Improved actuation mechanism for fatigue testing machine achieving in-situ imaging of synchrotron radiation light source

A fatigue testing machine and actuating mechanism technology, applied in the direction of applying repetitive force/pulsation force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of loosening, the test cannot be carried out smoothly, etc., to enhance the stability , the effect of high imaging accuracy and sensitivity, and high image signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

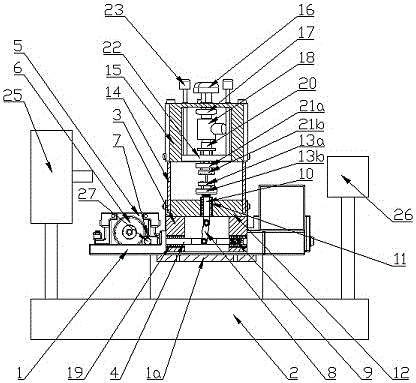

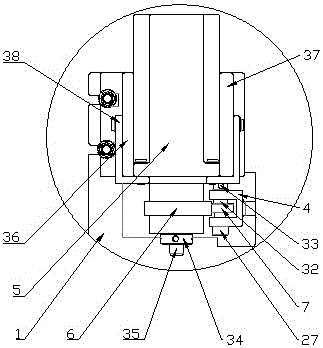

[0019] figure 1 , figure 2 It is shown that the fatigue testing machine for in-situ imaging with synchrotron radiation light source is composed of:

[0020] The cross 1a at the bottom of the base plate 1 is fitted on the platform 2 of the synchrotron radiation source, and the middle part of the upper surface of the base plate 1 is fixed with a cylindrical base 3; the push rod 4 is installed on the left wall of the base 3 through a horizontal linear bearing 2 19 and On the right wall; Servomotor 5 is installed on the left side of base plate 1 upper surface, and cam 6 is installed on servomotor 5 axles; The right edge of the push rod 4 is in contact with the middle part of the push rod 4 and the lower end of the connecting rod 8 is hinged, and the right end of the push rod 4 is connected to the right wall of the base 3 by a spring 9.

[0021] The improved actuating mechanism of the fatigue testing machine for in-situ imaging of the synchrotron radiation light source is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com