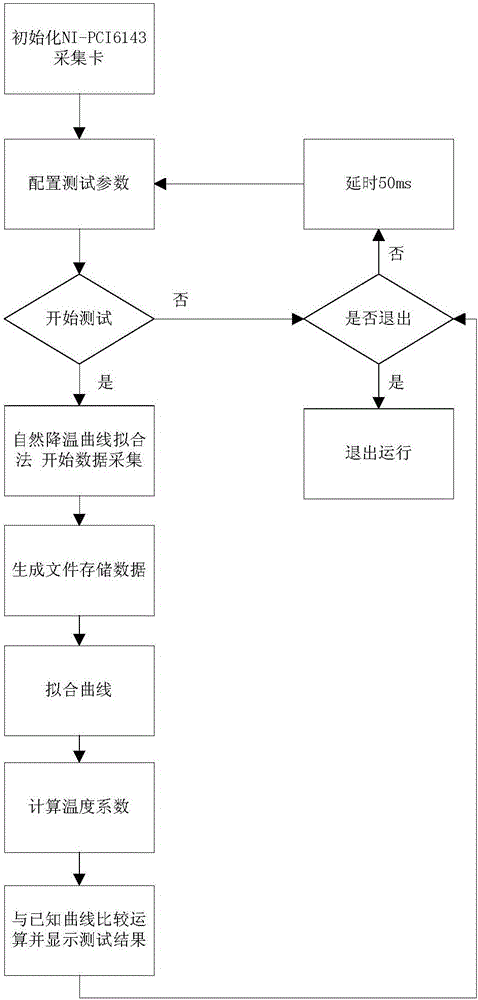

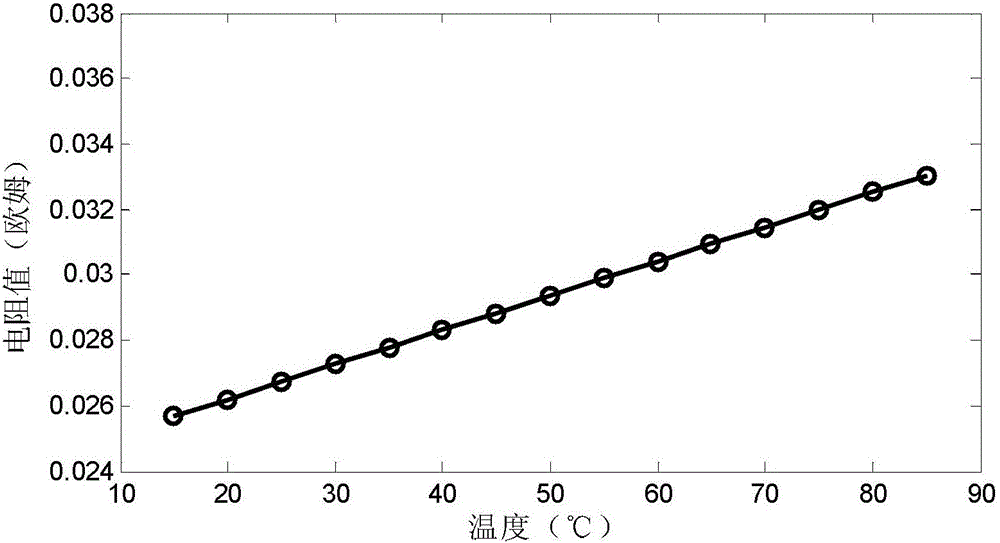

Device and method for nondestructively detecting materials for windings of power distribution transformers

PendingCN106353370AEasy to detectImprove work efficiencyMaterial resistanceConductor CoilSignal acquisition

The invention discloses a device and a method for nondestructively detecting materials for windings of power distribution transformers. The device comprises an acquisition sensor, a signal conditioning circuit, a signal acquisition card, a detection computer, a detection controller, a discharge circuit and a power module. The device and the method have the advantages that the materials for the windings of the power distribution transformers can be conveniently detected and nondestructively measured by power transformation operation and maintenance staffs, unlawful suppliers can be prevented from passing aluminum as copper, and accordingly the quality of network-connected power distribution transformer products can be guaranteed; the service lives of the power distribution transformers can be prolonged after the device and the method are applied, the stability of the power distribution transformers can be improved, and accordingly the device and the method can be further comprehensively popularized to cover admission detection work on power distribution transformers of power distribution network systems of the state grid corporation and have obvious direct and indirect benefits; the work efficiency of the power transformation operation and maintenance staffs can be effectively improved, and the management level of the power transformation operation and maintenance staffs can be upgraded; problems can be discovered early, accordingly, the power supply reliability can be improved, safe and reliable operation of power grids can be fundamentally guaranteed, and the device and the method have obvious economic benefits.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

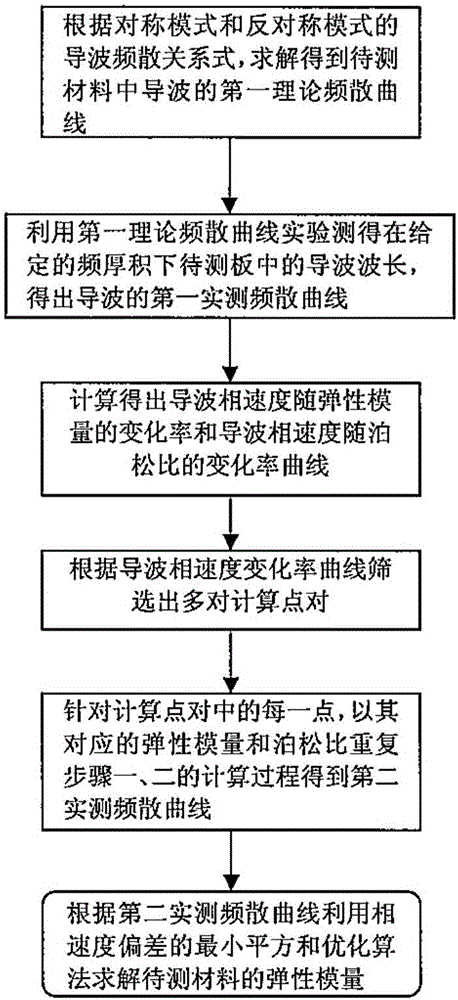

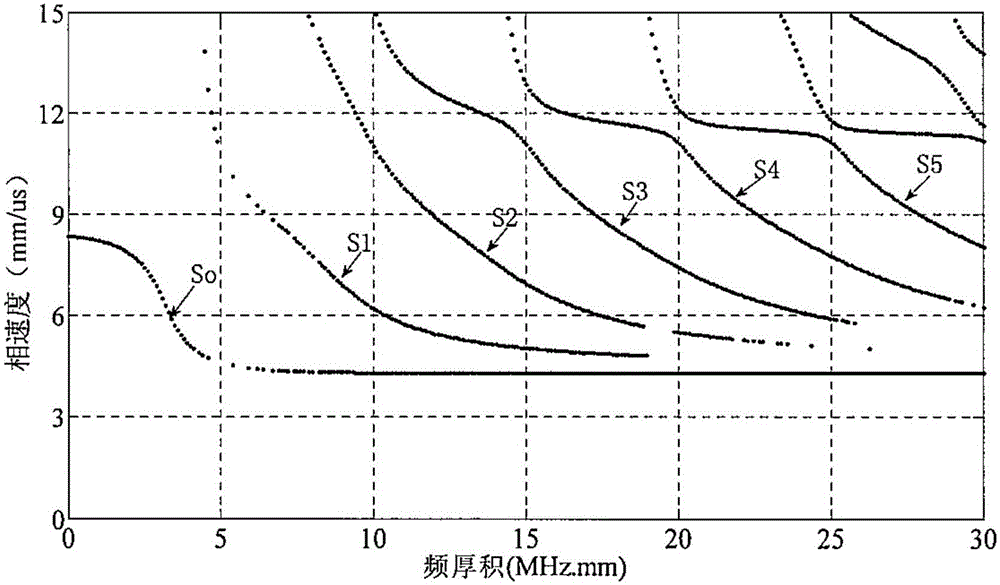

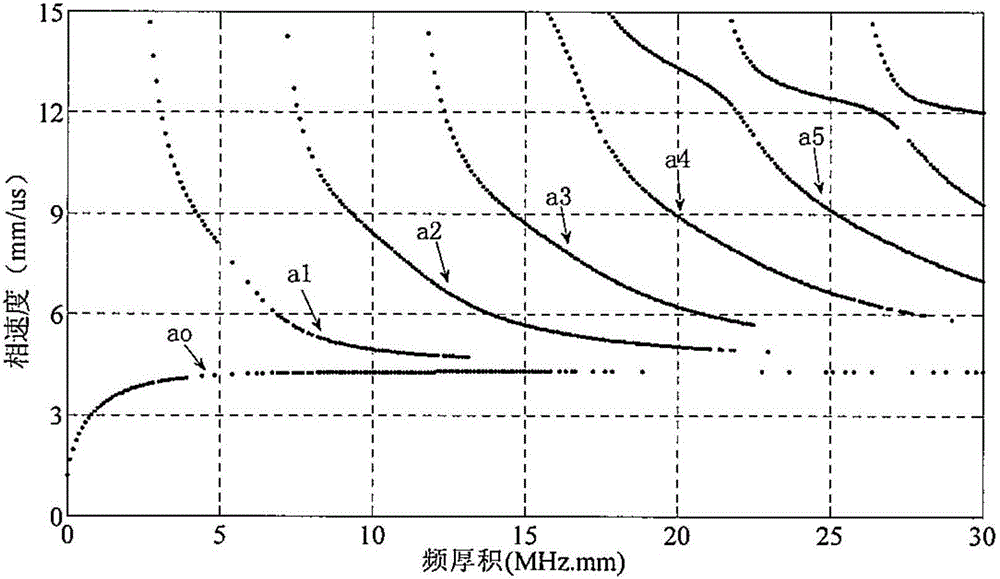

Air-coupled ultrasonic testing method for determining elastic modulus of material

ActiveCN106680375ARealize non-destructive measurementAccurate measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesPhase velocityTest material

The invention discloses an air-coupled ultrasonic testing method for determining the elastic modulus of a material. The air-coupled ultrasonic testing method comprises the following steps: solving according to a guided wave frequency dispersion relational expression of a symmetric mode and an anti-symmetric mode, thus obtaining a first theoretical frequency dispersion curve of guided waves; experimentally testing a guided wave wavelength in a to-be-tested board under a given frequency thickness product by using the first theoretical frequency dispersion curve, thus obtaining a first actually measured frequency dispersion curve of the guided waves; obtaining a change rate curve of a guided wave phase velocity along with the elastic modulus and a change rate curve of the guided wave phase velocity along with a poisson ratio by calculation; screening out multiple pairs of calculation point pairs according to the change rate curves of the guided wave phase velocities; aiming at every point in the calculation point pairs, repeating step one and step two by utilizing the elastic modulus and the poisson ratio which correspond to every point, thus obtaining a second actually measured frequency dispersion curve; solving the elastic modulus of a to-be-tested material by utilizing minimum square of phase velocity deviation and an optimization algorithm according to the second actually measured frequency dispersion curve. According to the air-coupled ultrasonic testing method disclosed by the invention, nondestructive measurement on the elastic modulus of the material can be realized, and a measurement result is accurate.

Owner:COMAC +1

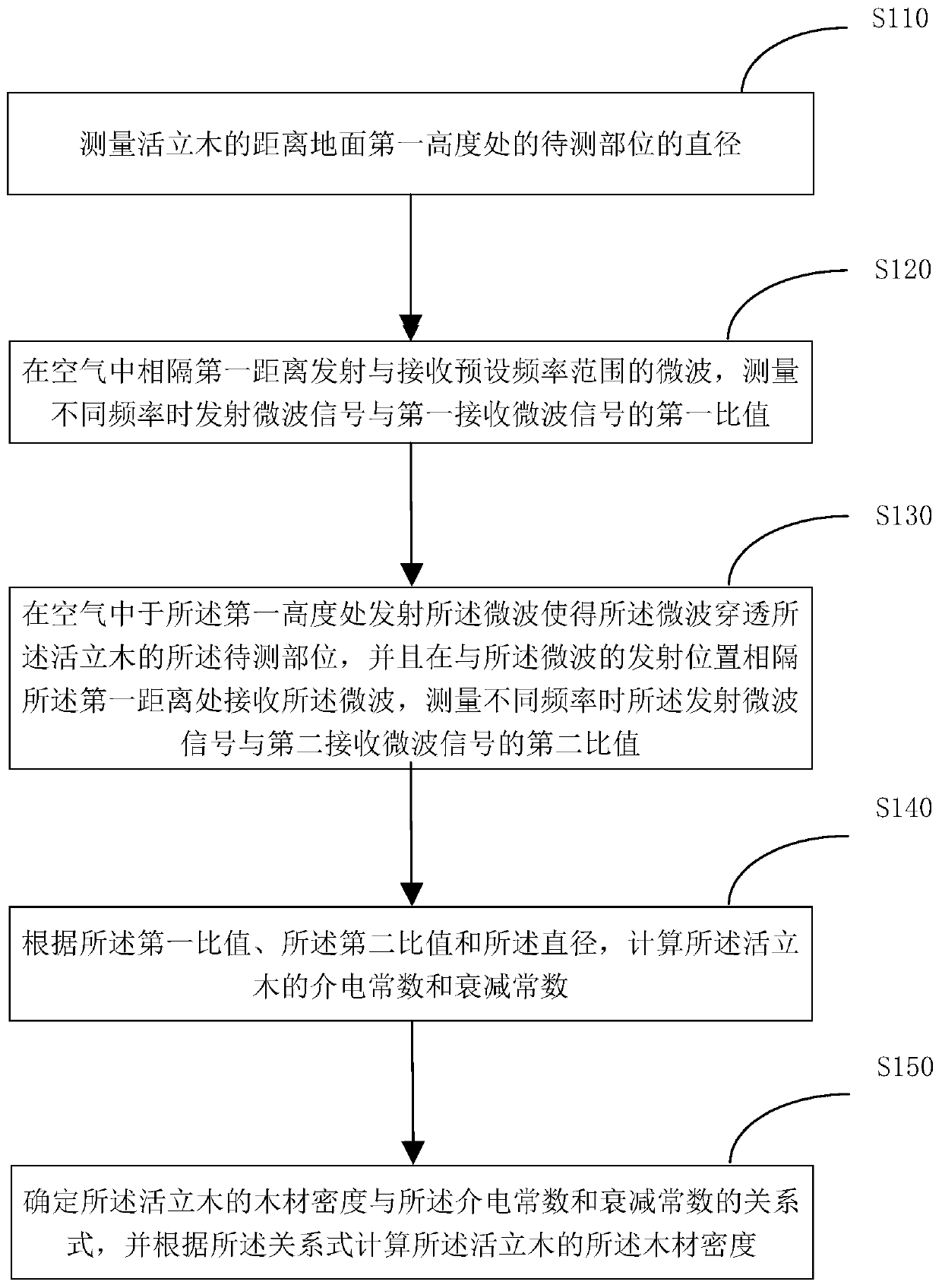

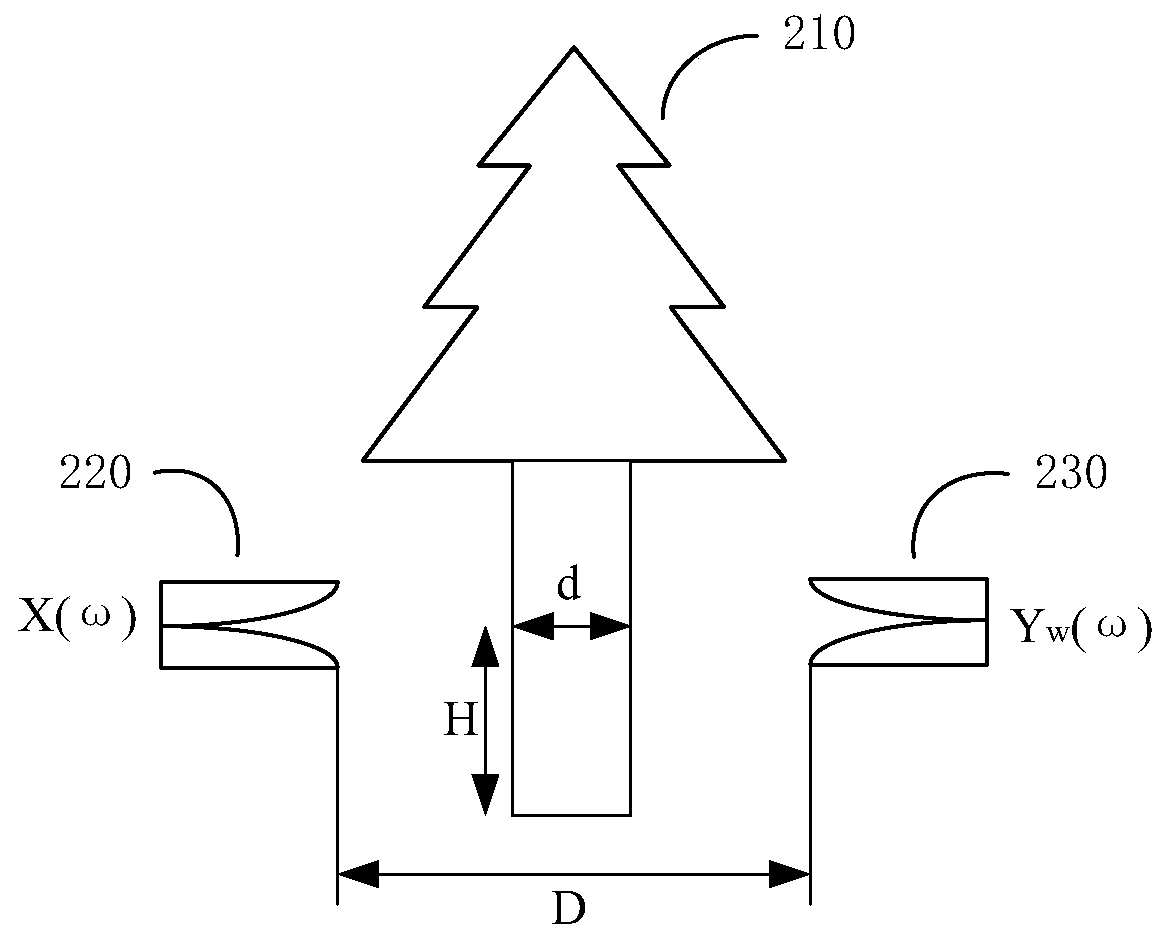

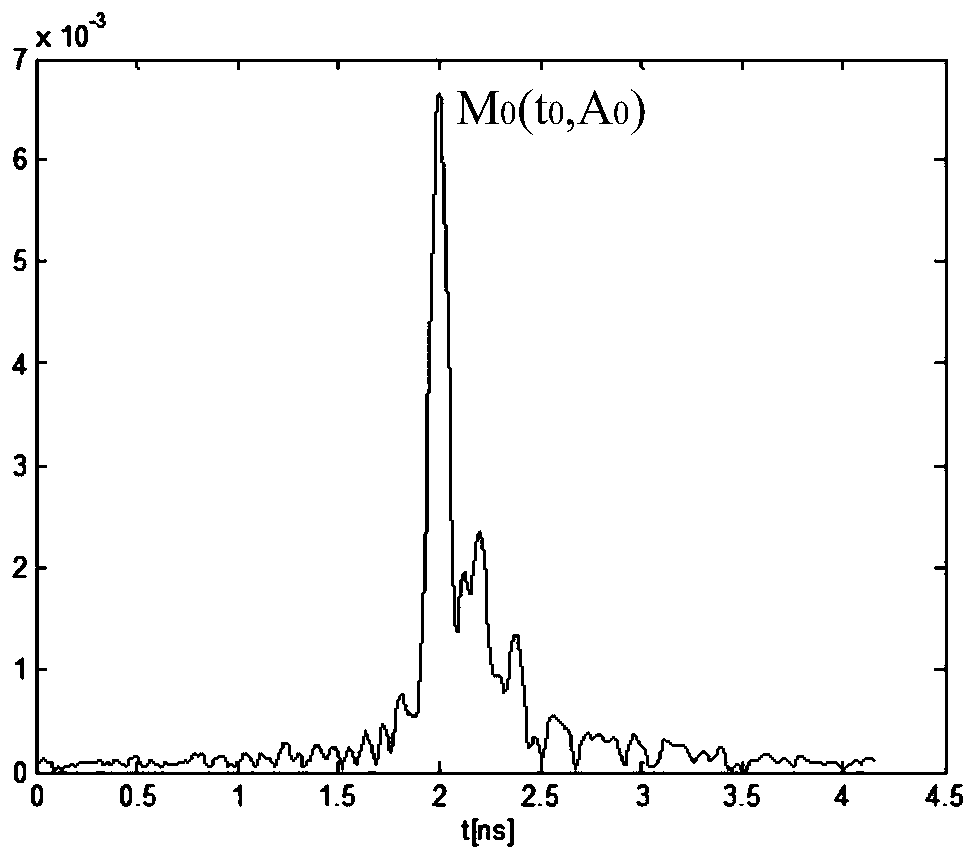

Method and device for measuring wood density of standing tree

ActiveCN110793979AEasy to measureImprove accuracyResistance/reactance/impedenceMaterial analysis using microwave meansDielectricAcoustics

