Patents

Literature

91results about How to "Reliable test basis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

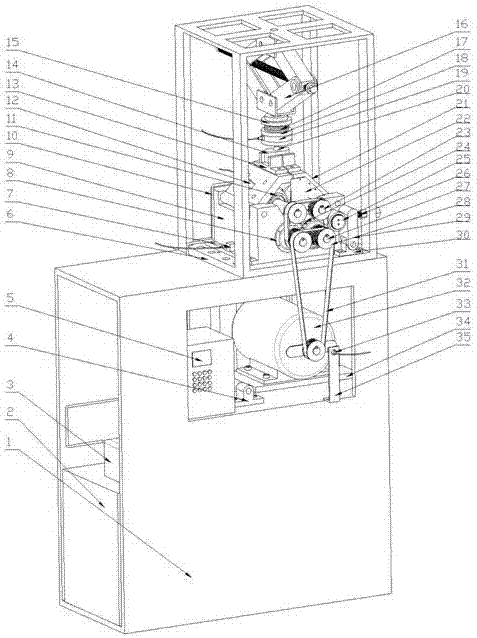

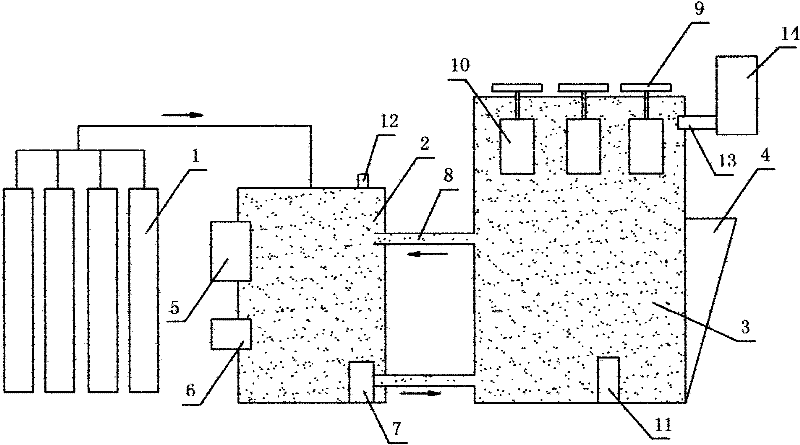

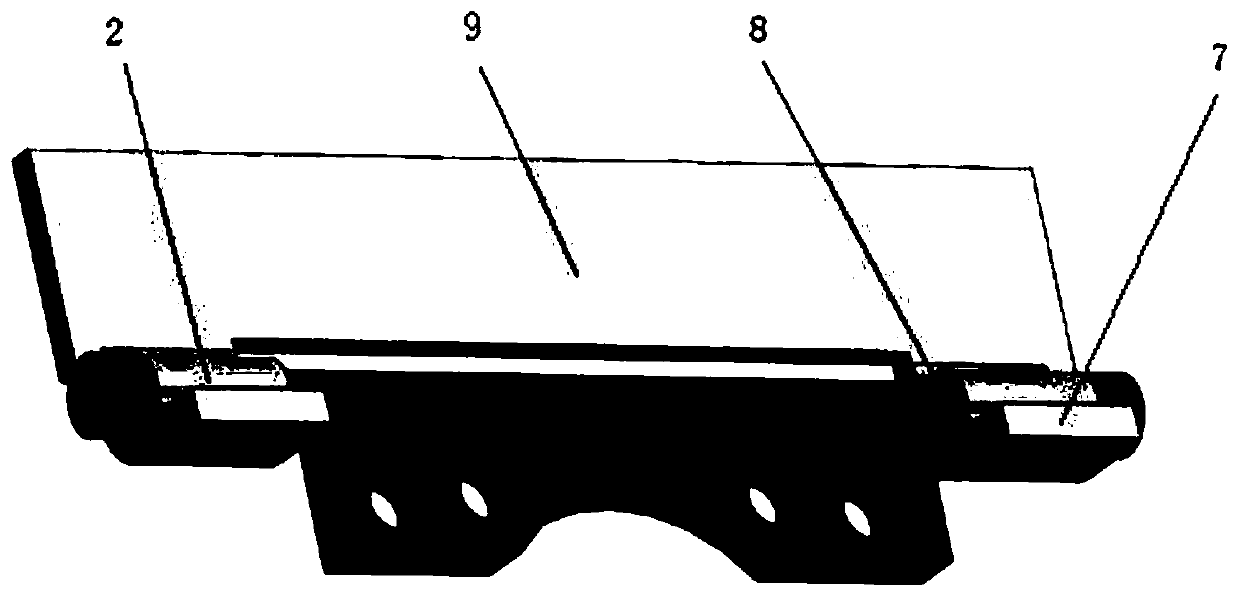

Reconfigurable lead screw pair and guide rail pair accelerated life electro-hydraulic servo test bench

InactiveCN102507182AHigh simulationComprehensive test dataMachine gearing/transmission testingElectro hydraulicElectric machinery

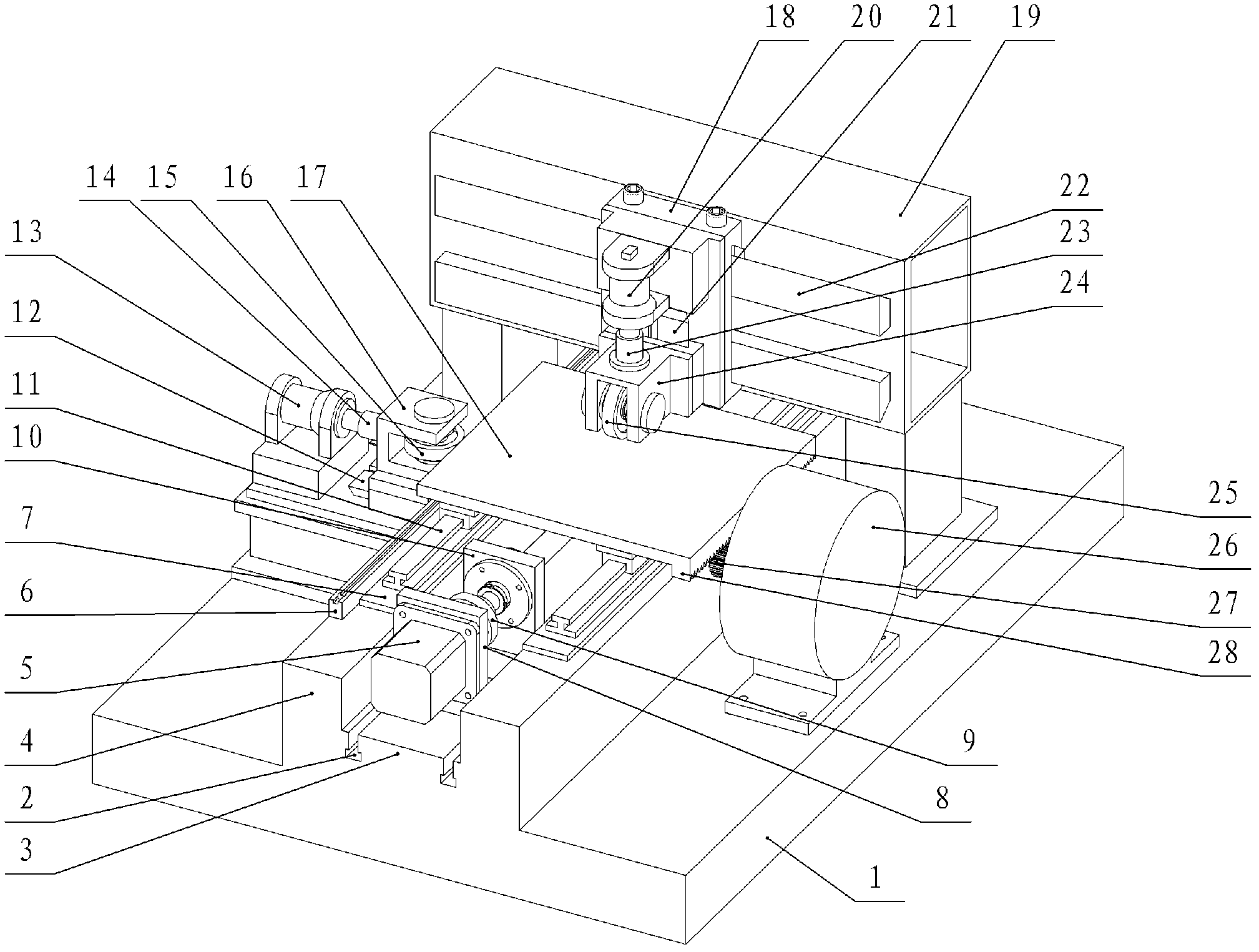

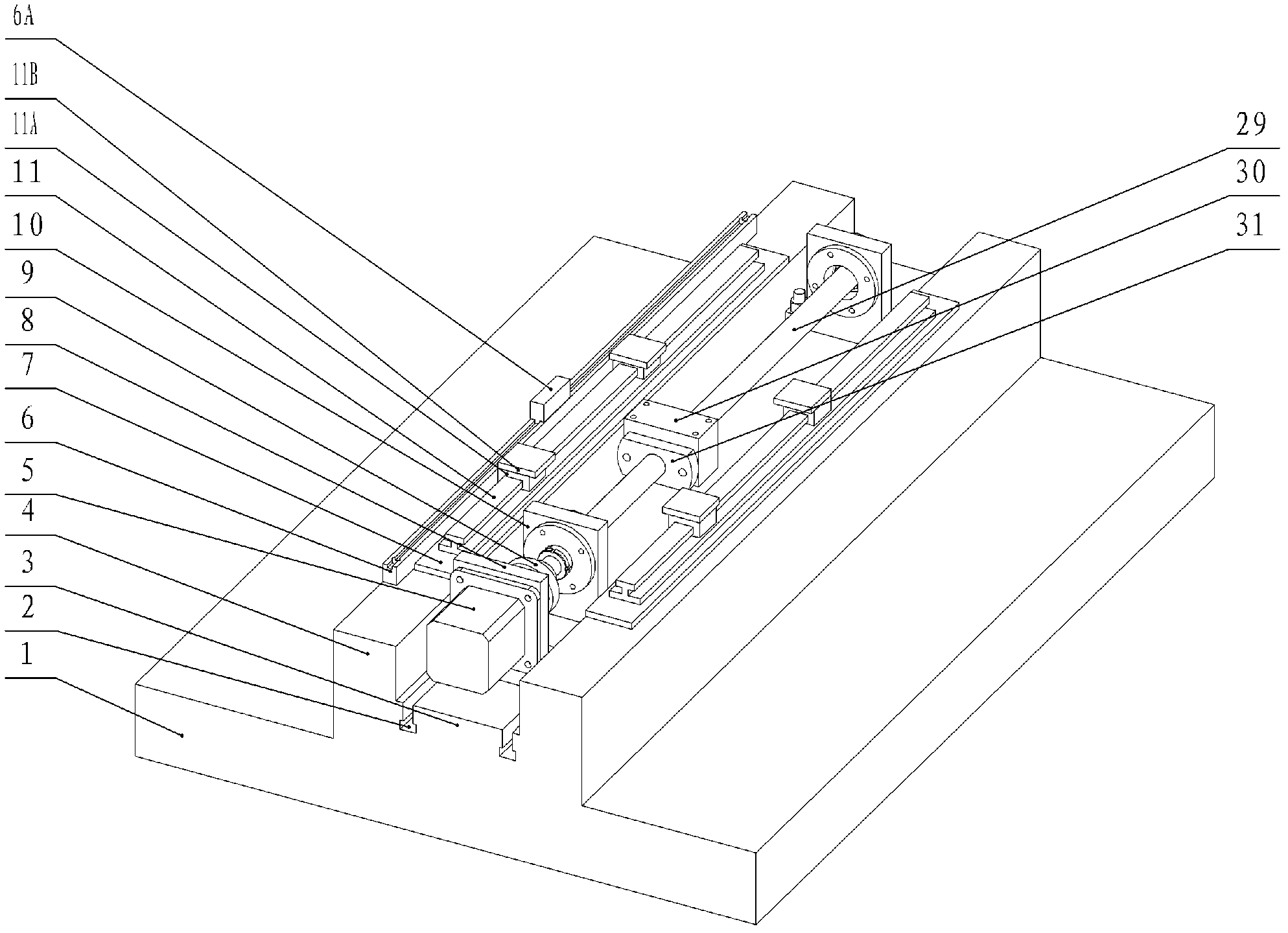

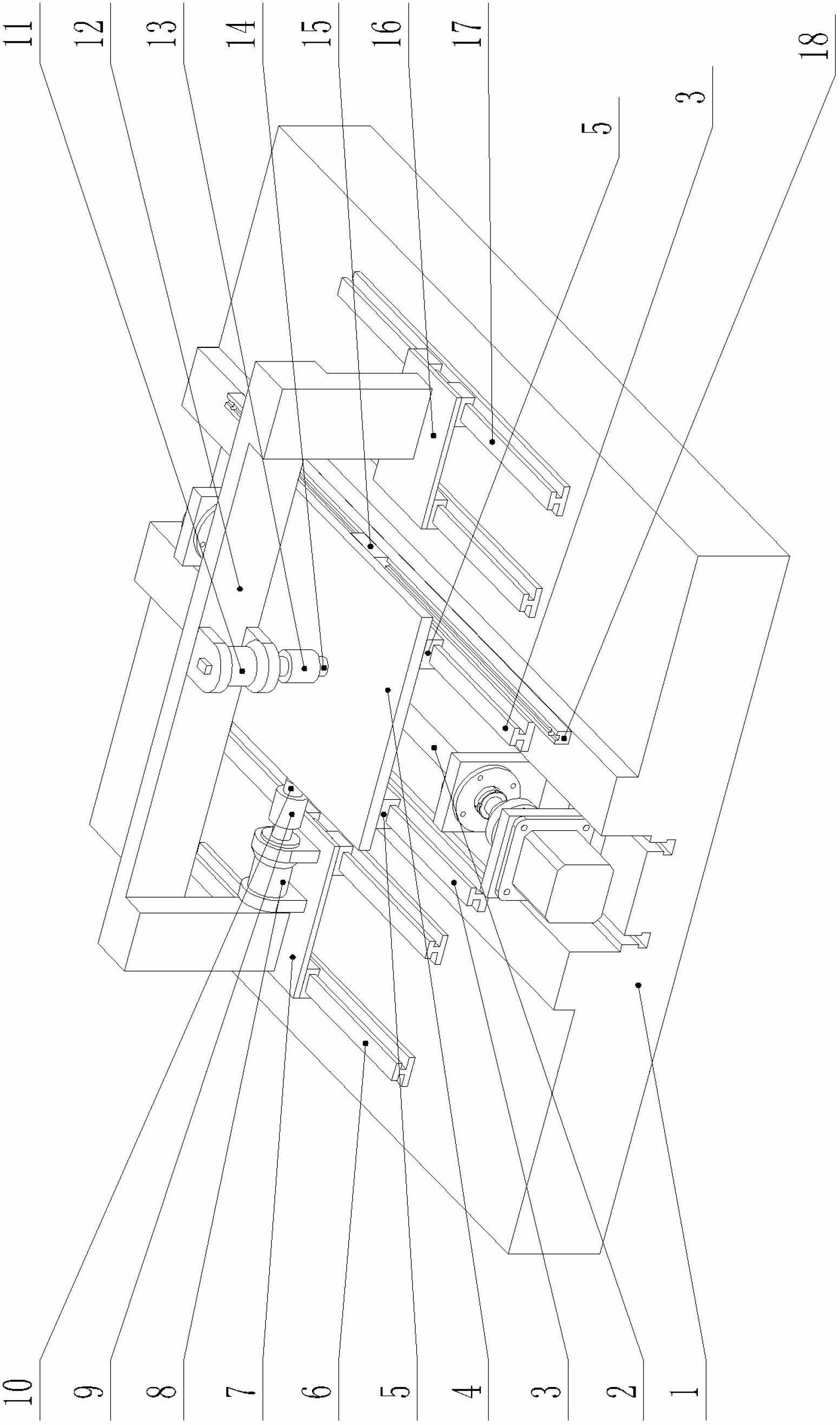

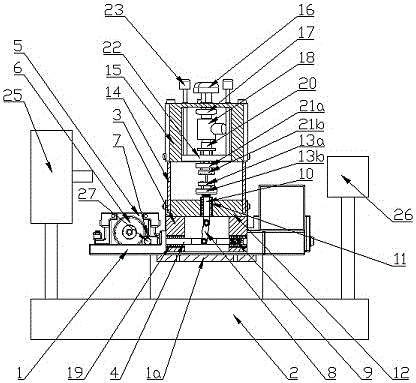

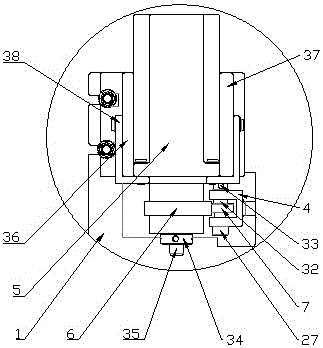

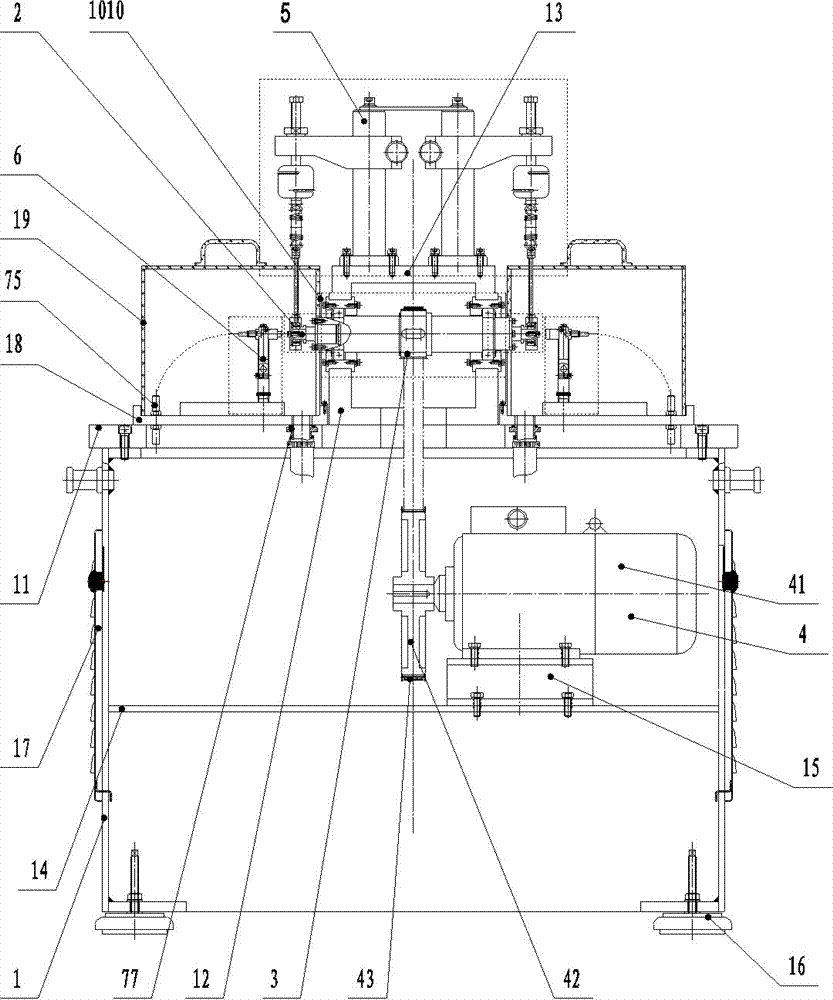

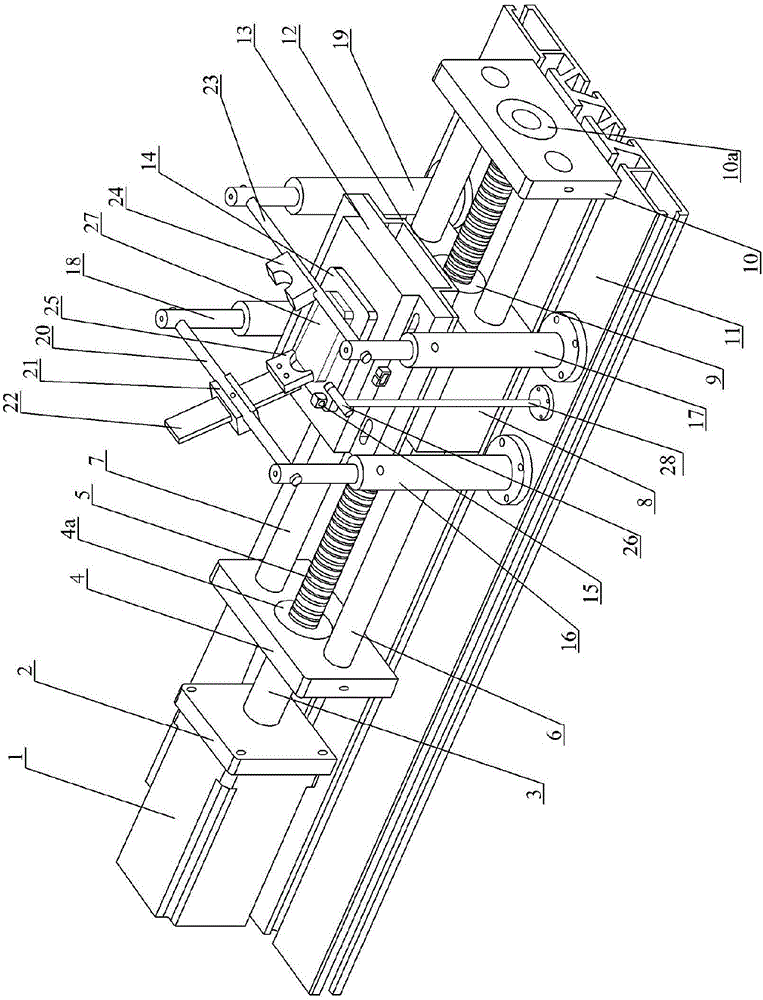

The invention provides a reconfigurable lead screw pair and guide rail pair accelerated life electro-hydraulic servo test bench which is characterized in that two lead screw bearing seats of a T-shaped table between two guide rail mounting tables on a base are provided with lead screws connected with a motor; guide rails on the guide rail mounting tables are matched with guide rail sliding blocks; guide rail sliding block backing plates on the guide rails, a grating bar reading head on one guide rail mounting table and nut bases on the nuts of the lead screws are connected with the bottom of a stressed sliding table; one side of the stressed sliding table is meshed with a gear at the end part of the output shaft of a magnetic powder brake through a gear rack; the other side face of the stressed sliding table is opposite to a force application wheel of a transverse loading mechanism; and the upper part of the stressed sliding table is opposite to a force application wheel of a vertical loading mechanism. The test bench provided by the invention can be used for realizing the accelerated life test of three-way dynamic loading of multiple types of lead screw pairs and guide rail pairs, collecting test data required for evaluating the residual lives and degradation mechanisms of the lead screw pairs and the guide rail pairs in real time, and providing more reliable test basis for the design and maintenance of the lead screw pairs and the guide rail pairs.

