Patents

Literature

141 results about "Embedded core" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

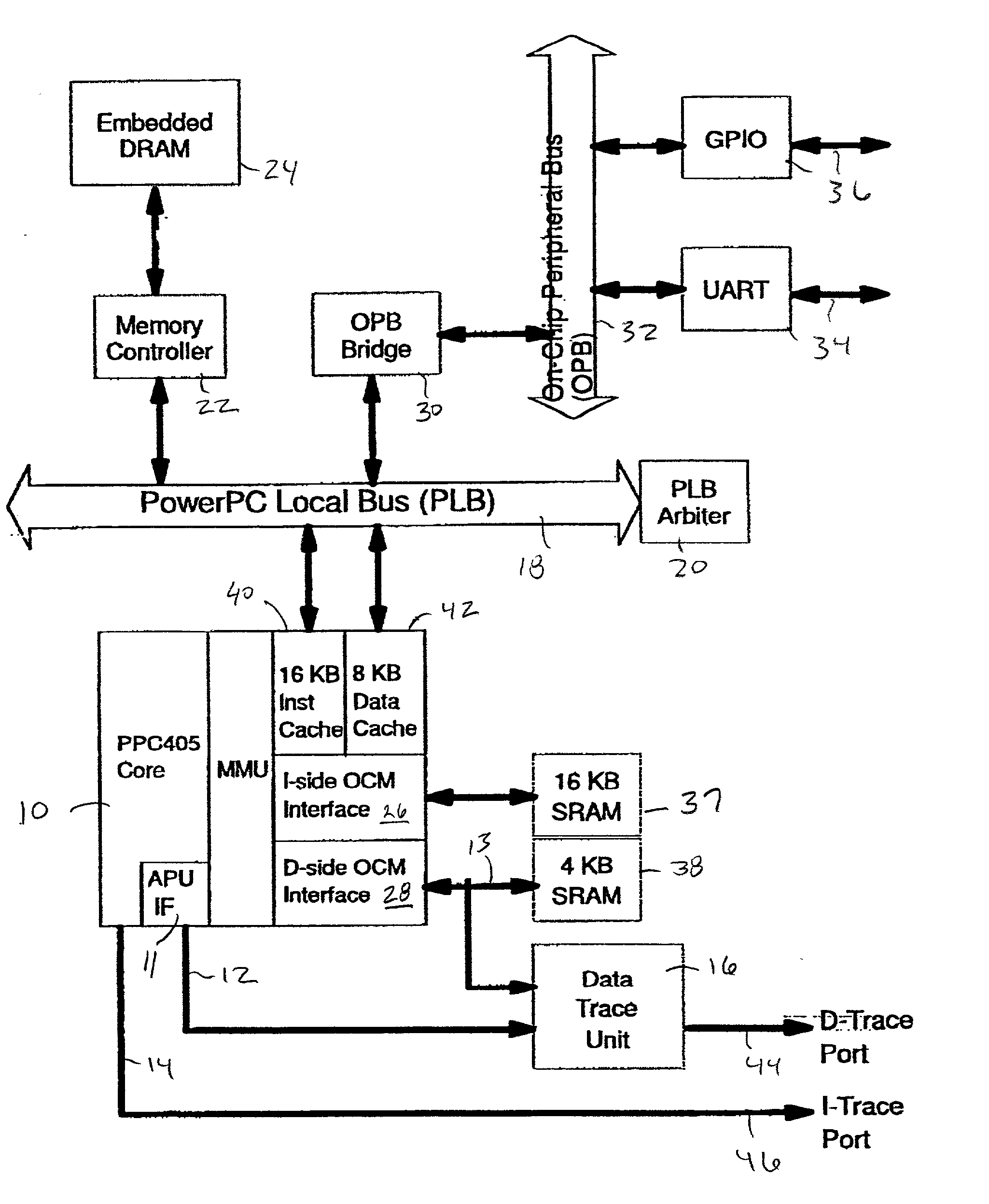

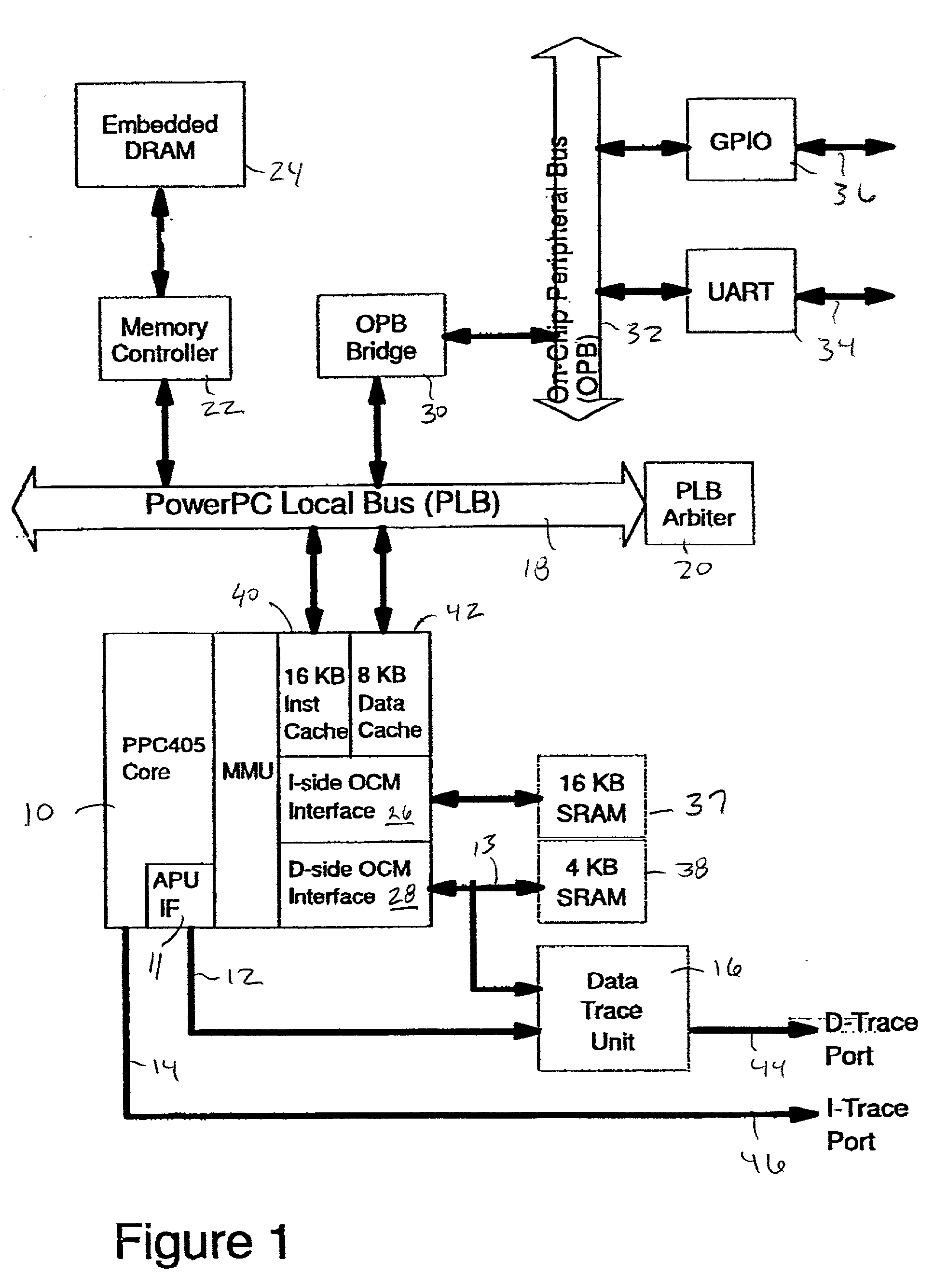

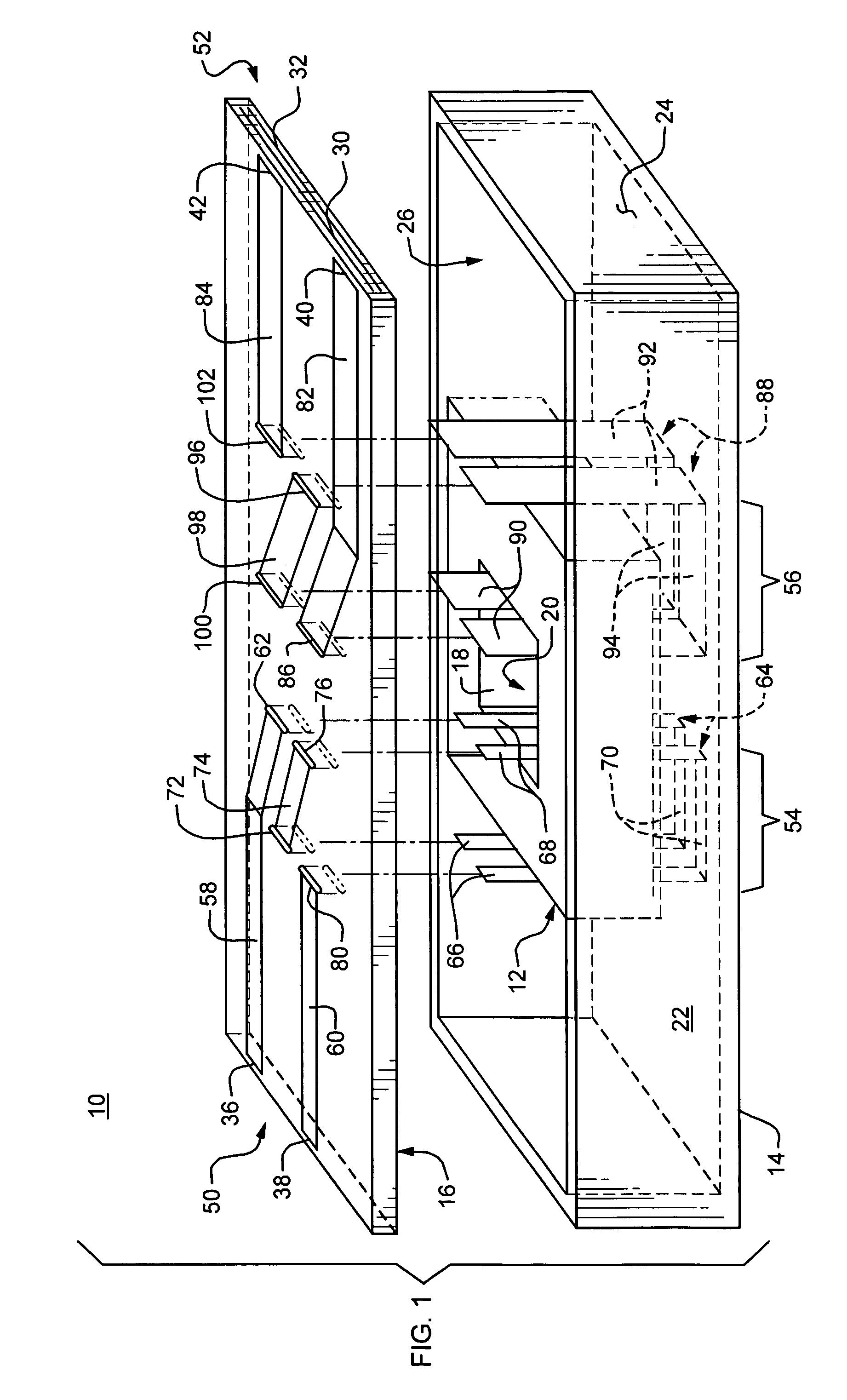

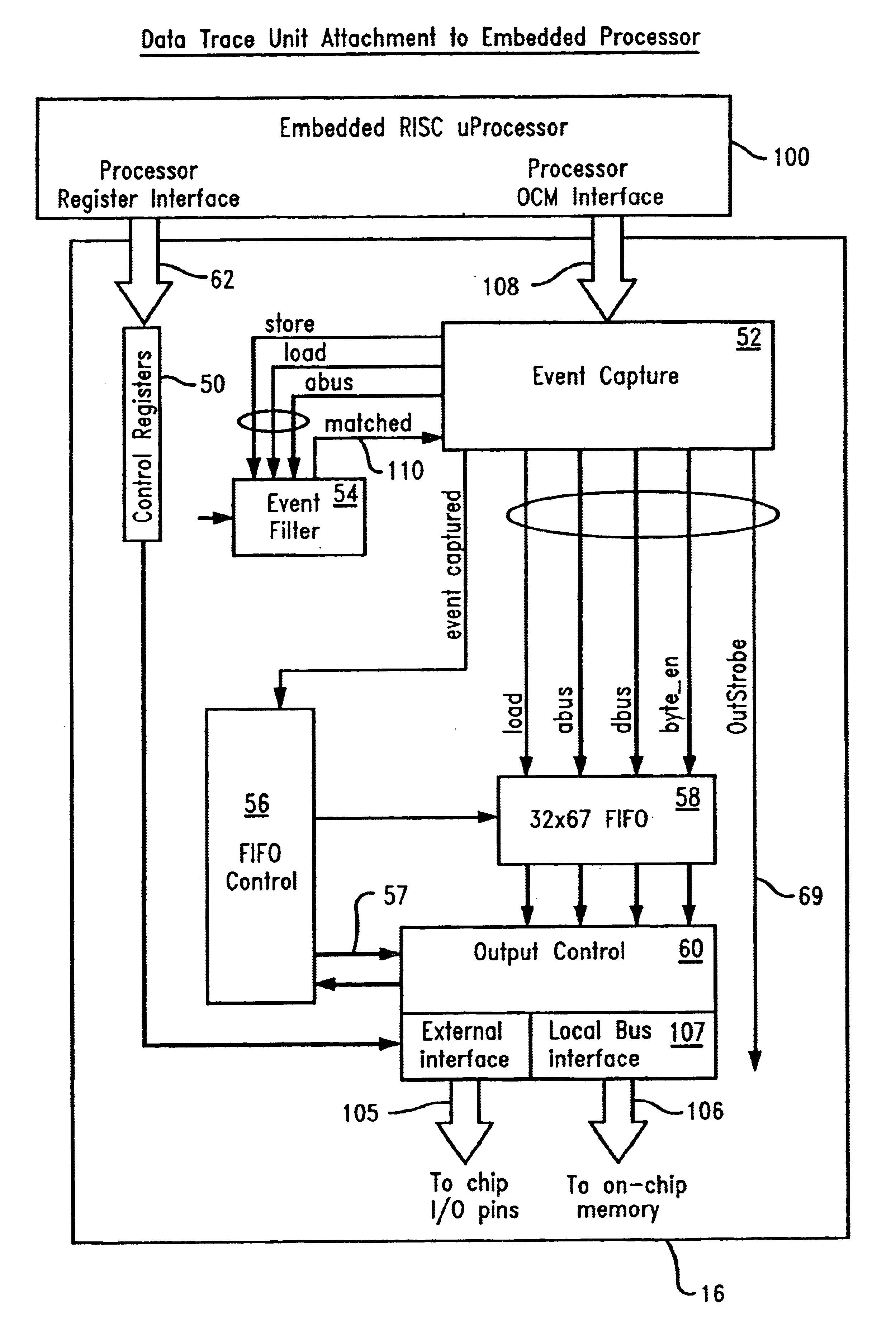

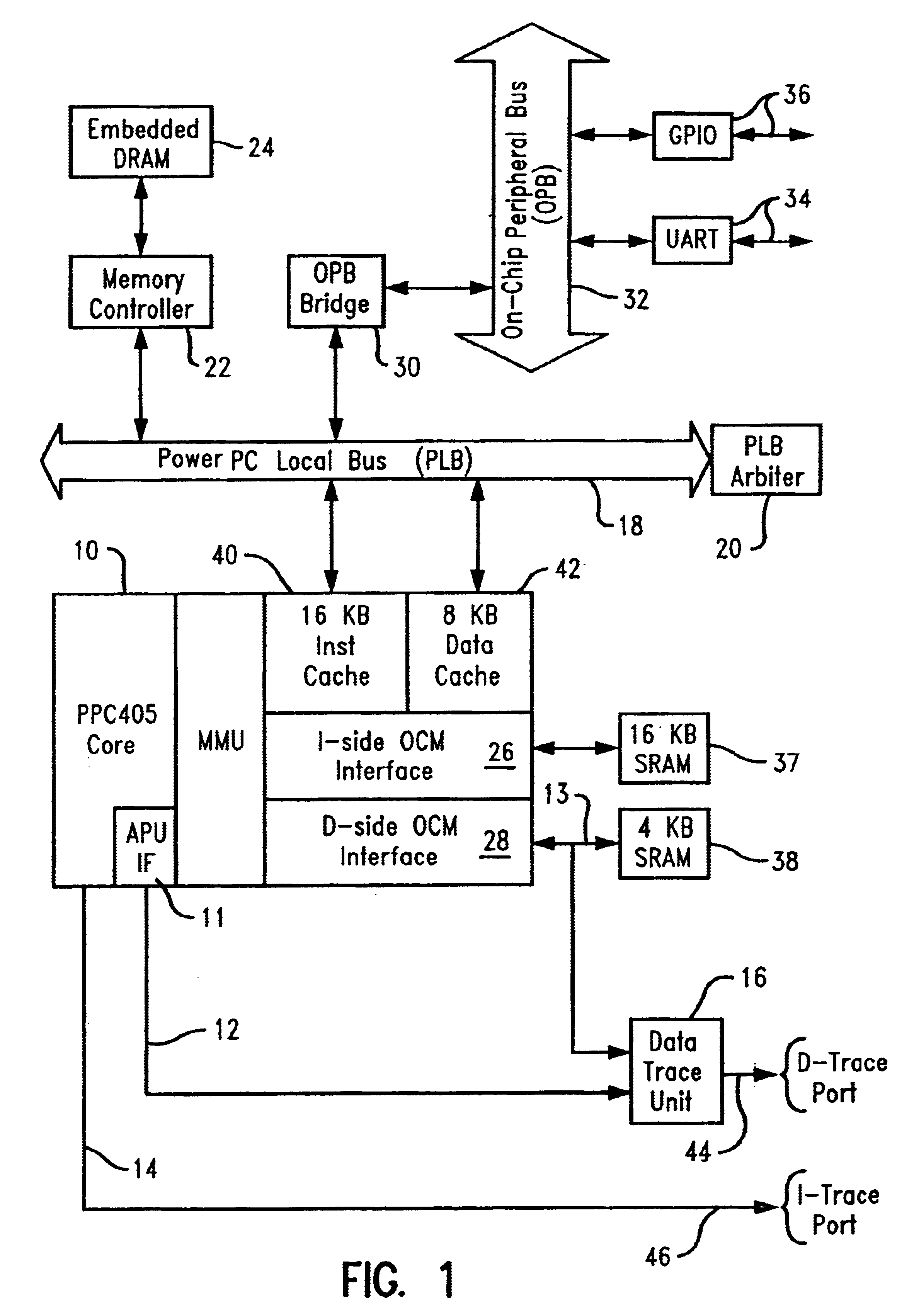

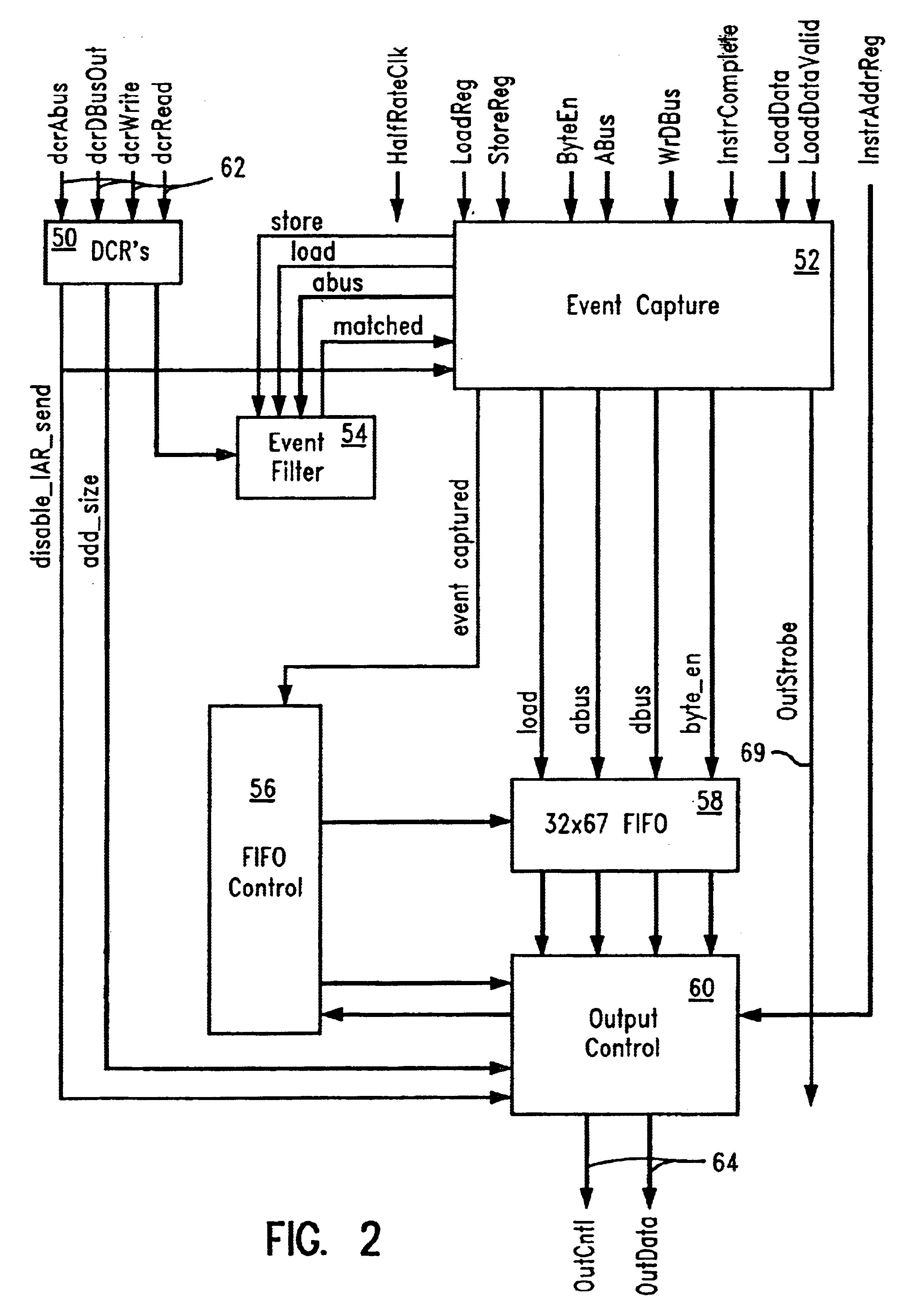

Integrated real-time data tracing with low pin count output

InactiveUS20030018929A1Low bandwidthAccurately indicatedHardware monitoringSoftware testing/debuggingReal-time dataData signal

An integrated circuit real-time data tracing apparatus for analyzing microprocessor based computer systems for monitoring, in real-time, parameters sufficient to define the load and store operations information that the embedded core controller may assert, and process information during events. Integral on this single chip apparatus is a data trace unit designed to access control, address, and data signal lines required to monitor the embedded core controller's activities; perform data tracing independent of instruction tracing; synchronize with an instruction trace stream; allow for selection of multiple ranges for data tracing; report lost events to a FIFO array; and, output strobe signals to give a cycle accurate indication of when an event has been captured.

