Method for nondestructive measurement of refractive index of transparent capillary wall and device thereof

A capillary, refractive index technology, used in the field of measuring the refractive index of the capillary wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

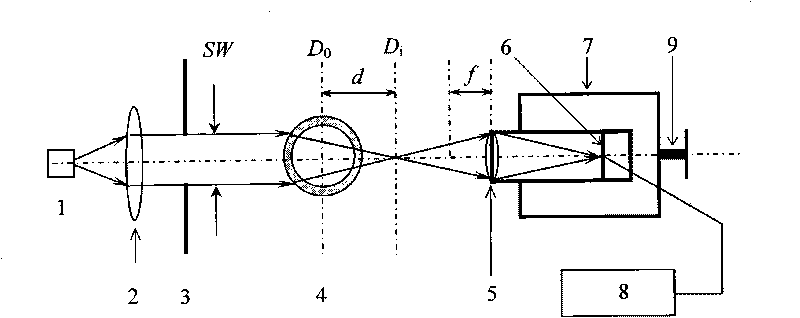

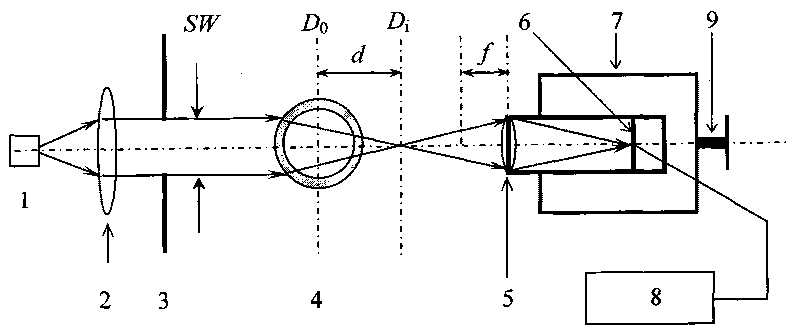

[0040]A light-emitting diode 1 with a central wavelength of λ=580nm and a spectral line half-width FWHM=32nm is used as a measurement light source after being collimated by a lens 2, and the collimated light beam enters the capillary through a slit 3 with adjustable width. When measuring, the slit width SW of the slit 3 is about smaller than the inner diameter of the capillary to meet the paraxial condition of the optical system; the glass capillary 4 after inhaling the standard liquid constitutes a cylindrical lens optical system composed of four coaxial cylinders, and is arranged on the lens 2 and the microscopic objective lens 5; the magnification is 10 times, the microscopic objective lens 5 of numerical aperture A=0.25 is arranged on the receiving field of view, and the field diaphragm of the image acquisition system 7 matches the light spot of the capillary 4 focal points, And the image acquisition system 7 is fixed on a one-dimensional translation stage 9 with a minimum ...

Embodiment 2

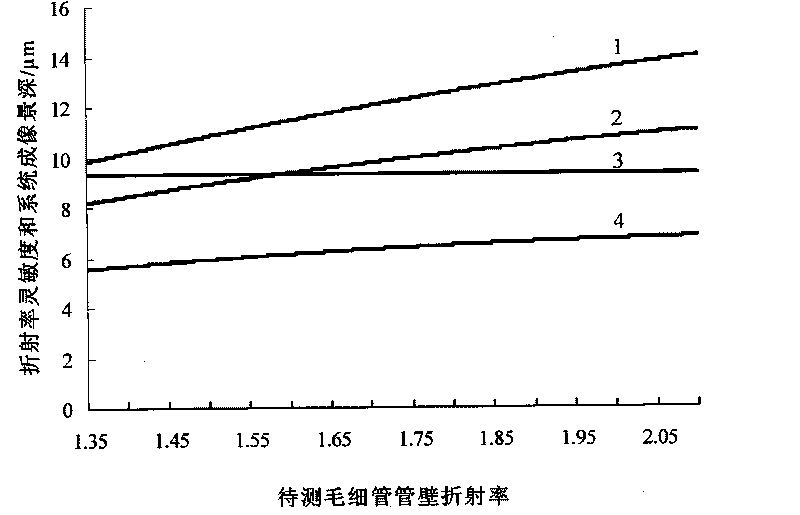

[0043] When determining the capillary wall refractive index according to (1), the focal length d value of the capillary must be measured, d=D i -D 0 , where D 0 is the position of the axis of the capillary, which is usually determined by measuring the position of the clear image of the outer contour of the capillary. Due to the diffraction effect when parallel light passes through the edge of the outer wall of the capillary, the position of the clear image of the outer contour of the capillary can be accurately judged D 0 is difficult, resulting in a measurement error in the d value.

Embodiment 3

[0045] Apply formulas (4) and (5), that is, use the standard liquid refractive index calibration method, and at the same time, apply formula (6) to calculate D 0 value, avoiding the need for D 0 The direct measurement of the value eliminates the need for D 0 The measurement error of the refractive index of the capillary tube wall is caused by the measurement error of the value.

[0046] According to the device and the method provided in the above embodiments, the present invention adopts three kinds of standard liquids (pure water n 1 = 1.3335, ethanol n 2 = 1.3618, ethylene glycol n 3 =1.4331) to calibrate the refractive index of the capillary. The refractive index of the liquid sample was measured with a 2WA-J Abbe refractometer, and the measurement error of the refractive index was 0.0002 (2WA-J Abbe refractometer instruction manual, produced by Shanghai Optical Instrument Fifth Factory).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com