High-temperature erosion testing device and method for thermal barrier coating of turbine blade of gas turbine

A technology for turbine blades and thermal barrier coatings, which is applied in the field of high-temperature erosion test devices for thermal barrier coatings of gas turbine blades, and can solve complex geometry of turbine blades, erosion and wear of coatings, and different motion states, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments, but the present invention is not limited to the following examples.

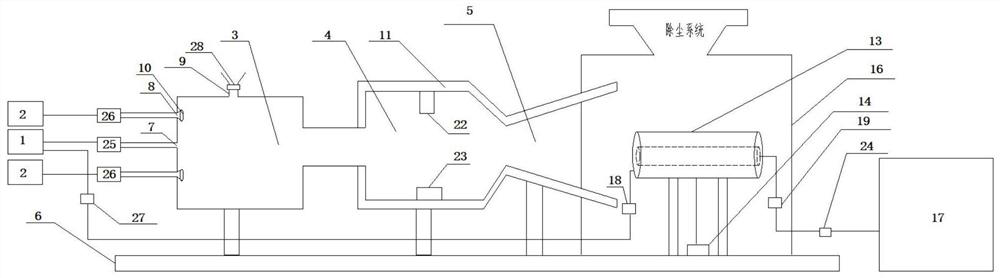

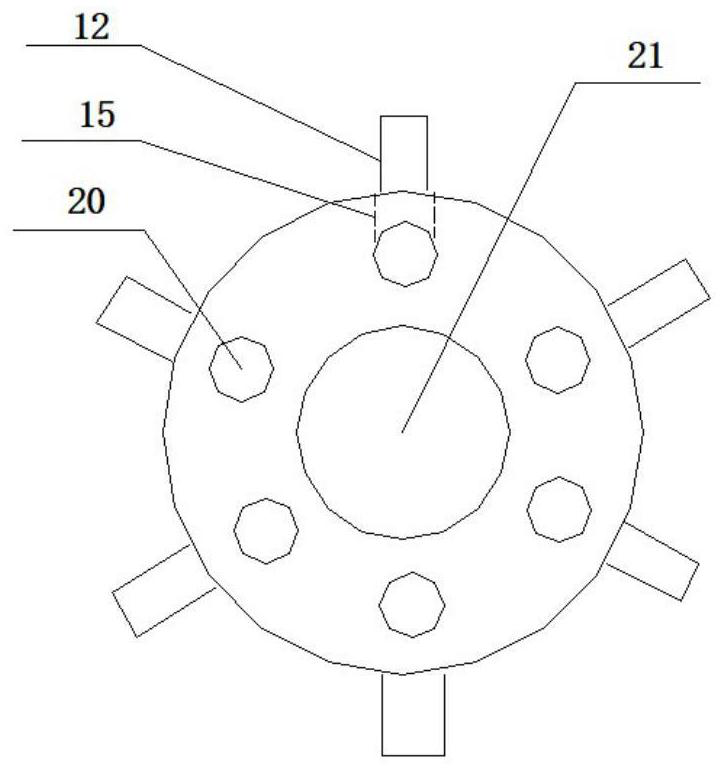

[0027] Such as figure 1 and figure 2 As shown, the present invention provides a high-temperature erosion test device for thermal barrier coatings of gas turbine blades, including a high-temperature spray gun system, a test system, a cooling system, a central control system, and a dust removal system; wherein, the high-temperature spray gun system is installed on the base 6, including a compressed air storage tank 1, a fuel storage tank 2, a mixing chamber 3, a combustion chamber 4 and an expanding nozzle 5, one end of the mixing chamber 3 is provided with a compressed air inlet 7 and two fuel inlets 8, and the top is provided with There is a solid particle inlet 9, and the two fuel storage tanks 2 are respectively connected to the corresponding fuel inlet 8 of the mixing chamber 3 through a fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com