Diameter-adjustable flexible core rod with novel structure

A new type of structure and mandrel technology is applied in the field of bending and forming of thin-walled metal pipe fittings, which can solve the problems of unsatisfactory effect, inconvenient penetration of pipe fittings, complex shape and structure, etc., saving materials, avoiding assembly and disassembly methods, and assembling and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with drawings and embodiments.

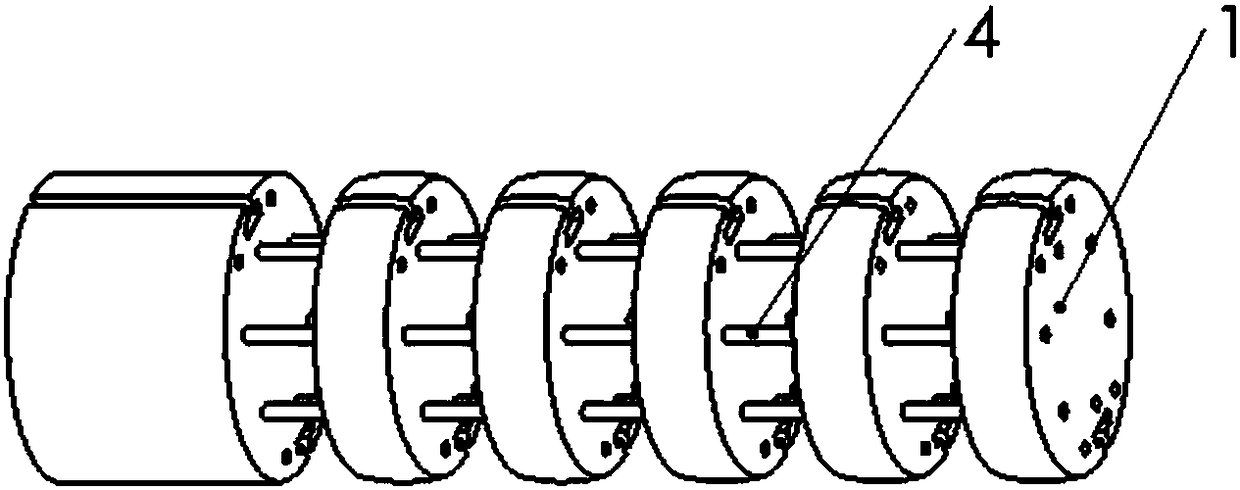

[0031] Such as figure 1 As shown, one embodiment of the present invention is that only the inner mandrel sub-sections 1 are sequentially connected in series on the elastic rubber rod 4, and a uniform distance is maintained between each inner mandrel sub-section 1, so that the diameter is within an adjustable range. A flexible mandrel at a minimum.