Owner:MARVELL ASIA PTE LTD

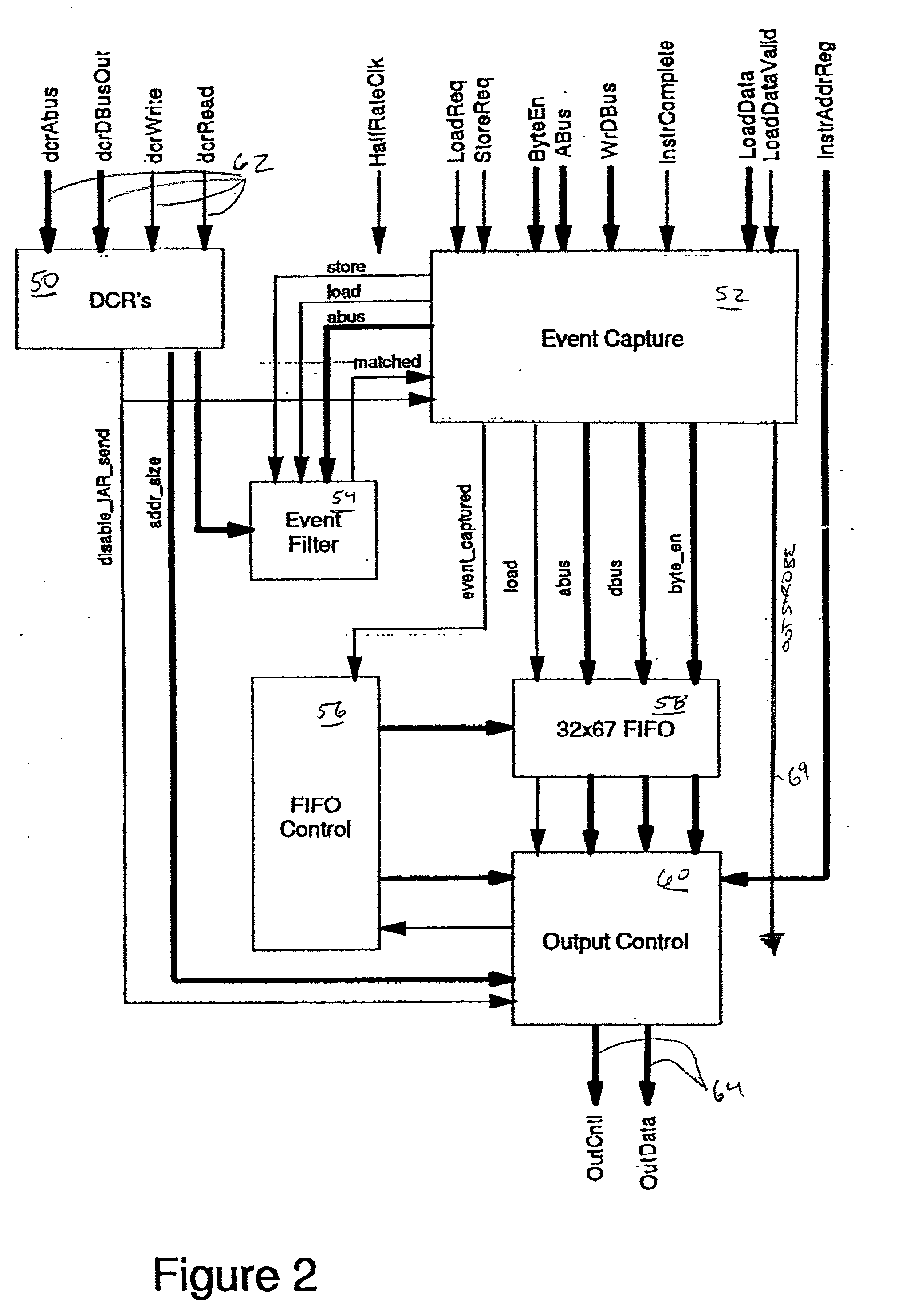

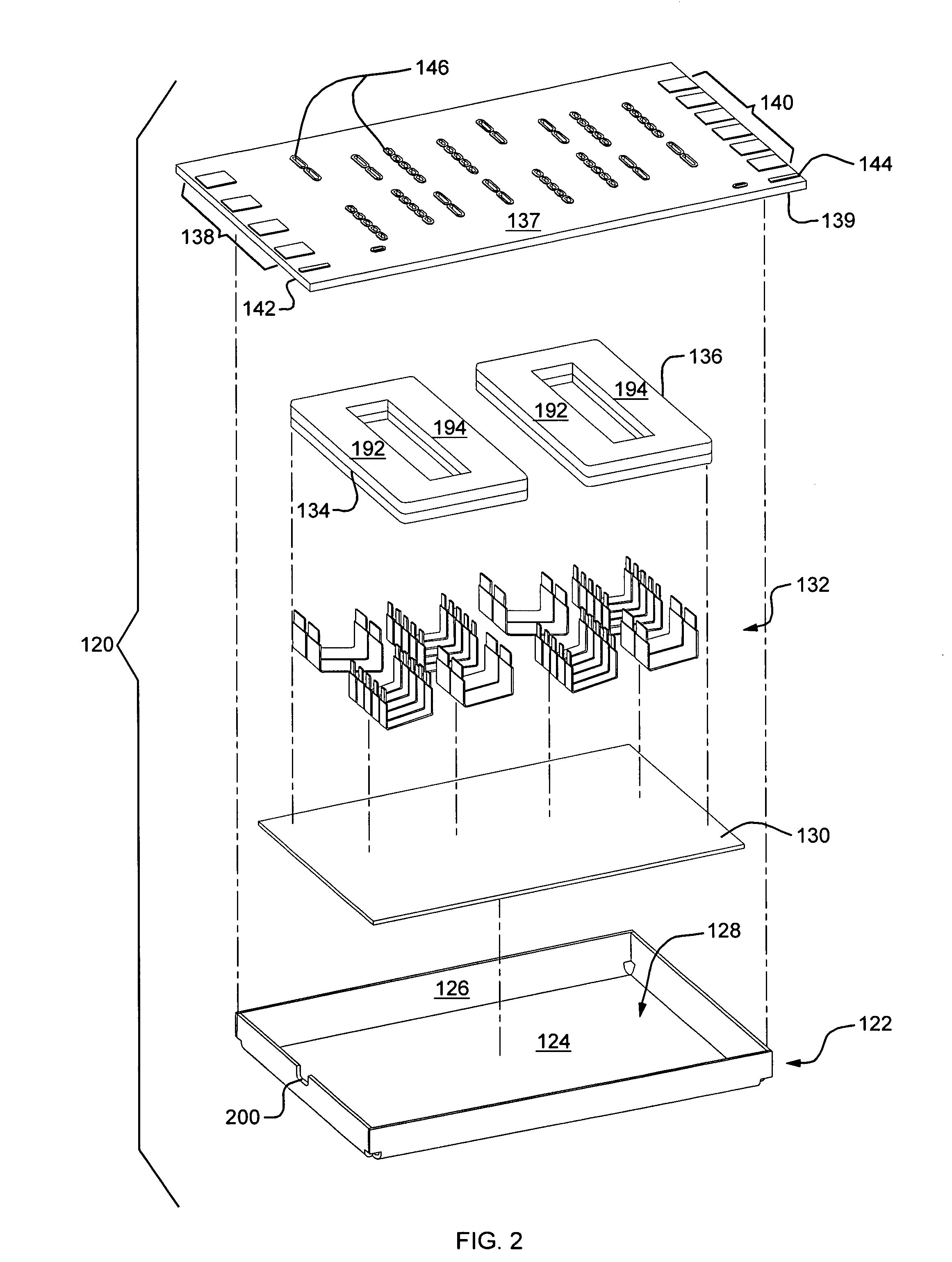

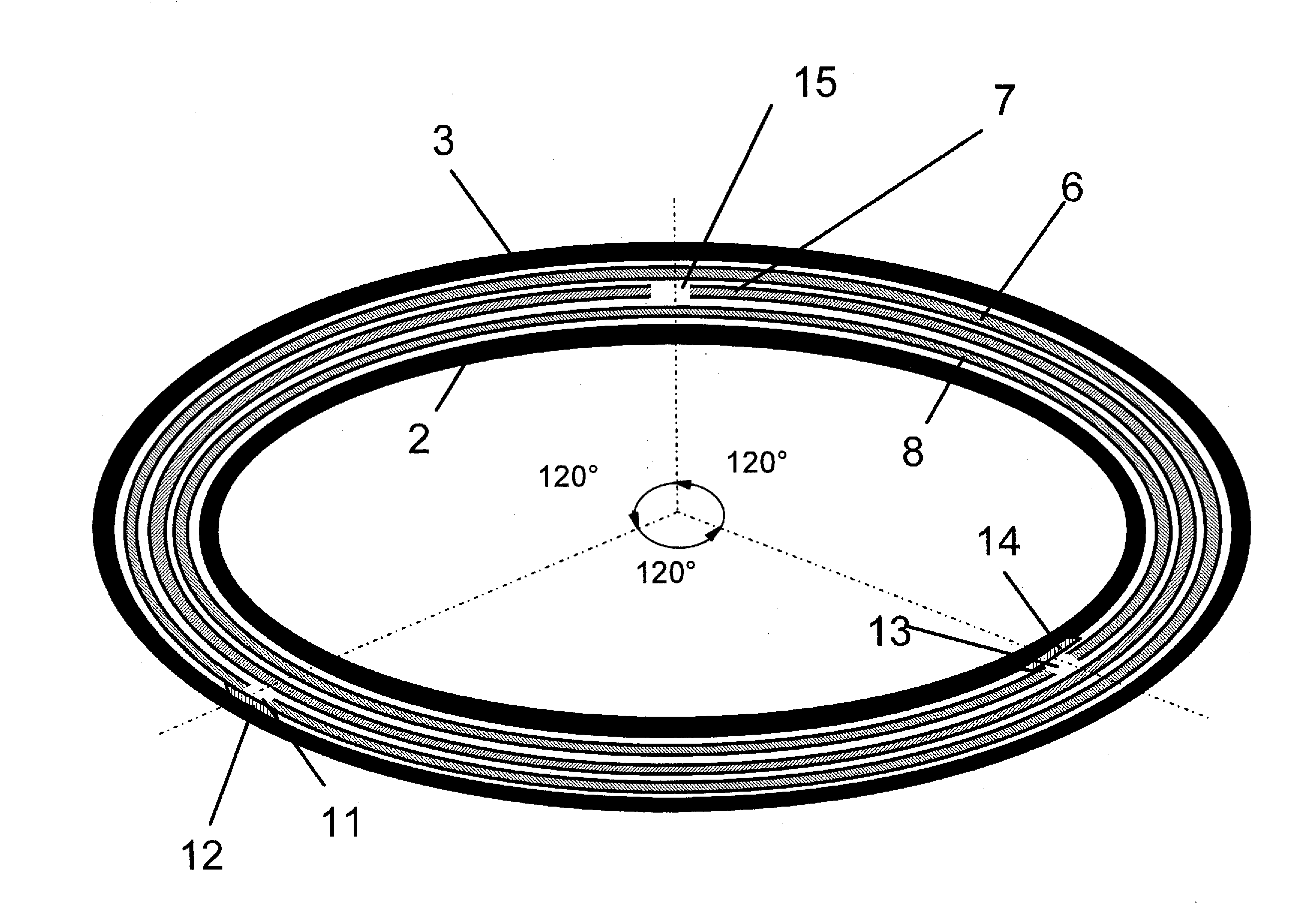

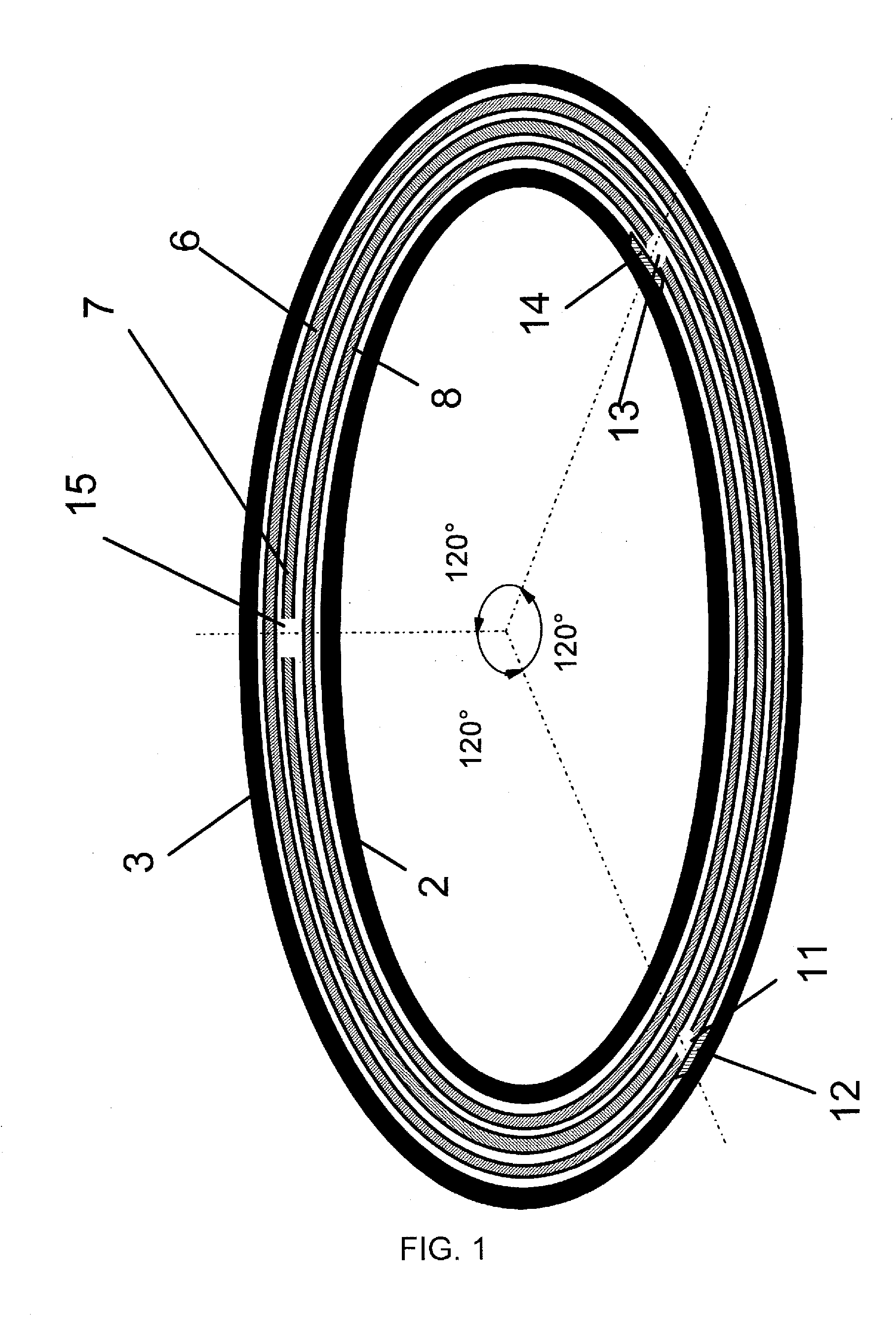

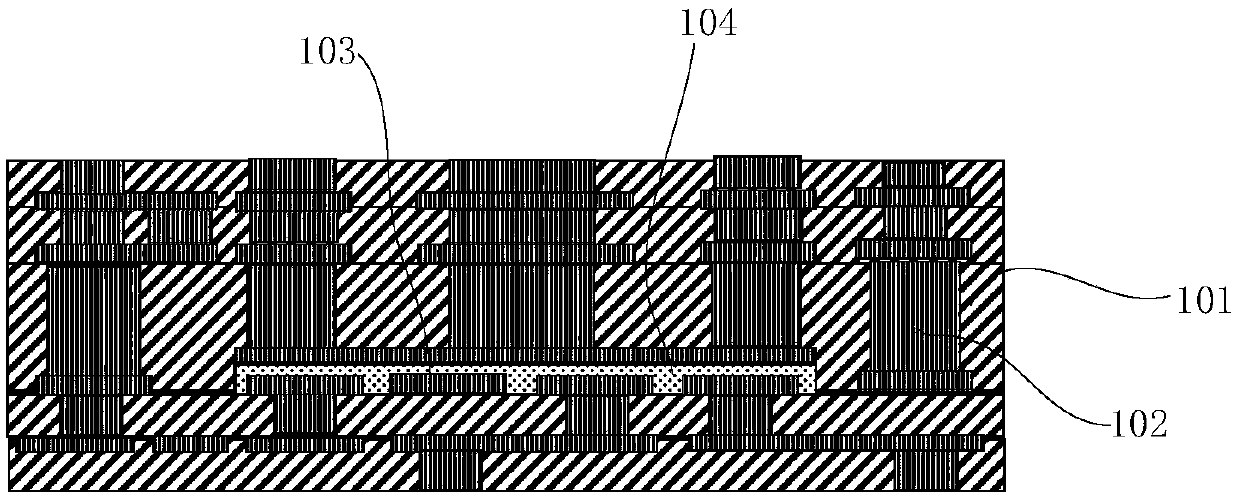

Fabrication method and structure for embedded core transformers

InactiveUS7489226B1Reduce in quantityImprove power densityTransformers/inductances coils/windings/connectionsDc currentSwitching frequency

An embedded core electrical transformer (120) for DC to DC current conversion at a switching frequency of 1 MHz has reduced volume and weight with increased power density. The electrical transformer (120) utilizes a plurality of conductive elements (132) disposed inside a hollow cavity (128) used to embed two magnetic cores (134, 136). The conductive elements (132) encircle three sides of the embedded cores (134, 136) and interface with a multilayer PCB (137) which includes conductive traces formed therein to encircle a fourth side of the embedded cores and to form primary and secondary winding circuits.

Owner:RAYTHEON CO

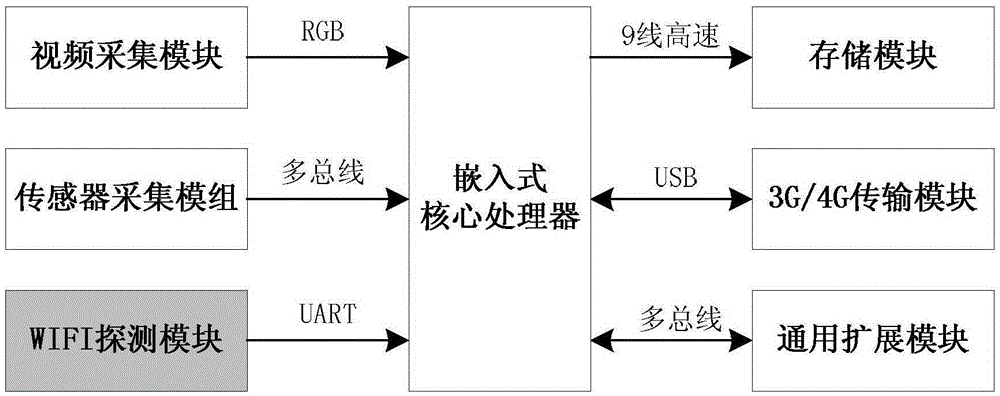

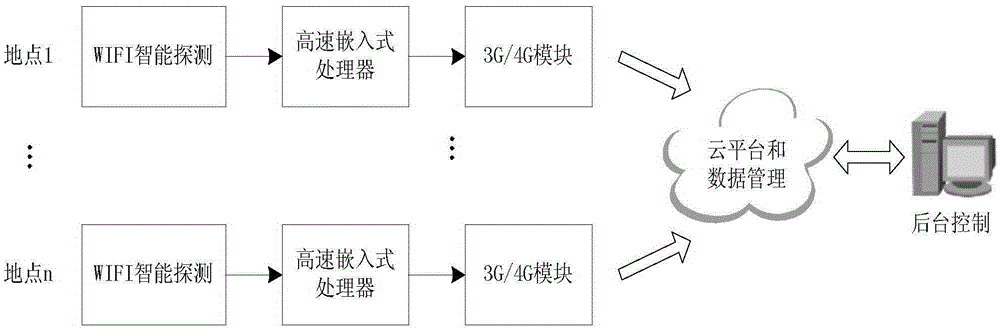

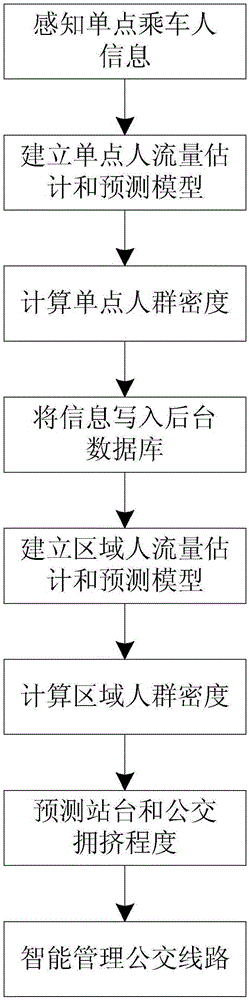

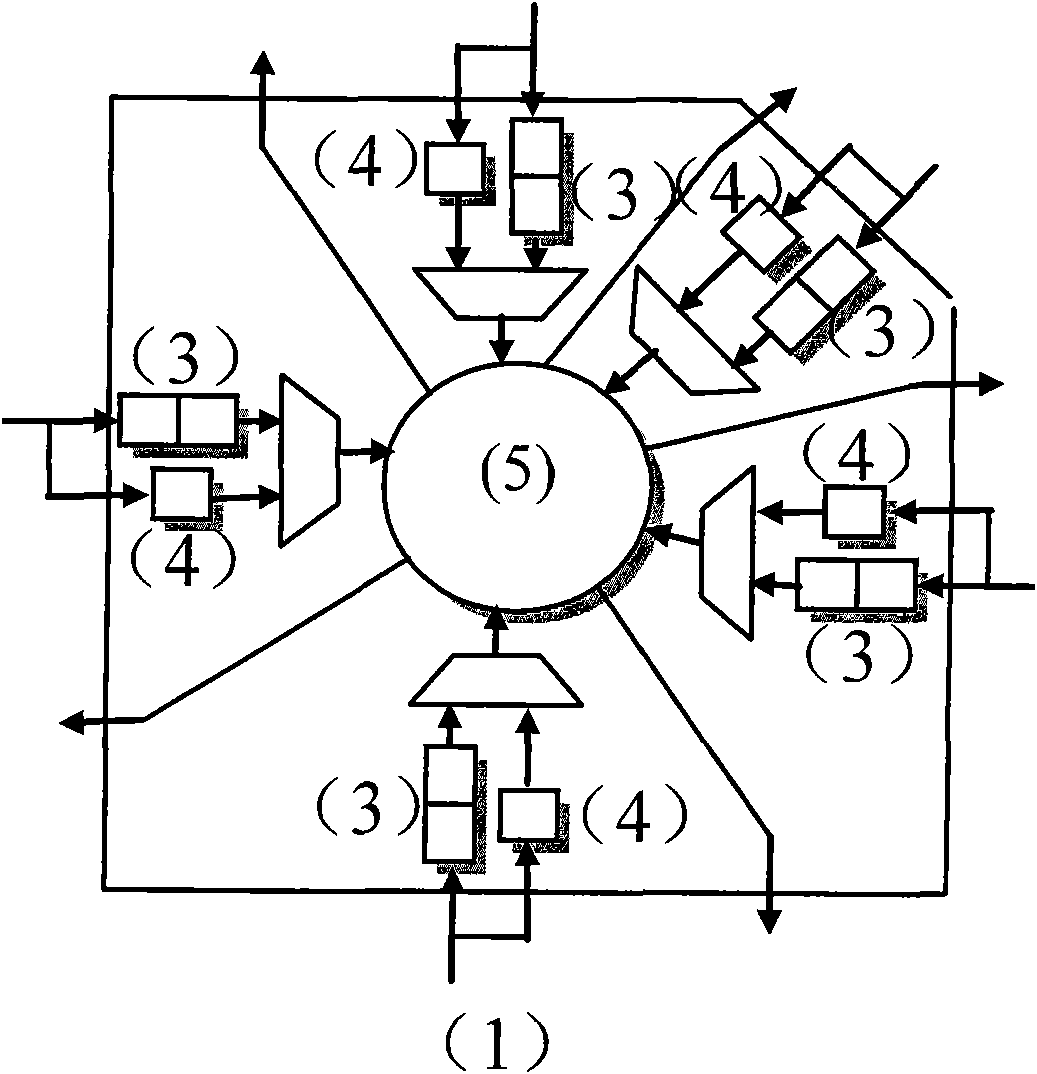

Electronic device for estimating passenger flow and application method thereof at bus stop

InactiveCN105282523AImprove the level of intelligent managementMake sure it lastsClosed circuit television systemsTransmissionComputer moduleThird generation

The invention provides an electronic device for estimating passenger flow which well covers main traffic nodes of a city and collects the large sample data of passenger flow, and an application method of the electronic device at a bus stop. The electronic device comprises a video acquisition module, a sensor acquisition module, a WIFI detection module, an embedded core processor, a storage module, a 3G / 4G transport module and a general extension module. The video acquisition module, the sensor acquisition module, the WIFI detection module, the storage module, the 3G / 4G transport module and the general extension module are all connected to the embedded core processor. The application method has following steps: first, performing statistics and screening based on the information recorded by the intelligent device; estimating the information of passenger flow of a single bus stop; then collecting the information of passenger flow of the whole bus stops of a city; establishing a dynamic distribution diagram and a prediction model of the passenger flow; and outputting optimized bus lines and departure times based on the model.

Owner:SHANGHAI YINGYI ELECTRONICS EQUIP

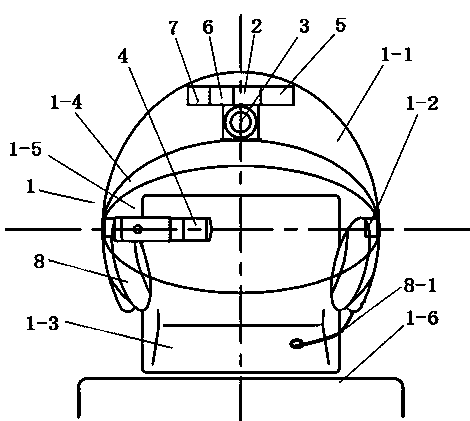

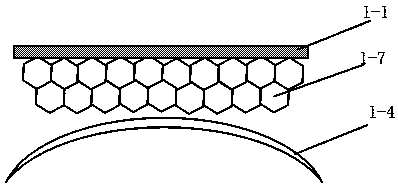

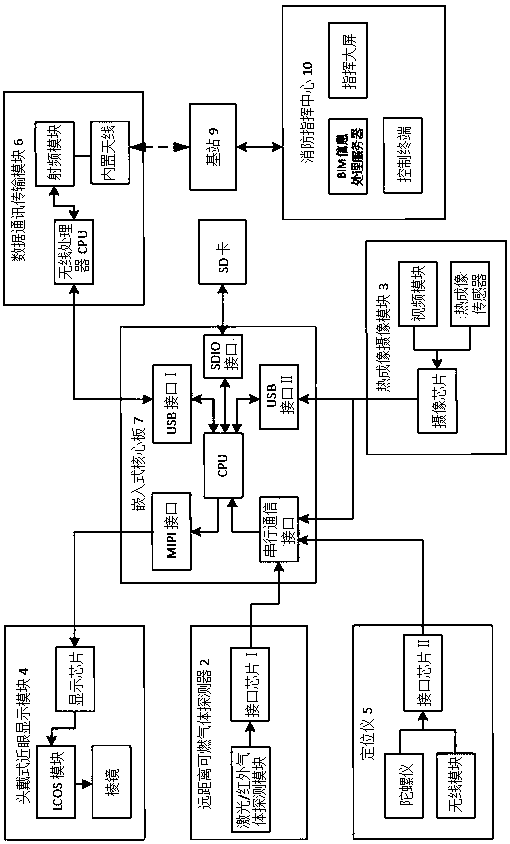

Burning and explosion accident sensing and risk predicting early-warning intelligent fire fighting helmet implementing method

ActiveCN108378450AImproving the scientific level of fire fighting and rescueImprove abilitiesAlarmsHelmetsTransmission technologyEngineering

The invention relates to a burning and explosion accident sensing and risk predicting early-warning intelligent fire fighting helmet implementing method. A fire fighting helmet, a long-distance combustible gas detector, a thermal imaging camera module, a head-mounted near-eye display module, a positioning instrument, a data communication and transmission module, an embedded core board, an earphone, a base station, and a fire fighting command centre are involved. According to the burning and explosion accident sensing and risk predicting early-warning intelligent fire fighting helmet implementing method, the real-time position of a fireman in a building can be displayed for the fireman by combining a fireman positioning technology, a building information model and real scene thermal image information, and projecting and displaying information through the head-mounted near-eye display module, so that the environment burning and explosion dangerousness and risk thereof are predicted in real time. When the fireman enters an unknown environmental place, a potential fire disaster explosion accident risk can be effectively predicted quickly; quick sensing and information communication ofthe fireman to a fire disaster accident scene can be realized through an advanced video and thermal imaging technology and an indoor positioning and communication transmission technology, so that thefire fighting rescuing scientific level and the capacity of the fireman are improved.

Owner:应急管理部天津消防研究所

Integrated real-time data tracing with low pin count output

InactiveUS6834365B2Low bandwidthAccurately indicatedHardware monitoringSoftware testing/debuggingLow Pin CountProcess information

Owner:MARVELL ASIA PTE LTD

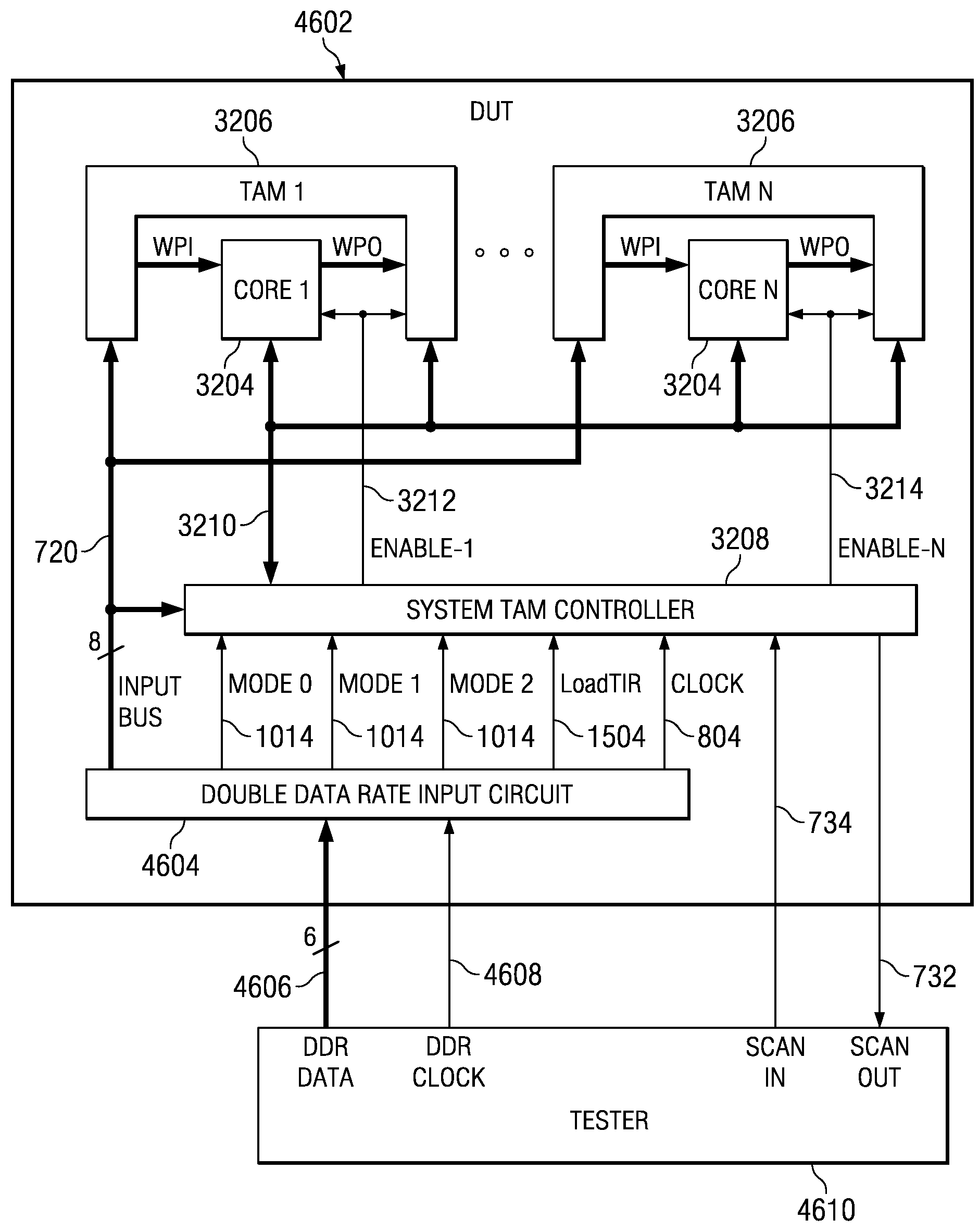

DDR input interface to IC test controller circuitry

ActiveUS7529996B2Efficient testingSimplifies testerElectronic circuit testingDouble data rateProgrammable logic controller

Owner:TEXAS INSTR INC

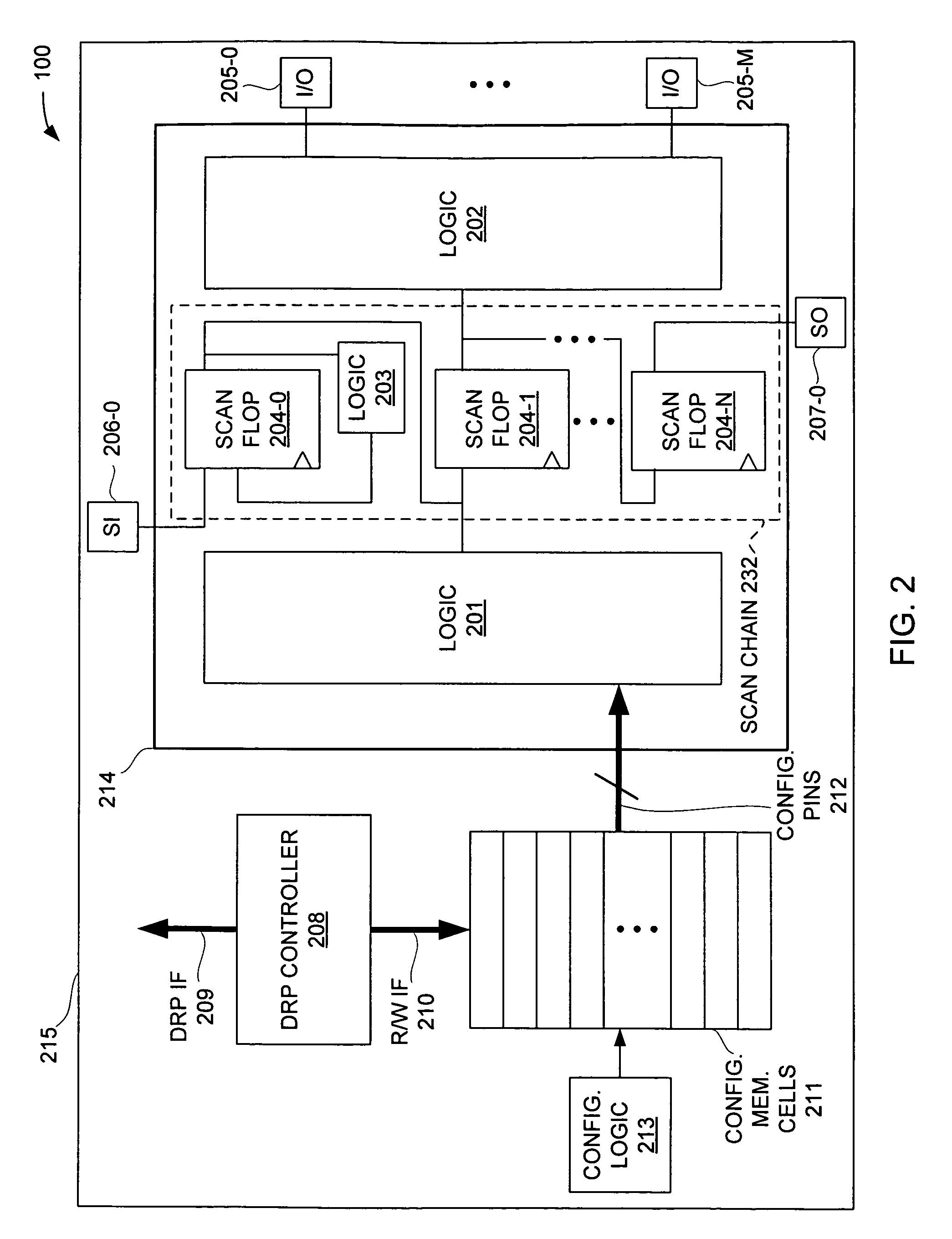

Testing an embedded core

A method of testing of an embedded core of an integrated circuit (“IC”) is described. An IC has a hardwired embedded core and memory coupled to each other in the IC. The method includes writing a test vector to the memory while the embedded core is operative. The test vector is input from the memory to the embedded core to mimic scan chain input to the embedded core. A test result is obtained from the embedded core responsive in part to the test vector input.

