Adjustable multifunctional high-speed debris flow friction test device and test method thereof

A test device and technology of debris flow, applied in the field of adjustable multifunctional high-speed debris flow friction test device, can solve the problems of inability to reveal the phenomenon of high-speed remote debris flow friction and breakage, particle collision and separation, failure to reach high-speed movement, Problems such as particle breakage changes and collision separation in debris flow cannot be observed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

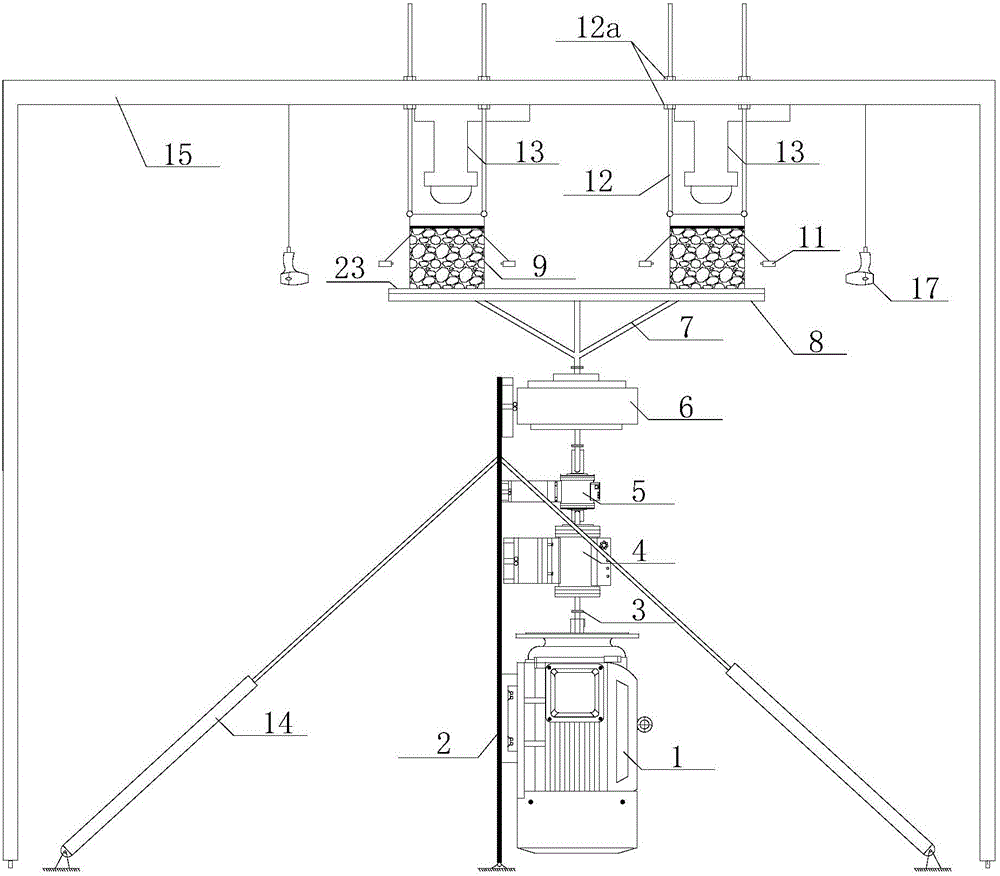

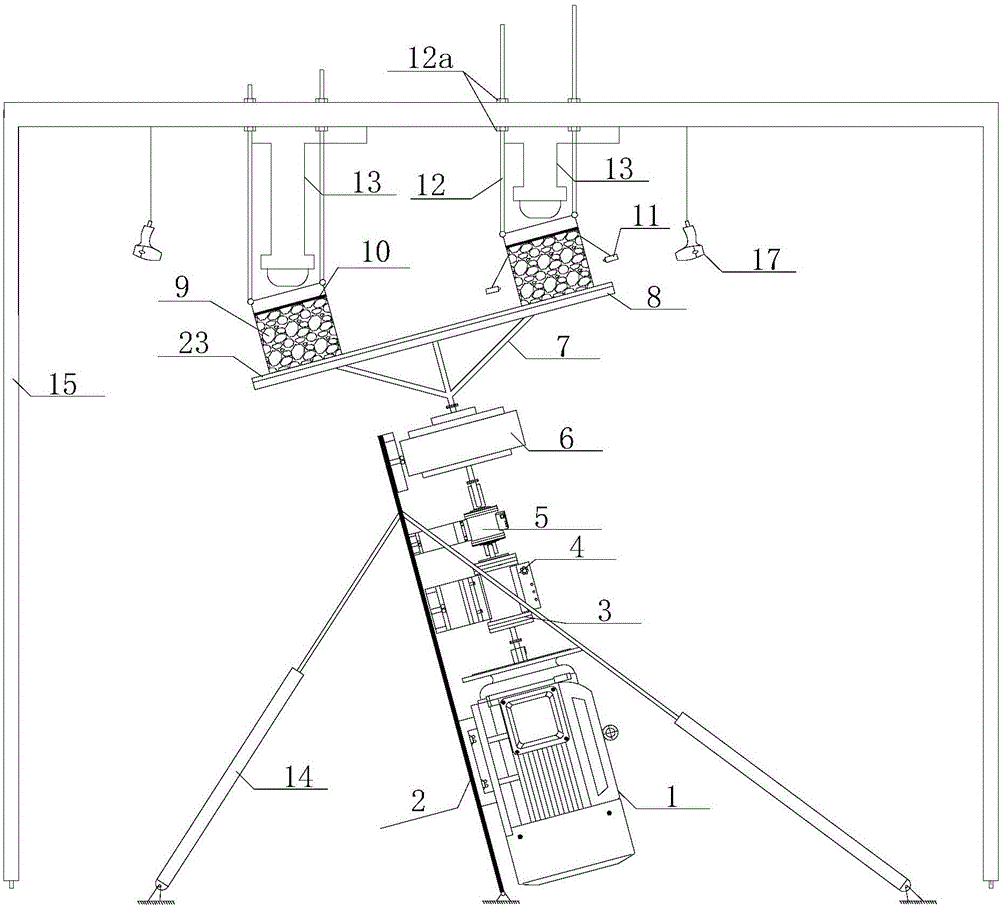

[0031] Figure 1-Figure 2 Shown, one embodiment of the present invention is: an adjustable multifunctional debris flow movement crushing test device, characterized in that:

[0032] The bottom of the vertical steel plate 2 is hinged to the ground, the upper part of the steel plate 2 is hinged to the top of the telescopic connecting rod 14, and the bottom end of the connecting rod 14 is hinged to the ground; 4, torque sensor 5 and bearing 6, the shaft of the motor 1 is connected to the lower end of the main shaft through the reducer 4 and the torque sensor 5 in sequence, the upper end of the main shaft is connected to the lower part of the bracket 7 through the bearing 6, and the upper part of the bracket 7 is fixed with a hollow circle disk 8;

[0033] Two square, bottomless, and transparent model boxes 9 are symmetrically placed on the top of the disc 8; the four corners on the top of the model box 9 are hinged with the lower ends of the corresponding upper links 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com