The invention discloses a method and a device for measuring the wood density of a standing tree, and relates to the technical field of measurement. The method comprises the steps of: measuring the diameter of a part to be measured at a first height from the ground of the standing tree; transmitting and receiving microwaves within a preset frequency range at a first distance in the air; measuring afirst ratio of transmitted microwave signals to first received microwave signals at different frequencies; transmitting microwaves at a first height in the air to allow the microwaves to penetrate the part to be measured of the standing tree, receiving the microwaves at a first distance from the microwave transmitting position, and measuring a second ratio of the transmitted microwave signals tosecond received microwave signals at different frequencies; calculating a dielectric constant and an attenuation constant of the standing tree according to the first ratio, the second ratio and the diameter; and determining a relational expression among the wood density of the standing tree, the dielectric constant and the attenuation constant, and calculating the wood density of the standing treeaccording to the relational expression. By adopting the measurement method disclosed by the embodiment of the invention, the measurement accuracy of the wood density is improved.

Owner:INST OF REMOTE SENSING & DIGITAL EARTH CHINESE ACADEMY OF SCI

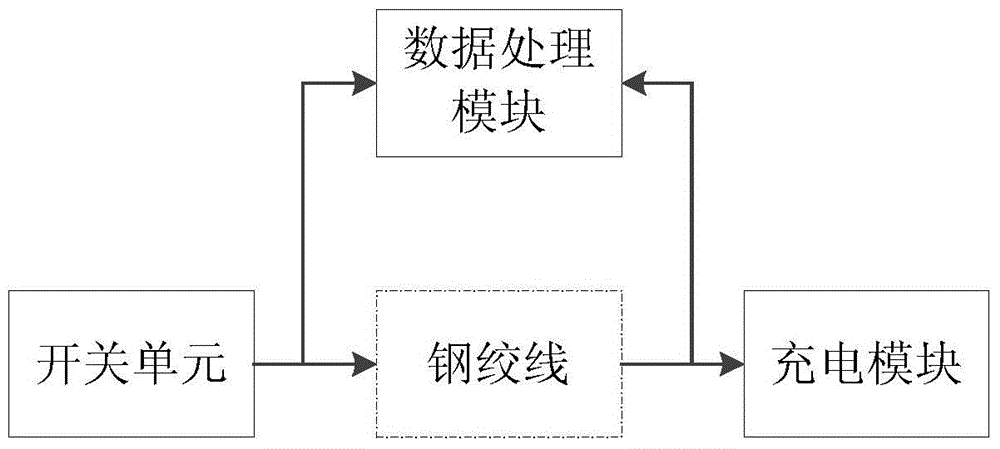

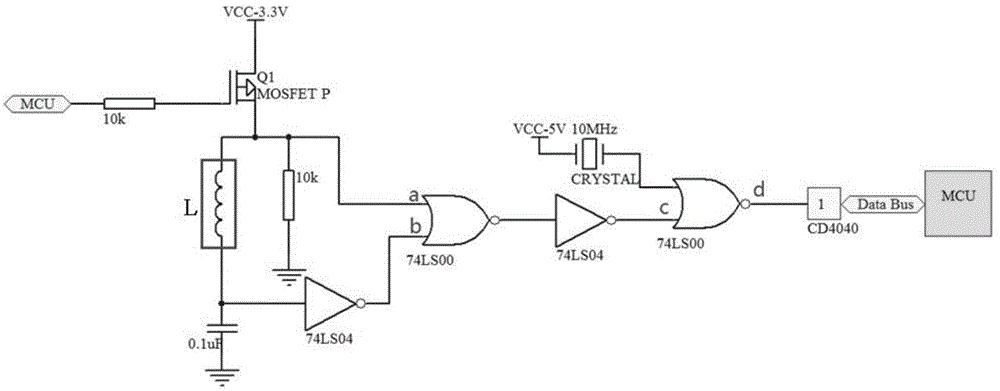

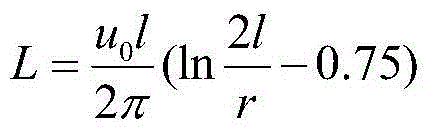

Pre-stressing force measurement apparatus and method for pre-stress steel strand

InactiveCN104880273AConvenient and quick prestress detectionHigh degree of equipment integrationTension measurementPre stressingEngineering

Disclosed in the invention is a pre-stressing force measurement apparatus for a pre-stress steel strand. The apparatus comprises a switching unit, a charging module, and a data processing module. The switching unit charges the charging module by a steel strand; the data processing module collects an input signal and an output signal of the steel strand and converts the input signal and output signal of the steel strand into a charging time signal of the charging module; and an inductance variation of the steel strand is obtained based on variation of the charging time, thereby obtaining pre-stress variation of the steel strand. According to the invention, non-destructive measurement can be realized; convenient and rapid pre-stressing force detection can be realized; no condition restriction exists; and the apparatus and method are suitable for pre-stressing force detection on various occasions.

Owner:CHONGQING JIAOTONG UNIVERSITY

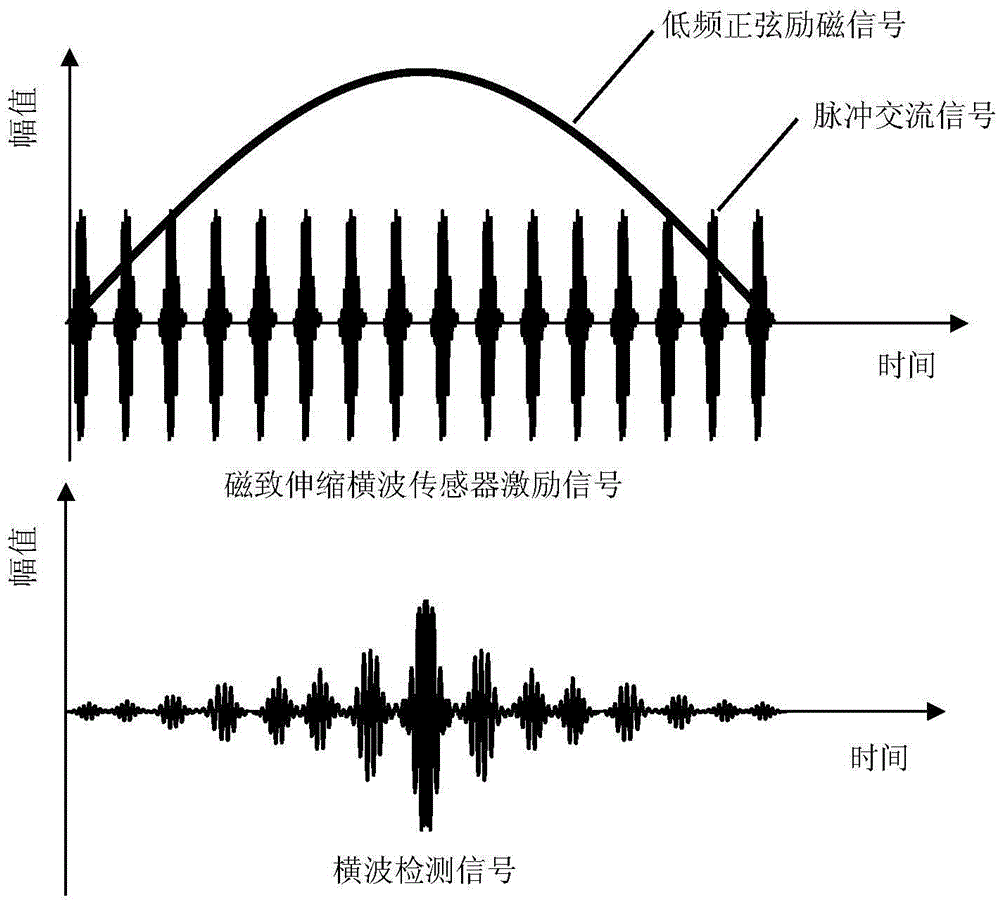

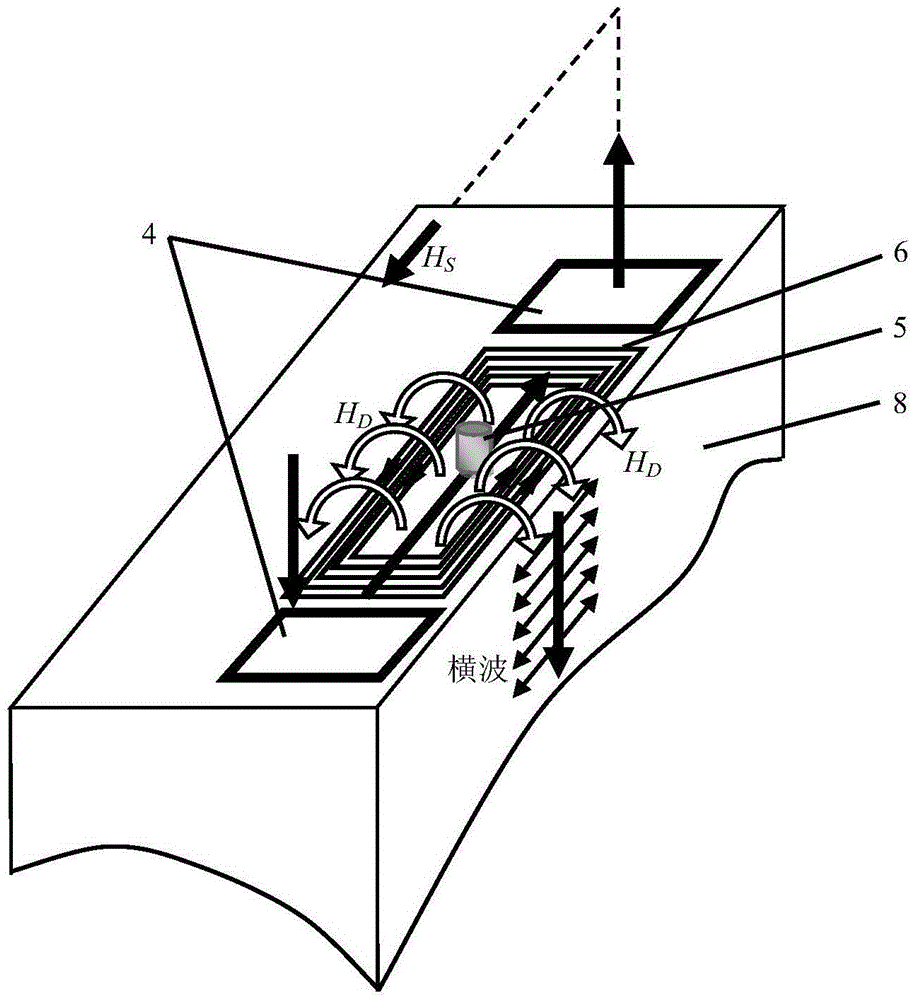

Welding residual stress ultrasonic evaluation method based on dynamic magnetostriction coefficient measurement

ActiveCN105606268ARealize non-destructive measurementForce measurement by measuring magnetic property varationMagnetic field magnitudeFerromagnetism

The invention discloses a welding residual stress ultrasonic evaluation method based on dynamic magnetostriction coefficient measurement. The fundamental principle of the welding residual stress ultrasonic evaluation method based on dynamic magnetostriction coefficient measurement is that a magnetostriction coefficient of ferro magnetic material is sensitive to stress; when the stress state of the ferro magnetic material is different, the magnetostriction coefficient curve changes so as to influence the magnetic-acoustic conversion efficiency. By means of measuring different magnetizing field intensity, a transverse wave reflection signal amplitude changing curve received by a magnetic induced shrinkage or elongation transverse wave sensor in a welding area can dynamically reflect the changing rule that the magnetostriction coefficient curve changes following the stress. By means of regulation and control of an electromagnet field current amplitude and a period, multi-time of equiamplitude excitation and reception for a transverse wave signal can be realized and a changing curve, that is a dynamic magnetostriction coefficient curve, that the amplitude of a transverse wave reflection signal changes following the change of a surface tangential magnetic field intensity. A transverse wave amplitude under any surface tangential magnetic field intensity or a gradient parameter of the dynamic magnetostriction coefficient curve can represent the magnitude of the residual stress of a welding area.