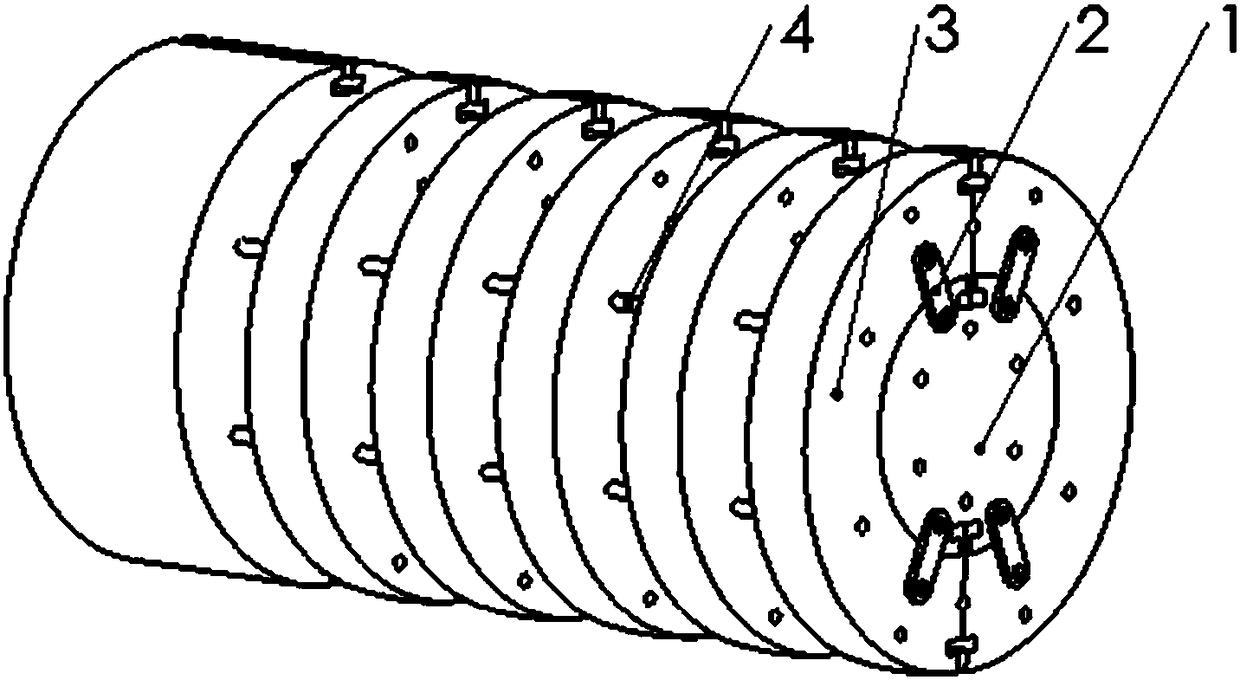

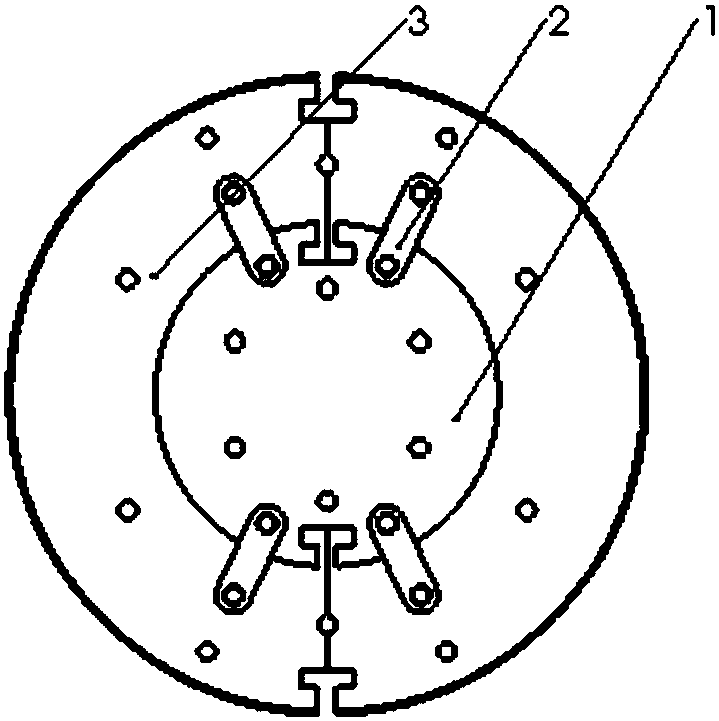

[0032] Such as figure 2 As shown, another specific implementation of the present invention includes an inner mandrel sub-section 1, a metal connecting buckle 2, an outer inlay mandrel sub-section 3, and an elastic rubber rod 4; an outer inlay mandrel sub-section 3 is nested in an inner sleeve Mandrel sub-section 1 forms an integral single-section mandrel section, and multi-section mandrel sections are connected in series through elastic rubber rods 4 axially to form a complete flexible mandrel; the inner sleeve core in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com