Owner:XILINX INC

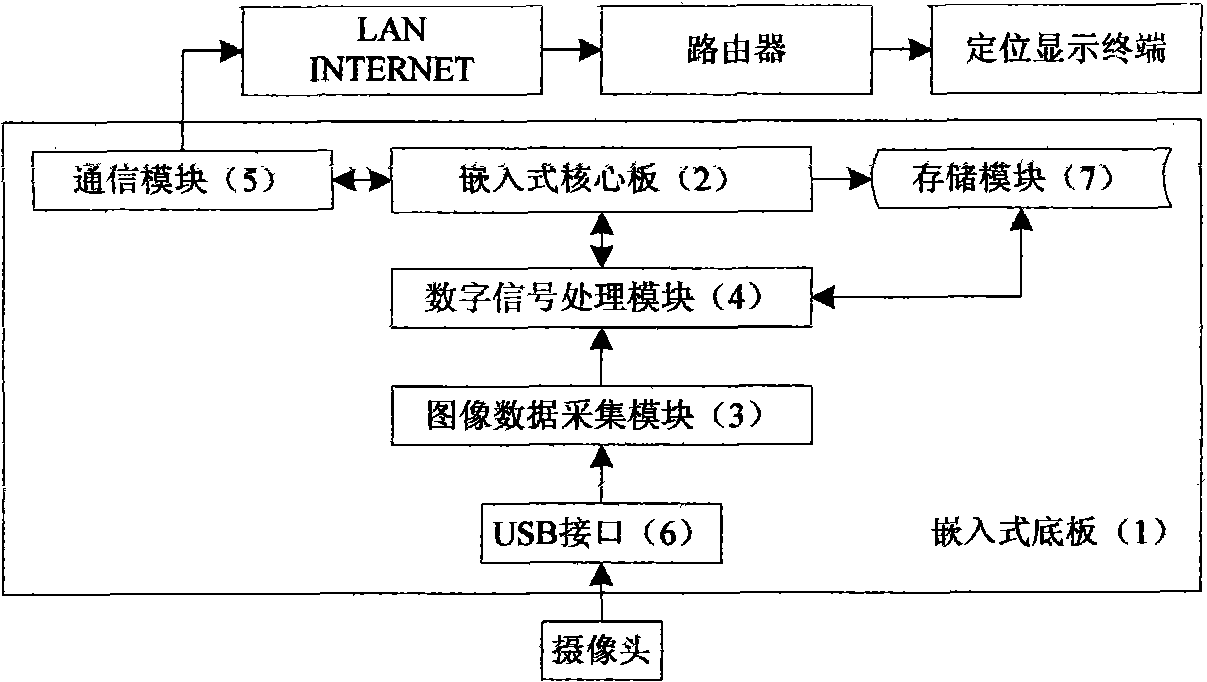

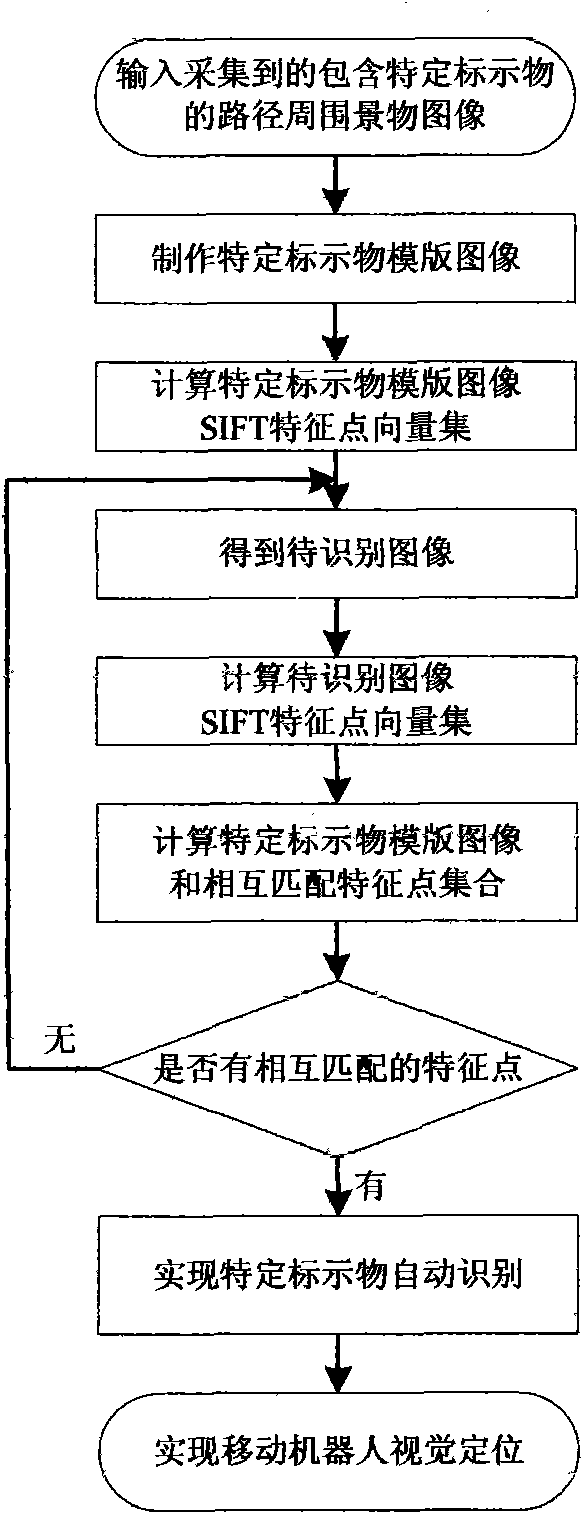

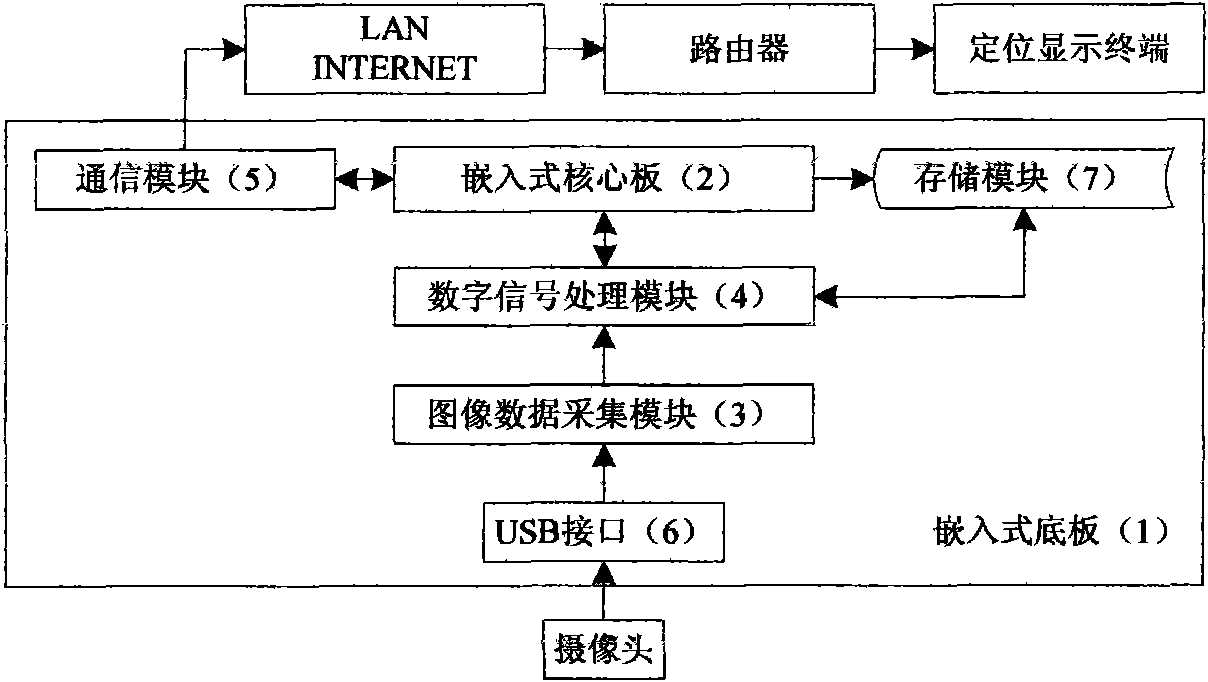

Rapid visual orientation and remote monitoring system and method based on embedded mobile robot

InactiveCN101957194AEasy to makeReduce workloadProgramme controlComputer controlDigital signal processingStructure of Management Information

The invention relates to rapid visual orientation and remote monitoring system and method based on an embedded mobile robot. The system mainly comprises an embedded base plate, an embedded core plate, an image data collecting module, a digital signal processing module, a network communication module, a storage module, a USB interface and a terminal device. The embedded core plate collects image information by the image data collecting module, forwards the image information to the digital signal processing module, rapidly extracts key characteristic points of the images according to improved SIFT (Scale Invariant Feature Transform) algorithm and compares the key characteristic points with the image characteristic point information of the special marker stored in the storage module so as to identify the images, further determine the position of the mobile robot according to coordinates of the special marker and complete visual orientation of the mobile robot. After determining the position of the marker, the digital signal processing module sends the positioning information through a communication module to the terminal device. The system is compact and reliable in structure, and can rapidly and effectively identify the special marker during remote orientation of the mobile robot which is oblique, deformed, dirty, partially sheltered and has a complicated background and changing light.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

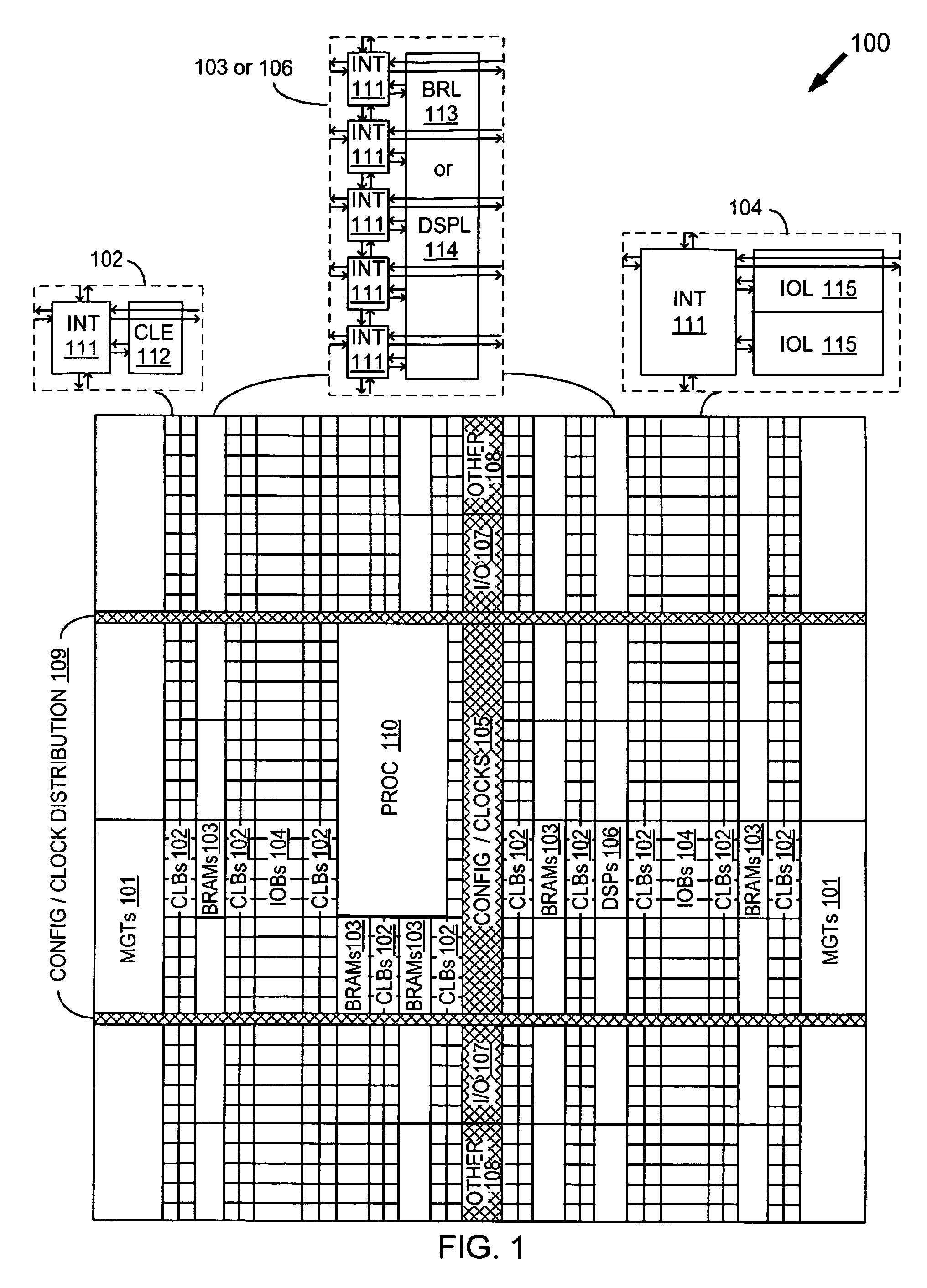

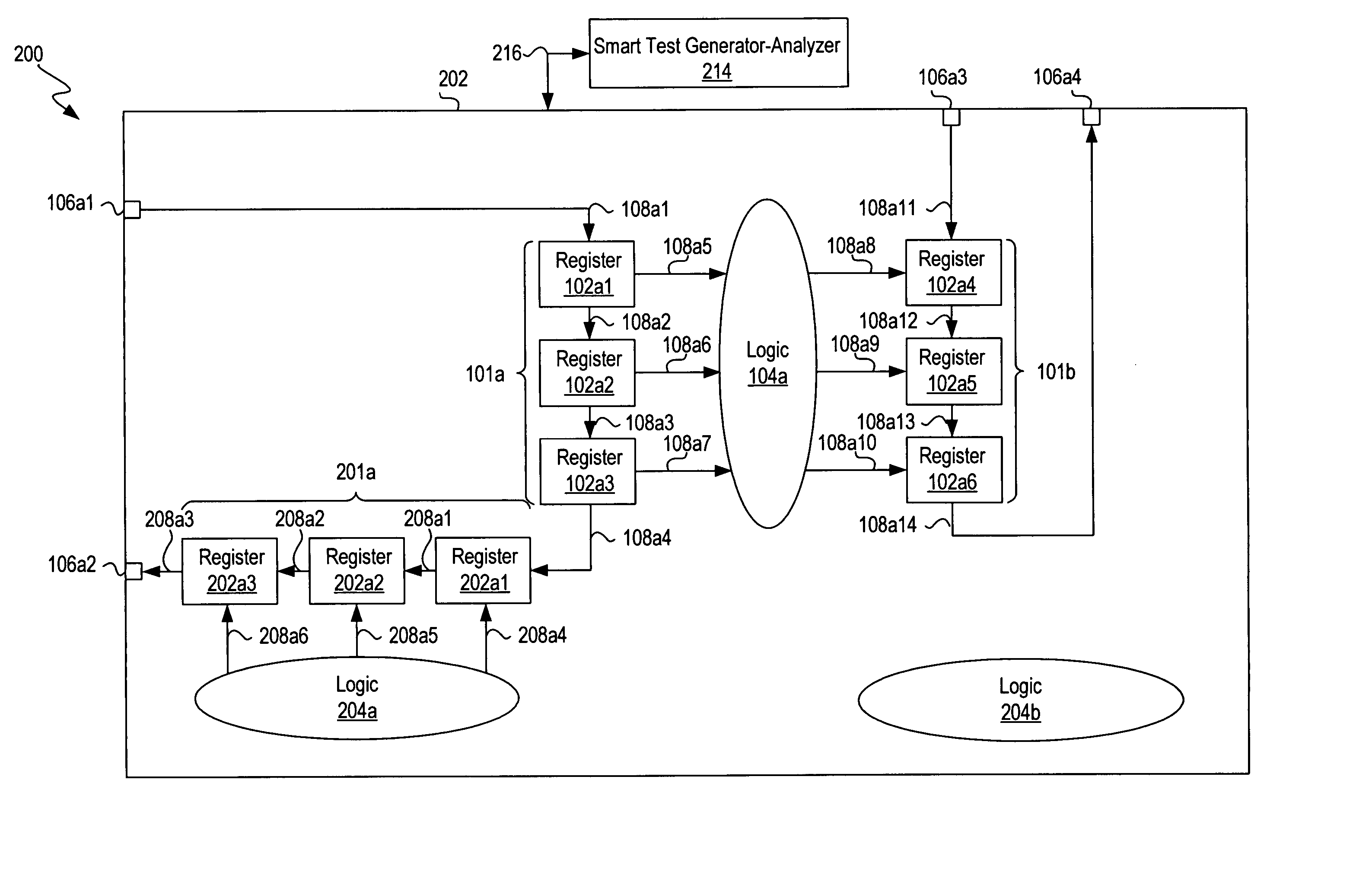

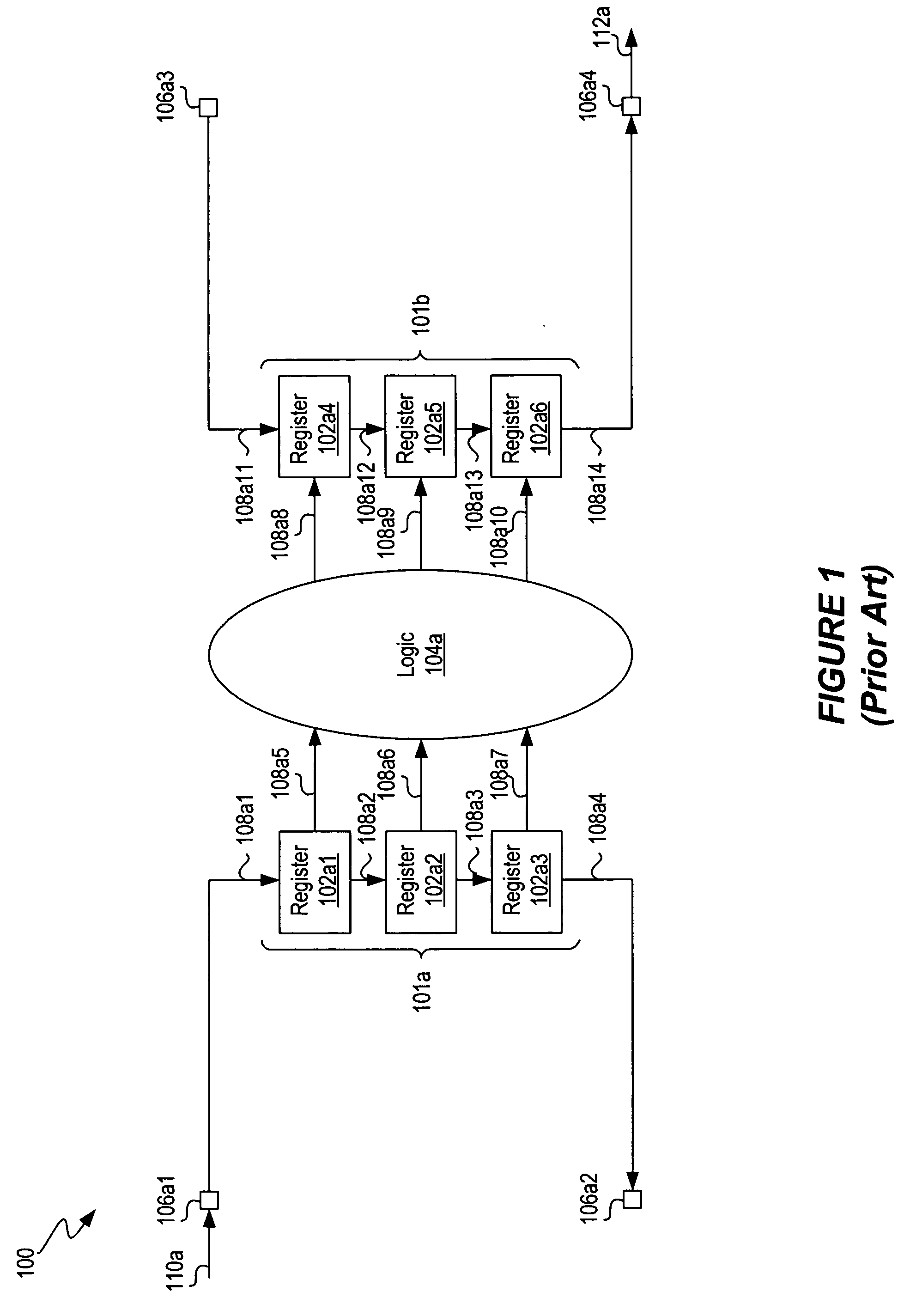

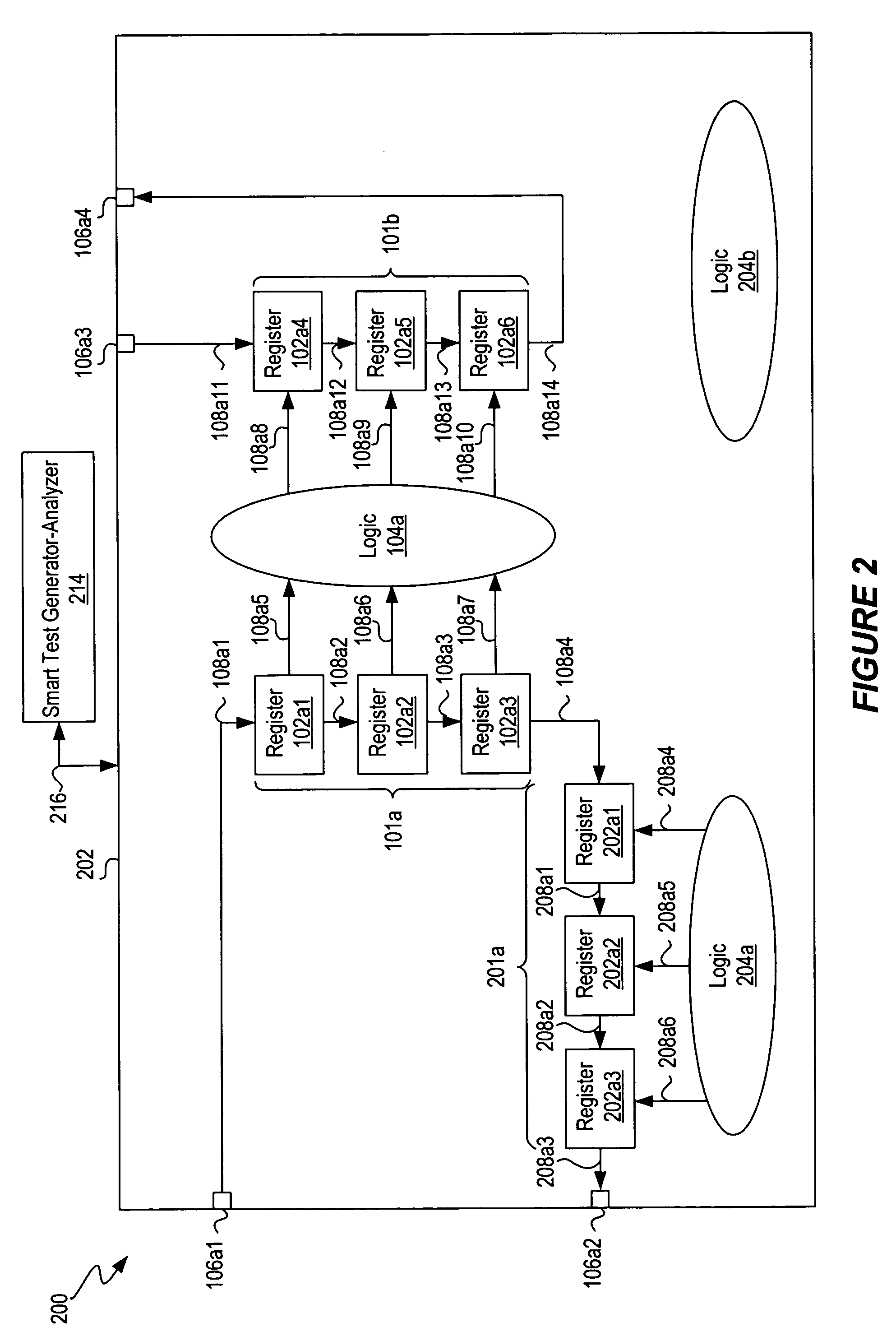

Pipelined scan structures for testing embedded cores

ActiveUS20060282729A1Minimizing impact to die costReduce scan testing timeElectronic circuit testingSystems designProgrammable logic device

A scan testing technique in which test data is pipelined to scan logic within an integrated circuit. In system on a programmable chip (SOPC) designs, pipelines are easily built in the programmable logic device (PLD) logic by configuring programmable interconnects to connect registers in a pipelined manner so that test data can be pipelined to scan the logic under test. In system on a chip (SOC) designs, a smart test generator-analyzer is configured to recursively extract pipeline information from a design-so that test data can be pipelined to scan the logic under test. Generally, test data is pipelined using existing functional logic and / or scan chains. Furthermore, a failure analysis (FA) platform is described. The FA platform is operable to take as its input a failing vector as well as a pipelined scan vector and unroll the pipeline sequence to determine which vector caused the failure.