Owner:SOUTHWEST JIAOTONG UNIV

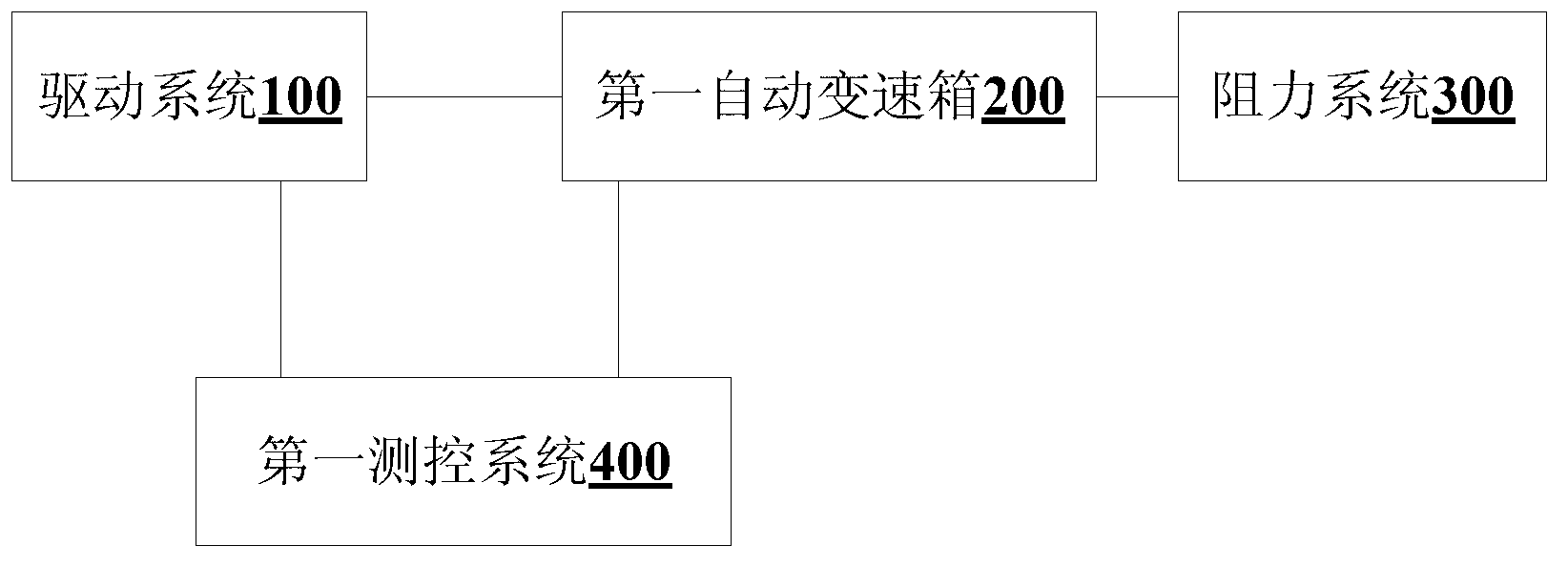

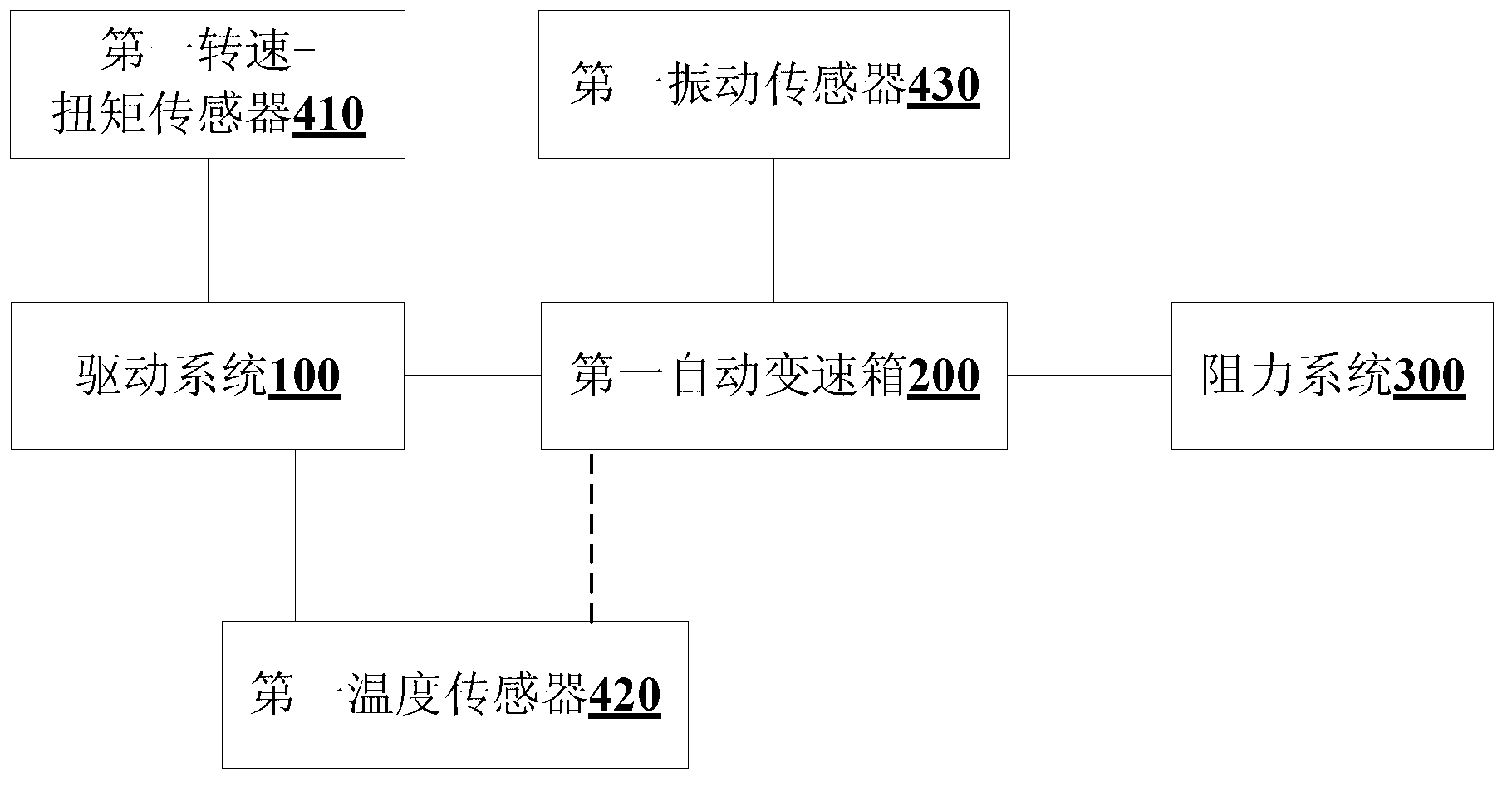

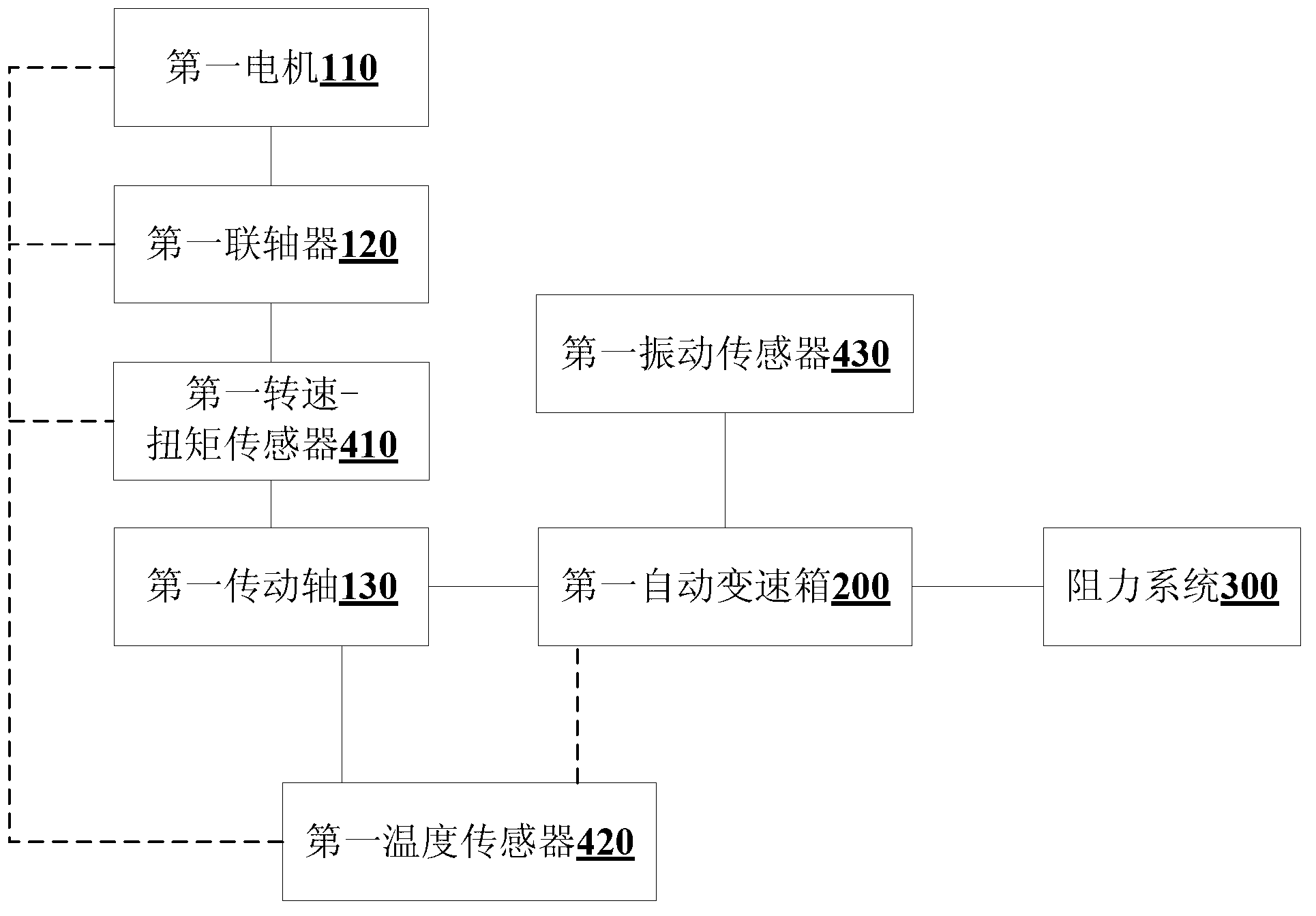

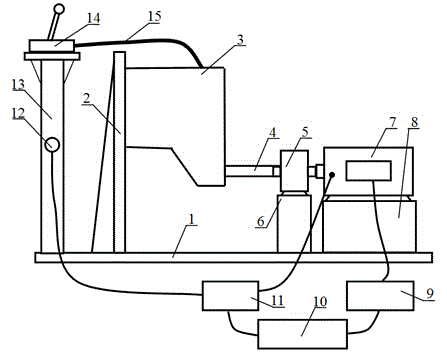

Test platform for testing automatic gearbox

InactiveCN102706558AReliable test basisMachine gearing/transmission testingControl systemTest platform

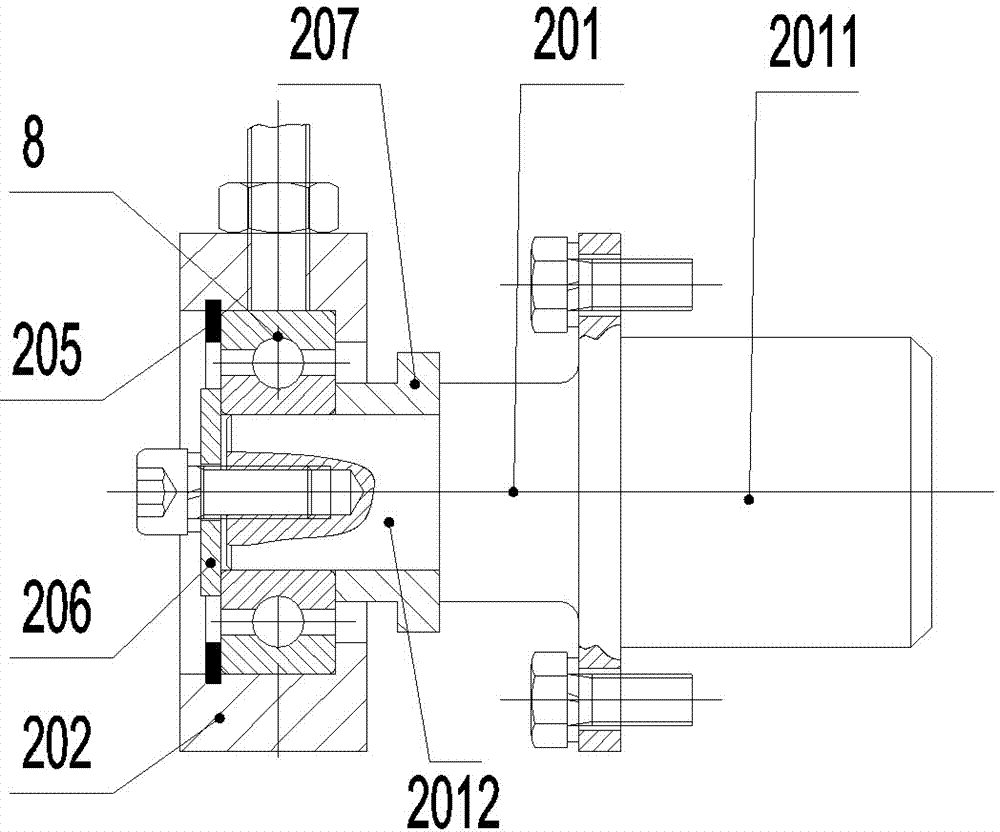

The invention discloses a test platform for testing an automatic gearbox, comprising a driving system, a resistance system and a first measurement and control system, wherein the power output end of the driving system is connected with a first automatic gearbox, and the first automatic gearbox is an automatic gearbox with comprehensive performance to be tested; the resistance output end of the resistance system and the first automatic gearbox are coaxially arranged for applying a second torque on the first automatic gearbox, and the second torque is be opposite to a first torque generated by the driving system in direction; and the first measurement and control system is respectively connected with the driving system and the first automatic gearbox and comprises a plurality of sensors used for measuring the performance of the first automatic gearbox. In the invention, multiple performance parameters are acquired after the comprehensive performance of the automatic gearbox is tested, thereby providing reliable test basis for the improvement and the optimization of the automatic gearbox.

