Method for ball-shape pressure head for determining shape memory alloy phase change property

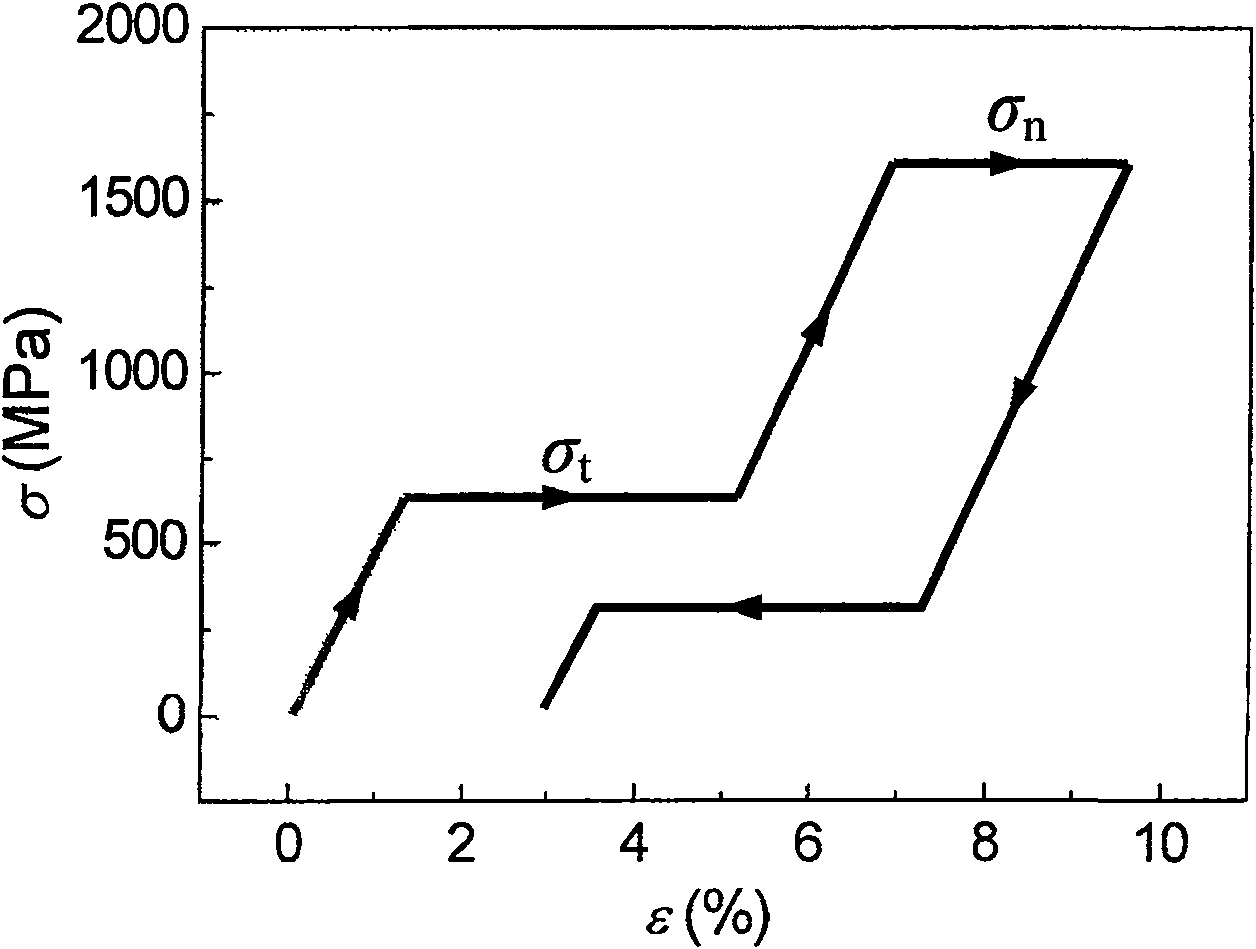

A technology of memory alloy and spherical indenter, which is applied in the direction of measuring devices, strength characteristics, special data processing applications, etc., can solve the problems of martensitic phase transformation deformation, martensitic yield deformation, and measurement of SMAs phase transformation characteristics, etc., to achieve The effect of small test area, avoiding damage and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Two nickel-titanium alloy polycrystalline sheets with a length and width of 10 mm and a thickness of 0.5 mm were used as test samples, one of which was a sample SE in a superelastic state, and the other was a sample SME in a shape memory state. Taking the test of these two samples as an example, the specific operation steps of the method of the present invention are illustrated. The steps are:

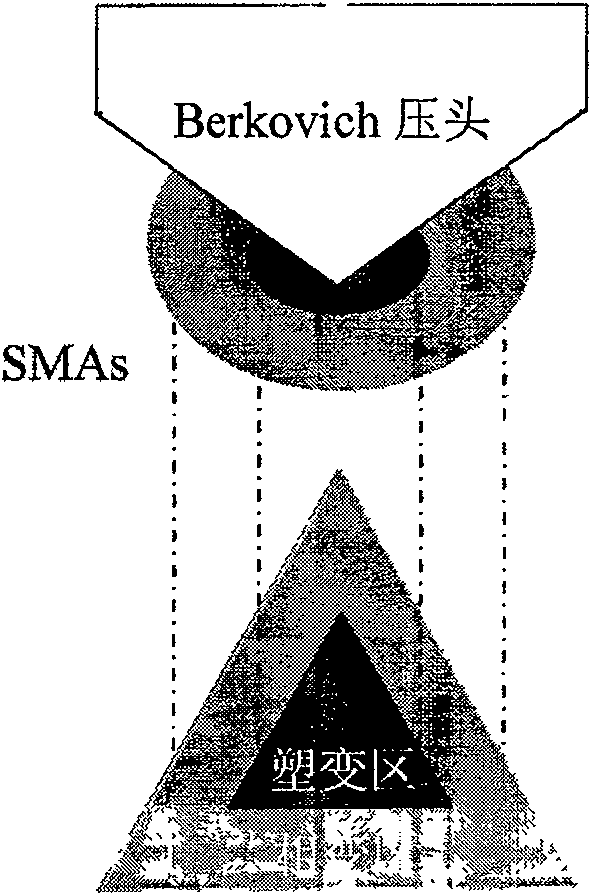

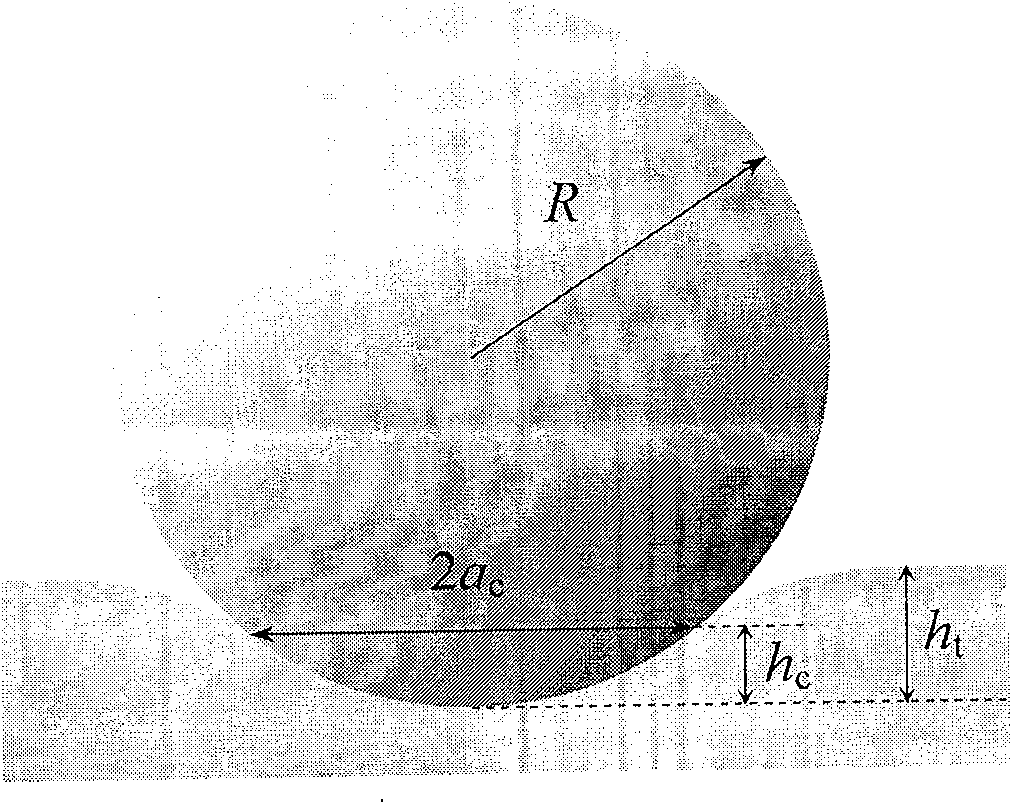

[0027] a. Using indentation equipment, a spherical indenter is used to radially press the surface of the shape memory alloy material to cause a stress-induced phase transition, and the load F and displacement h during the loading and unloading process are simultaneously and continuously detected by the sensor t signal, get the load F-displacement h of the shape memory alloy t curve. image 3 That is, a schematic diagram of a spherical indenter pressed into a shape memory alloy material during testing, where R is the radius of curvature of the spherical indenter, which can be c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com