Owner:BEIJING UNIV OF TECH

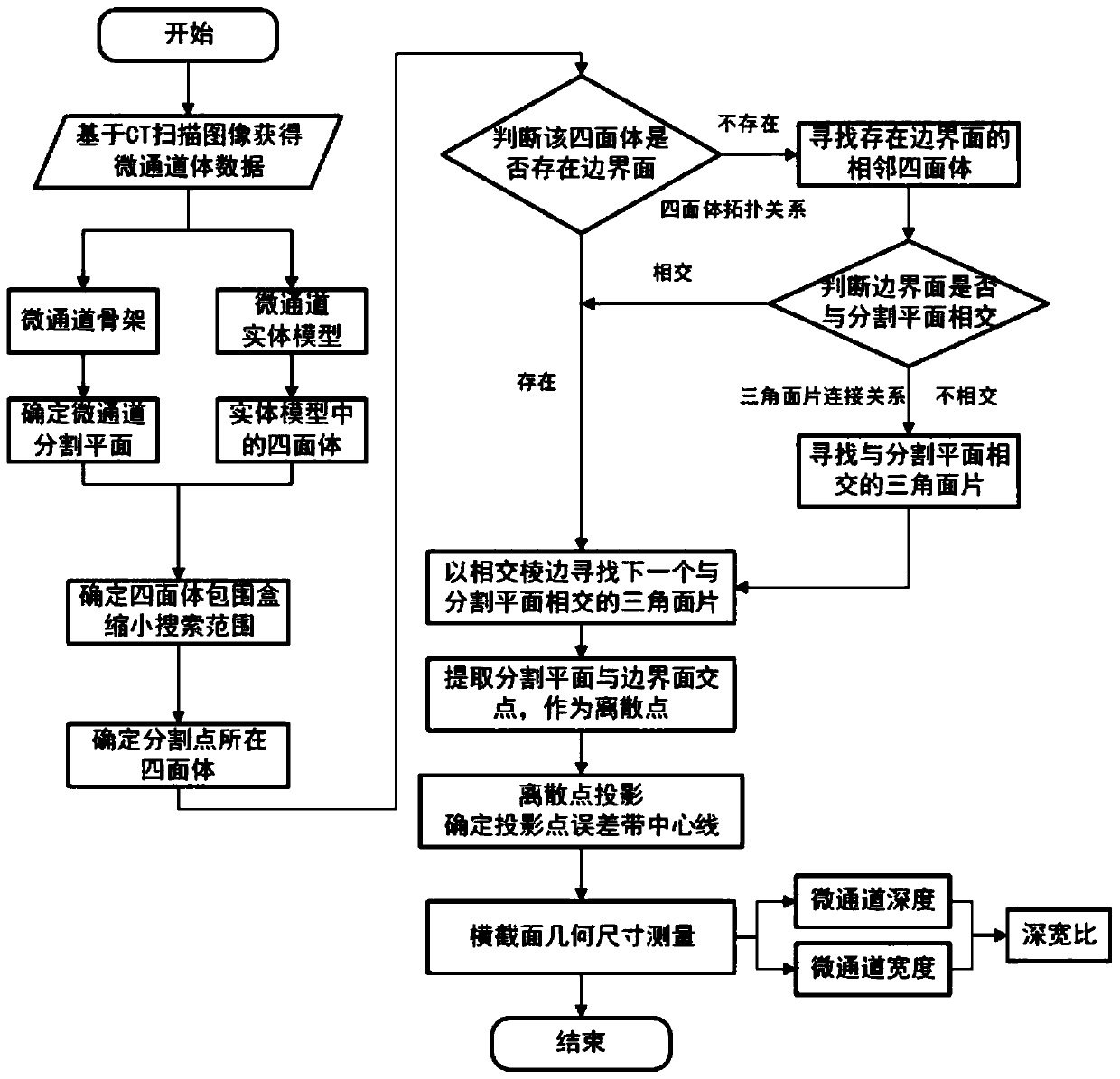

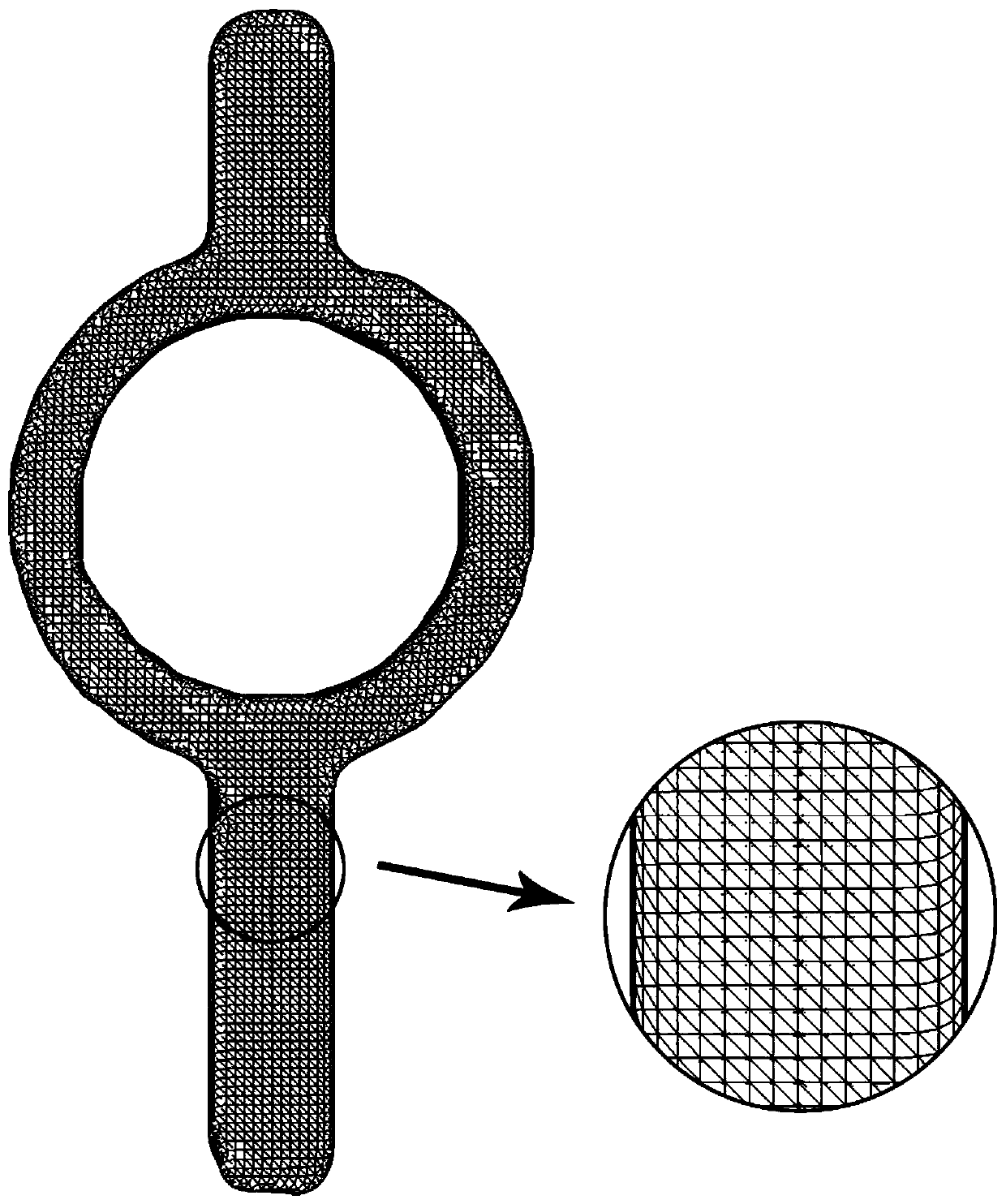

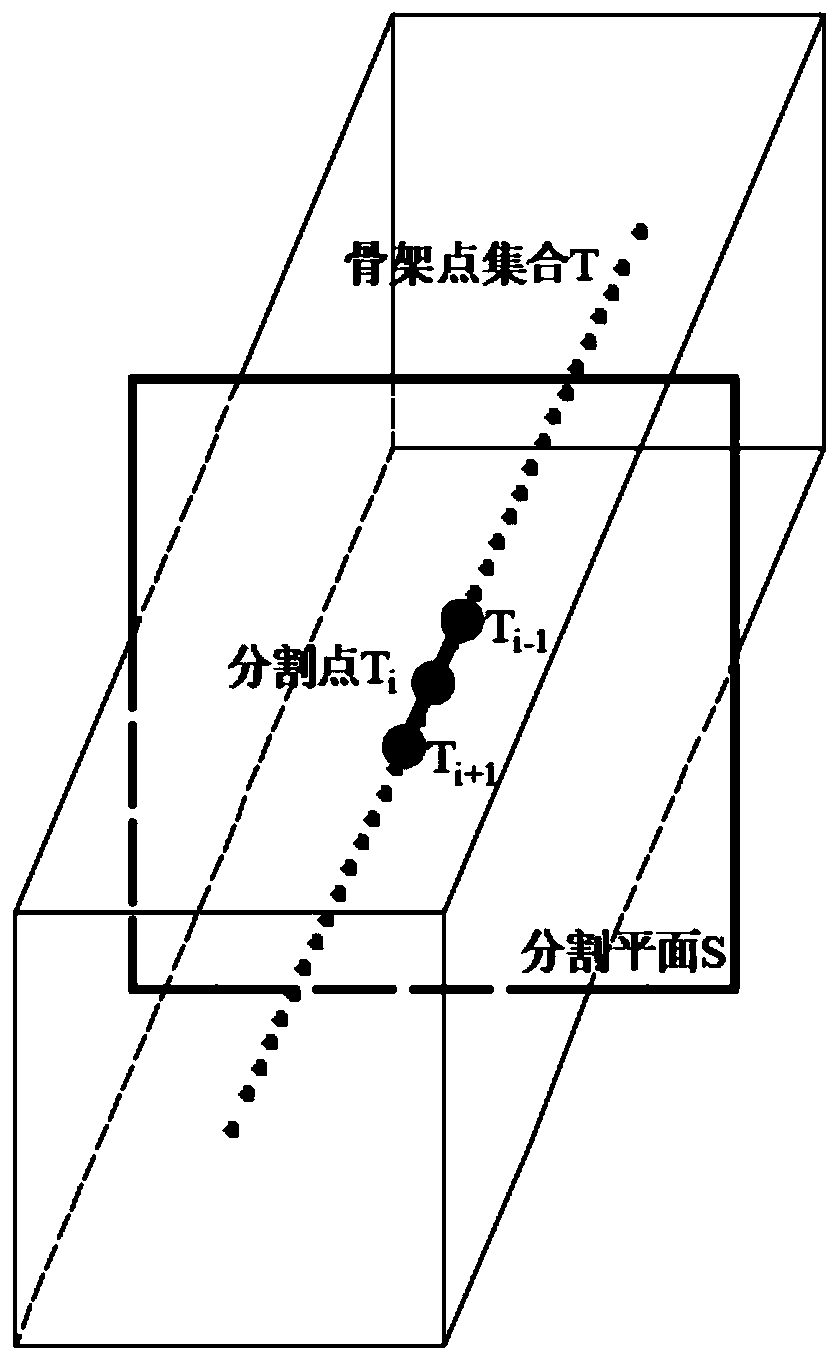

Micro-channel cross-section geometric dimension measurement method based on three-dimensional reconstruction model

ActiveCN109916935ARealize measurementRealize non-destructive measurementMaterial analysis using wave/particle radiationImage analysisDimension measurementComputer vision

The invention discloses a micro-channel cross-section geometric dimension measurement method based on a three-dimensional reconstruction model, comprising the steps of: establishing an entity model ofa micro-channel, and extracting a skeleton of the micro-channel; determining a micro-channel segmentation plane; extracting the intersections of the micro-channel segmentation plane and the tetrahedral boundary surface of the micro-channel entity model; and measuring the cross-section geometric dimension of the micro-channel. The micro-channel cross-section geometric dimension measurement methodbased on the three-dimensional reconstruction model can measure the cross-section geometric dimensions of different positions of the micro-channel with a high depth-to-width ratio, replaces a measuring method difficult to operate by the method of segmenting the entity model tetrahedron, and is easy to operate, wide in application range and accurate in cross-section segmentation. The method does not damage any structure, and realizes nondestructive measurement of the cross-section geometric dimension of the micro-channel.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

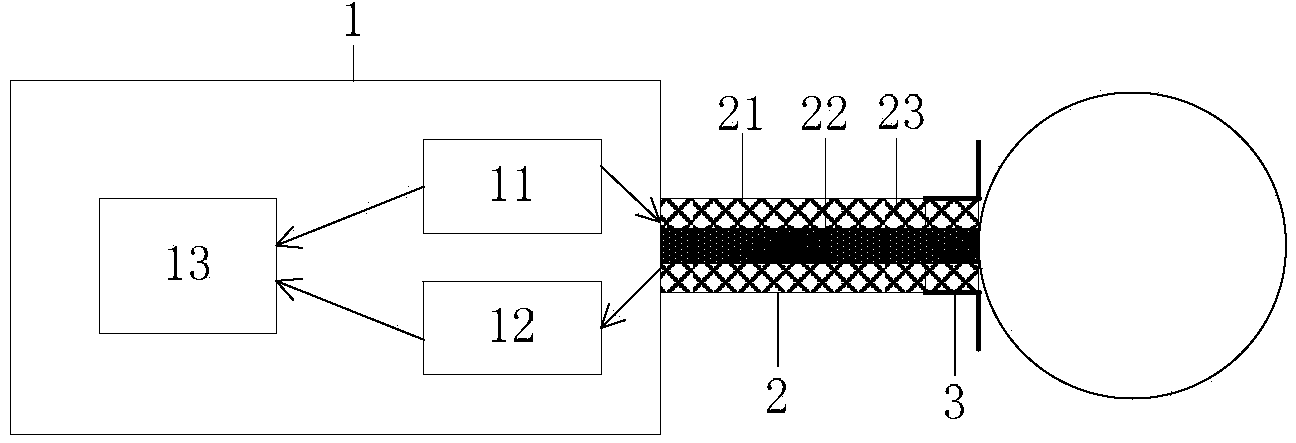

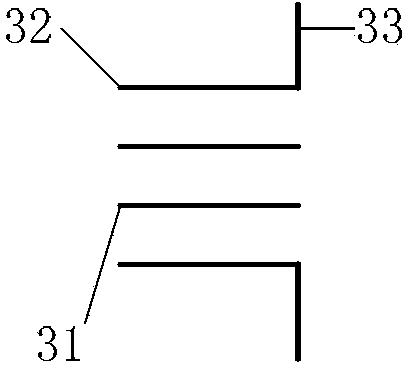

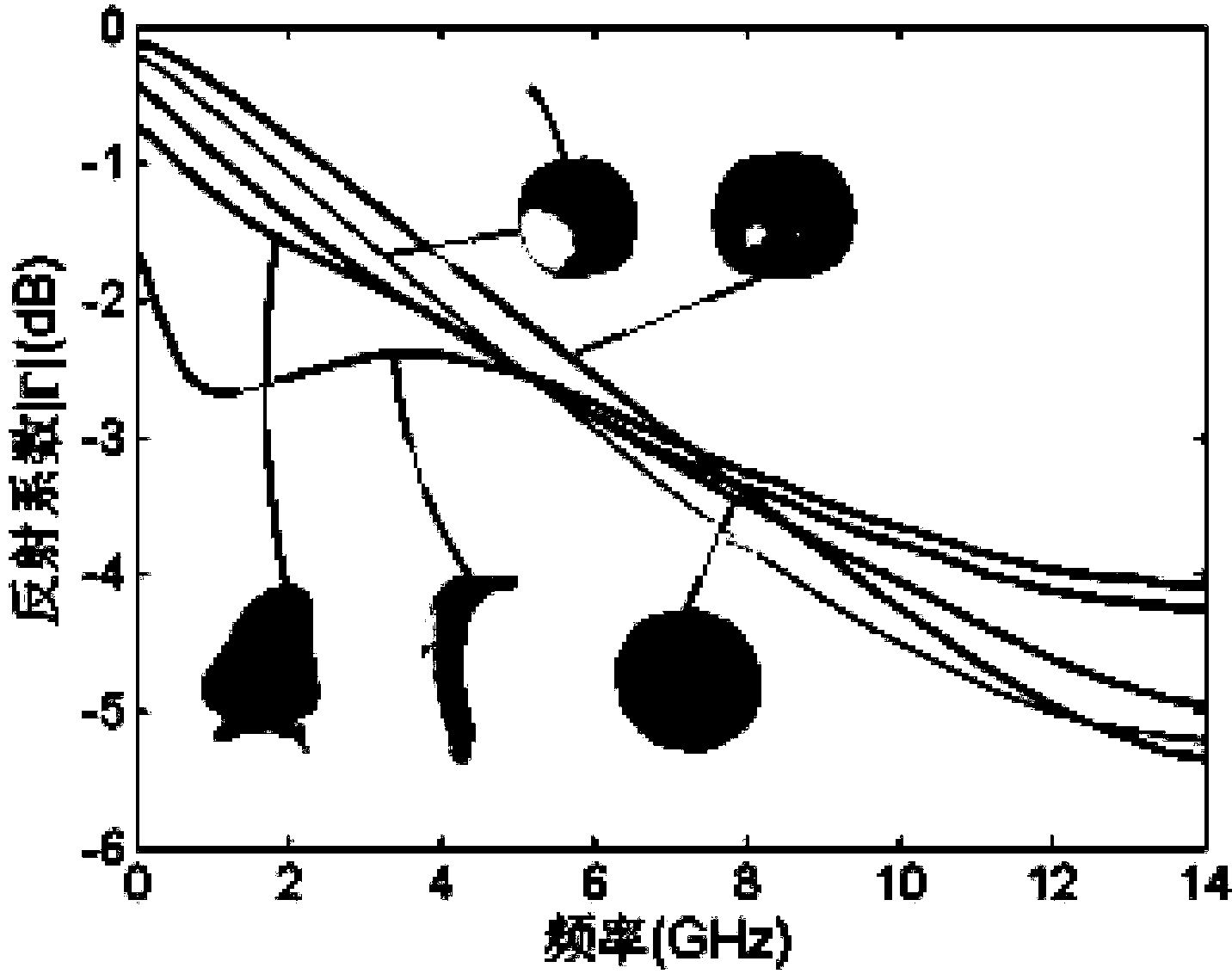

Device and method for carrying out microwave nondestructive measurement on characters of fruit and vegetable

InactiveCN103901049ARealize non-destructive measurementImprove discriminationMaterial analysis using microwave meansMicrowaveTransceiver

The invention discloses a device and a method for carrying out microwave nondestructive measurement on characters of fruit and vegetable. The device comprises a microwave transceiver, a microwave receiving and sending wire and a receiving and sending probe. The fruit and vegetable are measured by microwave, the microwave has the penetrability so as to be capable of penetrating through the surfaces of the fruit and vegetable and entering the interiors of the fruit and vegetable, the microwave is reflected when penetrating through the internal organization of the fruit and vegetable, and the total reflection wave reflects the moisture of the interiors of the fruit and vegetable and the situation of pulp organization. According to the device and the method for carrying out the microwave nondestructive measurement on the characters of the fruit and vegetable, the microwave nondestructive measurement on the characters of the fruit and vegetable is provided, so that the problem that the bought fruit and vegetable is not ideal caused by the fact that people can not well know the quality, especially the moisture content, of the fruit and vegetable in the daily life at present is solved, and the judgment and selection of the people on the quality of the fruit and vegetable in the daily life are facilitated; the main characteristic of the method is the realization of the nondestructive measurement on the characters of the fruit and vegetable, and meanwhile the operations are simple and convenient.

Owner:PEKING UNIV

High-sensitivity composite material structure health monitoring system

InactiveCN101865906AAvoid influenceRealize non-destructive measurementUsing fluid meansMaterial analysisFiberMonitoring system

The invention relates to a high-sensitivity composite material structure health monitoring system, which comprises a vacuum pump, a gas concentration sensor, a computer and two hollow fiber pipes which are alternatively parallel to each other and are arranged at intervals. One of the hollow fiber pipes is filled with special gas, and the other one of the hollow fiber pipes is vacuum pumped by a vacuum pump. When no crack exists, the special gas fiber pipe maintains at a given pressure value, the vacuum fiber pipe maintains at the vacuum state, and the pressure difference is constant. When crack exists, the special gas fiber pipe is communicated with the vacuum fiber pipe through the crack to cause the flow of the special gas under the driving of the pressure difference, so the concentrate of the gas inside the vacuum fiber pipe is changed. The concentration variation of the gas inside the vacuum fiber pipe is measured through the gas concentration sensor, and the size of the crack is calculated through the computer. The initiation and expansion process of the micro-crack can be monitored by monitoring the variation process of the gas concentration of the vacuum fiber pipe. The monitoring system has the advantages of real-time, simplicity, practicability and high reliability.

