Method and device for producing extrudate

A strand, product technology used in cable/conductor manufacturing, applications, household components, etc. to achieve high process speeds and reliable absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

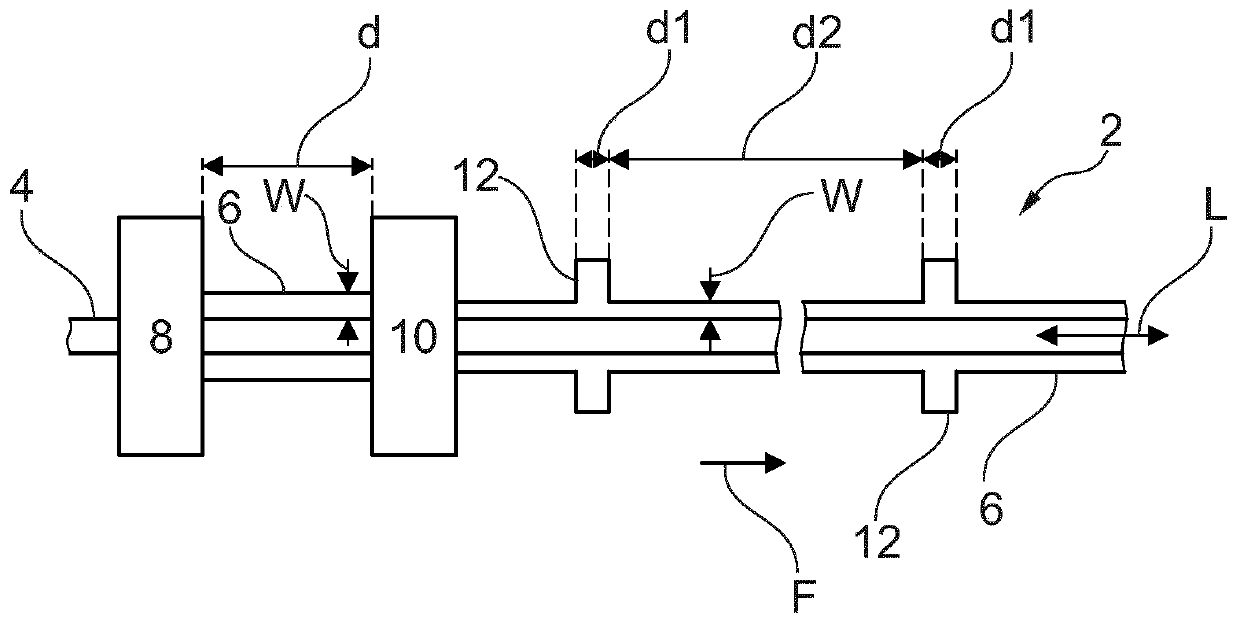

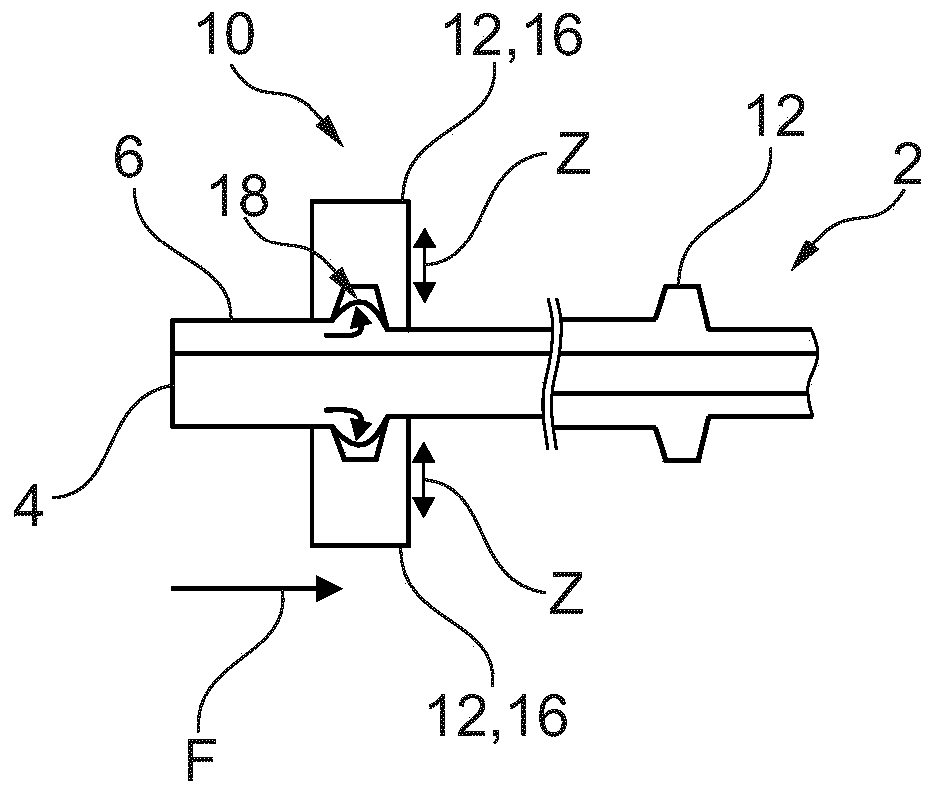

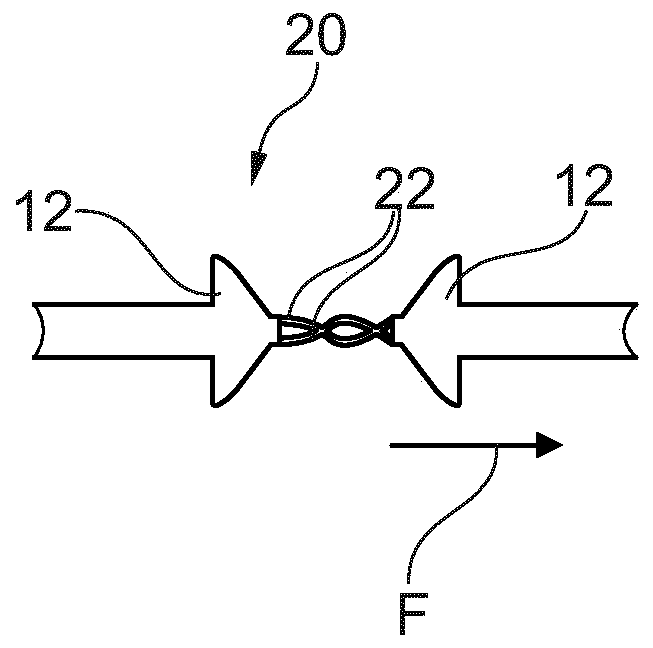

[0035] First, according to figure 1 The basic steps of the method for manufacturing strand-shaped article 2 by arresting material are explained. The figure shows in longitudinal section a strand-like article 2 extending in the longitudinal direction L, comprising an embedded core 4 and a sheath 6 applied to the core. The strand-shaped article 2 is here configured as a cable with a core, which is correspondingly a cable core and has, for example, one or more conductors, core wires, lines and / or sub-cables. Alternatively, the strand 2 is a hose and the core 4 is accordingly a hose core. In the embodiment shown here, the sheath 6 is in particular the outer sheath of the strand 2 . The strand-like product 2 can be constructed as a semi-finished product and still be processed further. To apply the sheath 6 , the core 4 is first fed in the conveying direction F to the extrusion unit 8 . By means of this extrusion unit, a predetermined material (usually plastic) is extruded onto ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com