Owner:ALTERA CORP

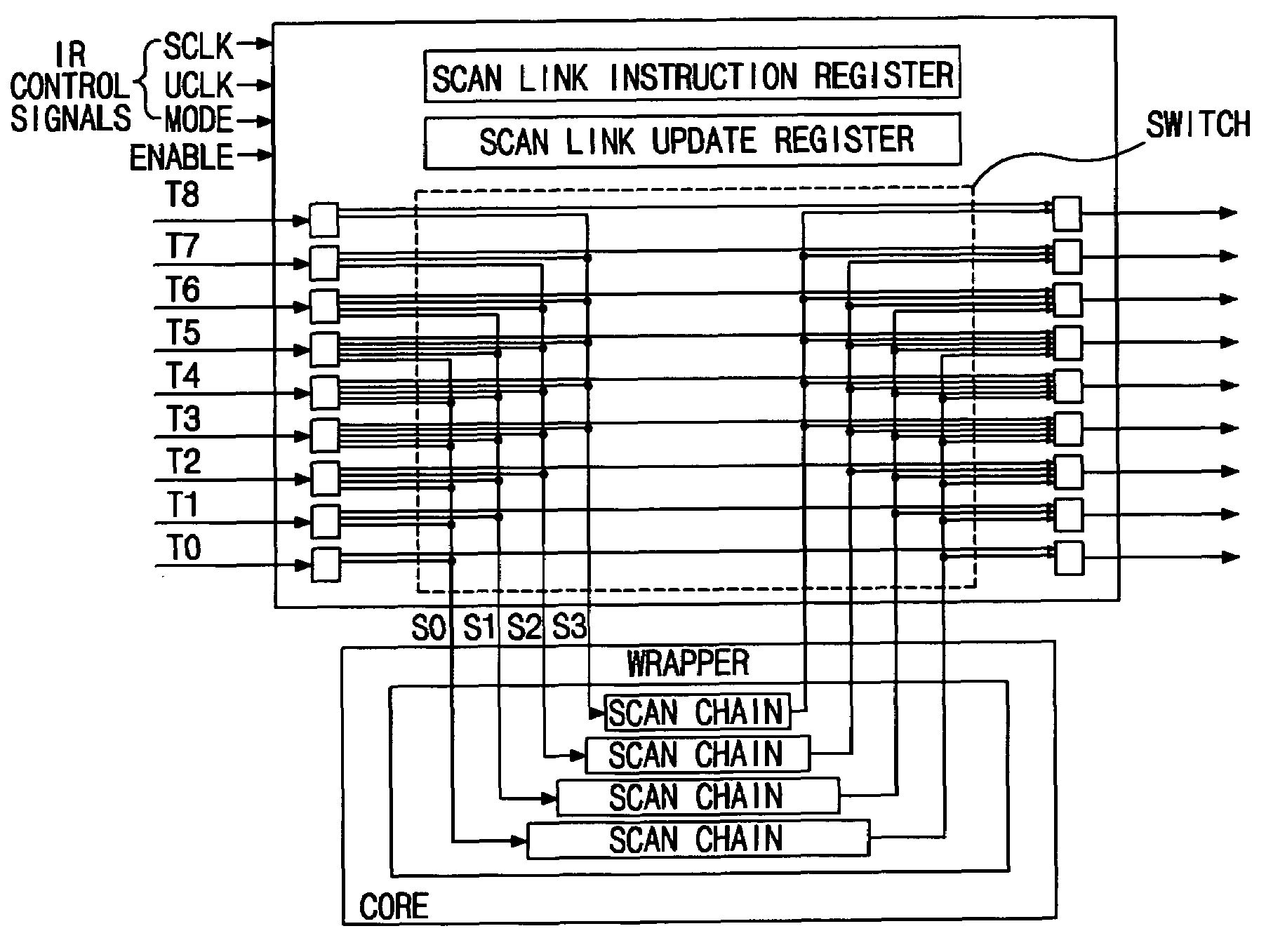

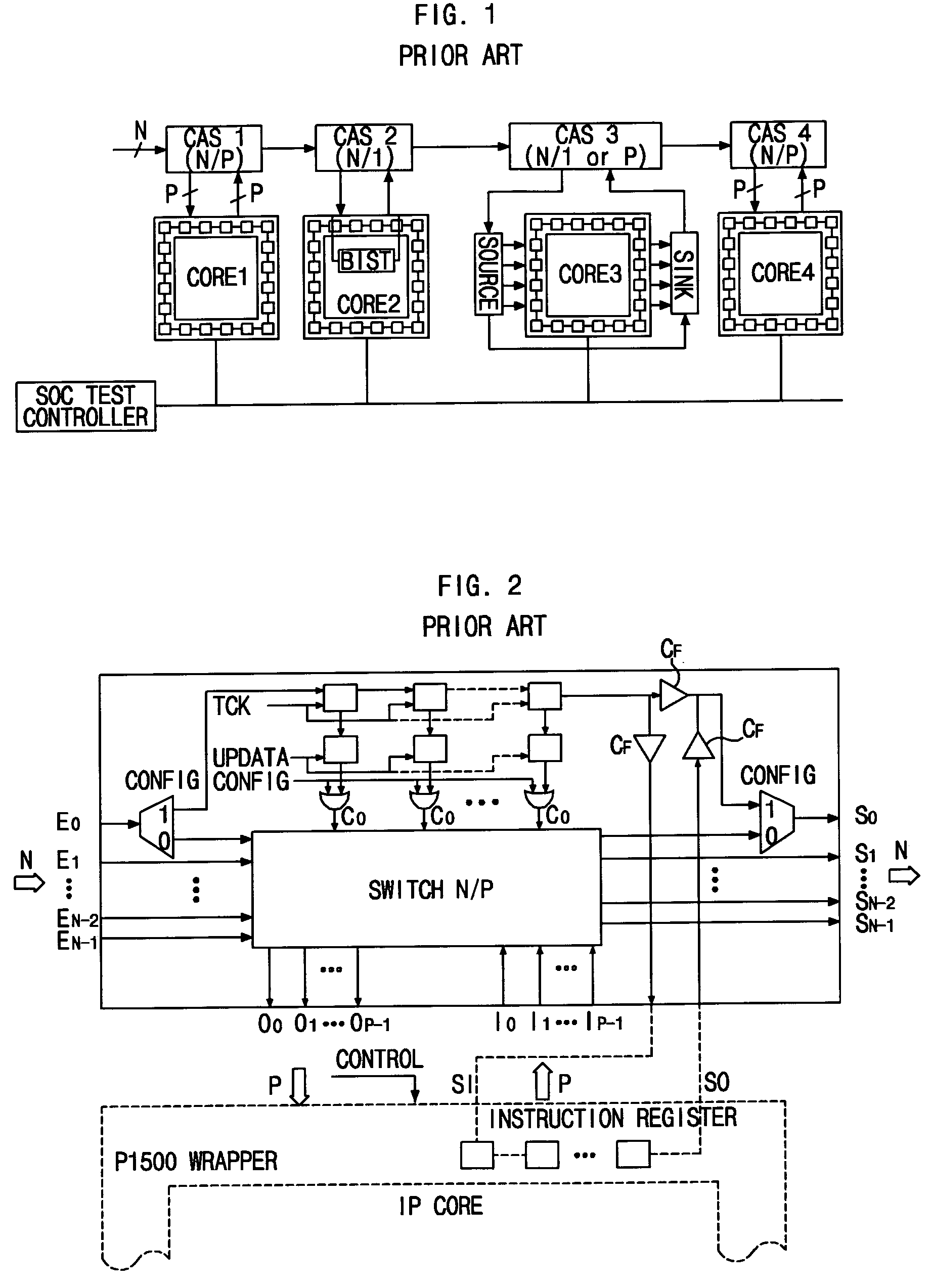

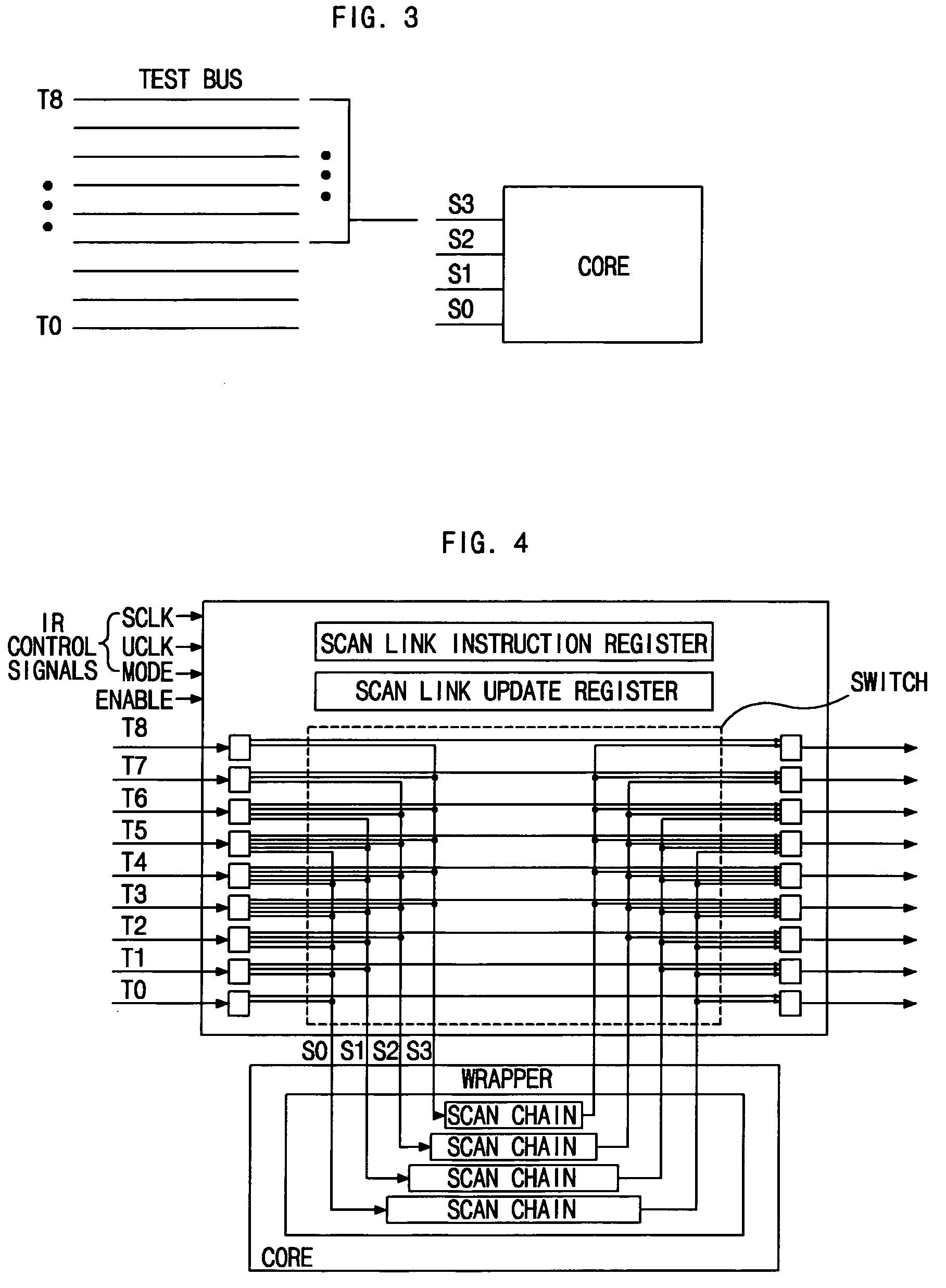

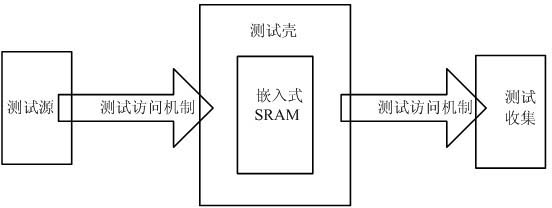

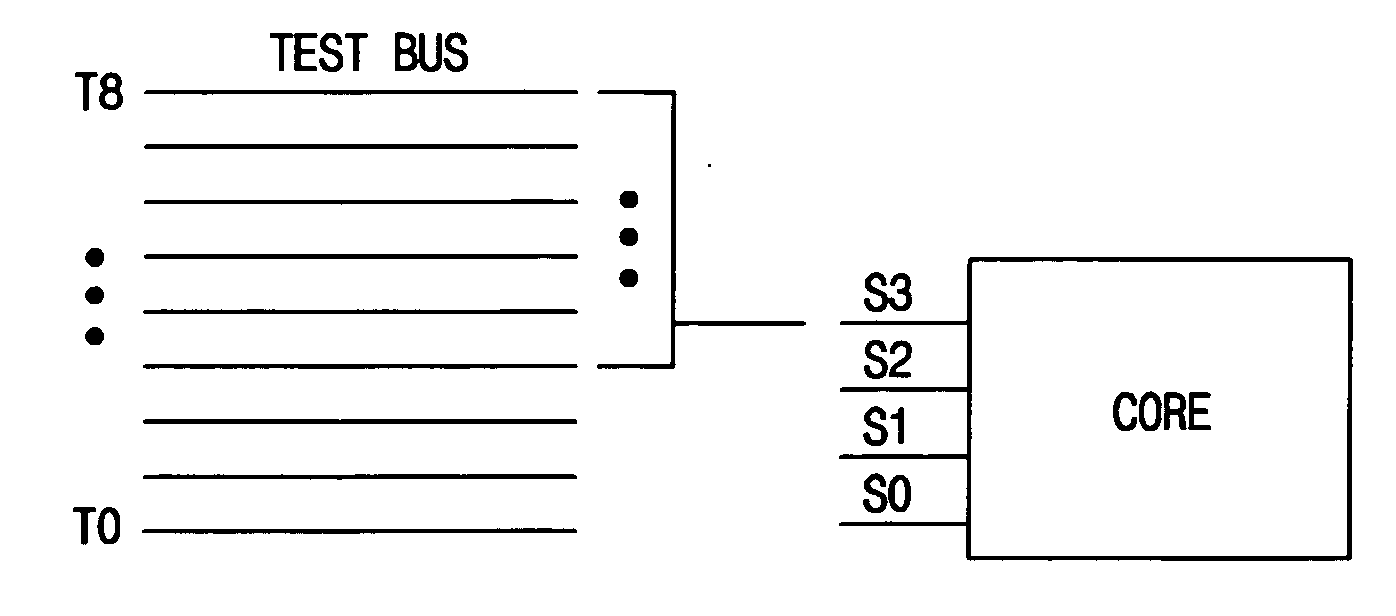

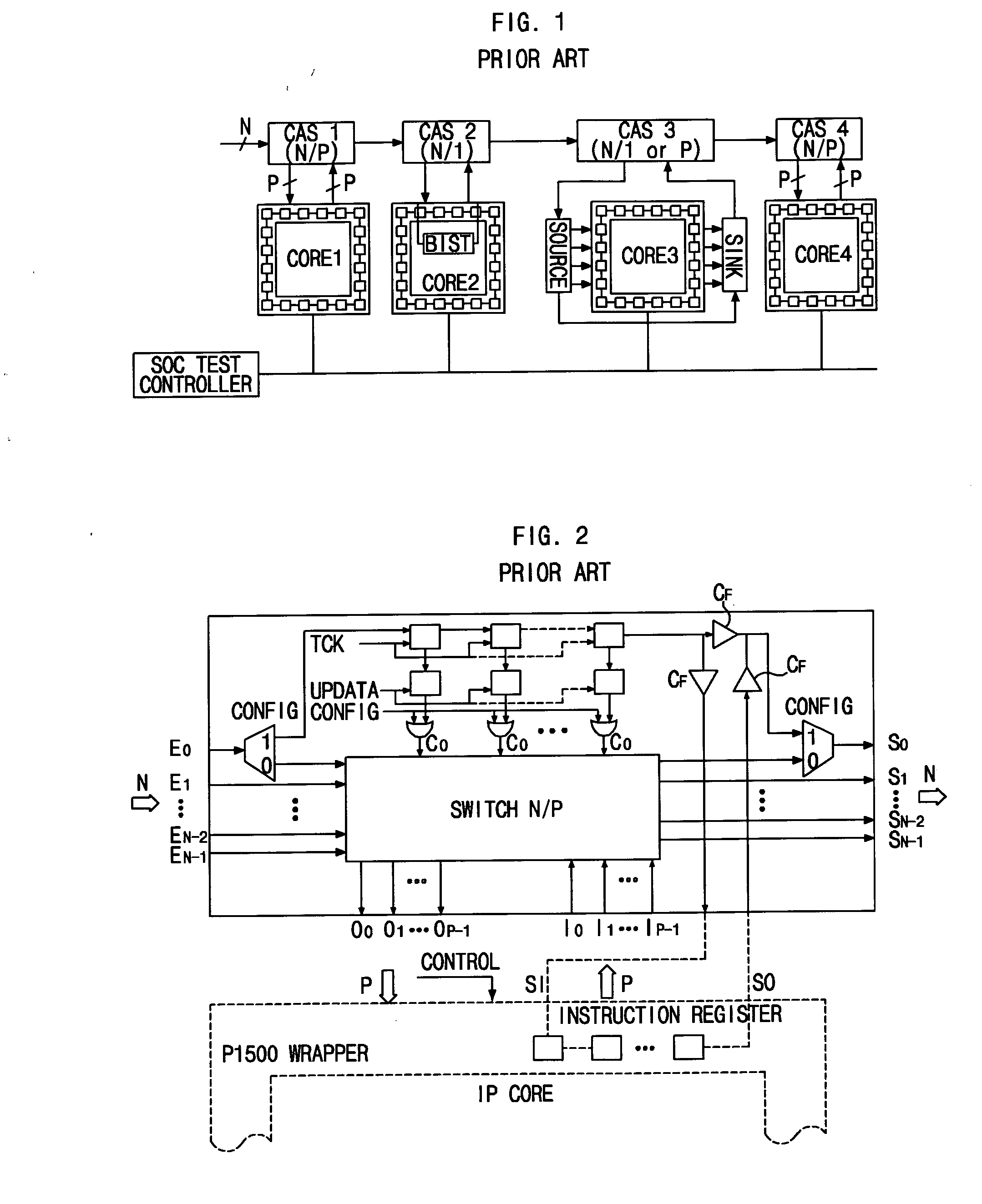

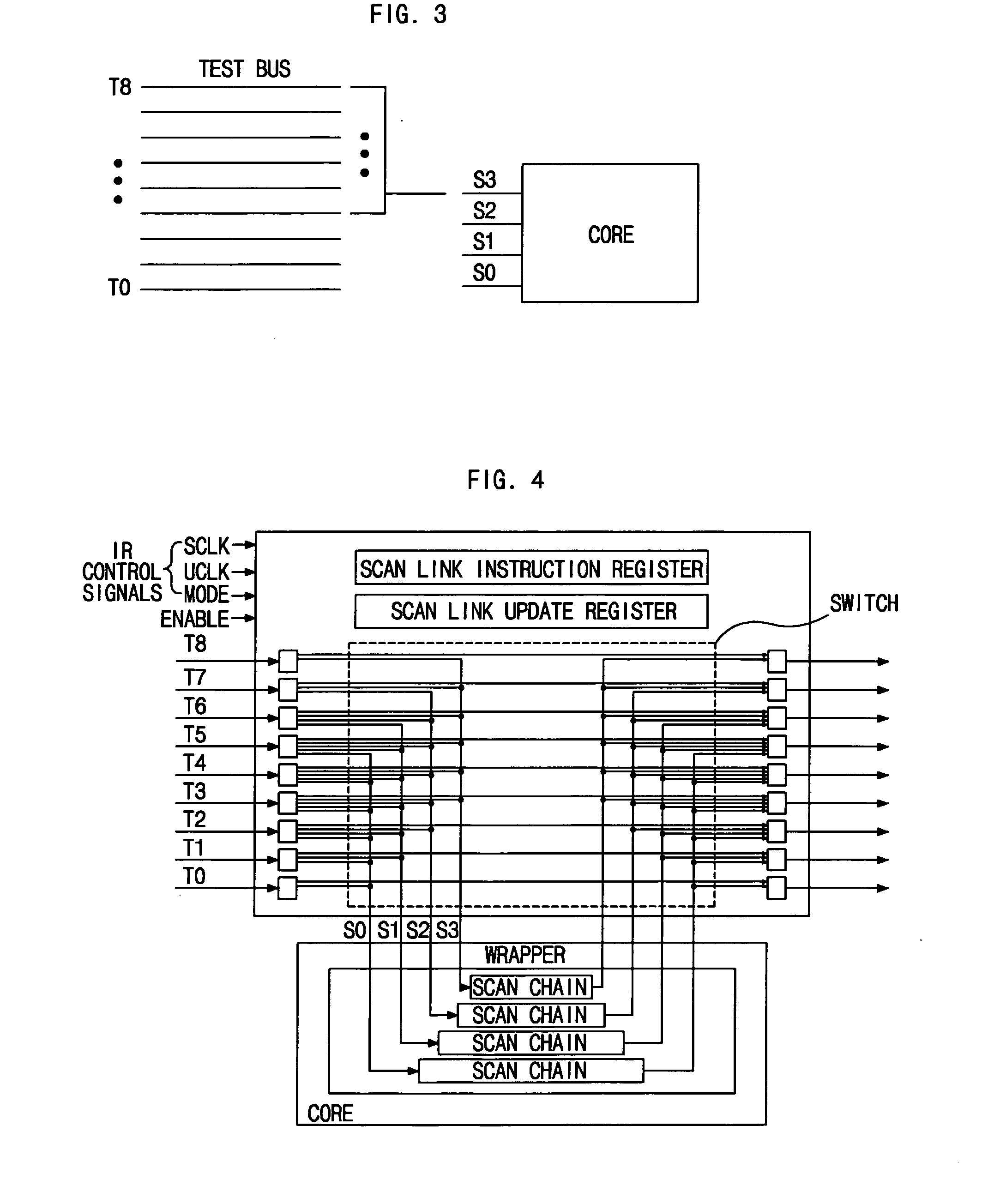

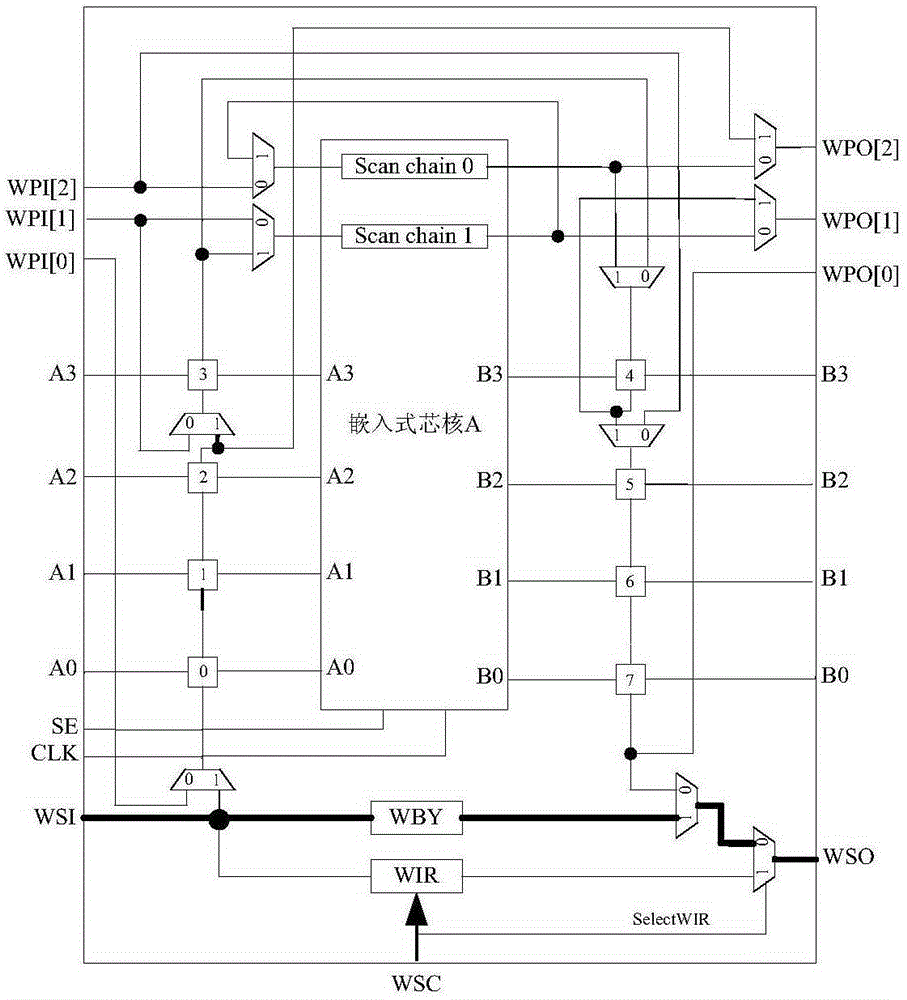

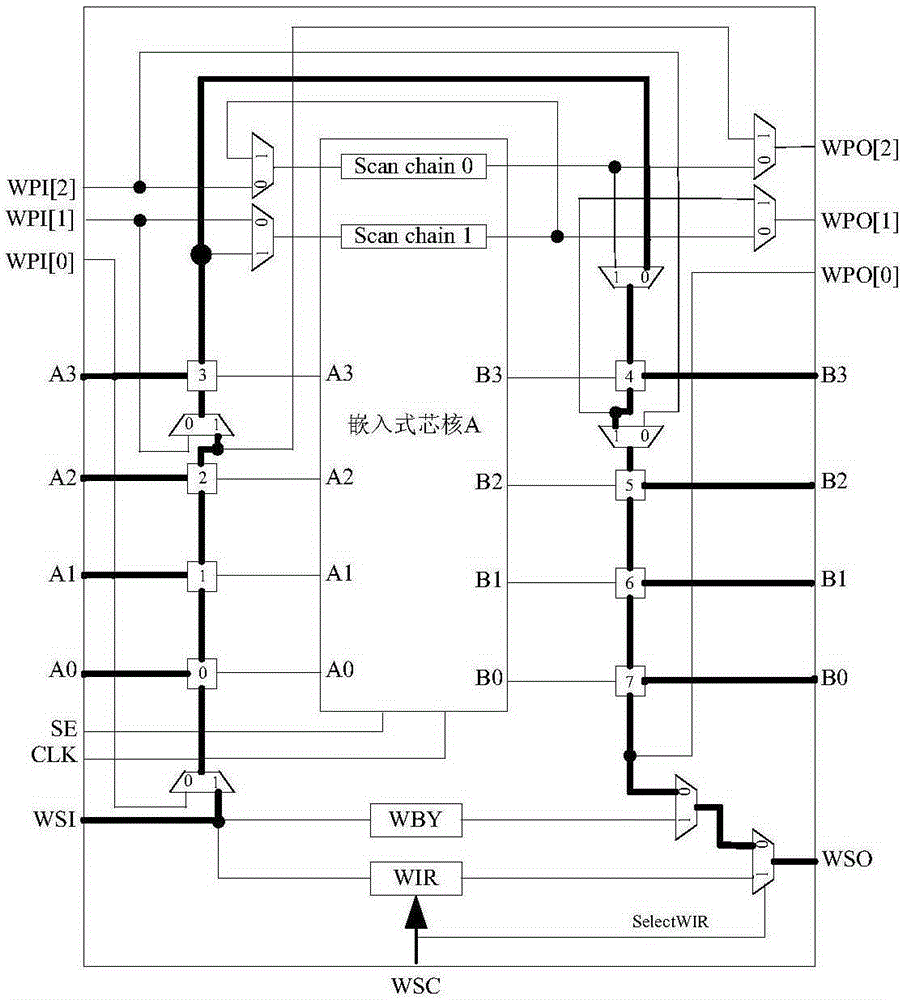

Soc-based core scan chain linkage switch

InactiveUS7296200B2Minimize overheadDynamic performanceElectronic circuit testingFunctional testingEngineeringEmbedded core

Disclosed herein is an SoC-based core scan chain linkage switch. The core scan chain linkage switch includes test bus terminals, scan chain input / output terminals, a switch unit and SCLK, UCLK, Mode and Enable signals. The test bus terminals apply instructions and input / output test data. The scan chain input / output terminals link with the scan chains of an embedded core. The switch unit completes a linkage configuration between the test bus terminals and the scan chain input / output terminals in response to the applied instructions. The SCLK, UCLK and Mode signals apply the instructions to dynamically reconfigure the switch unit and update the linkage configuration of the switch unit, and the Enable signal activates and deactivates the switch unit.

Owner:KOREA ELECTRONICS TECH INST

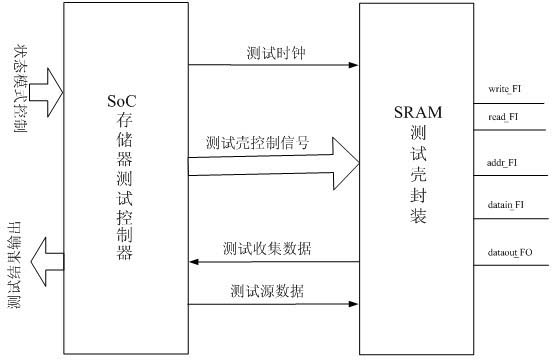

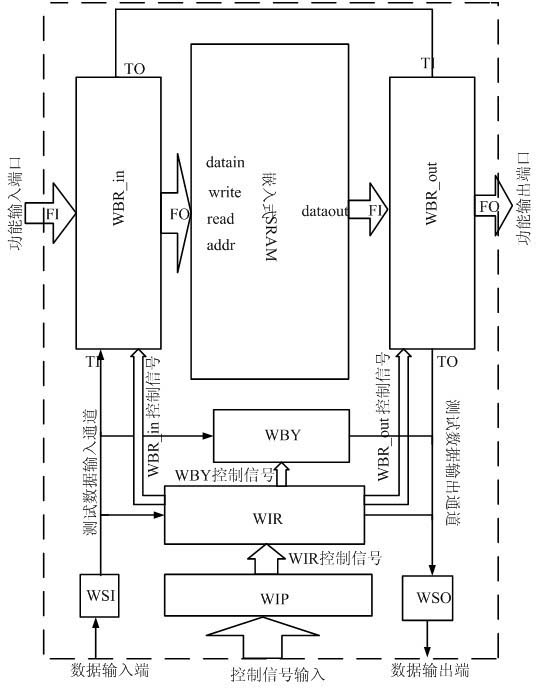

Embedded static random access memory (SRAM) test structure and test method based on institute of electrical and electronics engineers (IEEE) 1500

InactiveCN102332306AResolve Test AccessSolving Test IsolationStatic storageStatic random-access memoryTest algorithm

The invention discloses an embedded static random access memory (SRAM) test structure and an embedded SRAM test method based on institute of electrical and electronics engineers (IEEE) 1500. Methods for IEEE1500 standard for embedded core test and built-in self test (BIST) are combined in the test structure; the embedded SRAM test structure consists of a test shell package of an embedded SRAM and a SRAM test controller, wherein the test shell package is used for solving the problems of test access, test isolation and test control of the embedded SRAM; and the SRAM test controller is used for generating test incentive data, controlling a package shell Wrapper, performing response analysis and outputting a test result according to a test algorithm. By adoption of the test structure and the test method, a fault existing in the embedded SRAM can be detected, the test reuse of the embedded SRAM is facilitated, and the integration efficiency of system on a chip (SoC) can be effectively improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

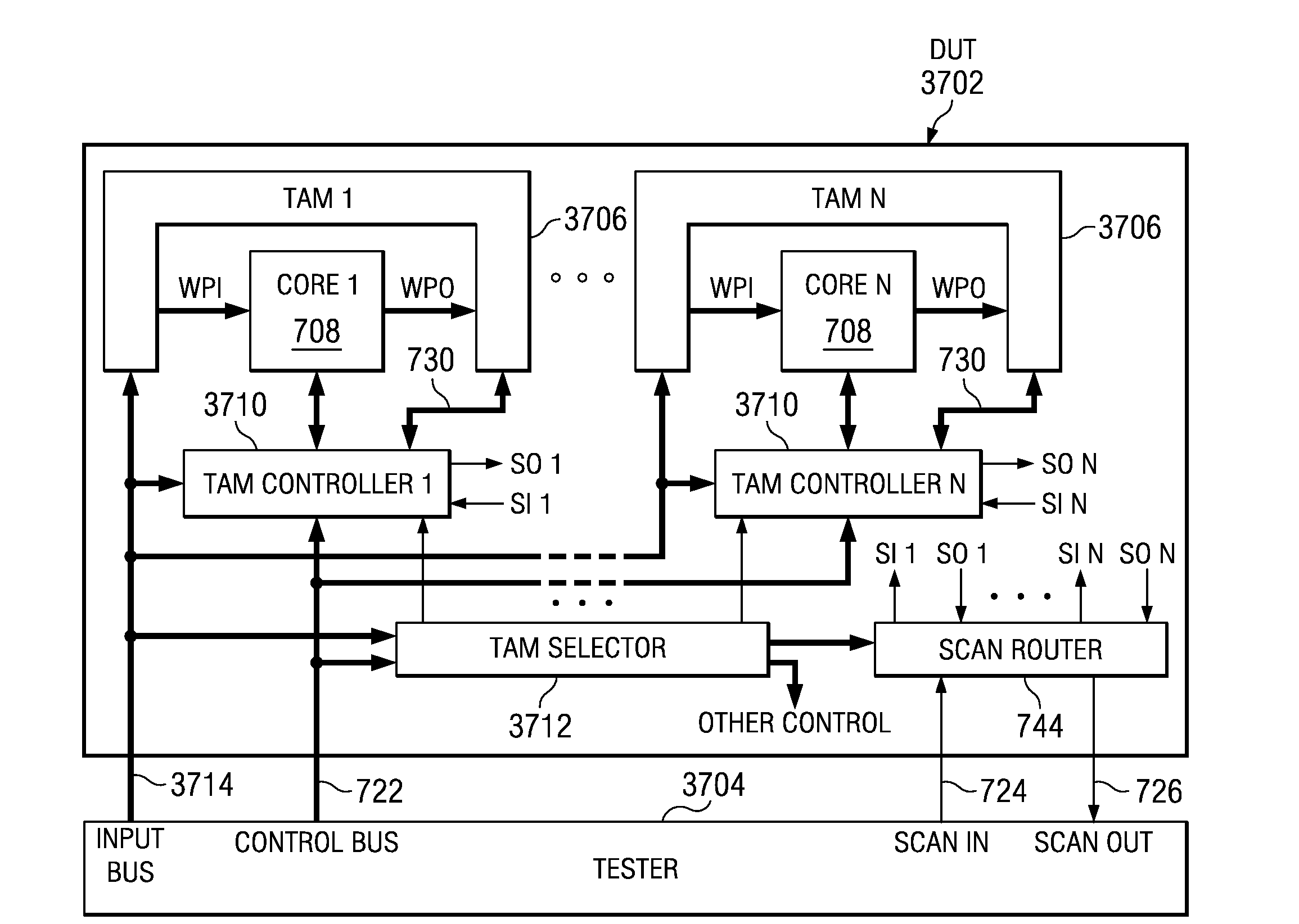

TAM controller for plural test access mechanisms

ActiveUS7519884B2Efficient testingSimplifies testerElectronic circuit testingComputer hardwareProgrammable logic controller

Owner:TEXAS INSTR INC

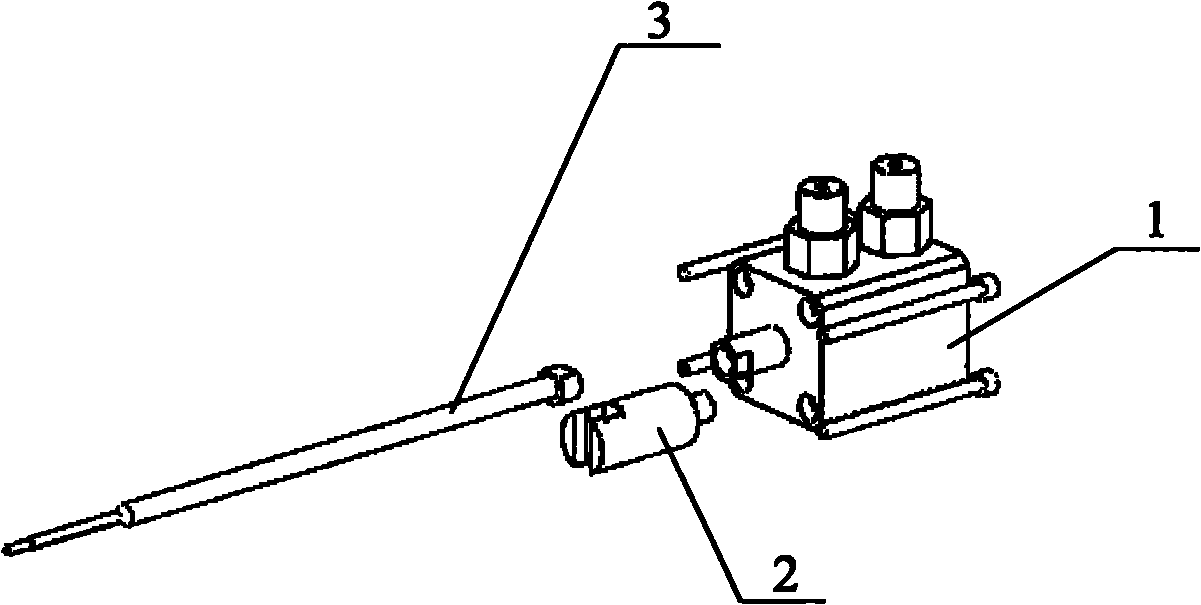

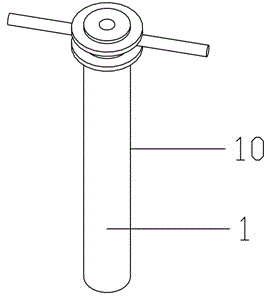

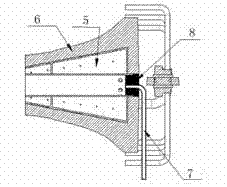

Oil cylinder core-loosening injection mould with spring self-locking mechanism

ActiveCN102555161AGuarantee the appearance qualityAvoid deformation damageLocking mechanismEngineering

The invention provides an oil cylinder core-loosening injection mould with a spring self-locking mechanism, which can solve the problem that the defect on the surface of a formed product is generated because a formed embedded core is easily beaten back when an oil cylinder is subjected to core loosening in the prior art. The cylinder core-loosening injection mould with a spring self-locking mechanism comprises a front template and an oil cylinder core-loosening mechanism, wherein the oil cylinder core-loosening mechanism comprises a formed embedded core, the oil cylinder and an oil cylinder joint; the spring self-locking mechanism is arranged between the formed embedded core and the oil cylinder joint and comprises an oil cylinder joint fixing block, an embedded core connecting block and a spring locking block; the front end of the oil cylinder joint fixing block is connected with the embedded core connecting block; the rear end of the oil cylinder joint fixing block is connected with the front end of the oil cylinder joint; and the front end of the embedded core connecting block is connected with the formed embedded core. By additionally arranging the spring self-locking mechanism, the formed embedded core is locked in the injection moulding process, the defects of trimming, burr and the like on the surface of the product caused by beating back of the formed embedded core as a piston rod of the oil cylinder is forced to backwards move by the large injection moulding force to drive the formed embedded core to retreat is avoided, and the appearance quality of the product is effectively guaranteed.