Owner:DONGHUA UNIV

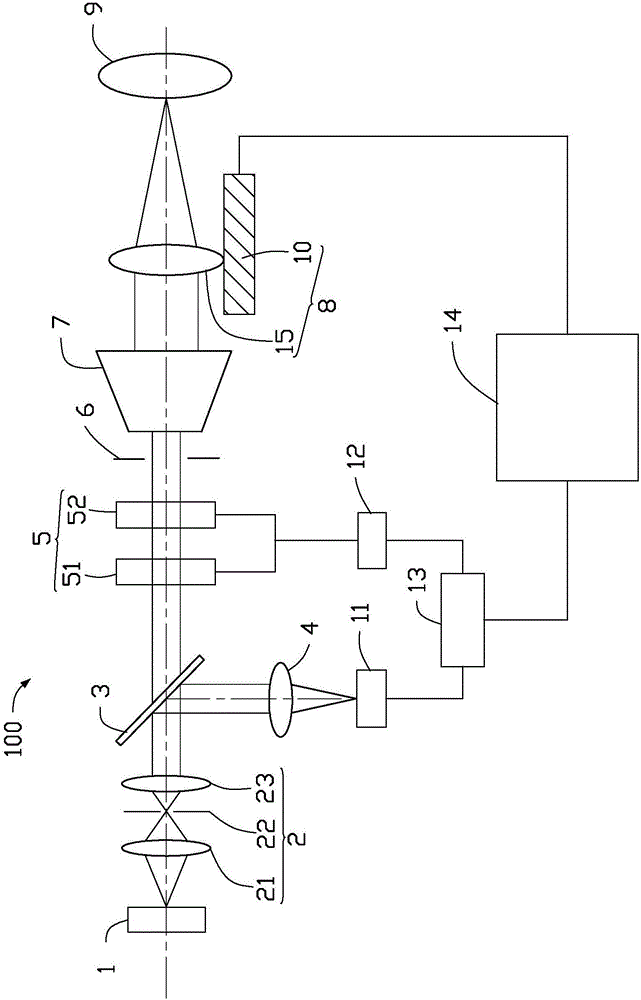

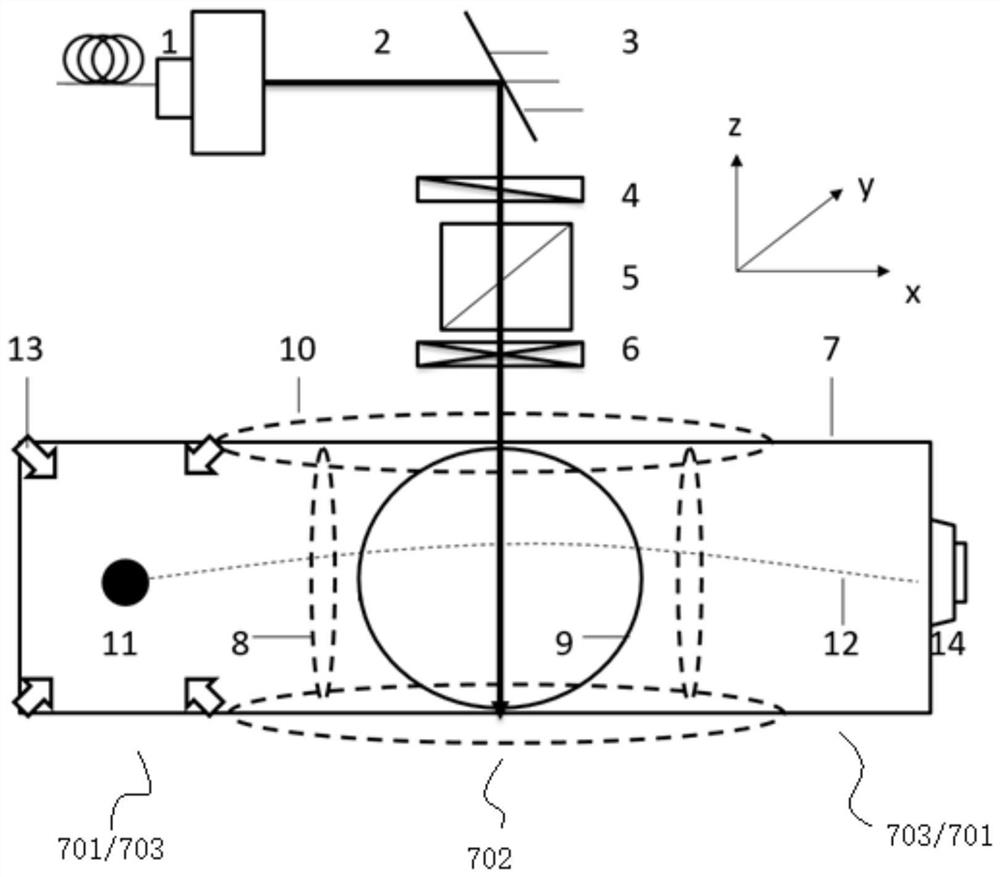

Apparatus and method for measuring spherical lens

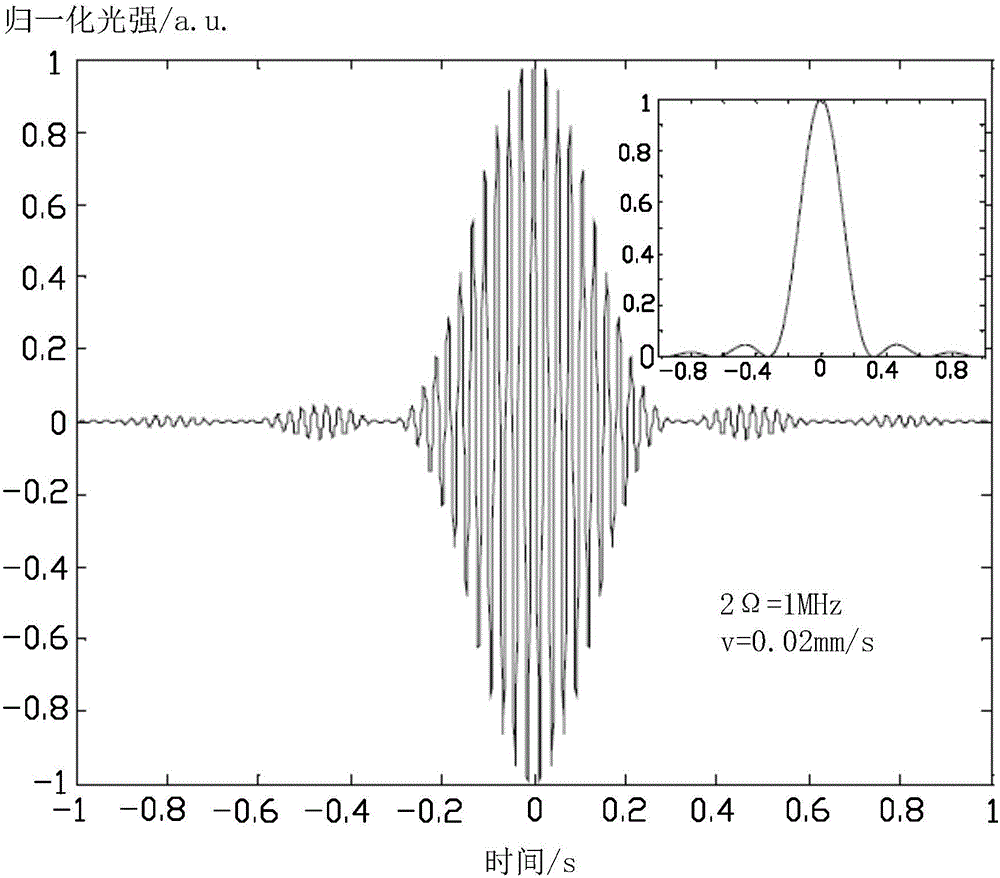

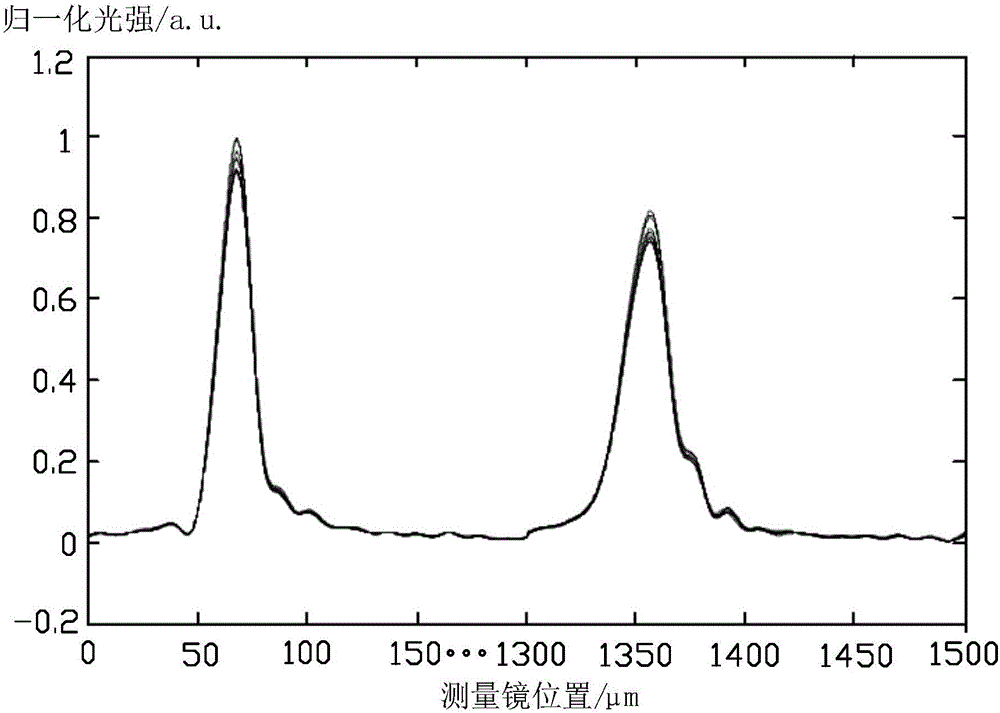

ActiveCN105783745ARealize simultaneous measurementRealize non-destructive measurementPhase-affecting property measurementsUsing optical meansPhotovoltaic detectorsLight beam

The invention provides an apparatus for measuring a spherical lens. The apparatus comprises a laser module group for continuously outputting laser, a spectroscope arranged on a laser path, an acousto-optic frequency shift module group arranged on transmitted light path to form measuring light, wherein the transmitted light is output by the spectroscope, a diaphragm and a beam expanding lens respectively arranged on the measuring light path to form beam expanding light, a measuring module group including a first measuring lens and a second measuring lens alternatively arranged on the beam expanding light path to form convergent laser beams, a lens to be measured arranged on the convergent laser beam path, a photoelectric detector arranged on the optical path of the reflected light output by the spectroscope, a referential signal module group connected with the acousto-optic frequency shift module group, a signal processing module group respectively connected with the photoelectric detector and the referential signal module group, and a computer connected with the signal processing module group and the measuring module group. The invention further relates to a method for measuring a spherical lens.

Owner:TSINGHUA UNIV

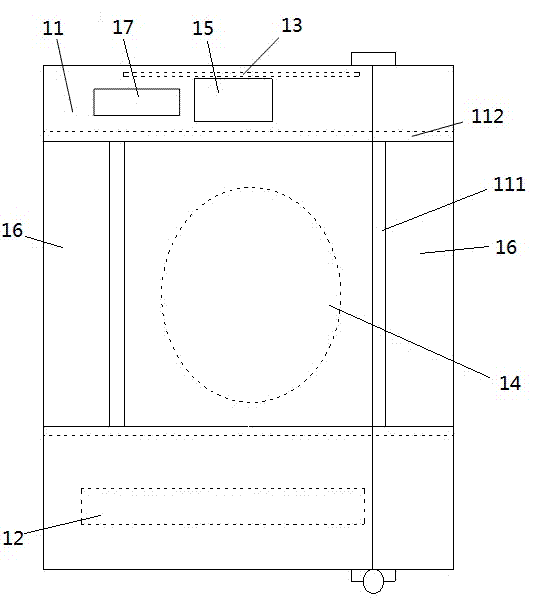

Workpiece thickness ultrasonic automatic detection system and method

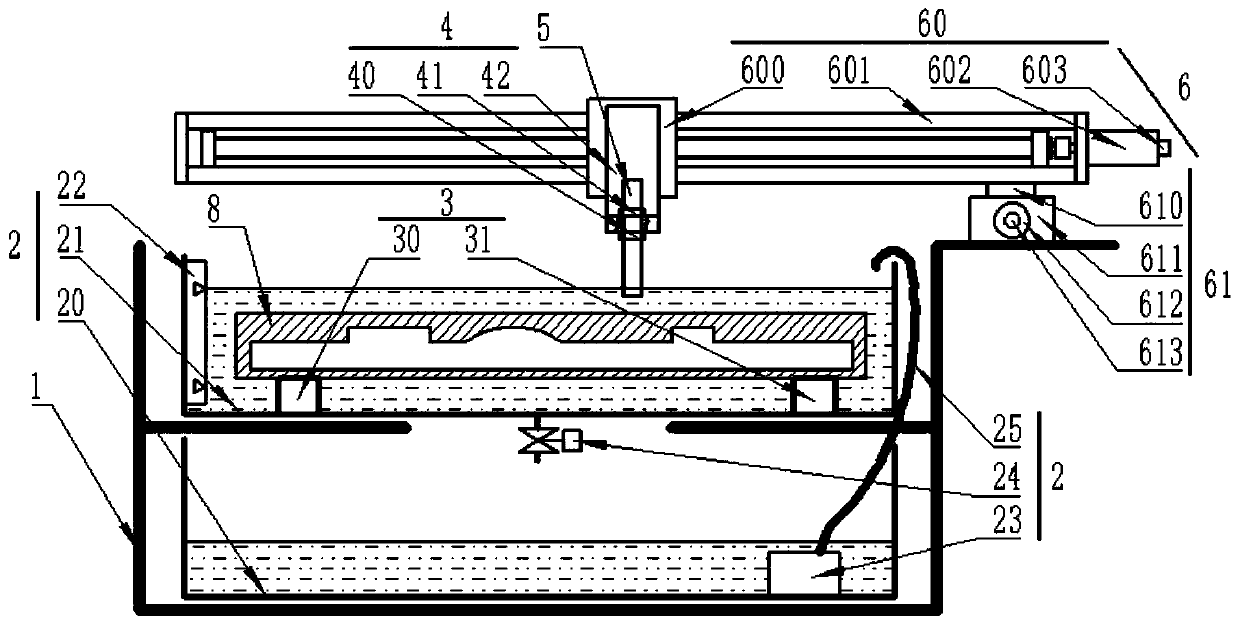

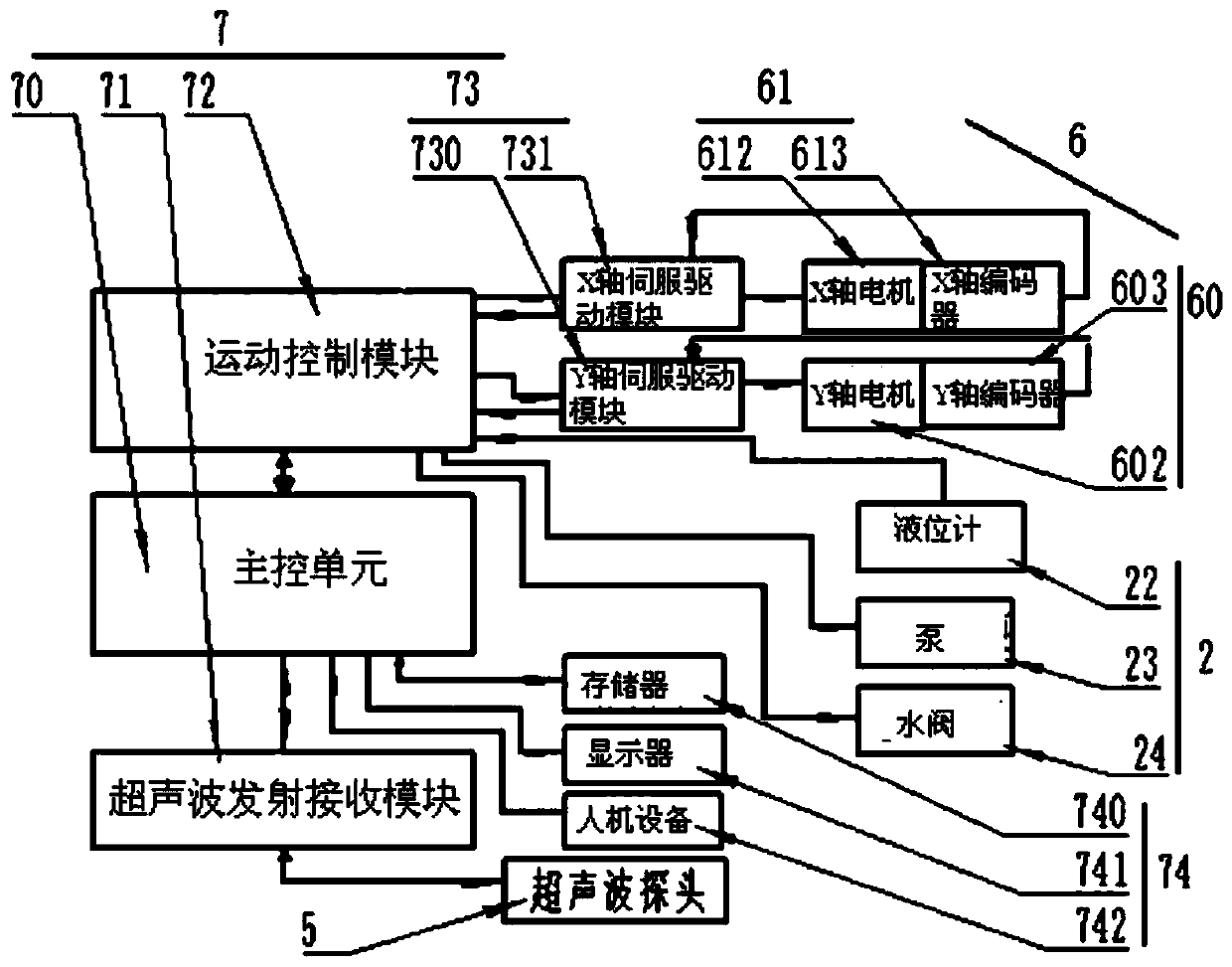

PendingCN110763170ARealize non-destructive measurementReduce thickness detection timeUsing subsonic/sonic/ultrasonic vibration meansNuclear energy generationElectric machineryPhysics

The invention discloses a workpiece thickness ultrasonic automatic detection system. In the system, an X axis main body is fixed on a side face of the top of a rack, an X axis sliding block is arranged on the X axis main body and can slide along an X axis on the X axis main body under driving of an X axis motor, one end of a Y axis main body is fixed on the X axis sliding block, and a Y axis sliding block is arranged on the Y axis main body and can slide along a Y axis on the Y axis main body under driving of a Y axis motor; a coupling agent storage vessel and a coupling agent working vessel are arranged in the rack, a pump is used for pumping the coupling agent in the coupling agent storage vessel into the coupling agent working vessel, and the coupling agent in the coupling agent workingvessel can flow back to the coupling agent storage vessel through a water valve; and an ultrasonic probe is mounted on the Y axis sliding block. The system provided by the invention realizes nondestructive measurement of workpiece thickness.