Owner:SUOTE TRANSMISSION EQUIP

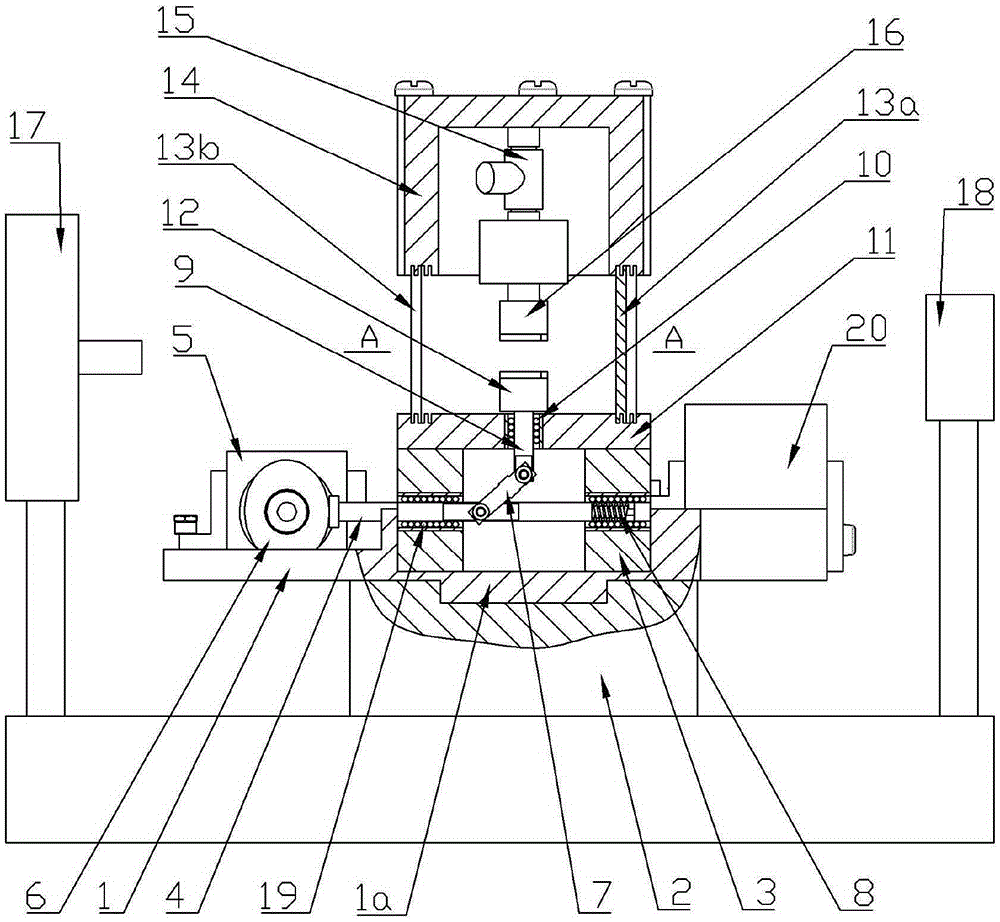

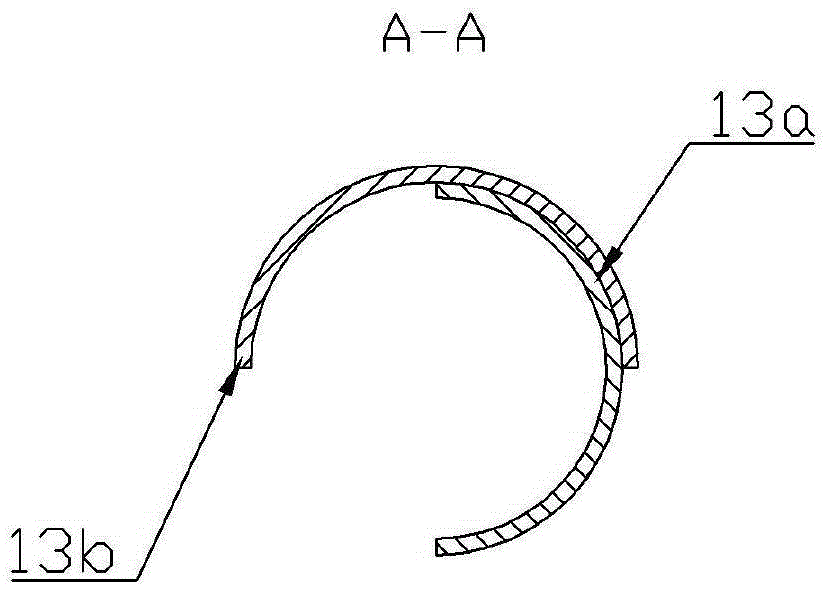

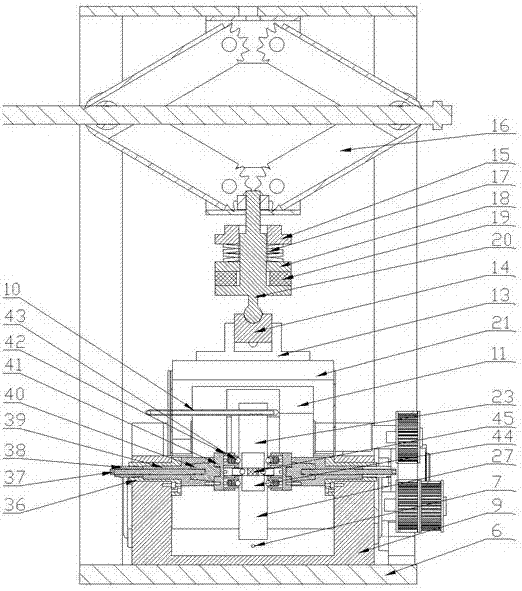

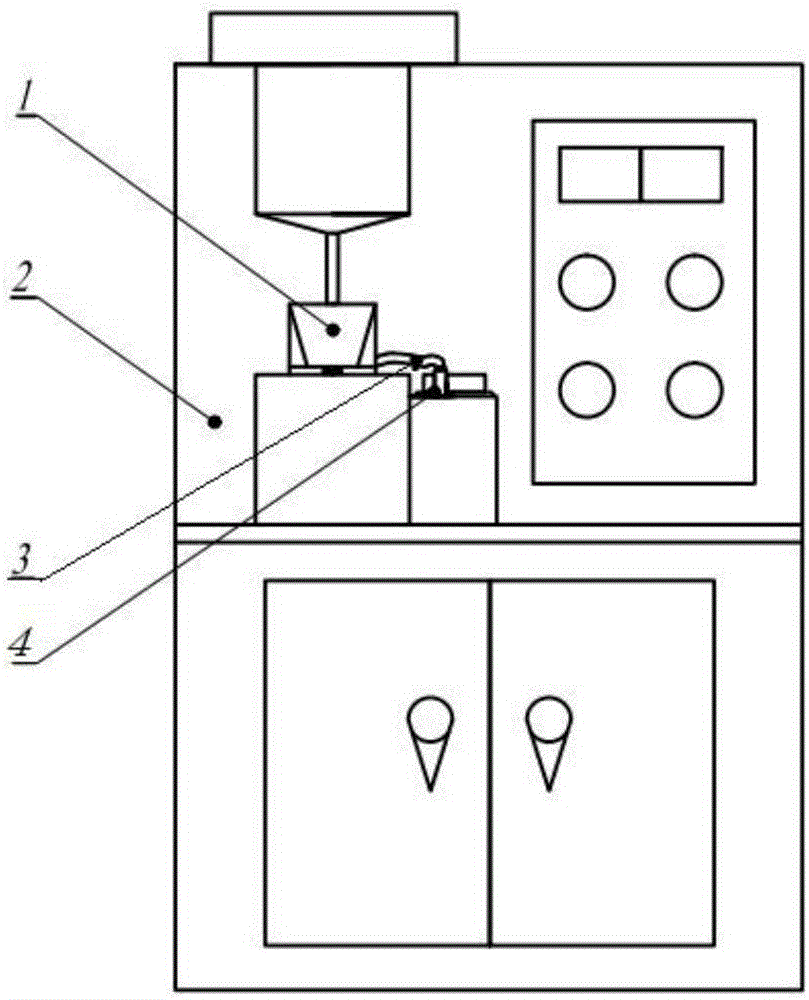

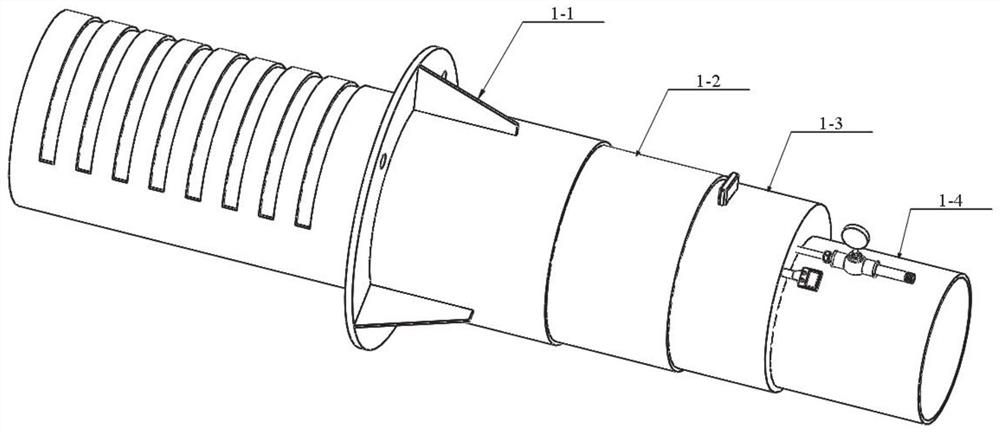

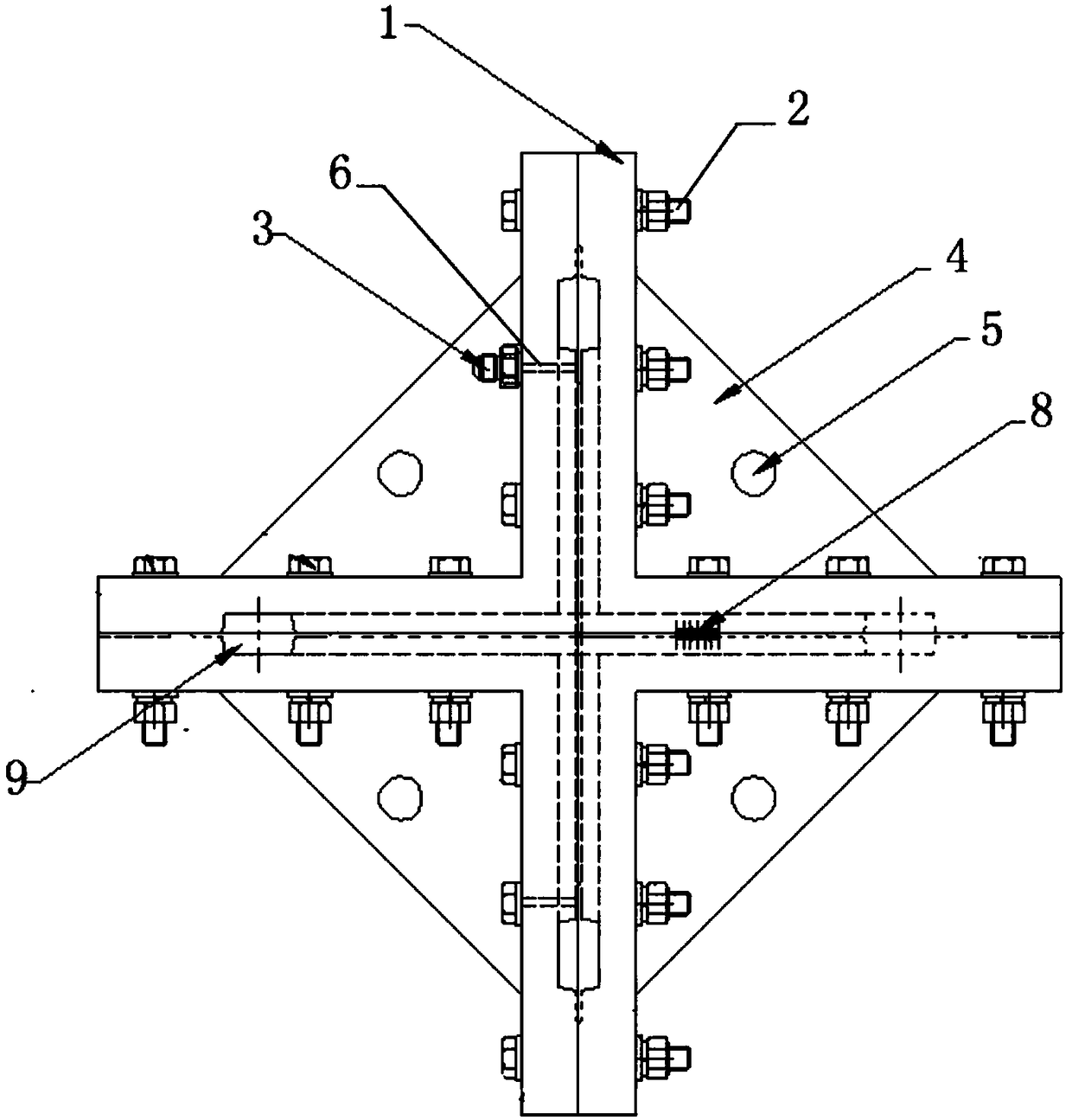

Fatigue testing machine and testing method capable of synchronously radiating light source for in-site imaging

ActiveCN105334237AIncrease brightnessImprove image signal-to-noise ratioMaterial analysis by transmitting radiationElectricityRadiation imaging

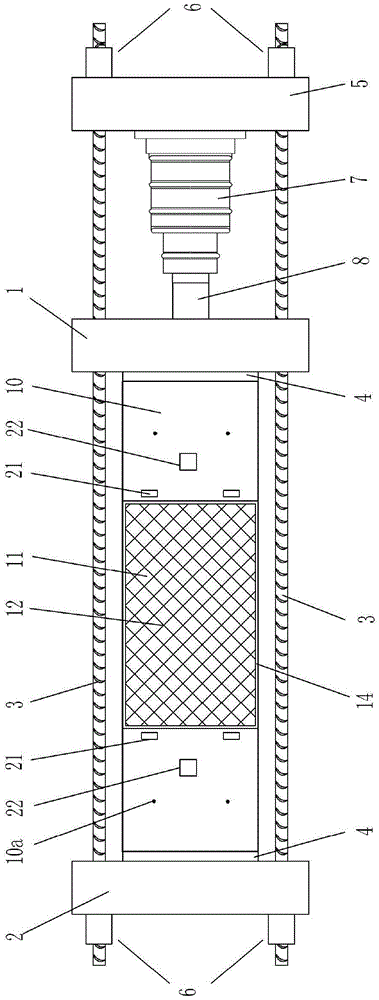

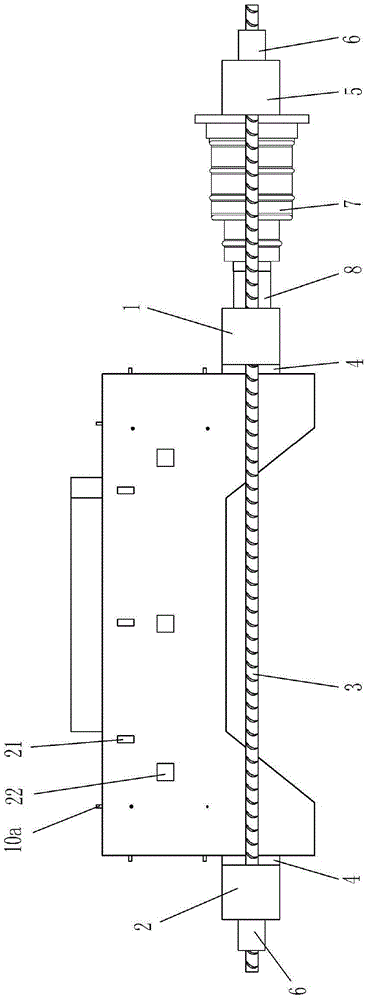

The invention provides a fatigue testing machine and testing method capable of synchronously radiating a light source for in-site imaging. According to the composition of the testing machine, a cross at the bottom of a bottom plate is embedded to a synchronous light source radiation platform; a servo motor of the bottom plate is connected with the lower end of a lower clamp on a base of the bottom plate through a cam link mechanism; a semi-annular organic glass inner cover and a semi-annular organic glass outer cover are movably embedded to the upper surface of a cover plate of the base, the organic glass inner cover and the top of the organic glass outer cover are connected with a top cover in an embedded mode, the middle of the bottom face of the top cover is connected with the upper end of a load sensor, and the lower end of the load sensor is connected with an upper clamp; the upper clamp is located over the lower clamp; the servo motor and the load sensor are both electrically connected with a data processing and control device. In the fatigue testing process of the testing machine, synchronous radiation imaging can be performed on fatigue testing samples, and a three-dimensional image in a material is obtained; the mechanical properties of materials and the evolution rule of a microscopic structure can be more clearly and accurately reflected.

Owner:SOUTHWEST JIAOTONG UNIV

Discharging strength conversion method based on ultraviolet imaging method

InactiveCN103744005AStrong contrastReliable test basisTesting dielectric strengthPower gridImage detection

The invention provides a discharging strength conversion method based on an ultraviolet imaging method. The invention provides a corresponding conversion method by designing an ultraviolet imaging detection discharging model, analyzing videos and processing a digital image, comprehensively considering a testing distance, an instrument gain and a relation between the discharging strength and ultraviolet imaging pattern quantized data, and analyzing all parameters and data to obtain a corresponding curve. The discharging strength conversion method can effectively guide the sensitivity and the accuracy of a typical defect ultraviolet imaging detection analysis of regional power grid electric transmission and transformation equipment, and provides a reliable testing basis for the discharging strength of the equipment.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID QINGHAI ELECTRIC POWER COMPANY

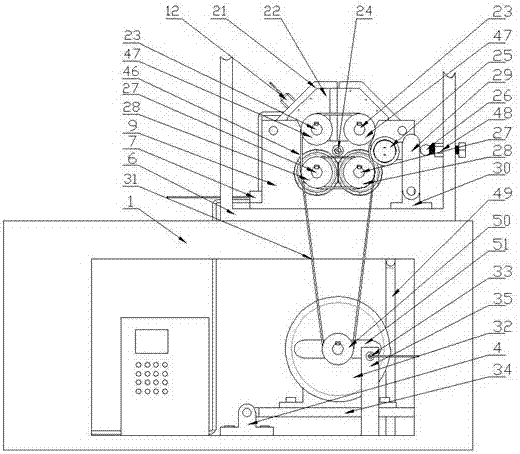

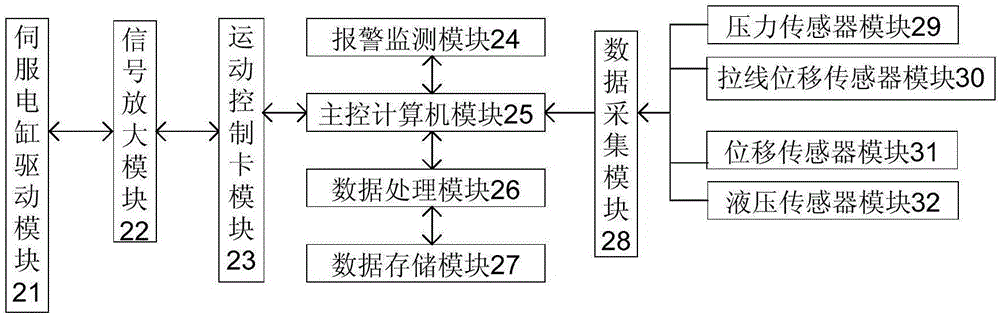

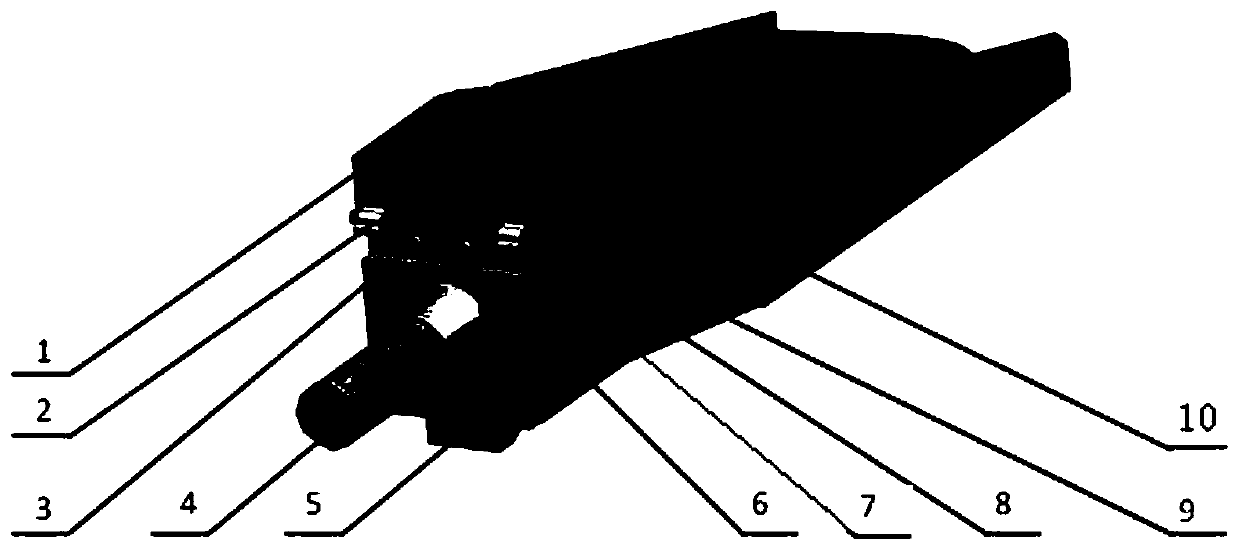

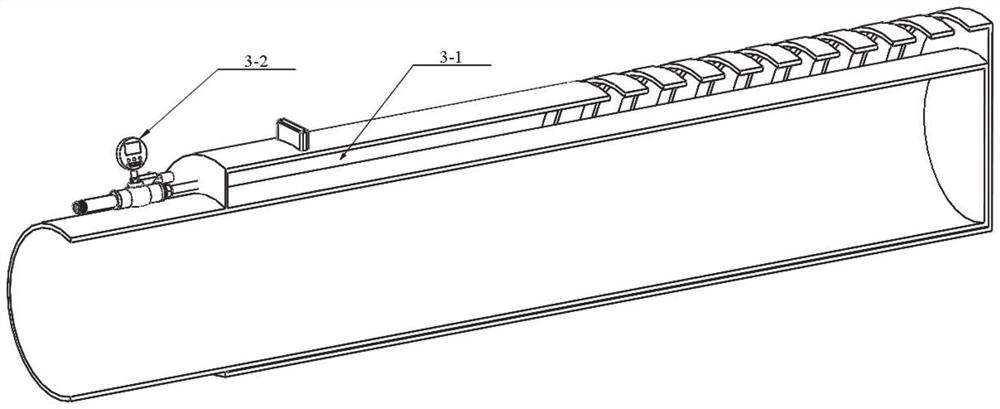

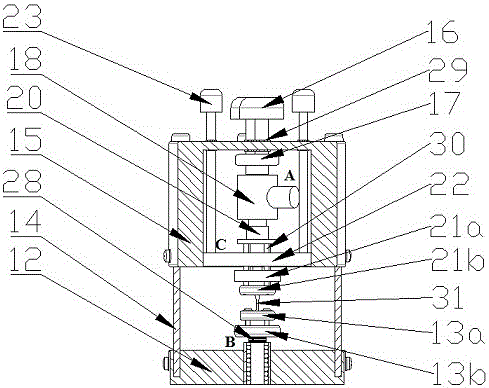

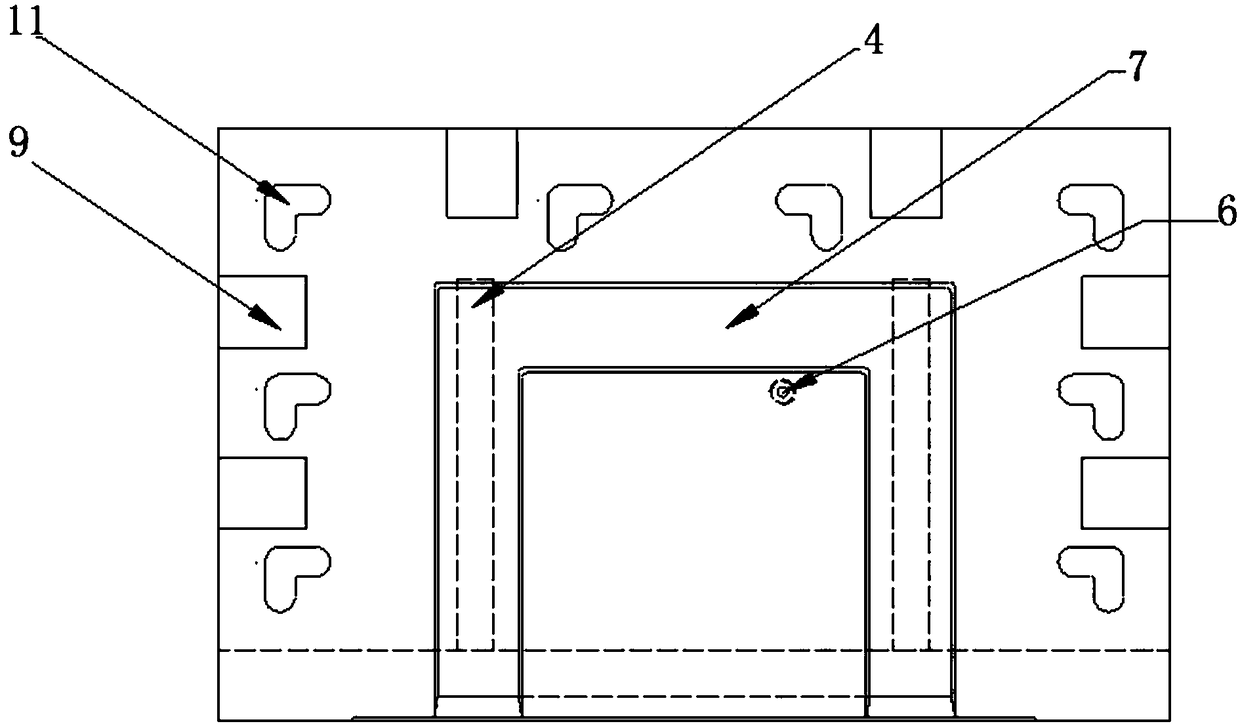

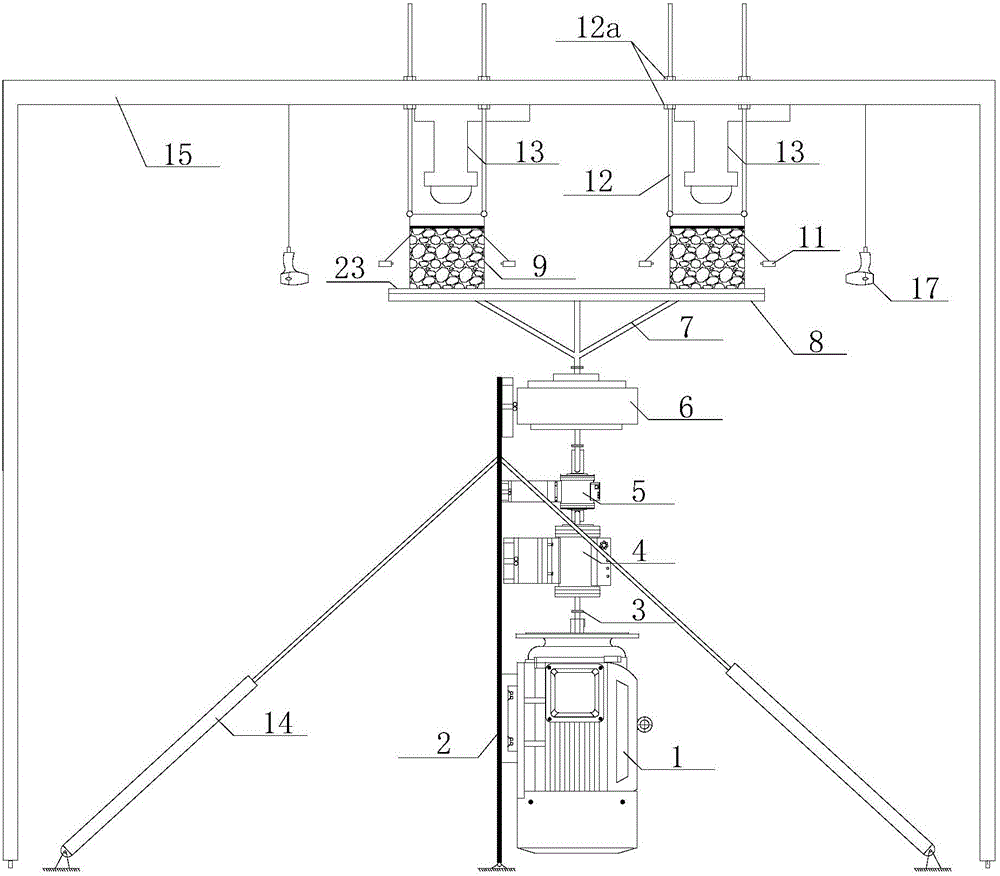

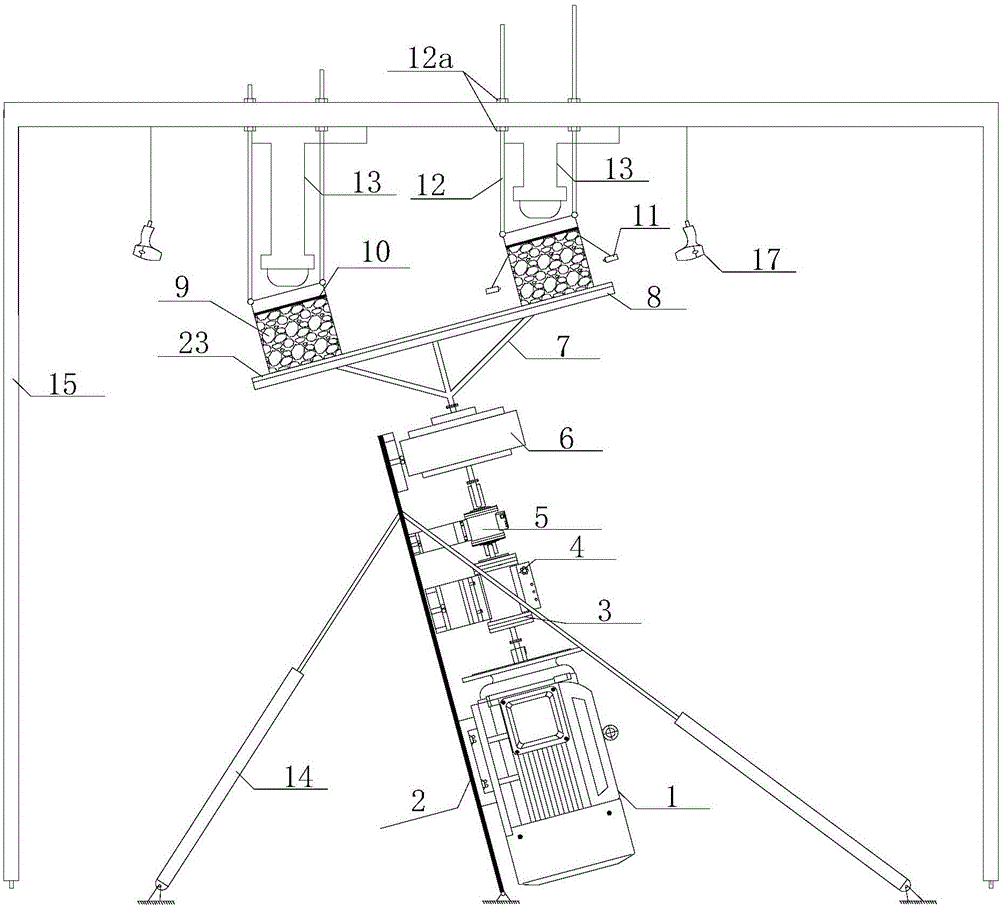

Passive follow-up force-applied linear guiderail pair test bed with controllable load