Owner:QINGDAO HAIER MOLDS

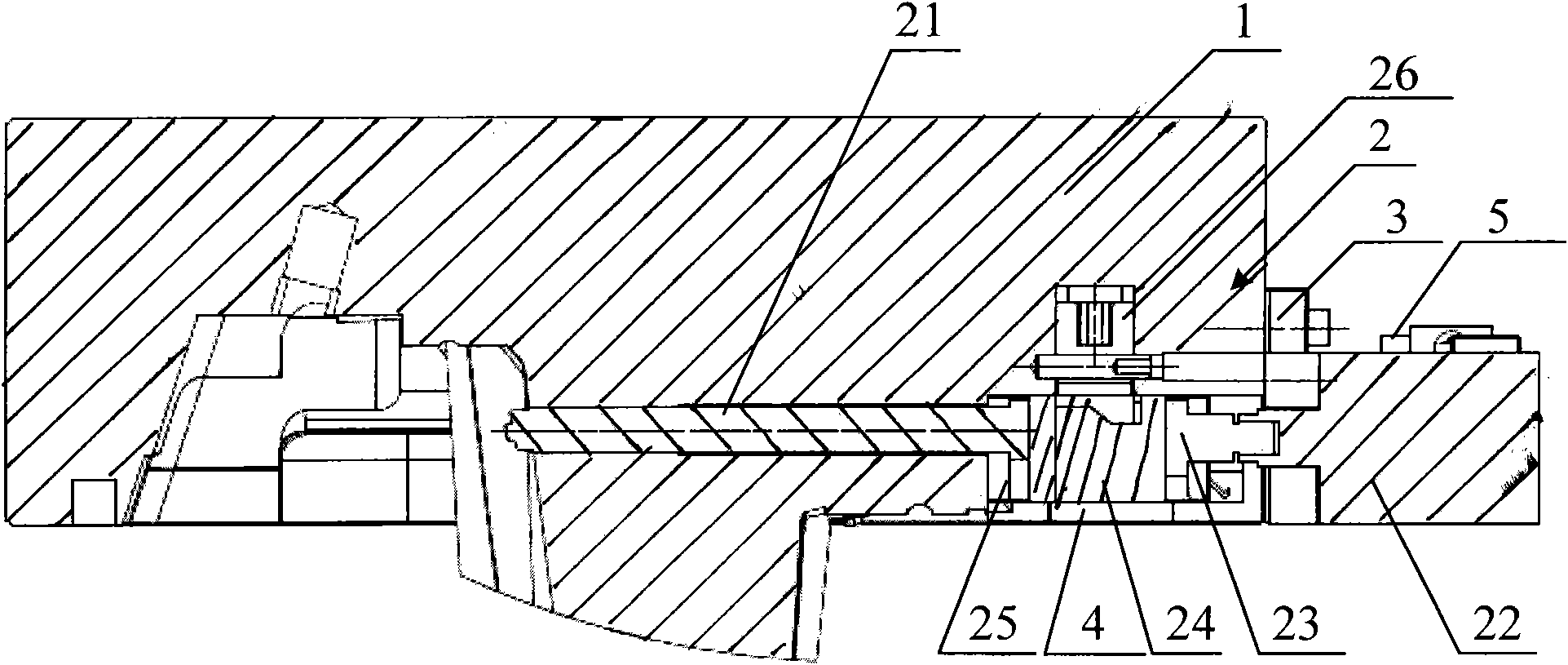

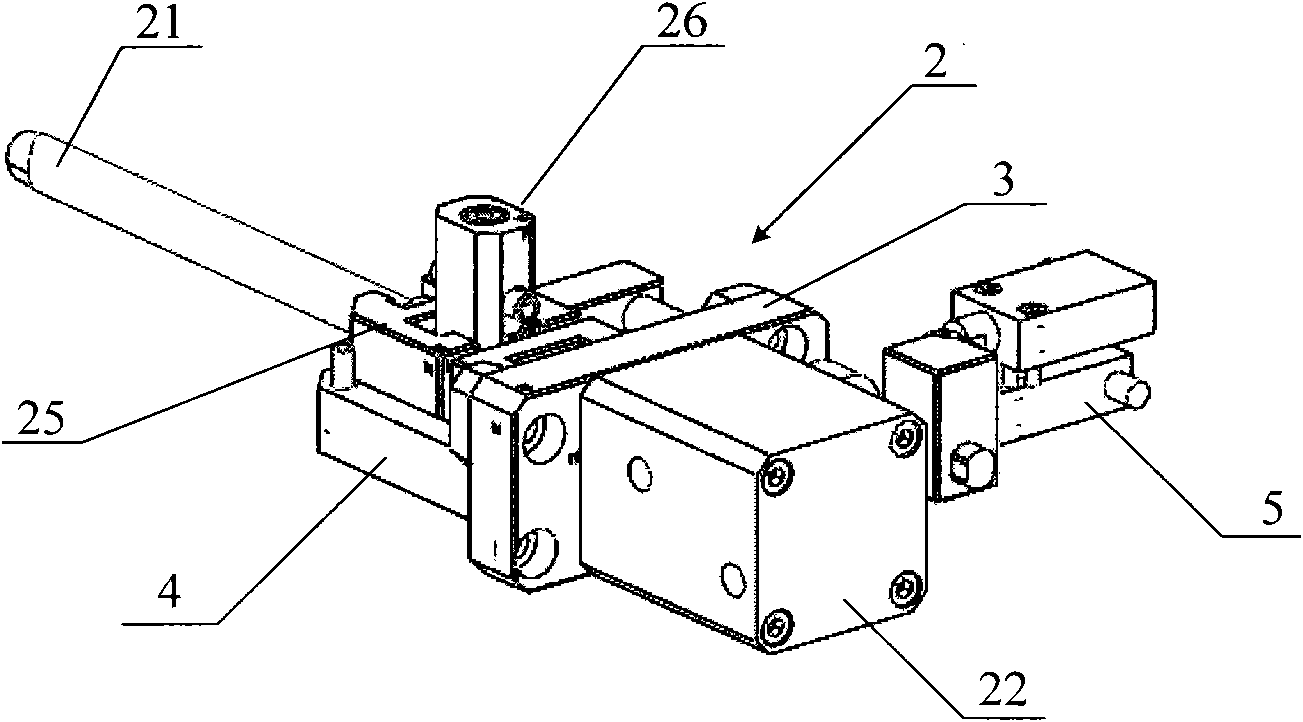

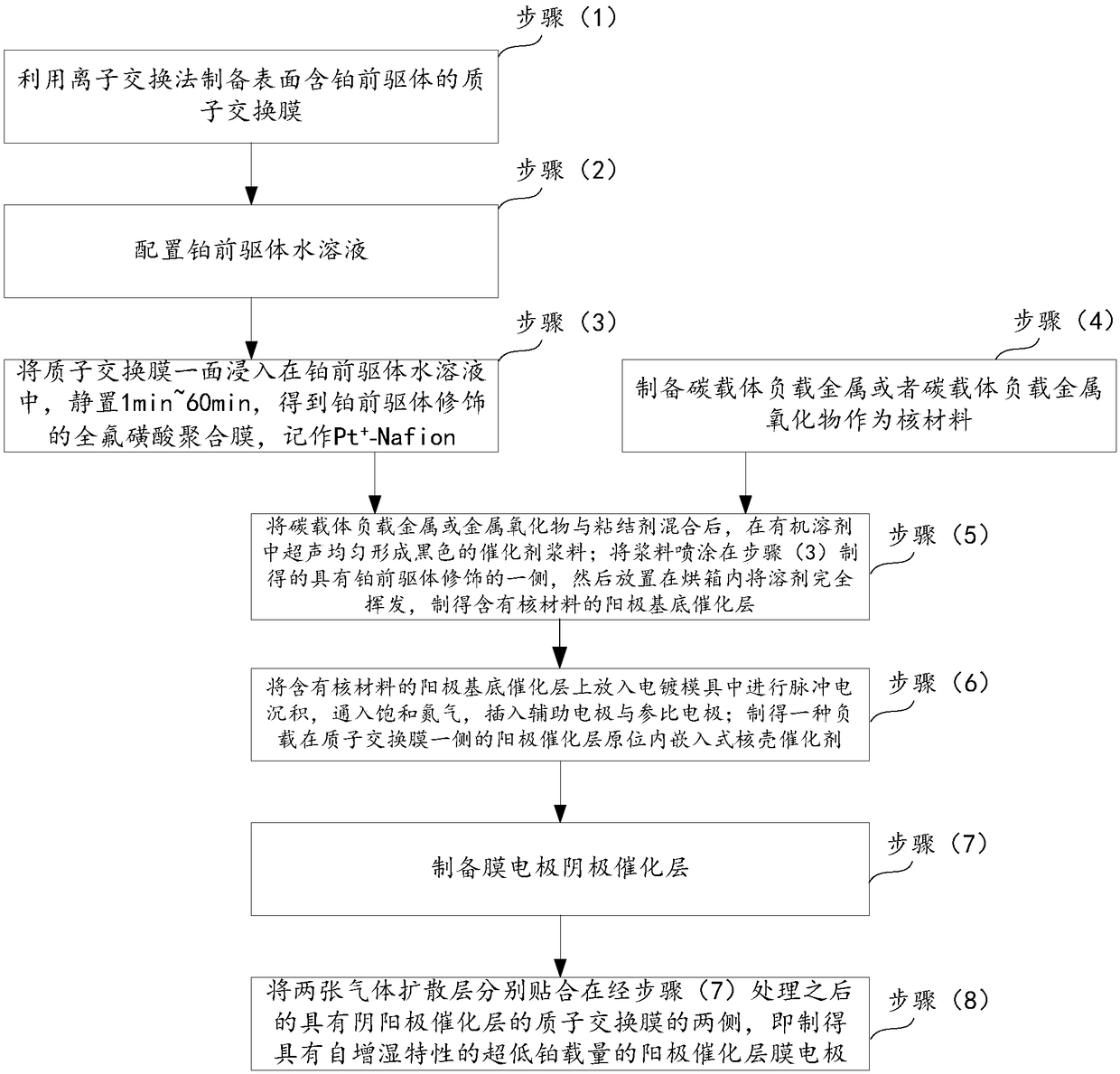

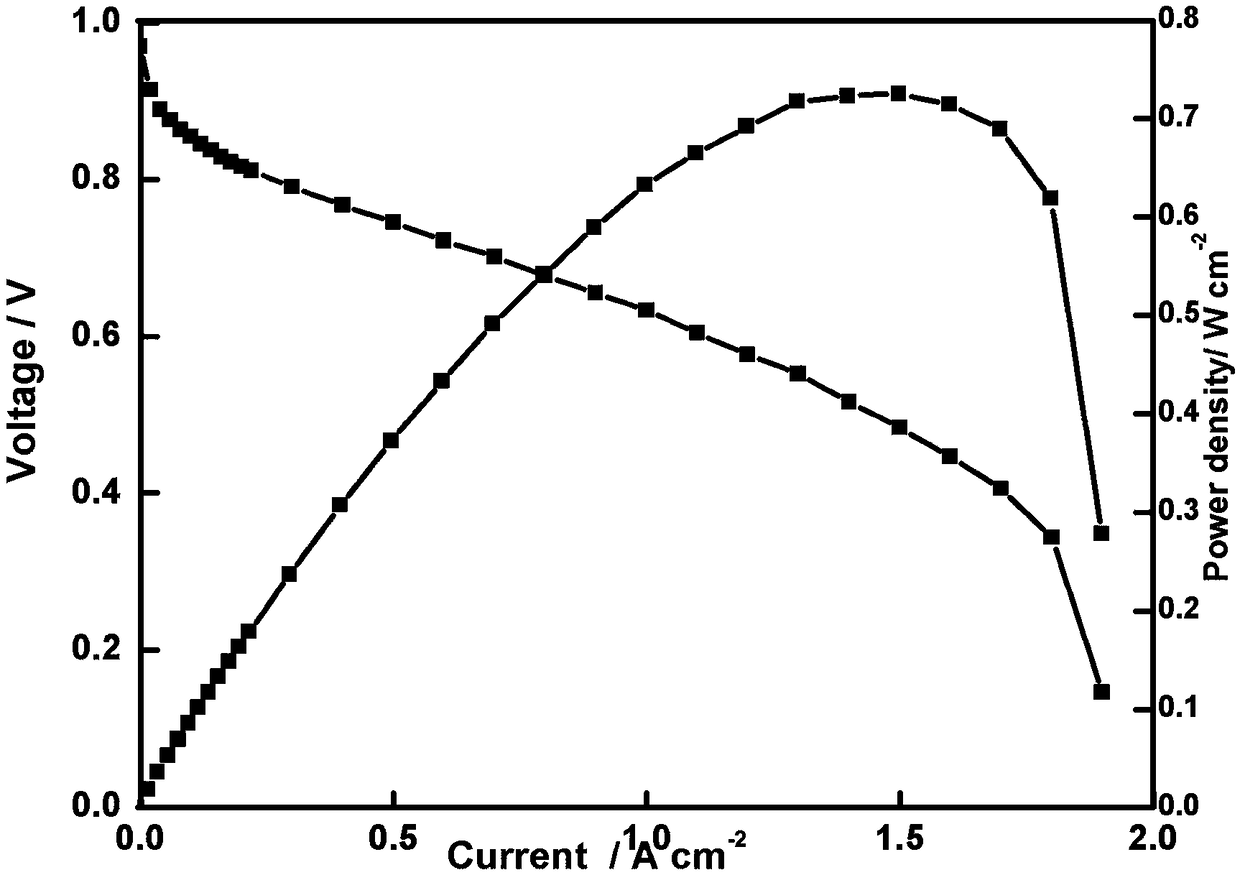

Preparation method of membrane electrode and preparation method of membrane electrode anode catalytic layer

The invention discloses a preparation method of a membrane electrode and a preparation method of a membrane electrode anode catalytic layer. The preparation method comprises the following steps of immersing one surface of a proton exchange membrane into a platinum precursor / water solution; mixing a carbon carrier metal or a metal oxide with perfluorinated sulfonic acid resin, and after mixing, performing ultrasonic and uniform mixing in an organic solvent to form a black catalyst slurry; putting a prepared anode substrate catalytic layer into an electroplating grinding tool for pulse electrodeposition, introducing saturated nitrogen, and inserting an auxiliary electrode and a reference electrode; and setting the pulse frequency, the conduction and disconnection time and the pulse deposition total time, so as to prepare an anode catalytic layer in-situ embedded core-shell catalyst. By virtue of the preparation method of the membrane electrode, and the preparation method of the membraneelectrode anode catalytic layer provided by the invention, the preparation efficiency, the controllability and the precision of the preparation process are improved, and the cost can be lowered.

Owner:山东潍氢动力科技有限公司

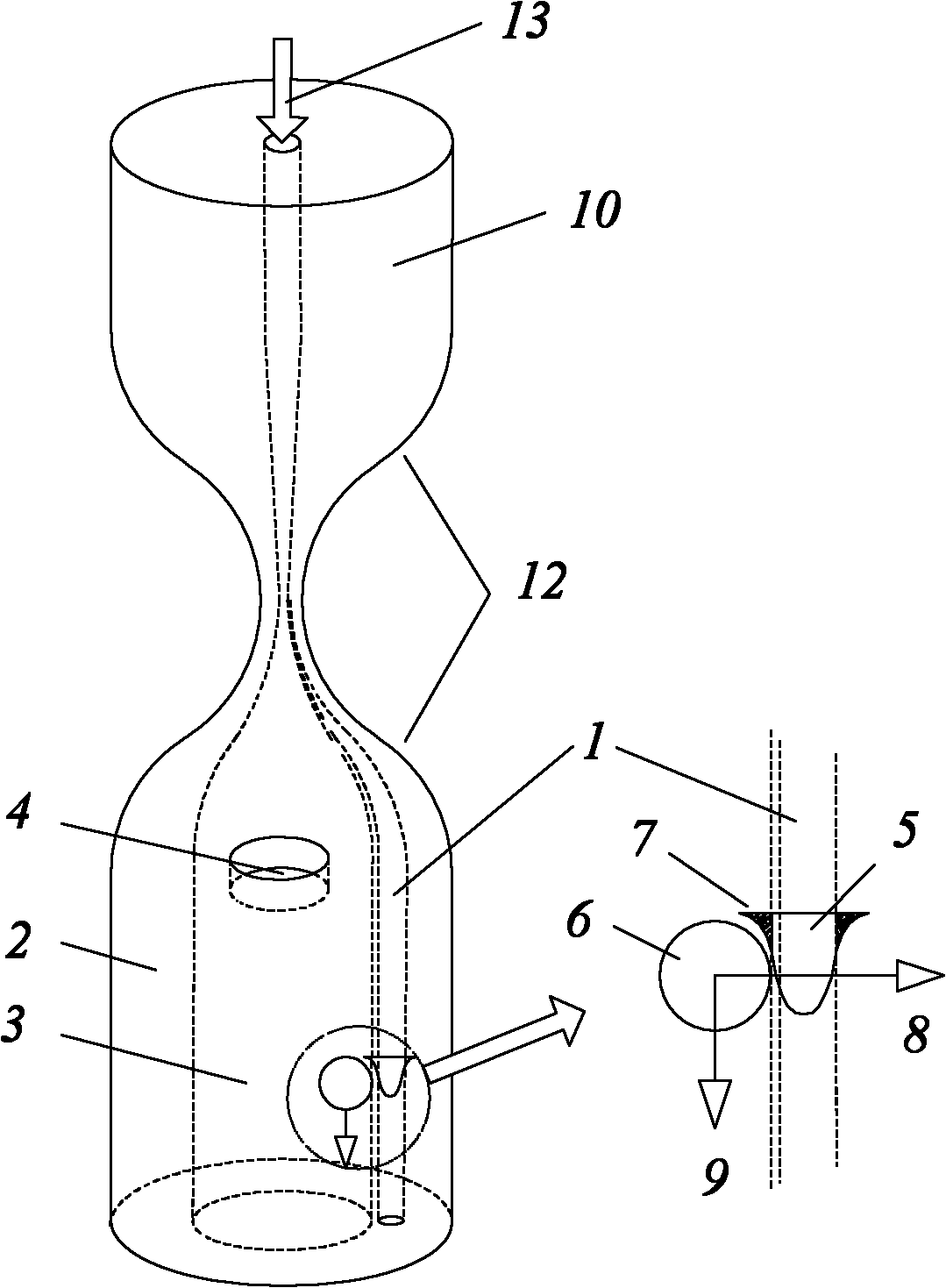

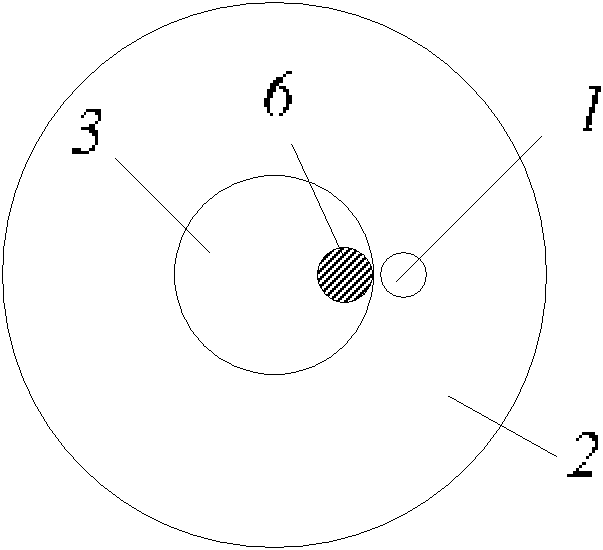

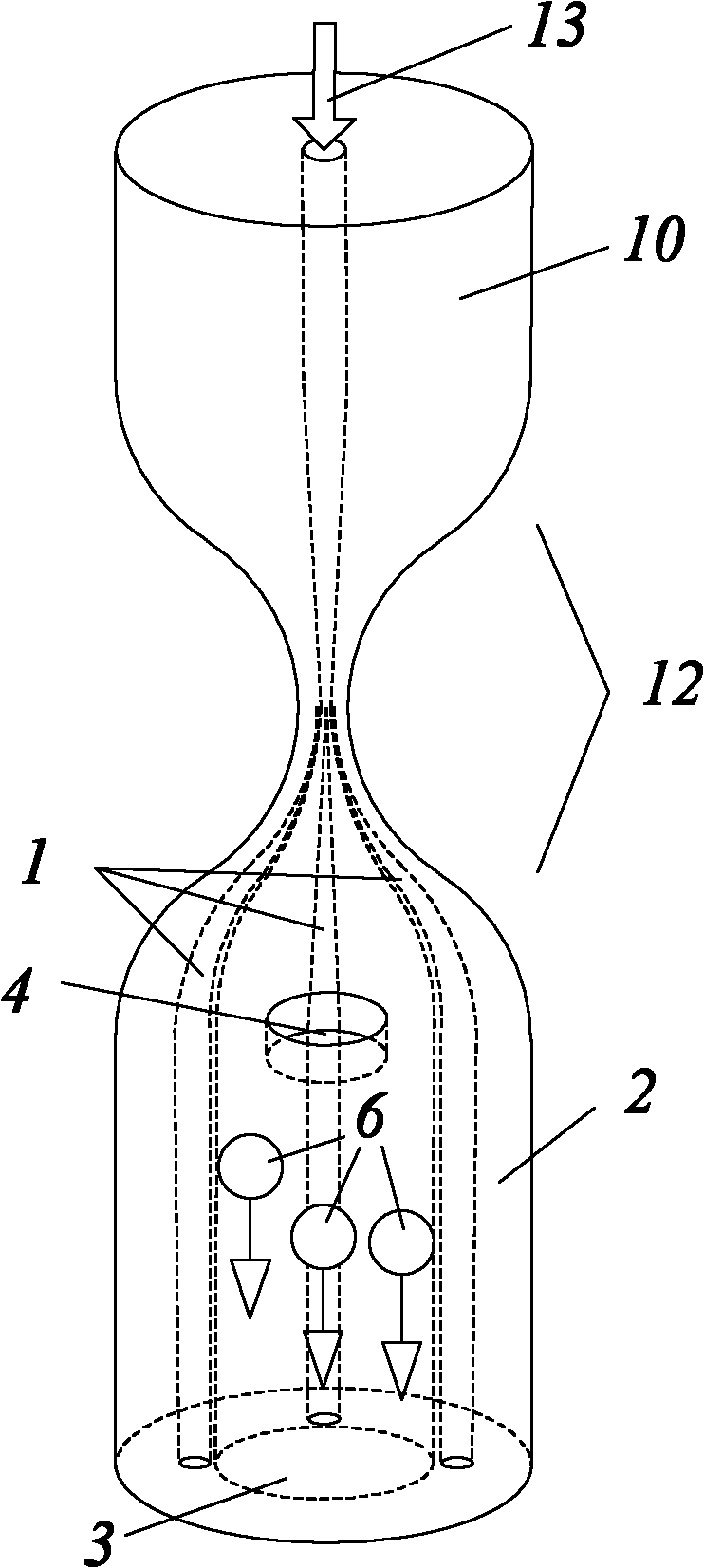

Tiny particle conveying device and method based on hollow melt-embedded core capillary optical fiber

InactiveCN102147502AControl output typeControl the number of shipmentsRadiation/particle handlingCoupling light guidesBiological cellWhole body

The invention provides a tiny particle conveying device and a method based on a hollow melt-embedded core capillary optical fiber. The tiny particle conveying device comprises a section of hollow melt-embedded core capillary optical fiber; the hollow melt-embedded core capillary optical fiber can lead transmission lights in a fiber core to transmit a cladding layer in an evanescent field mode and enter the hollow melt-embedded core capillary optical fiber in a capillary; one side of the middle part of the hollow melt-embedded core capillary optical fiber is provided with a small hole; the small hole is connected with an air pressure adjusting device; one end of the hollow melt-embedded core capillary optical fiber is welded with a section of standard solid optical fiber; and the standard solid optical fiber is connected with the hollow melt-embedded core capillary optical fiber into a whole body by a cone transition region formed by drawing a welding part. The device and the method can be used for screening, transferring, transporting, detecting and the like for tiny particles such as biological molecules, biological cells, nanometer clusters, colloidal particles, media particles and the like.