Owner:DONGFENG COMML VEHICLE CO LTD

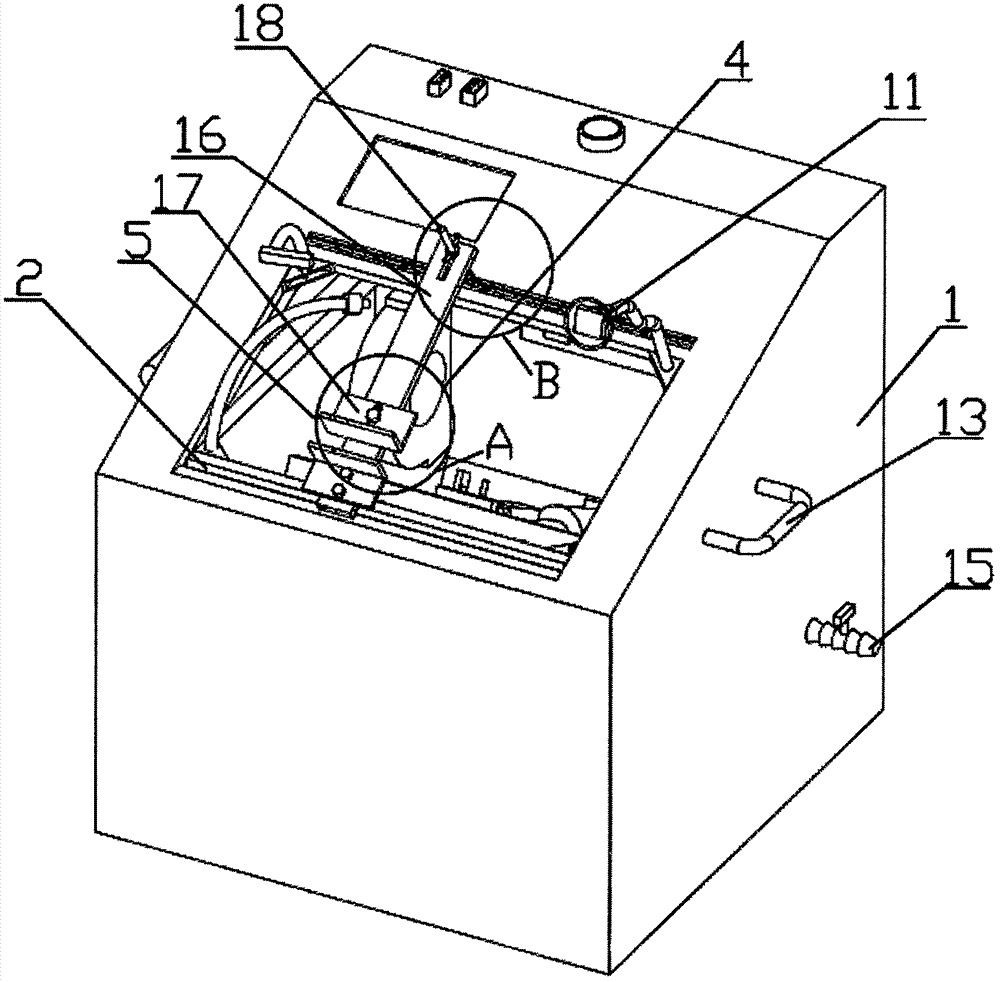

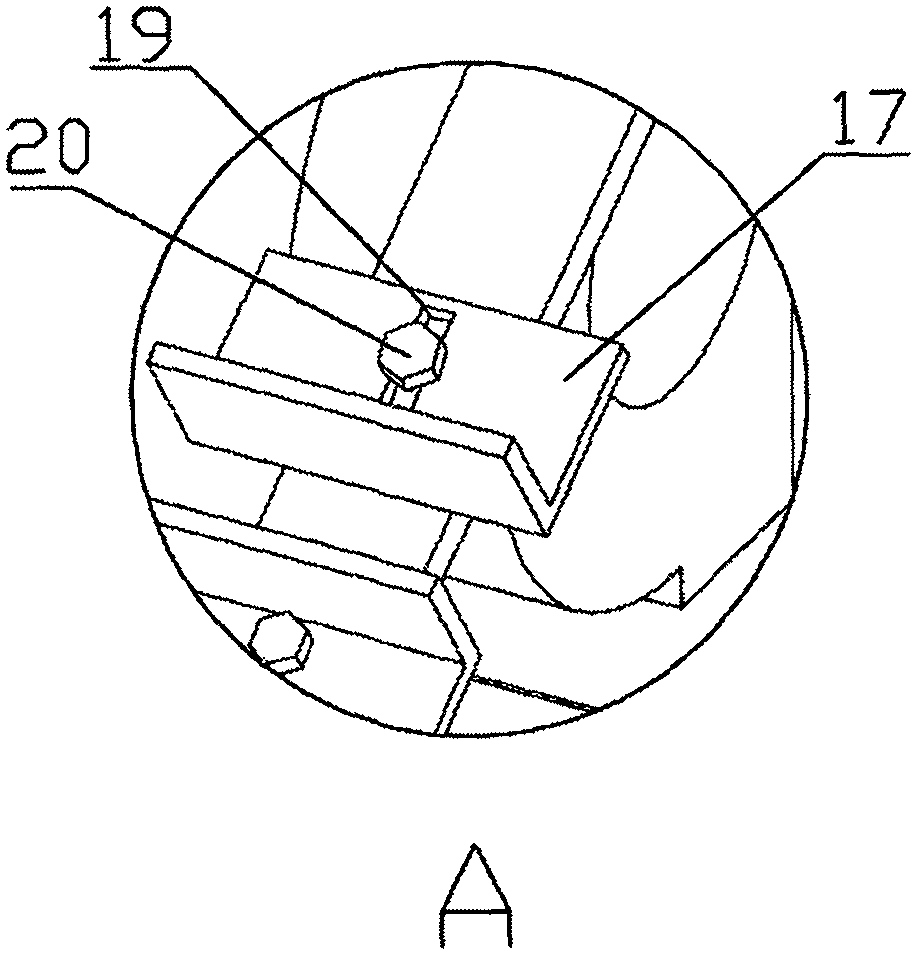

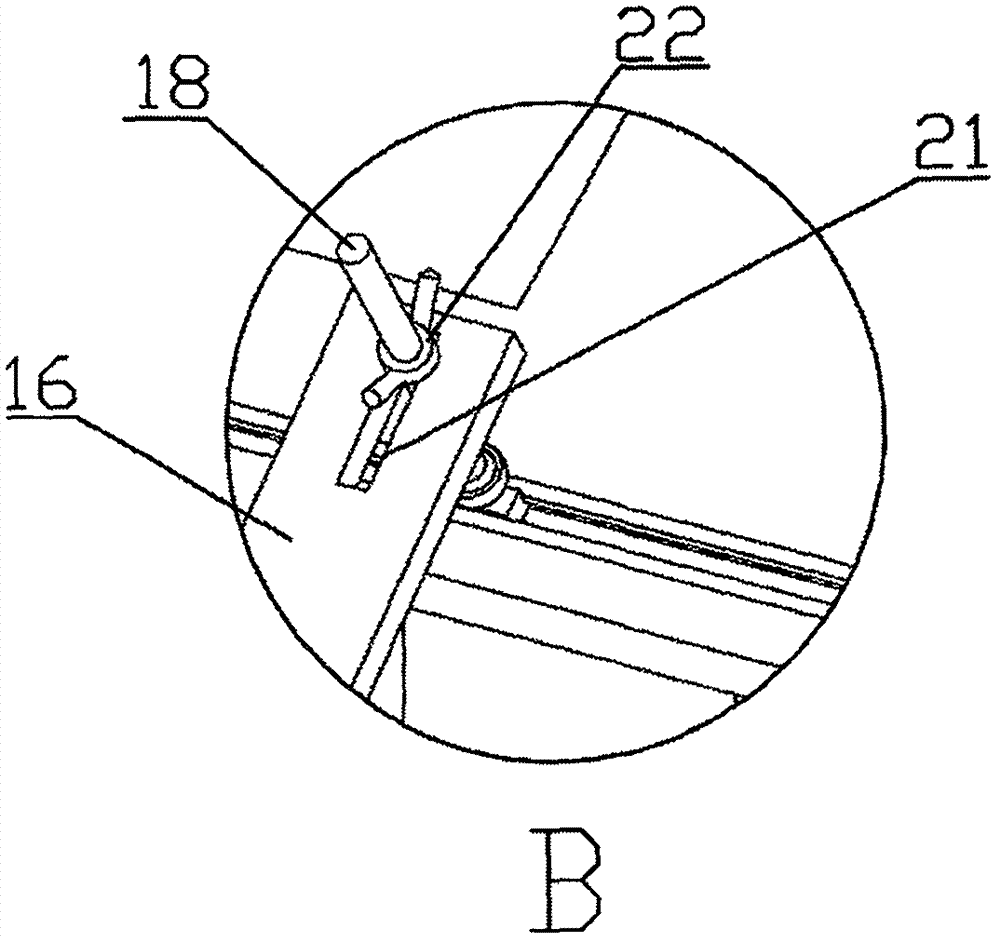

Comprehensive calibration apparatus for magnet-yoke magnetic particle flaw detector

PendingCN106940342ARealize non-destructive measurementHigh precisionMaterial magnetic variablesAviationElectrical resistance and conductance

The invention discloses a comprehensive calibration apparatus for a magnet-yoke magnetic particle flaw detector. The comprehensive calibration apparatus comprises an apparatus body, a magnetization current measuring mechanism, a force measuring mechanism and an image acquisition mechanism. According to the invention, a Hall sensor is arranged, a switching cable is individually defined, and standard aviation plugs are selected and used, so the comprehensive calibration apparatus can be matched with most to-be-detected flaw detectors, built-in cables in the to-be-detected flaw detectors are prevented from breaking and dismounting, and nondestructive measurement of magnetization current is realized; a sliding rail and a high-precision tension and pressure transducer (a strain gauge type transducer) are mounted, so force values are accurately measured, and the comprehensive calibration apparatus has high precision, a wide measurement range, long service life, simple structure and good frequency response characteristics; and an arranged image acquisition module employs a contrast focusing type CCD photosensitive element with 3000, 000 physical pixels, so the comprehensive calibration apparatus has the advantages of high resolution, low interference by thermal noise, high automatic focusing efficiency, etc.

Owner:沧州市计量测试所

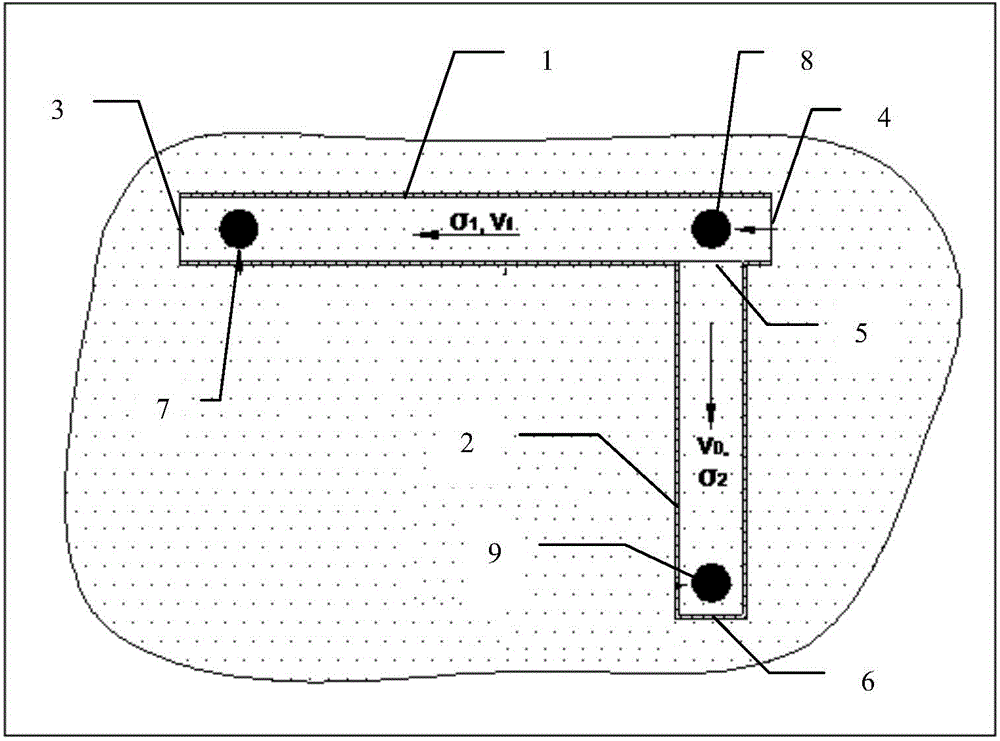

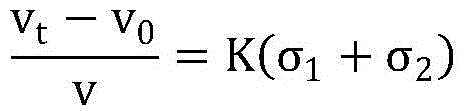

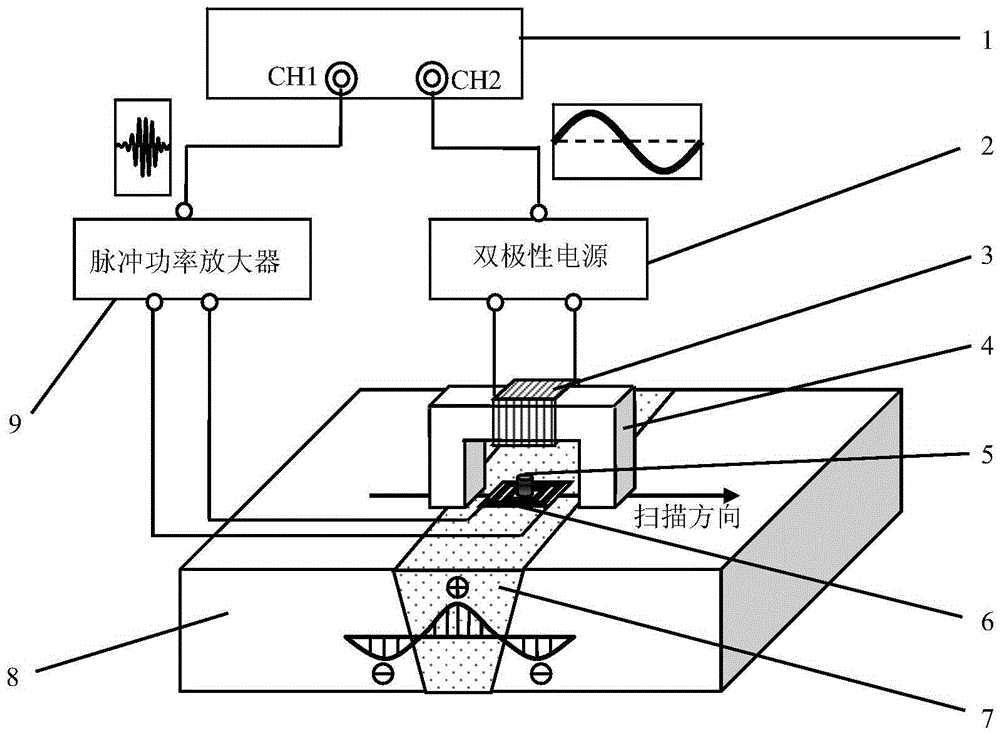

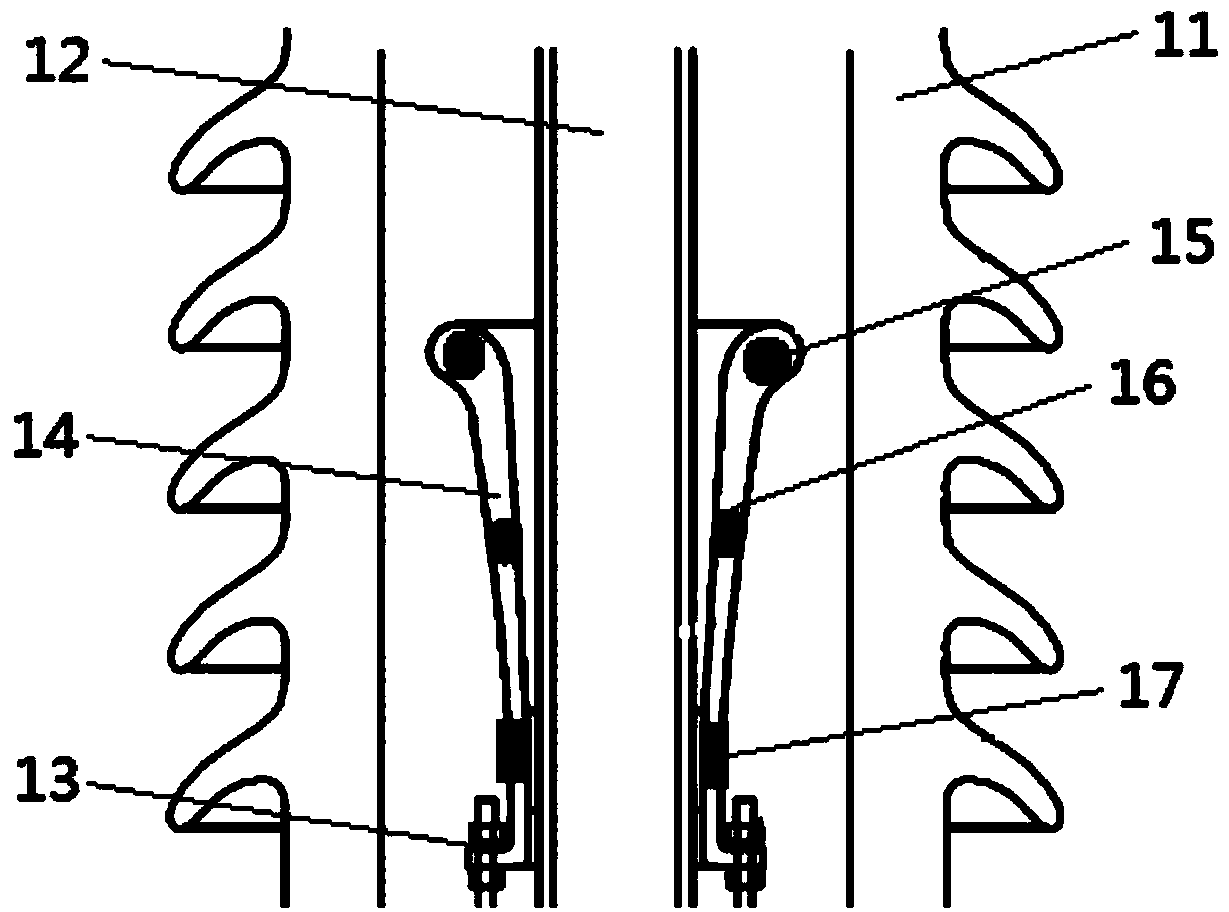

Stress distribution measuring device and method based on ultrasonic side waves

The invention provides a stress distribution measuring device and method based on ultrasonic side waves and belongs to the field of nondestructive testing. A lifting platform in the device fixes and lifts a measured assembly to a designated position; the motion control module can realize accurate positioning of the angle-adjustable probe and accurate control of scanning motion; the transmitting orreceiving angle of the angle-adjustable probe is adjusted according to the calculated first critical angle; X-direction and Y-direction scanning step lengths are set, and the angle-adjustable probe is driven to perform X-direction and Y-direction scanning by the motion control module till measurement of the whole contact interface is completed; in the measurement process, an ultrasonic side wavesignal measured by the angle-adjustable probe is transmitted to the PC through the control loop; and the stress distribution of the contact interface is obtained according to the relationship betweenthe ultrasonic side wave signal and the contact stress. According to the method, measurement of contact interface stress distribution of assemblies with different structures can be realized, measurement precision is high, the universality is good, the automation degree is high, and the method can be applied to measurement of large-batch and complex-structure assemblies.

Owner:HARBIN ENG UNIV

Measurement device of diameter of plant stalk

InactiveCN103090803AAvoid damageRealize non-destructive measurementUsing optical meansMechanical measuring arrangementsElectrical resistance and conductanceMeasurement device

The invention relates to the field of agricultural engineering, in particular to a measurement device of the diameter of a plant stalk. The measurement device comprises a bracket, a light source and a photoresistance. The bracket comprises a surrounded wall and a valve which commonly define a measurement hole for the stalk of a plant to be measured to enter from the valve. The light source and the photoresistance are assembled on the bracket in a mutual contraposition mode and are arranged on two sides of measurement hole. A display screen is connected on the photoresistance through an analog-digital (A / D) conversion device. When the measurement device is used, at first, the valve is opened to ensure that the stalk of the plant to be measured is arranged inside the measurement hole along a radial direction and certain distance is kept between the plant stalk and the bracket; then the valve is closed, the light source is opened, light of the light source arrives at the surface of the photoresistance through gaps between the stalk and the bracket, and therefore lighting regions of the photoresistance differ, and the photoresistance correspondingly outputs different resistance values; and the resistance values are converted by the A / D conversion device and the diameter of the plant stalk is directly displayed on the display screen, precision is guaranteed in the measurement process and the stalk can be prevented from being damaged.