InactiveCN102692319AReliable controlReliable test basisMachine part testingEngineeringPressure sensor

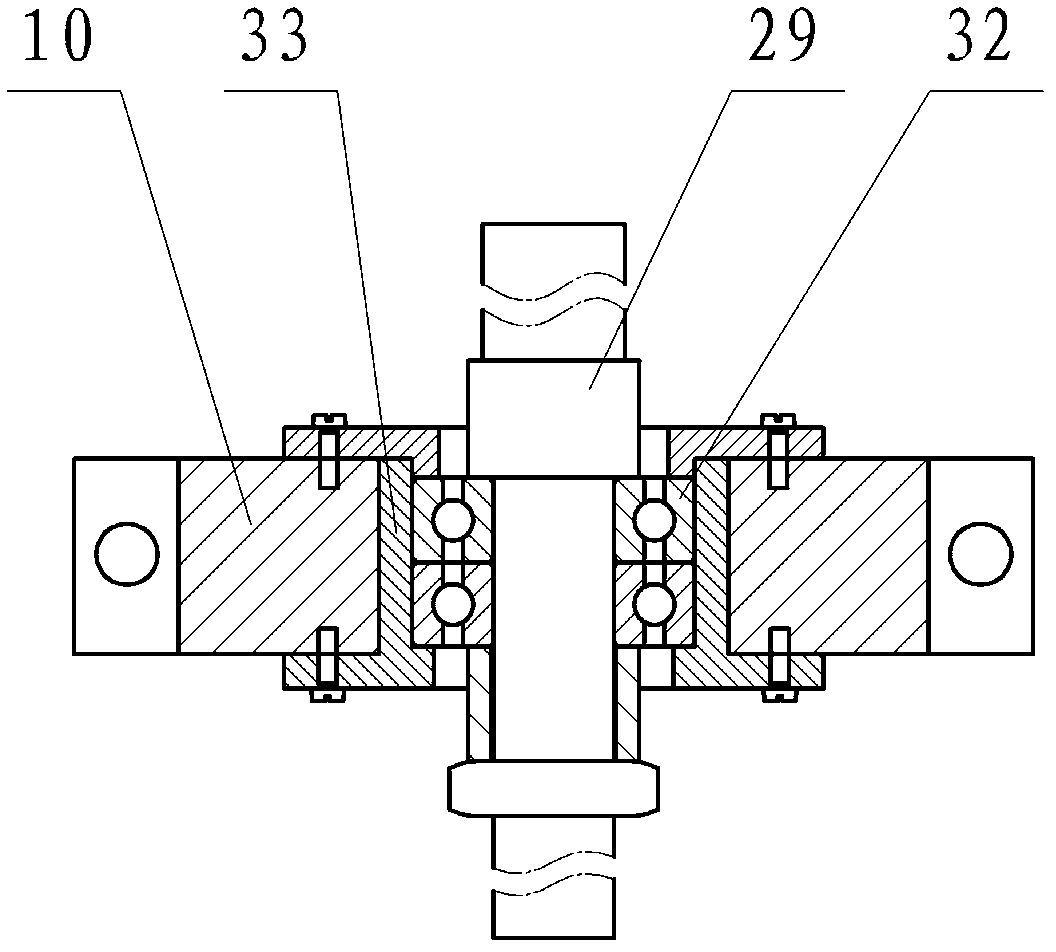

The invention relates to a passive follow-up force-applied linear guiderail pair test bed with controllable load. A horizontal load application mechanism is characterized in that a horizontal force application device is connected with a horizontal force application head by a horizontal pull pressure sensor, the end of the horizontal force application head is connected on the side surface of a stressed sliding table, and a base of the horizontal force application device is fixed on a stand by a left side linear guiderail pair; a vertical load application mechanism is characterized in that a vertical force application device is connected with a vertical force application head by a vertical force application device, the end of the vertical force application head is connected at the center of the stressed sliding table, the vertical force application device is arranged on a cross beam of a portal frame, a base at the right side of the portal frame is arranged on the stand by a right side linear guiderail pair, and the left side of the portal frame is fixed on the base of the horizontal force application device. The test bed realizes controllable dynamic load of horizontal load and radial load of the guiderail slider, can more accurately and reliably evaluate the relationship between the properties and service life of the guiderail pair, thus providing reliable test basis for design and maintenance of the guiderail pair.

Owner:SOUTHWEST JIAOTONG UNIV

CT-based three-dimensional deformation measurement system and method of tissue or material

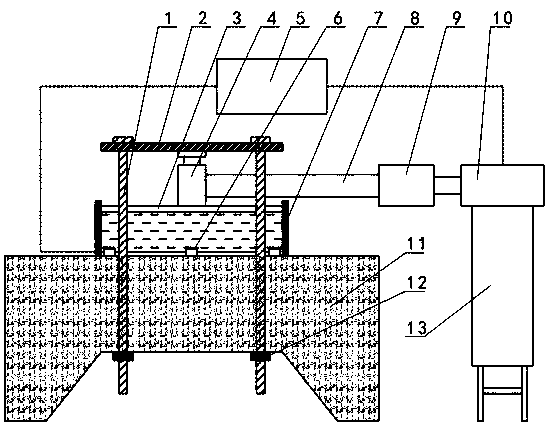

InactiveCN102293658AAvoid interferenceRealize internal microtopographyComputerised tomographsTomographyComputing tomographyCorrelation analysis

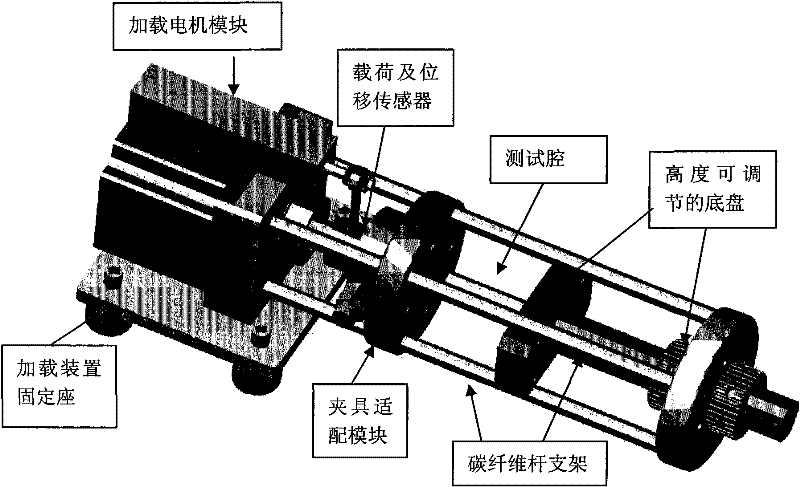

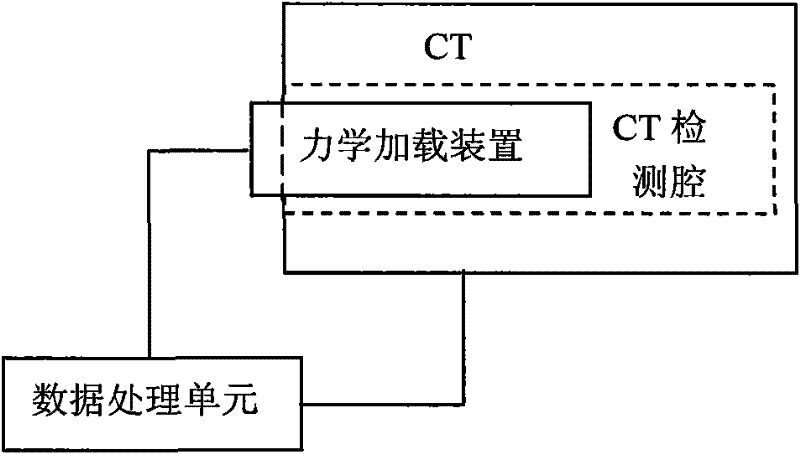

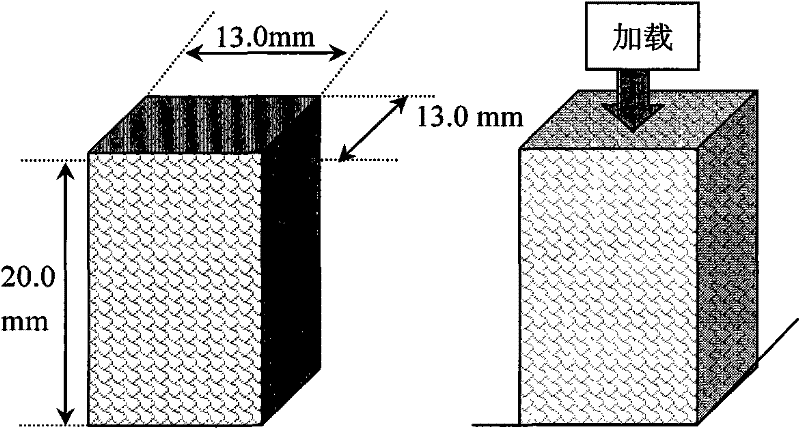

The invention relates to a CT (computed tomography)-based tissue or material interior three-dimensional deformation measuring system and measuring method, belonging to the technical field of novel detecting instruments for medical treatment and scientific research. The method comprises the following steps: 1) putting a minitype mechanical loading device fixed with a specimen into a CT scanning cavity, wherein the test cavity support of the minitype mechanical loading device is a roentgenolucent support; 2) respectively scanning the three-dimensional image of the specimen during forceful loading and forceless loading; and 3) carrying out image correlation analysis on the data of the two scanned three-dimensional images to obtain a three-dimensional deformation field in the specimen. The system comprises a minitype mechanical loading device, a CT machine and a data processing unit, wherein the test cavity support of the minitype mechanical loading device is a roentgenolucent support. Compared with the prior art, the invention can provide reliable testing foundation for observing microscopic imaging and biomechanical experiments in real time, and has the characteristics of simple structure, high reliability and wide application range.

Owner:卢世璧

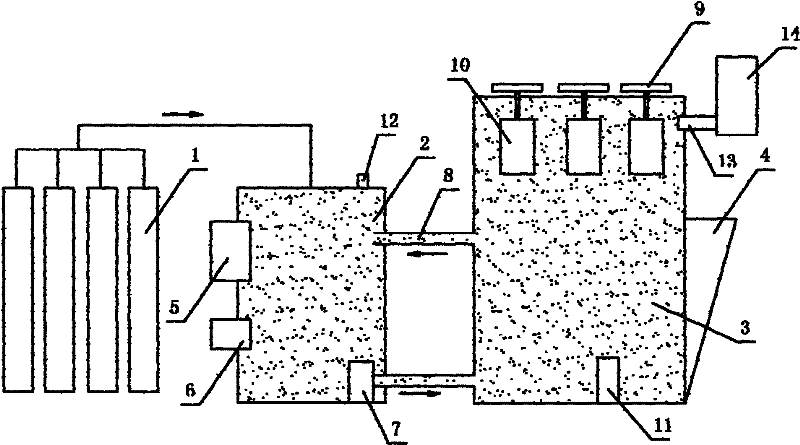

Testing system and method for seepage field model of tunnel in construction and operation periods

ActiveCN104880334AEnsure safetyReliable test basisStructural/machines measurementPilot systemData acquisition

The invention discloses a testing system and method for a seepage field model of a tunnel in construction and operation periods, and the testing system comprises a seepage field model box body and data collection device. The top of the seepage field model box body is provided with a pressure meter, and the bottom of a side wall of the seepage field model box body is provided with an overflowing hole. The top and bottom of a side wall of the seepage field model box body are respectively provided with an upper water inlet of the model box and a lower water inlet of the model box. Two opposite side walls are respectively provided with a tunnel hole. Two ends of each fixed steel reinforcement cage are fixed on inner walls of the edges of the tunnel holes, and the fixed steel reinforcement cages are respectively wrapped by a soil isolating layer. Peripheral bolts of flange plates are fixed on outer walls of edges of the tunnel holes, and the internal and external steel reinforcement cages are fixed between the two tunnel holes through the flange plates. Inner holes of the flange plates are provided with cover plates. A construction-period soil isolating plate is connected between the internal and external steel reinforcement cages in a threaded manner. A tunnel face water-blocking plate is fixed in the internal steel reinforcement cage in a threaded manner. Moreover, the construction-period soil isolating plate and the tunnel face water-blocking plate are located on the same vertical section. The system can test the conditions of the seepage field of the tunnel conveniently, accurately and truly in the construction and operation periods under the action of the seepage field.

Owner:SOUTHWEST JIAOTONG UNIV

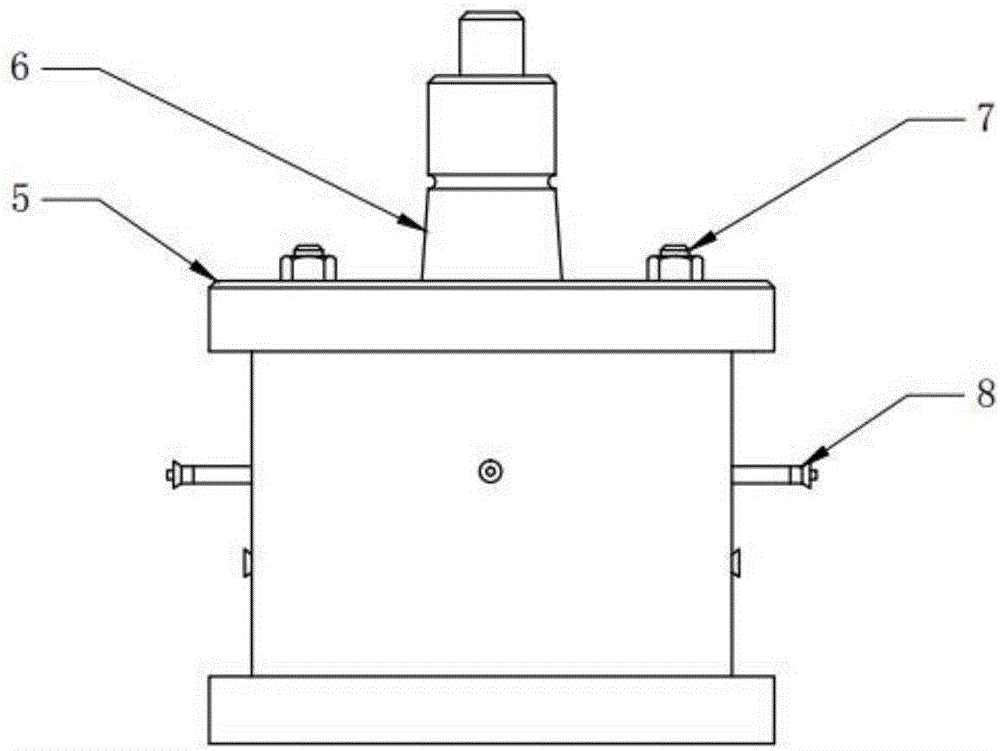

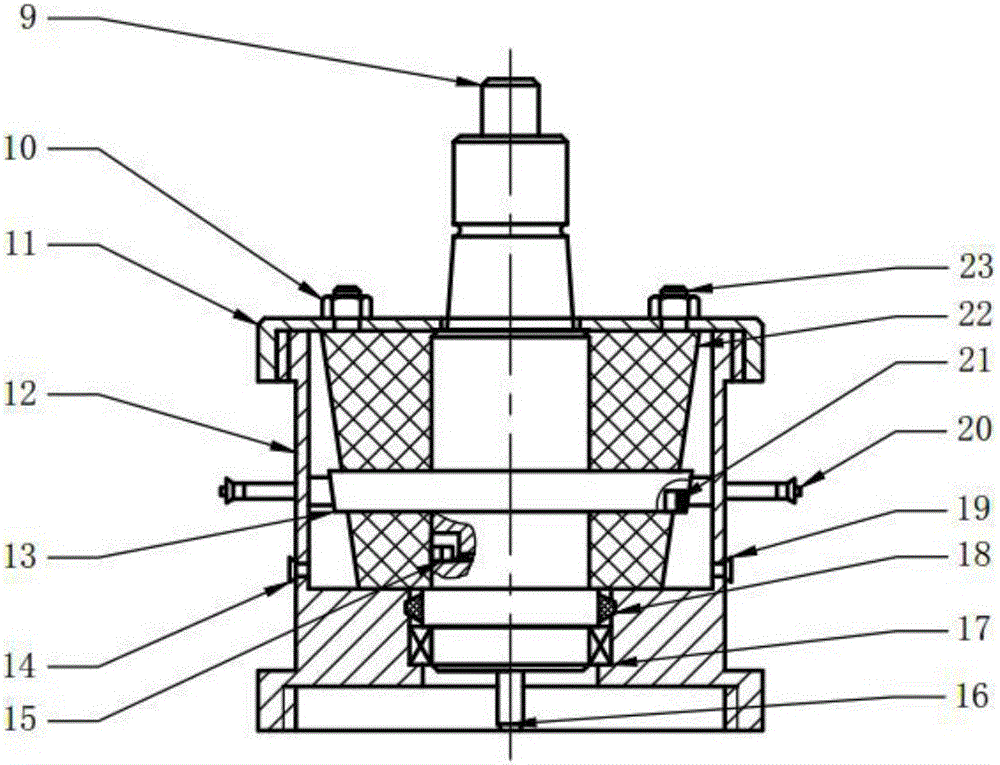

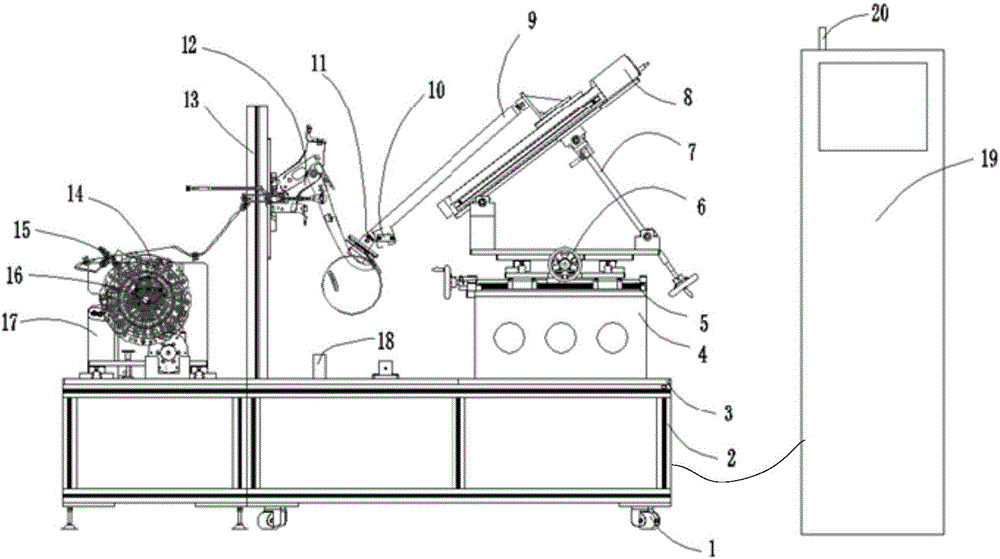

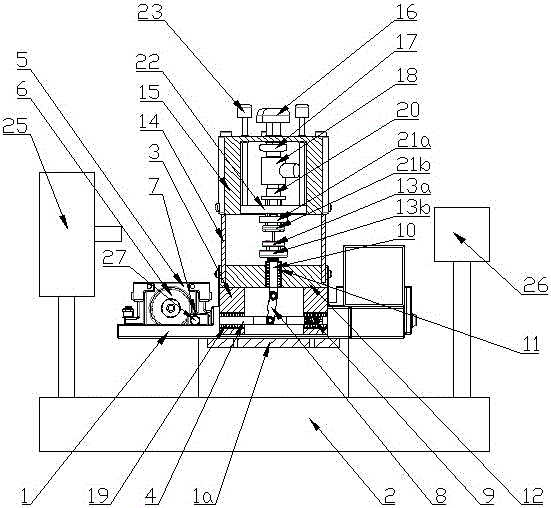

Biaxial-loading four-line-contact fatigue life testing machine for pure-rolling cylindrical roller