Owner:HARBIN ENG UNIV

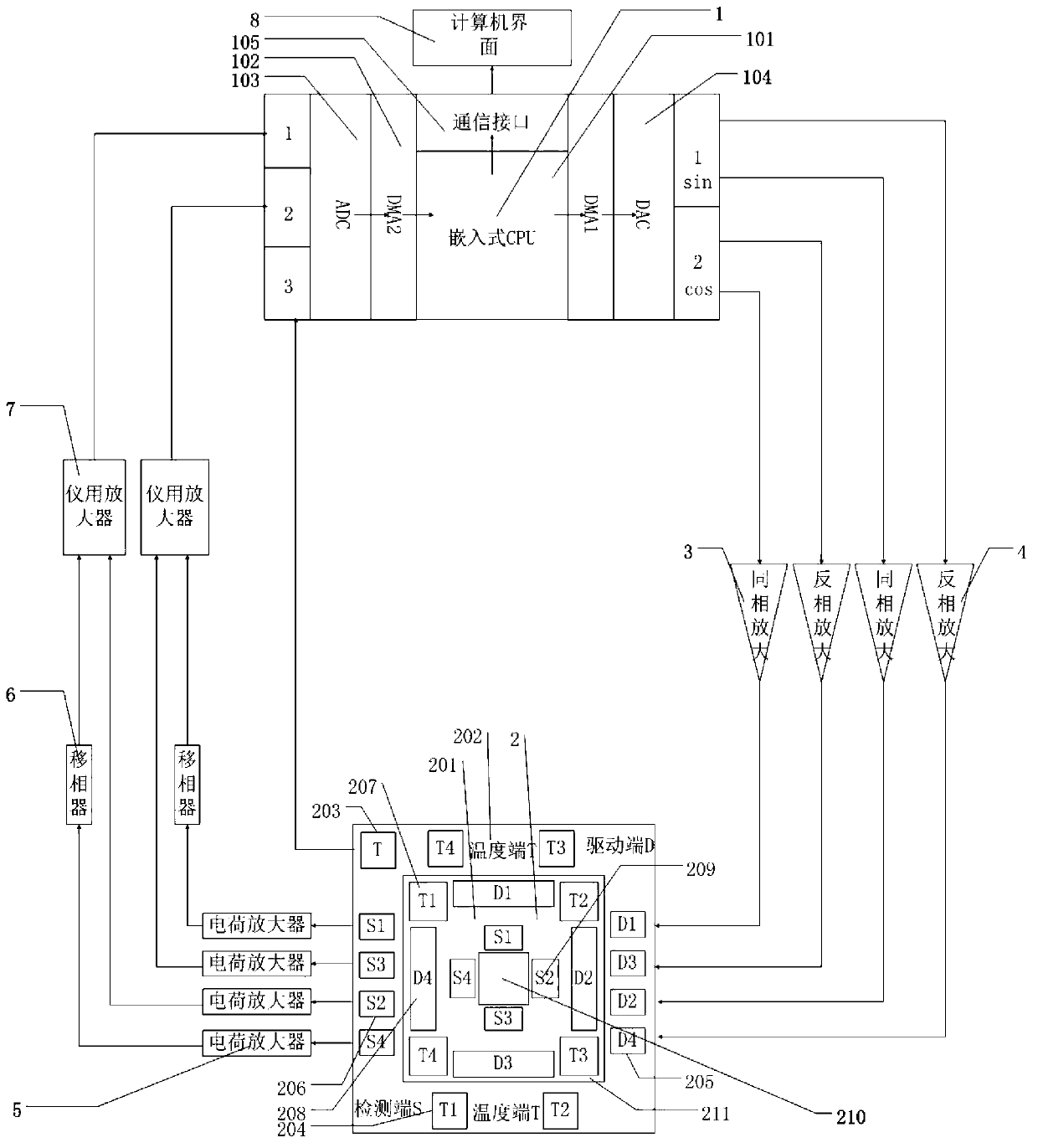

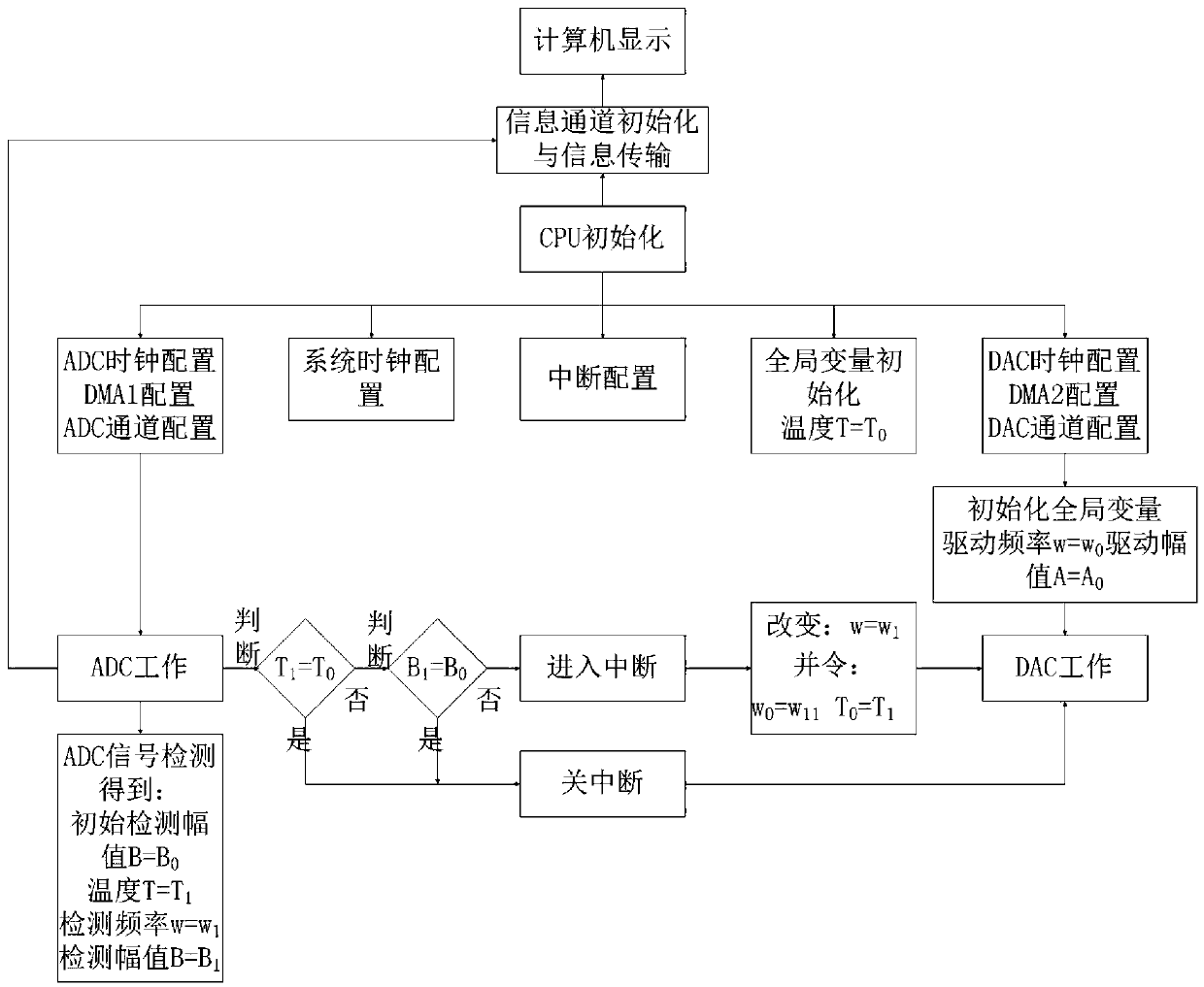

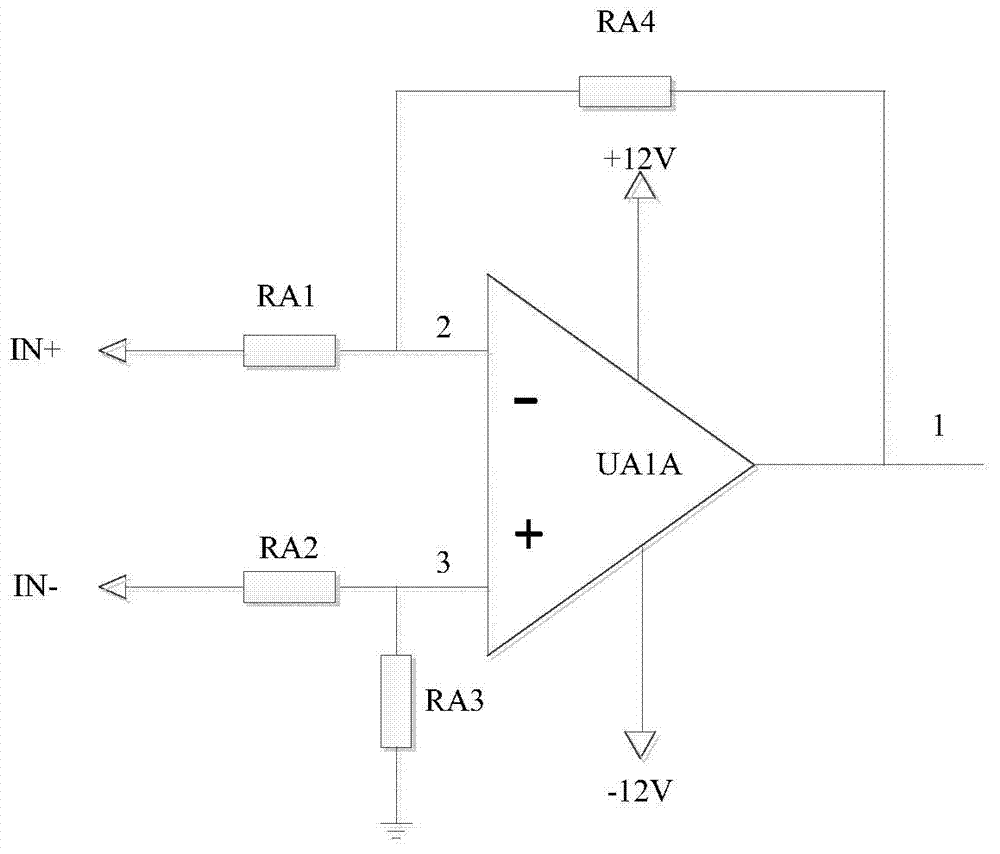

Shaking-quality bulk acoustic wave solid-fluctuation microgyroscope driving and detecting circuit

ActiveCN103344228AAvoid cumbersomeStable and effective drive signalTurn-sensitive devicesGyroscopeClosed loop

The invention provides a shaking-quality bulk acoustic wave solid-fluctuation microgyroscope driving and detecting circuit, which comprises an embedded core part, a peripheral circuit part, a shaking-quality bulk acoustic wave solid-fluctuation microgyroscope part and a computer display part, wherein the embedded core part is connected with the peripheral circuit part, then is connected with the shaking-quality bulk acoustic wave solid-fluctuation microgyroscope part, and finally returns through the peripheral circuit part; meanwhile, the embedded core part is directly connected and is communicated with the computer display part in real time; the driving and defection for the gyroscope are mainly completed at the embedded core part, the peripheral circuit part plays a helping role, and therefore the gyroscope is controlled and is sensitive to output. The circuit can provide a stable and effective driving signal for the shaking-quality bulk acoustic wave solid-fluctuation microgyroscope, ensures that the gyroscope is in a resonant state at all time, effectively realizes the feedback mechanism of gyroscope driving and detection, forms a closed-loop system, and detects a gyroscope signal.

Owner:SHANGHAI JIAO TONG UNIV

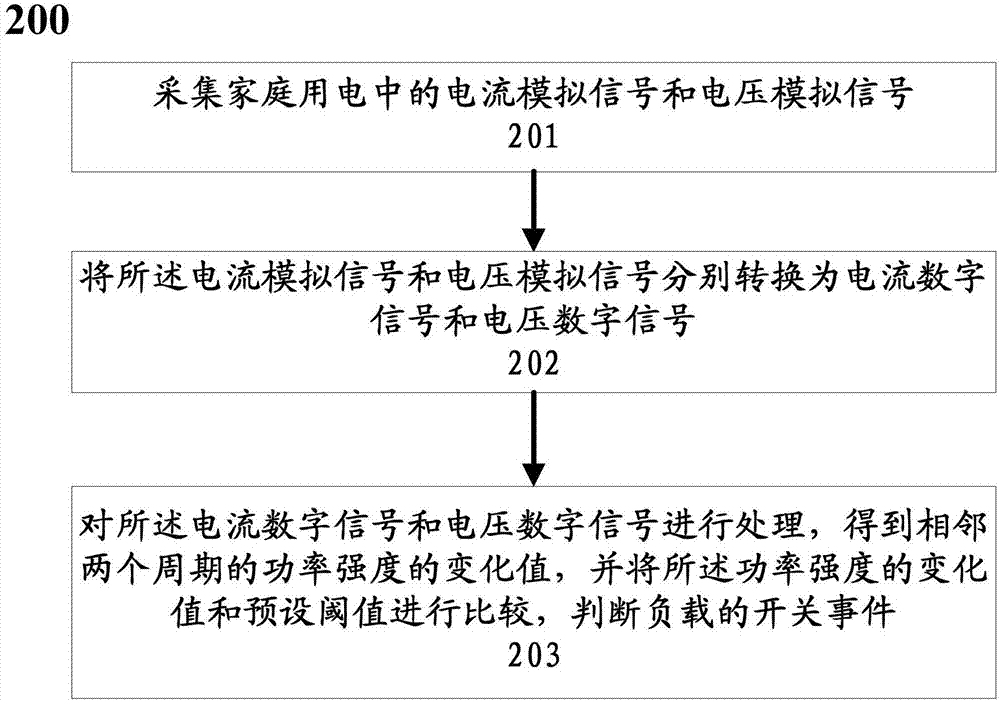

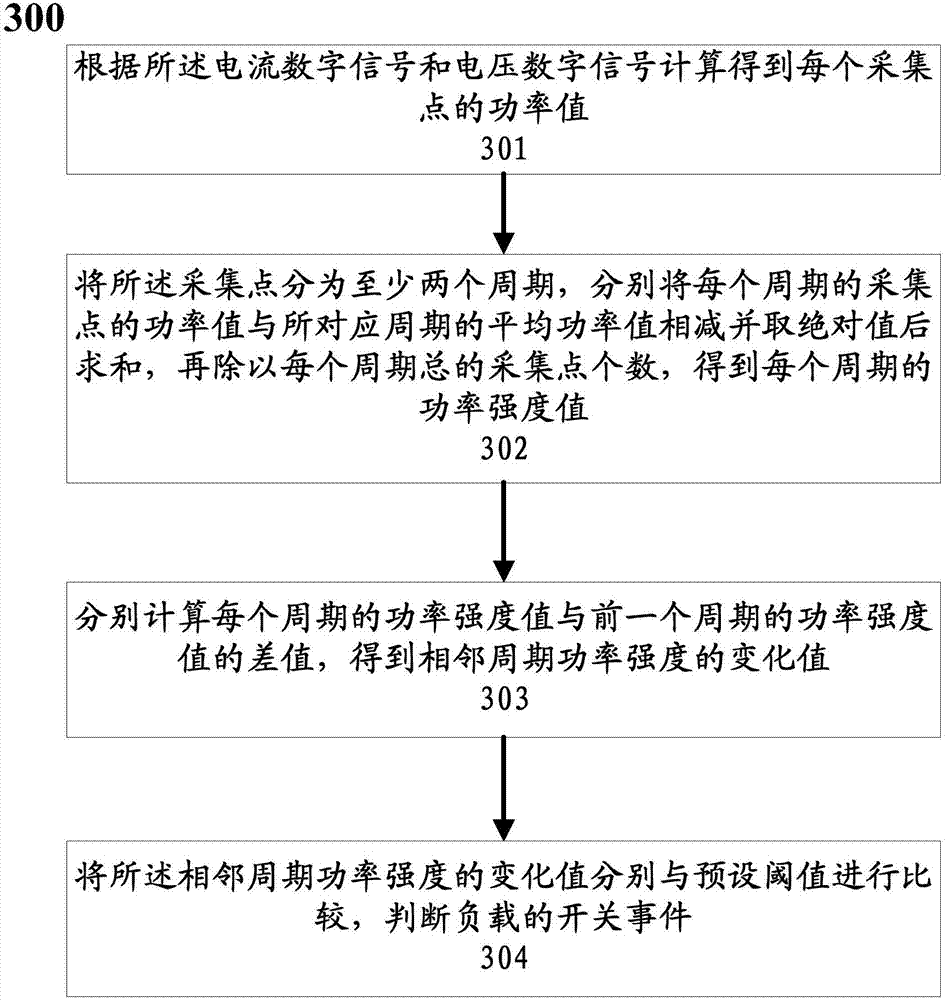

Load switch testing method and load switch testing method based on power

InactiveCN106908657AGuaranteed accuracyImprove accuracyPower measurement by digital techniqueEngineeringAnalog signal

The invention relates to a load switch testing device based on power. The load switch testing device comprises the components of a current sensor which is used for testing a current analog signal in household power consumption and transmits the current analog signal to an A / D conversion module; a voltage sensor which is used for testing a voltage signal in household power consumption and transmits the voltage signal to the A / D conversion module; the A / D conversion module which is used for converting the current analog signal and a voltage analog signal to a current digital signal and a voltage digital signal, and transmitting the signals to an ARM embedded core processing module; the ARM embedded core processing module which is used for processing the current digital signal and the voltage digital signal, acquiring a power strength change value between two adjacent periods, comparing the power strength change value with a preset threshold, determining a load switching event and extracting signal characteristic data of the current digital signal and the voltage digital signal; and a memory module which is used for storing the current digital signal, the voltage digital signal and the signal characteristic data.

Owner:OCEAN UNIV OF CHINA

Construction method for anti-seismic rammed earth wall with reinforced surface skin and core columns

The invention relates to a construction method for an anti-seismic rammed earth wall with a reinforced surface skin and core columns and belongs to the technical field of construction engineering. According to the method, a rammed earth wall formwork is manufactured, and pre-embedded core molds are placed into the rammed earth wall formwork. The effect of the surface skin is reinforced under the tying and connecting action of two kinds dovetail joint type earth materials in the mode that different earth materials are added twice; the anti-seismic performance of the rammed earth wall is enhanced under the action of criss-cross tying and connecting action by prefabricating the pore-forming core columns, earth mass reinforcing columns and steel wire sewn mesh sheets. The method has the advantages that the construction cost of the rammed earth wall is lowered, and the durability and reliability of the rammed earth wall are improved.

Owner:KUNMING UNIV OF SCI & TECH

Soc-based core scan chain linkage switch

InactiveUS20050149797A1Guarantee reconfiguration capabilityMinimizing hardware overheadElectronic circuit testingFunctional testingEngineeringEmbedded core

Disclosed herein is an SoC-based core scan chain linkage switch. The core scan chain linkage switch includes test bus terminals, scan chain input / output terminals, a switch unit and SCLK, UCLK, Mode and Enable signals. The test bus terminals apply instructions and input / output test data. The scan chain input / output terminals link with the scan chains of an embedded core. The switch unit completes a linkage configuration between the test bus terminals and the scan chain input / output terminals in response to the applied instructions. The SCLK, UCLK and Mode signals apply the instructions to dynamically reconfigure the switch unit and update the linkage configuration of the switch unit, and the Enable signal activates and deactivates the switch unit.

Owner:KOREA ELECTRONICS TECH INST

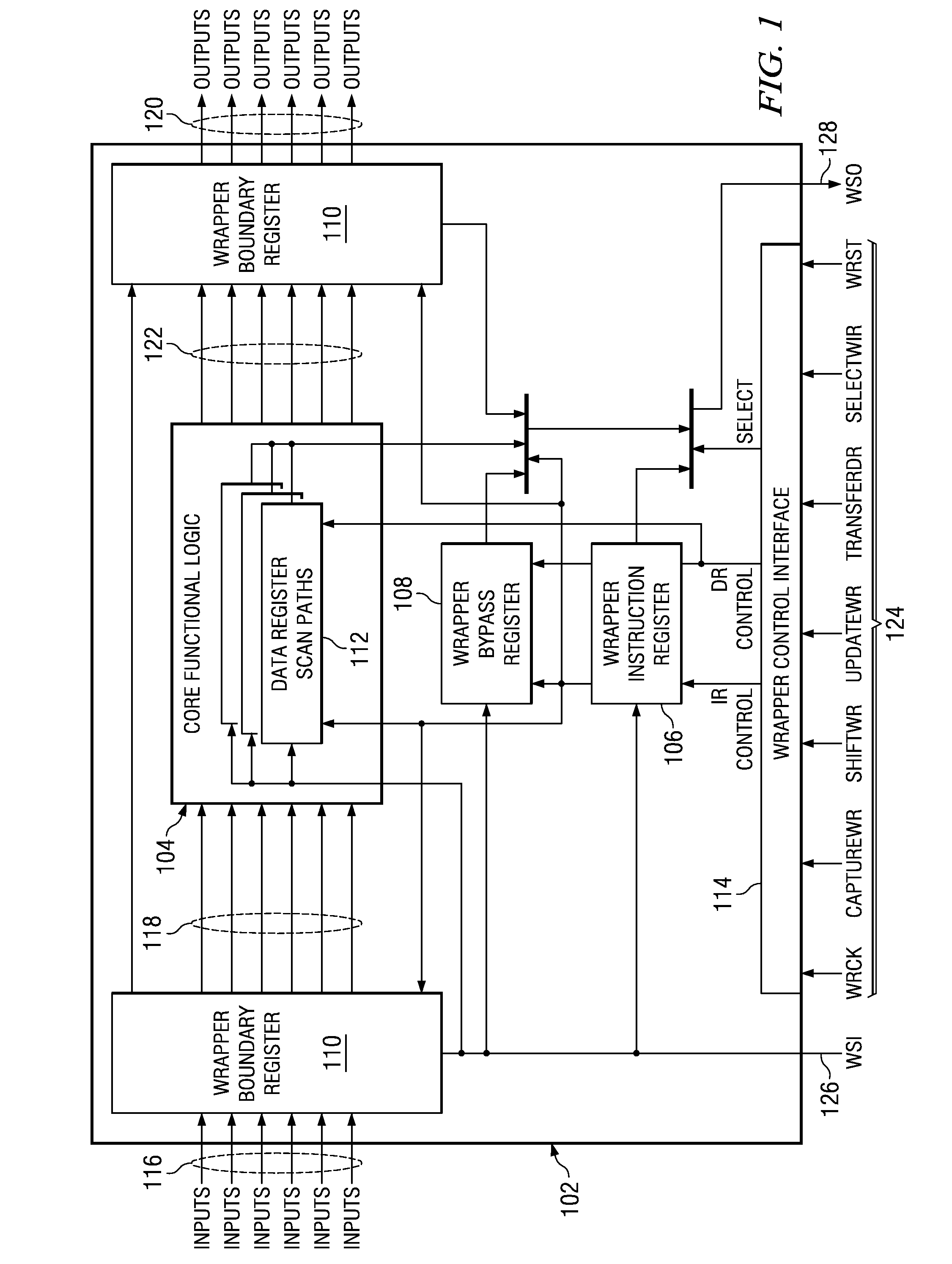

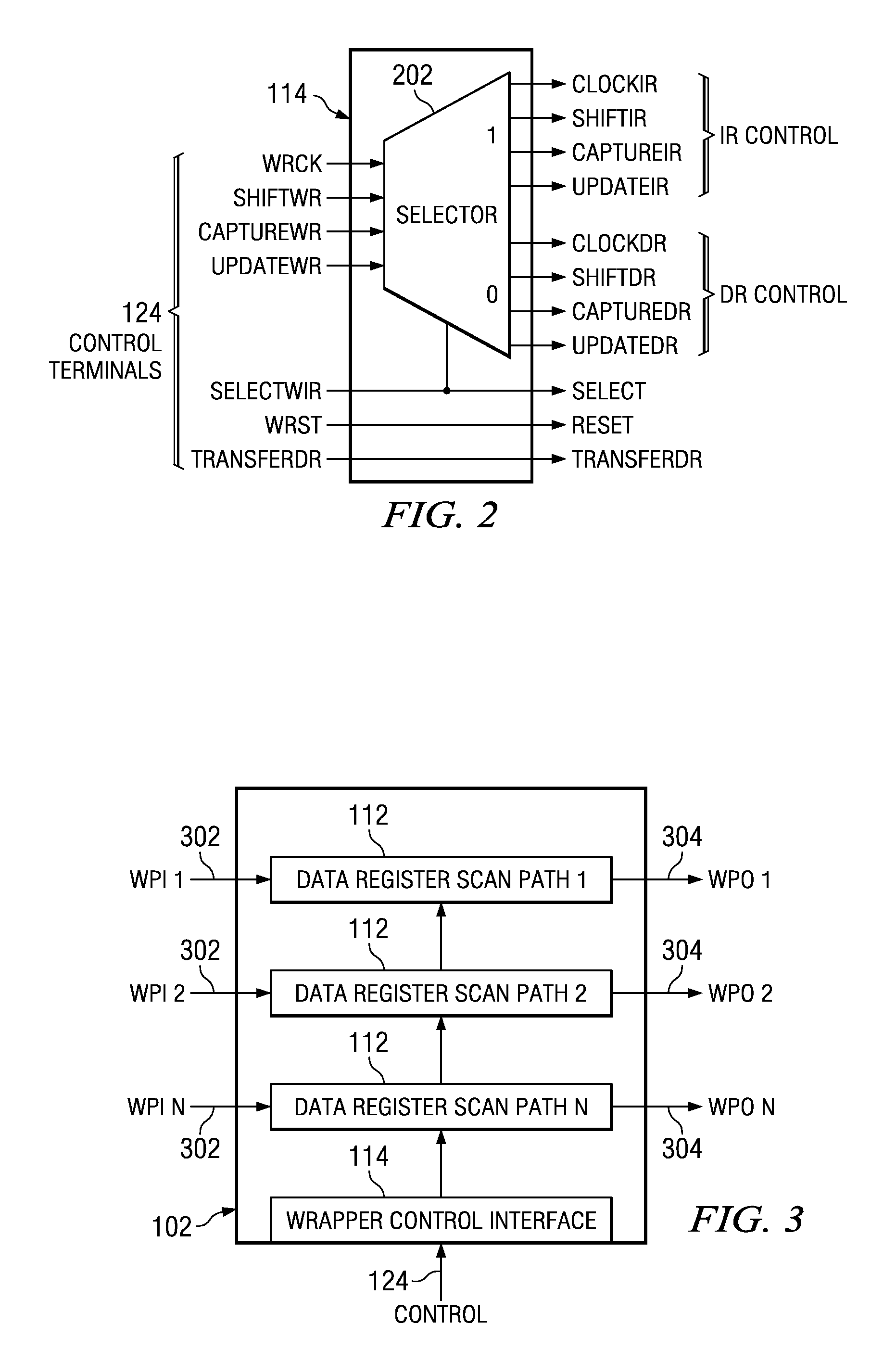

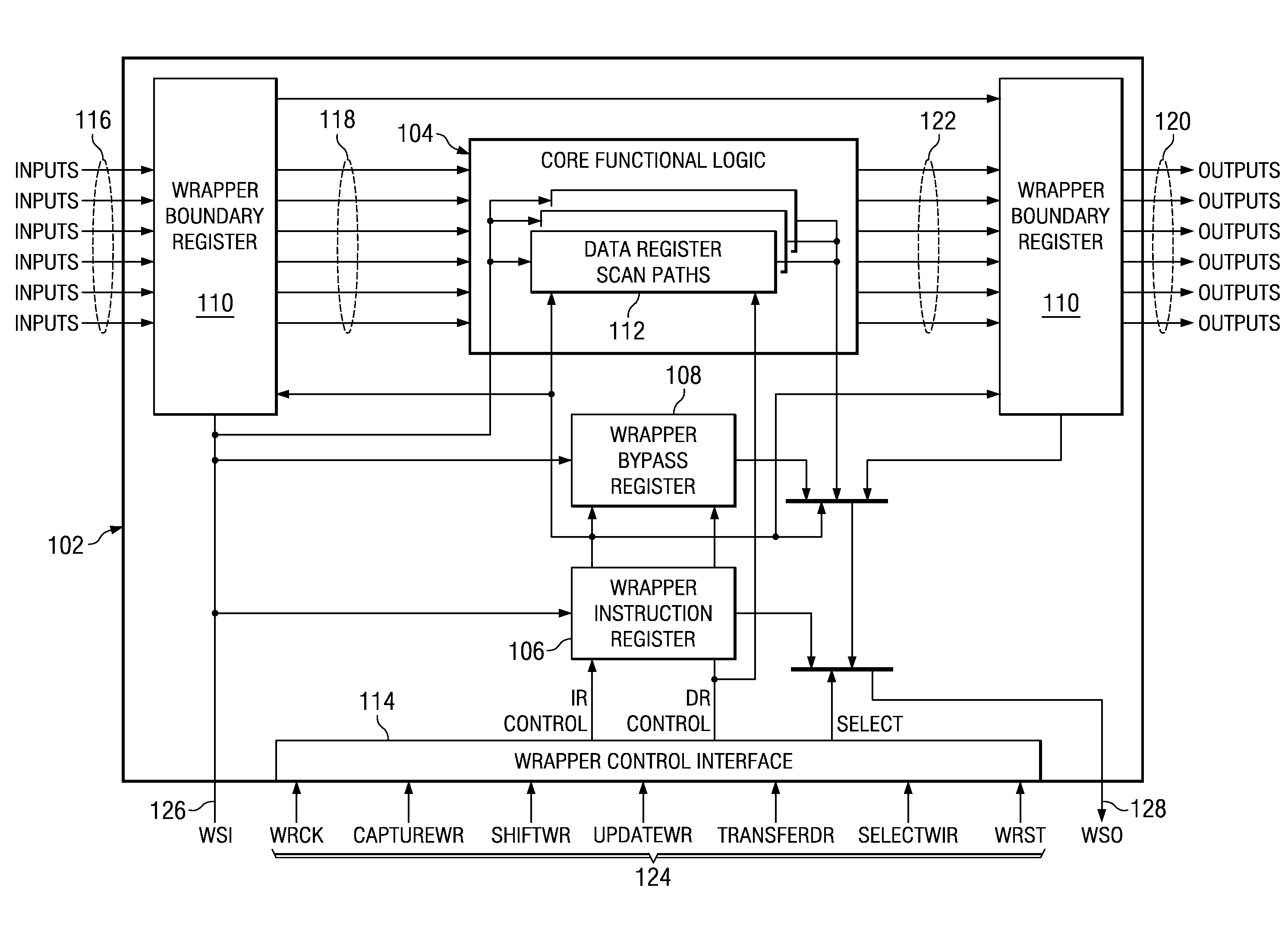

Device testing architecture, method, and system

ActiveUS20080010569A1Efficient testingSimplifies testerElectronic circuit testingComputer hardwareTest response

A device test architecture and interface is provided to enable efficient testing embedded cores within devices. The test architecture interfaces to standard IEEE 1500 core test wrappers and provides high test data bandwidth to the wrappers from an external tester. The test architecture includes compare circuits that allow for comparison of test response data to be performed within the device. The test architecture further includes a memory for storing the results of the test response comparisons. The test architecture includes a programmable test controller to allow for various test control operations by simply inputting an instruction to the programmable test controller from the external tester. The test architecture includes a selector circuit for selecting a core for testing. Additional features and embodiments of the device test architectures are also disclosed.

Owner:TEXAS INSTR INC

Virtual test bus circuit for network-on-chip system and test method thereof

ActiveCN101588273AEliminate redundant test timeImplement test data broadcastingData switching networksTest efficiencyControl signal

The invention provides a virtual test bus circuit for a network-on-chip system and a test method thereof. The virtual test bus circuit comprises a plurality of router modules which are connected with each other; each router module comprises an input control circuit module and an information forwarding module; and the information forwarding module generates a routing control signal for testing data when the network-on-chip system is in a test state, and forwards the data to other router modules or embedded cores. The test method comprises the steps of: 1) setting a test enable signal of a chip as valid; step 2) generating the routing control signal by the information forwarding module and forming a plurality of virtual test buses; and step 3) externally outputting a test vector, and implementing the test on the embedded cores through the virtual test buses. The virtual test bus circuit and the test method can eliminate redundancy time caused by protocols, and can better utilize existing interconnection resources of the network-on-chip system, thereby effectively improving the test efficiency and shortening the test time.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

Moulding method for slag pot structure

InactiveCN103447457AOmit the connectionLess places to connectFoundry mouldsFoundry coresSlagEmbedded core

A moulding method for a slag pot structure. A slag pot involved in the invention employs a handstand moulding (with an upward dome). The method is as below: scraping an inner cavity contour by using a scraper plate moulding method; forming a separating layer on the surface of the scraped inner cavity contour by brushing paint; scraping a slag pot external surface contour (hangers not included) out of the separating layer on the surface of the scraped inner cavity contour; forming a separating layer on the external contour by brushing paint and laying waste paper; filling in sand cores for forming a trunnion seat at the periphery; filling in hangers (hangers of the slag pot are forging pieces); placing sandboxes at the periphery; placing a runner and a sink head according to technology; forming an upper case; filling in pre-embedded cores; pounding firmly and blowing hard; removing the upper case; removing sands between the profile contour and the inner cavity contour; carrying out mould assembling; and inspecting dimension. The method provided by the invention employs repetitious usage of scraper plate to omit sand cores for forming the external surface contour and inner cavity contour and reduce joints of the sand cores; and the method not only saves time but also has low cost. A casting has few casting fins on the surface, high precision and an integral and beautiful structure.