Owner:HENAN UNIV OF SCI & TECH

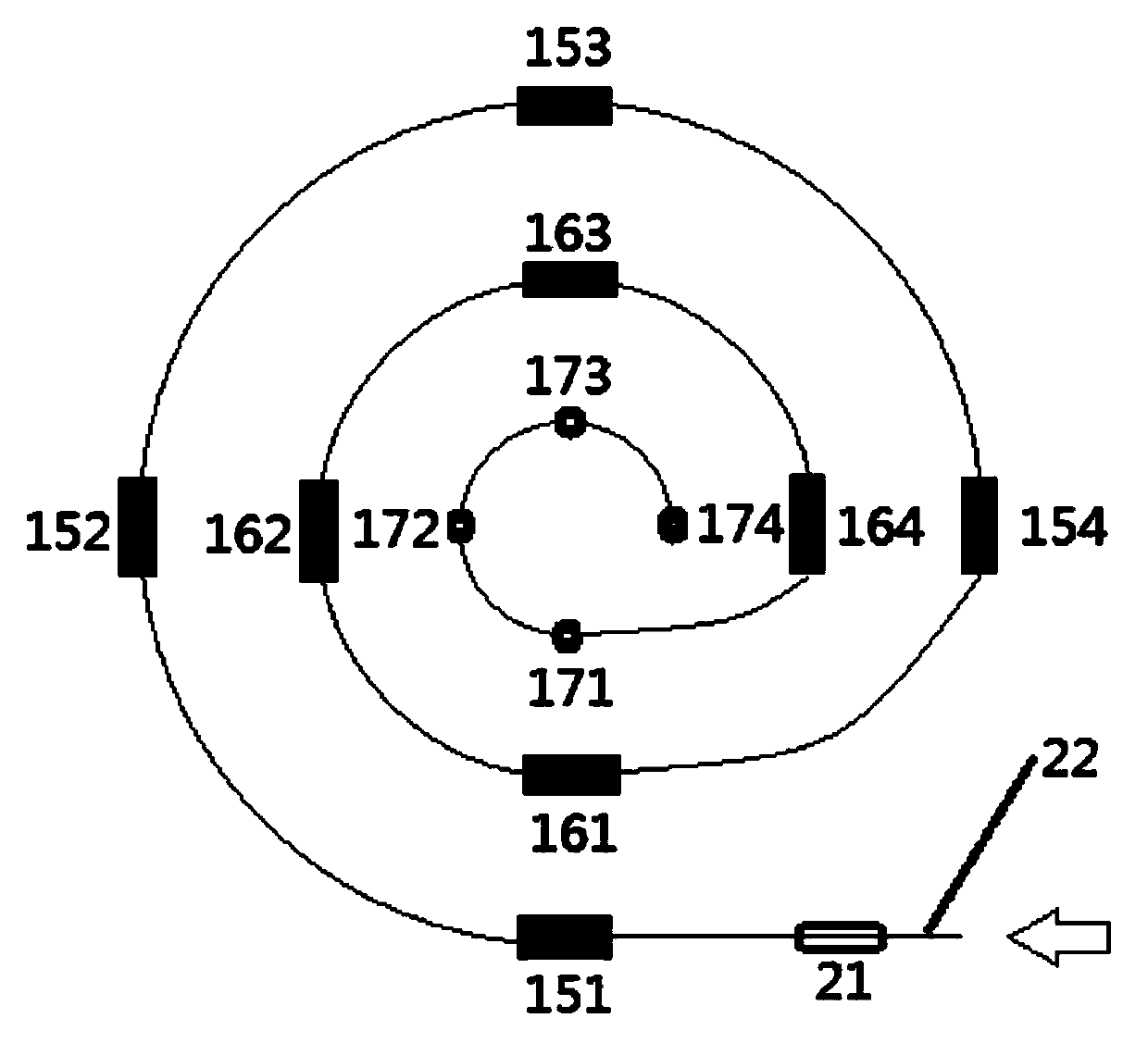

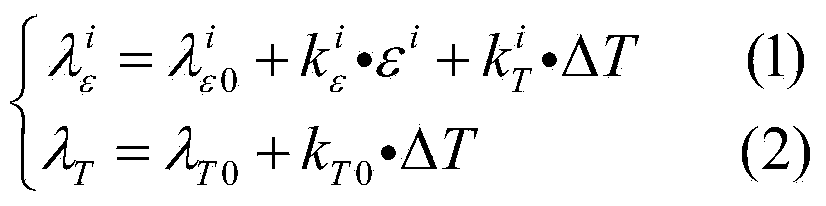

Intelligent cable stress cone

InactiveCN104197990AInsulation properties do not affectLittle impact on mechanical propertiesCable fittingsConverting sensor output opticallyStress distributionGrating

The invention discloses an intelligent cable stress cone comprising a porcelain sleeve, a cable insulation arranged in the porcelain sleeve, earthing bolts and a rubber stress cone body. The rubber stress cone body is fixed on a place nearing the ground through the earthing bolts and internally provided with a stress sensing fiber grating and a temperature sensing fiber bragg grating. The stress sensing fiber grating and the temperature sensing fiber grating are sequentially connected through a tightly-jacketed optical cable and spirally embedded in the rubber stress cone body when the rubber stress cone body grouts. According to the arrangement, during production of the stress cone, the stress sensing fiber grating and the temperature sensing fiber grating are directly embedded, stress distribution of the cable stress cone is calculated according to the real-time measurement of wave length of the fiber grating, and thus deformation of the stress cone is monitored in real time.

Owner:KINGSHORE NEW RESOURCES ELECTRIC JIANGSU

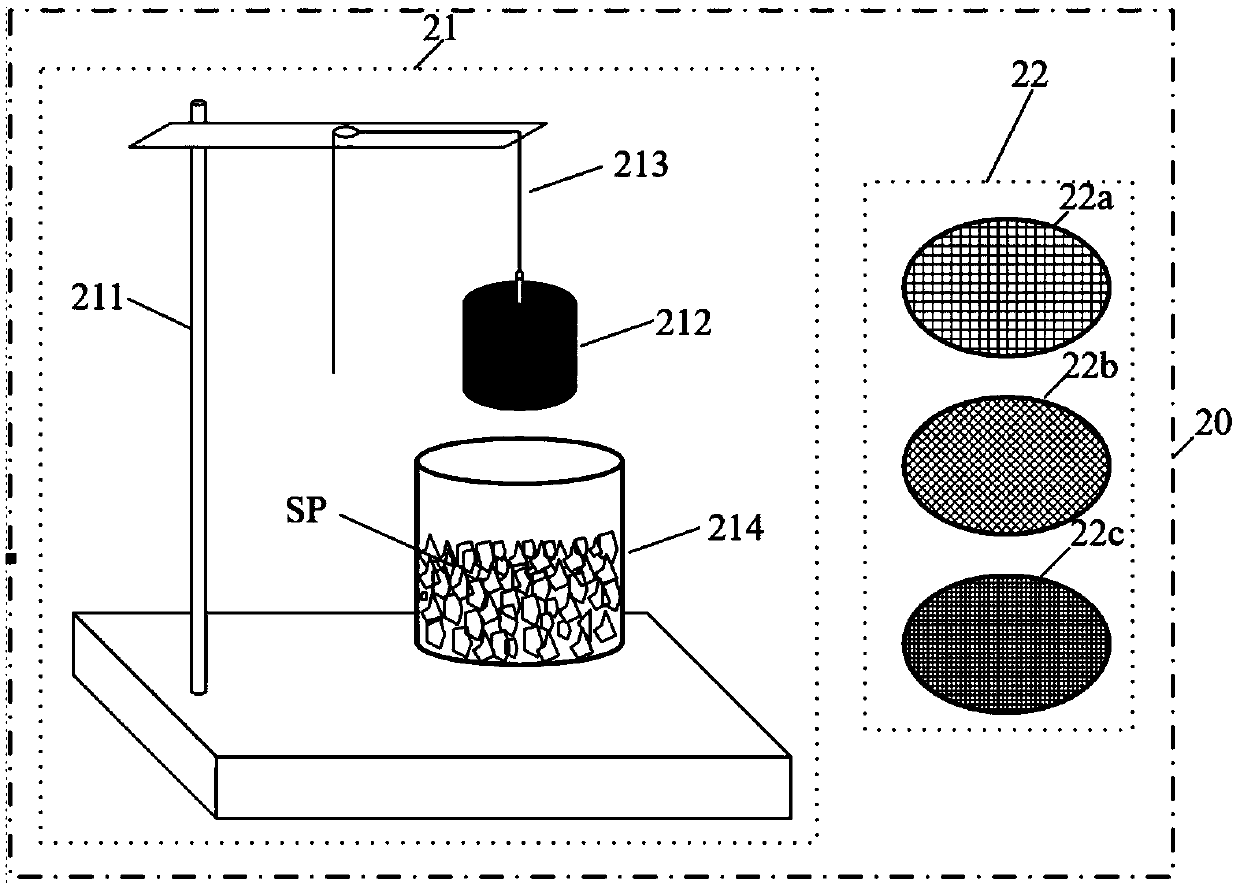

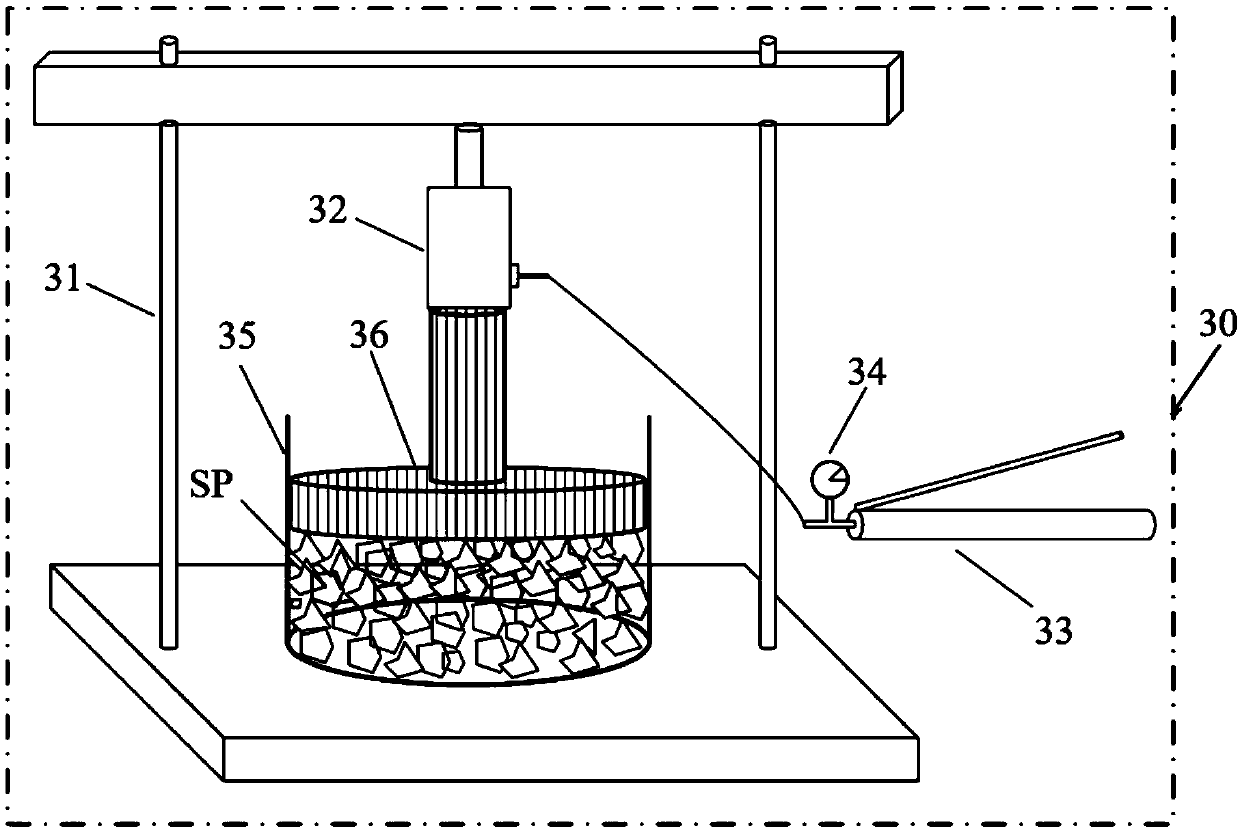

Coal-measure rock residual expansion coefficient measuring method and system

ActiveCN109521185ARealize non-destructive measurementPowerfulEarth material testingCoal measuresFixed frame

The invention provides a coal-measure rock residual expansion coefficient measuring method and system. The coal-measure rock residual expansion coefficient measuring method is characterized by comprising the steps that 1, the initial volume V initialization is measured; 2, a to-be-measured rock is placed in a stamping cylinder, through a cotton rope, a drop hammer is fixed into a fixing frame, andis lifted to be at a certain height, the fine rope is loosened to make drop hammer fall into the stamping cylinder to crush the rock, crushing operation is repeated until the fragmentation of the to-be-measured rock meets the requirements, and fragments of the to-be-measured rock are placed in sampling meshes for separation; 3, the fragments of the to-be-measured rock are placed in a pressing cylinder, through a hydraulic oil pump, a portable hydraulic jack installed on a rack is driven to extend for a certain height, then a load transmission column is pushed to transmit downward pressure tothe fragments of the to-be-measured rock in the pressing cylinder, stress pressure is applied on the fragments of the to-be-measured rock, and the volume after crushing is conducted is calculated; 4,a rock residual expansion coefficient is calculated.