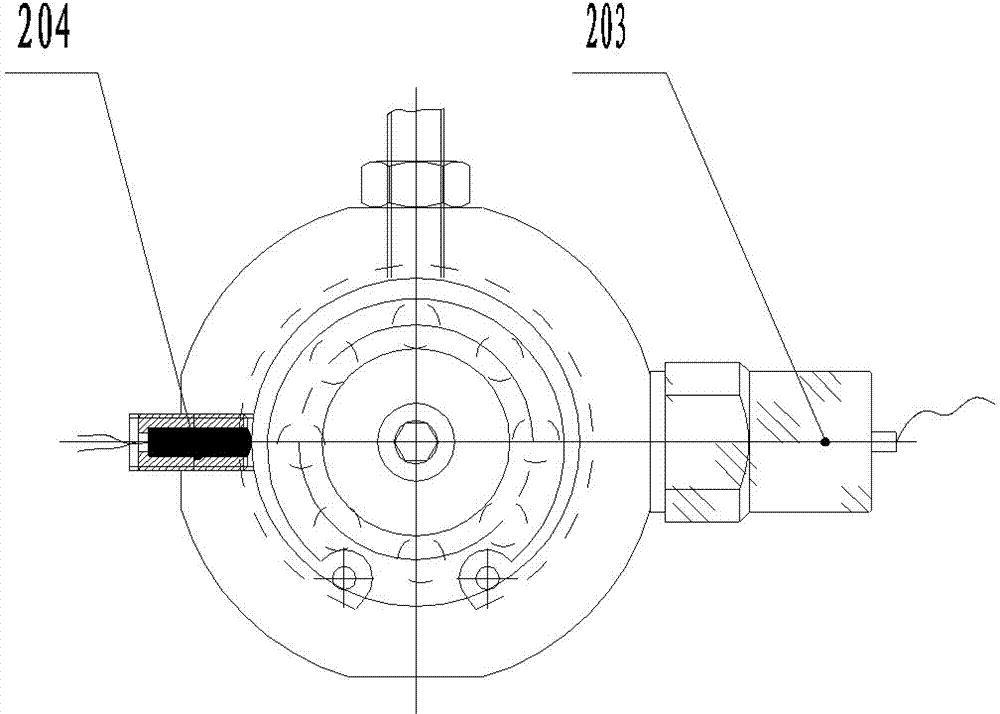

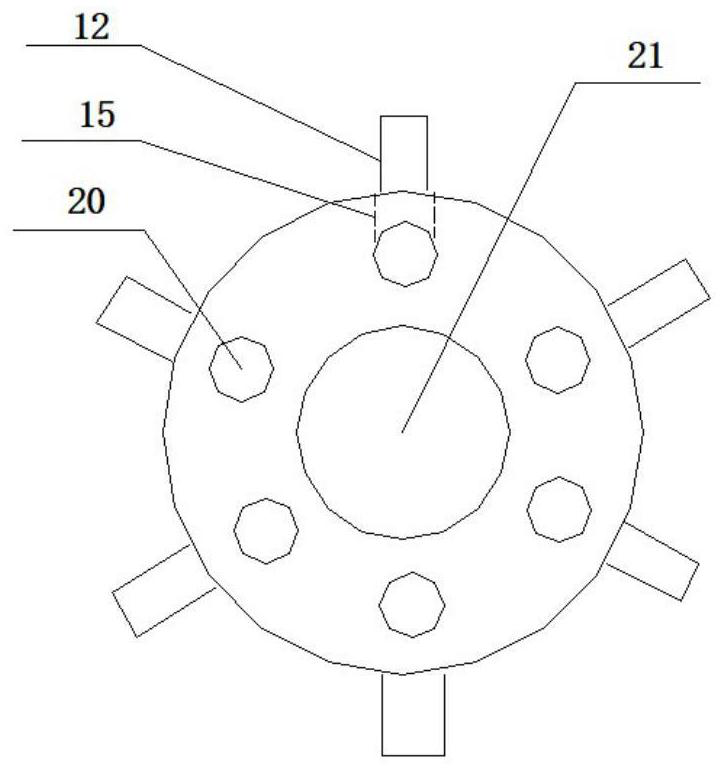

ActiveCN106855480AAccurate testing of fatigue lifeReliable test basisMaterial strength using repeated/pulsating forcesContact testBiaxial load

The invention relates to a biaxial-loading four-line-contact fatigue life testing machine for a pure-rolling cylindrical roller. The testing machine comprises a machine base, an oil tank, an oil pump, a motor, a core testing apparatus, a loading mechanism, a transmission mechanism and a data acquisition system, wherein the oil tank, the oil pump and the motor are arranged in the machine base; an upper support is mounted on the machine base; the core testing apparatus employs two axles for simultaneous application of same load to realize effective adjustment of the centering performance of test rollers of different diameters, is a core mechanism capable of carrying out four-line-contact pure-rolling contact test on the test rollers, and is mounted in the upper support; the oil tank is connected with the core testing apparatus via the oil pump and supplies oil to the core testing apparatus for lubrication of the core testing apparatus; the loading mechanism is arranged on the upper part of the upper support and connected with the core testing apparatus, and can realize test loading; and the motor is connected with the core testing apparatus via the transmission mechanism for realization of rolling fatigue testing of the cylindrical roller. The biaxial-loading four-line-contact fatigue life testing machine for the pure-rolling cylindrical roller in the invention can realize four-line equal-load contact and pure rolling of the test rollers and guarantees that four-line-contact stress of is symmetrical and equal during testing of rollers of different diameters, so the cylindrical test roller undergoes completely-identical uniformly-distributed-line-load pure-rolling contact four times in each intact rotation during fatigue life testing; and thus, the purpose of improving the accuracy and reliability of test results is achieved.

Owner:SHANGHAI UNIV +1

Tangential final-motion frictional wear test equipment

InactiveCN102590002AAchieve decouplingRealize the application of vertical loadInvestigating abrasion/wear resistanceControl systemData acquisition

The invention discloses tangential final-motion frictional wear test equipment. The equipment is characterized in that a lateral hydraulic piston connected with a data acquisition and control system is connected with a hinged shaft at the middle upper part of a vertical connecting rod; the upper end of the connecting rod is connected with one side of an upper test piece chuck through a cross bar; the other side of the upper test piece chuck is connected with a tangential displacement sensor fixed on the side wall of an experiment medium cavity; the upper test piece chuck is used for clamping a spherical test piece; a lower test piece chuck for clamping a plane test piece is arranged right below the upper test piece chuck; the lower test piece chuck is fixed at the bottom of the experiment medium cavity; the bottom of the experiment medium cavity is arrange on two longitudinal supporting rods; and a deformation sensor is arranged between the top of the longitudinal supporting rods and the bottom of the experiment medium cavity. The tangential final-motion frictional wear test equipment can effectively simulate the tangential final-motion friction and has the advantages of simple structure and high test precision, is convenient to maintain, can carry out a final-motion frictional test under the medium conditions, such as controllable high temperature, lubrication and liquid, and can provide more accurate and reliable test bases for designing, manufacturing and maintaining relevant parts.

Owner:SOUTHWEST JIAOTONG UNIV

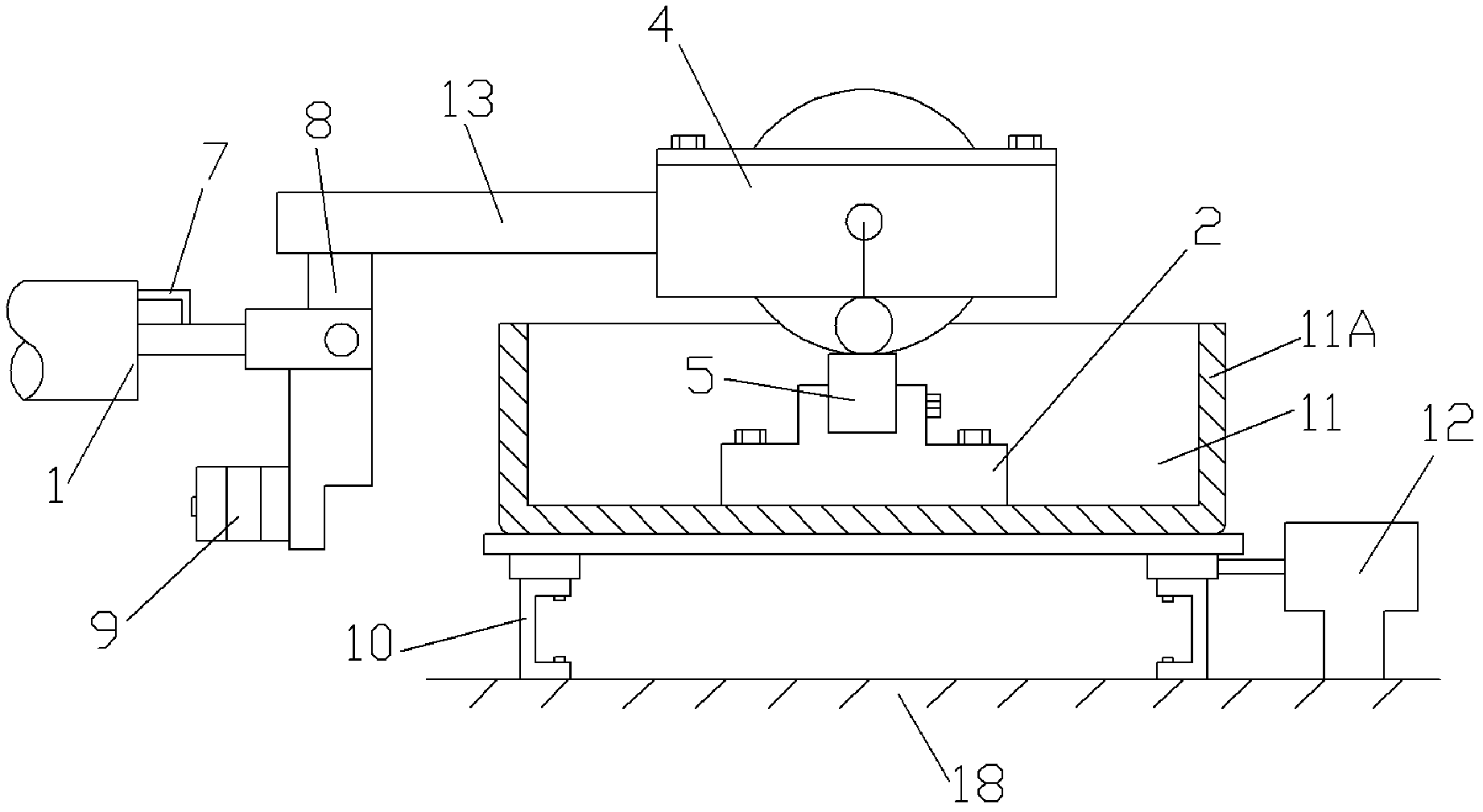

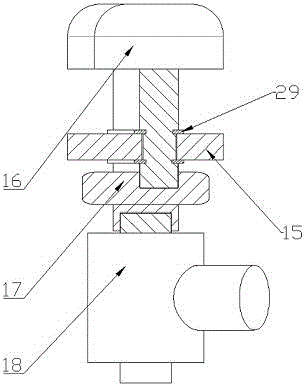

Improved actuation mechanism for fatigue testing machine achieving in-situ imaging of synchrotron radiation light source

ActiveCN106018140AIncrease brightnessImprove image signal-to-noise ratioMaterial strength using repeated/pulsating forcesTest sampleCam

The invention discloses an improved actuation mechanism for a fatigue testing machine achieving in-situ imaging of a synchrotron radiation light source. The actuation mechanism is arranged on a cylinder-shaped base plate on a platform of the synchrotron radiation light source and used for applying a vertical reciprocating displacement load to a test sample on the fatigue testing machine achieving in-situ imaging of the synchrotron radiation light source. Compared with the last generation of fatigue testing machines, further improvement is conducted, friction generated by a cam actuation mode is reduced, therefore, energy consumption of the fatigue testing machine is reduced, and the noise reduction performance of the fatigue testing machine is further improved; the load applied to the test sample is further guaranteed, and compared with the last generation of the fatigue testing machines, the details in the test implementation process are considered more detailedly.

Owner:SOUTHWEST JIAOTONG UNIV

Accelerated corrosion and deterioration testing device for tunnel lining structure in bearing state

ActiveCN105547983AAccelerated Corrosion Deterioration TestAccurately reflect the evolution law of performance declineWeather/light/corrosion resistanceMaterial strength using steady bending forcesEngineeringRebar

The invention relates to an accelerated corrosion and deterioration testing device for a tunnel lining structure in the bearing state. The accelerated corrosion and deterioration testing device is a loading device composed of thread brace rods, a left loading crossbeam, a right loading crossbeam, a self-reaction force beam and a hydraulic jack; the loading device is used for controllably loading a tunnel lining structural member in a moment and axial force introduction manner and truly simulating the actual stress state of a tunnel lining structure during the operation period. Meanwhile, a steady flow direct-current power supply, corrosive liquid in a top surface corrosion area or an omnidirectional corrosion area, a stainless steel mesh in the corrosive liquid and a steel bar of the tunnel lining structural member form an electrochemical accelerated corrosion system; the electrochemical accelerated corrosion system is used for the accelerated corrosion and deterioration of the tunnel lining structural member. A strain gauge, a displacement meter, a pressure sensor and the like are used for measuring strain, deformation displacement and other data of the tunnel lining structural member in real time, thereby realizing the accelerated corrosion and deterioration test of the tunnel lining structure in the bearing state. The test environment of the accelerated corrosion and deterioration testing device provided by the invention is an environment under the combined action of load and erosion, is closer to a real underground environment of the tunnel lining structure and can more accurately reflect a real performance degradation evolution law of the tunnel lining structure, thereby providing a more reliable test basis for design and maintenance of tunnel engineering.

Owner:SOUTHWEST JIAOTONG UNIV

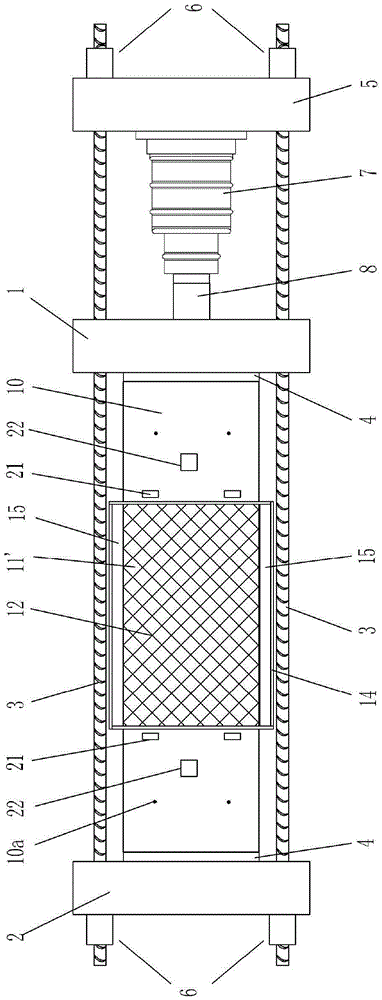

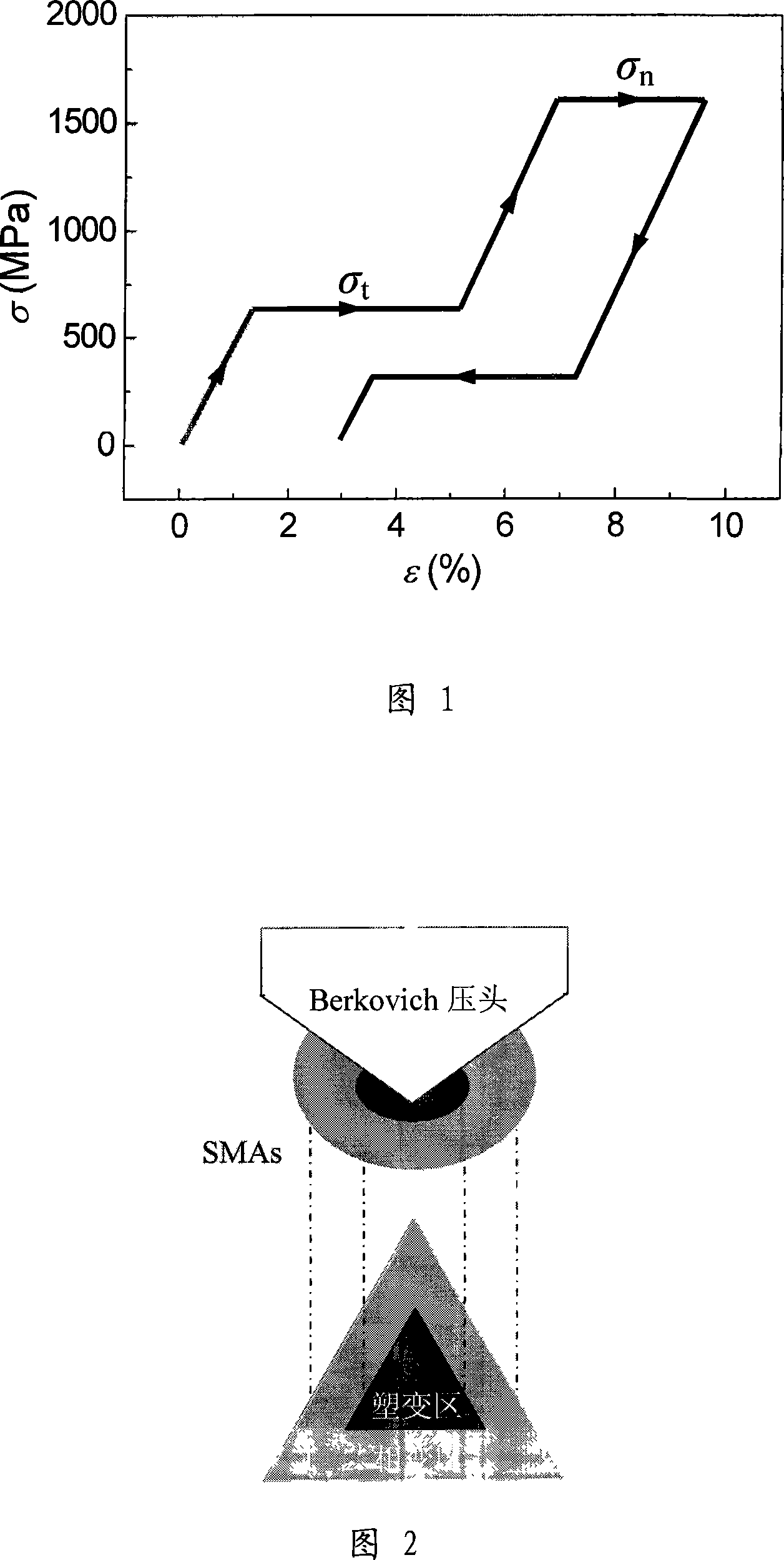

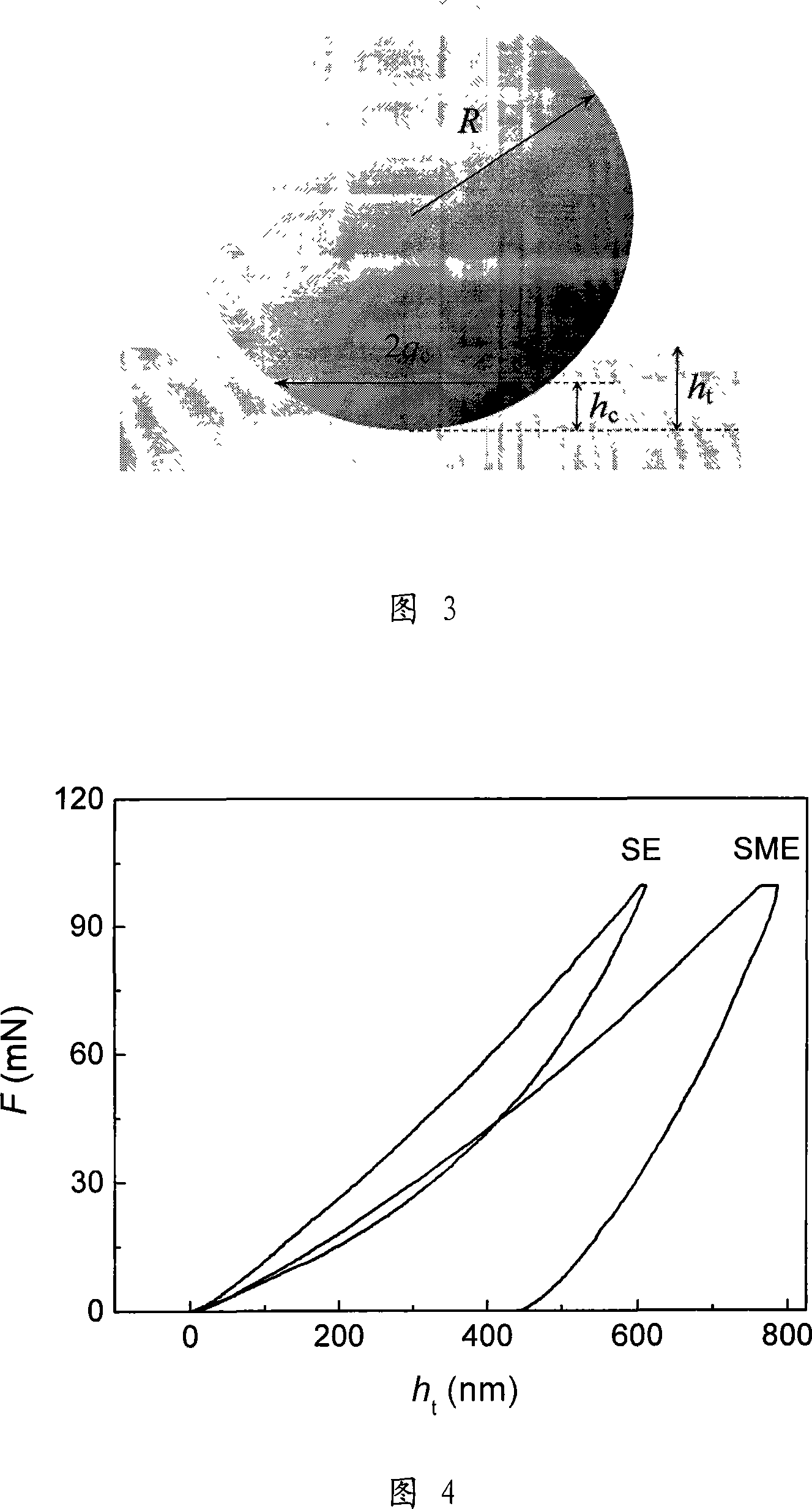

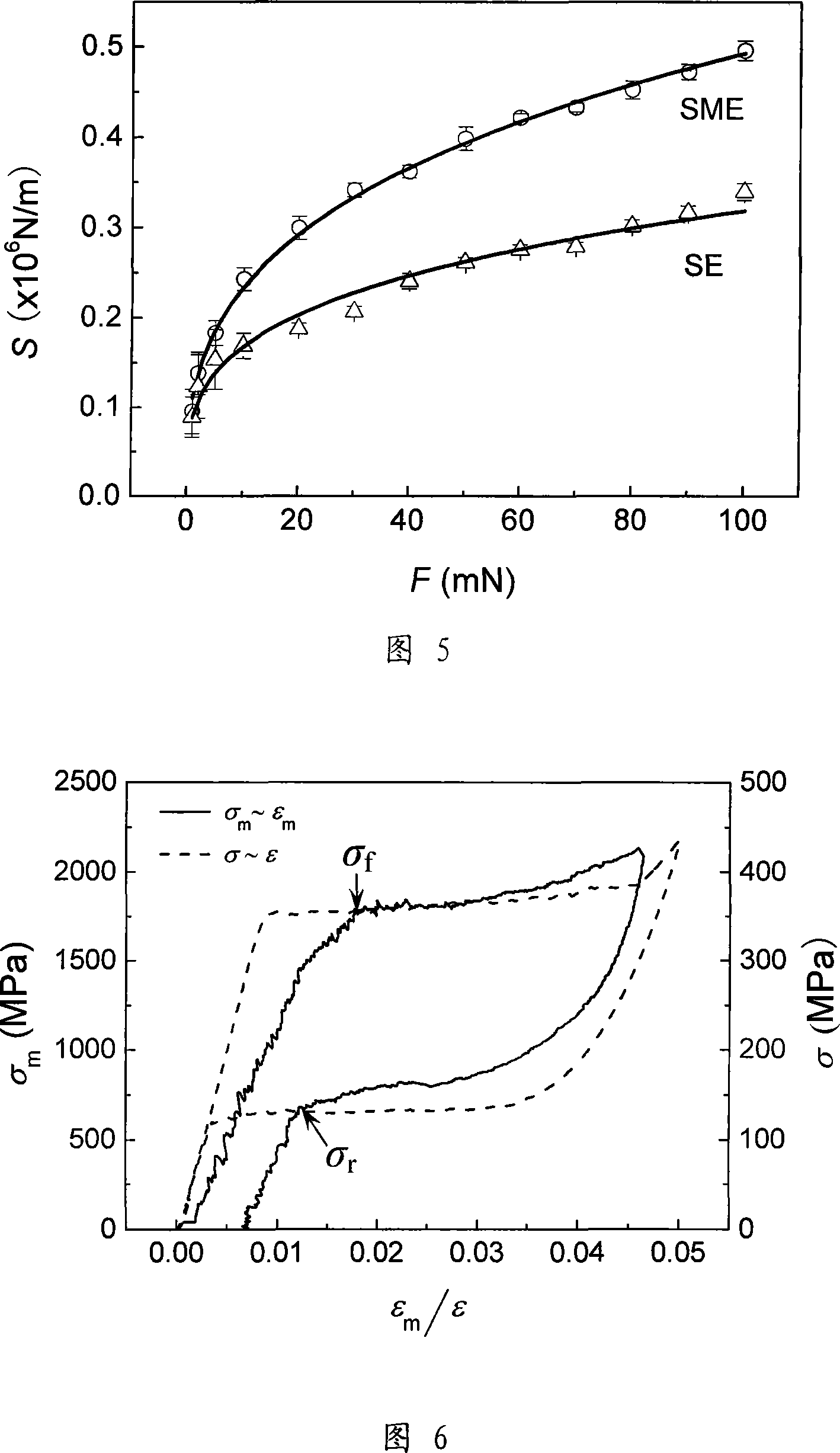

Method for ball-shape pressure head for determining shape memory alloy phase change property

InactiveCN101126692AEasy to operateAvoid damageComplex mathematical operationsStrength propertiesMicrometerShape-memory alloy

The utility model discloses a method using a spherical indenter for measuring the phase transition properties of shape memory alloy (SMAs). The phase transition is induced under the pressure of the spherical indenter pressed into the surface of the shape memory alloy; the load signals and the displacement signals in the unloading process are detected by a sensor at the same time, and the ht curve of the load F-displacement is obtained; the load-displacement curve obtained in the test is transformed to a corresponding nominal stress Sigmam-nominal stress Epsilonm curve according to the analysis; then properties of the transformation stress, the elastic modulus and other aspects of the SMAs can be obtained. The test method has advantages that the method is easy in operation, and the nondestructive measurement of the materials can be elementally realized; the method not only can be widely used in the measurement of the phase transition properties of various super-elastic and shape memory SMAs, but also is particularly suitable for the phase transition measurement of the SMAs films with the low thickness only up to a plurality of micrometers or the SMAs micro devices with the micrometer order typical structure size; the method has accurate and precise measured value, which can supply the reliable measurement basis of the phase transition property for the application of the SMAs in the micro-electro-mechanical system.