Owner:LUOYANG LUOBEI HEAVY IND MACHINERY

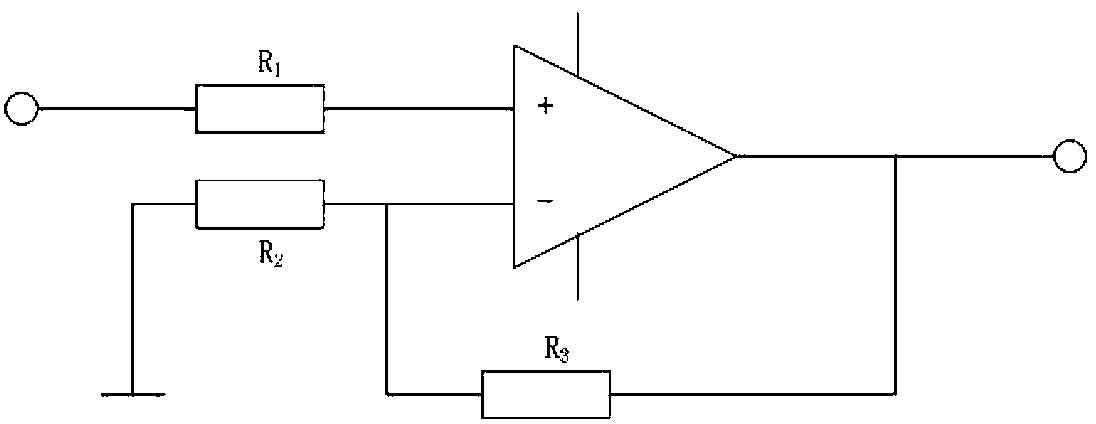

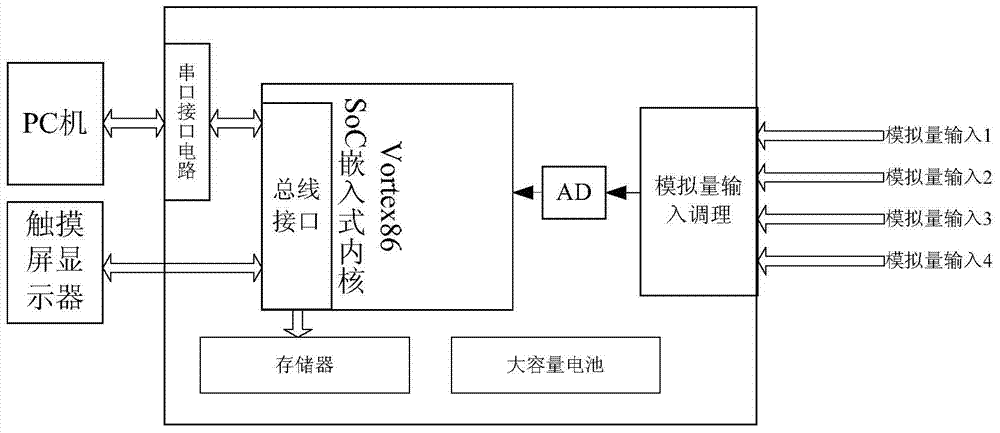

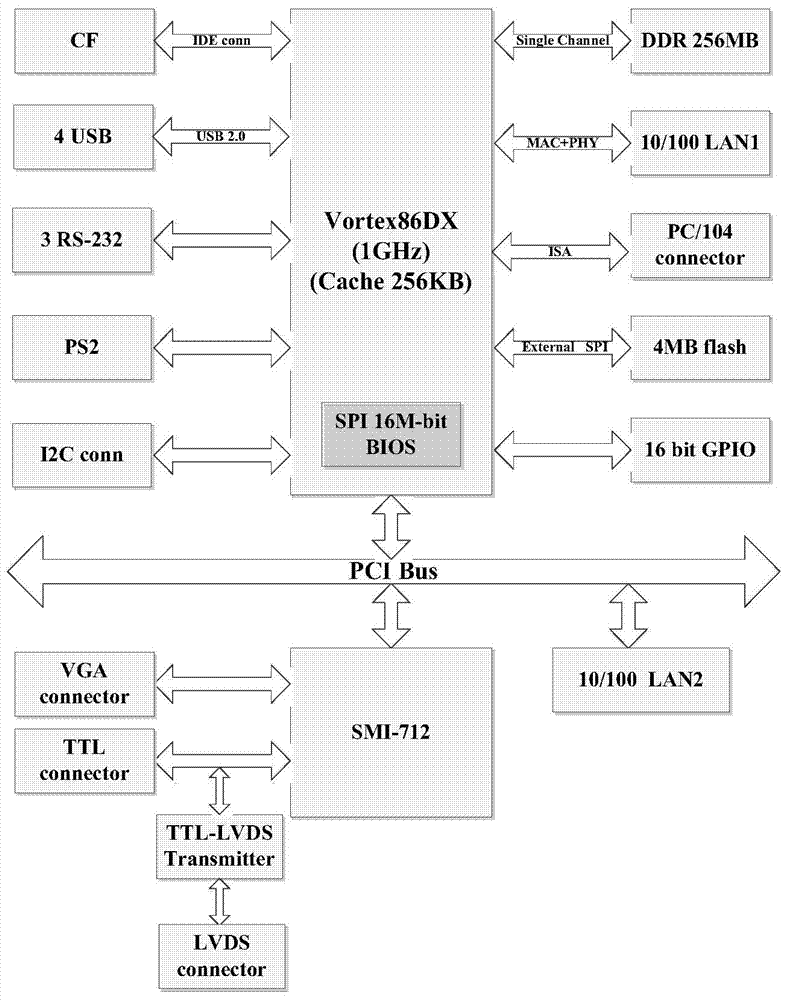

Portable hydroelectric generating set vibration and swing degree data detecting system and method

InactiveCN104280114ASimple designImprove sampling accuracySubsonic/sonic/ultrasonic wave measurementUsing electrical meansComputer moduleAnalog signal

The invention discloses a portable hydroelectric generating set vibration and swing degree data detecting system and method. The portable hydroelectric generating set vibration and swing degree data detecting system comprises an SoC embedded core, an analog signal acquisition module, an analog input conditioning circuit, an A / D converter and a memorizer, wherein the analog signal acquisition module, the analog input conditioning circuit, the A / D converter and the SoC embedded core are connected in sequence, the memorizer is connected with the SoC embedded core, the analog signal acquisition module comprises an electrical vortex sensor and a vibration sensor, the analog input conditioning circuit comprises an amplification circuit serving as a front-stage circuit and a filter circuit serving as a rear-stage circuit. According to the portable hydroelectric generating set vibration and swing degree data detecting system and method, the detection precision is high, implementation is easy, and the data filtering effect is good.

Owner:STATE GRID CORP OF CHINA +2

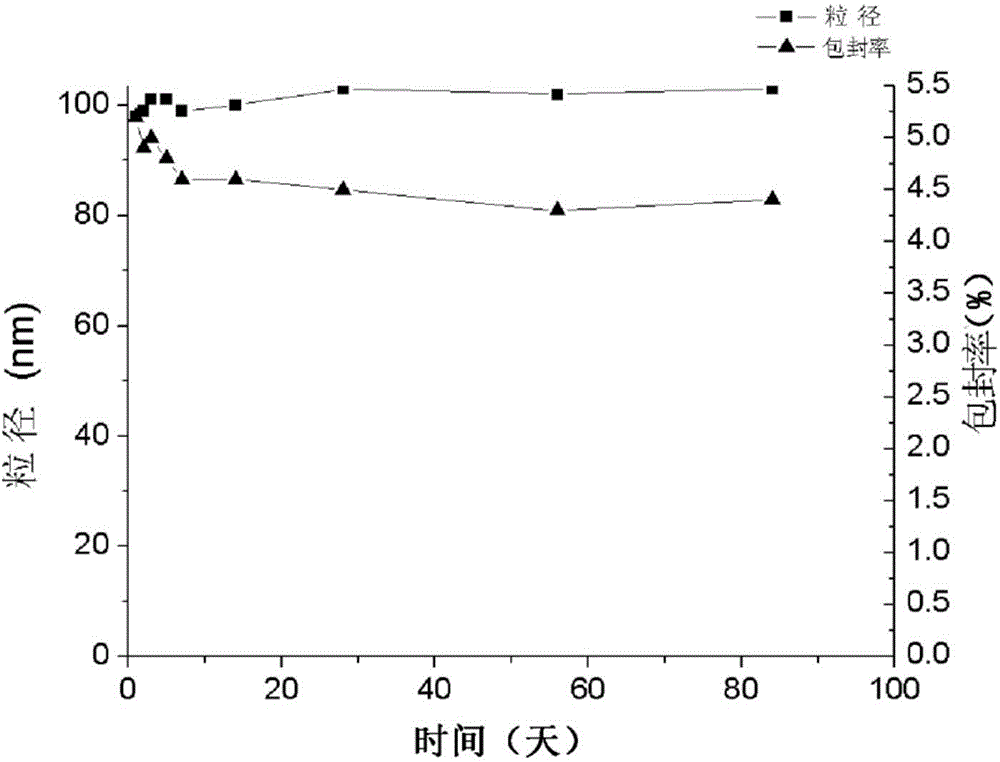

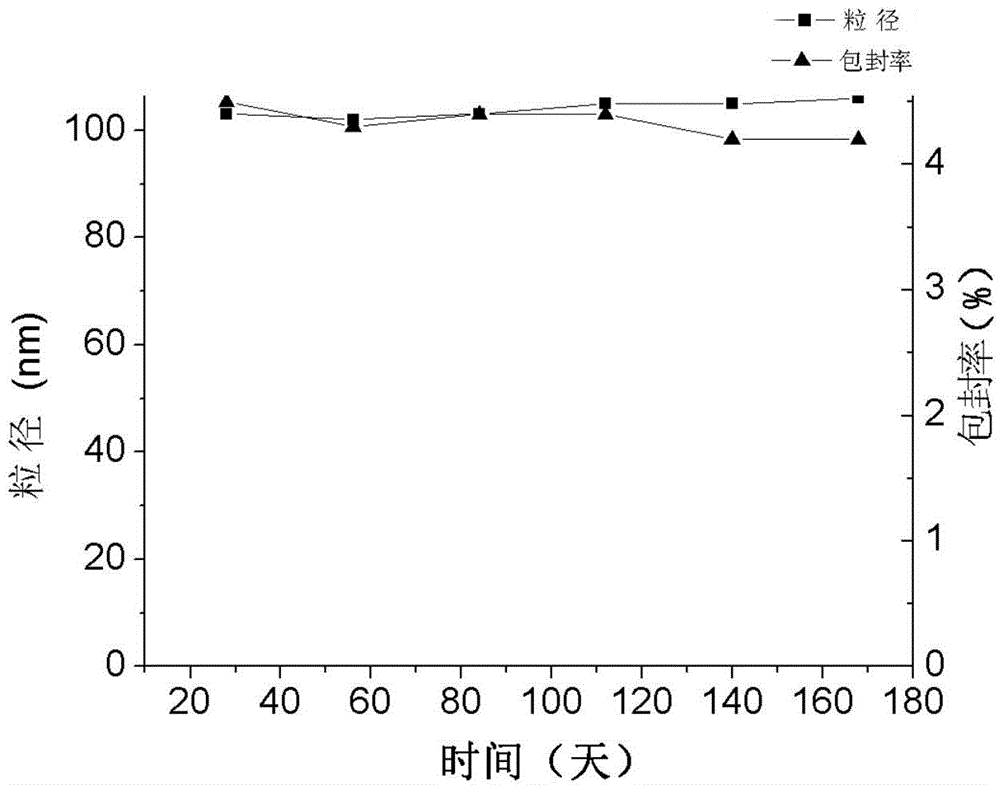

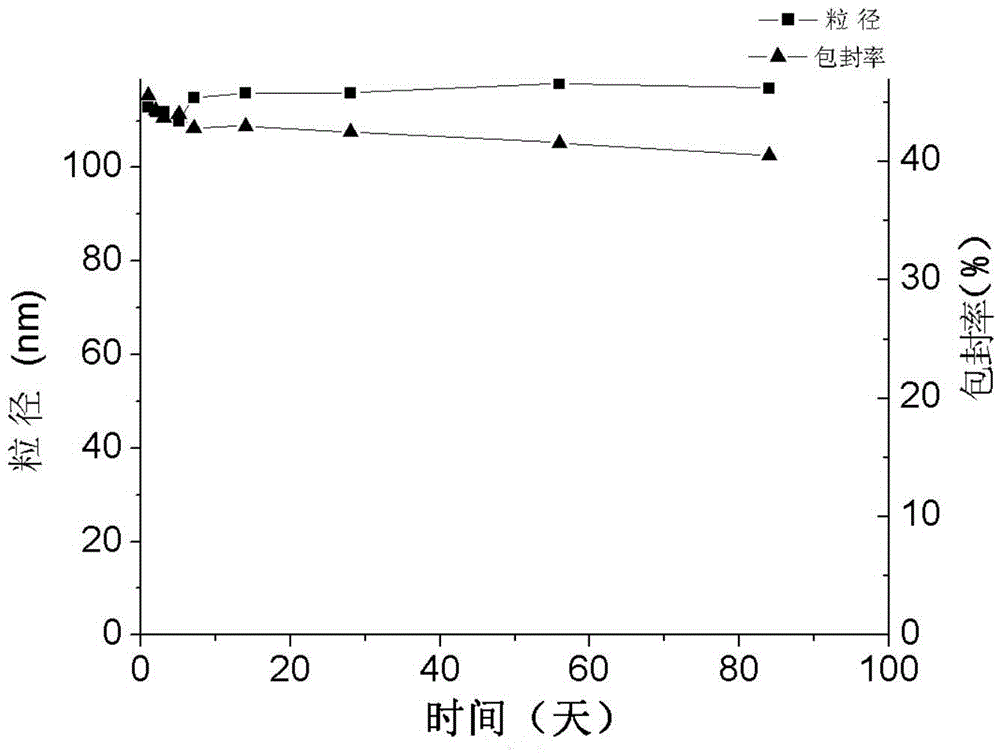

Long-circulating lipidosome as well as preparation method and application thereof

The invention discloses a long-circulating lipidosome as well as a preparation method and an application thereof. The long-circulating lipidosome is prepared by taking phospholipid as a lipidosome membrane material, and adding a membrane structure modifier and a long-circulating material. The lipidosome has a better embedding effect to flavor substances which have water solubility and oil solubility, and various water soluble ingredients and oil soluble flavor ingredients can be embedded at the same time; furthermore, the lipidosome is dried and then prepared into powder; meanwhile, the lipidosome is better in storage stability and is added into cigarettes, the stability of the long-circulating lipidosome can be kept in the storage process, and embedded core materials can be released when the cigarettes are smoked.

Owner:JIANGNAN UNIV

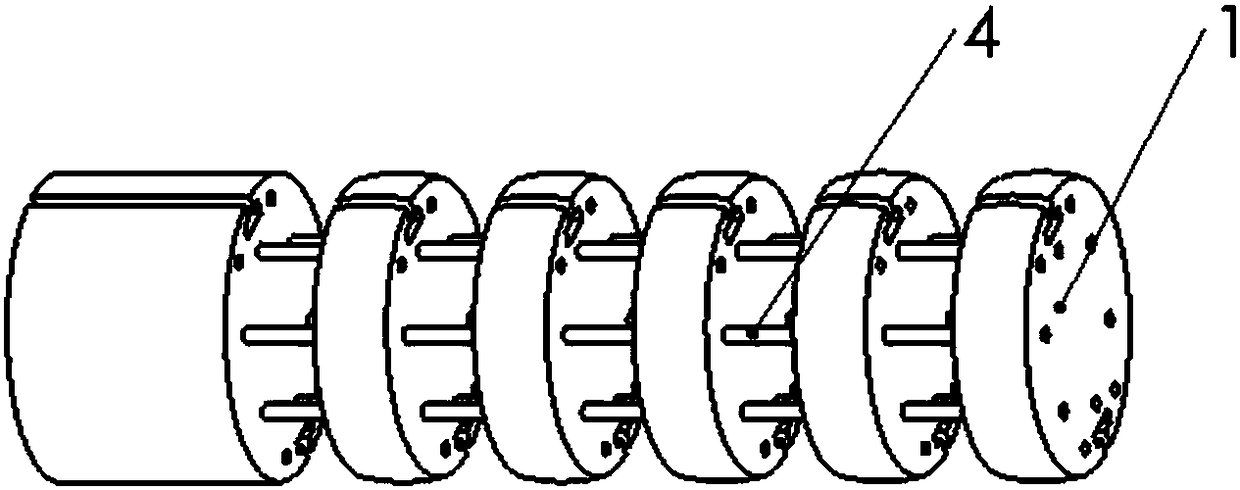

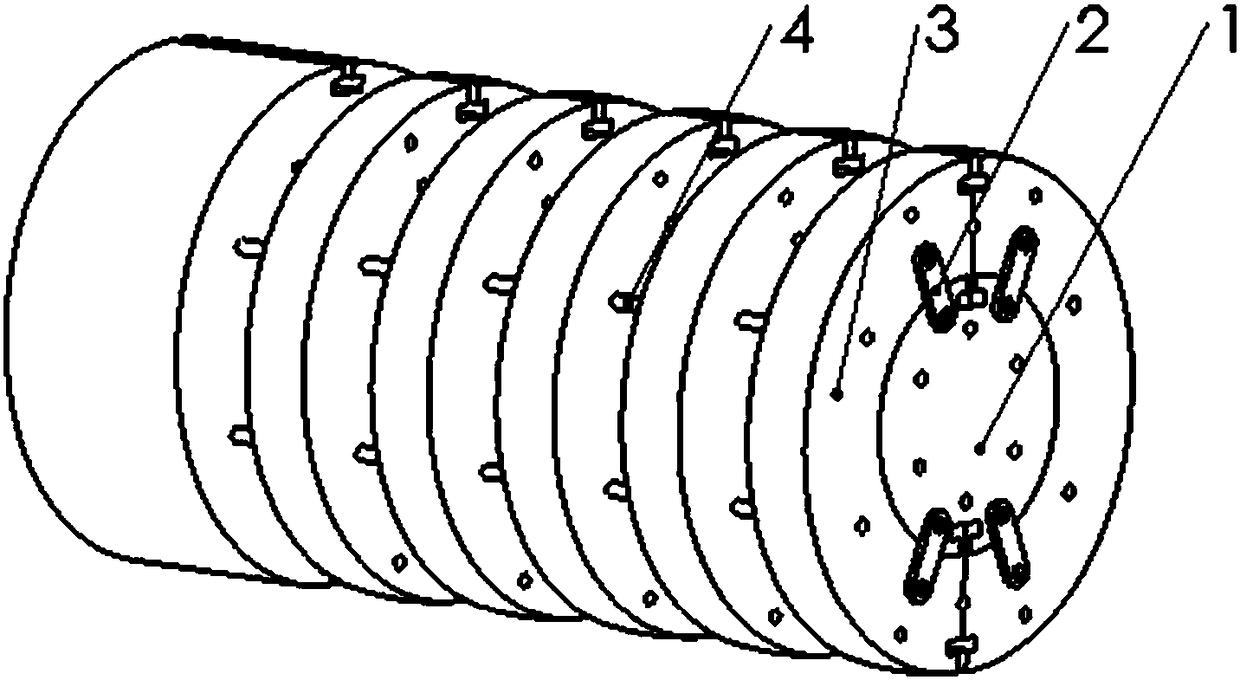

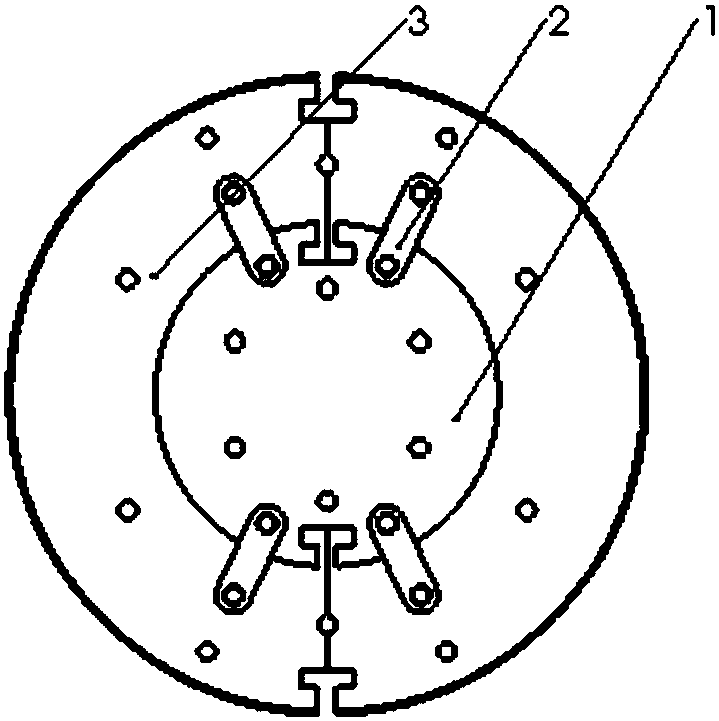

Diameter-adjustable flexible core rod with novel structure

The invention discloses a diameter-adjustable flexible core rod with a novel structure. The complete flexible core rod is formed by axial series connection of a plurality of inner sleeved core rod subsections through elastic rubber rods, the elastic rubber rods are arranged at through holes in the inner sleeved core rod subsections in a penetrating mode to enable the inner sleeved core rod subsections of a plurality of core rod sections to be elastically connected in series, and outer embedded core rod subsections are mutually nested on the outer portions of the inner sleeved core rod subsections to form the integral single core rod sections; and the multiple core rod sections are axially connected in series through the elastic rubber rods to form the complete flexible core rod, and the elastic rubber rods are arranged at the through holes in the inner sleeved core rod subsections / the outer embedded core rod subsections in a penetrating mode to conduct elastic series connection. According to the diameter-adjustable flexible core rod, the structure is simple, machining and assembling are easy, the core rod sections with the diameters being different can be formed through mutual nesting and connecting of the inner sleeved core rod subsections and the outer embedded core rod subsections, the function that the diameter of the flexible core rod can be adjusted is achieved, the diameter-adjustable flexible core rod can be suitable for bent pipe fittings with different pipe diameters, the flexible adjustability is achieved, materials can be saved, and the cost is reduced.