Owner:WUHAN UNIV

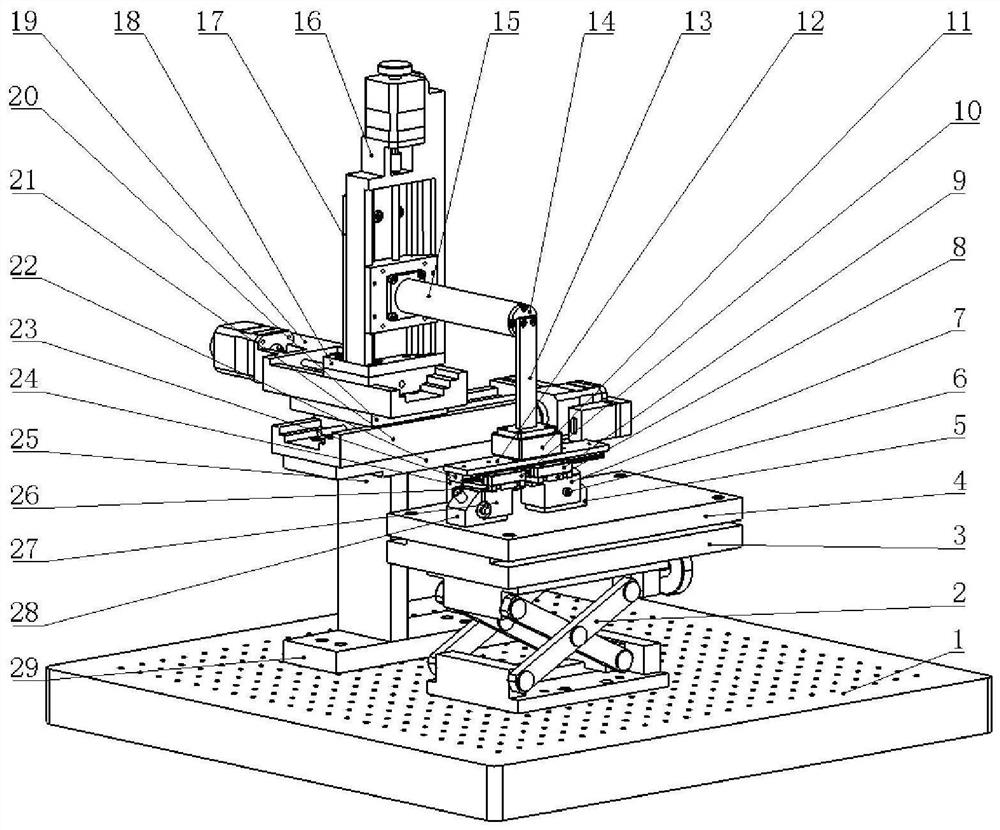

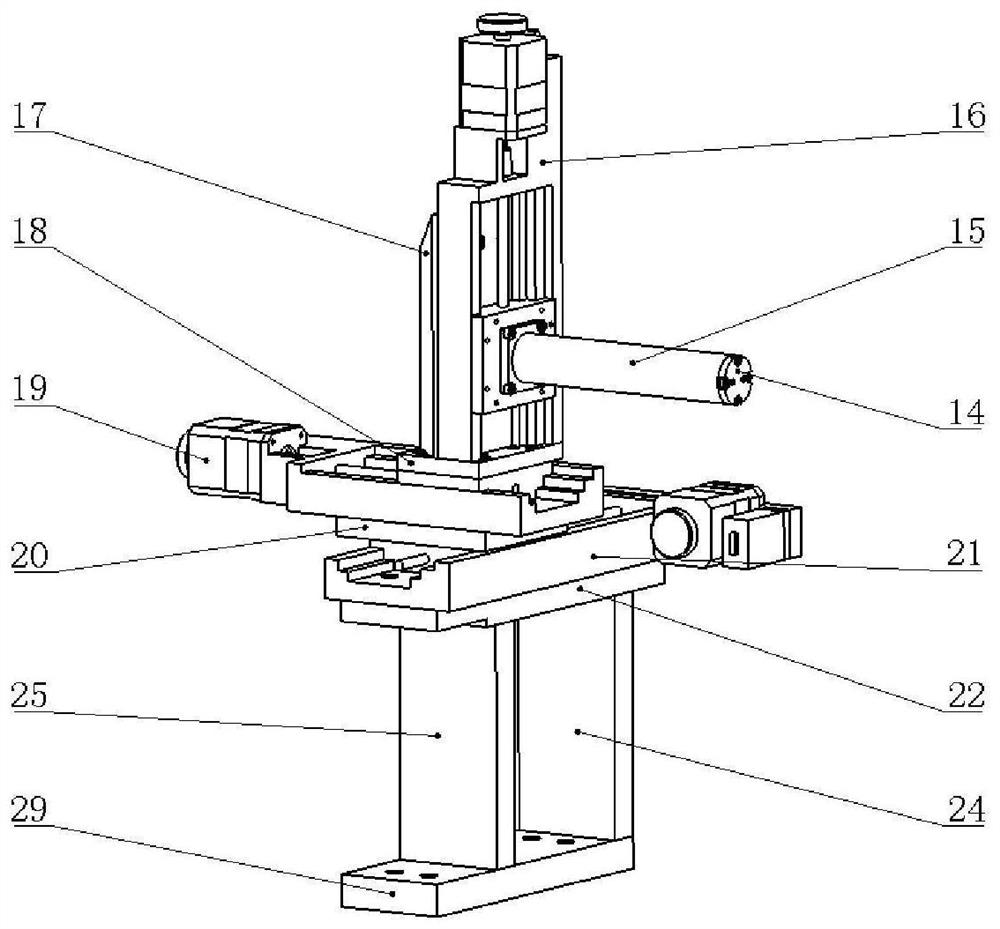

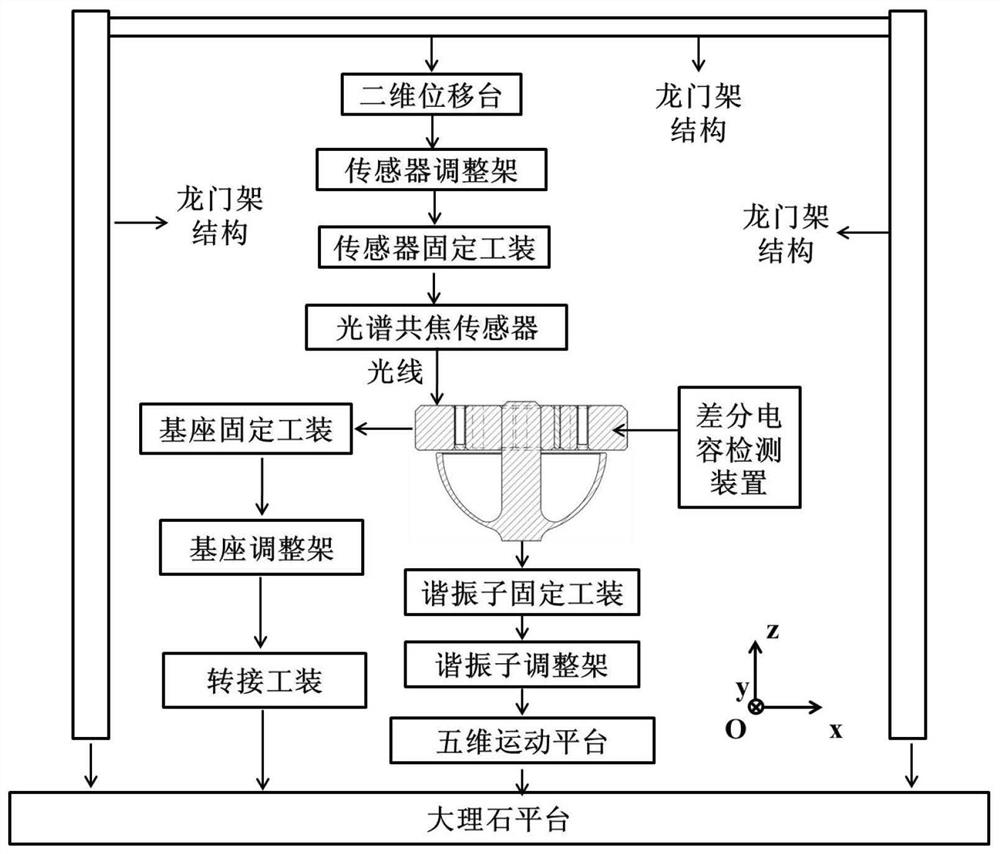

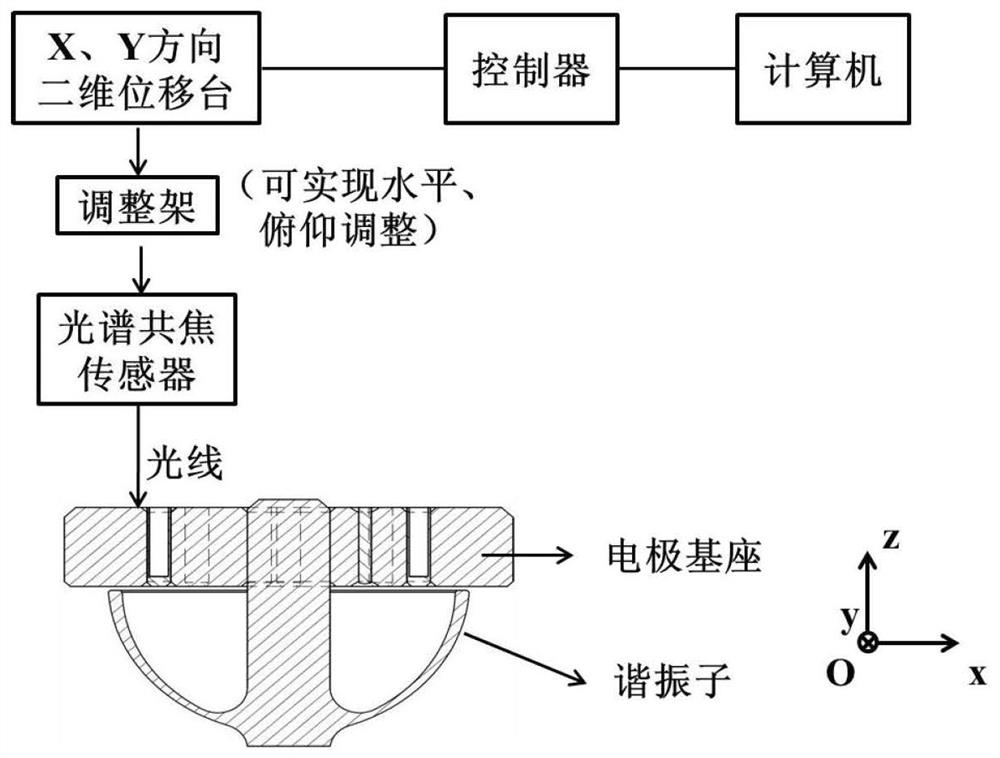

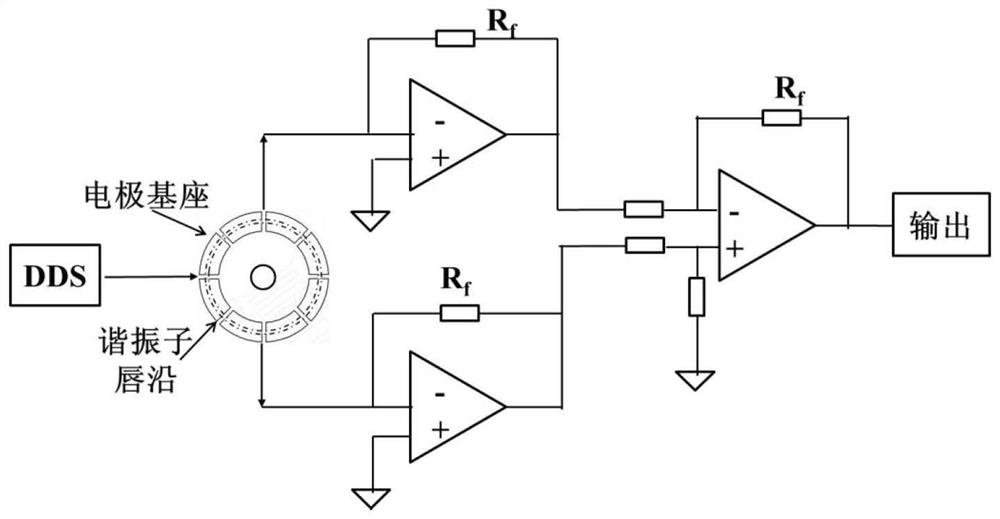

Precision assembly device and method for hemispherical resonator gyroscope with planar electrode structure

ActiveCN113804172ASolving accurate measurementsImprove performanceSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesPlanar electrodeRadial position

The invention relates to a precision assembly device and method for a hemispherical resonator gyroscope with a planar electrode structure. The method comprises the steps of obtaining a gap between a harmonic oscillator and a base electrode through a spectrum confocal sensor, and achieving the adjustment of the gap through a multi-degree-of-freedom positioning platform according to the numerical values of the gap in four directions; and obtaining the radial position deviations of the oscillator and the electrode base in the X-axis direction and the Y-axis direction through a differential capacitance detection device, feeding the radial position deviations back to a multi-axis displacement platform control system, and then achieving the function of high-precision adjustment of the radial position deviation. According to the invention, the position deviation and pitching and rolling deviation between the harmonic oscillator and the electrode base in the X, Y and Z directions can be detected and adjusted in a high-precision manner, the problems of accurate measurement and adjustment of the gap and radial position deviation between the harmonic oscillator and the base electrode of the hemispherical resonator gyroscope with the planar electrode structure are solved, the consistency of a gyroscope header is improved, the gyroscope performance is further improved, and the development requirements of a high-precision hemispherical resonator gyroscope are met.

Owner:TIANJIN NAVIGATION INSTR RES INST

Shaft force measuring sensor

The invention discloses a shaft force measuring sensor that can be used to measure an instant impact force on an installing shaft in the complex condition. The sensor comprises a group of strain gauges arranged in radial symmetry and a sensor body. When a load is acted on the radial direction of the shaft force sensor, a Wheatstone half-bridge circuit composed of the foil gauges measure the bending strain of the sensor body. The size of the sensor is the same with that of the installing shaft of a device, and can be replaced without loss in the using process. The problems that a traditional shaft force sensor is large in size, high in additional weight, changes the original installation state and further causes a large measurement error are solved.

Owner:NANJING UNIV OF SCI & TECH

Method for calculating tree crown surface area based on three-dimensional laser scanning data

The invention discloses a method for calculating tree crown surface area based on three-dimensional laser scanning data. According to the method, voxel treatment of tree point cloud data acquired by athree-dimensional laser scanner are performed by the three-dimensional laser scanner, voxels are projected onto a horizontal plane, the number of independent edges of all layers is counted, summed and then multiplied with the areas of the voxels to obtain the tree crown surface area. According to the method, field investigation cost is reduced by the aid of characteristics of flexibility and highefficiency of the three-dimensional laser scanner, the efficiency and the accuracy of field operation and indoor treatment of the volume and the area of a tree crown are improved, and the method overcomes the shortcomings that a past method causes high damage to a forest and is high in cost.

Owner:BEIJING FORESTRY UNIVERSITY

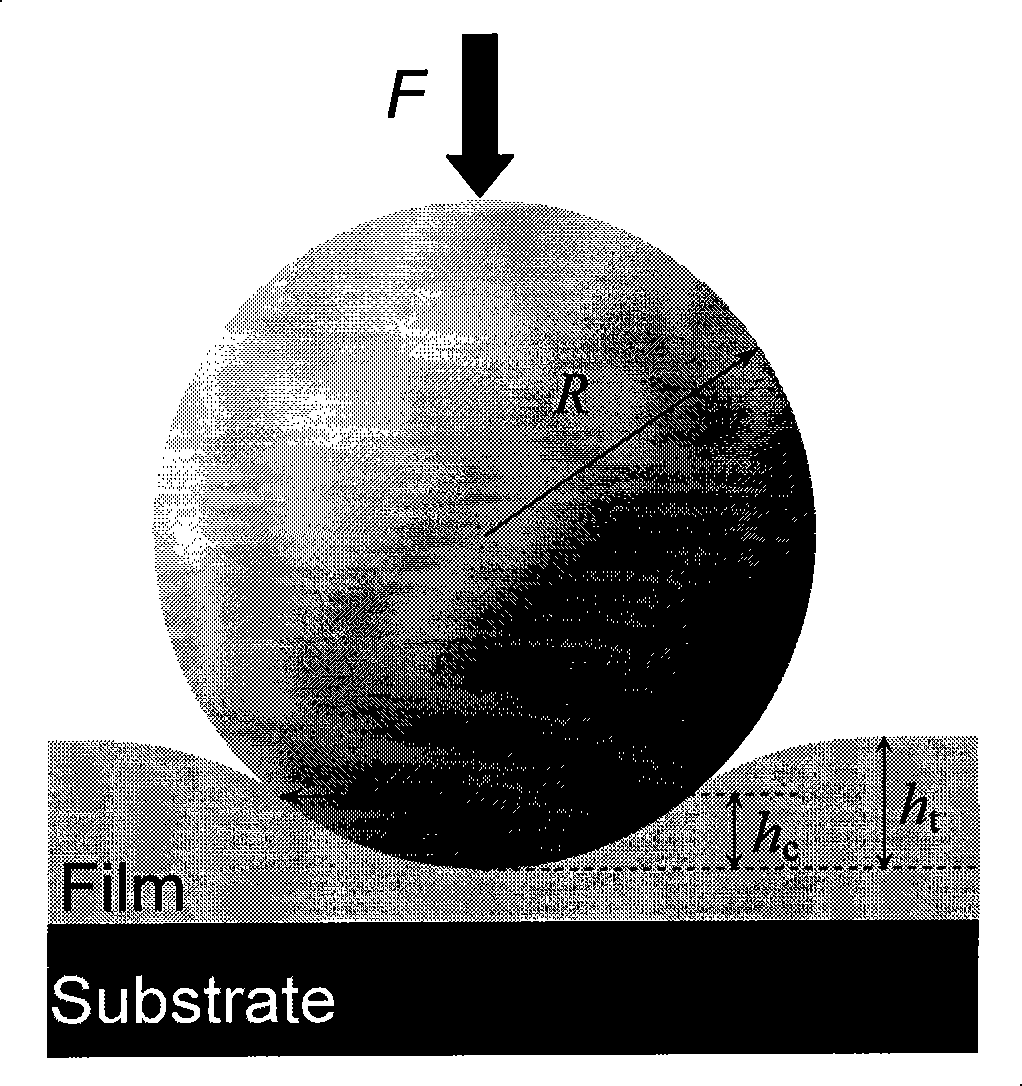

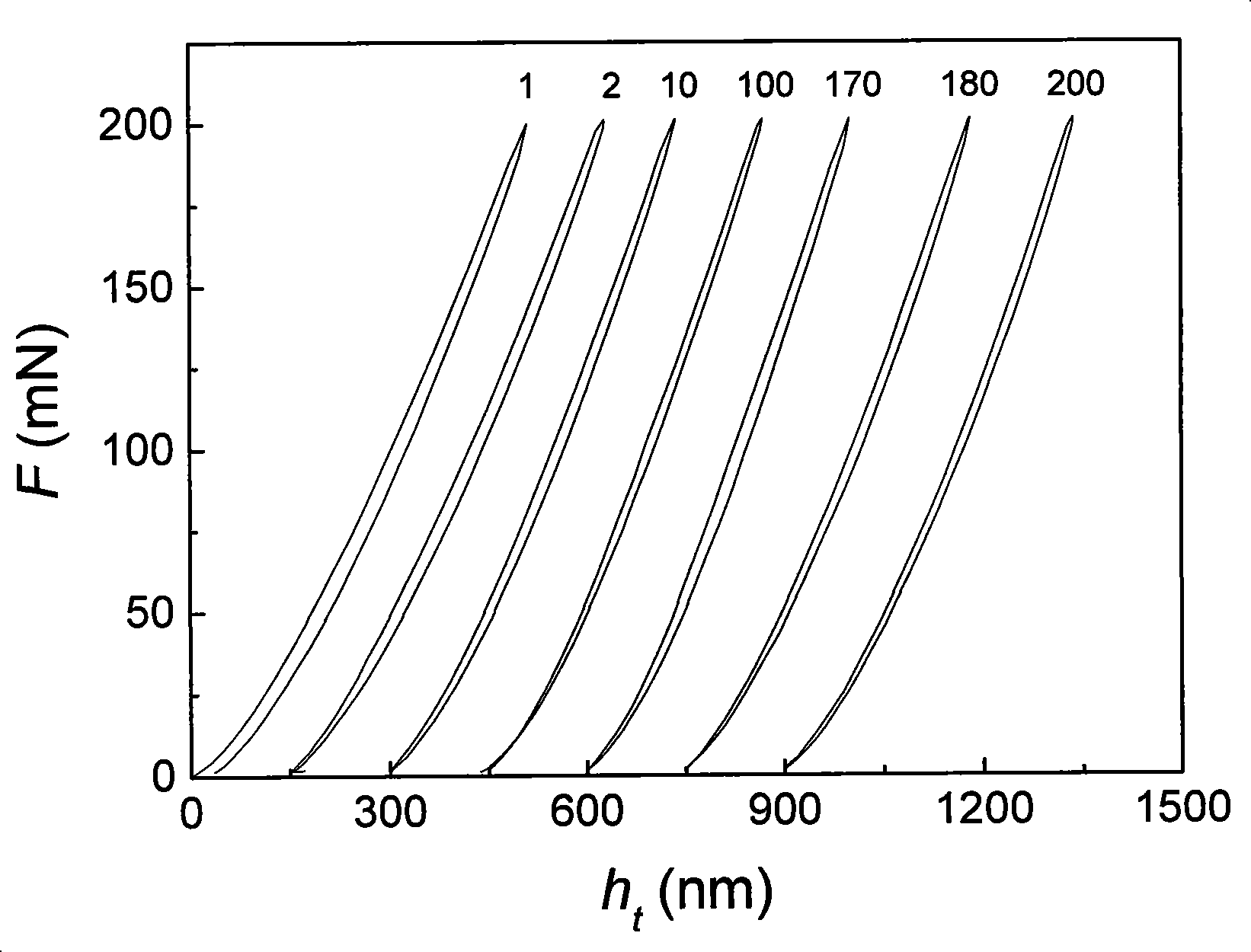

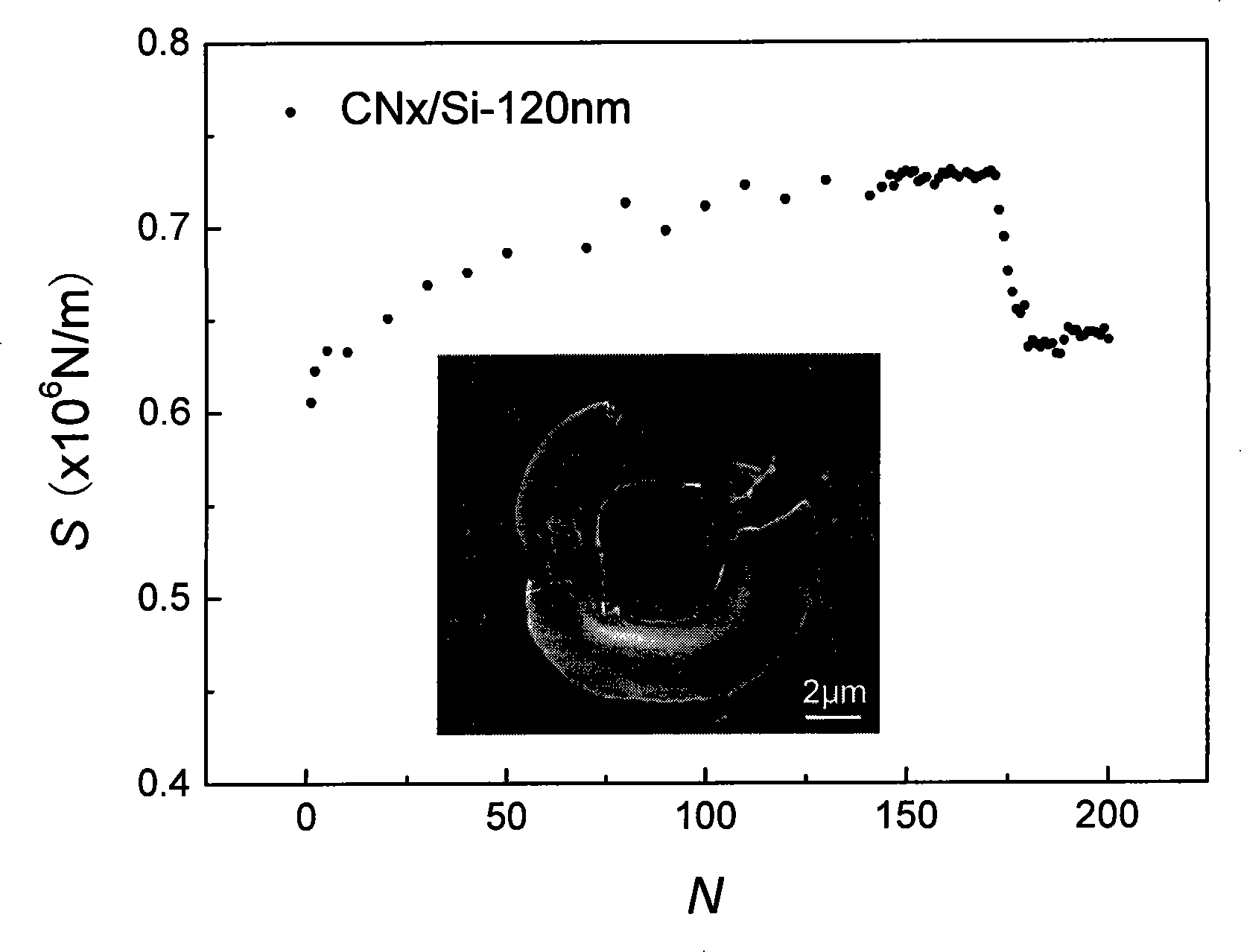

Method for testing nano thickness thin film endurance character

InactiveCN101251456BConvenient and reliable basis for judgmentHigh precisionMaterial strength using tensile/compressive forcesEngineeringNanometre