Owner:SOUTHWEST JIAOTONG UNIV

Sealed deep groove ball bearing waterproofness testing method and testing device

ActiveCN103196631AVerification and assessment of water resistanceRealize alternate water spray functionMachine bearings testingFluid-tightness measurement using fluid/vacuumBall bearingDrive shaft

The invention relates to the field of bearing test technology, in particular to a sealed deep groove ball bearing waterproofness testing method and a testing device using the testing method. The sealed deep groove ball bearing waterproofness testing method includes the steps of driving an inner ring of a bearing to be tested to rotate through a transmission shaft outputting rotating motion, exerting radial load on an outer ring of the bearing to be tested through a radial loading system, spraying water to an end face of the bearing to be tested through a water spraying system, and then detecting waterproofness of the bearing to be tested. The sealed deep groove ball bearing waterproofness testing method and the testing device can truly simulate rotating speed and loading conditions of the sealed deep groove ball bearing in the actual working process. The water spraying system can be used for spraying water to the end face of the bearing. After the water spraying, the waterproofness of the bearing can be verified and checked through observation of water inflow conditions of the interior of the bearing.

Owner:LUOYANG BEARING RES INST CO LTD

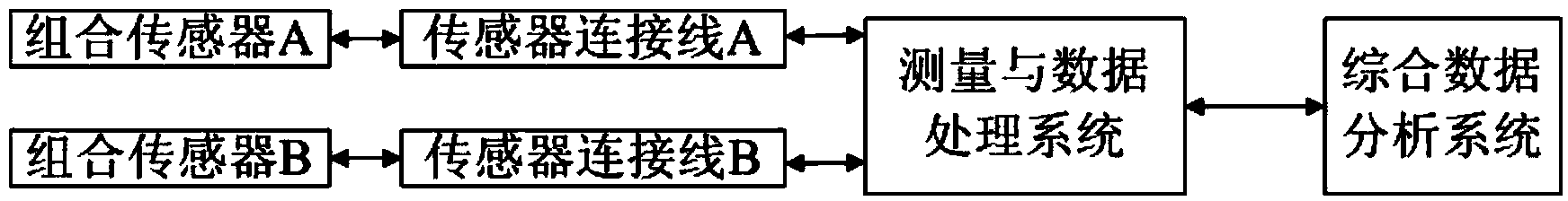

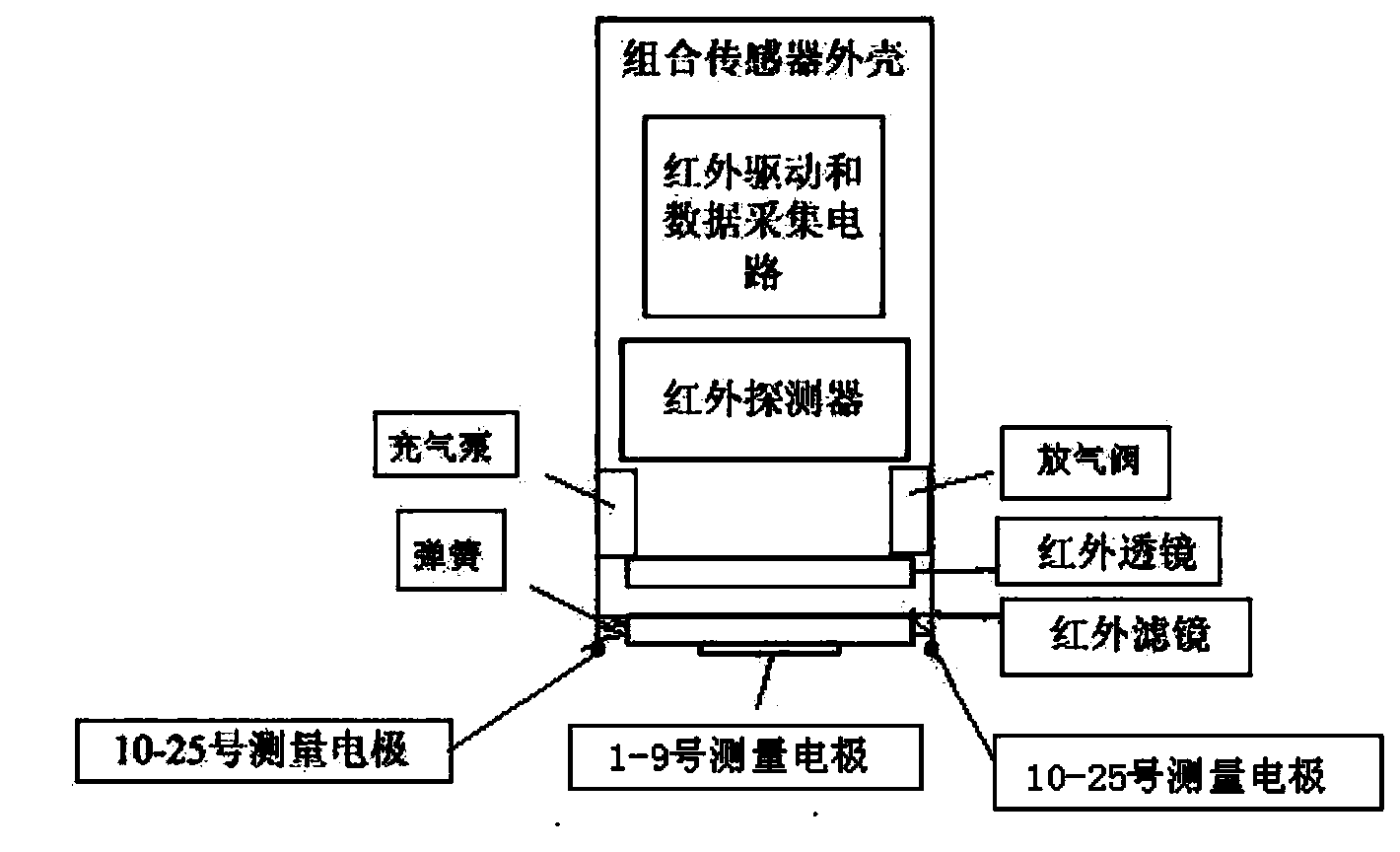

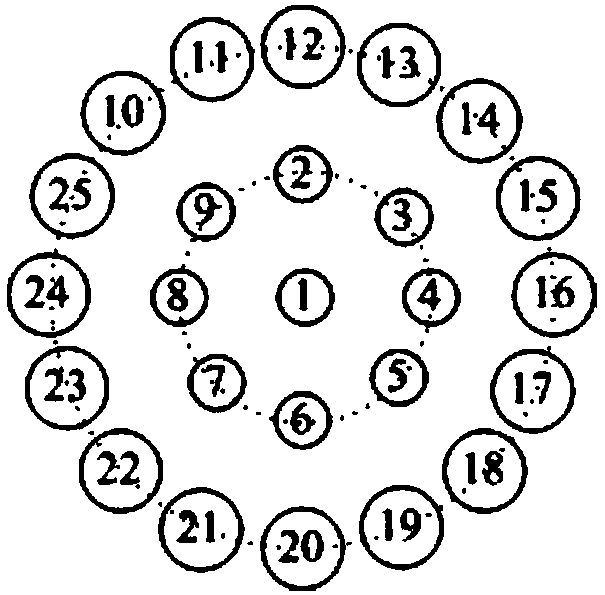

Distributed vessel and acupoint multi-parameter tester and testing method

InactiveCN103750838AReliable test basisDevices for locating reflex pointsDiagnostic recording/measuringSpectroscopyEngineering

The invention discloses a distributed vessel and acupoint multi-parameter tester and testing method. The tester is composed of a combined sensor A, a combined sensor B, sensor connection lines, a measuring and data processing system and a comprehensive data analyzing system. Twenty-five electrodes are distributed according to shape rules of a circle center, an inner ring and an outer ring. By means of a gate circuit, parameters and parameter distribution of impedance spectroscopy, impedance imaging and oxygen partial pressure of gates of the electrodes are measured. Temperature and temperature distribution are measured through an infrared measuring mode. The measured parameters are measured and collected through the measuring and data processing system, the comprehensive data analyzing system carries out data analysis, and the testing process is controlled through a computer. By means of the tester, four kinds of parameters and parameter distribution of a vessel and acupoint area can be detected, and is a research device used for physicochemical property research of acupoints through parameter comparison. Modern technologies are used for analyzing and sorting a large quantity of data and researching mutual relations of the parameters and parameter distribution and distribution rules, and a basic instrument is provided for theoretical research of traditional Chinese medicine vessels and acupoints.