Owner:ZHEJIANG UNIV

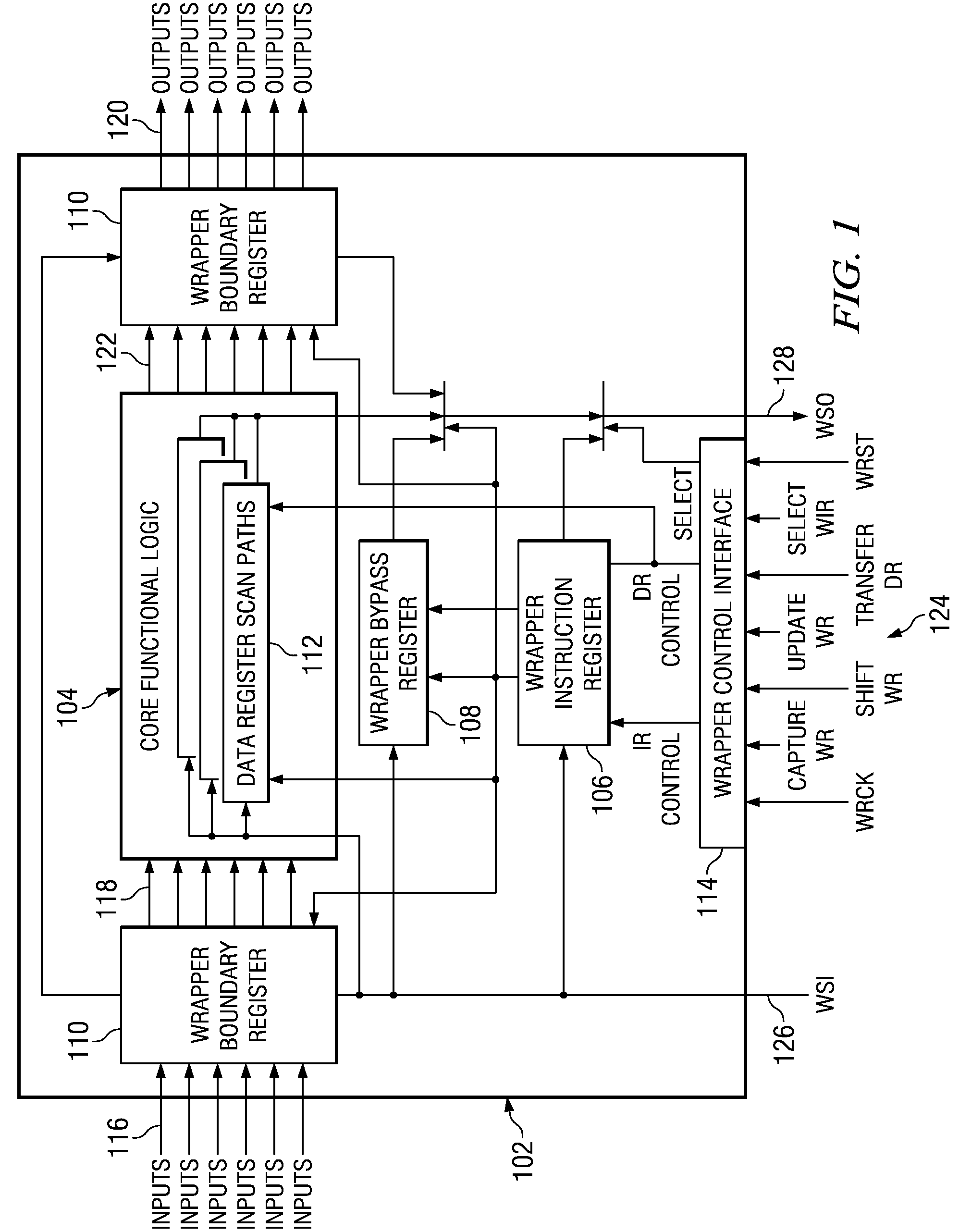

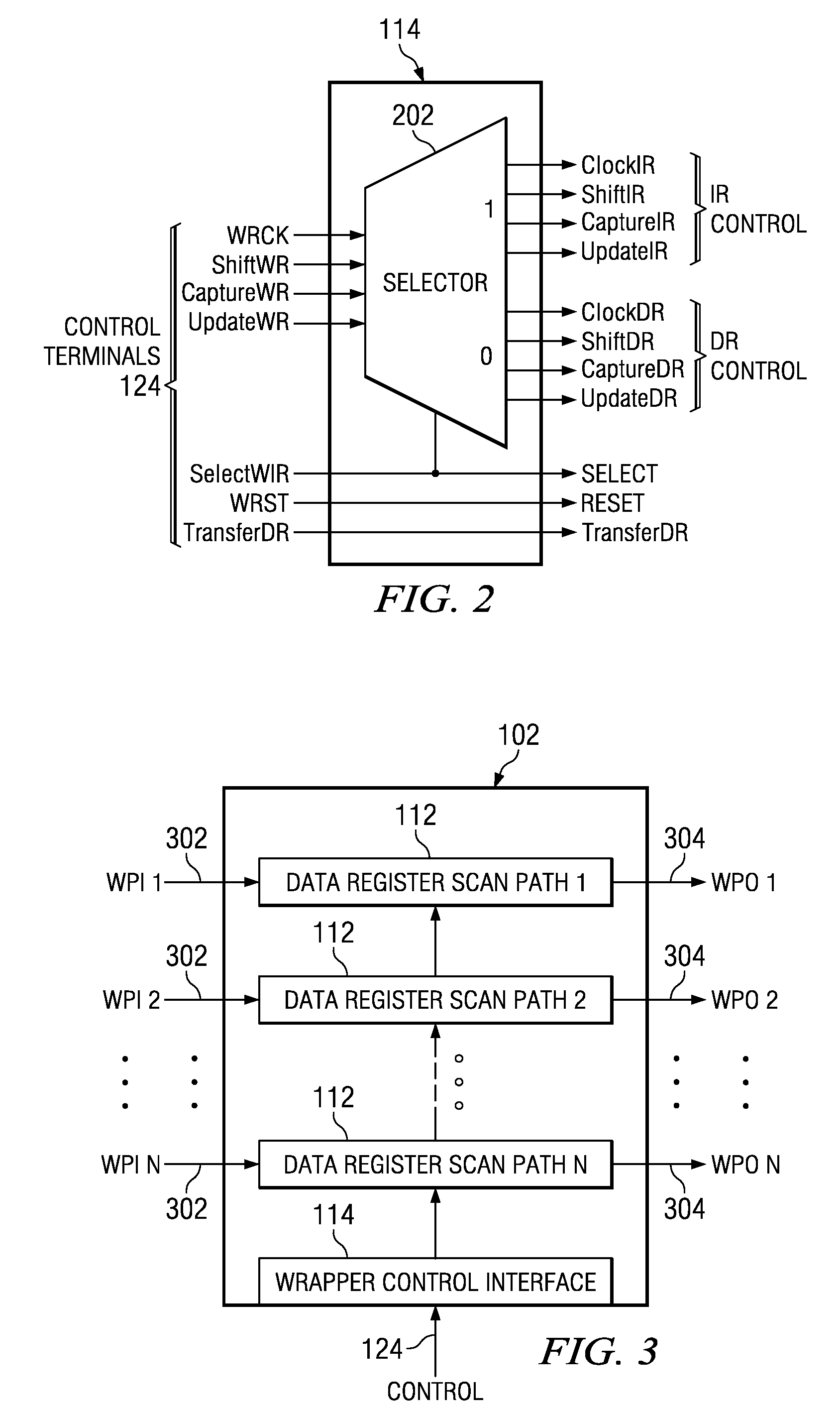

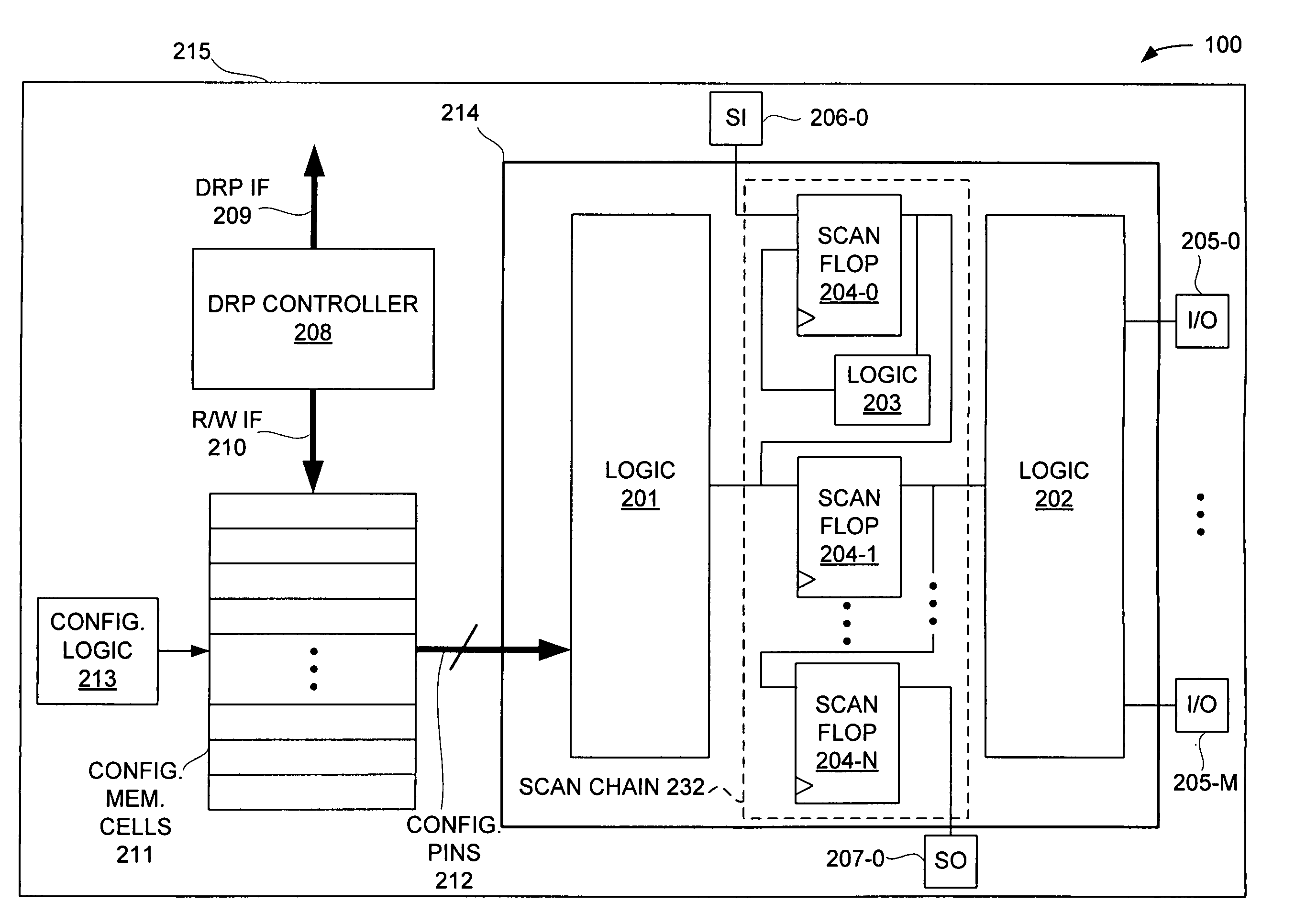

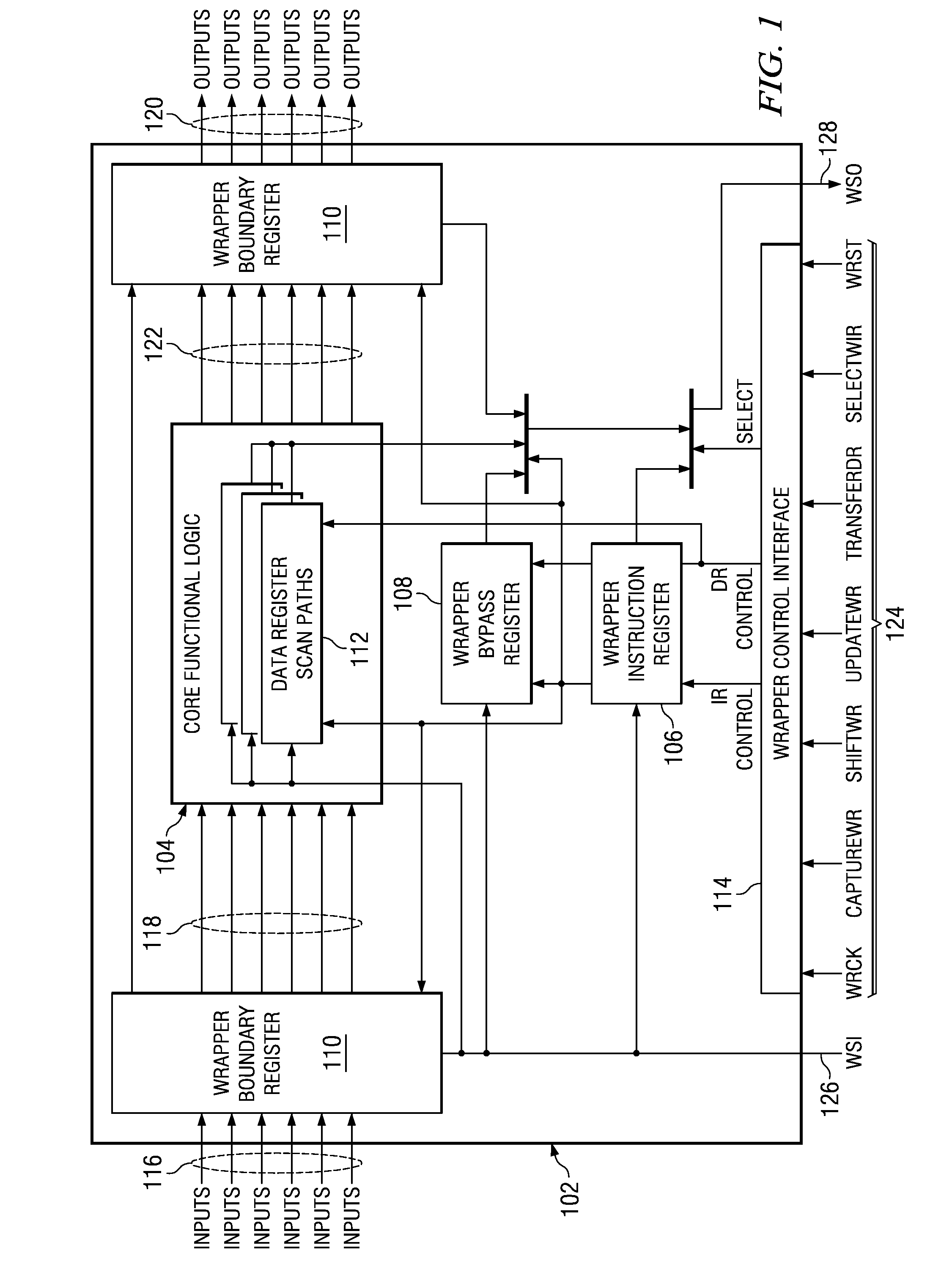

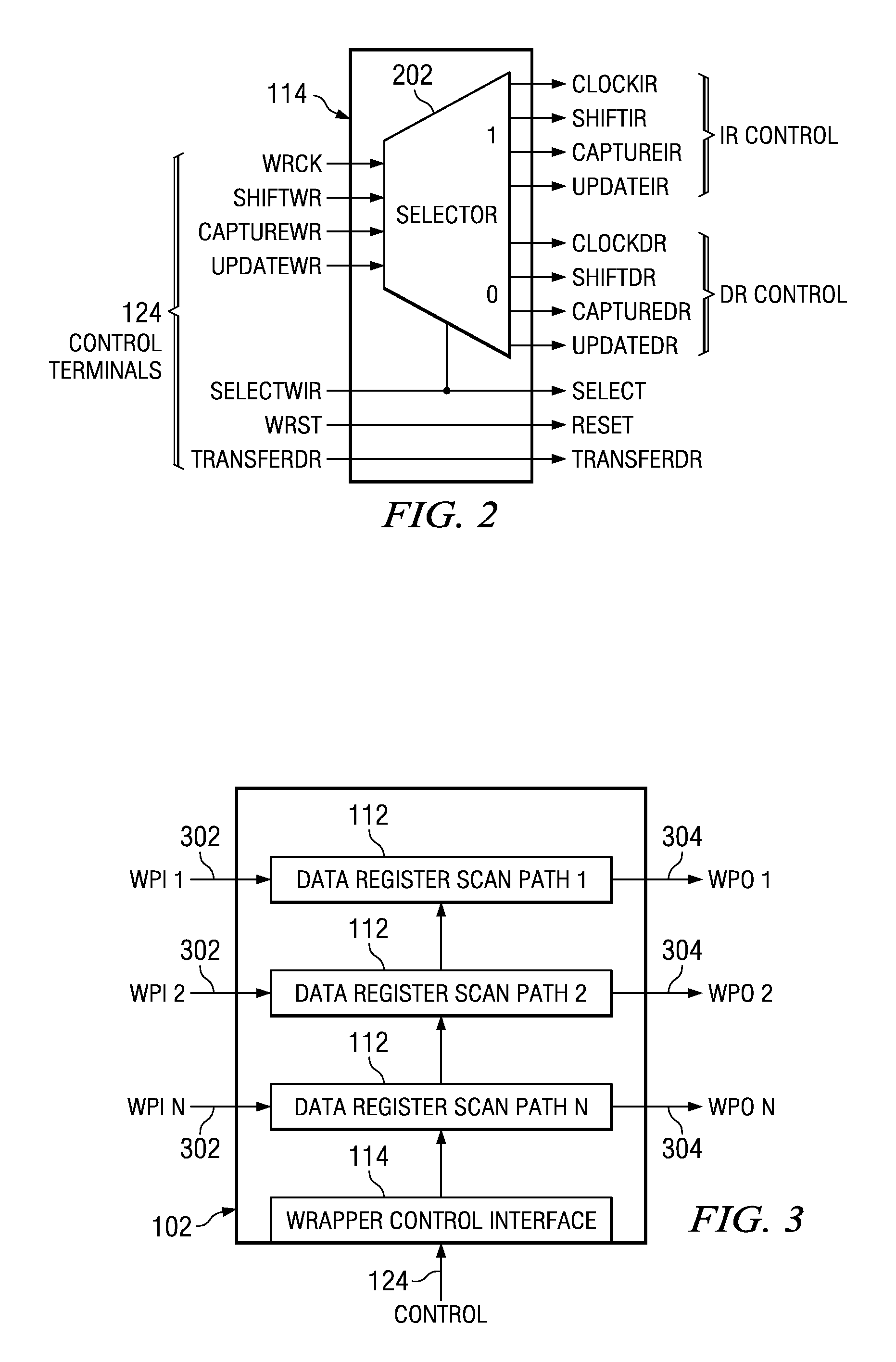

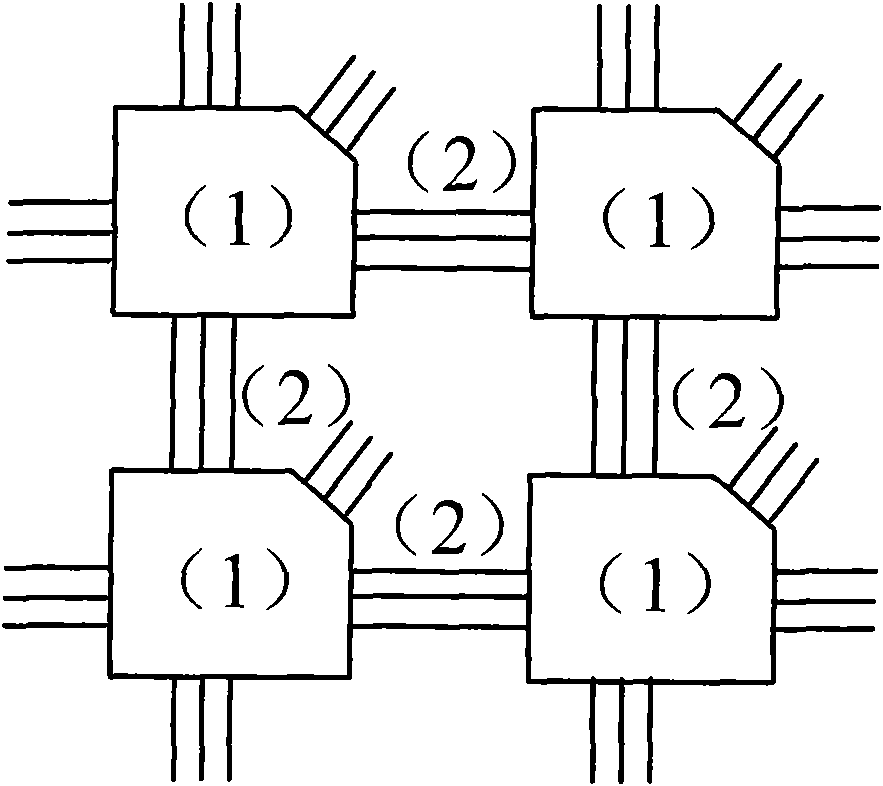

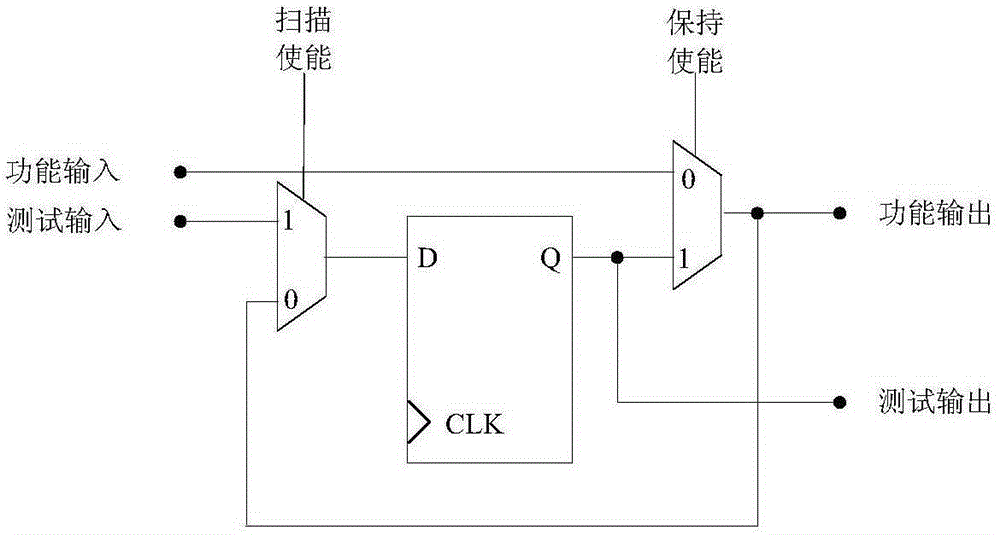

Embedded core wrapper device and design method thereof

ActiveCN105203946AEasy to transformImprove reuse rateElectronic circuit testingControl signalEmbedded core

The embodiment of the invention discloses an embedded core wrapper device which comprises a wrapper instruction register (WIR), a wrapper boundary register (WBR), a wrapper bypass register (WBY), a multiplex select generator (MSG), a first multiplex and a second multiplex, wherein the MSG generates a multiplex selection signal sequence according to the sequence of control signals outputted by the WIR, and outputs the multiplex selection signal sequence to a corresponding multiplex (MUX) in the WBR in a mapping manner according to a preset mapping rule; the mapping rule is set according to the mode of connection between WBR units in the WBR and each MUX as well as function of each MUX. Therefore, when the WBR connection mode is changed, MUX functions, MUX input signal connection and the position of each MUX in a wrapper scanning chain are analyzed according to a new WBR, and the embedded core wrapper device of which the MSG mapping rule is regenerated is applicable to the new WBR.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

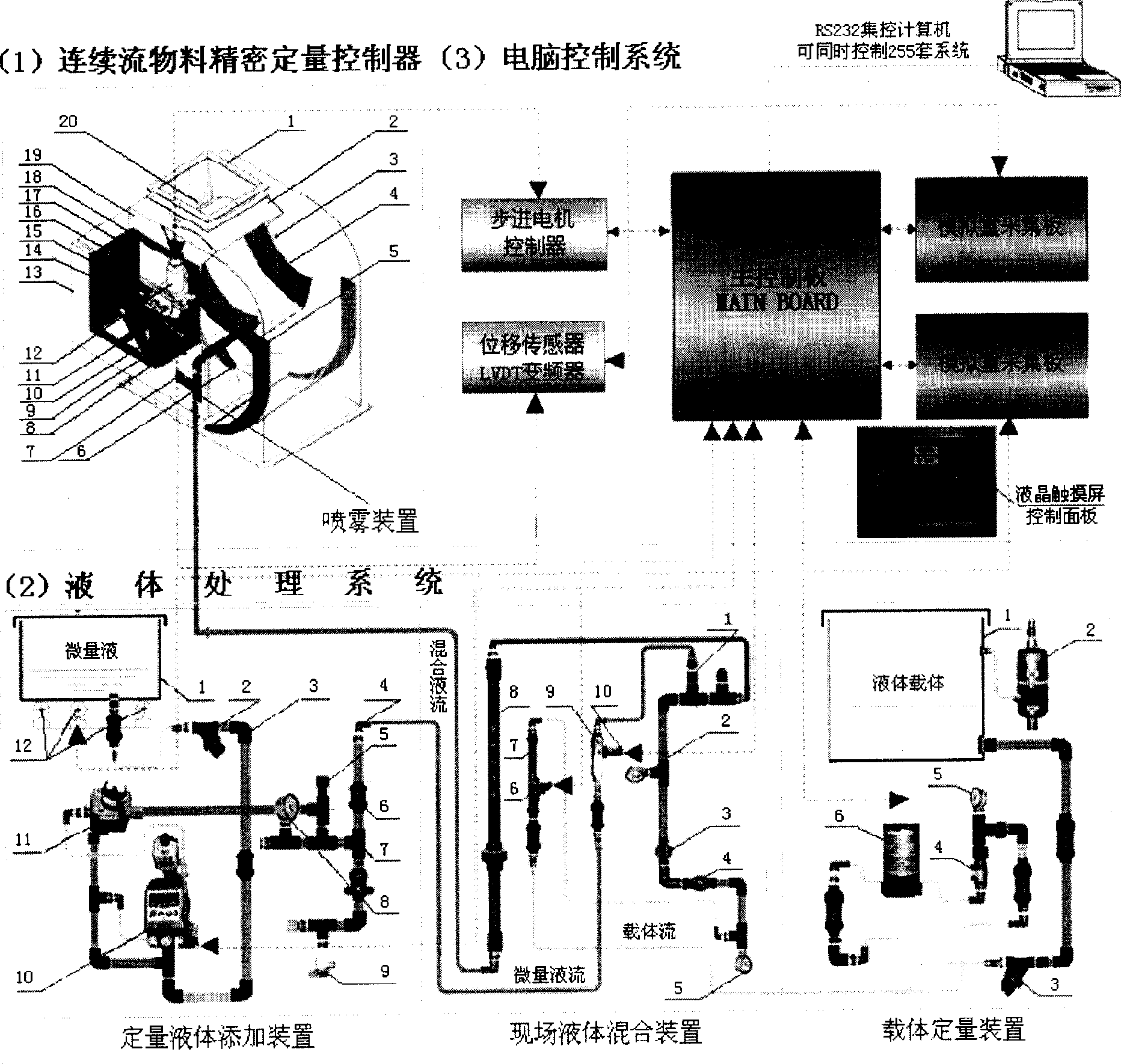

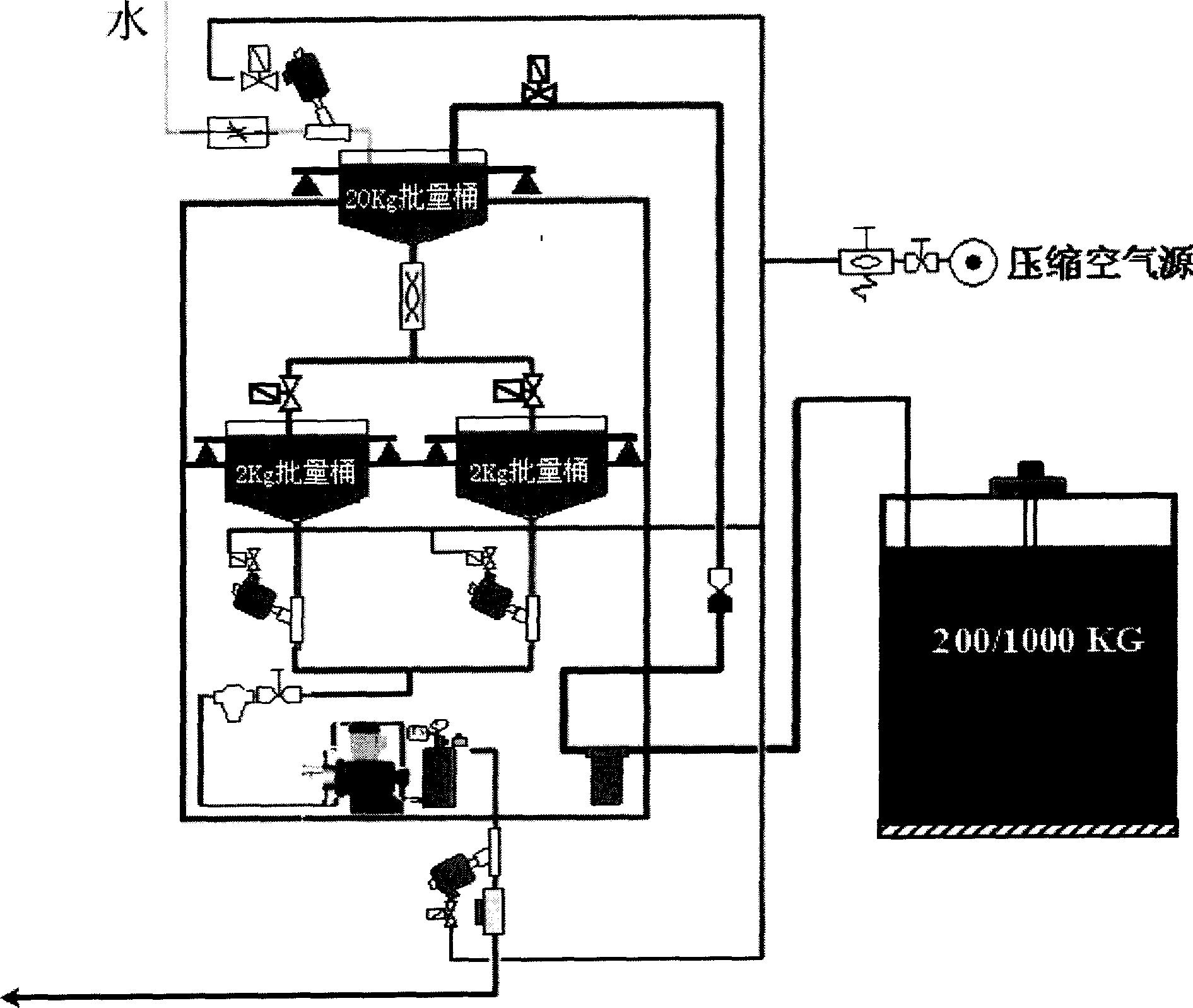

Proportionate dosing post pelleting liquid application (PPLA) system

InactiveCN1730166AControlling ratio of multiple fluid flowsMixer accessoriesElectrical controlContinuous flow

The invention relates to a dynamic proportioning liquid after-spraying system, which uses continuous flow material fine flow controller to detect flow quantity of mass diffuse matter continuously and controls thickness of feed layer precisely after computer gets the value of instantaneous delivery. Meanwhile the invention uses microscale liquid processing unit to spray microdosage on target object. PPLA system adopts ARM build-in core technology to process both centralized telecontrol and independent control. The invention integrates fluid technology, mechanical technology, electrical control, computer soft-hardware control and so on.

Owner:章春根

Continuous annular baler press belt and method for the production thereof

ActiveUS20120015572A1Improve the level ofEasy to useConveyorsSynthetic resin layered productsEmbedded coreMechanical engineering

A rubber continuous annular baler press belt is made of at least one of rubber and rubber-like materials. The press belt includes an embedded core of a reinforcing fabric and has at least two individual superimposed fabric layers (6, 7, 8). The ends of each fabric layer mutually abut and do not overlap each other at the abutment location. The abutment locations (11, 13, 15) are arranged over the periphery of the press belt so as to be offset from each other.

Owner:CONTITECH TRANSPORTBANDSYSTEME GMBH

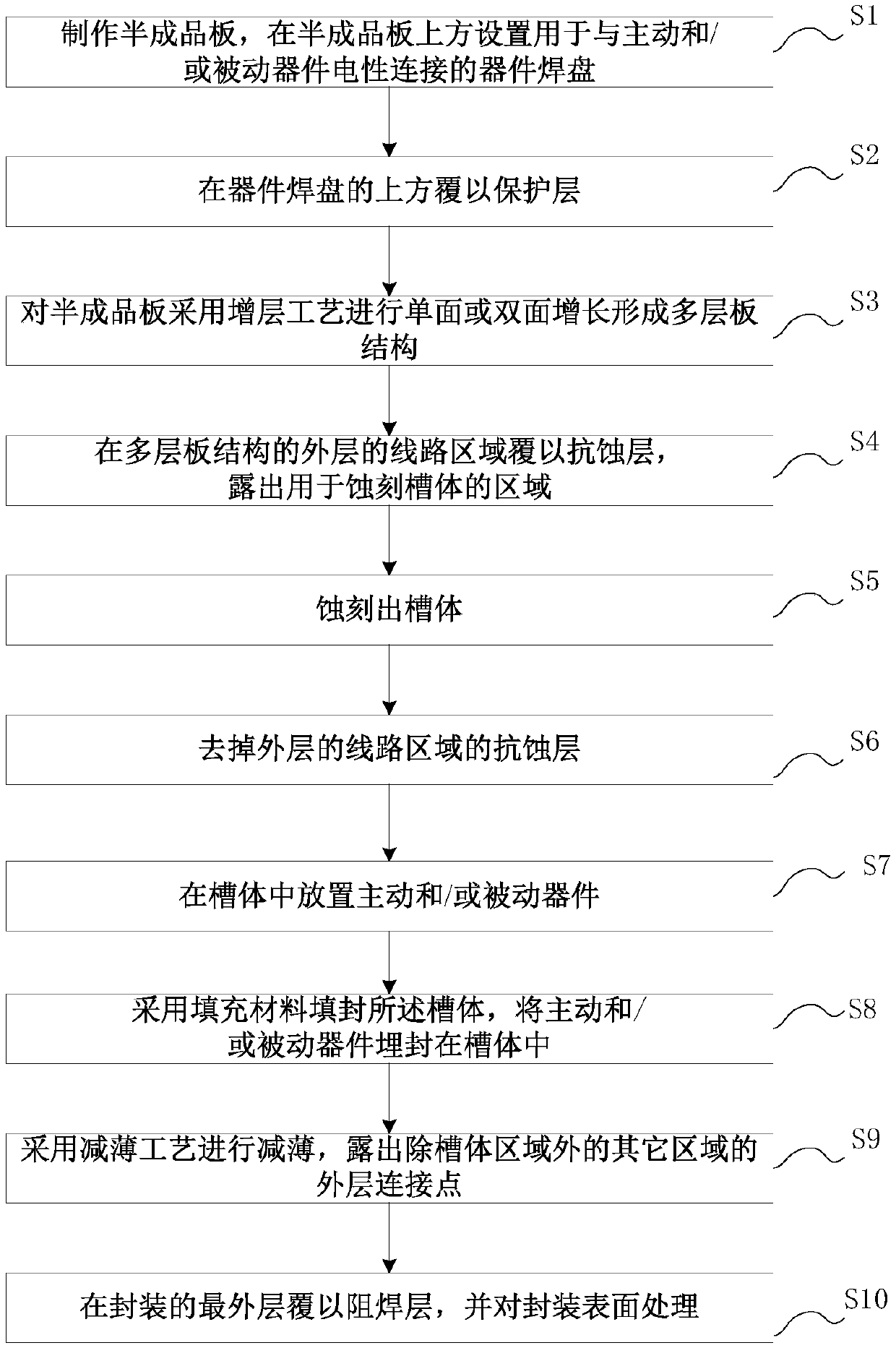

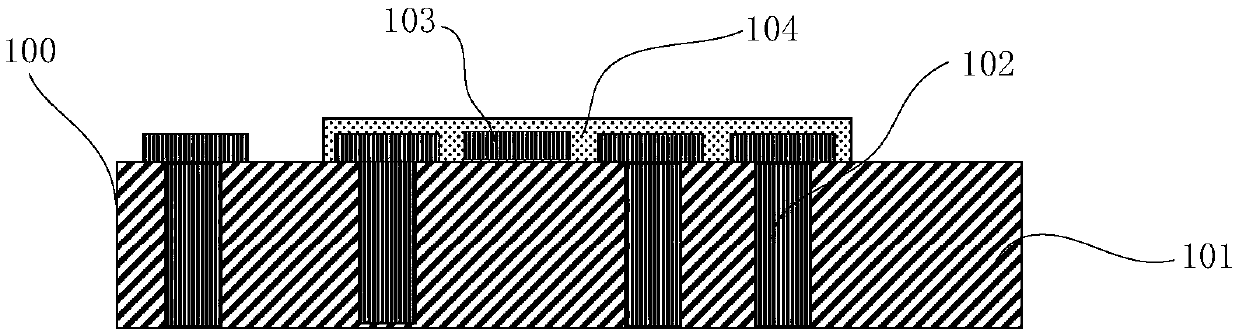

Integrated circuit packaging method with postpositional embedded core flow and package structure

ActiveCN109659239AReduce volumeThin and lightSemiconductor/solid-state device detailsSolid-state devicesLead bondingElectrical performance

The present invention discloses an integrated circuit packaging method with a postpositional buried core flow and a package structure. A multi-layered board is formed by firstly adding layers, then atrench body is etched to embed active and / or passive devices, and then the sealing process is performed, thereby effectively simplifying the manufacturing process. In the second aspect, the advantagesof lead bonding and flip-chip bonding are compatible to cancel to a metal wire or a tin shot in the lead bonding and the flip-chip bonding and reduce the production cost; in the third aspect, the active and / or passive devices are inlaid in the package and are in seamless connection with the package material to improve the electrical performance, improve heat dissipation performance of the chip, achieve the package volume, shorten the connection with the outside, and allow the package size to be lighter and thinner. The integrated circuit packaging method with the postpositional buried core flow and the package structure can be widely applied to various integrated circuit package.

Owner:NANTONG ACCESS SEMICON CO LTD

Forced cooling method for wind power cast

The invention relates to a forced cooling method for a wind power cast, in particular to a forced cooling method for a wind power cast. The method comprises the following steps of manufacturing a heat exchanger, when producing a sand core, embedding core iron into casting san, and placing the heat exchanger into an inner cavity of the sand core; embedding a ceramic pipe communicated with the heat exchanger into the central position of the end face of a core head of the sand core during modeling, and enabling the ceramic pipe to be connected with the outside of a sand box; when the box is closed, after placing the sand core into a cavity, connecting the core iron of the sand core and the ceramic pipe embedded in the cavity through the ceramic pipe, and filling the core sand into the rear portion of the heat exchanger; after the box is closed, communicating the ceramic pipe and a compressed air port through a flexible hose; and during pouring, when iron liquid of the cavity is full, feeding gas into the heat exchanger. The forced cooling method for the wind power cast is unique in process, the cast is cooled through air blowing by utilizing the heat exchanger, heat dissipation of the sand core of the inner cavity is accelerated, iron liquid crusting is accelerated while vibration ramming is utilized to enable the inside of the cast to be compact, and the requirements for flaw detection can be met.

Owner:KOCEL GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com