Owner:SOUTHWEST JIAOTONG UNIV

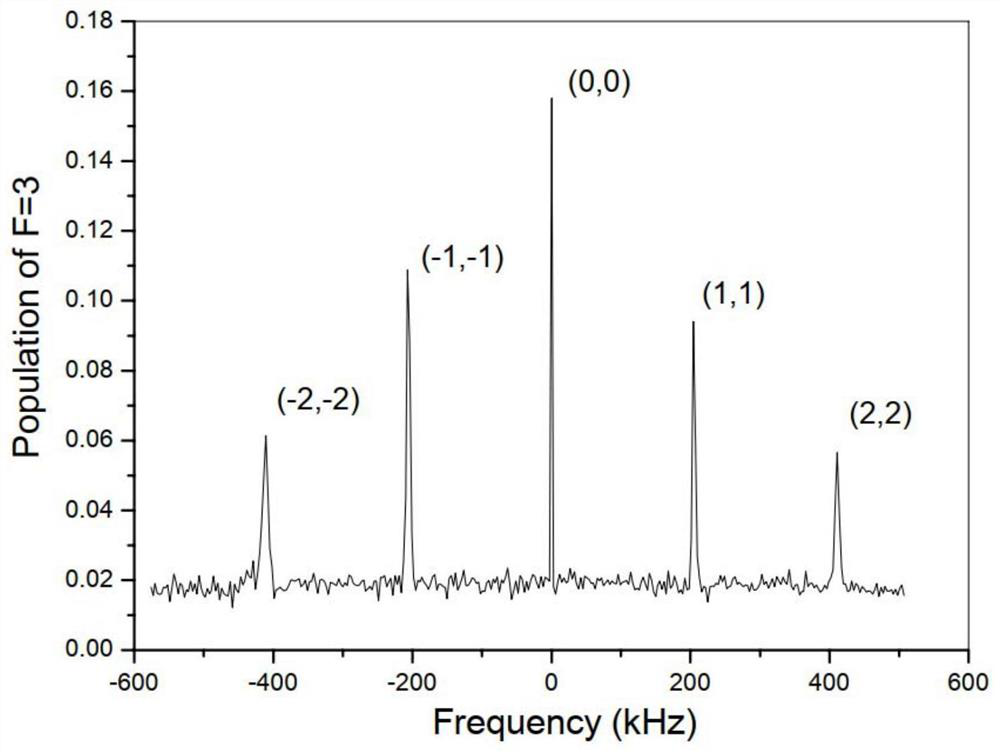

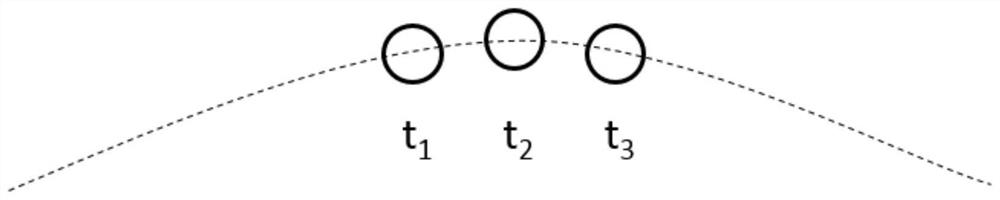

Method and device for measuring track of atomic group in atomic interferometer

ActiveCN112485822AHigh precisionAccurate locationRadiation particle trackingKtp laserPhotovoltaic detectors

The invention discloses a method for measuring the track of an atomic group in an atomic interferometer. According to the method, the position of the atomic group in the three-dimensional direction can be measured, the track measurement precision can be improved, no additional device is added on the basis of a separated three-pulse atomic interferometer in the measurement process, the operation issimple, and the measurement process can be simplified. The invention further discloses a device for measuring the track of the atomic group in the atomic interferometer. The device comprises a physical system composed of a vacuum cavity, a magnetic field coil and the like, an optical system composed of Raman laser, cooling laser and the like, and a circuit system composed of a photoelectric detector and the like. The method and device can be applied to the field of atomic inertia measurement, and the performance of the atomic interferometer is improved.

Owner:INNOVATION ACAD FOR PRECISION MEASUREMENT SCI & TECH CAS +1

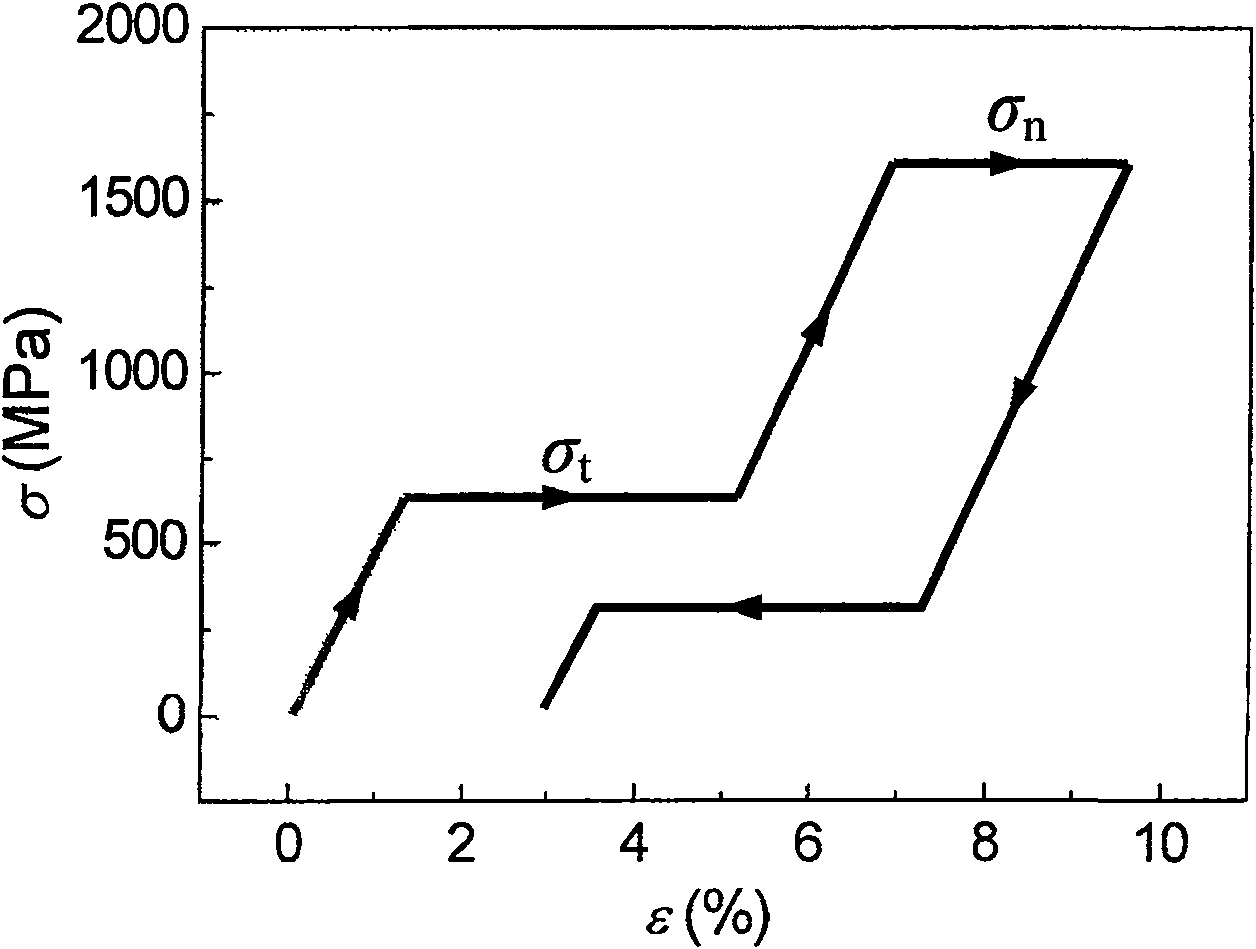

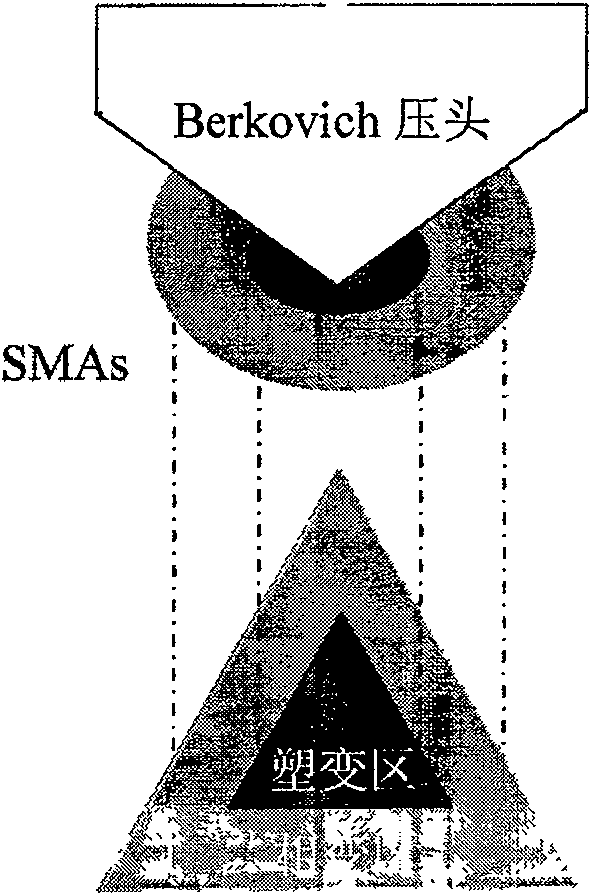

Method for ball-shape pressure head for determining shape memory alloy phase change property

InactiveCN100561175CGood reproducibilityReliable test basisComplex mathematical operationsStrength propertiesMicrometerShape-memory alloy

The utility model discloses a method using a spherical indenter for measuring the phase transition properties of shape memory alloy (SMAs). The phase transition is induced under the pressure of the spherical indenter pressed into the surface of the shape memory alloy; the load signals and the displacement signals in the unloading process are detected by a sensor at the same time, and the ht curve of the load F-displacement is obtained; the load-displacement curve obtained in the test is transformed to a corresponding nominal stress Sigmam-nominal stress Epsilonm curve according to the analysis; then properties of the transformation stress, the elastic modulus and other aspects of the SMAs can be obtained. The test method has advantages that the method is easy in operation, and the nondestructive measurement of the materials can be elementally realized; the method not only can be widely used in the measurement of the phase transition properties of various super-elastic and shape memory SMAs, but also is particularly suitable for the phase transition measurement of the SMAs films with the low thickness only up to a plurality of micrometers or the SMAs micro devices with the micrometer order typical structure size; the method has accurate and precise measured value, which can supply the reliable measurement basis of the phase transition property for the application of the SMAs in the micro-electro-mechanical system.

Owner:SOUTHWEST JIAOTONG UNIV

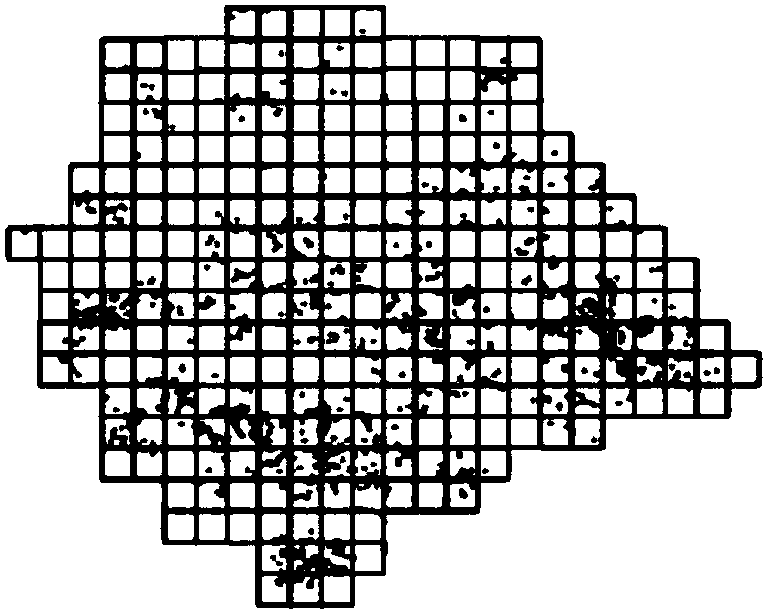

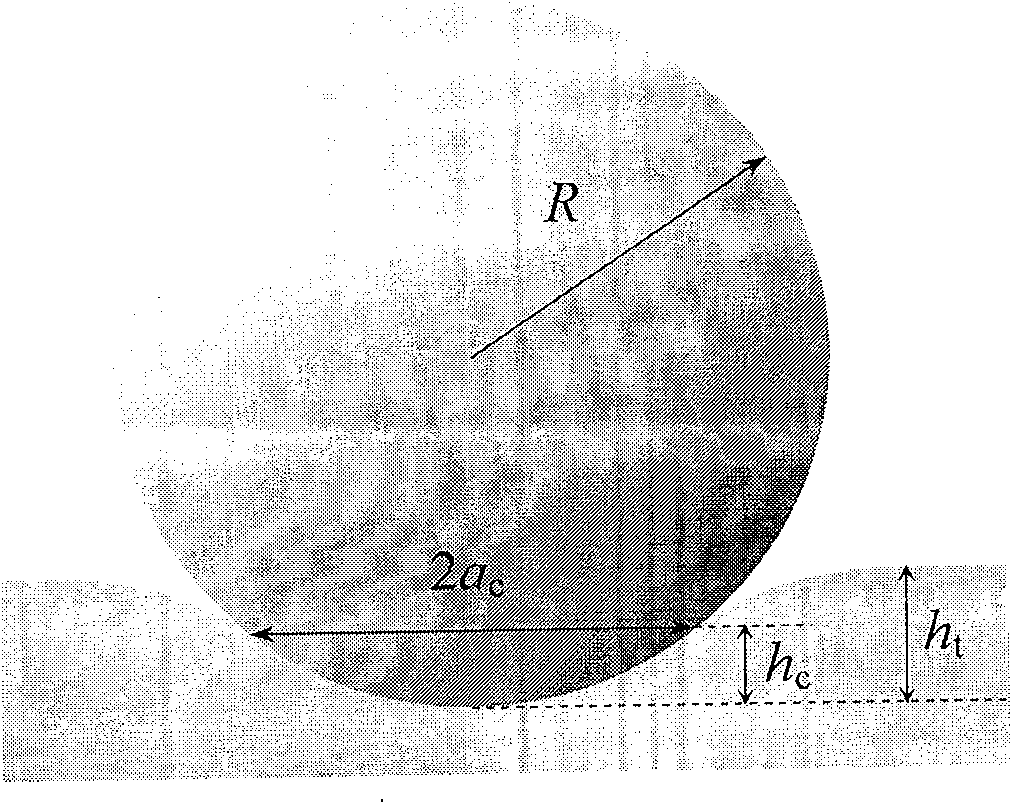

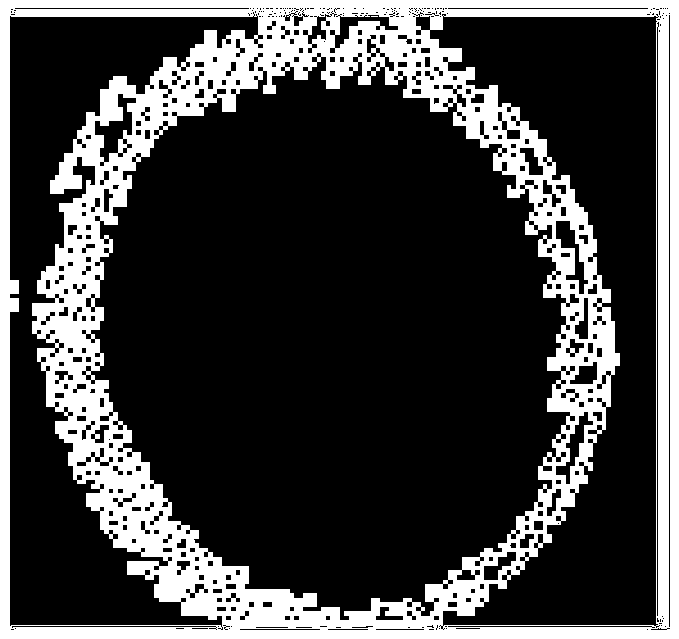

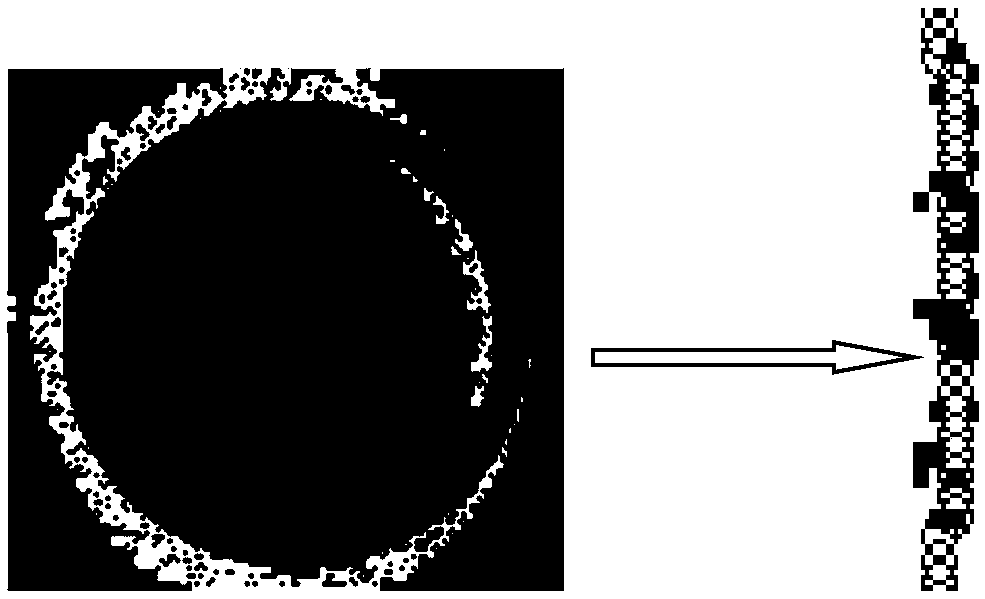

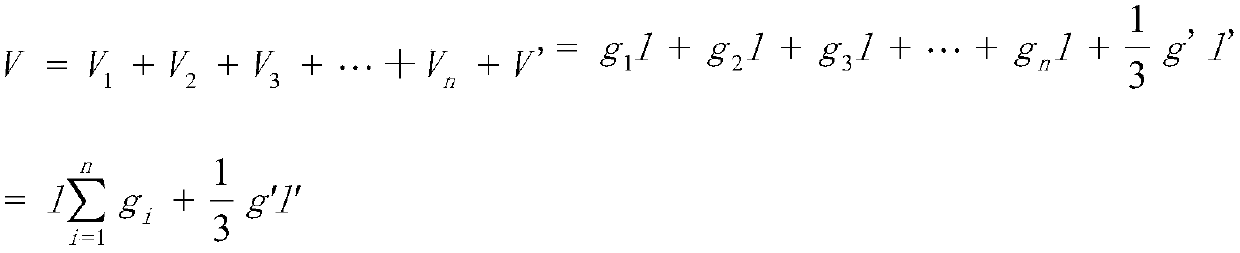

Method capable of calculating standing tree volume by using laser radar point cloud data based on improved Hough change

The invention discloses a method capable of calculating the standing tree volume by using laser radar point cloud data based on an improved Hough change. Tree point cloud data are obtained by taking athree-dimensional laser scanner as a tool, and by performing slice processing on high point cloud data of any tree, slice point cloud data are projected into a same horizontal plane and transformed into a grid map. By using a Hough transformation method, a fitting circle of the slice point cloud data is extracted as the diameter of a trunk at the place, and then the trunk volume is calculated byusing a sectional area differentiating quadrature method. According to the method, the flexibility and the high efficiency of the three-dimensional laser scanner are fully utilized, the cost of fieldinvestigation is reduced, the defect of invalid accumulation of random Hough transformation in previous research is overcome, and the efficiency and the precision of calculating standing tree volume field operation and interior processing are improved.

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com