Owner:SICHUAN UNIV

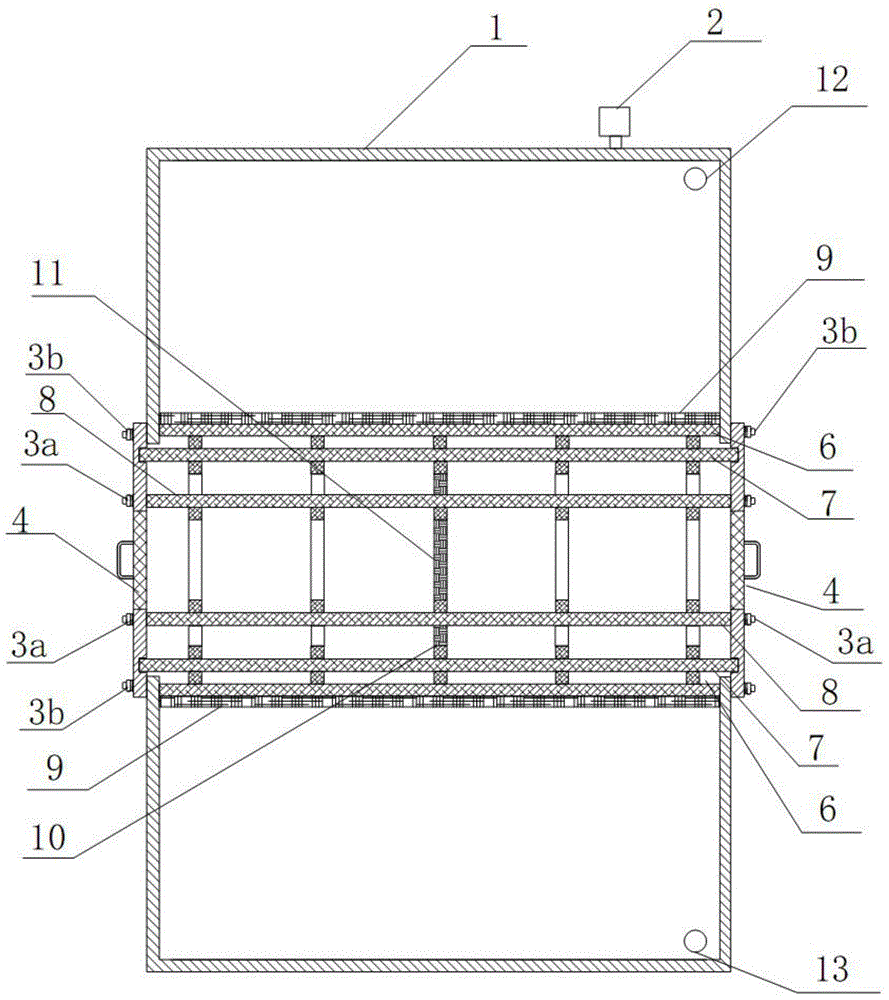

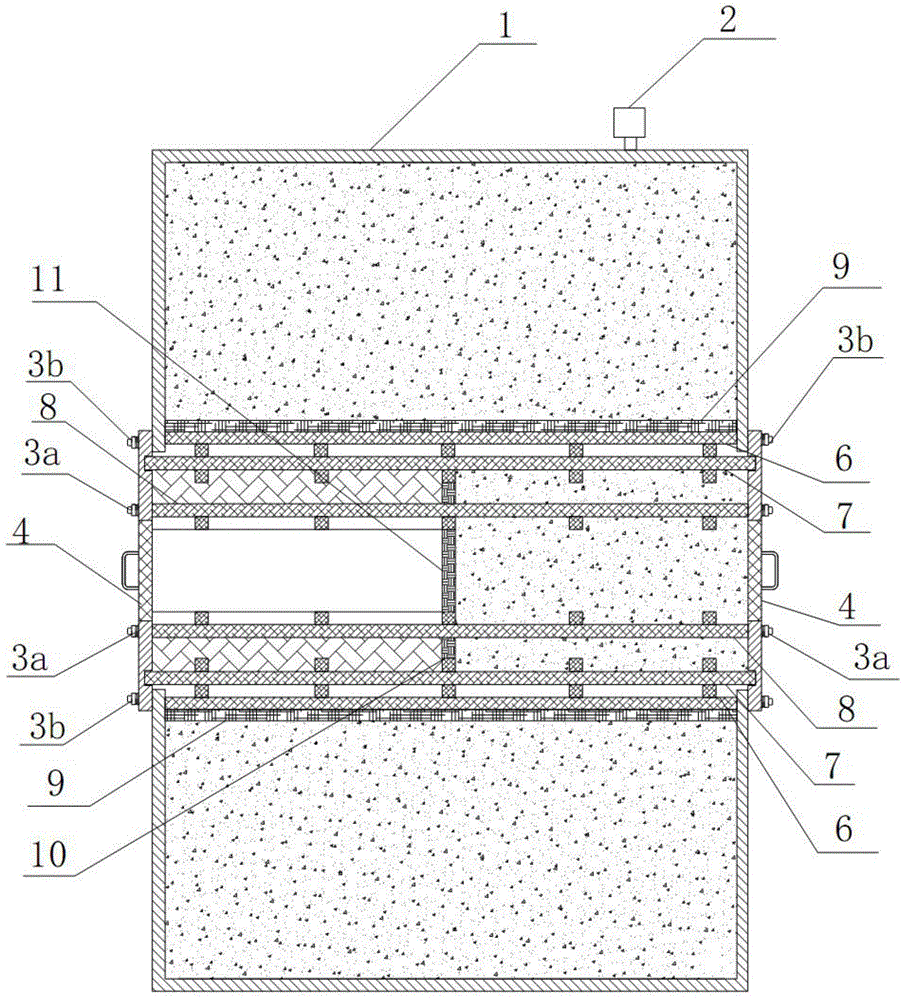

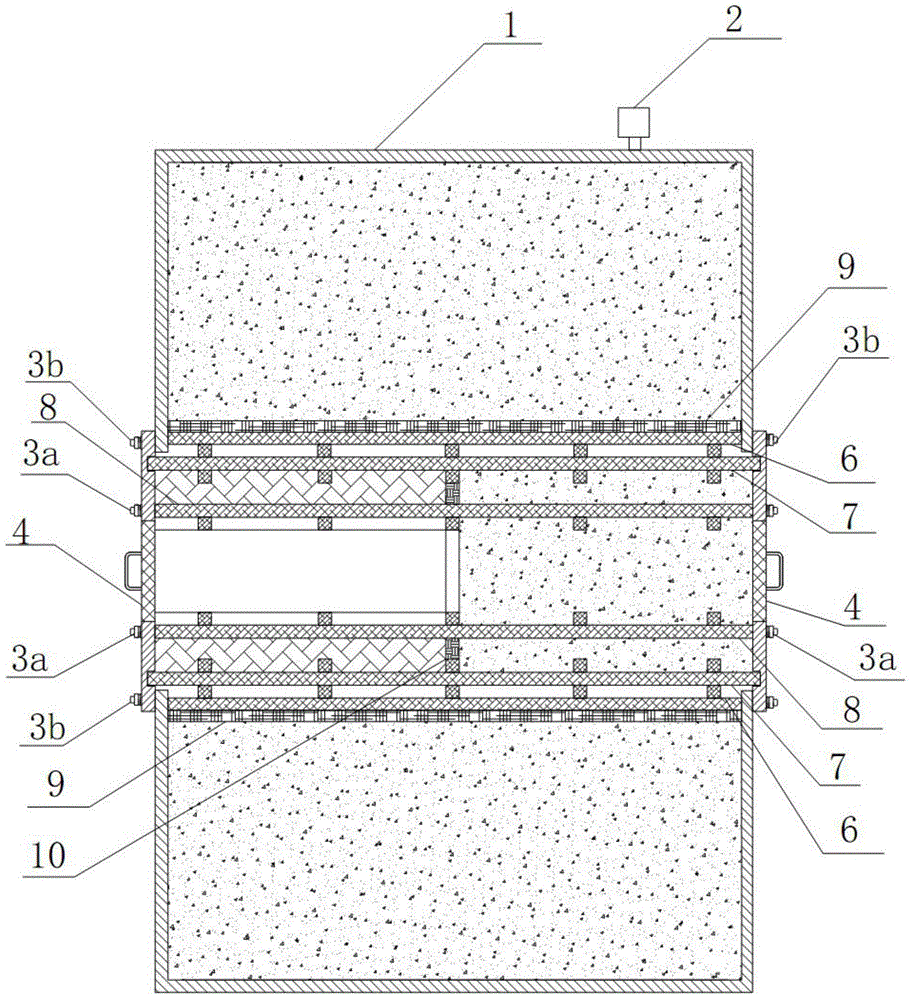

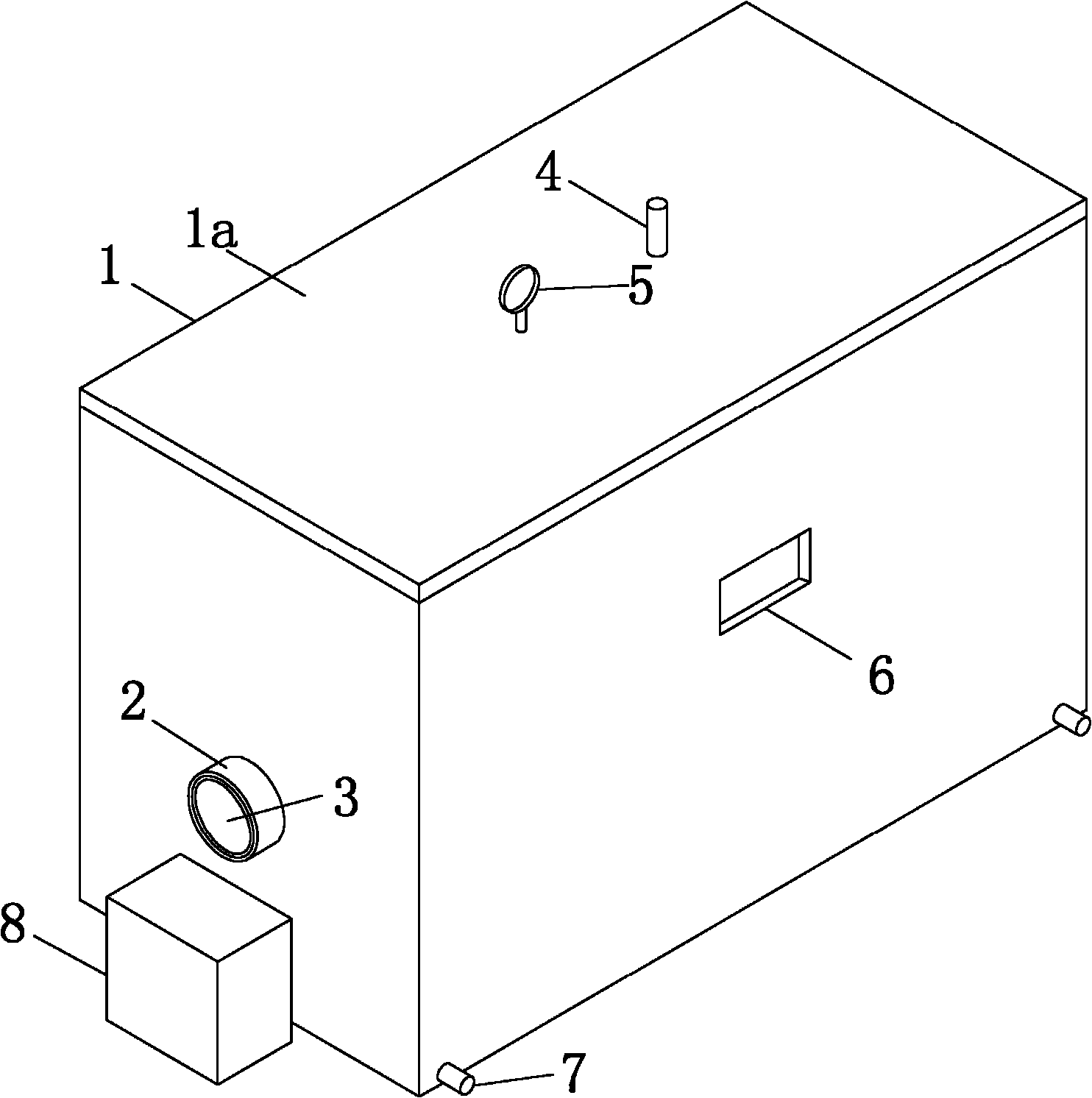

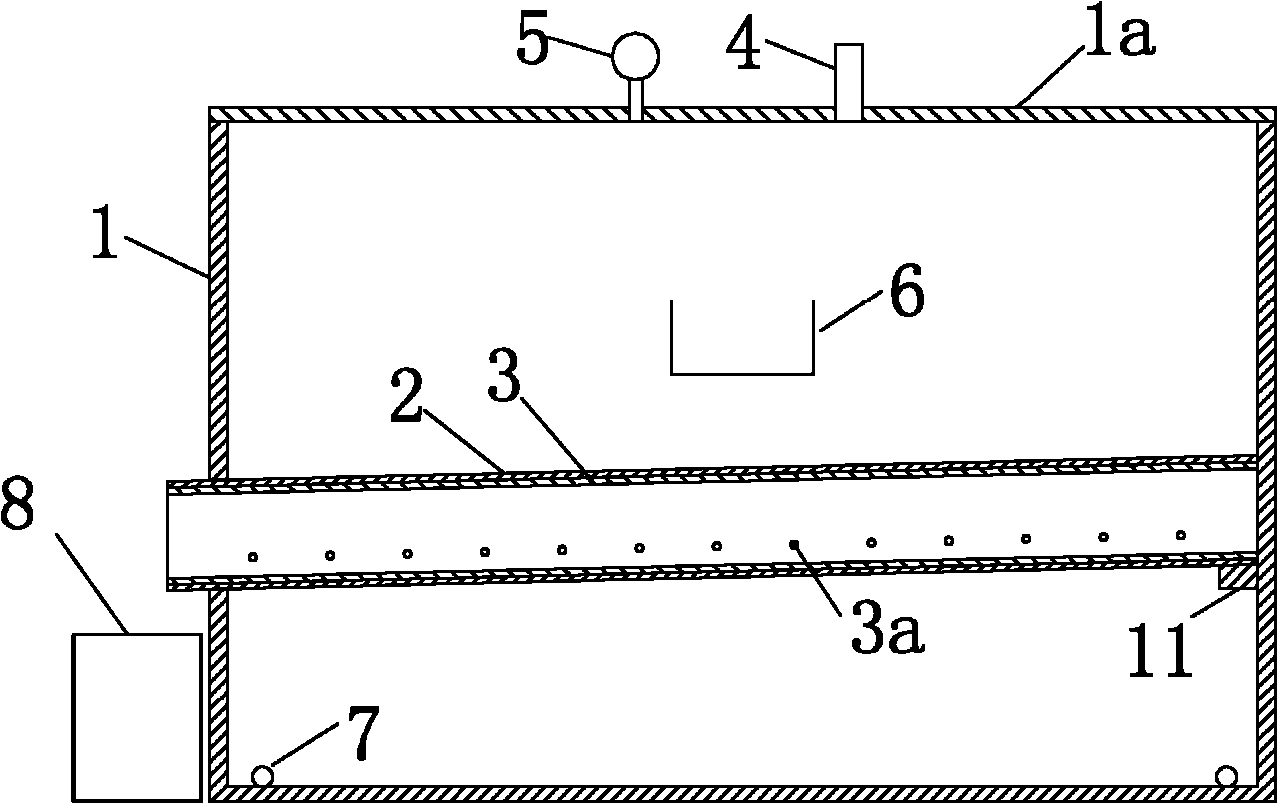

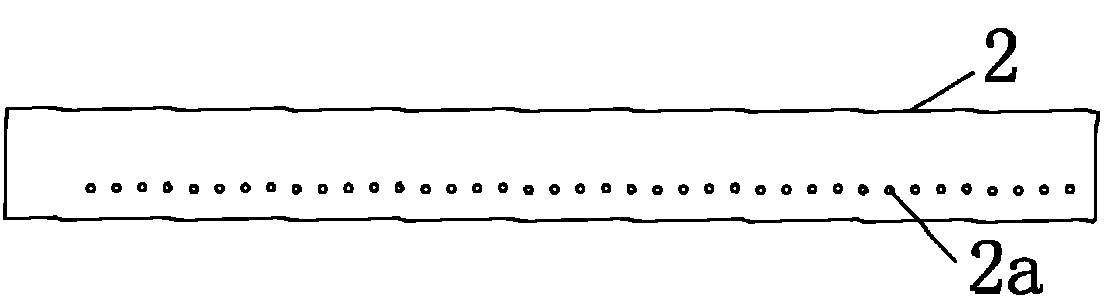

Drainage type segment lining model pore hydrostatic test device

InactiveCN102135491AGood adhesionShorten the timePermeability/surface area analysisWater storageEngineering

The invention discloses a drainage type segment lining model pore hydrostatic test device. An inner die (3) which is constructed by a circular PVC (Poly Vinyl Chloride) tube is longitudinally arranged in a box body (1) of the device; the lower part of the inner die (3) is provided with inner die drainage holes (3a); a water outlet end of the inner die (3) extends out of a side wall of the box body (1); a water storage container (8) is arranged below the water outlet end of the inner die (3); a steel outer die (2) is sleeved outside the inner die (3) and is provided with outer die drainage holes (2a) with the same circumferential positions as the inner die drainage holes (3a); the number of the inner die drainage holes (3a) is less than or equal to that of the outer die drainage holes (2a); and any inner die drainage hole (3a) is aligned with a corresponding outer die drainage hole (2a). The test device is easy for test operation, has a short test period, high test data accuracy and high reliability and can provide a more effective, reliable and accurate test basis for design and construction of a shield tunnel, so that safety and economy of the tunnel are guaranteed better.

Owner:SOUTHWEST JIAOTONG UNIV

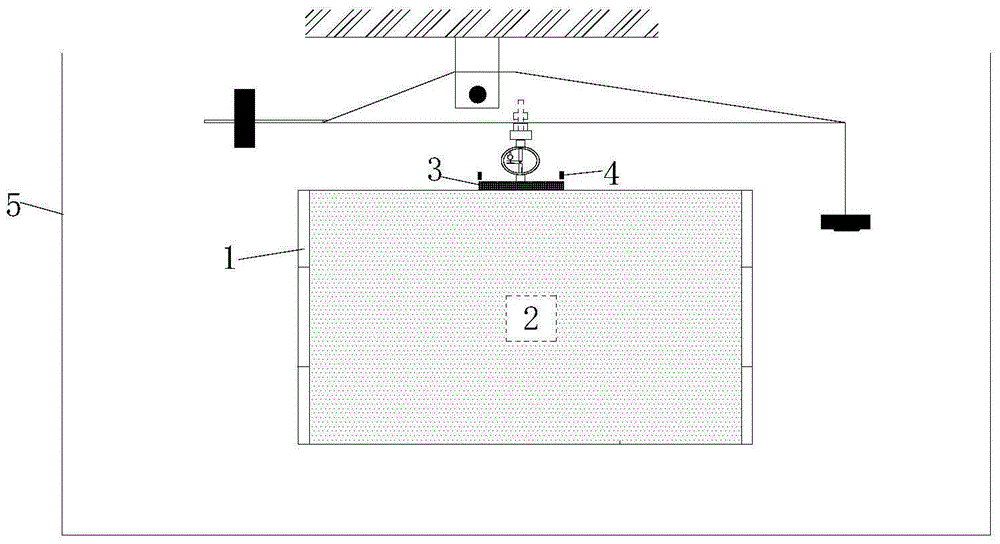

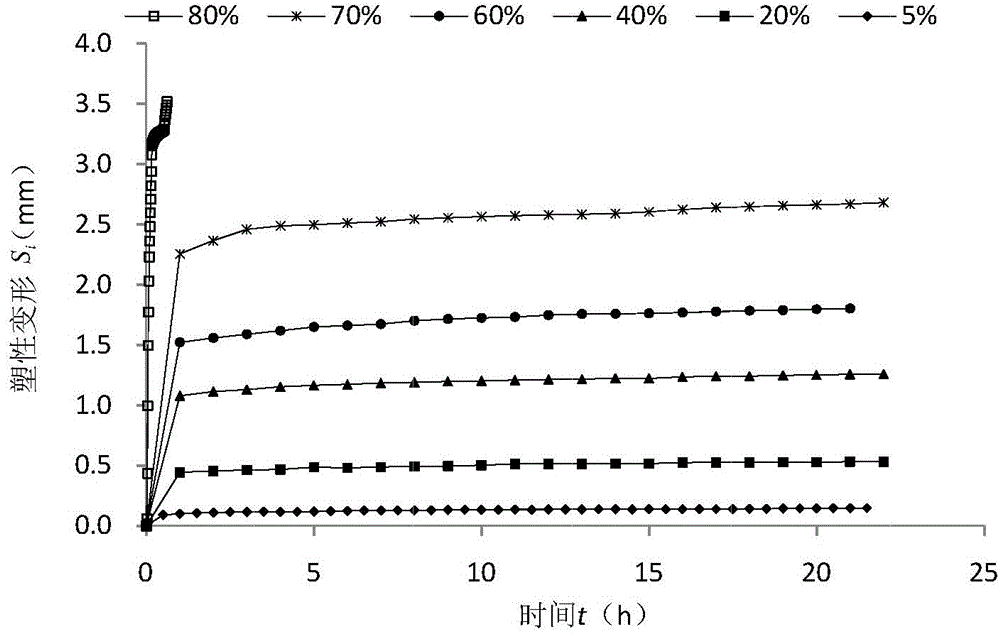

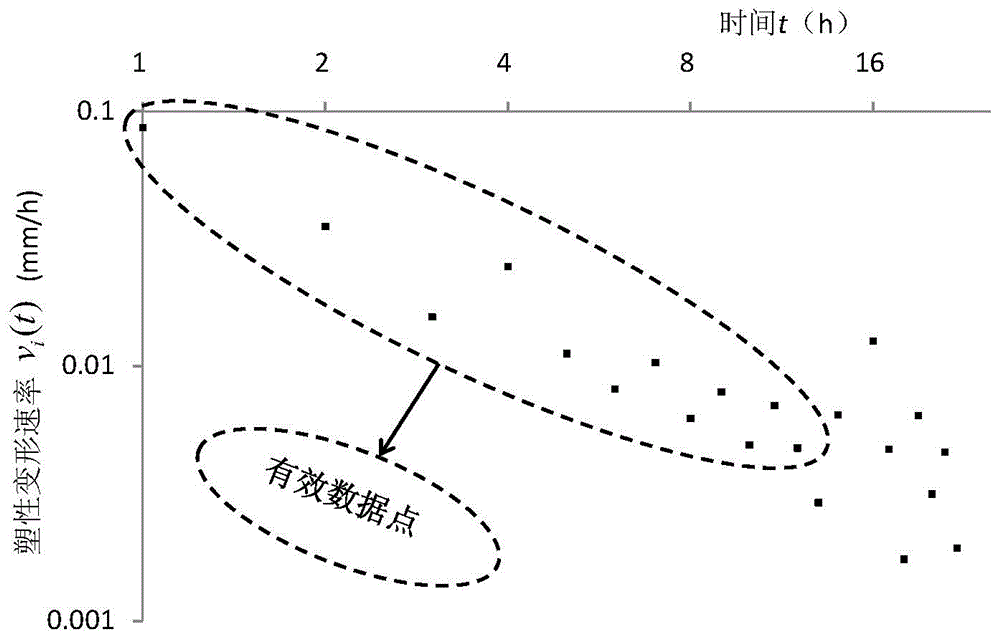

Method for measuring load threshold value of soil deformation state of railroad bed under static load

ActiveCN104535420AStable moisture contentGuaranteed accuracyMaterial strength using tensile/compressive forcesNegative powerEngineering

The invention relates to a method for measuring a load threshold value of a soil deformation state of a railroad bed under a static load. The method is characterized by comprising the following operating steps: building a filling model in a model case formed by rigid side walls and applying static loads in grade to the filling model by using a round rigid loading plate according to different proportionality coefficient lambda of the ultimate bearing capacity; measuring and calculating plastic deformation rates vi(t) of soil at different moments t in a loading process by using a displacement sensor, taking data points of the rates and fitting the data points according to a negative power function v(t)=At-alpha; and obtaining a power exponent alphai value corresponding to the load proportionality coefficient lambda, and fitting the power exponent alphai value to obtain an alpha-lambda curve according to a cubic polynomial, wherein taking loads piI=lambdaIsigmaf and piII=lambdaIIsigmaf corresponding to lambdaI and lambdaII of two curature maximum values of the alpha-lambda curve are adopted as the load threshold value of the soil deformation state. piI and piII can be used for providing test grounds for design and optimization of ballastless / ballast track beds of a high speed railway and a deformation state evaluation and regulation principal, respectively. The method has the characteristics of being relatively short in testing time and specific in criterion, and the obtained load threshold value is relatively accurate and reliable.

Owner:SOUTHWEST JIAOTONG UNIV

Finger friction test device

PendingCN106568705AThe parameters are accurateWide range of applicationsUsing mechanical meansMaterial analysisElectric machineryFriction test

A finger friction test device is mainly structured as follows: a servo motor on a rectangular pedestal drives a sliding table through a leading screw and nut mechanism to slide side to side; the upper surface of the sliding table is connected with a sample stage through a strain-type two-direction force sensor; a three-dimensional acceleration sensor is installed on the sample stage; a sound sensor is arranged; a left connecting rod and a right connecting rod which can rotate and can be fastened are mounted on the pedestal; a finger support block is fixed on the right connecting rod, and the left connecting rod is connected with a finger press block, which can move up and down and can be fastened, through an installation block and a loading plate; and the servo motor, the strain-type two-direction force sensor, the three-dimensional acceleration sensor and the sound sensor are all electrically connected to a control and signal acquisition and processing system. The device of the invention can reliably and accurately analyze and study the relations of test parameters and friction coefficients including friction angle, friction normal force, relative sliding speed, etc., vibration acceleration and acoustical signals when the finger is in contact friction with a substance, thus providing the basis for surface design of relevant products and touch simulation design of an intelligent robot.

Owner:SOUTHWEST JIAOTONG UNIV

High-temperature erosion testing device and method for thermal barrier coating of turbine blade of gas turbine

PendingCN112326491AReliable test basisMachine part testingWeather/light/corrosion resistanceDust controlSolid particle

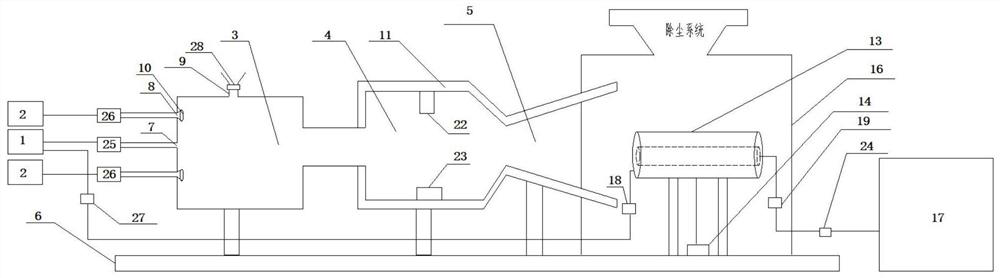

The invention discloses a high-temperature erosion testing device and method for a thermal barrier coating of a turbine blade of a gas turbine. The high-temperature erosion testing device comprises ahigh-temperature spray gun system, a testing system, a cooling system, a central control system and a dust removal system. By using the testing device and the testing method provided by the invention,the high-temperature erosion environment of the turbine blade of the gas turbine in a working state can be simulated to the greatest extent, and the positions and speeds of solid particles impactingthe surface of the thermal barrier coating, and the angles relative to the surface of the coating are simulated, and service environments that after the rebounding of the particles impacting the surface of the thermal barrier coating, other positions of the thermal barrier coating or the surfaces of other blades are impacted in different motion states, and such as multiple times of erosive wear are generated for the coating are simualted. The test result can provide a reliable test basis for researching the service life of the thermal barrier coating, selecting a thermal barrier coating material and the like.

Owner:XIAN THERMAL POWER RES INST CO LTD

Pressurization type accelerated corrosion test device of tunnel lining structure, and pressurization control method

ActiveCN109100296AReliable test basisControl lift distanceWeather/light/corrosion resistanceMaterial analysis by electric/magnetic meansCorrosionWater storage tank

The invention discloses a pressurization type accelerated corrosion test device of a tunnel lining structure. The device comprises a water storage tank arranged on the outer side of the tunnel liningstructure and used for accumulating corrosive liquid, a vertical pull rod, a cross beam, a piston, a sealing plate, an electric cylinder, a speed reducer, a motor, a pressure sensor and a controller,wherein the pressure sensor is installed on an inner bottom of the water storage tank, the pressure sensor and the motor are respectively connected with the controller, the motor drives the speed reducer, the electric cylinder, the piston and the sealing plate in sequence, and the sealing plate is placed at the top of an inner end of the water storage tank. The invention further discloses a pressurization control method adopted by the pressurization type accelerated corrosion test device of the tunnel lining structure. The operation of the motor is controlled by collecting the data of the pressure sensor so as to accurately control the pressure of the corrosive liquid in the water storage tank on the outer side of the tunnel lining structure. The pressurization type accelerated corrosion test device disclosed by the invention can accurately and truly simulate the actual service environment of the tunnel lining structure under the action of water pressure, and provides a more reliable test basis for the design and maintenance of the tunnel engineering.

Owner:SOUTHWEST JIAOTONG UNIV

Rotating control head rubber core abrasion experiment equipment

ActiveCN105954133ASimple structureSimple and efficient operationInvestigating abrasion/wear resistanceUnderbalanced drillingMeasuring equipment

The invention discloses rotating control head rubber core abrasion experiment equipment and belongs to the technical field of abrasion experiment measuring equipment. The rotating control head rubber core abrasion experiment equipment comprises a vertical universal friction and abrasion testing machine, a test-piece rubber core clamp, a guide pipe and a stepping adjustable mud pump. Test-piece rubber cores fixed through a shell assembly and a fixing device in a main shaft and the clamp form a rotation pair and rotate relative to each other, a temperature control device and the stepping adjustable mud pump provide different experiment conditions for the experiment equipment, and the abrasive particle abrasion situation of the rubber cores in the unbalanced drilling process of a rotating control head is effectively simulated. The rotating control head rubber core abrasion experiment equipment solves the problem that at present, experiment equipment in the field does not achieve systematization and standardization, and research on the abrasion mechanism and the damage evolutional law is promoted; an accurate and reliable experiment basis can be provided for design, manufacturing and maintenance of parts related to the rotating control head rubber cores and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Deep soft rock adsorption gas experimental system in hot and humid environment

ActiveCN102262030AAccurate readingReliable test basisWeighing by absorbing componentSystems analysisRock engineering

The invention discloses an experimental system for gas absorption of a deep soft rock in a hot and humid environment, comprising a gas source, a gas preparation chamber, a soft rock-gas absorption chamber, a weighing sub-system and a manipulation sub-system. The gas source fills various experimental gases for the mutually communicated gas preparation chamber and soft rock-gas absorption chamber, the gas preparation chamber controls the humiture and the concentration of the experimental gas, the weighing sub-system measures a gas absorption process of a soft rock sample in the soft rock-gas absorption chamber in real time, and finally, the manipulation sub-system analyzes the characteristics, the mechanism and the influence of key factors of gas absorbed by the deep soft rock. In the experimental system, the experimental process has steady environment, the read data is accurate, the experiment result is reliable, and the overall research result not only has academic significance, but also has far-reaching engineering application prospect in designing, constructing and maintaining steady support and protection for deep soft rock engineering, safety production and the like.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Automobile clutch performance matching measurement test apparatus

InactiveCN106124201AImprove accuracyIncrease authenticityMachine gearing/transmission testingClutch controlWork performance

The invention provides an automobile clutch performance matching measurement test apparatus which comprises footmaster casters and the like. The footmaster casters are under a movable test stand. A test platen is above the movable test stand. An adjusting force application direction device, a clutch transmission mechanism mounting fixture, and an emergency stopper are on the test platen. A horizontal left and right regulator is connected to the upper end of the adjusting force application direction device. A horizontal front and back regulator is connected to the horizontal left and right regulator.The invention has a standard for the quantitative calculating and test method of the dynamic transmission efficiency in the whole clutch control system work process as a reference, the working performance of a whole automobile clutch system operating mechanism can be accurately and quantitatively evaluated, the dynamic measurement of the control transmission efficiency of a simulation clutch in a real automobile installation state can be realized, the authenticity and accuracy of measurement data are improved, and the structure is simple.

Owner:SHANGHAI ANXUAN AUTOMATION TECH CO LTD

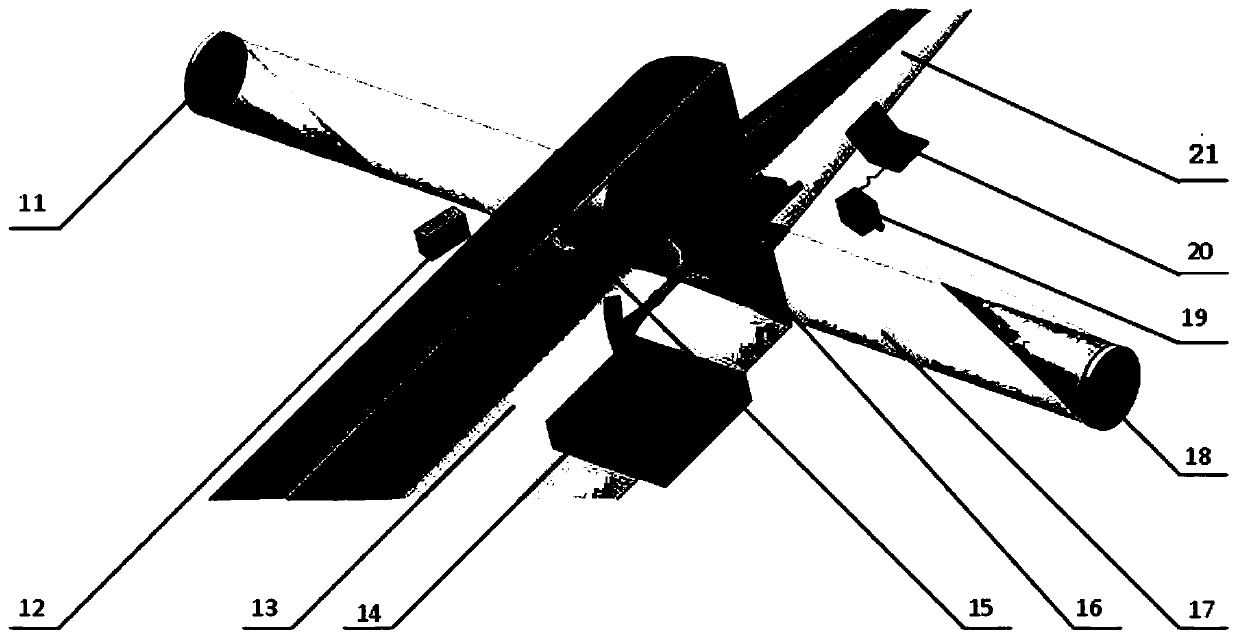

Pneumatic revolving door device and method for self-starting test outlet of shock tunnel air inlet channel

ActiveCN110333044AEffective automatic throttle controlReliable test basisAerodynamic testingShock waveSpeed of sound

The invention provides a pneumatic revolving door device for a self-starting test outlet of a shock tunnel air inlet channel, a method for performing high-speed photography on the action process of the self-starting test outlet pneumatic revolving door of the shock tunnel air inlet channel by using the device, and a throttling method for performing the self-starting test of the shock tunnel air inlet channel. The device comprises a door plate positioned at the end part of the outlet of the air inlet channel, the door plate is rotatably connected with a rotating shaft through a shaft sleeve, the rotating shaft is fixed below the outlet end part of the air inlet channel, the lower edge of the door plate is vertically connected with a limiting step, the included angle between the inclined door plate and the end surface of the outlet of the air inlet channel is 3-5 degrees, and after the flow field of a wind tunnel is stable, the pneumatic revolving door rotates around the rotating shaft under the pushing of air flow and is opened to start the air inlet channel; and the method can conveniently carry out effective automatic throttling control on the self-starting test of the shock tunnel air inlet channel, and provides reliable test basis for mastering the flow control rule of the air inlet channel and the design of the hypersonic speed air inlet channel.

Owner:CHINA AERODYNAMICS RES & DEV CENT

Tunnel model test device and test method capable of controlling soil loss rate

PendingCN112485125AControl loss rateReliable test basisMaterial strength using tensile/compressive forcesEarth material testingAgricultural engineeringThin membrane

The invention discloses a tunnel model test device and test method capable of controlling the soil loss rate, which solve the problem that the soil loss rate cannot be controlled in the prior art, andhave the beneficial effect of accurately controlling the soil loss rate. The following specific scheme is adopted: the device comprises a tunnel main body structure module and a hydraulic control module; the tunnel main body structure module comprises a multi-stage sleeve structure provided with at least three sleeves, the multi-stage sleeve structure can be installed in a model test box, the innermost sleeve in the multi-stage sleeve structure is annularly closed, the multiple sleeves except the innermost sleeve are arranged in a hollowed-out mode, and in the moving process, every two adjacent sleeves can be communicated, so that sand in the model test box enters the multi-stage sleeve structure; and the hydraulic control module comprises a thin film sealing bin internally provided withliquid, the thin film sealing bin is arranged on the outer side of the innermost sleeve in the multi-stage sleeve structure, and the liquid in the thin film sealing bin can flow out of the multi-stagesleeve structure.

Owner:SHANDONG JIANZHU UNIV

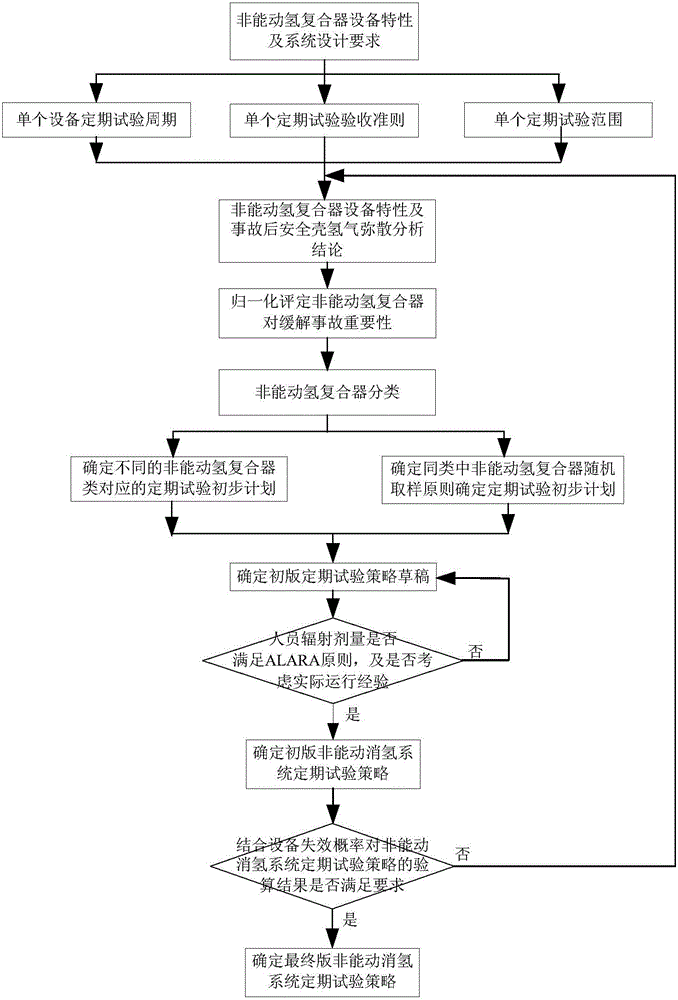

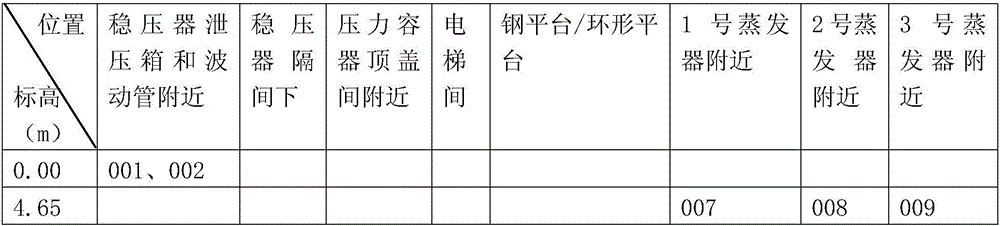

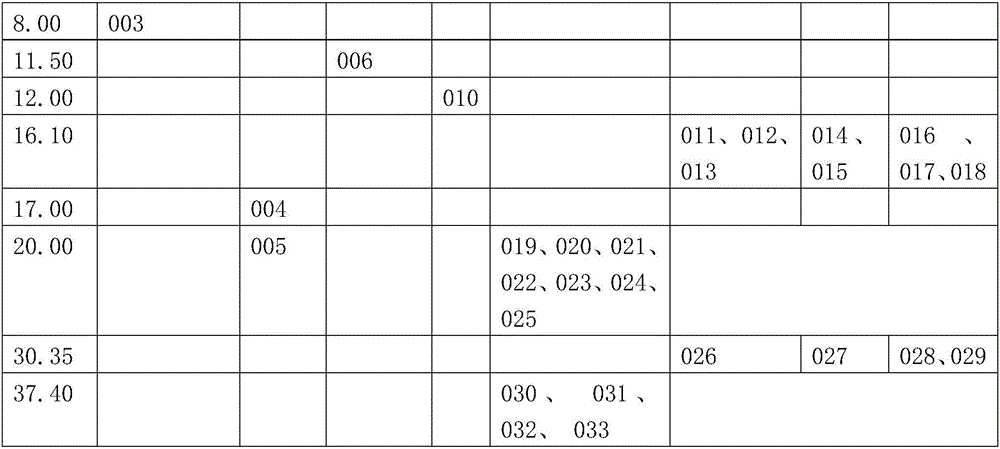

Periodic test strategic analysis method of nuclear power plant containment passive hydrogen elimination system

ActiveCN106448754AGuaranteed hydrogen concentrationEffective control of hydrogen concentrationNuclear energy generationEmergency protection arrangementsNuclear plantHydrogen

The invention belongs to a reactor designing technology, and particularly relates to a periodic test strategic analysis method of a nuclear power plant containment passive hydrogen elimination system. According to the method, various kinds of information such as containment passive hydrogen elimination system equipment information, hydrogen dispersion state in the containment after an accident, personnel exposure dose rate, nuclear power plant practical operating experience feedbacks are taken into overall consideration, and a verification method aimed at the periodic test strategies of the containment passive hydrogen elimination system is innovatively put forward, so that periodic test strategies of the containment passive hydrogen elimination system is determined to be reasonable and scientific, thus guaranteeing that a system function can meet design requirements.

Owner:CHINA NUCLEAR POWER ENG CO LTD

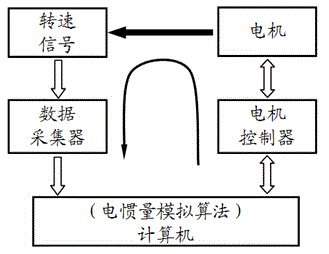

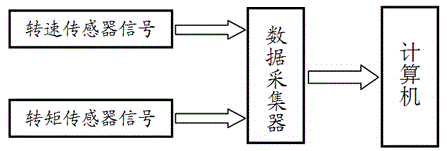

Test measuring method for critical P-gear parking automobile speed of automobile automatic gearbox

InactiveCN104697790AEasy to implementReliable working principleMachine gearing/transmission testingAutomotive engineeringVariator

The invention discloses a test measuring method for the critical P-gear parking automobile speed of an automobile automatic gearbox. According to the method, a computer regulates the speed of a driving motor to a set rotating speed, and an electrical inertia simulation control model is started; the computer collects the rotating speed of an axle shaft of the automatic gearbox to be measured in real time and obtains the preset rotating speed value of the driving motor at the next moment through calculation, and meanwhile the computer sends the preset rotating speed value to the driving motor in real time, and sequential circulation control is performed; when the rotating speed of the axle shaft meets the requirement for P-gear parking, a tester manually operates a gear shifting device to park at the P gear, and when the computer measures that the rotating speed of the axle shaft is zero, the driving motor is controlled to stop, and one time of testing is ended. The critical P-gear parking automobile speed can be accurately measured through simulating the whole test working conditions of the automobile gearbox, and the accurate and reliable support is provided for test research performed on the critical P-gear parking automobile speed of the automobile gearbox.

Owner:CHONGQING UNIV OF TECH +1

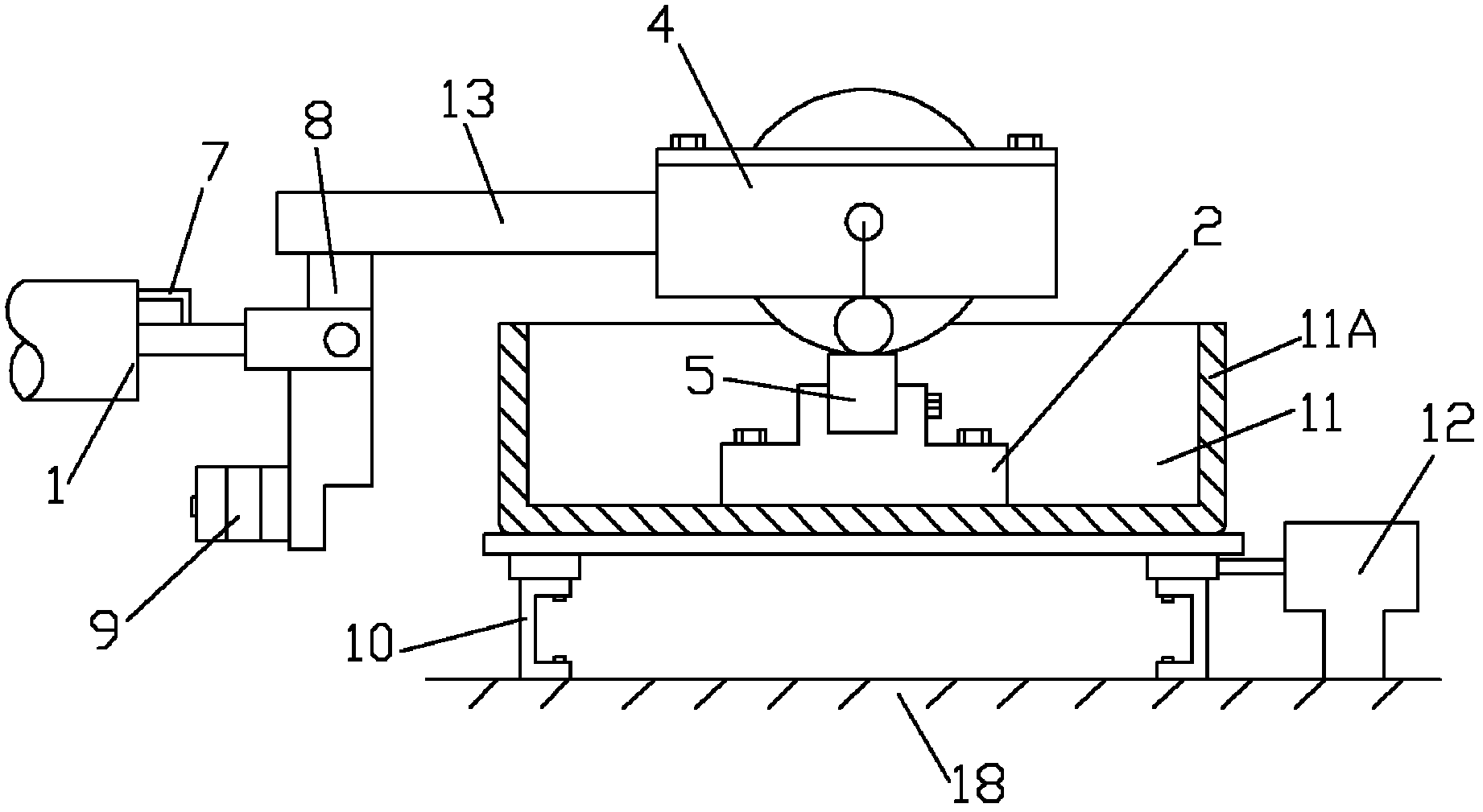

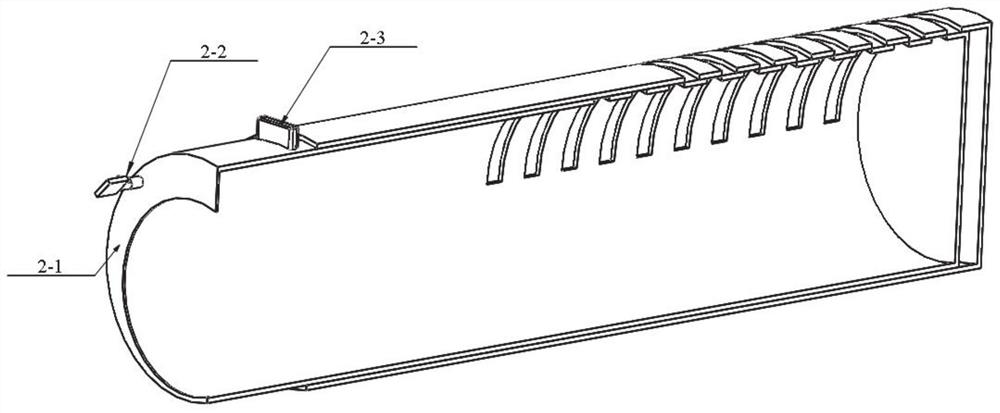

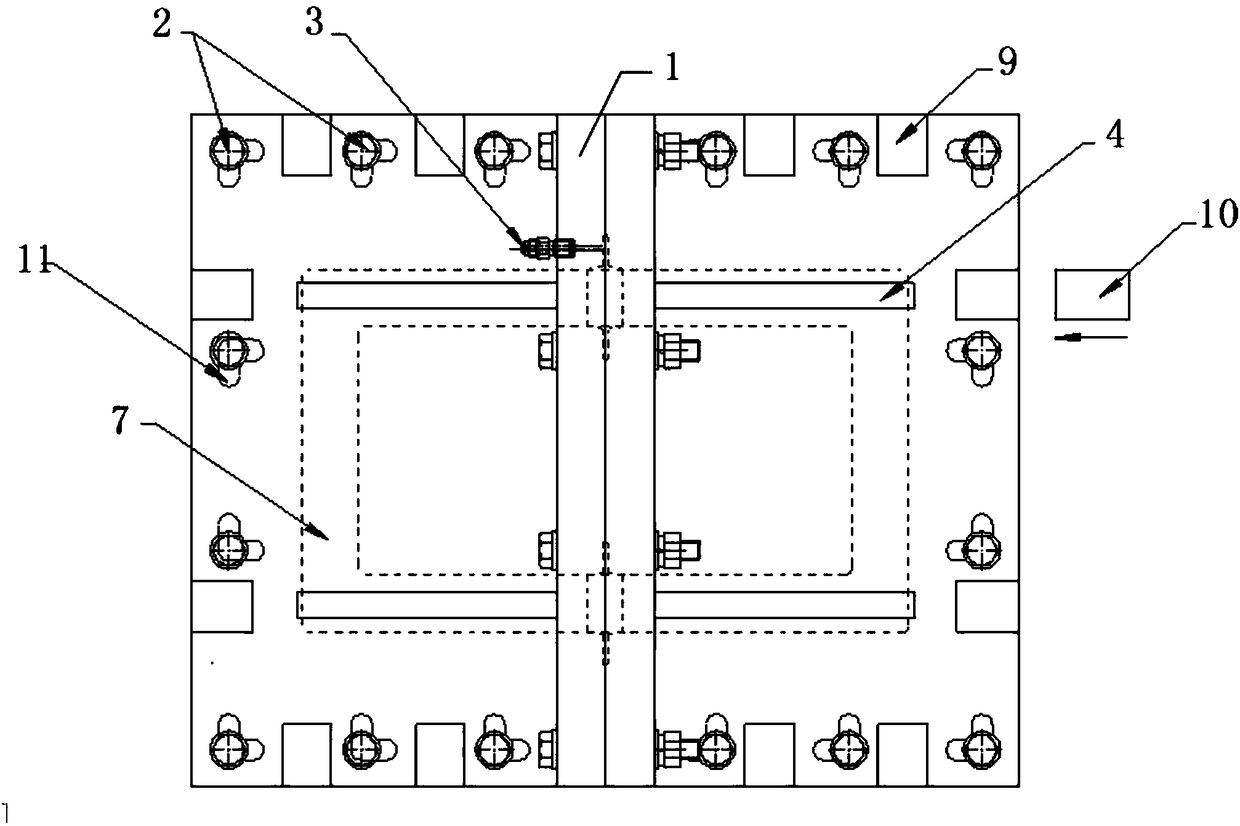

Improved clamping mechanism of fatigue testing machine for in-situ imaging of synchronous radiation light source

ActiveCN105751104AIncrease brightnessImprove image signal-to-noise ratioWork holdersOptically investigating flaws/contaminationVibration attenuationEngineering

The invention discloses an improved clamping mechanism of a fatigue testing machine for in-situ imaging of a synchronous radiation light source, which is arranged on a platform cylindrical base of the synchronous radiation light source. The improved clamping mechanism comprises a sample clamping unit and a plastic deformation additional adjusting unit, wherein the sample clamping unit is vertically arranged along the axle wire of the base of the fatigue testing machine and is divided into two parts of a lower clamping head section and an upper clamping head section, and the upper clamping head section is provided with the plastic deformation additional adjusting unit. Compared with a fatigue testing machine in the previous generation, the improved clamping mechanism of the fatigue testing machine for the in-situ imaging of the synchronous radiation light source, disclosed by the invention, is further improved, and the properties of buffer vibration attenuation and noise reduction of a system are increased; on the premise that load is fully enabled to be applied to a sample, the integral bearing performance of the fatigue testing machine is ensured; the plastic deformation additional adjusting unit can be used for adjusting the size of an applied force after plastic deformation of the sample happens in compaison with the fatigue testing machine in the previous generation, detailed problems in a test implementing process are more detailedly considered.

Owner:SOUTHWEST JIAOTONG UNIV

Cross waterproof test device for shield tunnel segment joints

PendingCN108279097AAuthentic and fully simulatedAccurate Performance Evolution LawMeasurement of fluid loss/gain rateEngineeringShield tunnelling

The invention discloses a cross waterproof test device for shield tunnel segment joints and belongs to the technical field of shield tunnel projects. The cross waterproof test device has the advantages that the cross waterproof test device can perform a cross waterproof test; when two right-angle plates are demounted and reassembled into a flat-plate-shaped unit substrate in the prior art, a T-shaped water test can be performed; the device is quite convenient to assemble and capable of performing tests of various technical schemes; the device can truly and comprehensively simulate the waterproof environments of the shield tunnel segment joints so as to achieve accurate waterproof test results and accurately reflect the performance development law of a real shield tunnel segment joint waterproof sealing pad, and accordingly a reliable test basis is provided for the design and maintenance of shield tunnel segment joint waterproofing.

Owner:SOUTHWEST JIAOTONG UNIV +1

Detection method of insulator surface water content based on hyperspectral technology

ActiveCN109765192AReduce reflectivitySpectral feature dropColor/spectral properties measurementsGeomorphologySurface water

The invention discloses a detection method of insulator surface water content based on hyperspectral technology. The detection method comprises the following steps: shooting insulator surfaces with known different surface water contents by utilizing a hyperspectral imager so as to obtain a corresponding hyperspectral image, performing black-white correction, multiplicative scatter correction and smooth denoising on the hyperspectral image to obtain a hyperspectral line Xi of the surface water content Si, and then obtaining a water content BP neural network prediction model; shooting to obtaina hyperspectral image of a to-be-detected insulator, performing black-white correction, multiplicative scatter correction and smooth denoising to obtain the hyperspectral line X0 of the to-be-detectedinsulator, inputting the hyperspectral line X0 of the to-be-detected insulator into a prediction model to obtain the surface content of the to-be-detected insulator. Through the method disclosed by the invention, the non-contact real-time detection can be performed on the field insulator under an electrified condition, the operation is simple and the realization is simple; and the method can provide reliable and accurate test evidence for the dampproof and moisture-resistant design, manufacturing and maintenance of the insulator.

Owner:SOUTHWEST JIAOTONG UNIV

Adjustable multifunctional high-speed debris flow friction test device and test method thereof

InactiveCN105973798AAdjust relative speedUncovering Friction Fracture PhenomenaUsing mechanical meansMaterial analysisCircular discReduction drive

The invention discloses an adjustable multifunctional high-speed debris flow friction test device and a test method thereof. The adjustable multifunctional high-speed debris flow friction test device is characterized in that the bottom of a vertical steel plate is hinged with the ground; the upper part of the steel plate is hinged with the top end of a telescopic connecting rod; a motor, a speed reducer, a torque sensor and a bearing are sequentially fixed from bottom to top of the working surface of the steel plate; a motor shaft is connected with the lower end of a spindle through a speed reducer and the torque sensor; the upper end of the spindle is connected with the lower part of a bracket through bearings; a disc is fixed at the upper part of the bracket; two square, bottomless, coverless and transparent model boxes are symmetrically arranged at the upper part of the disc; four corners at the tops of the model boxes are hinged with the lower ends of upper connecting rods; upper ends of upper connecting rods penetrate through a transverse through groove in a gantry transverse beam upwards; pressure bearing steel covers are embedded inside the two model boxes; jacks are fixed on the gantry transverse beam; top rods of the jacks are aligned to the middle parts of the pressure bearing steel covers; high-speed cameras are mounted on side surfaces of the model boxes through camera connecting rods.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com